Ball-milling type pyrolysis activation furnace

An activation furnace and pyrolysis technology, applied in the field of ball mill type pyrolysis activation furnace, can solve the problems of affecting pyrolysis, bearing sintering stuck, stirring shaft failure, etc., to achieve rapid response, good pyrolysis effect, and prevent sintering stuck. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

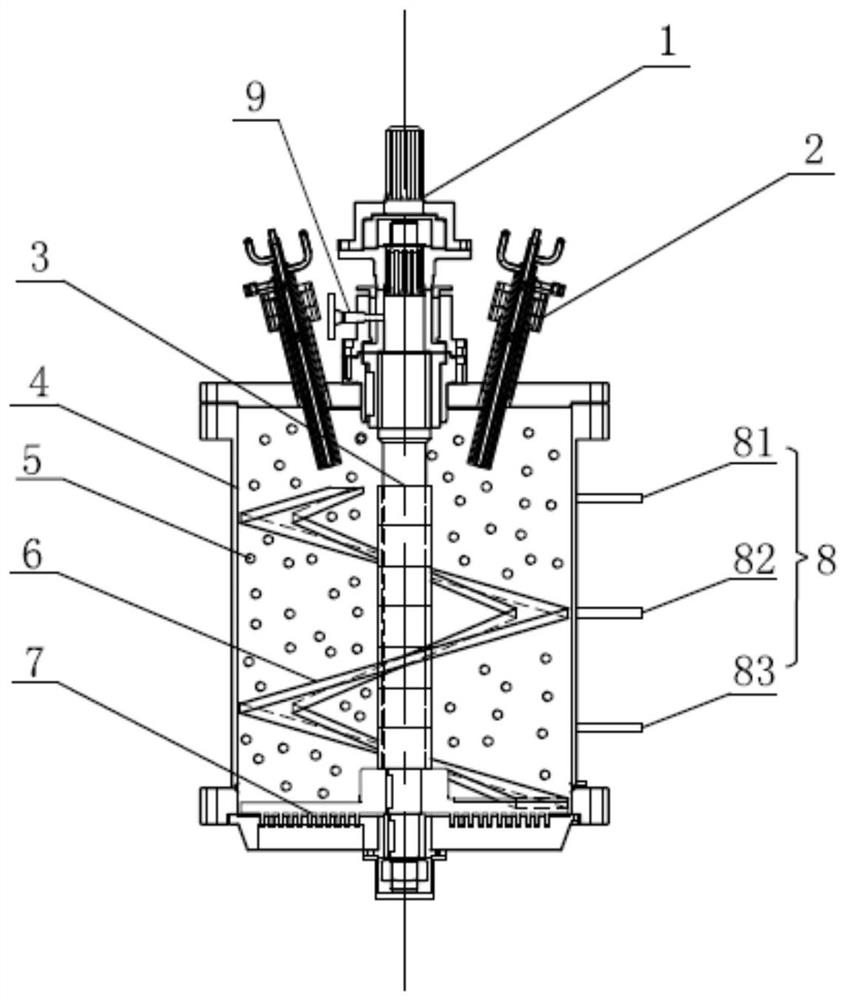

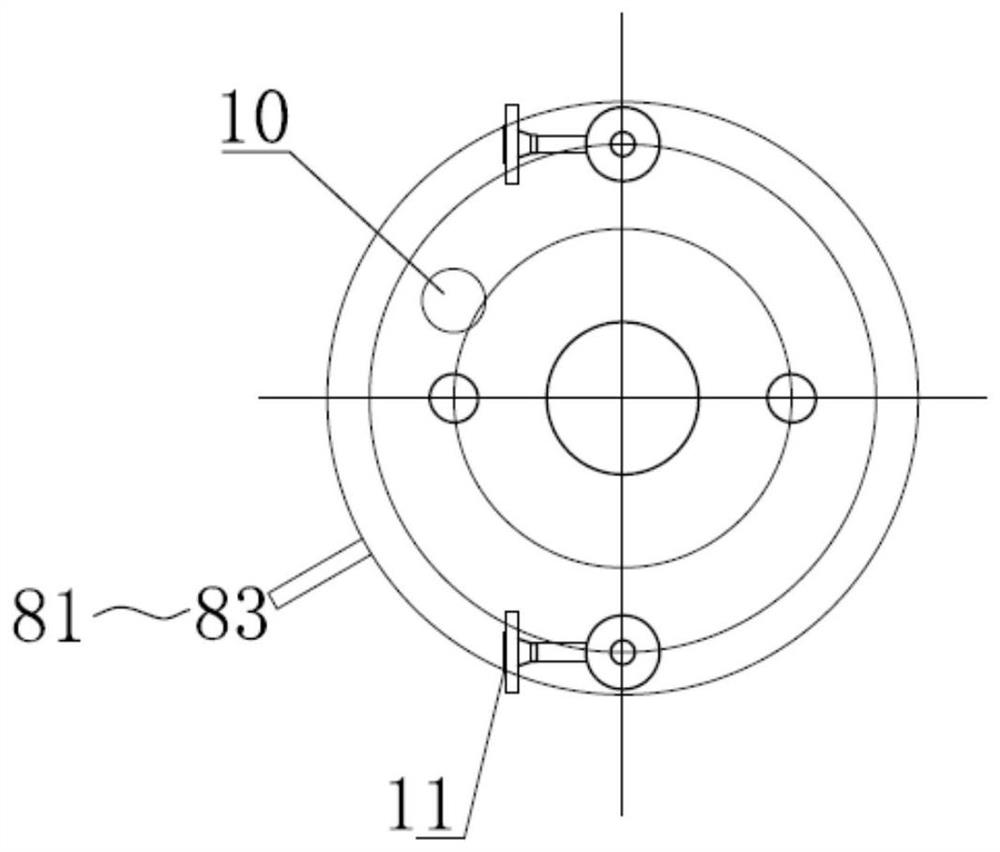

[0025] like Figure 1-3 As shown, a ball mill type pyrolysis activation furnace includes a furnace body 4, a drive device 1 fixed above the furnace body 4, a stirring shaft 3 connected to the drive device 1, a nozzle 2 inserted into the top of the furnace body 4 at one end, and wound on The heating belt 8 on the outside of the furnace body 4, several stainless steel balls 5 filled in the furnace body 4; one end of the stirring shaft 3 is rotationally connected with the driving device 1, and the other end of the stirring shaft 3 extends into the furnace body 4 , the stirring shaft 3 is provided with a stirring paddle 6, and the stirring paddle 6 is placed in the furnace body 4 to rotate together with the stirring shaft 3. The furnace body 4, the stirring shaft 3, the stirring paddle 6 and the driving device 1 are all made of heat-resistant alloy and can work continuously at high temperature.

