Molten metal solidification device and heat preservation method thereof

A technology of liquid metal and heat preservation cover, which is applied in the field of liquid metal solidification and heat preservation, which can solve the problems of sharp increase in thermal stress of steel ingot molds, long condensation time of liquid metal, uneven chemical composition, etc., and achieve the elimination of dendrite segregation and thermal stress Reduced, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

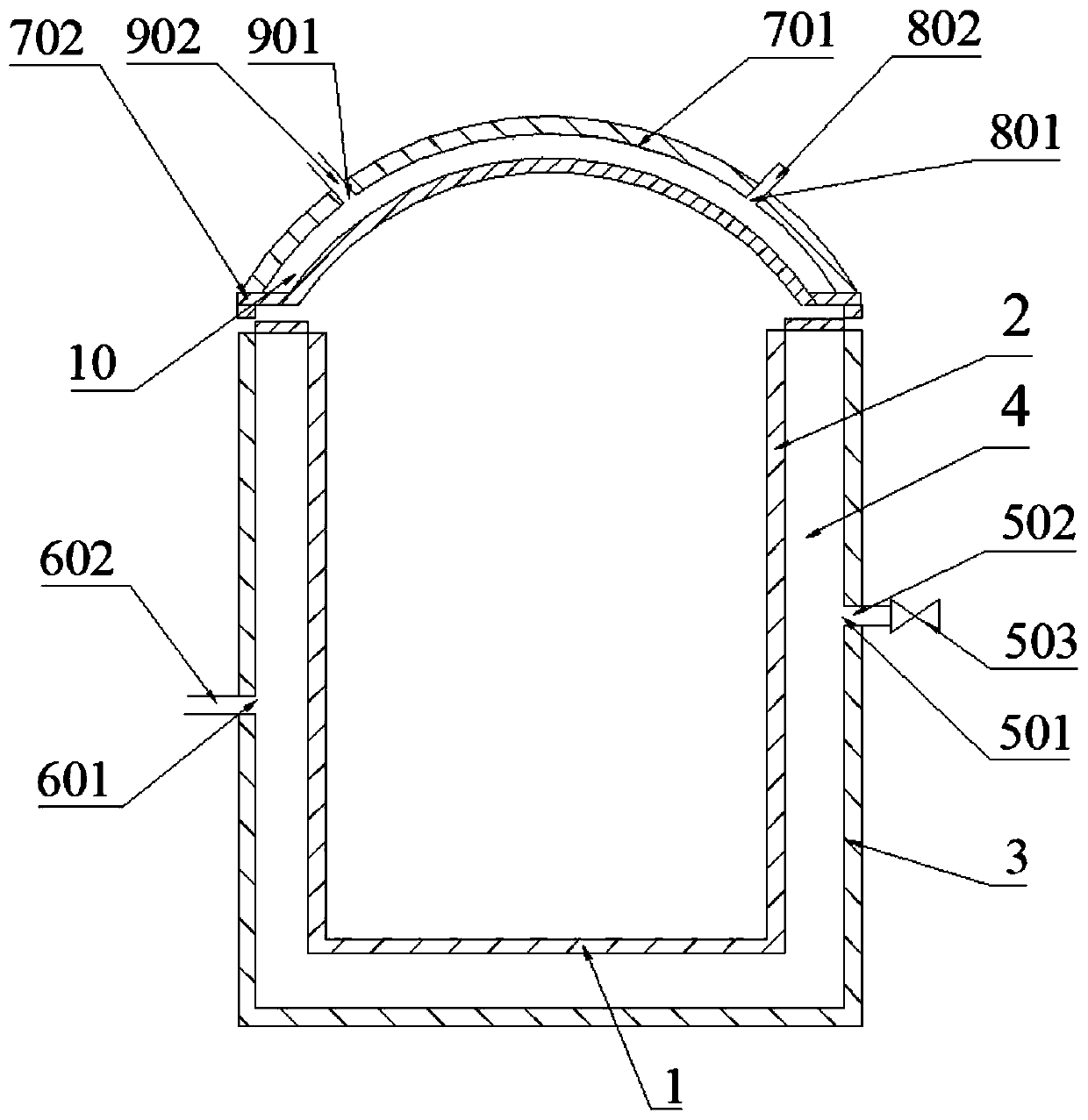

Embodiment 1

[0029] The thickness of the hollow body of the molten metal solidification device in this embodiment is 40mm.

[0030] For casting Q345B octagonal steel ingots with a unit weight of 15 tons, the heat preservation method is as follows:

[0031] Inject molten Q345B octagonal steel into the ingot body of the ingot mold of the vacuum solidification device and fasten the insulation cover with the ingot mold, close the exhaust pipe with a valve, and then connect the suction port of the vacuum pump to the air suction port of the shell through the shell suction pipe in turn Vacuumize the hollow cavity of the shell, connect the exhaust tube of the outer cover to the exhaust port of the outer cover, and evacuate the hollow cavity of the cover. After the vacuum degree of the hollow cavity reaches 100Pa, turn off the valve, keep it for 15 hours, and then take off the heat preservation cover. Remove the mold and hang out the steel ingot.

[0032] Compared with conventional casting, the le...

Embodiment 2

[0034] In this embodiment, the thickness of the hollow cavity of the molten metal solidification device is 5 mm.

[0035] For casting Q345B octagonal steel ingots with a unit weight of 15 tons, the heat preservation method is as follows:

[0036] Inject molten Q345B octagonal steel into the ingot body of the ingot mold of the solidification device, fasten the insulation cover with the ingot mold, close the exhaust pipe with a valve, and then connect the suction port of the vacuum pump to the air suction port of the shell through the shell suction pipe in turn. Vacuumize the hollow cavity of the shell, connect the exhaust tube of the outer cover to the exhaust port of the outer cover, and then evacuate the hollow cavity of the cover. After the vacuum degree of the hollow cavity reaches 0.1Pa, close the valve, keep it for 20 hours, and then take off the heat preservation cover. Remove the mold and hang out the steel ingot.

[0037] Compared with conventional casting, the levels...

Embodiment 3

[0039] In this embodiment, the thickness of the hollow cavity of the molten metal solidification device is 60mm.

[0040] For casting Q345B octagonal steel ingots with a unit weight of 15 tons, the heat preservation method is as follows:

[0041] Inject molten Q345B octagonal steel into the ingot body of the ingot mold of the solidification device, fasten the insulation cover with the ingot mold, close the exhaust pipe with a valve, and then connect the suction port of the vacuum pump to the air suction port of the shell through the shell suction pipe in turn. Vacuumize the hollow cavity of the shell, connect the exhaust pipe of the outer cover to the exhaust port of the outer cover, and then evacuate the hollow cavity of the cover. After the vacuum degree of the hollow cavity is pumped to 1000Pa, turn off the valve and keep it for 10 hours. mold, and lift out the steel ingot.

[0042] Compared with conventional casting, the grades of defects such as center segregation and cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com