ERW submarine pipeline steel plate coil and production process thereof

A technology for submarine pipelines and production processes, applied in the direction of manufacturing converters, etc., can solve problems such as vertical strength increase, and achieve the effects of reducing the amount of addition, saving energy and costs, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

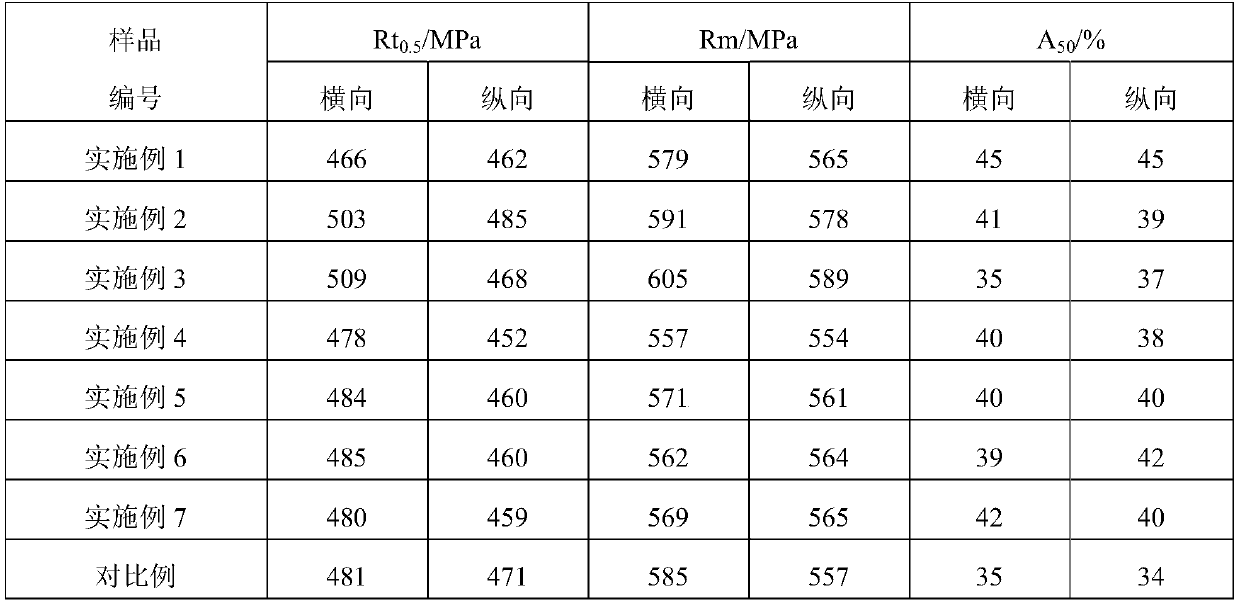

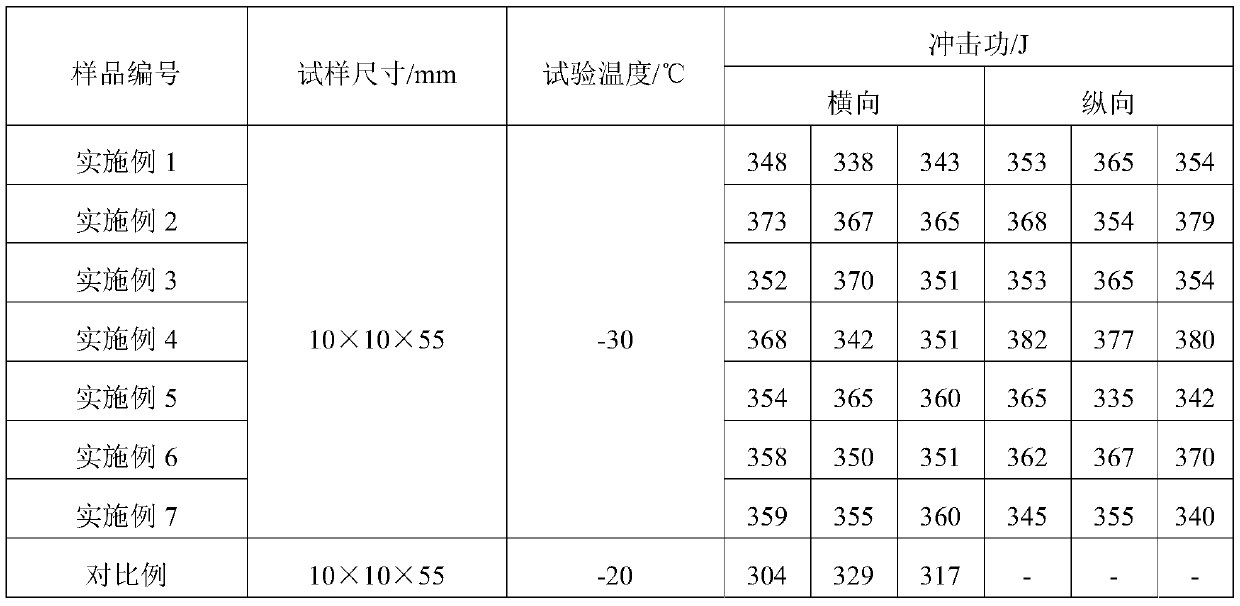

[0065] An ERW submarine pipeline steel coil in this embodiment, its main chemical composition and mass percentage are shown in Example 1 in Table 1.

[0066] A kind of production technology of ERW submarine pipeline steel coil of the present embodiment, comprises the following steps:

[0067]S1. Pretreatment of molten iron: pretreatment of molten iron is carried out by removing slag before and after desulfurization, and [S]≤0.0050% according to the mass percentage after desulfurization of the molten iron.

[0068] S2. Converter top-bottom compound blowing; strengthen dephosphorization, tap steel for deoxidation and microalloying.

[0069] S3. Alloy fine-tuning; adding aluminum particles to molten iron, stirring vigorously to reduce top slag.

[0070] S4, LF and RH furnace refining; LF furnace treatment, fully reduce the ladle top slag, adjust the chemical elements C, Si, Mn, Nb, Mo, V to the target value; RH furnace treatment, adjust the chemical composition Als, Ti to Targe...

Embodiment 2

[0077] An ERW submarine pipeline steel coil of this embodiment, its main chemical composition and mass percentage are shown in Example 2 in Table 1.

[0078] A kind of production technology of ERW submarine pipeline steel coil of the present embodiment, comprises the following steps:

