Manufacturing method of titanium bronze alloy cast ingot

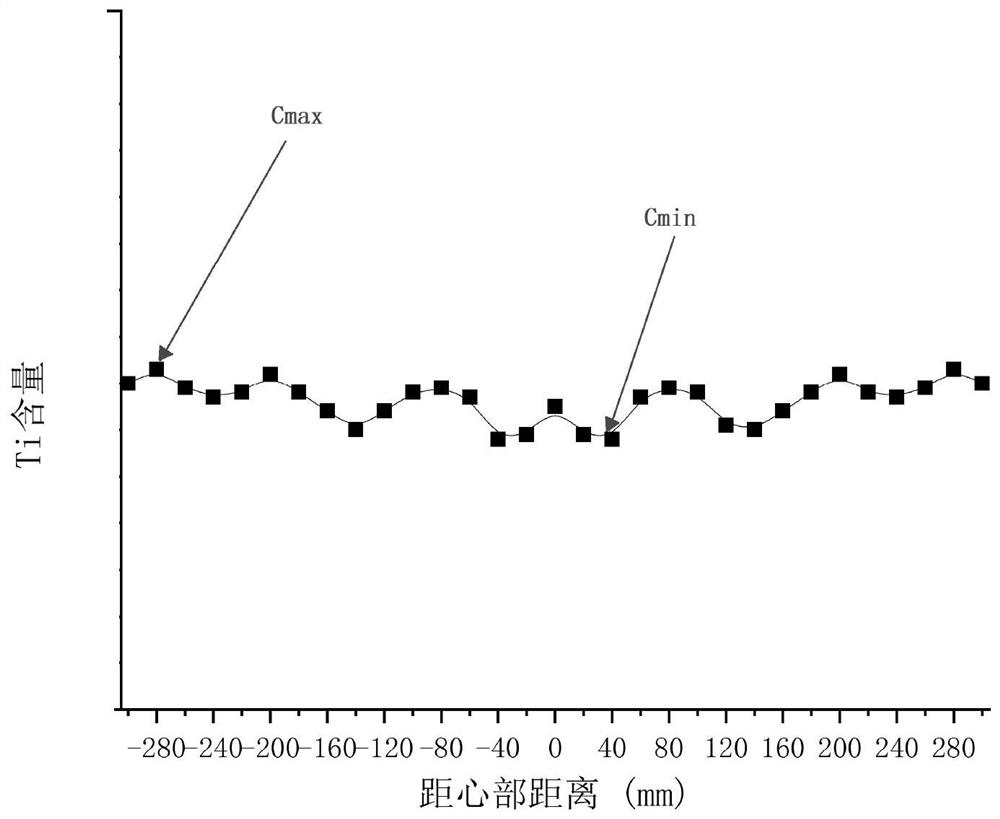

A technology for alloy ingot and titanium bronze, which is applied in the field of preparation of titanium bronze alloy ingot, can solve problems such as the inability to completely eliminate macrosegregation, achieve good application prospects, reduce superheat and increase the effect of fine grain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

