Biomass pyrolysis gas-oil poly-generation system

A biomass pyrolysis and polygeneration technology, which is used in the fields of biofuels, gas purification of condensed non-gaseous materials, and gas dust removal. The effect of low risk, high production efficiency and good control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

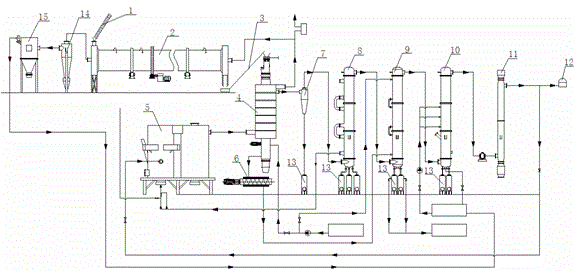

[0017] see figure 1 , a biomass pyrolysis carbon gas-oil polygeneration system, including a conveyor belt conveyor 1, a rotary baking furnace 2, a straight-through pyrolysis furnace 4, a screw discharge machine 6, a cyclone separator I7, an air cooling tower 8, and a water cooling tower Tower 9, washing tower 10, purification tower 11 and gas storage tank 12.

[0018] see figure 1 , the rotary baking furnace 2 is provided with rotary power by a motor and a reduction box, and is transmitted to the rotary baking furnace 2 through a gear mechanism; The driven gear is installed on the 2 outer circumferences of the rotary baking furnace. The drying raw material adopts the rotary baking furnace 2, which ensures the drying effect.

[0019] see figure 1 , the straight-through pyrolysis furnace 4 sequentially includes a preheating zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com