Patents

Literature

97results about How to "Improve pyrolysis effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

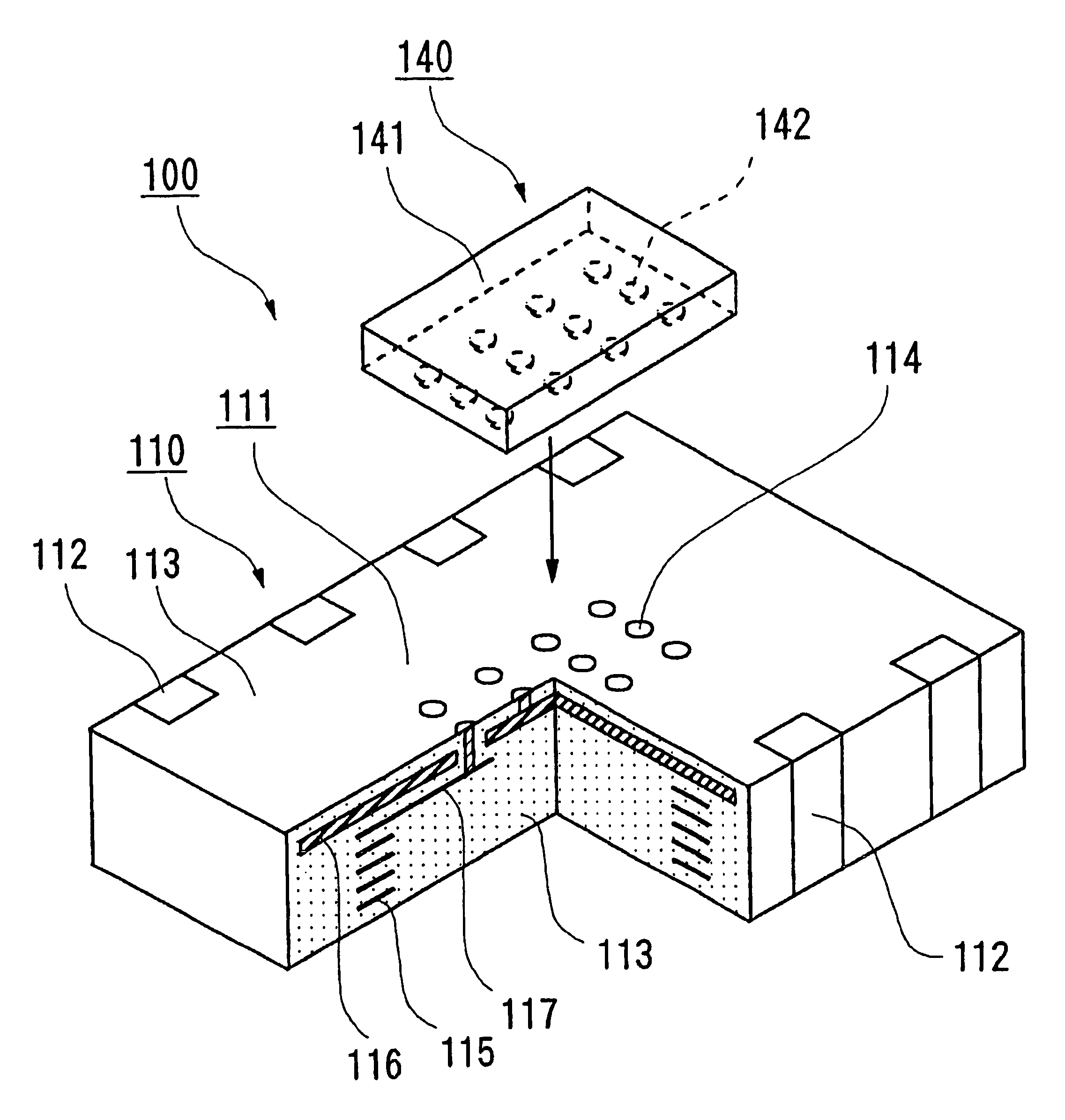

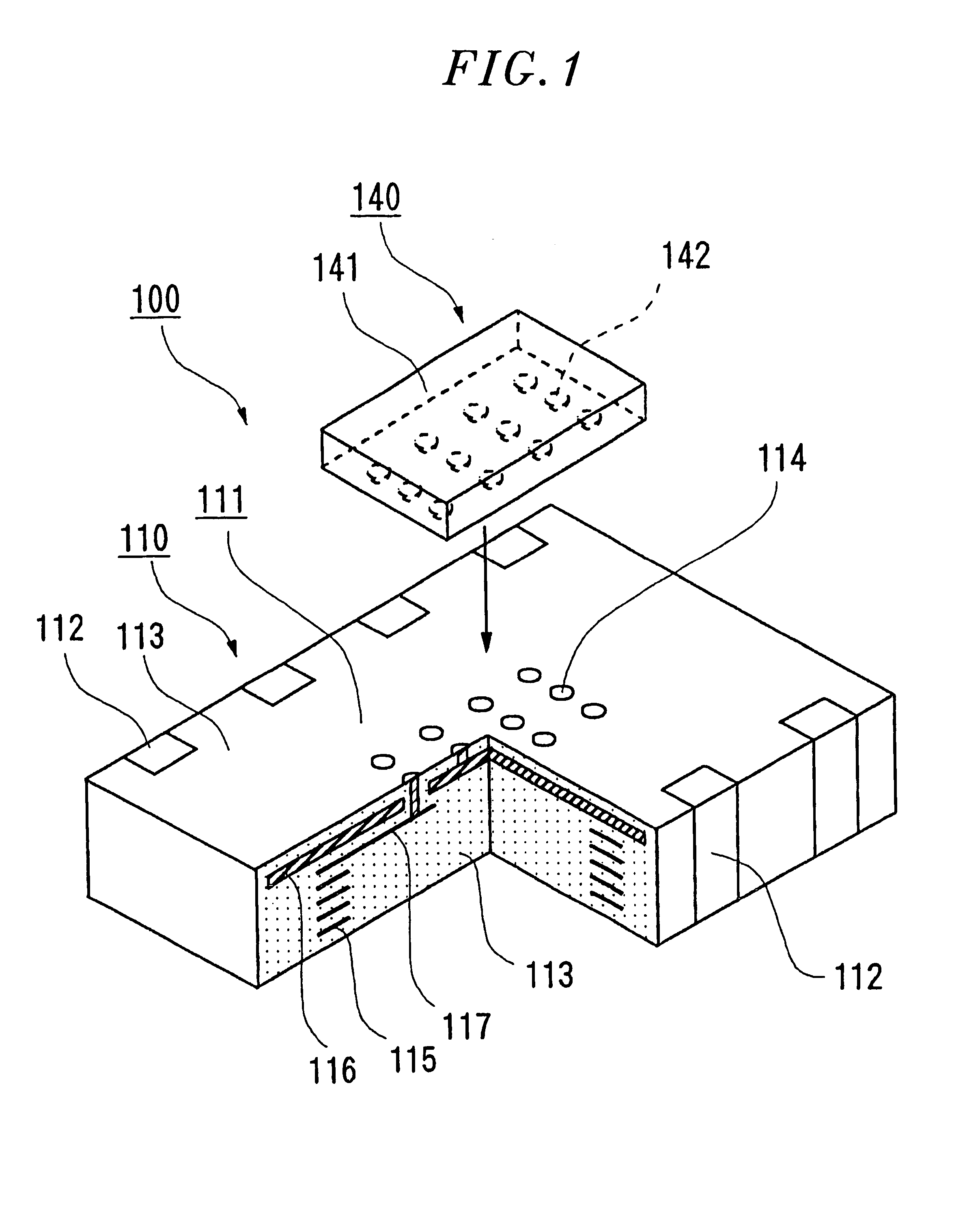

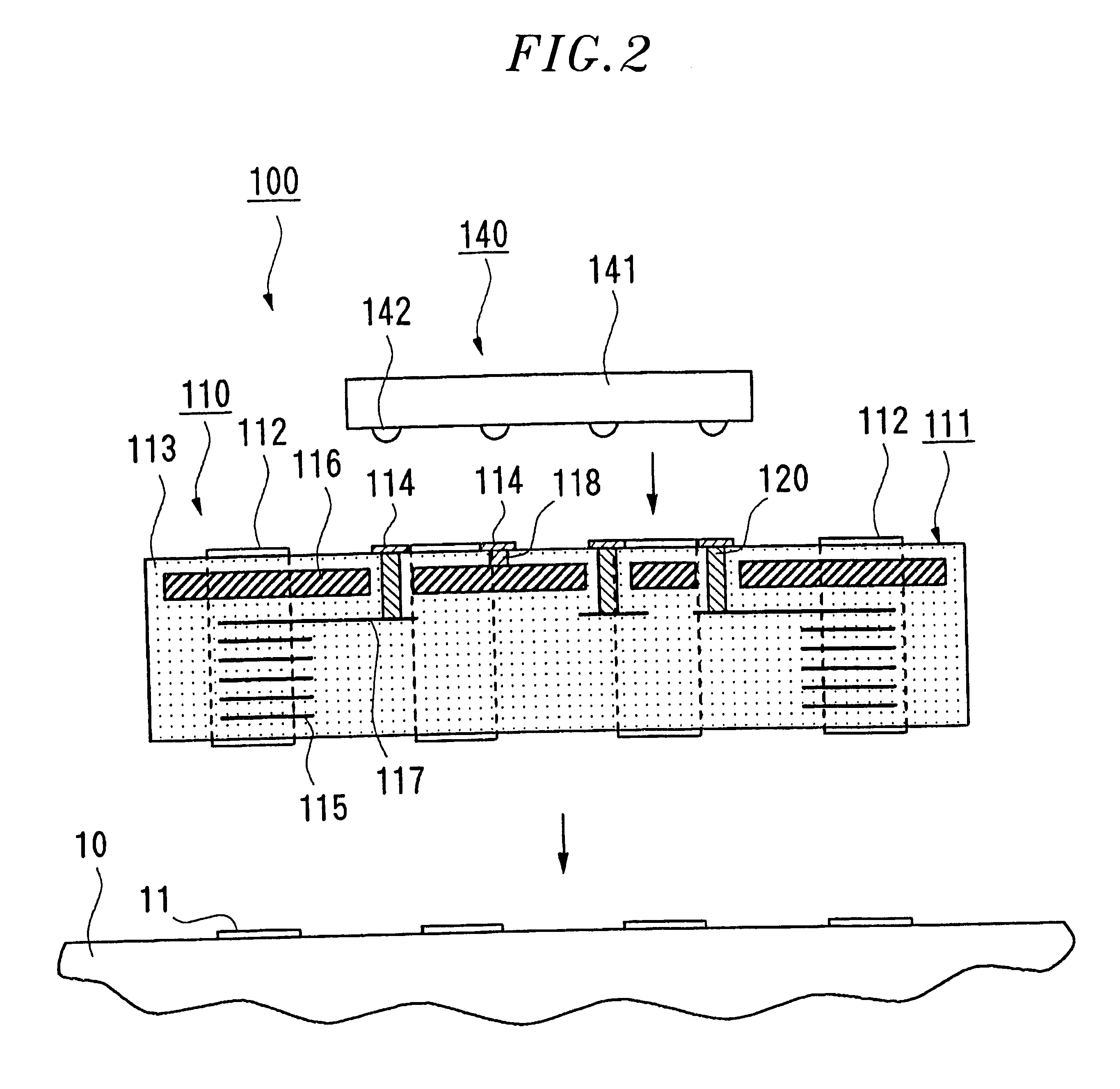

Multilayered electronic part and electronic circuit module including therein the multilayered electronic part

InactiveUS6301114B1Improve pyrolysis effectMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationSemiconductor chip

The present invention provides a multilayered electronic component (110) having improved thermolytic effect for an electronic circuit module (100), facilitating the realization of a miniaturization of the electronic circuit module (100). The multilayered electronic component (110) is provided with a first surface (111), a second opposite surface and side surfaces. A heat dissipation pattern (116) is formed in the multilayered electronic component (110) in a vicinity of the first surface (111) thereof on which a plurality of lands (114) is formed, in such a way that at least one land (114) is electrically connected to the heat dissipation pattern (116). A semiconductor chip (140) is mounted on the first surface (111) of the multilayered electronic component (110), thereby forming the electronic circuit module (100). Heat induced in the semiconductor chip (140) is emitted from the heat dissipation pattern (116), which will, in turn, make a thermolytic effect of the electronic circuit module (100) be improved.

Owner:TAIYO YUDEN KK

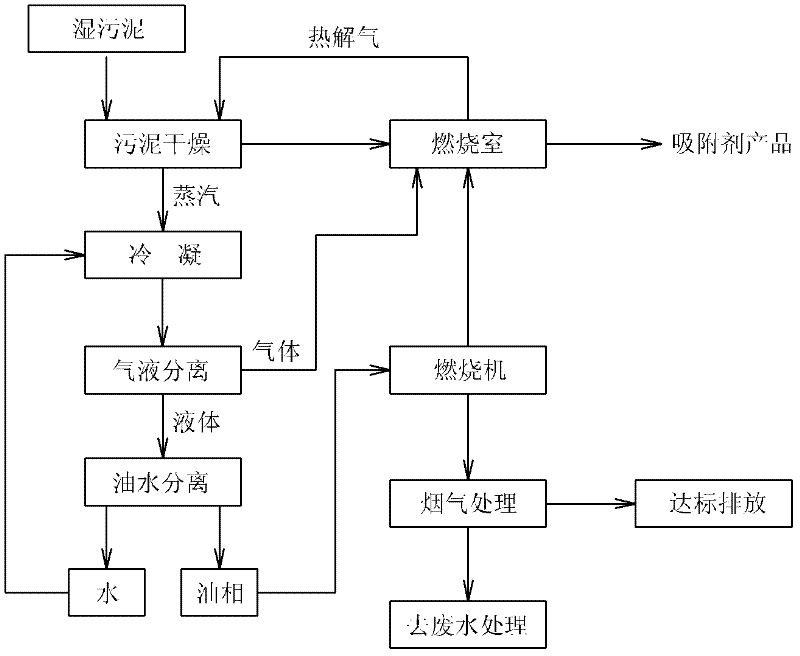

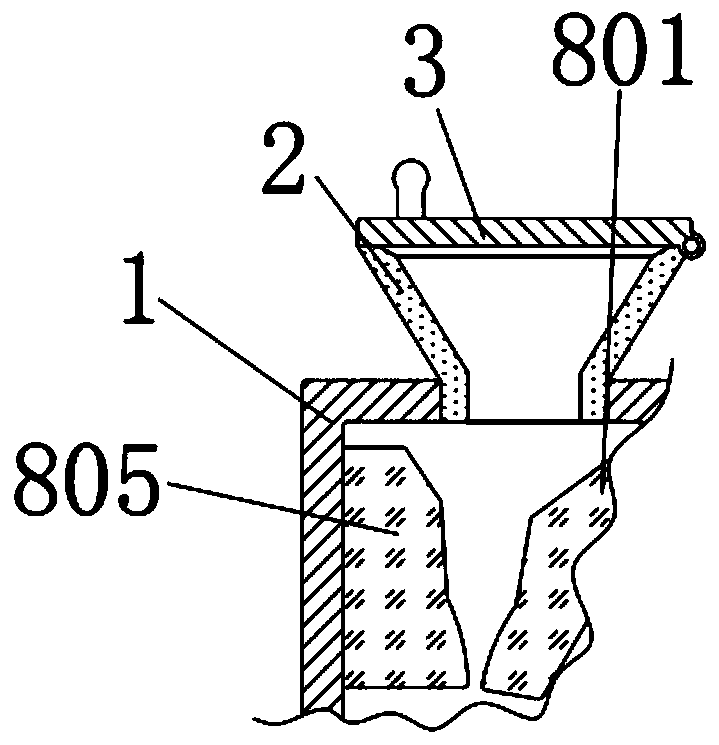

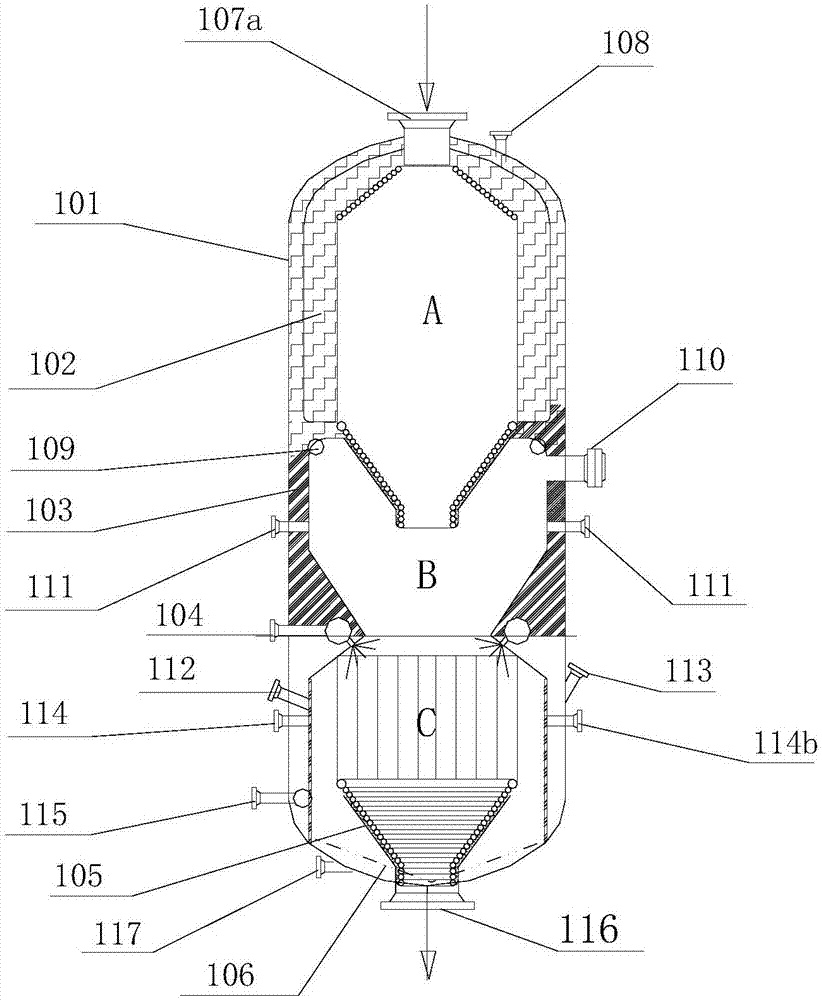

Printing and dyeing sludge pyrolysis treatment device and sludge treatment method

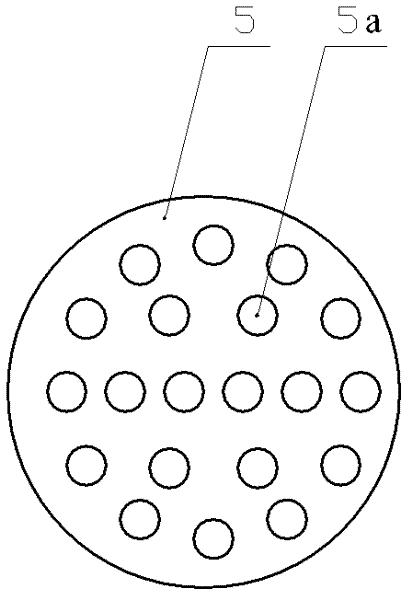

InactiveCN102344234APollution controlAvoid direct dischargeSludge treatment by pyrolysisByproduct vaporizationCombustion chamberSludge

The invention discloses a printing and dyeing sludge pyrolysis treatment device which successively comprises a sludge chamber, a combustion chamber and a product collecting chamber from top to bottom, wherein a feed port is arranged on the sludge chamber, and a support plate with holes is arranged between the sludge chamber and the combustion chamber; the combustion chamber is connected with a combustion engine, and a pyrolysis cavity is arranged in the combustion chamber; and a dump valve is arranged between the combustion chamber product collecting chamber. The invention also discloses a printing and dyeing sludge treatment method. In the invention, by adopting the vertical arrangement from top to bottom, the automatic flowing nature of the substance is fully utilized, and the problems of high viscosity and hard feeding of printing and dyeing sludge are solved. Sludge drying, pyrolysis, pyrolysis gas recycling and control are integrated, and energy consumption is effectively reduced. Not only is the recycling of the printing and dyeing sludge realized, but also the harm to environment is greatly lowered. Therefore, the demands of industry development and environmental protection can be well adapted and satisfied.

