Method for synthesizing GMA acrylic resin by microchannel reaction

An acrylic resin, microchannel reaction technology, applied in the field of chemical synthesis engineering, can solve the problems of narrow polymer molecular weight distribution, polymer material performance, difficult to guarantee the safety of the reaction device, poor product quality stability, etc. Narrow molecular weight distribution and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for synthesizing GMA acrylic resin in this embodiment comprises the following steps:

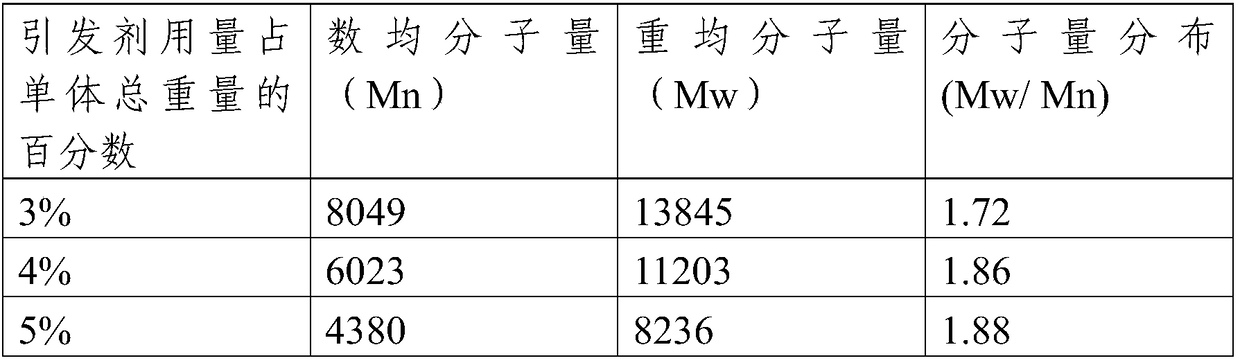

[0040] (1) Add the first solvent toluene, monomer and composite initiator into the pre-mixing tank, mix them uniformly initially, and obtain the reaction raw materials; wherein the monomer adopts methyl methacrylate, styrene, ethyl acrylate, butyl acrylate four The first monomer is compounded at 2:2:1:1, and the composite initiator is compounded with azobisisobutyronitrile and benzoyl peroxide at a ratio of 3:2. The amount of the first solvent toluene is the monomer and compound 25% of the total amount of initiators; among them, composite initiators accounted for 3%, 4% and 5% of the total mass of monomers, making three groups;

[0041] (2) Microchannel reactor is put into constant temperature reaction tank, and microchannel reactor is connected with two feed pumps; Wherein the temperature of constant temperature reaction tank is set to 105 ℃;

[0042] (3) By a feed pump, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com