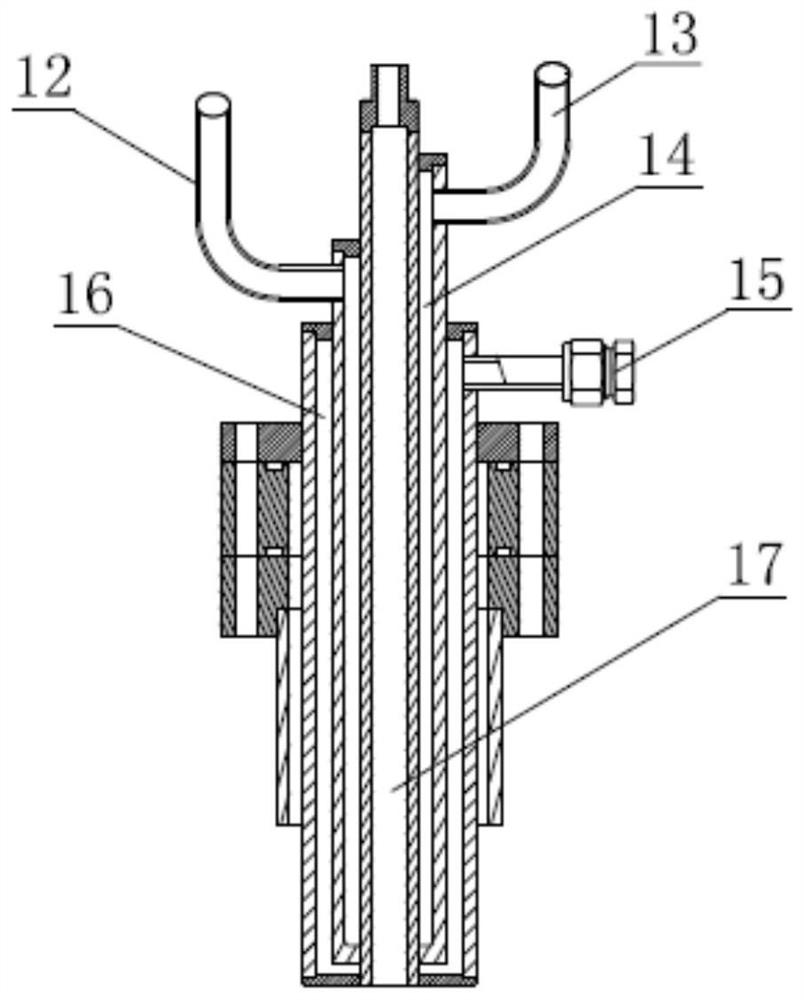

[0026] The driving device 1 and the stirring shaft 3 are connected by shaft bearings...

Embodiment 2

[0036] like Figure 1-4 As shown, this embodiment provides an integrated device for pyrolysis, activation and purification, which is formed by improving the ball mill type pyrolysis and activation furnace in Embodiment 1. A dust collection bin 19 can be arranged under the pyrolysis activation furnace 18 in this embodiment, and a dust removal device 20 can be arranged on the dust collection bin 19 . The dust processed by the pyrolysis activation furnace 18 falls into the dust collection bin 19 .

[0037] The dust removal device 20 is provided with a high-temperature flue gas filter element, and the clean gas is discharged after being filtered by the high-temperature flue gas filter element. The dust removal device 20 is also provided with a backflushing device, which periodically backflushes the filter element to maintain the cleanliness of the filter element. The bottom of the dust collection bin 19 is provided with a sewage outlet for regular sewage treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com