Owner:GUANGZHOU UNIVERSITY

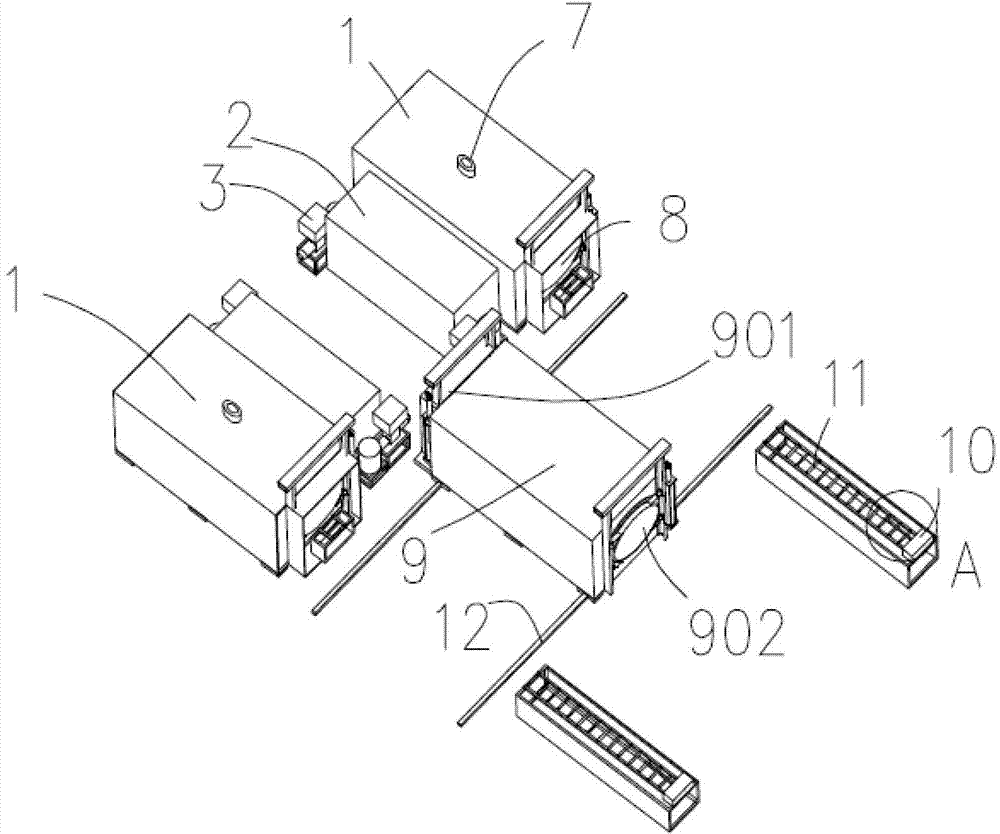

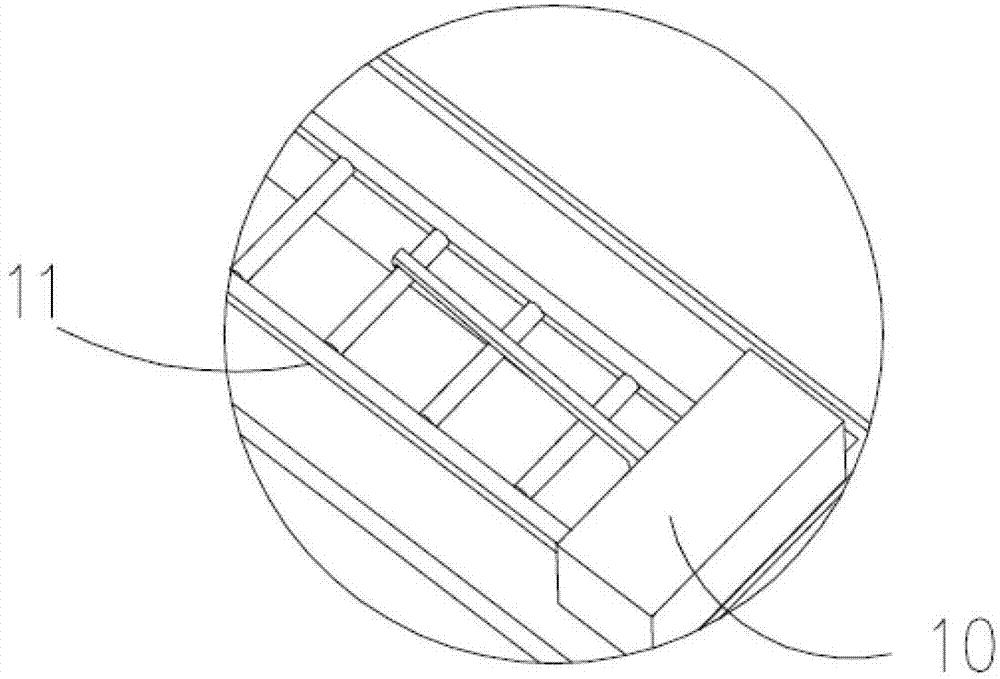

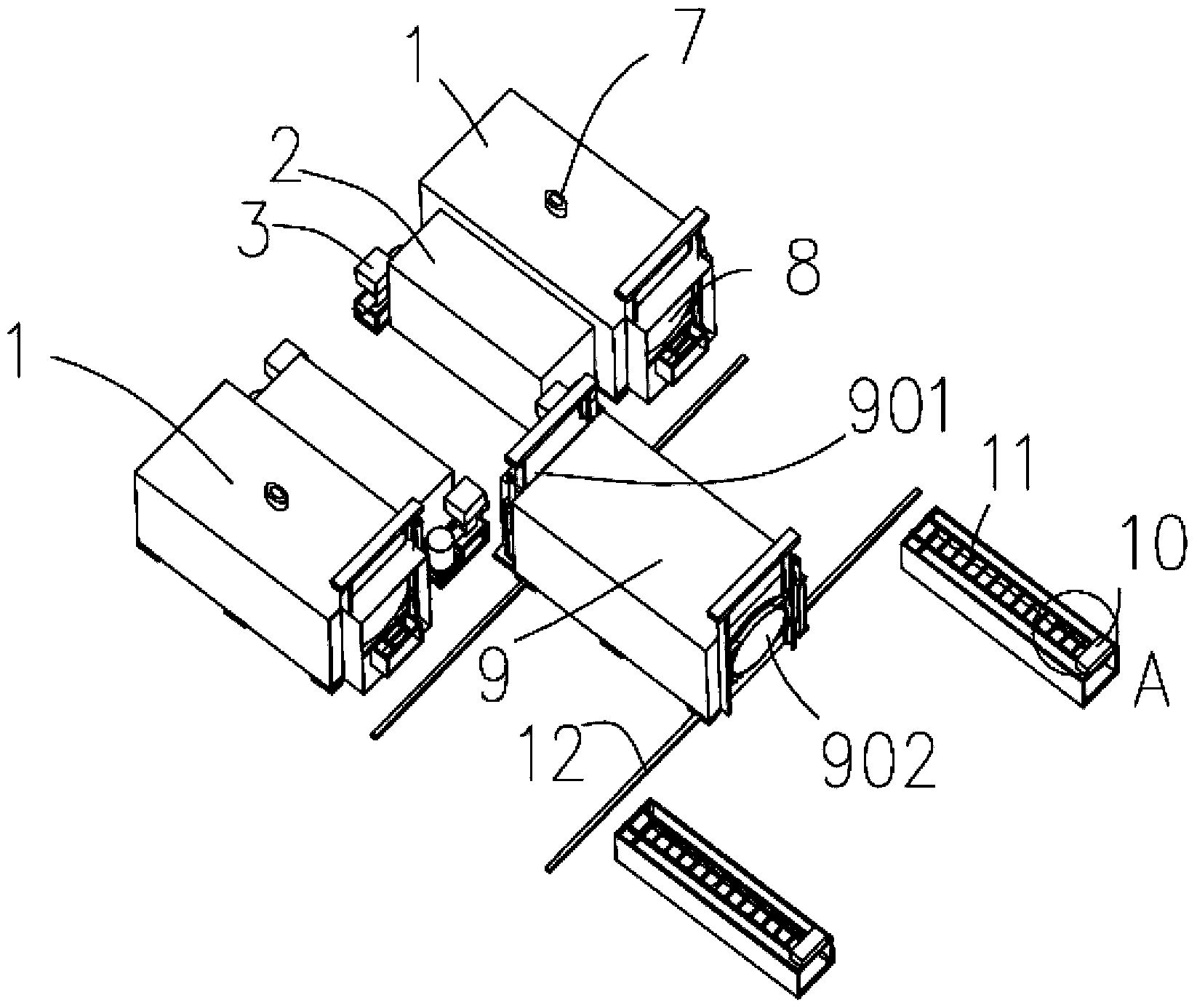

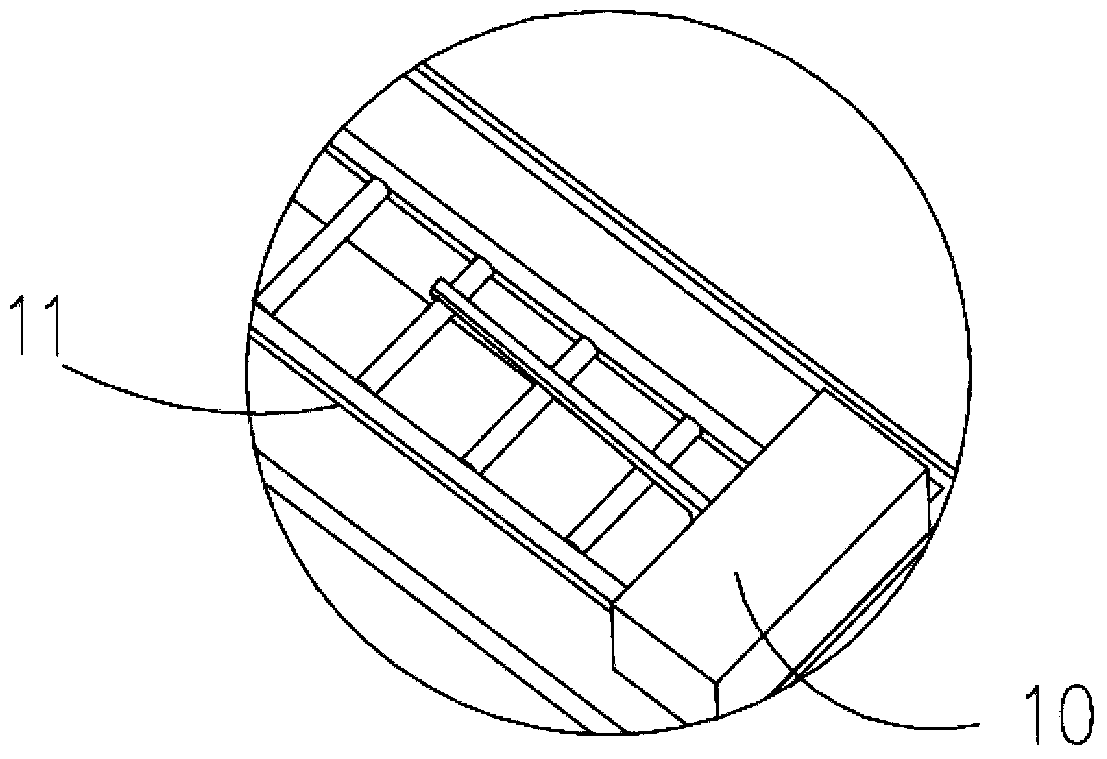

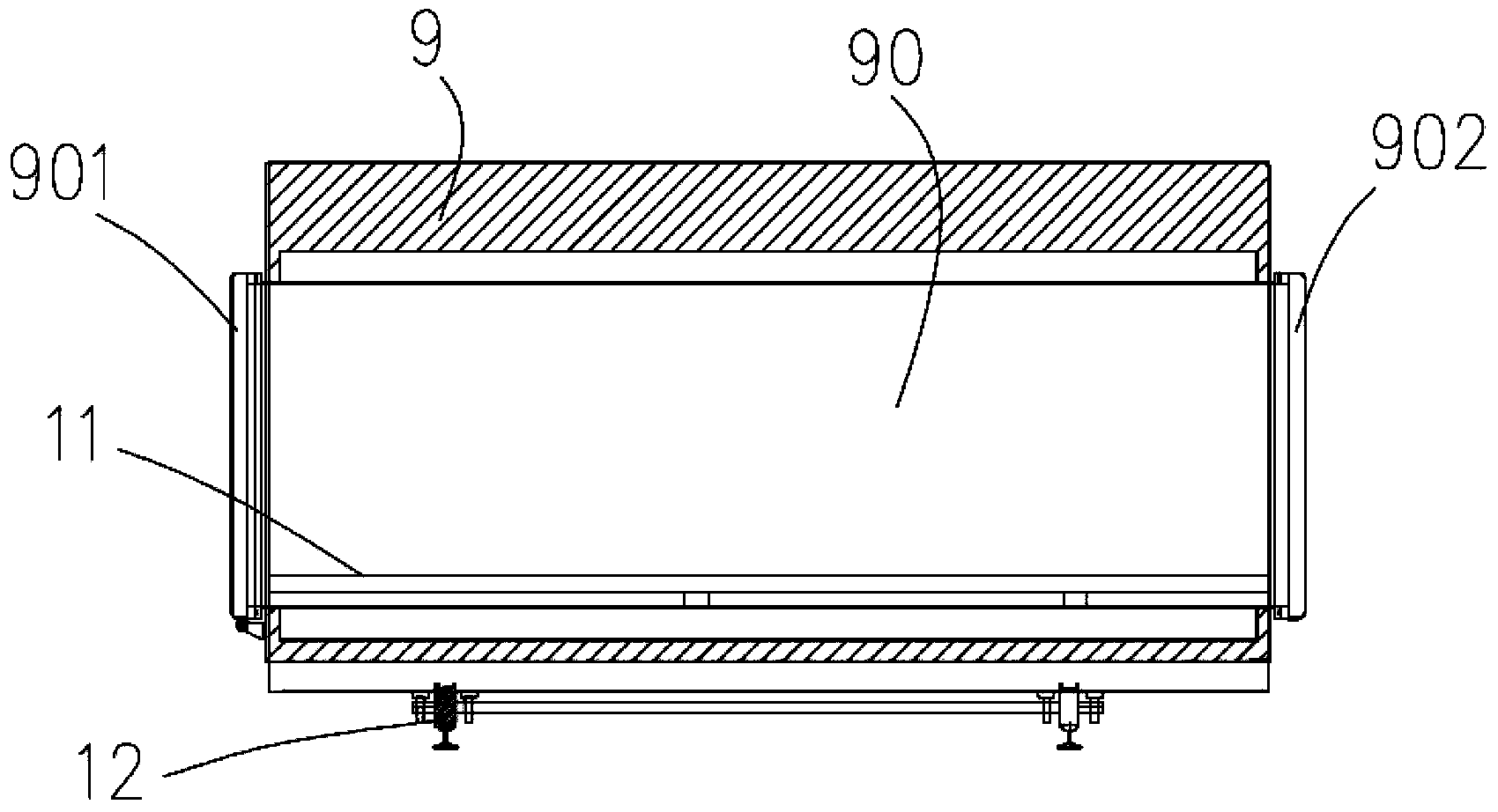

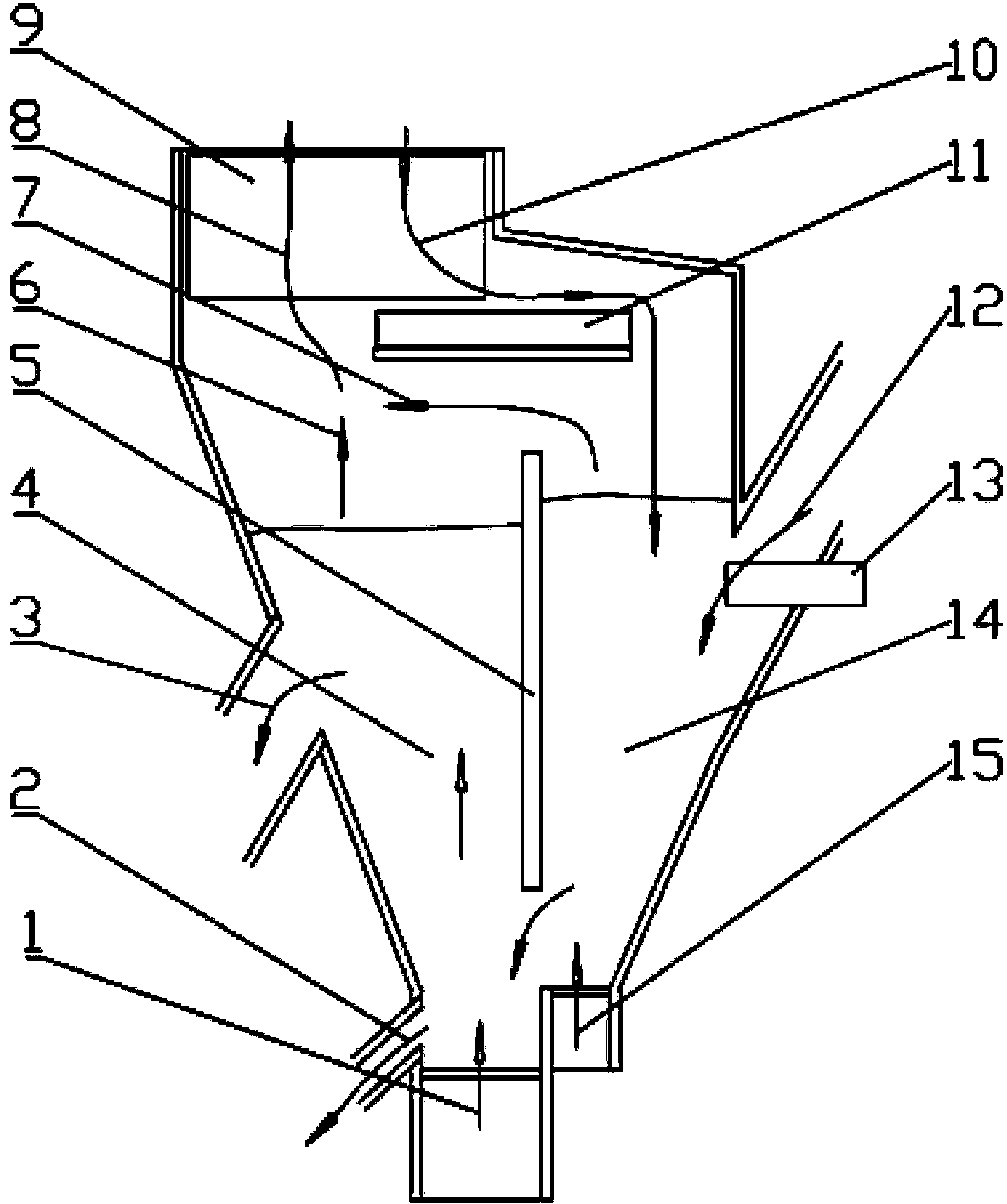

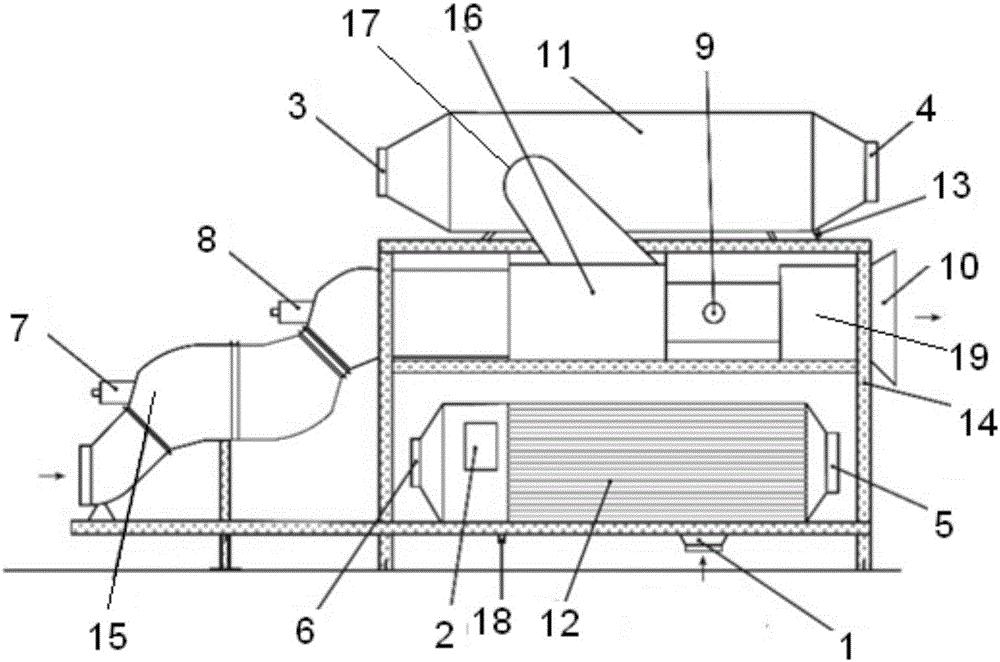

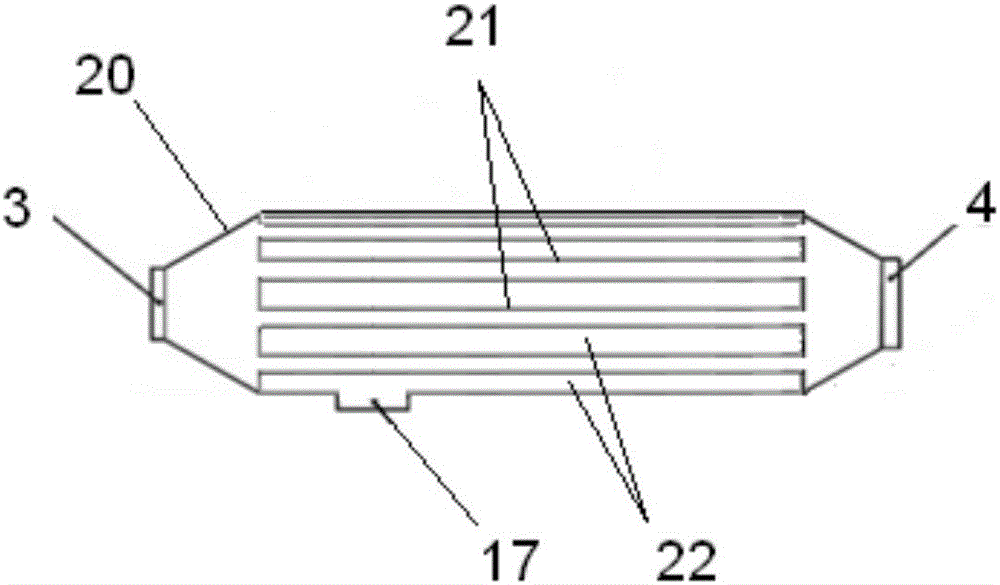

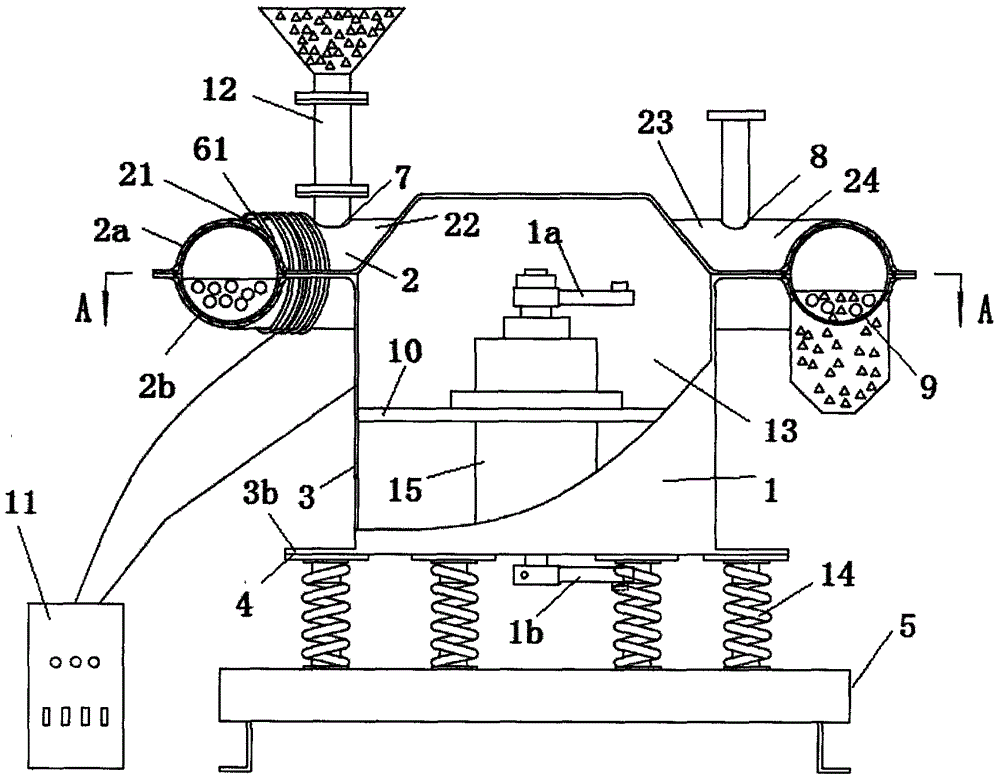

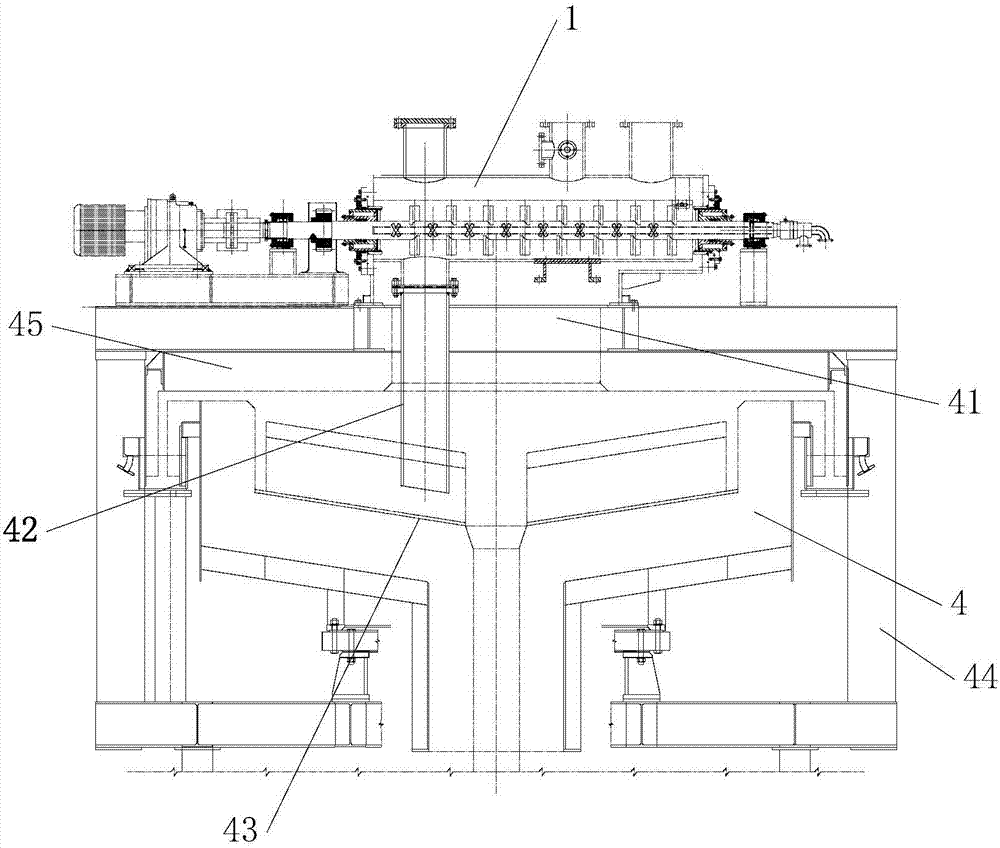

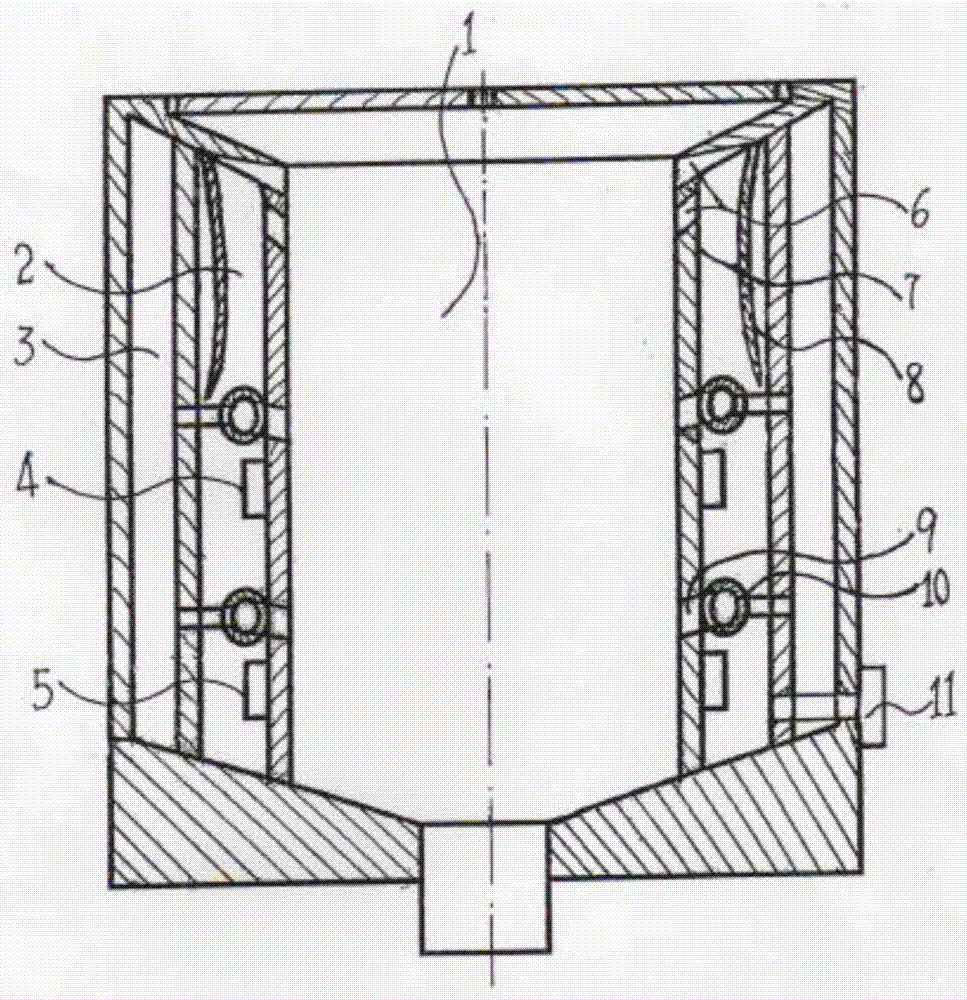

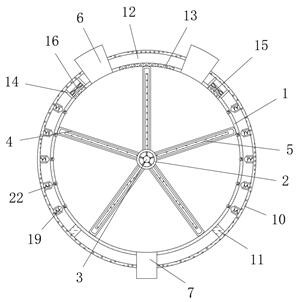

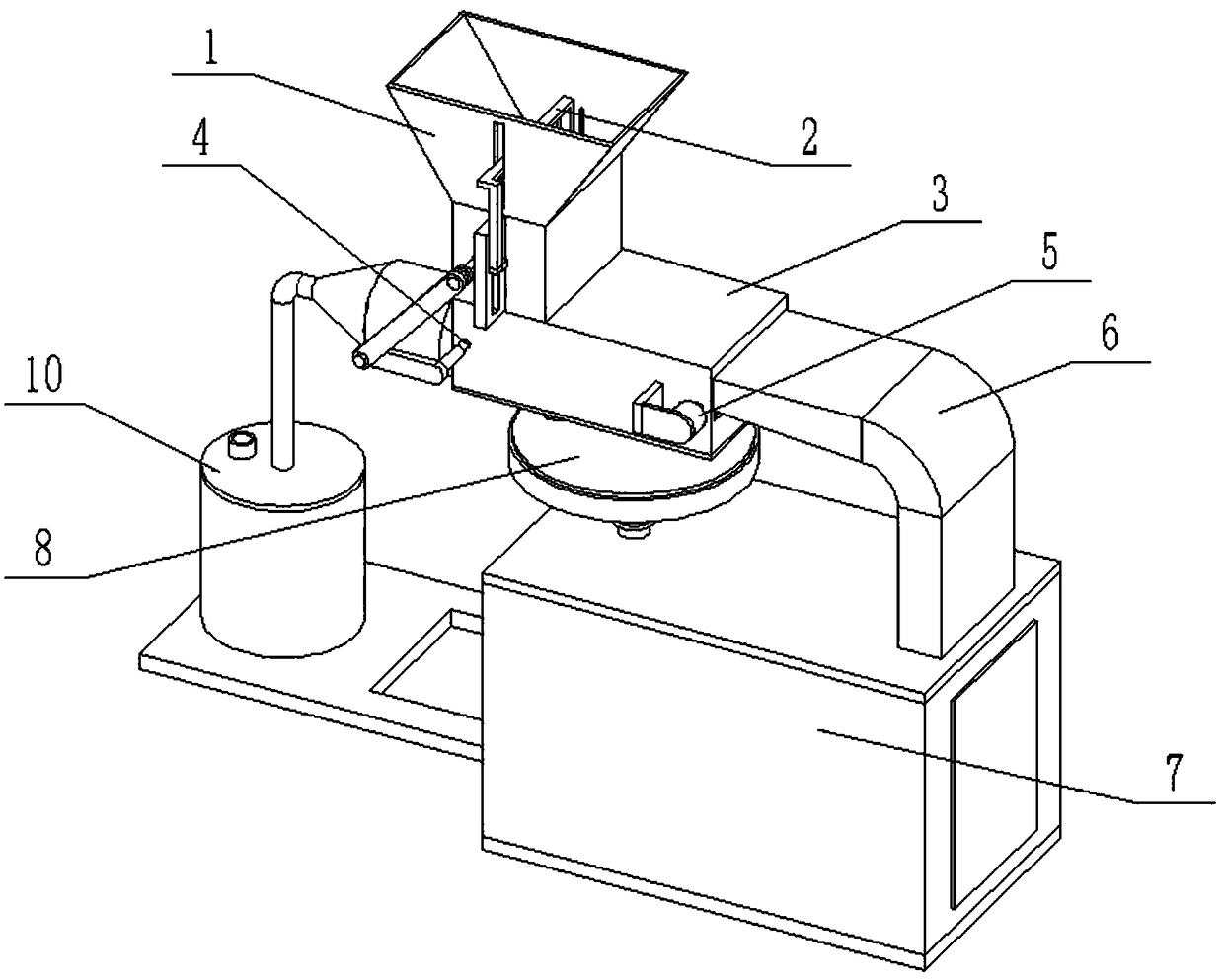

Efficient carcass pyrolysis treatment device and method

InactiveCN103484135AReasonable structureGood effectIndirect heating destructive distillationSpecial form destructive distillationCombustion chamberCombustor

The invention relates to an efficient carcass pyrolysis treatment device and method. The treatment device comprises one or more pyrolysis chambers (1), combustion chambers (2), biomass combustors (3), and a cooling chamber (9), wherein a pyrolysis tank (6) is arranged in each pyrolysis chamber (1); a material basket (60), a material basket guide rail (601) and a pyrolysis gas lead-out pipe (61) are arranged in each pyrolysis tank (6); the cooling chamber (9) is separated from the pyrolysis chambers (1); a cooling tank (90) fitted with the material baskets (60) is arranged in the cooling chamber (9); the combustion chambers (2) are positioned on the side surfaces of the pyrolysis chambers (1); a flue gas deflector (15) is arranged in each pyrolysis chamber (1). Correspondingly, the invention further provides an efficient carcass pyrolysis treatment method. The efficient carcass pyrolysis treatment device and the method have the advantages of reasonable structure and obvious effect, the treatment cycle can be shorted, the pyrolysis effect can be improved, and the energy utilization efficiency is high.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

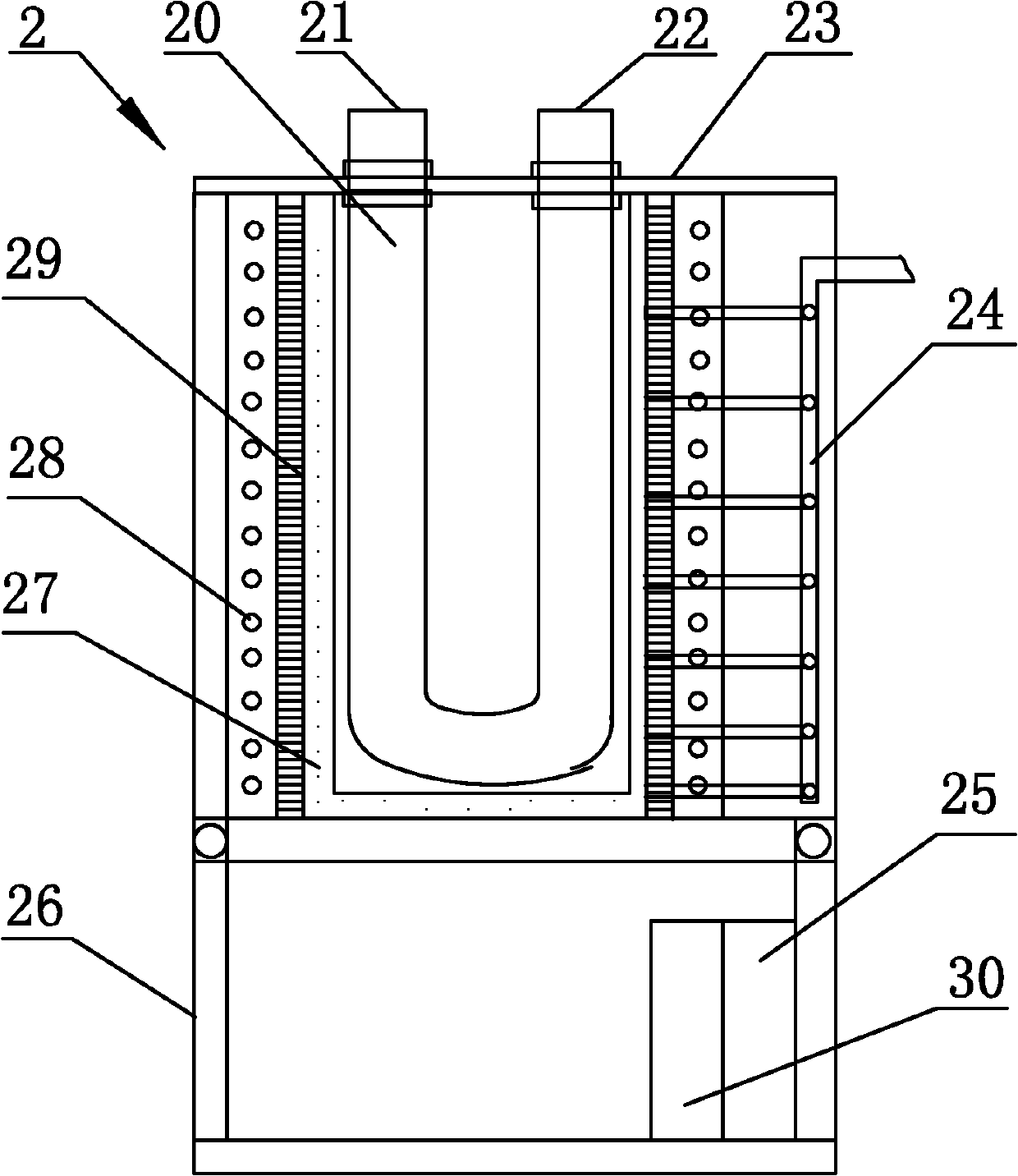

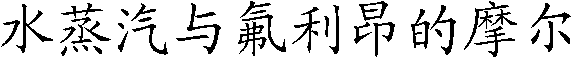

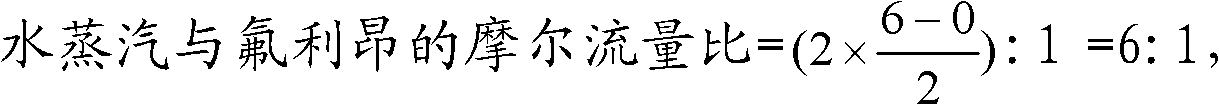

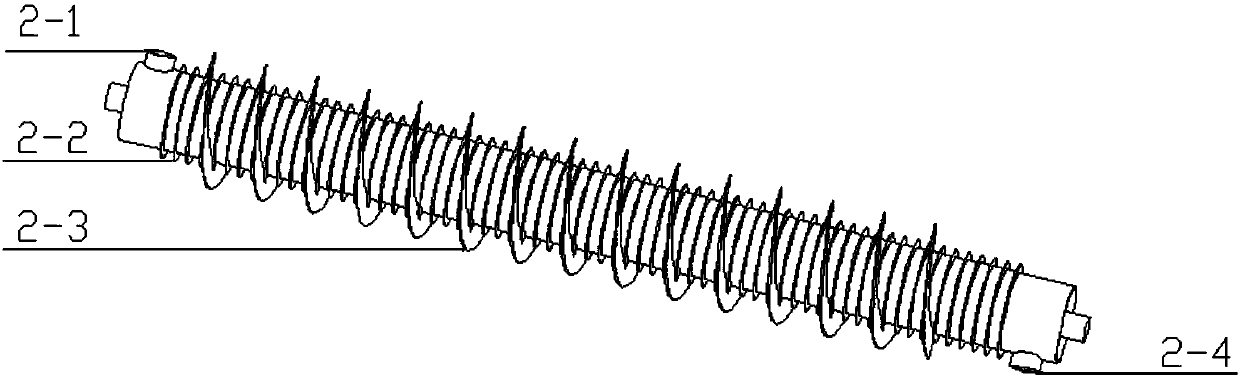

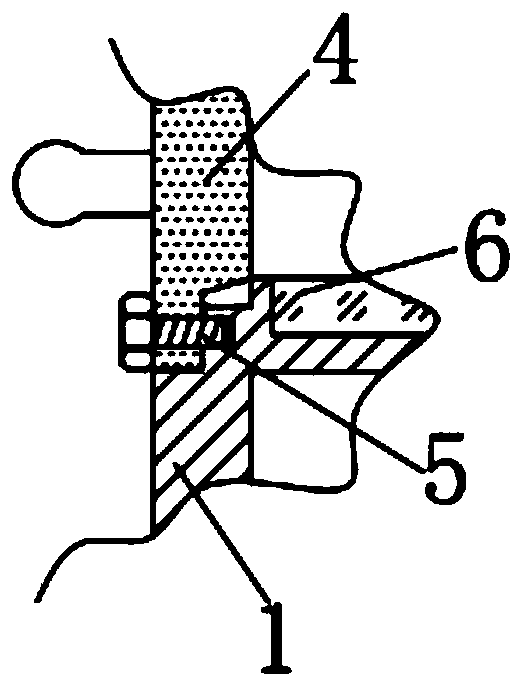

Bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and pyrolysis induction heating furnace

ActiveCN101829488ANo generationFast heatingDispersed particle separationCrucible furnacesDichlorodifluoromethaneHigh energy

The invention relates to a bio-safety disposal method for dispelling dichlorodifluoromethane by induction heating and a pyrolysis induction heating furnace. The method is characterized by comprising steps of carrying out pyrolytic reaction on a preheated feed gas which is a mixed gas of dichlorodifluoromethane, steam and air in a high-temperature environment generated by induction heating and carrying out absorption and inversion on pyrolysis products, wherein the proportioning of the feed gas is as follows: the flow ratio of the steam to the dichlorodifluoromethane is shown in the specification, the flow ratio of the air to the dichlorodifluoromethane is shown in the specification, and in the formula, a, b and c are respectively the number of carbon, hydrogen and halogen atoms of one dichlorodifluoromethane molecule. The pyrolysis induction heating furnace is characterized in that a crucible in the traditional pyrolysis induction heating furnace is internally provided with an acid corrosion resistant and thermostability bending-shaped metal coiler, the supply frequency is 10-300kHz and the power is 10-50kW. The invention has the advantages of quick warming speed, little power consumption, high energy utilization rate and pyrolysis efficiency, convenient starting operation, good operation safety and easy scale realization.