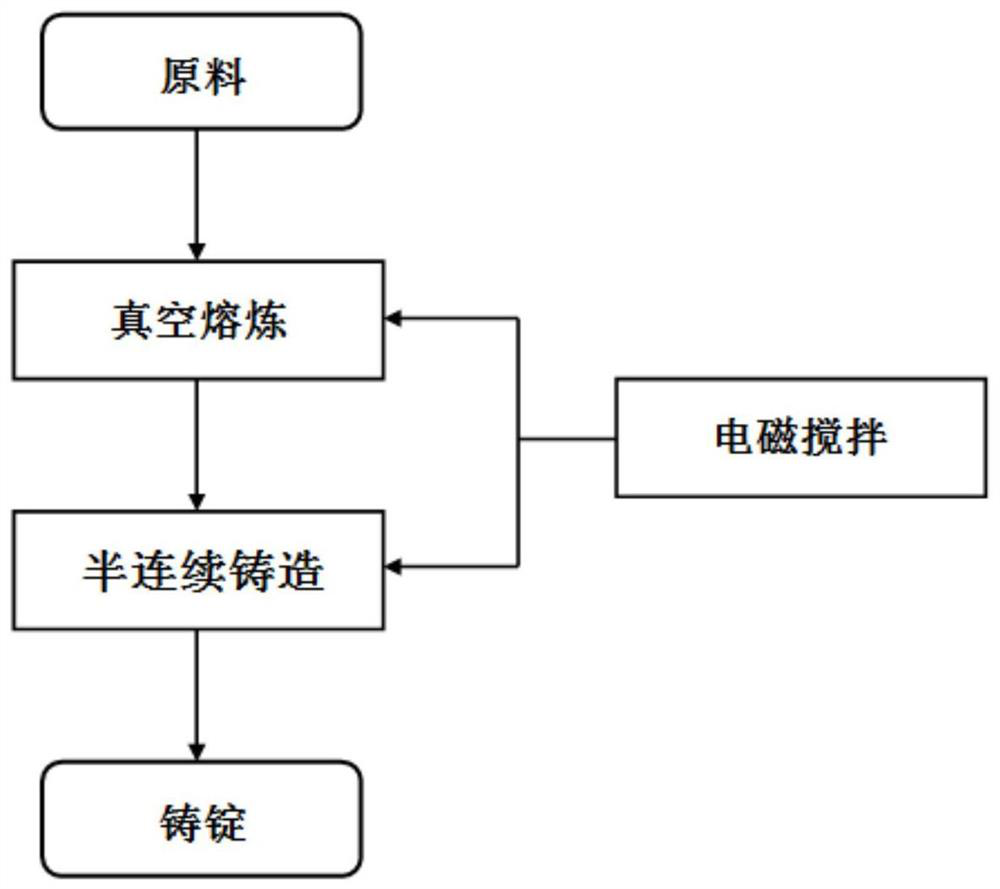

Method used

Image

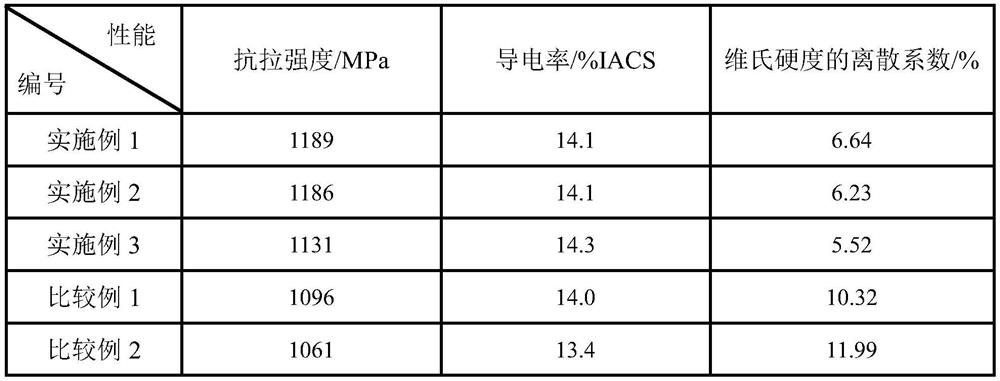

Examples

Embodiment 1

[0032] Embodiment 1: Adopt the method of the present invention to prepare the Cu-3.17Ti titanium bronze alloy ingot of length 4000mm, size specification is 200mm * 600mm, and its preparation process is:

[0033] (1) Batching: take the required raw materials according to the mass percentage composition of Ti: 3.17%, balance being Cu;

[0034] (2) Vacuum smelting: Put the raw materials into a vacuum intermediate frequency induction furnace for smelting, the vacuum degree is controlled below 10Pa, the vacuum smelting temperature is controlled at 1200°C, and the melt is electromagnetically stirred during the vacuum smelting process, and the stirring current is controlled at 7000A. The frequency is controlled at 40Hz, and the direction of the stirring current is a single direction;

[0035] (3) Semi-continuous casting: adopt the semi-continuous casting process combined with electromagnetic stirring technology, control the casting temperature to 1150°C, and the casting speed to 60mm...

Embodiment 2

[0036] Embodiment 2: Adopt the method of the present invention to prepare the Cu-3.17Ti titanium bronze alloy ingot of length 4000mm, size specification is 200mm * 600mm, and its preparation process is:

[0037] (1) Batching: take the required raw materials according to the mass percentage composition of Ti: 3.17%, balance being Cu;

[0038] (2) Vacuum smelting: Put the raw materials into a vacuum intermediate frequency induction furnace for smelting, the vacuum degree is controlled below 10Pa, the vacuum smelting temperature is controlled at 1200°C, and the melt is electromagnetically stirred during the vacuum smelting process, and the stirring current is controlled at 7000A. The frequency is controlled at 40Hz, and the direction of the stirring current is a single direction;

[0039] (3) Semi-continuous casting: adopt the semi-continuous casting process combined with electromagnetic stirring technology, control the casting temperature to 1150°C, and the casting speed to 60mm...

Embodiment 3

[0040] Embodiment 3: Adopt the method of the present invention to prepare the Cu-3.17Ti titanium bronze alloy ingot of length 4000mm, size specification is 200mm * 600mm, and its preparation process is:

[0041] (1) Batching: take the required raw materials according to the mass percentage composition of Ti: 3.17%, balance being Cu;

[0042] (2) Vacuum smelting: Put the raw materials into a vacuum intermediate frequency induction furnace for smelting, the vacuum degree is controlled below 10Pa, the vacuum smelting temperature is controlled at 1200°C, and the melt is electromagnetically stirred during the vacuum smelting process, and the stirring current is controlled at 7000A. The frequency is controlled at 40Hz, and the direction of the stirring current is a single direction;

[0043] (3) Semi-continuous casting: adopt the semi-continuous casting process combined with electromagnetic stirring technology, control the casting temperature to 1150°C, and the casting speed to 60mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com