[0079] S1. Pretreatment of molten iron: pretreatment of molten iron is carried out by removing slag before and after desulfurization, and [S]≤0.0050% according to the mass percentage after desulfurization of the molten iron.

[0080] S2. Converter top-bottom compound blowing; strengthen dephosphorization, tap steel for deoxidation and microalloying.

[0081] S3. Alloy fine-tuning; adding aluminum particles to molten iron, stirring vigorously to reduce top slag.

[0082] S4, LF and RH furnace refining; LF furnace treatment, fully reduce the ladle top slag, adjust the chemical elements C, Si, Mn, Nb, Mo, V to the target value; RH furnace treatment, adjust the chemical composition Als, Ti to Targ...

Embodiment 3

[0089] An ERW submarine pipeline steel coil of this embodiment, its main chemical composition and mass percentage are shown in Example 3 in Table 1.

[0090] A kind of production technology of ERW submarine pipeline steel coil of the present embodiment, comprises the following steps:

[0091] S1. Pretreatment of molten iron: pretreatment of molten iron is carried out by removing slag before and after desulfurization, and [S]≤0.0050% according to the mass percentage after desulfurization of the molten iron.

[0092] S2. Converter top-bottom compound blowing; strengthen dephosphorization, tap steel for deoxidation and microalloying.

[0093] S3. Alloy fine-tuning; adding aluminum particles to molten iron, stirring vigorously to reduce top slag.

[0094] S4, LF and RH furnace refining; LF furnace treatment, fully reduce the ladle top slag, adjust the chemical elements C, Si, Mn, Nb, Mo, V to the target value; RH furnace treatment, adjust the chemical composition Als, Ti to Targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal impact work | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com