Owner:TIANJIN HEJIA VEOLIA ENVIRONMENTAL SERVICES

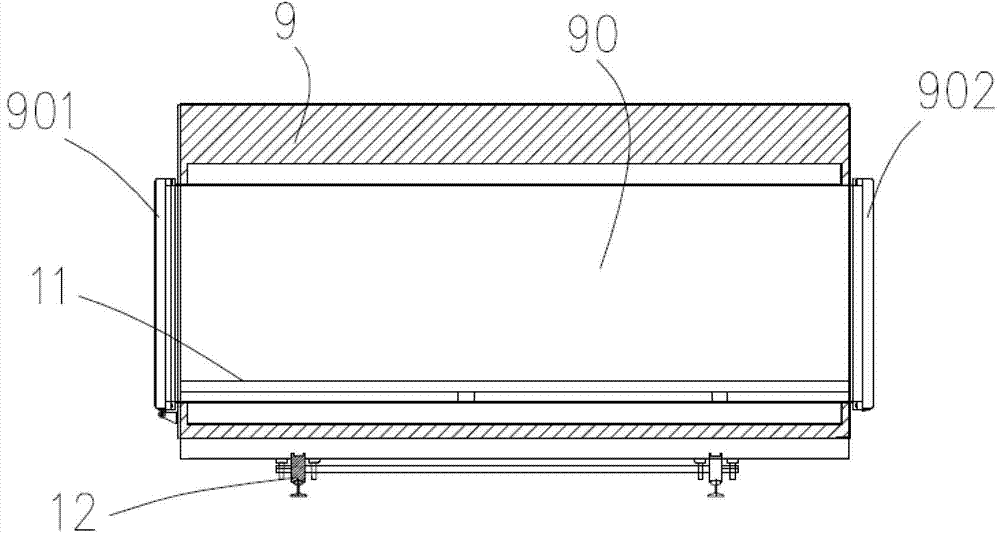

Efficient carcass pyrolysis treatment device and method

InactiveCN103484135BReasonable structureGood effectIndirect heating destructive distillationSpecial form destructive distillationCombustion chamberCombustor

The invention relates to an efficient carcass pyrolysis treatment device and method. The treatment device comprises one or more pyrolysis chambers (1), combustion chambers (2), biomass combustors (3), and a cooling chamber (9), wherein a pyrolysis tank (6) is arranged in each pyrolysis chamber (1); a material basket (60), a material basket guide rail (601) and a pyrolysis gas lead-out pipe (61) are arranged in each pyrolysis tank (6); the cooling chamber (9) is separated from the pyrolysis chambers (1); a cooling tank (90) fitted with the material baskets (60) is arranged in the cooling chamber (9); the combustion chambers (2) are positioned on the side surfaces of the pyrolysis chambers (1); a flue gas deflector (15) is arranged in each pyrolysis chamber (1). Correspondingly, the invention further provides an efficient carcass pyrolysis treatment method. The efficient carcass pyrolysis treatment device and the method have the advantages of reasonable structure and obvious effect, the treatment cycle can be shorted, the pyrolysis effect can be improved, and the energy utilization efficiency is high.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

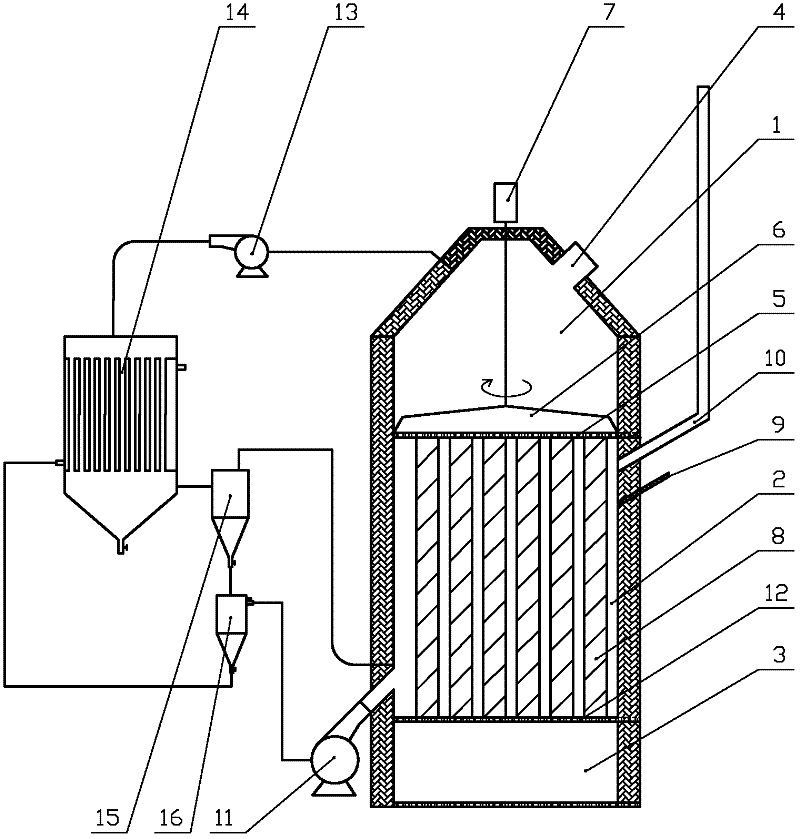

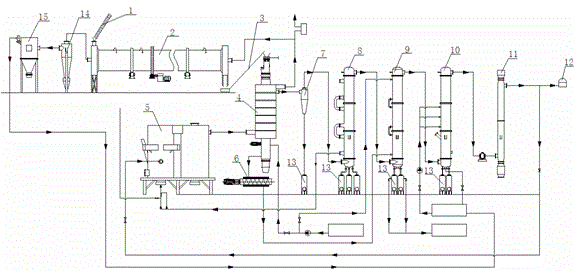

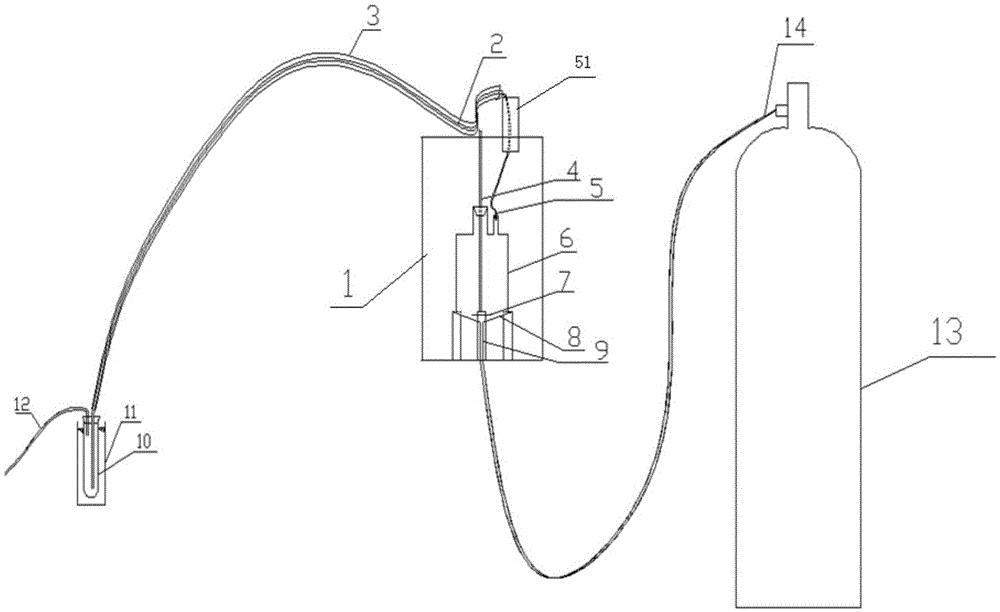

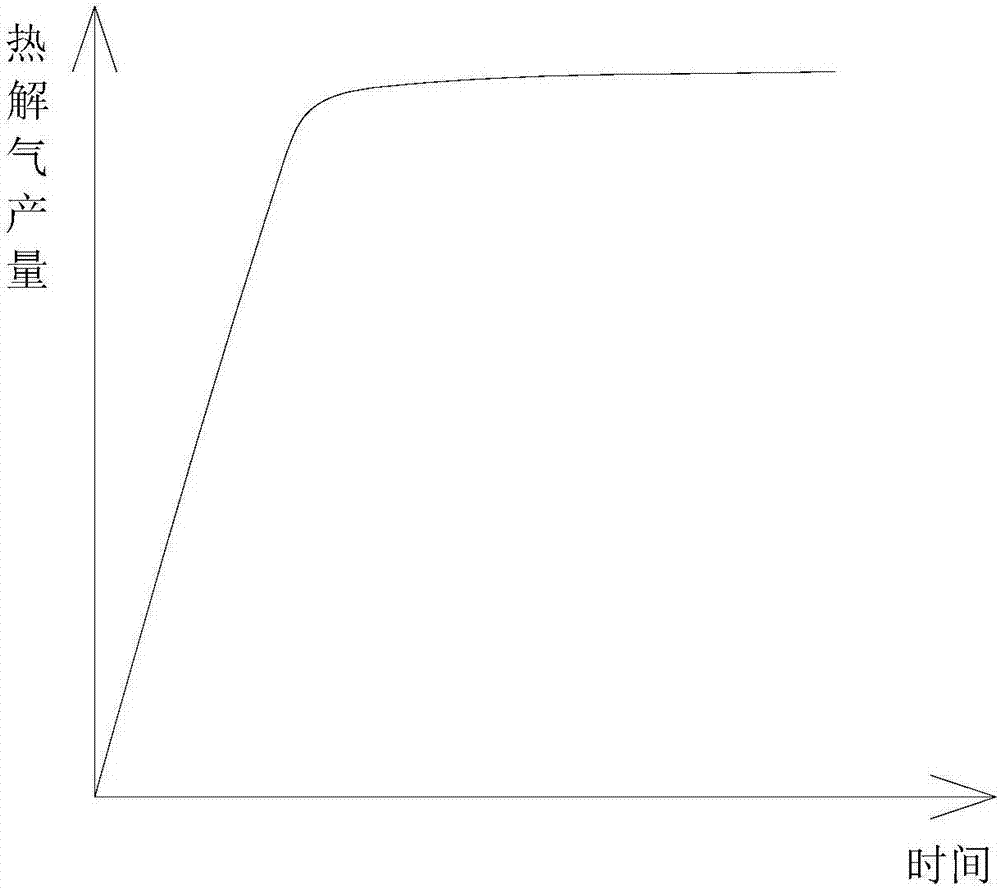

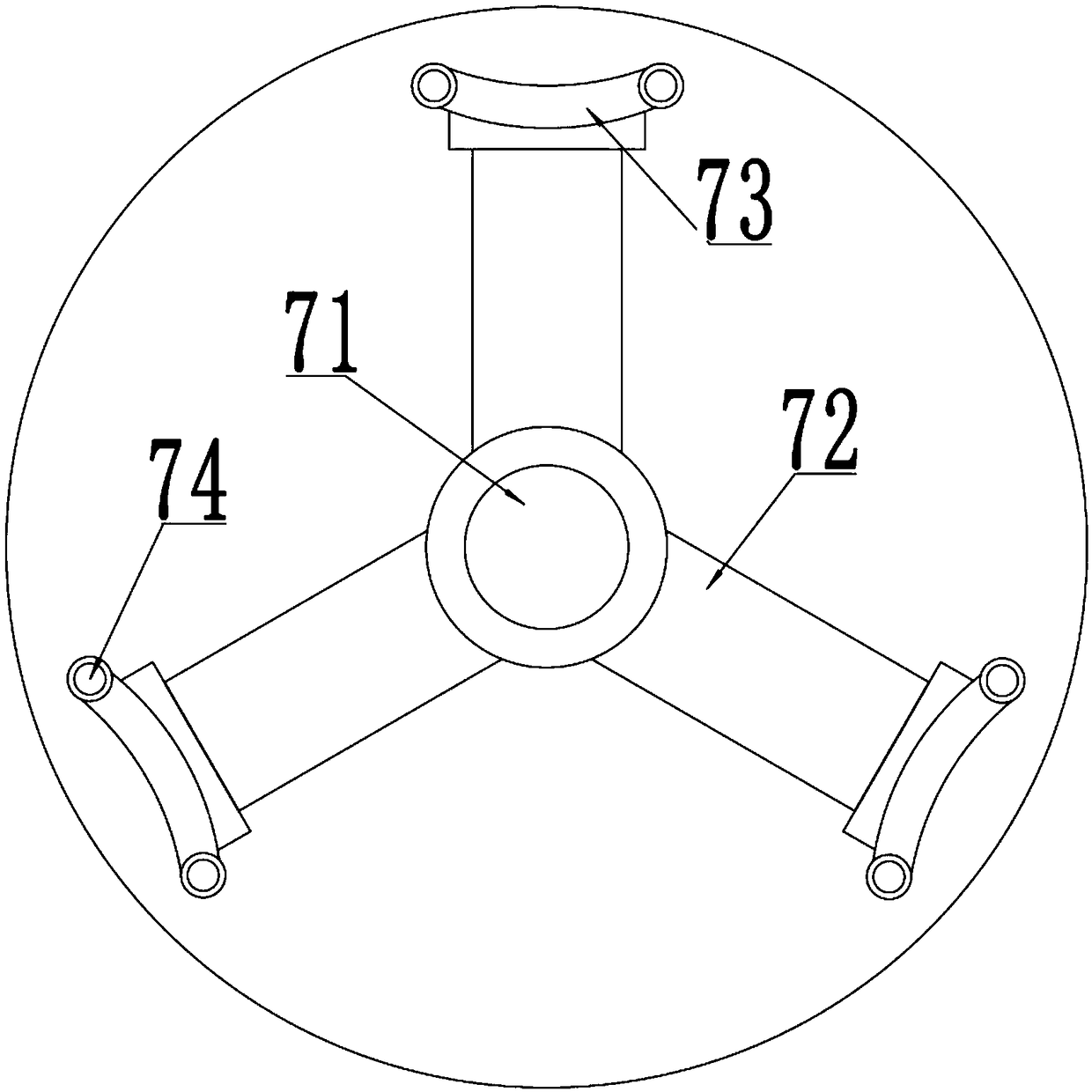

Biomass pyrolysis gas-oil poly-generation system

ActiveCN104861996AImprove qualityImprove pyrolysis effectBiofuelsIndirect heating destructive distillationCooling towerThermodynamics

The invention discloses a biomass pyrolysis gas-oil poly-generation system. The biomass pyrolysis gas-oil poly-generation system comprises a belt conveyor (1), a rotary baking furnace (2), a straight-through type pyrolyzing furnace (4), a spiral discharging machine (6), a cyclone separator I (7), an air cooling tower (8), a water cooling tower (9), a scrubbing tower (10), a purification tower (11) and a gas storage tank (12), wherein the pyrolysis gas outlet at the upper part of the straight-throguh type pyrolyzing furnace (4) is connected to the gas inlet of the cyclone separator I (7); the gas outlet of the cyclone separator I (7) is connected to the gas inlet of the gas storage tank (12) through the air cooling tower (8), the water cooling tower (9), the scrubbing tower (10) and the purification tower (11); the liquid outlets of the cyclone separator I (7), the air cooling tower (8), the water cooling tower (9) and the scrubbing tower (10) are connected with an inlet of a water-sealing tank (13) respectively. The biomass pyrolysis gas-oil poly-generation system is easy to control technological parameters, relatively good in pyrolysis effect and relatively high in production efficiency.

Owner:武汉光谷蓝焰新能源股份有限公司

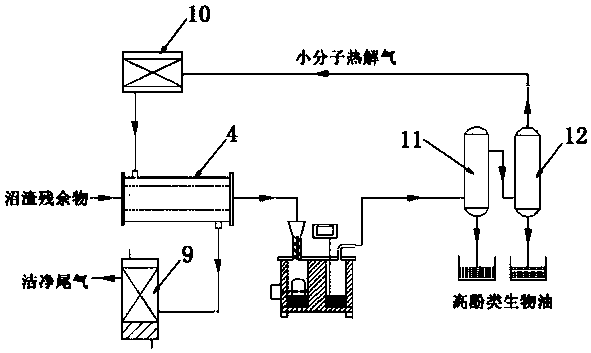

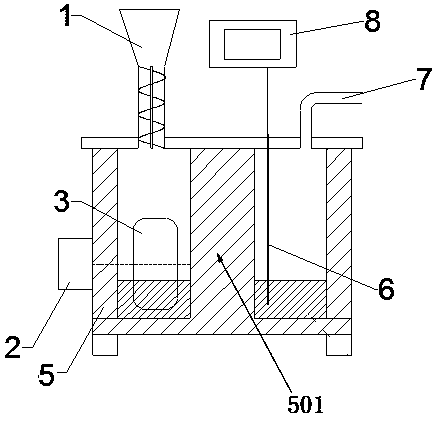

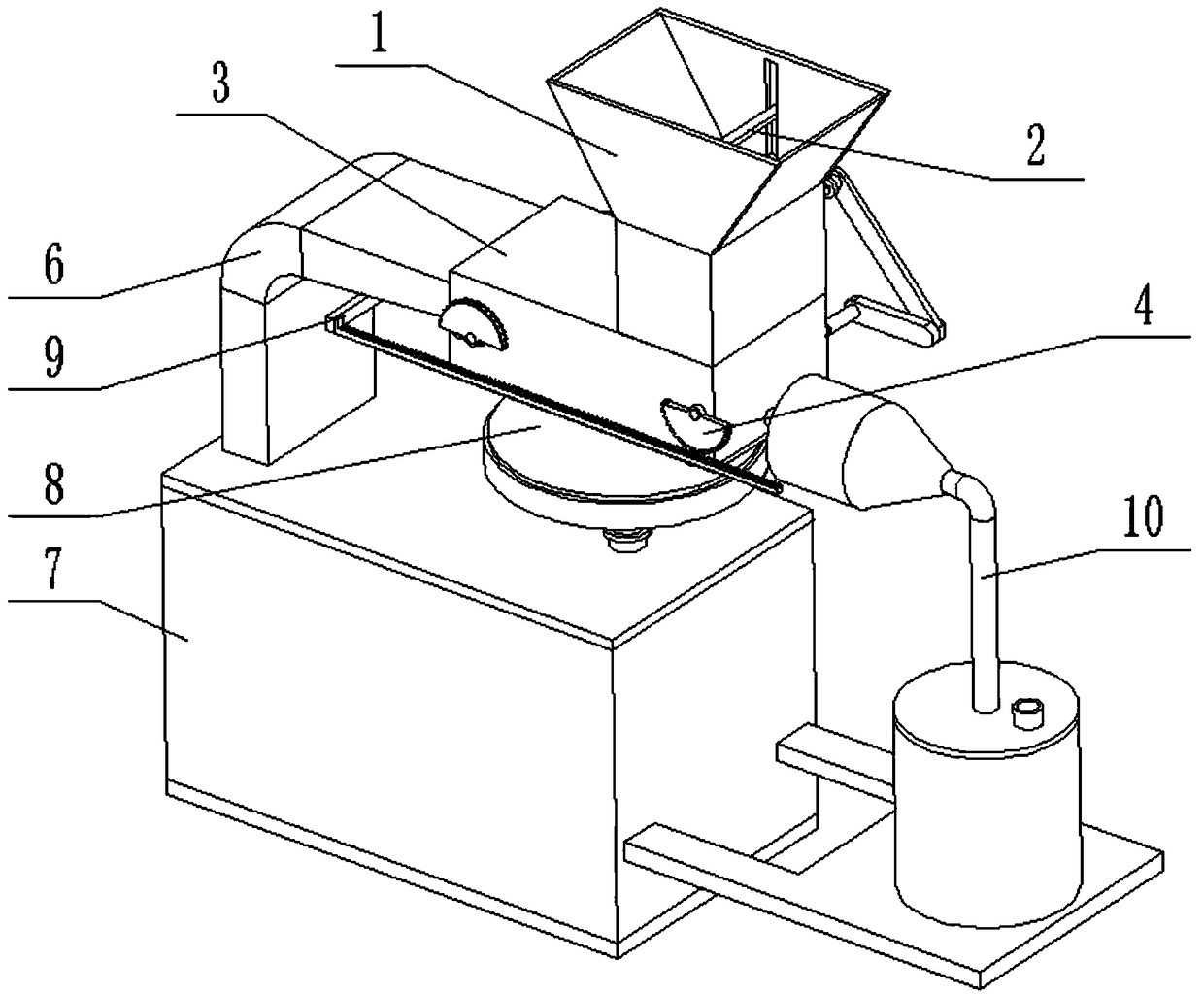

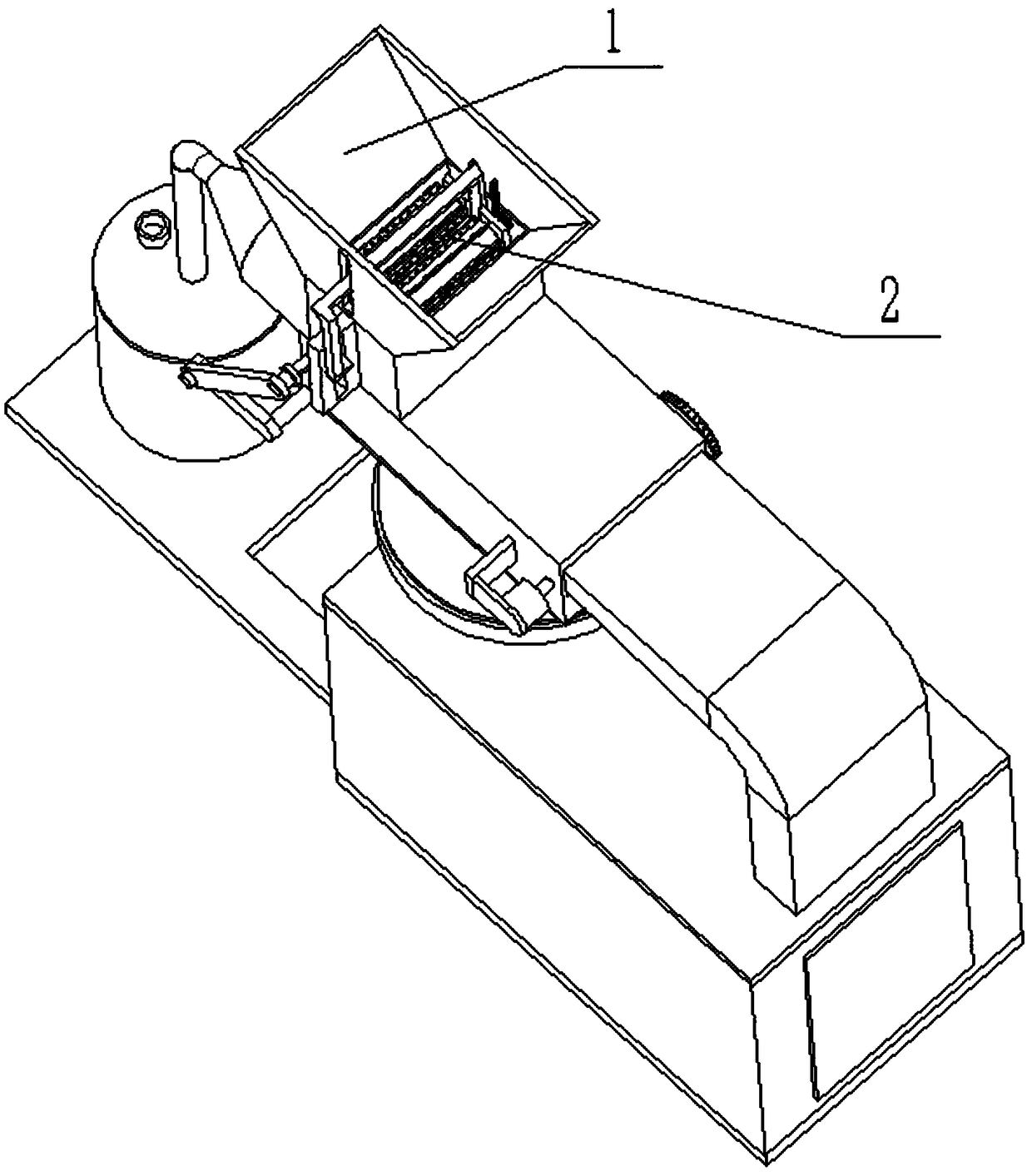

Technology and device for pyrolyzing biogas residues by molten salt and preparing phenol compounds

The invention discloses a technology and a device for pyrolyzing biogas residues by molten salt and preparing phenol compounds. The device for pyrolyzing the biogas residues by the molten salt and preparing phenol compounds comprises a biogas residue smashing and feeding device, a pyrolysis reaction device and a product collecting and treating device, wherein the pyrolysis reaction device comprises a pyrolysis reaction kettle, a separation column arranged in the pyrolysis reaction kettle, a stirring device and an electric heating sleeve arranged on the outer side of the pyrolysis reaction kettle, a cavity in the pyrolysis reaction kettle is of a cylindrical structure, and the separation column divides inside of the pyrolysis reaction kettle into ring cylindrical cavity structures; the molten salt is contained in the pyrolysis reaction kettle, a discharge port of the biogas residue smashing and feeding device is connected with a biogas residue feed port in the top of the pyrolysis reaction kettle through a pipeline, and a gas outlet in the top of the pyrolysis reaction kettle is connected with a gas inlet of the product collecting and treating device through a pipeline. A traditional biogas residue fertilizing method is replaced with biogas residue pyrolysis by the molten salt, the molten salt has a catalytic effect on biogas residue pyrolysis, so that resources are sufficientlyutilized, and the pyrolysis yield of the biogas residues is increased.

Owner:ZHEJIANG UNIV OF TECH

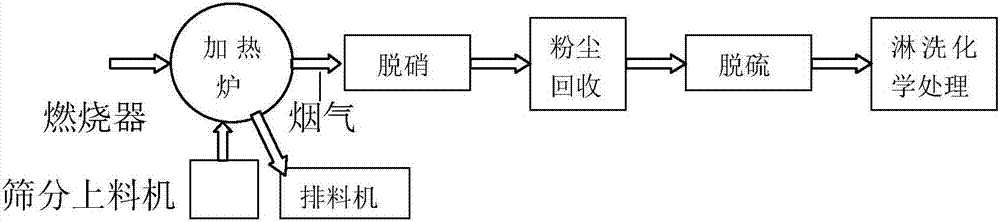

Efficient and low-pollution rural waste pyrolysis method and device

ActiveCN107741017APyrolysis achievedChange handlingBiofuelsIndirect heating destructive distillationFlue gasSpiral blade

The invention discloses an efficient and low-pollution rural waste pyrolysis method and device. The rural waste pyrolysis device comprises an outer cylinder, a middle cylinder and an inner cylinder, wherein the outer cylinder, the middle cylinder and the inner cylinder are sequentially arranged in a sleeving mode from outside to inside; the inner cylinder serves as a first flue gas passage, a cavity formed between the inner cylinder and the middle cylinder serves as a waste pyrolysis cavity, and a cavity formed between the middle cylinder and the outer cylinder serves as a second flue gas passage; spiral blades used for pushing the waste are arranged on the outer circumferential wall surface of the inner cylinder; spiral flow guide blades are arranged on the outer circumferential wall surface of the middle cylinder so that flue gas can flow in the second flue gas passage according to the spiral flow guide track of the spiral flow guide blades; the high-temperature flue gas flows through the two flue gas passages to transfer heat to the waste pyrolysis cavity and heats the waste inside the waste pyrolysis cavity; and the waste is pyrolyzed as the waste moves ahead in the waste pyrolysis cavity under the pushing of the spiral blades. According to the pyrolysis process of the device, products which are generated after the waste is subjected to pyrolysis can be combusted and reused, and on one hand, the products can be used for generating the high-temperature flue gas to provide heat to a waste drying device and a waste pyrolysis device, on the other hand, the products can be used for residential life as well as industrial and agricultural production.

Owner:SOUTH CHINA UNIV OF TECH

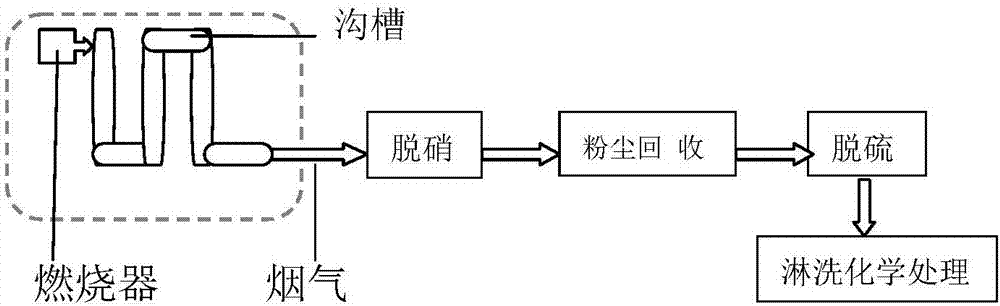

Heat repairing method for organic contaminated soil

PendingCN106903154AImprove pyrolysis effectStrong thermal decompositionContaminated soil reclamationHalohydrocarbonDecomposition

The invention provides a heat repairing method for organic contaminated soil. Smoke of a combustion furnace is used for heating the organic contaminated soil in an in-situ or different-position manner, and heavy metal type pollution, pesticide type pollution, hydrocarbon pollution and biology and nutrient type pollution are separated from the soil. According to the method, the strong heat decomposition and stabilizing functions are achieved for the pollutants which belong to the heavy metal type such as chromium, cadmium, mercury, arsenic, lead, copper, zinc and nickel; the organic pollutants which belong to the pesticide type such as insecticide, acaricide, bactericide, herbicide, nematicide and a plant growth regulator can be effectively desorbed at the high temperature; the extremely high pyrolysis effect is achieved for hydrocarbon pollutants including petroleum hydrocarbon, halohydrocarbon, polycyclic aromatic hydrocarbon and the like; and the biology and nutrient type pollutants can be completely decomposed at the high temperature.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

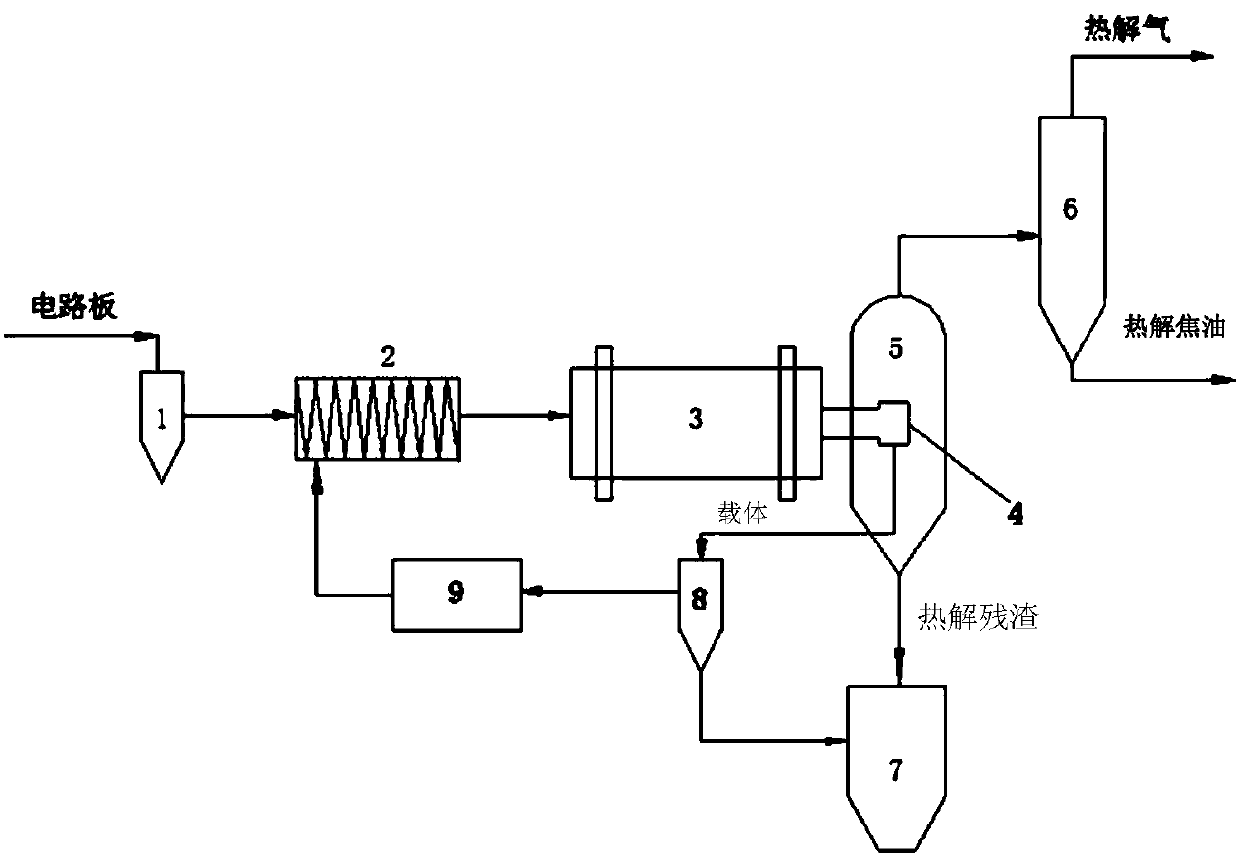

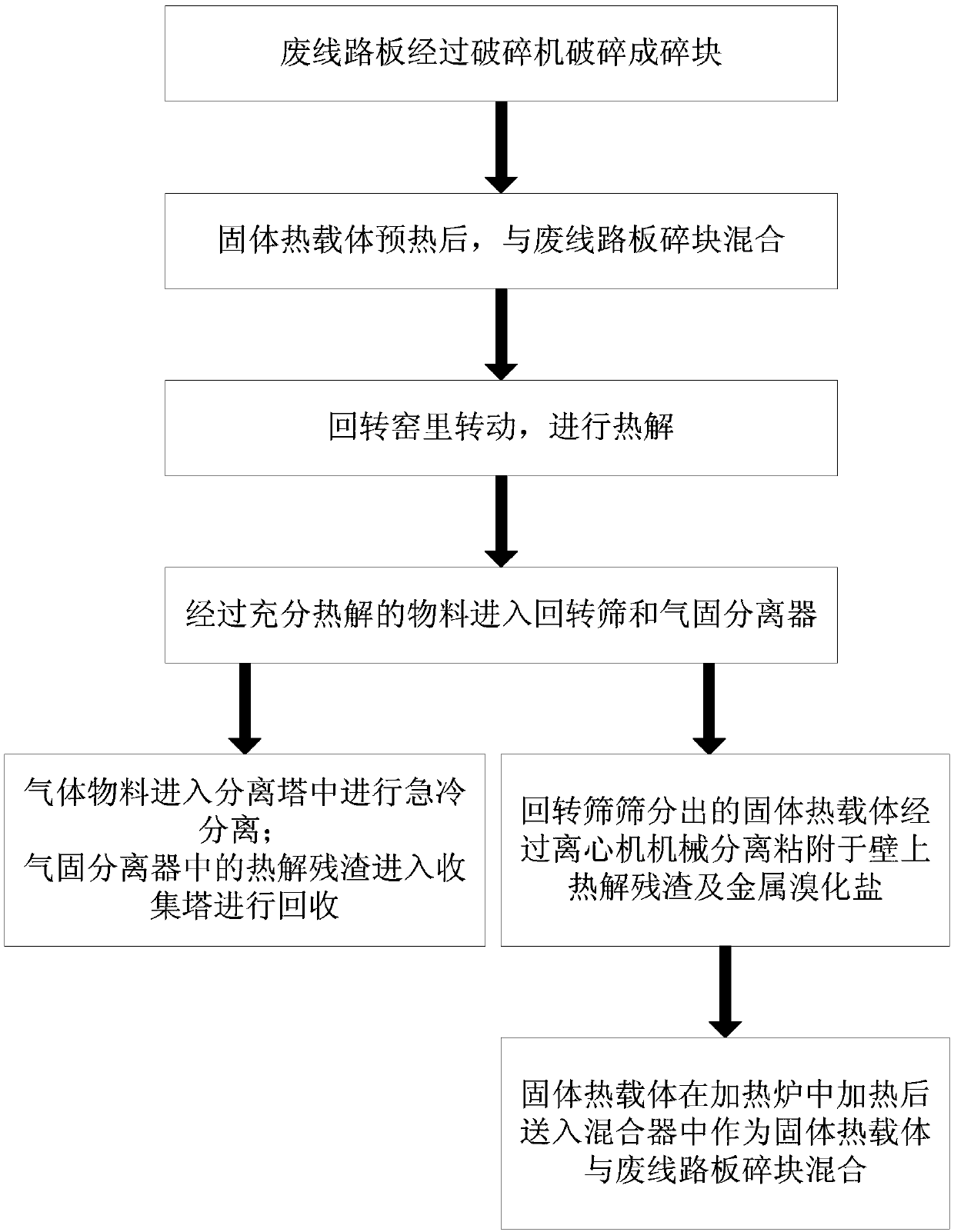

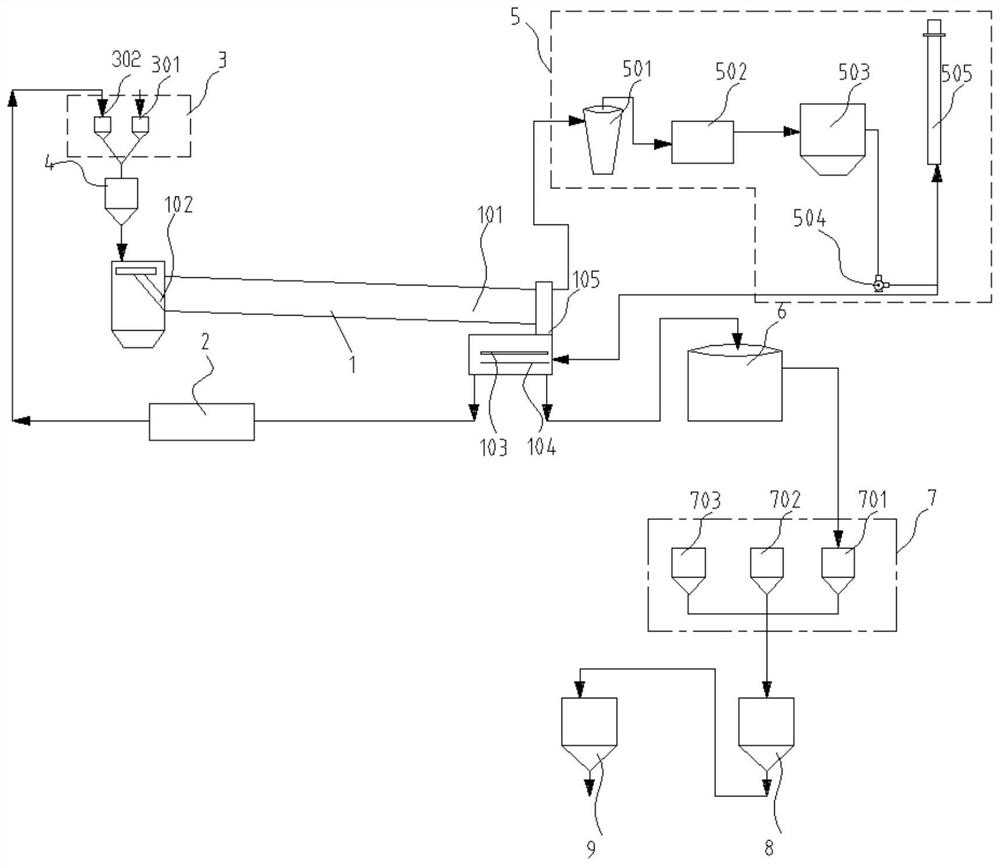

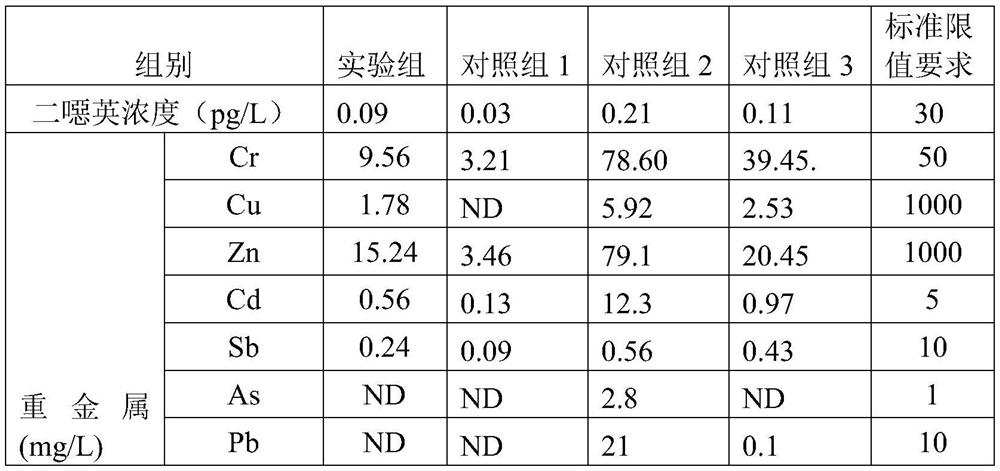

Method and system for pyrolyzing and debrominating waste circuit boards

PendingCN107891053AReduce processing costsFully contactedTransportation and packagingSolid waste disposalEngineeringCopper oxide

The invention relates to a method for pyrolyzing and debrominating waste circuit boards. The method comprises the following steps: 1) crushing the waste circuit boards; 2) mixing solid thermal carriers with the waste circuit boards; 3) pyrolyzing; 4) using a gas solid separator; and 5) performing quenching separation to obtain pyrolysis gas and pyrolysis oil. The invention further relates to a system for pyrolyzing and debrominating the waste circuit boards. The system comprises a separation tower, a crusher, a mixer, a rotary kiln, a rotary sieve, a gas solid separator, a centrifugal machine,a heating furnace and a collecting tower. According to the method and system for pyrolyzing and debrominating the waste circuit boards, a metal oxide as the solid thermal carriers is fully mixed withthe waste circuit boards, and the metal oxides such as ferric oxide and copper oxide are used to absorb the substances such as Br2 and HBr generated by the pyrolysis reaction, thereby effectively removing the halide in the waste circuit boards, and generating metal bromide to prevent the device corrosion and the influence on tar.

Owner:SHENWU TECH GRP CO LTD

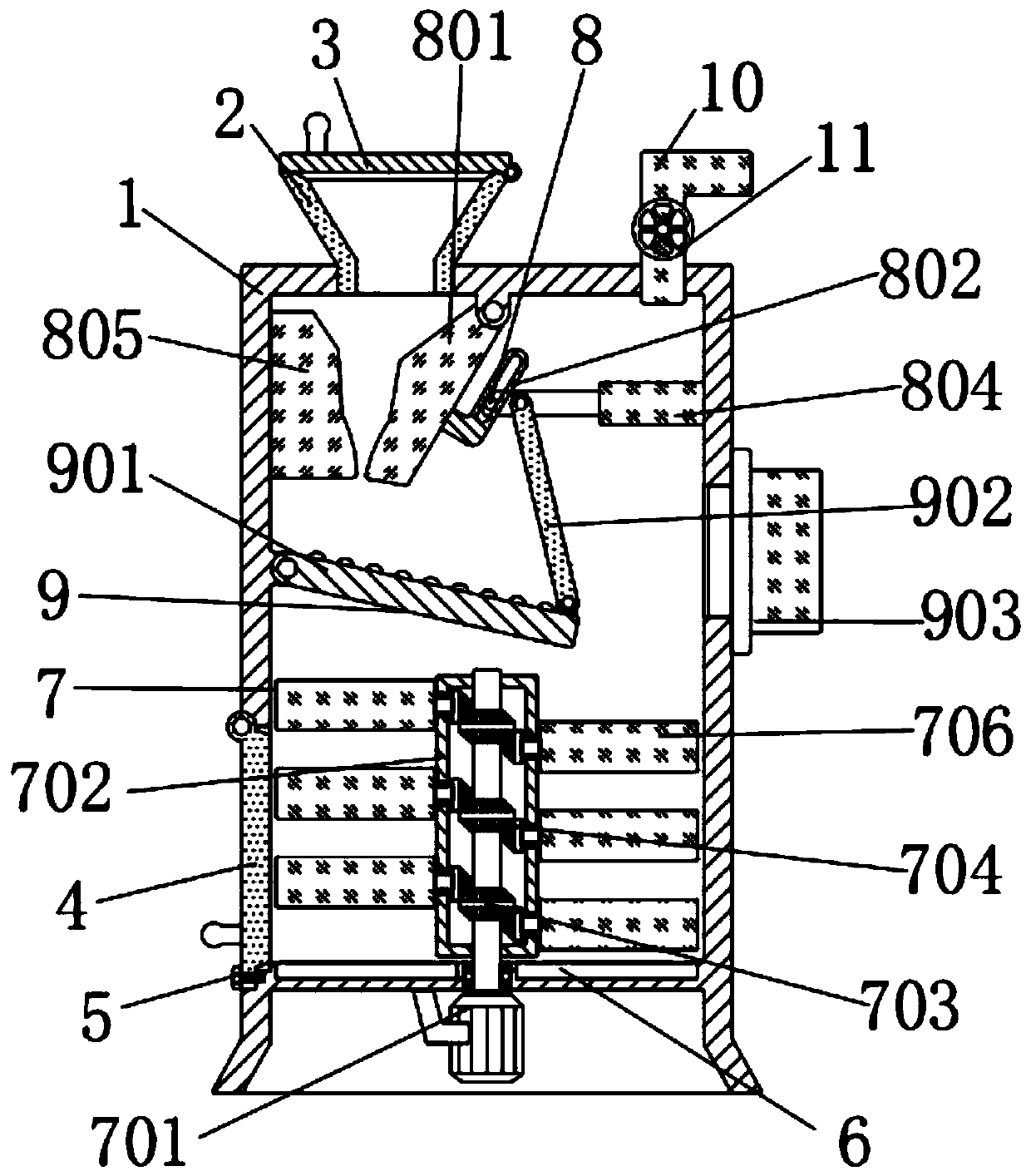

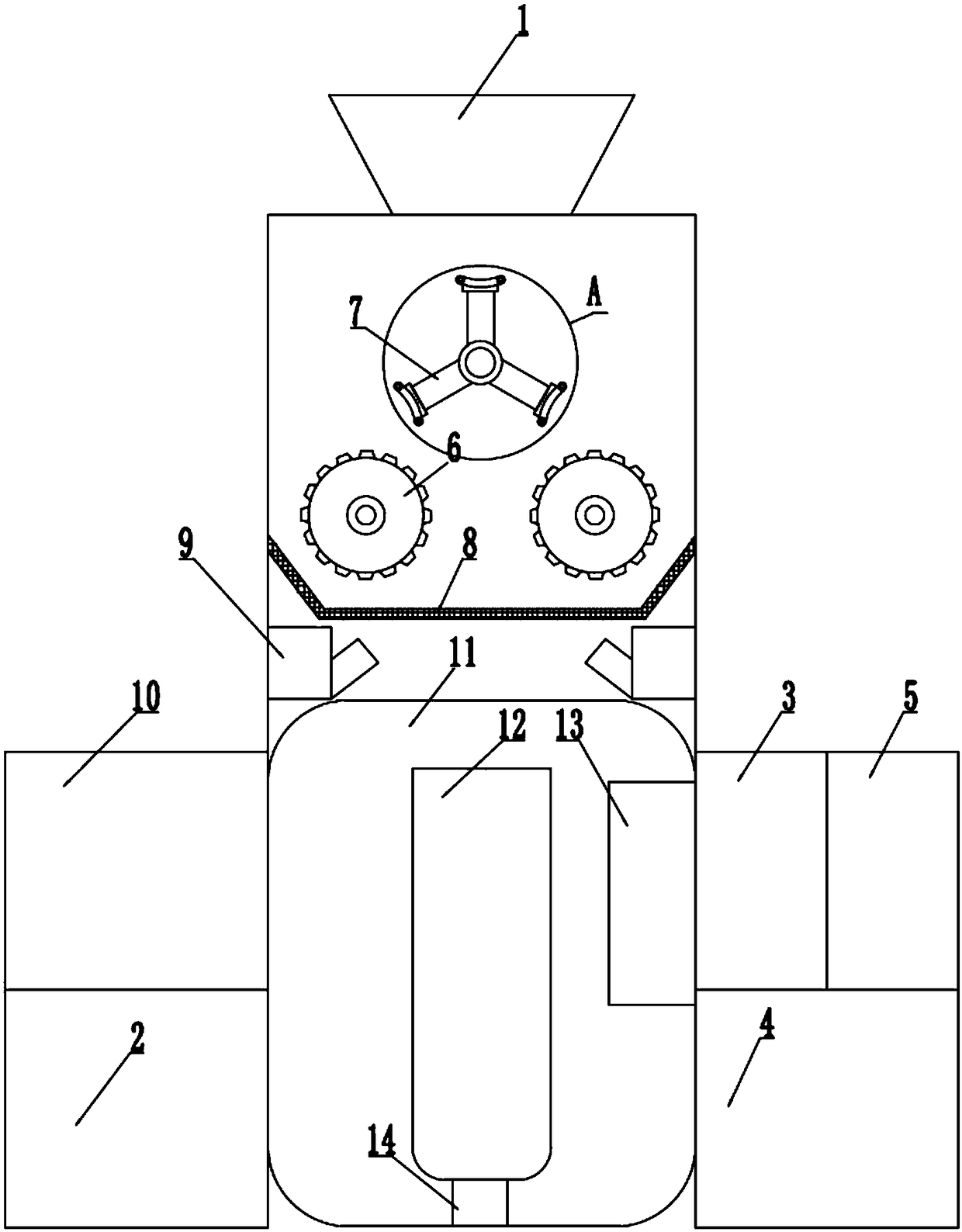

Solid waste pyrolysis treatment equipment

InactiveCN111043603AScientific and reasonable structureEasy to useIncinerator apparatusGrain treatmentsElectric machineryProcess engineering

The invention discloses solid waste pyrolysis treatment equipment. The equipment comprises a box body, wherein a feed hopper is fixedly connected to the top of the box body, a curved pipe communicateswith the top of the box body, a valve is arranged on the front surface of the curved pipe, and a turnover assembly is arranged below the interior of the box body. According to the solid waste pyrolysis treatment equipment, an electric heating plate, the box body and the turnover assembly are matched, so that the equipment carries out pyrolysis on solid waste in a vacuum environment, a turnover plate rotates along with the revolution and rotation of a motor, then the solid waste is turned, the heating uniformity of the solid waste is improved, and the pyrolysis efficiency of the solid waste isimproved; a crushing assembly, the feed hopper and the box body are matched, so that the solid waste is crushed before pyrolysis, and the pyrolysis efficiency of the solid waste is improved; and a drying assembly and the box body are matched, so that the surface of the solid waste is dried after being crushed, and the pyrolysis of the solid waste is assisted.

Owner:罗运宏

Integrated pyrolysis device and pyrolysis method of household garbage and oil shale

ActiveCN105462604AGood economic benefitsImprove pyrolysis efficiencyLiquid hydrocarbon mixture productionSpecial form destructive distillationThermal radiationOil shale

The invention discloses an integrated pyrolysis device and a pyrolysis method of household garbage and oil shale. A material platform is arranged in a microwave generating cavity of a microwave generator and is used for placing a to-be-pyrolyzed material, and the material platform is supported on the bottom in the generating cavity through a support frame; a movable cover body is arranged on the support frame and is used for covering the to-be-pyrolyzed material; a gas collecting device is arranged on the top of the microwave generator and is connected to an end opening of a gas outlet pipeline through a pipeline, then the gas collecting device is connected to a product collecting pipe, and an outlet of the product collecting pipe is formed in a beaker outside the microwave generator; the beaker is arranged in a container which is filled with an ice water mixture. The device has the advantage of simple structure, and microwave pyrolysis is performed on a mixture of the oil shale and the household garbage under the action of wave absorbers and catalysts, so that good economic benefits can be obtained; compared with traditional thermal conduction, thermal convection and thermal radiation, the microwave pyrolysis has the advantages of instantaneity, high pyrolysis efficiency and the like, and heat is emitted from inside to outside.

Owner:SOUTH CHINA UNIV OF TECH

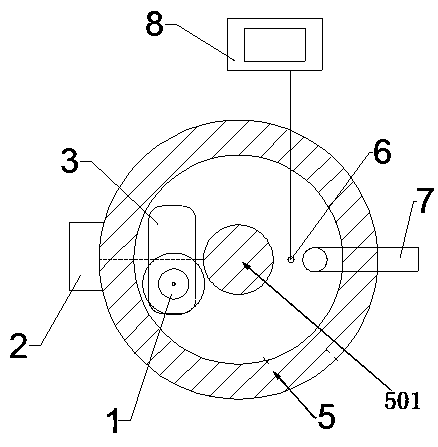

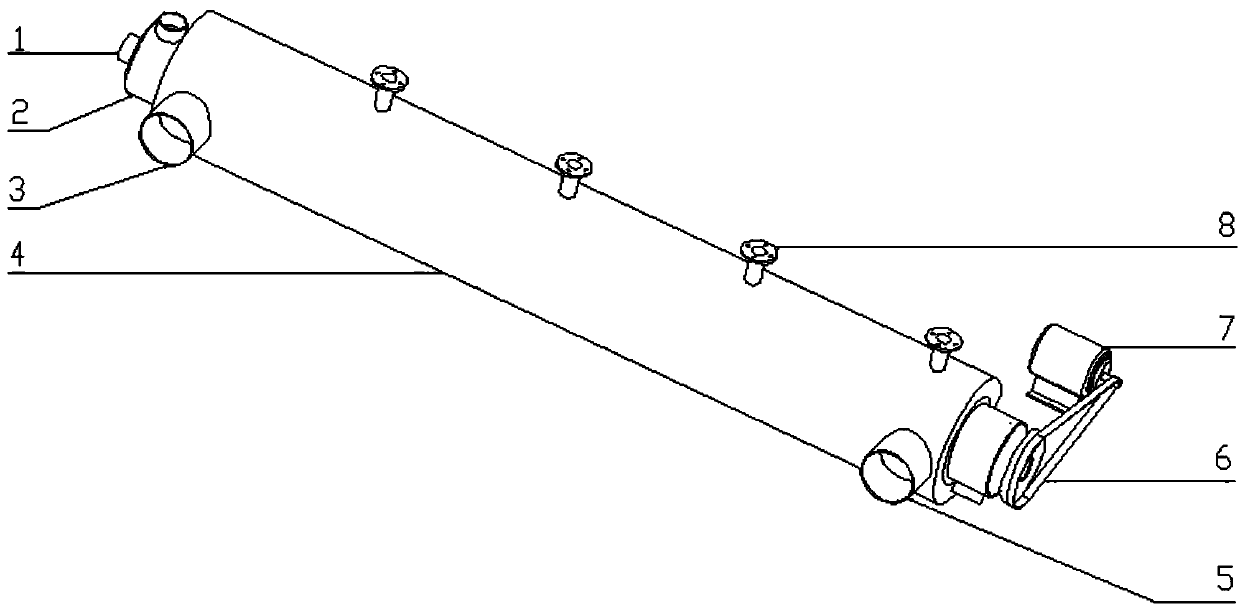

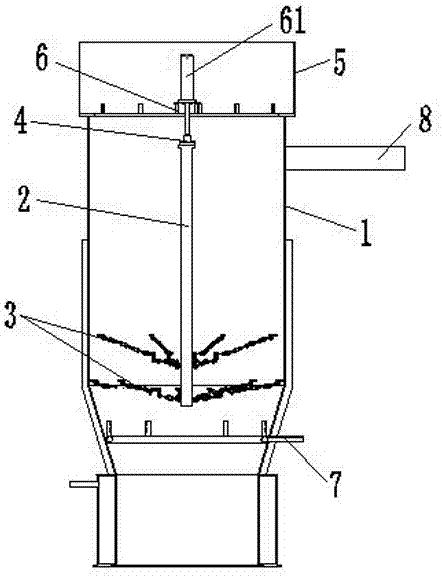

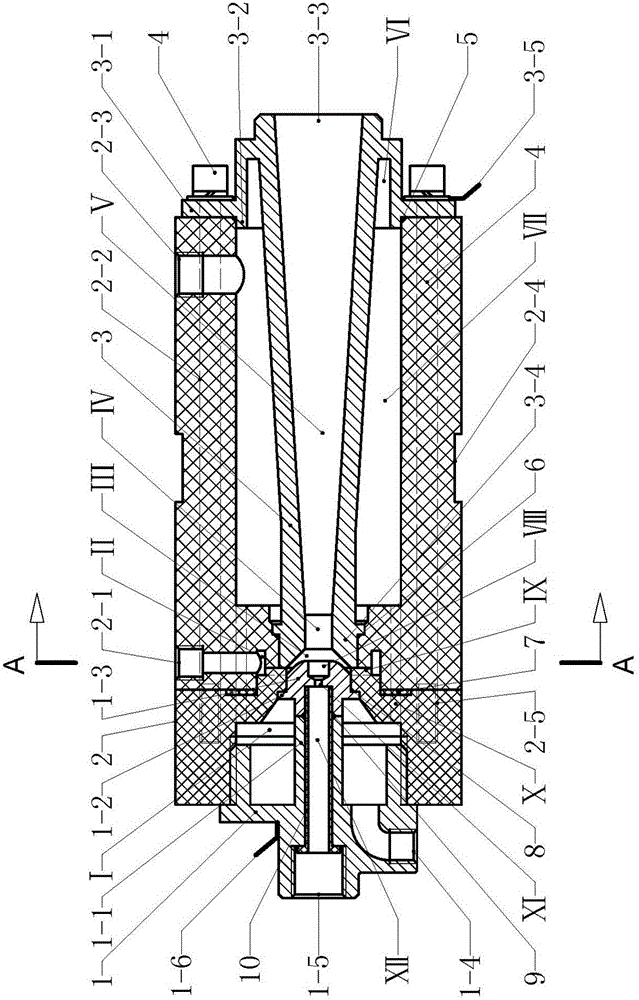

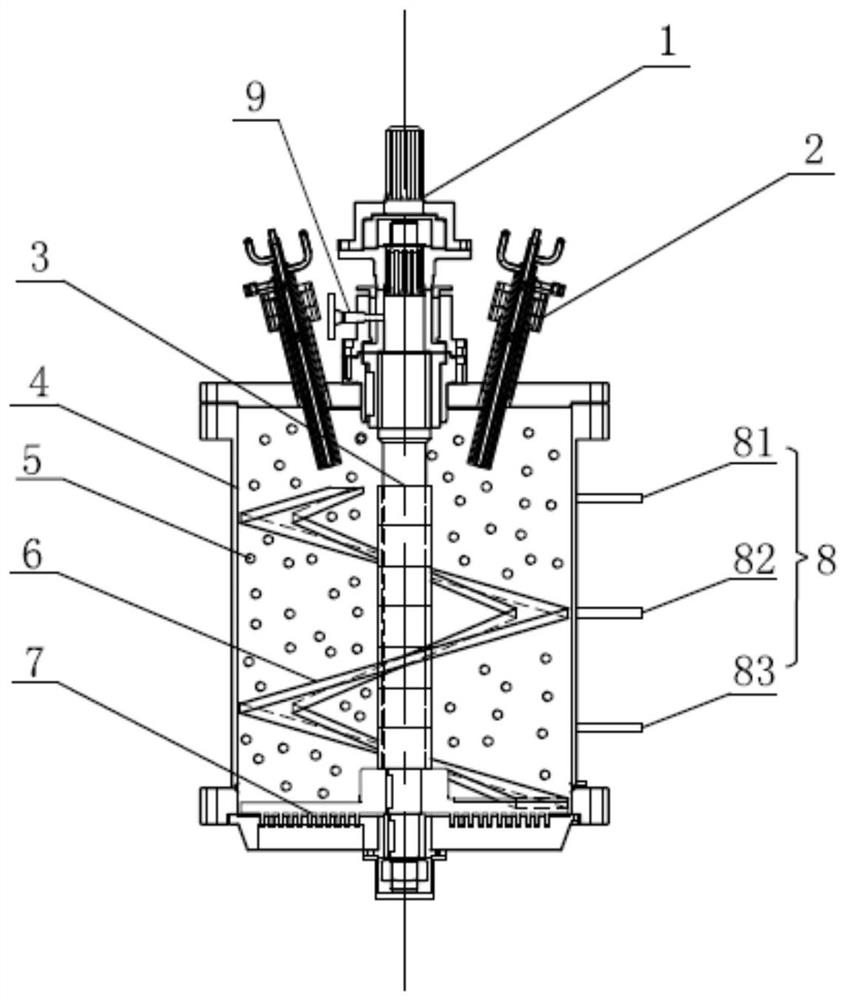

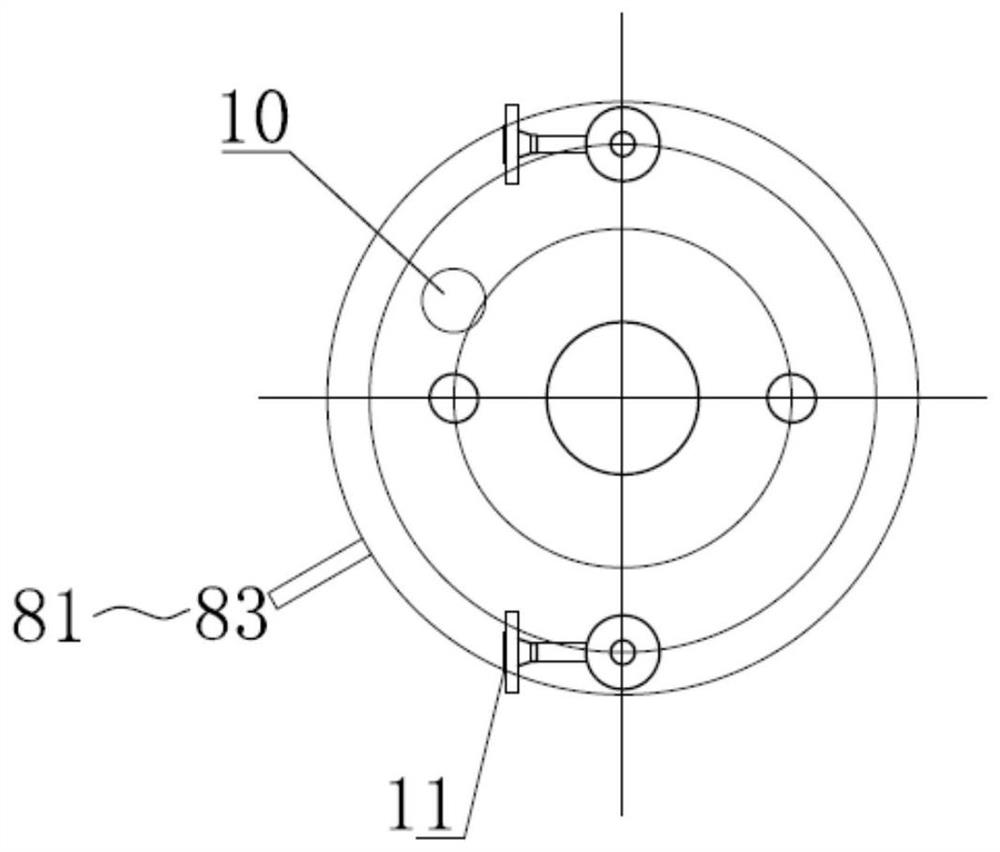

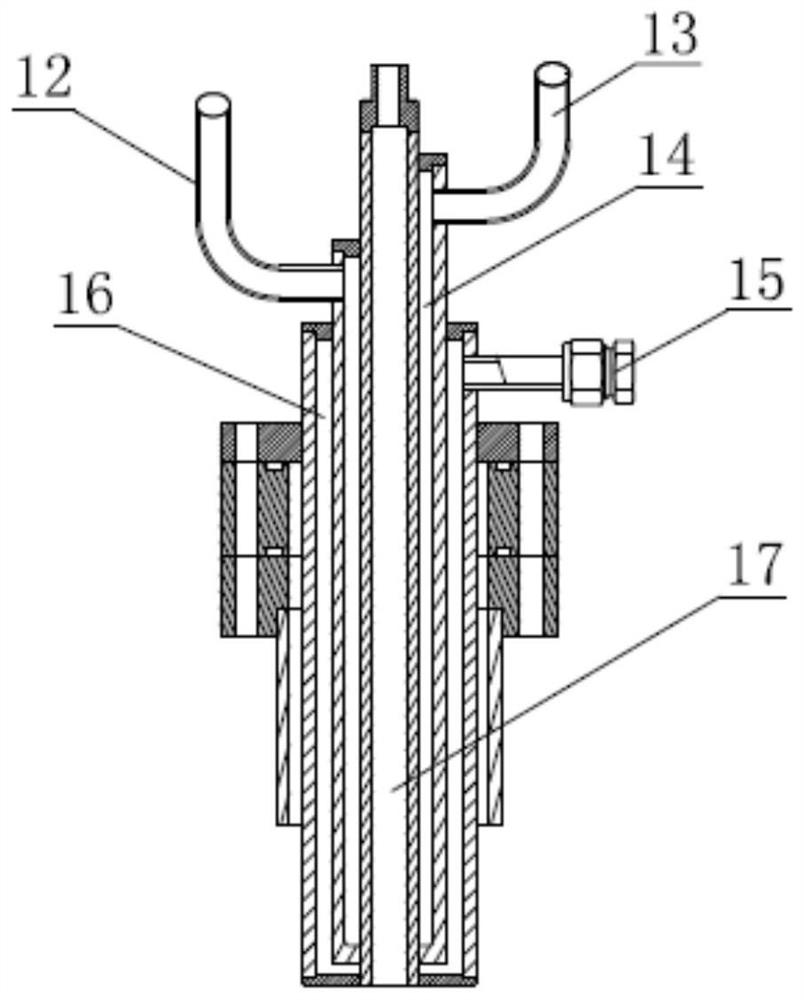

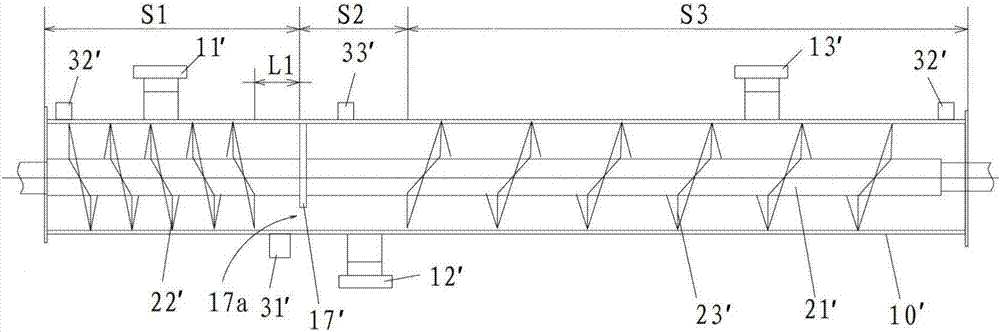

Material bridging preventing device of vertical type pyrolyzing furnace

InactiveCN107461751AImprove pyrolysis effectPrevent bridgingIncinerator apparatusReciprocating motionPush pull

The invention discloses a material bridging preventing device of a vertical type pyrolyzing furnace. The material bridging preventing device is mounted in the pyrolyzing furnace and comprises a linkage rod, chains, a connecting flange, a water seal tank, an oil cylinder support, an oil cylinder, an oil cylinder push-pull rod, an air distribution tube and a material inlet. The oil cylinder is started to push the oil cylinder push-pull rod to move, the linkage rod is driven by the oil cylinder push-pull rod to reciprocate up and down, then the chains on the upper layer and the lower layer are driven by the linkage rod to reciprocate up and down, and therefore materials in the pyrolyzing furnace are disturbed by the chains to fail in bridging; the materials are disturbed through continuous up-and-down reciprocating motion, and the phenomenon of bridging of the materials in the pyrolyzing furnace in the pyrolysis process is prevented; and the materials can be continuously added during pyrolysis of the pyrolyzing furnace, and pyrolyzed materials can be continuously discharged, so that the effect that the pyrolysis process of the materials in the pyrolyzing furnace can be continuously operated is guaranteed. The material bridging preventing device of the vertical type pyrolyzing furnace is high in working efficiency, convenient to use and flexible to operate, and the pyrolysis effect of the pyrolyzing furnace is good.

Owner:李文福

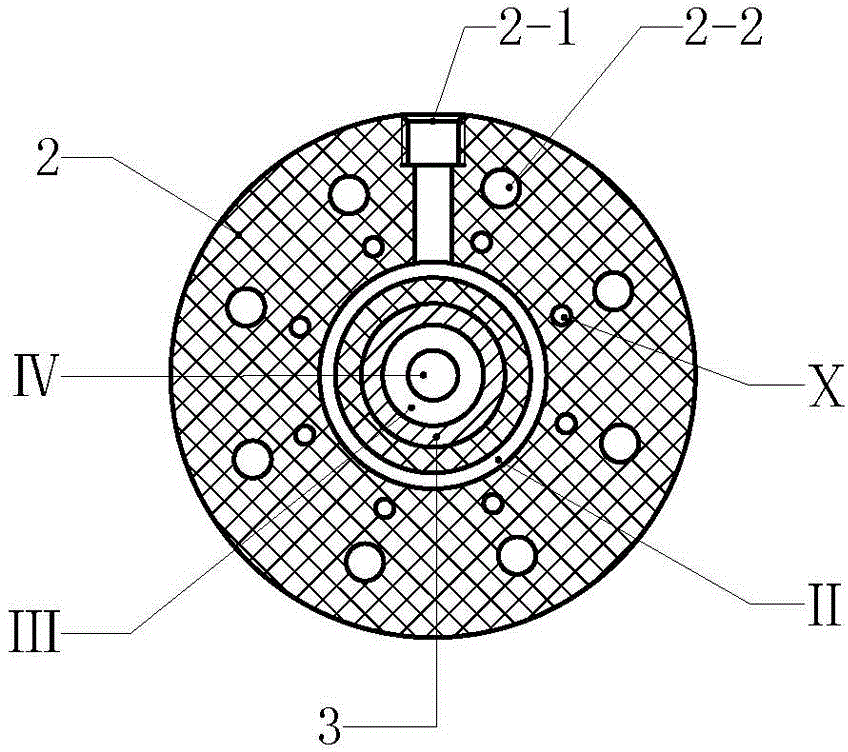

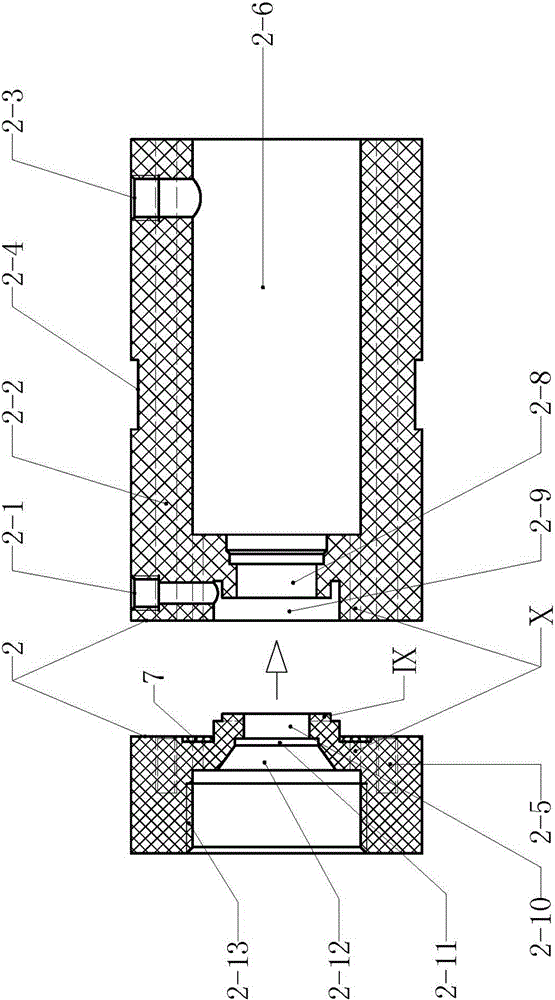

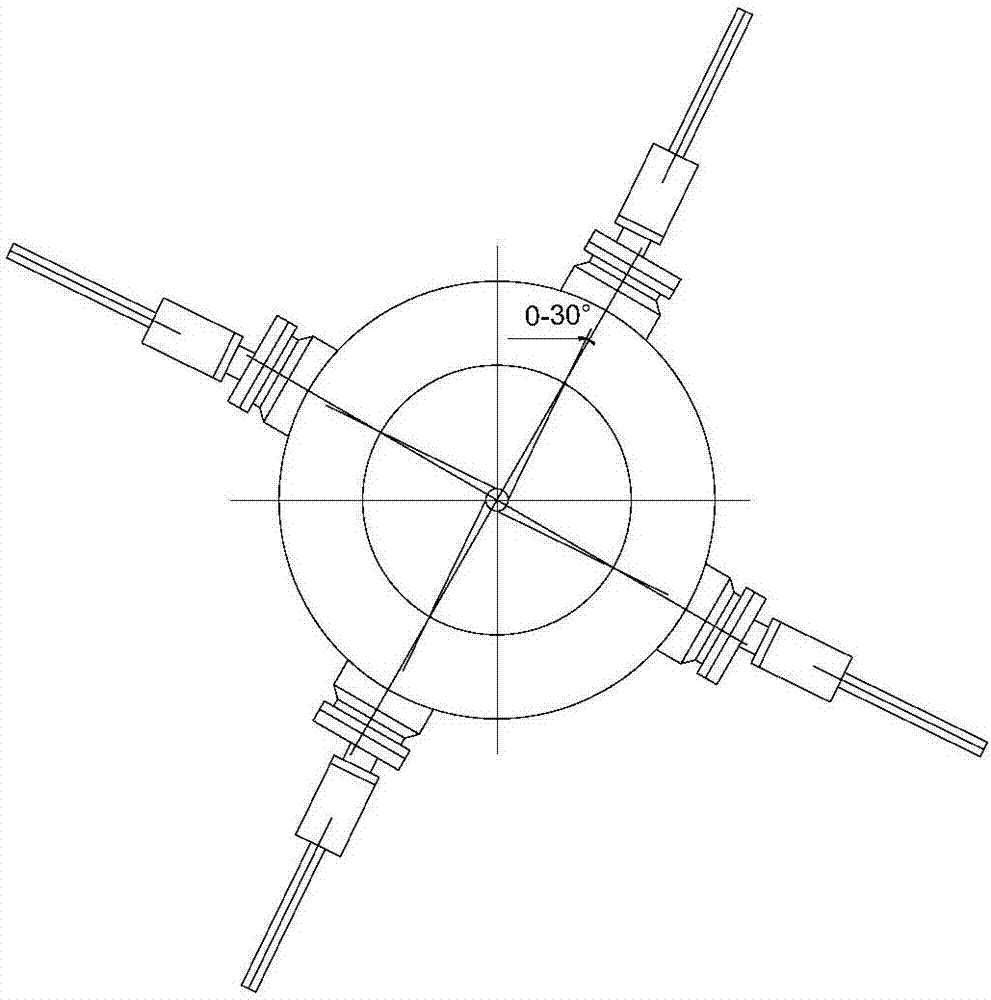

Coal gasification spray gun

ActiveCN104869742AImprove pyrolysis effectEffective protectionPlasma techniqueAutomotive engineeringAnode

The invention discloses a coal gasification spray gun, and relates to a plasma spray gun which comprises an insulating gun rack, a cathode and an anode, wherein the insulating gun rack comprises a rear cavity, a middle cavity and a front cavity; a via hole is formed between the rear and middle cavities; a socket hole is formed between the middle and front cavities; a through hole is formed in the axial center of a cathode head; a convex edge which protrudes towards the periphery is formed on the wall body of the cathode head; a tenon is arranged on the rear wall body of the anode; a positioning lug boss is arranged on the front wall body of the anode; the anode is mounted in the front cavity of the insulating gun rack; a bell mouth in the rear end of the anode enters the front cavity of the middle cavity; a cooling water jacket is defined by the space between the outer wall of the anode and the inner wall of the front cavity of the insulating gun rack; the cathode is mounted in the rear cavity of the insulating gun rack; the head end of the cathode head enters the bell mouth space in the rear end of the anode; a ring-shaped cooling cavity is defined by the space between the outer wall at the rear part of the cathode head and the inner wall of the rear cavity of the insulating gun rack. Through the adoption of the coal gasification spray gun, coal gasification can be quickly performed in the coal gasification spray gun, the gasification rate approaches 100%, and the application requirements for coal gasification production can be met.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Fluidized bed hierarchical coal pyrolysis reactor and coal pyrolysis method

InactiveCN103031135BImprove heat transfer performanceImprove heat transfer effectDirect heating destructive distillationBiofuelsFluidized bedMixed materials

The invention discloses a fluidized bed hierarchical coal pyrolysis reactor. The fluidized bed hierarchical coal pyrolysis reactor comprises a pyrolysis chamber, a separating wall, a pyrolytic gas waste heat recovery device, a coal conveying device, a large granule outlet, a mixed material outlet and an ash conveying device, wherein the pyrolysis chamber comprises a low-temperature pyrolysis chamber and a high-temperature pyrolysis chamber. The invention further discloses a method for performing coal pyrolysis by using the device. By the method, the yield of gas is high, the yield of tar is low, high-efficiency and complete pyrolysis of coal is realized, the gas flow is less fluidized, and excellent fluidized heat exchange and conveying of coal, semicoke and circulating ash are realized, so that energy consumption and heat loss caused by fluidized gas are reduced. Low-temperature pyrolytic gas and high-temperature pyrolytic gas are mixed, so secondary pyrolysis of the lightweight tar of the low-temperature pyrolytic gas is realized, the yield of the pyrolytic gas is increased and the amount of the tar is reduced; and the temperature of the medium-temperature gas after mixing is reduced compared with the pyrolysis final temperature of the coal pyrolysis reactor, so the capacity and the flowing resistance of the pyrolytic gas waste heat recovery device can be reduced, the cost of equipment materials is reduced and the reliability of the equipment is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

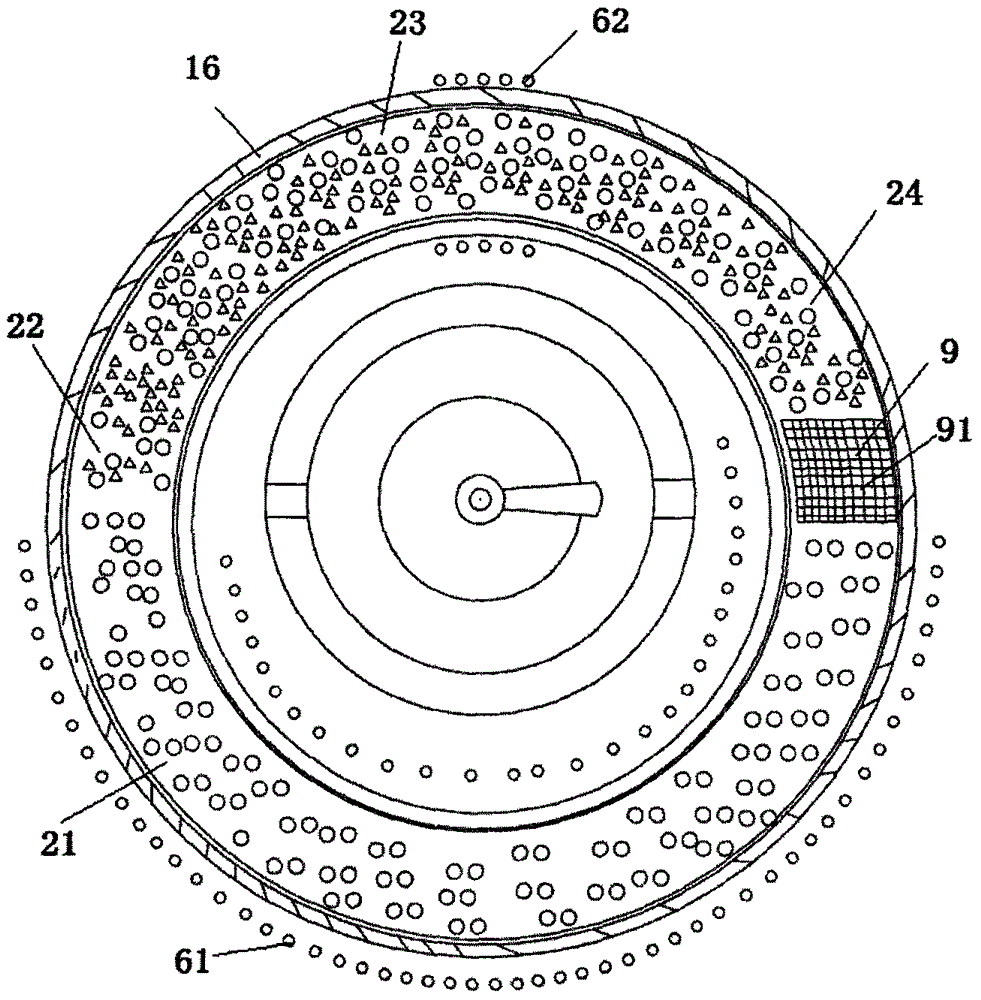

Ball-milling type pyrolysis activation furnace

PendingCN112013402AGood pyrolysis effectRapid responseDispersed particle filtrationRotary stirring mixersGrindingPyrolysis

The invention provides a ball-milling type pyrolysis activation furnace. The ball-milling type pyrolysis activation furnace comprises a furnace body, a driving device located on the top of the furnacebody, a stirring shaft connected with the driving device, nozzles with the same ends inserted into the top of the furnace body, a heat tracing band wound around the outer side of the furnace body anda plurality of stainless steel balls arranged in the furnace body in a filled mode. One end of the stirring shaft is rotationally connected with the driving device, the other end of the stirring shaft extends into the furnace body, and a stirring paddle is arranged on the stirring shaft, is arranged in the furnace body and rotates along with the stirring shaft. The stainless steel balls in the ball-milling type pyrolysis activation furnace have three motion modes, materials can be fully ground, and the pyrolysis effect is better. In addition, three different temperature zones are arranged, sothat rapid reaction, grinding and decomposition of a radioactive organic solvent are realized; the multiple nozzles are used for continuously feeding the materials, decomposed substances enter a rearsection to be processed through a screening plate at the bottom of the furnace body, and the continuous work can be realized; and the stirring shaft with a hollow structure is arranged, and a bearingon the stirring shaft is prevented from being sintered and stuck through cooling liquid.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

Garbage air drying treatment system and method

ActiveCN106642146ARemarkable drying efficiencyEasy to storeDrying gas arrangementsDrying machines with non-progressive movementsDehydrationTreatment system

The invention discloses a garbage air drying treatment system. The garbage air drying treatment system comprises a low-temperature air drying production device and a connected garbage air drying treatment device. The garbage air drying treatment device includes a first garbage air drying cylinder provided with a first spiral turning plate on the inner wall; the first spiral turning plate is overturned under rotation of the first garbage air drying cylinder to push garbage to move; an intake port of the first garbage air drying cylinder is connected with the low-temperature air drying production device; low-temperature dry air is blown out in the axial direction of the first garbage air drying cylinder; and the operation direction of the low-temperature dry air is the same with the pushing direction of the garbage. The garbage air drying treatment device further includes a second garbage air drying cylinder; and the operation direction of the low-temperature dry air in the second garbage air drying cylinder is opposite to the pushing direction of the garbage. The invention further discloses a treatment method of the garbage air drying treatment system. The garbage air drying treatment system uses high-temperature tail gas as a hot air source and natural wind and fed wind to produce the low-temperature dry air; and the low-temperature dry air performs dehydration and air drying for garbage raw materials, so that the storage and the transportation are facilitated, the garbage pyrolysis efficiency is improved, and the effects of environmental protection and feasibility are achieved.

Owner:BEIJING ZHONGJI TORCH ENVIRONMENTAL PROTECTION TECH CO LTD

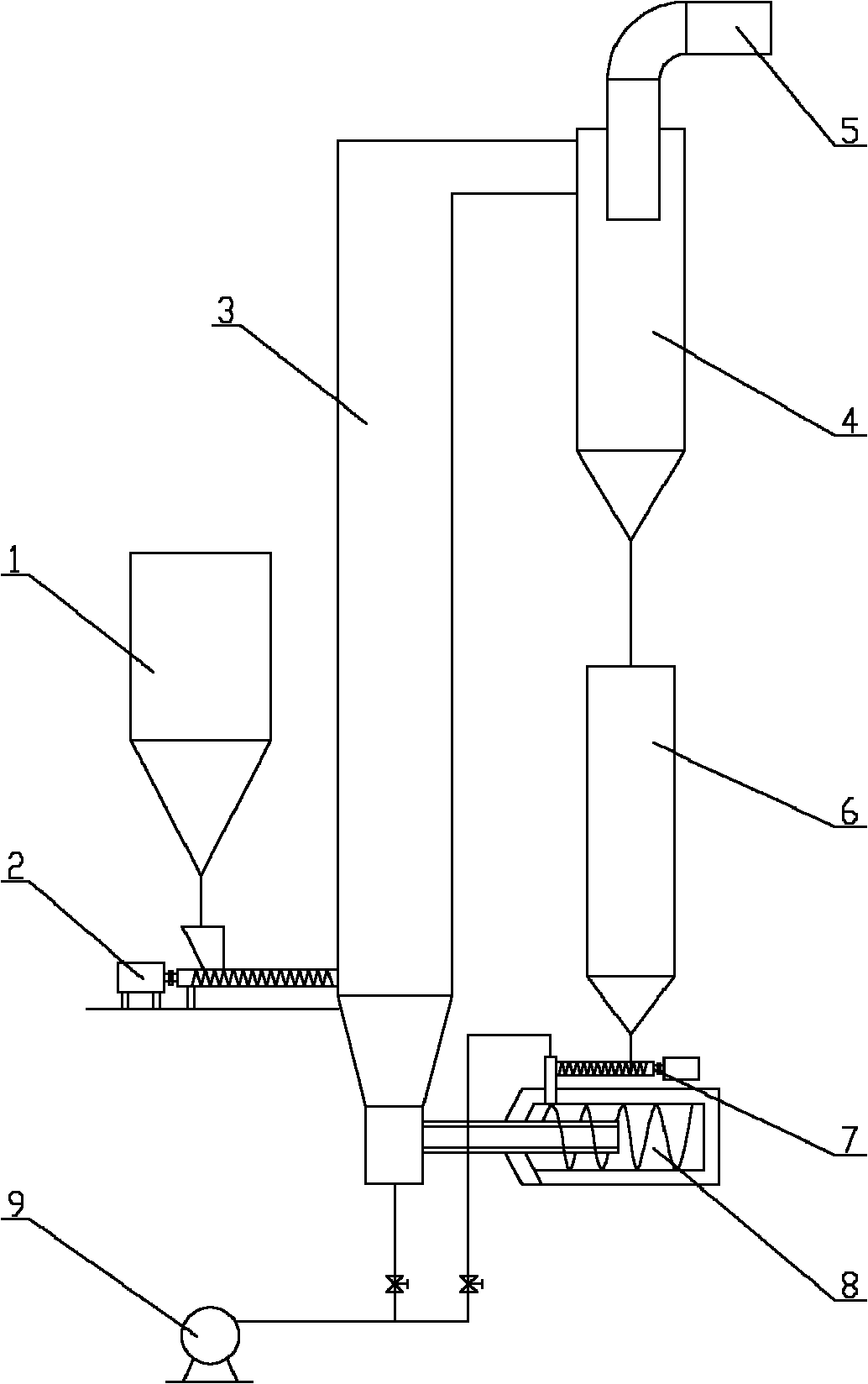

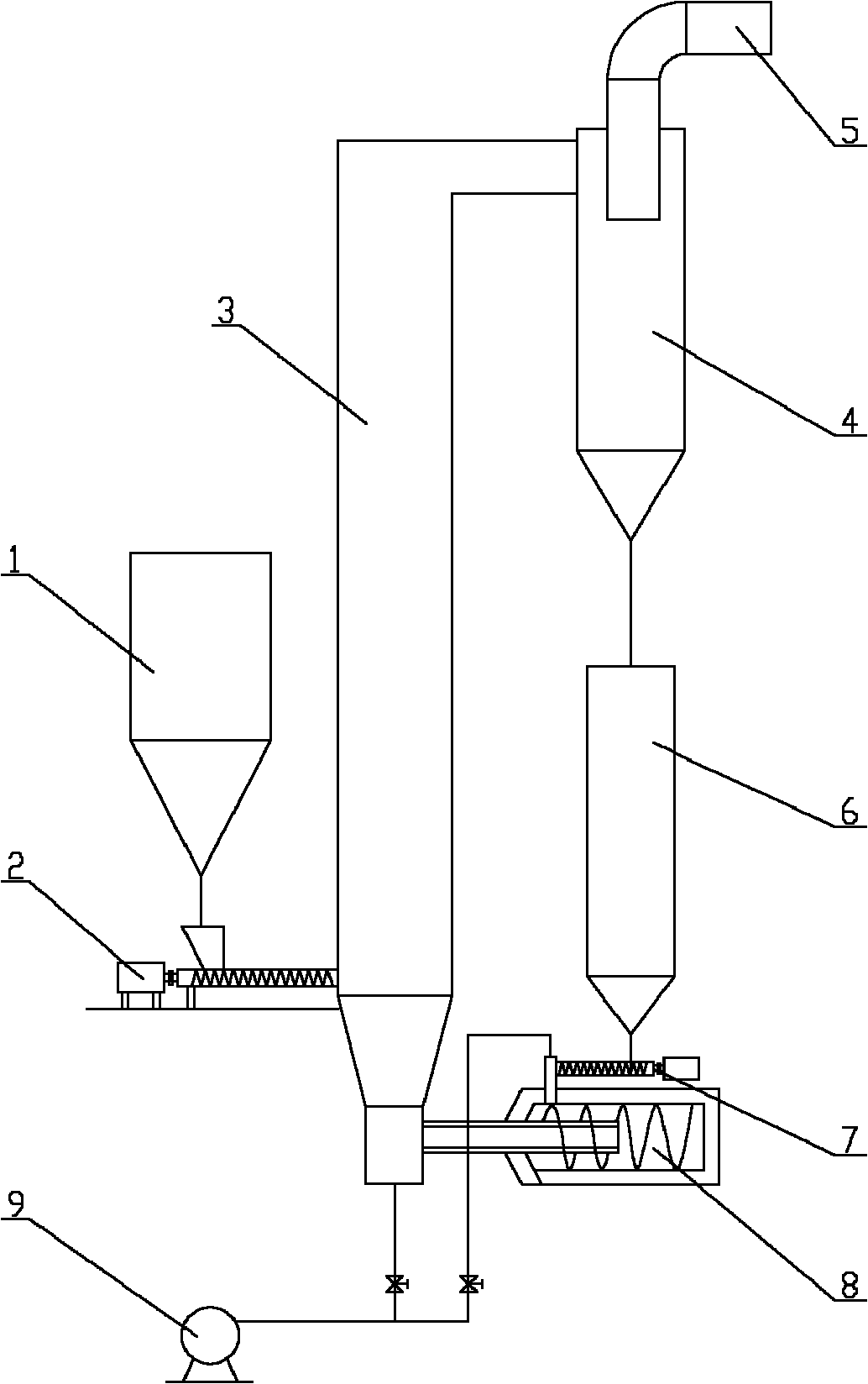

Two-section circulating fluidized bed biomass gasification system

InactiveCN102031155AGood pyrolysis effectNo wasteEnergy inputCombustible gas productionThermal energyFluidized bed gasifier

The invention discloses a two-section circulating fluidized bed biomass gasification system. The system comprises a fluidized bed gasification furnace, a bin, a feeder, an ash remover fan, an ash bucket and a second feeder, wherein the fluidized bed gasification furnace is provided with a second inlet; the outlet of the ash bucket is connected with the second feeder; the outlet of the second feeder is connected with an air supply inlet of a burner; the outlet of the burner is connected with the second inlet of the fluidized bed gasification furnace; and biomass char collected by the ash bucket is conveyed into the air supply inlet by the second feeder and fed into a cyclone burner for pyrolysis under the action of wind power to replenish heat for the fluidized bed gasification furnace. Through the system, good pyrolysis effect of biomass powder in the gasification furnace is guaranteed, fixed carbon in the biomass char is fully pyrolyzed through a cyclone burning chamber, and thermal circulation is provided for the fluidized bed gasification furnace for pyrolysis; therefore, waste of heat energy of the biomass powder is avoided, and thermal efficiency of the gasification system can be effectively improved.

Owner:GUANGZHOU DEVOTION THERMAL TECH

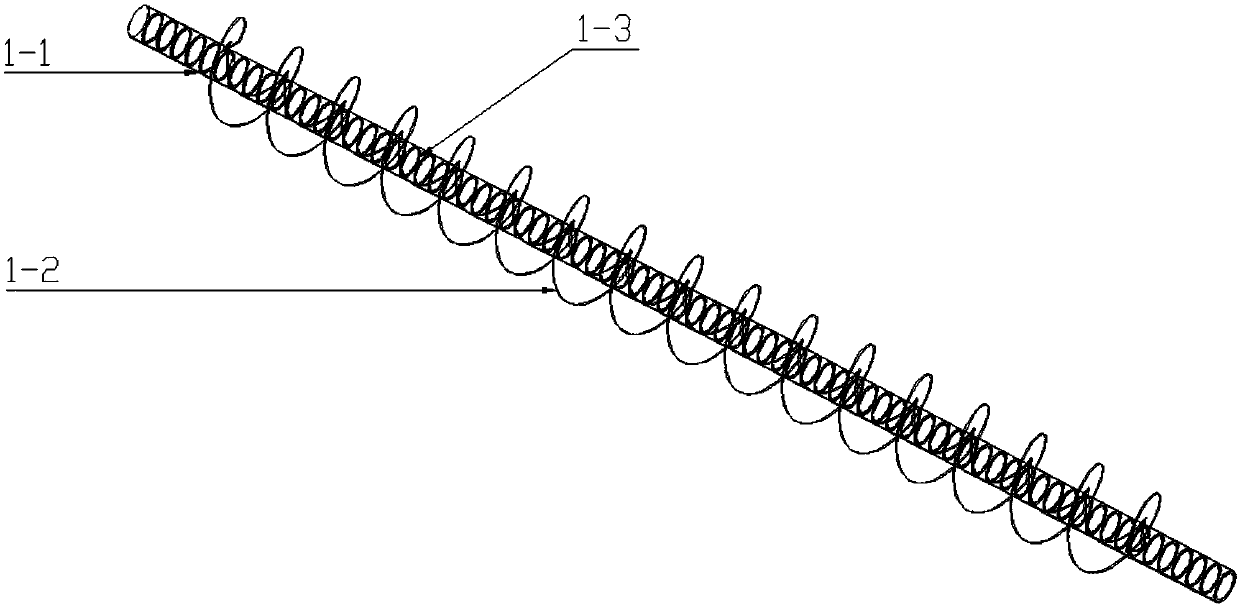

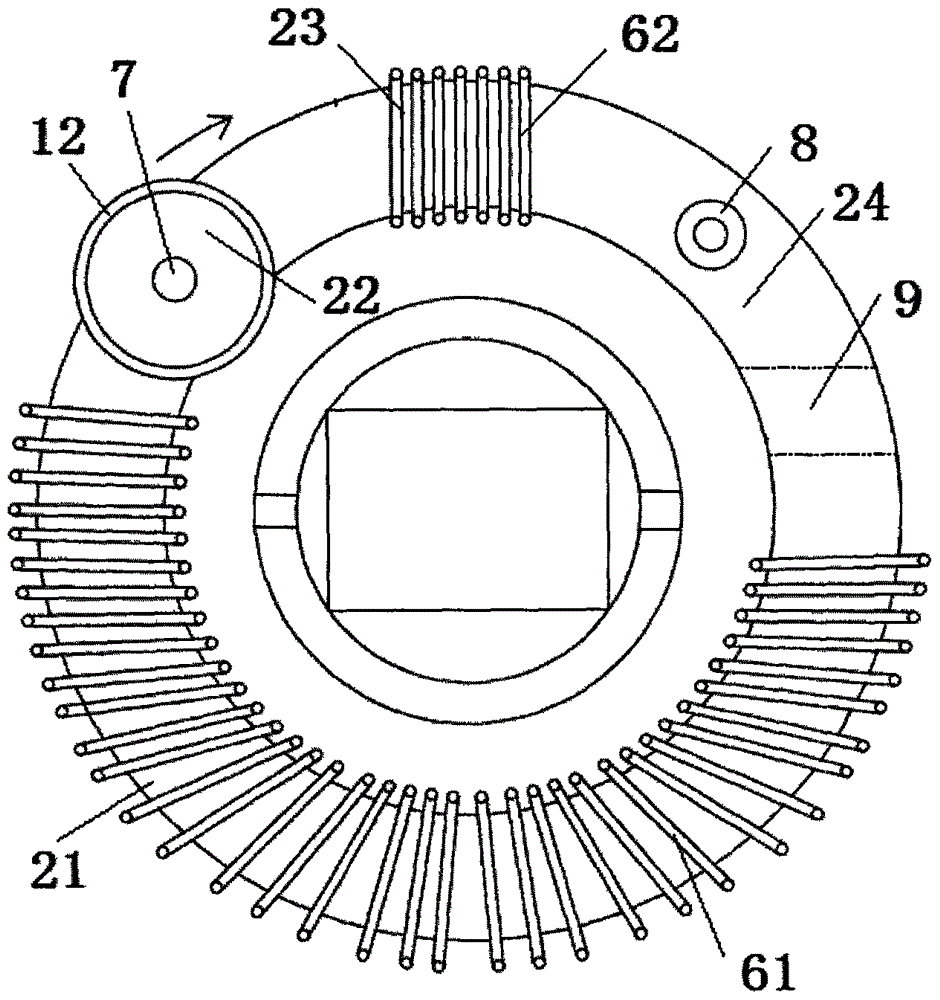

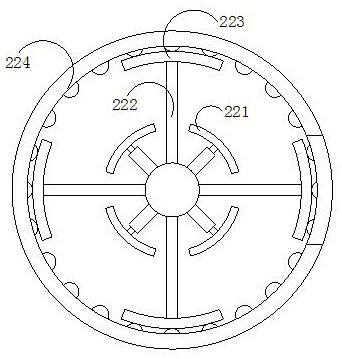

Biomass spiral-vibration electromagnetic induction pyrolysis reactor and pyrolysis treatment method thereof

ActiveCN103333708AImprove general performanceIncrease temperatureDirect heating destructive distillationBiofuelsHeat carrierMotor drive

The invention relates to a biomass spiral-vibration electromagnetic induction pyrolysis reactor and a pyrolysis treatment method thereof. The pyrolysis reactor is composed of a casing and a heater, the casing comprises a feeding bin, a vibrating box, a support, a spring and a vibrating motor. The pyrolysis method is characterized in that a vibrating source generated by the vibrating motor drives the vibrating box to vibrate, the induction heater heats the hollow cylinder of the vibrating box in an induction heating manner, vibration and power-heat exchange of a heat carrier and biomass particles in the hollow cylinder are carried out in the vibrating and heating processes of the hollow cylinder, the pyrolysis treatment of the biomass particles is completed in the hollow cylinder, and the exciting force of the vibrating motor and the heating power and time of an induction heating coil are adjusted and controlled to control the realization of three different pyrolysis modes comprising pyrolysis liquefaction, pyrolysis gasification and pyrolysis charring of the biomass particles. The pyrolysis reactor and the pyrolysis method have the advantages of strong versatility, high pyrolysis efficiency, stable pyrolysis process and strong reliability.

Owner:HUZHOU TEACHERS COLLEGE

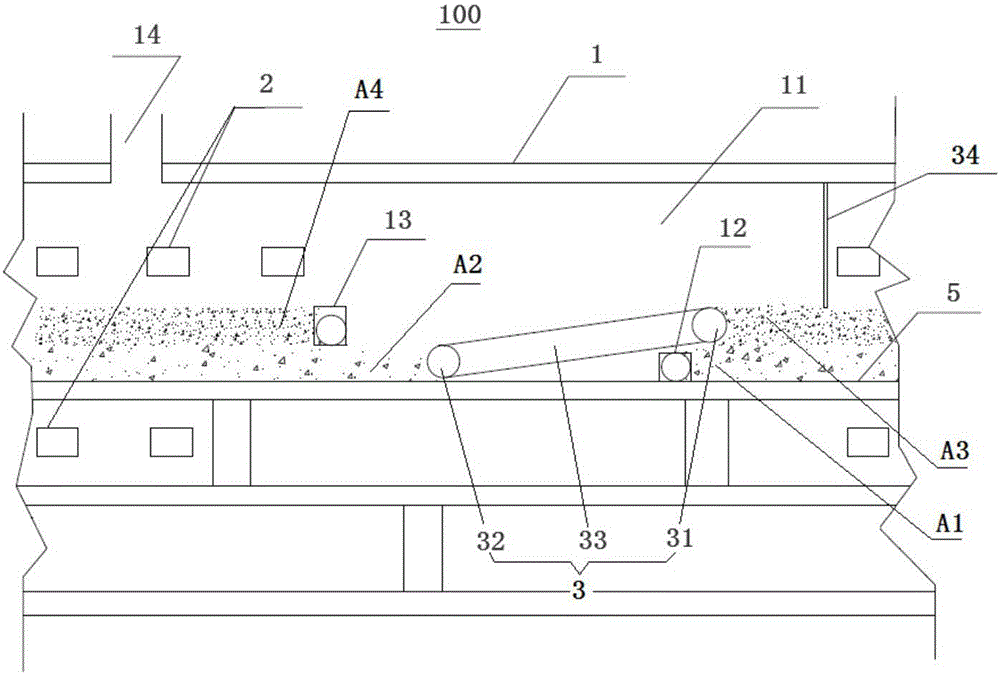

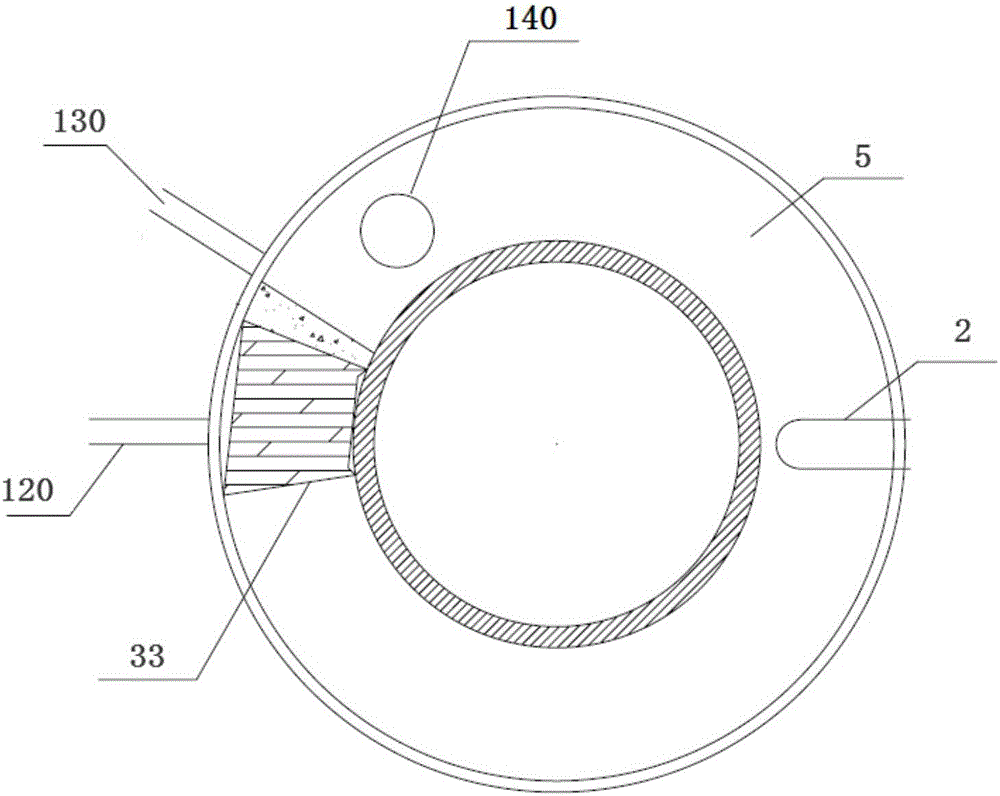

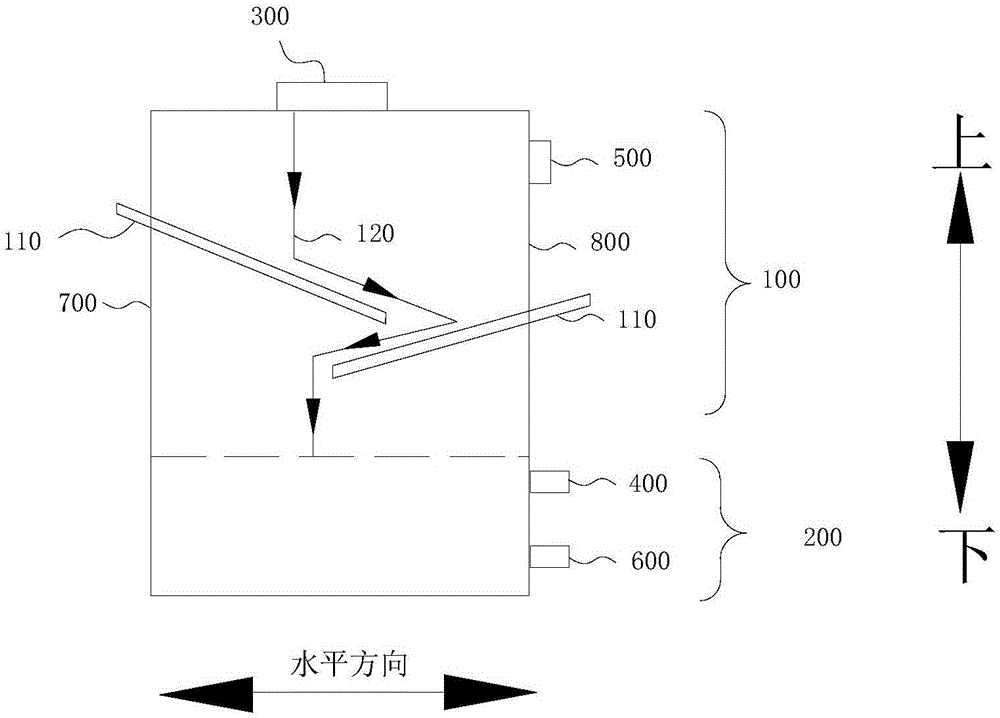

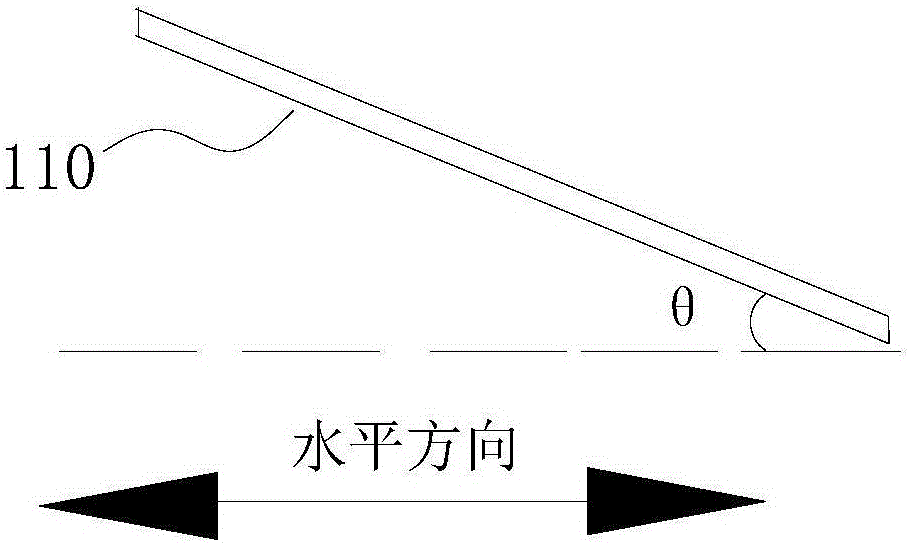

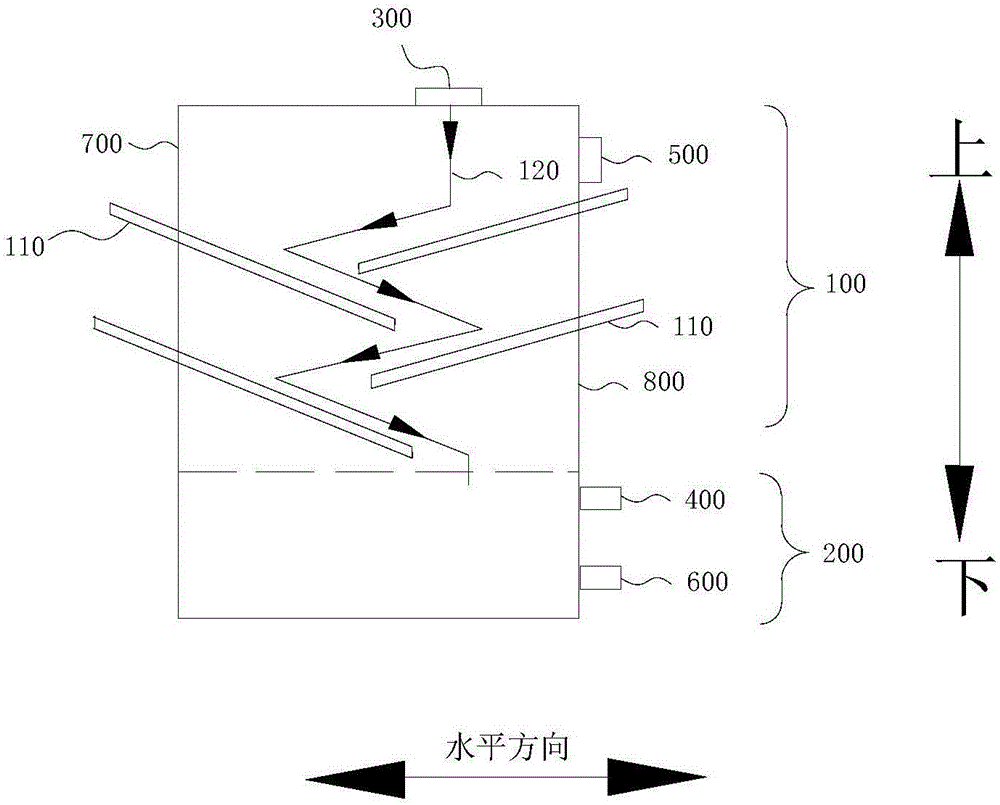

Pyrolysis device and method

ActiveCN105802643AImprove pyrolysis effectGuaranteed uptimeSpecial form destructive distillationCoke ovens heatingMechanical engineeringPyrolysis

The invention discloses a pyrolysis device and method. The pyrolysis device comprises a furnace, a heating device and a transfer device. The furnace comprises a hollow annular cavity, an annular laying plate capable of horizontally rotating is arranged on the bottom face of the cavity, a feeding port and a discharging port are formed in the side wall of the cavity, and the arrangement height of the discharging port is larger than that of the feeding port. The heating device is used for providing a heat source for pyrolysis. The transfer device is arranged in the cavity and comprises a first roller, a second roller and a lifting belt. In the operating direction of the laying plate, the first roller is arranged on the downstream side of the feeding port, and the second roller is arranged on the downstream side of the discharging port. In the vertical direction, the first roller is located above the feeding port and is adjacent to the feeding port, the second roller is located below the discharging port and is adjacent to the discharging port, and the lifting belt is arranged on the first roller and the second roller in a sleeving mode to cyclically roll. According to the pyrolysis device, the pyrolysis effect is good.

Owner:SHENWU TECH GRP CO LTD

GPG-IV gasification and pyrolysis integrated top-spray reactor and production equipment and technology

InactiveCN106947544ABig increase in oil extraction rateImprove pyrolysis effectGasification processes detailsGranular/pulverulent flues gasificationCoal waterEconomic benefits

The invention specifically relates to a GPG-IV gasification and pyrolysis integrated top-spray reactor and production equipment and a technology. The technical problems such as low oil extraction rate, immature technology, low utilization rate of raw materials, serious wastage and inconspicuous economic benefit of existing coal-to-oil equipment are solved. Heat of gasification from upper and lower sections of the reactor is simultaneously supplied to a pyrolysis section. The heat source generated by gasification is fully utilized for secondary gasification of generated coke ash. Thus, one-step conversion of coal-to-oil can be realized, pyrolysis capability of a single reactor is greatly enhanced, and coal category adaptability is wide. According to the invention, the product is diversified; comprehensive energy efficiency and technologies such as conventional pulverized coal gasification, coal water slurry gasification, etc. are high; energy consumption is lower; use amount of water is small; and handling capacity is large. Gasification + pyrolysis + semicoke gasification integrated technology is realized. The invention has advantages as follows: the technology is mature; product quality is stable; the structure is simple and reliable; utilization rate of raw materials is high; oil extraction rate is high; energy is saved and environment is protected; the technology is economic and safe; and large-scale industrial production can be realized.

Owner:中美新能源技术研发(山西)有限公司

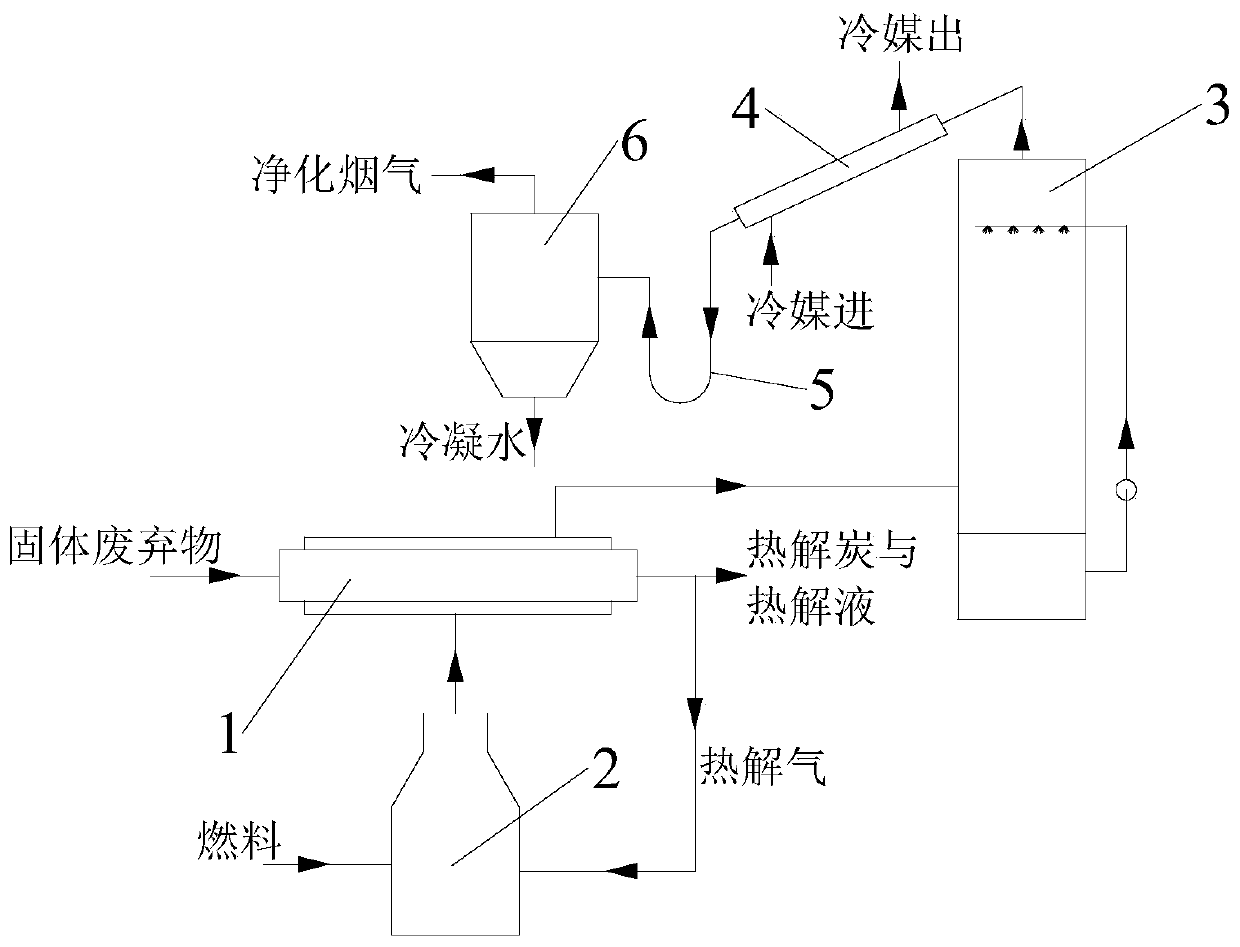

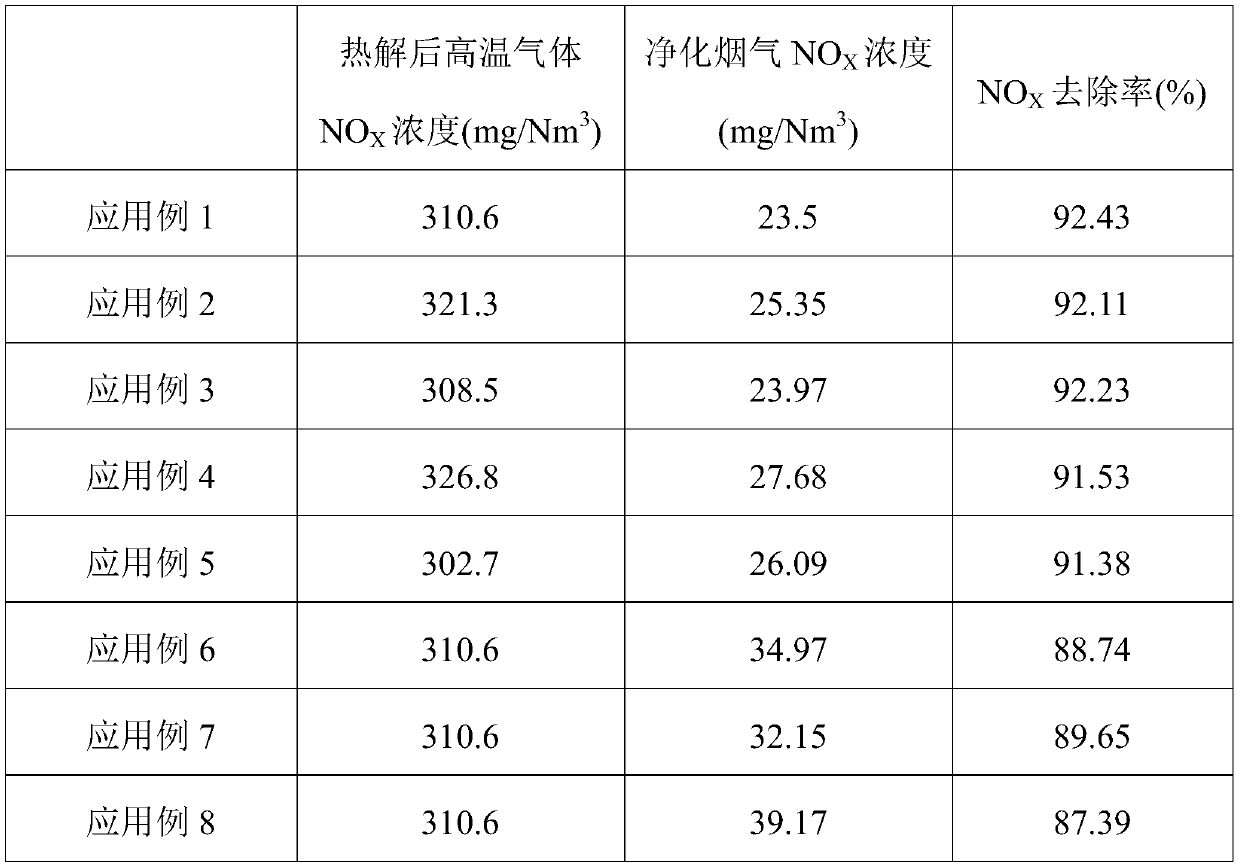

Gasification pyrolysis system for recycling flue gas and application of gasification pyrolysis system

PendingCN110746995AReduce the effect of prone to white fogExtend heat exchange timeDirect heating destructive distillationSpecial form destructive distillationThermodynamicsNitrogen oxides

The invention discloses a gasification pyrolysis system for recycling flue gas and an application of the gasification pyrolysis system. The system comprises a pyrolysis unit, an absorption column anda condensation unit which are sequentially connected, wherein the pyrolysis unit comprises a pyrolyzing furnace and a combustion furnace, a flue gas outlet of the pyrolyzing furnace is connected witha gas inlet of the combustion furnace, and high-temperature gas generated by the combustion furnace is used for providing heat required for pyrolysis for the pyrolyzing furnace; and the condensation unit comprises a heat exchange device, a U tube and a gas-liquid separation device which are sequentially connected. Pyrolyzed gas generated from pyrolysis of solid wastes is combusted in the combustion furnace, heat generated from combustion is applied to pyrolysis, and gas generated from combustion is subjected to nitrogen oxide and sulfur oxide absorption by the absorption column and then is subjected to heat exchange condensation in the condensation unit. By applying the system, the utilization ratio of heat of flue gas generated from pyrolysis can be increased, pollution caused by nitrogenoxides and sulfur oxides in the flue gas can also be reduced, and moisture can be recycled to achieve the effects of removing white smoke and reducing consumption.

Owner:上海和惠生态环境科技有限公司

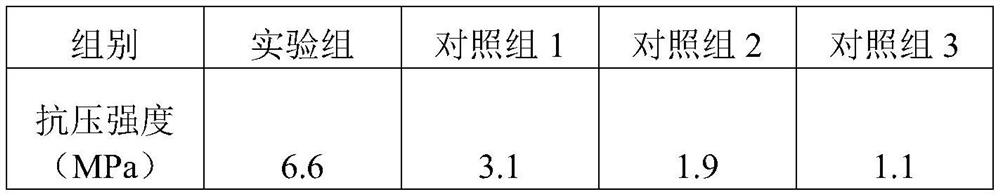

Novel fly ash efficient resource utilization system and method

ActiveCN114349452AImprove heating uniformityImprove single furnace processing capacitySlagProcess engineering

The invention relates to the technical field of environmental protection, in particular to a novel fly ash efficient resource utilization system and method.The method comprises the steps that fly ash is subjected to heat treatment, and a fly ash product obtained after heat treatment is mixed with slag and desulfurized gypsum to prepare a solid waste-based cementing material. The novel fly ash efficient resource utilization system comprises a back-mixing pyrolysis reactor, a preheater, a feeding bin, a mixing bin, a gas purification system, a finished product bin, a solid waste-based cementing material mixing device, a solid waste-based cementing material preparation device and a solid waste-based cementing material finished product bin. The invention provides a novel fly ash efficient resource utilization system which can greatly improve the cracking efficiency of organic compounds, reduce equipment faults, reduce the occupied area of equipment, thoroughly solve the problem of non-uniform local pyrolysis caused by non-uniform heating of materials, greatly reduce energy consumption and prolong the service life of the equipment.

Owner:北科蕴宏环保科技(北京)有限公司 +1

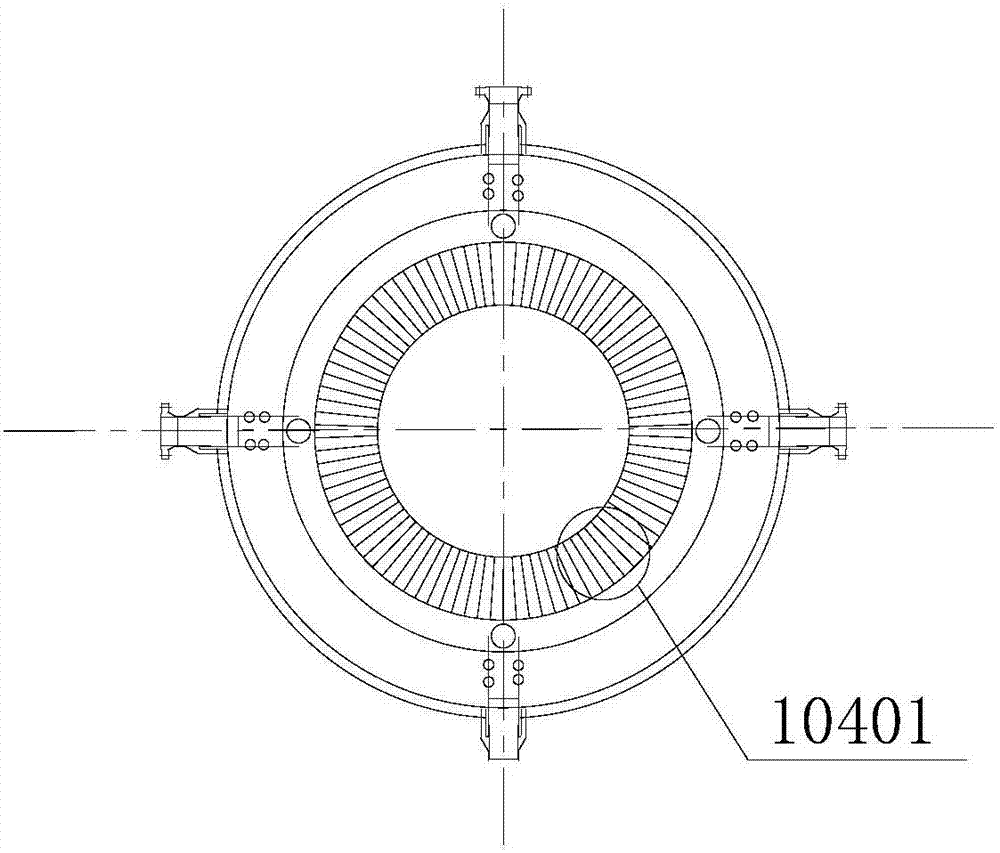

A pyrolysis reactor

ActiveCN107043633ALower airtightness levelImprove pyrolysis effectDirect heating destructive distillationHeat carrierNuclear engineering

A pyrolysis reactor is provided. The pyrolysis reactor includes a pyrolysis reactor main body (4) and a premixing device (1) used for premixing a material and a heat carrier and conveying a mixture formed by premixing the material and the heat carrier to the pyrolysis reactor main body (4). A flowing space allowing a gas generated when the material and the heat carrier are premixed to flow is disposed in the premixing device (1), and is communicated with the pyrolysis reactor main body (4) so as to lead the gas generated in the premixing device (1) to the pyrolysis reactor main body (4). The pyrolysis reactor can achieve uniform mixing between the solid heat carrier and the material, reduces the air impermeability level of the premixing device and overcomes a problem of pyrolysis gas backward flowing.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Environment-friendly pleuripotent garbage pyrolysis device

ActiveCN107300178APyrolysis continues to be stableLower pyrolysis costsIncinerator apparatusCombustion chamberEngineering

The invention discloses an environment-friendly pleuripotent garbage pyrolysis device. To overcome the insufficiencies that existing garbage pyrolysis flue gas guide treatment is not ideal, and hot air is difficult to obtain and deliver, a flue gas chamber and a hot gas chamber are arranged outside the combustion chamber, a drying mechanism and an evaporating mechanism are installed in the flue gas chamber, a flue gas channel communicated with the combustion chamber and the flue gas chamber is arranged beside the combustion chamber and the flue gas chamber, a smoke guide mechanism is arranged at the lower portion of the side wall of the flue gas chamber, and is connected with a flue gas treatment mechanism, the flue gas chamber is provided with a moisture removing mechanism, and the gas delivering pipe surrounds the flue gas chamber and is communicated with the combustion chamber through a gas delivering channel beside the gas delivering pipe. The environment-friendly pleuripotent garbage pyrolysis device is mainly used for garbage pyrolysis treatment, can better guide and treat pyrolysis flue gas, better supply hot air needed for pyrolysis, better treat garbage moisture, lower the equipment maintenance and garbage pyrolysis cost, improve the garbage pyrolysis effect, and improve the garbage pyrolysis efficiency; meanwhile, the environment-friendly pleuripotent garbage pyrolysis device enables garbage pyrolysis to be continually and stably conducted with the standard reached.

Owner:袁甫新 +1

Pyrolysis device for waste plastic oil-production processing

InactiveCN112500880AIncrease speedImprove pyrolysis efficiencyDispersed particle filtrationLiquid hydrocarbon mixture productionOil processingThermodynamics

The invention belongs to the technical field of waste plastic-to-oil processing, particularly relates to a pyrolysis device for waste plastic oil-production processing, and provides the following scheme aiming at the problem of poor pyrolysis efficiency of plastic raw materials in the prior art: the pyrolysis device comprises a pyrolysis tank, the pyrolysis tank is arranged to be of a horizontally-placed cylindrical structure, sealing cover plates are arranged at the two ends of the pyrolysis tank, a fixing pipe is rotatably connected to the middle position between the inner walls of the two ends of the pyrolysis tank, one end of the fixing pipe is in transmission connection with a driving motor, a first heating piece is fixed to the position, corresponding to the fixing pipe, of the innerwall of the end, away from the driving motor, of the pyrolysis tank, and a plurality of dispersing pieces are fixed to the outer wall of the fixing pipe. The plastic is heated and dissolved at all positions in the pyrolysis tank, the pyrolysis efficiency is prevented from being affected by single-point heating, plastic raw materials in the pyrolysis tank are dispersed in cooperation with the dispersion piece and the dispersion strips on the dispersion piece, and the situation that heat conduction heat is difficult to diffuse due to accumulation is avoided.

Owner:王培培

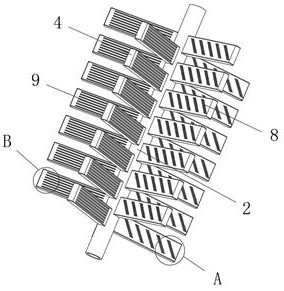

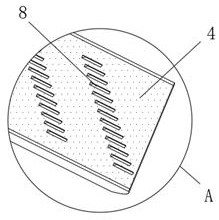

Calcium carbide furnace and method for preparing calcium carbide

The invention discloses a calcium carbide furnace and a method for preparing calcium carbide. The calcium carbide furnace comprises a pyrolytic reaction region and a calcium carbide reaction region from top to bottom, a plurality of heating boards, a heating channel, a material inlet, an oxygen-containing gas inlet and a calcium carbide outlet, wherein some heating boards are arranged on the first side wall of the calcium carbide furnace, the other heating boards are arranged on the second side wall opposite to the first side wall, the heating boards located on the first side wall and the heating boards located on the second side wall are distributed in a staggered mode, and the heating channel applicable to material heating is defined by the heating boards jointly. Medium and low order raw coal can be subjected to upgrading through a pyrolytic reaction in the pyrolytic reaction region, and the heating boards arranged inside the pyrolytic reaction region can improve the pyrolytic efficiency and effect of the pyrolytic reaction region.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Distribution type garbage treating device free of emission of low temperature pyrolysis gas

InactiveCN108844074AEffective pyrolysisImprove pyrolysis efficiencyIncinerator apparatusGas compressorCombustible gas

The invention relates to the field of garbage treatment and particularly relates to a distribution type garbage treating device free of emission of low temperature pyrolysis gas. The distribution typegarbage treating device comprises a garbage drop can, a lift type garbage pressing and falling mechanism, a garbage conveying and preheating box, a garbage conveying mechanism, a driving motor, a bent falling pipeline, a low-temperature pyrolyzing furnace, a pyrolysis gas conveying mechanism, a gas compressor and a waste gas emission treating device; the garbage drop can is fixedly connected andcommunicates with the upper end of the garbage conveying and preheating box; the right end of the garbage conveying and preheating box is fixedly connected and communicates with the upper end of the bent falling pipeline; and the lower end of the bent falling pipeline is fixedly connected and communicates with the low-temperature pyrolyzing furnace. The distribution type garbage treating device provided by the invention can be used for effectively carrying out pyrolysis treatment on the garbage and can also preheat and dry the to-be-treated garbage by utilizing combustible gas generated in pyrolysis of the garbage, and thus the pyrolysis efficiency and the pyrolysis effect of the garbage are improved.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

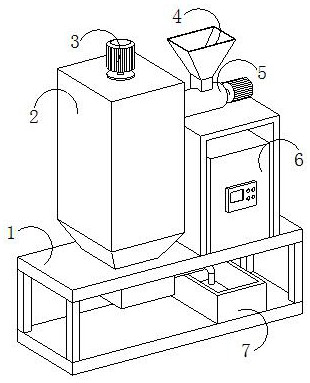

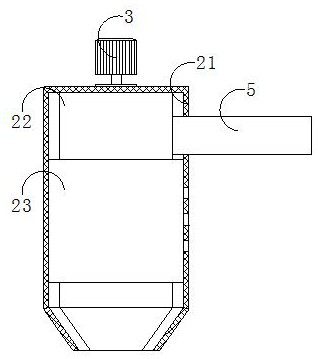

Sludge biochar soil conditioner production device

InactiveCN113307467AImprove uniformityEvenly heatedRotary stirring mixersTransportation and packagingSludgeElectric machine

The invention discloses a sludge biochar soil conditioner production device which structurally comprises a supporting table, a pyrolysis device, a motor, a hopper, a material guide pipe, a heater and a collecting box, the pyrolysis device is fixedly installed on the upper end face of the left side of the supporting table, the motor is fixedly installed at the top of the pyrolysis device, and a rotating rod is driven to rotate through rotation of the motor, so that certain outward throwing force is generated, at that moment, a sliding shaft slides in a fixed pipe sleeve, so that a push rod is driven to push the sludge outwards in the fixed pipe sleeve, the heating uniformity of the sludge is improved, heat is dispersed into a plurality of heat guide pipes through branch guide pipes, and after the heat enters the heat guide pipes, through extrusion of convex blocks, spraying out from nozzles is accelerated; through the plurality of nozzles which are vertically arranged, the overall circular outer side of a heat preservation container body is subjected to more uniform heat, the sludge in the heat preservation container body is overall and uniformly heated, and the overall pyrolysis effect of the sludge is improved.

Owner:GUIYANG UNIV

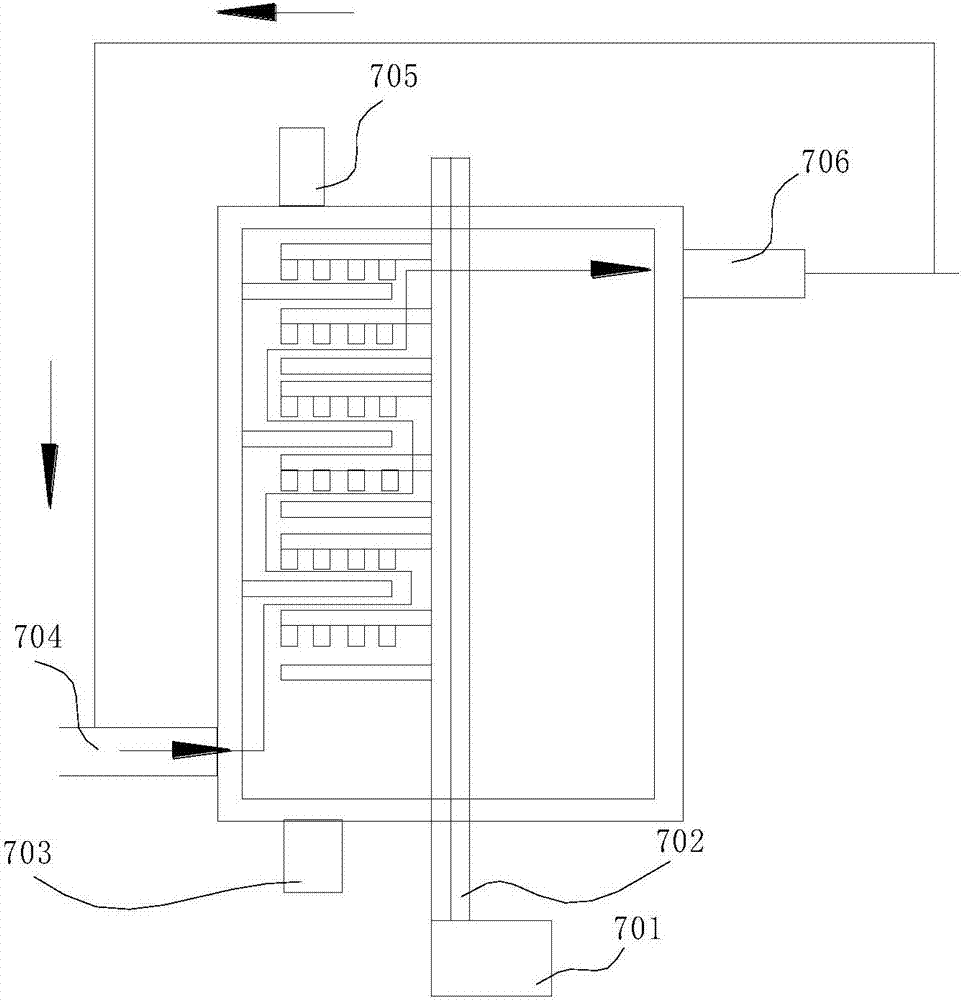

Waste PCB board pyrolyzation device

InactiveCN108707468AAvoid wastingFully recycleLiquid hydrocarbon mixture productionGrain treatmentsCombustionGas passing

The invention discloses a waste PCB board pyrolyzation device. The waste PCB board pyrolyzation device comprises a feeding hole and a crushing chamber, wherein the feeding hole is formed in the upperpart of the crushing chamber, a heating chamber is connected to the lower part of the crushing chamber through a screening gate, an inert gas supplying device is connected to the left side of the heating chamber, a condenser is connected to the right side of the heating chamber, a pyrolytic oil recycling device is connected to the lower part of the condenser, one end of a gas circulating device isconnected to the upper part of the condenser, and the other end of the gas circulating device is connected to the heating chamber. According to the waste PCB board pyrolyzation device, waste PCB boards can be crushed and pyrolyzed, solid products generated by pyrolyzation are remained in a quartz reaction pipe, a gas product generated by pyrolyzation is condensed into non-condensable gas and pyrolytic oil, the pyrolytic oil flows into the pyrolytic oil recycling device and is recycled, and the non-condensable gas enters the heating chamber and is taken as a combustion improver for the heatingchamber, so that the recycling is adequate, the wasting of resources is avoided, and secondary pollution is avoided.

Owner:ANHUI SHENZE ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com