Furnace platform rotary type thermal cracker

A thermal cracking and rotary technology, applied in coking ovens, special forms of dry distillation, indirect heating dry distillation, etc., can solve the problems of high temperature resistance, corrosion resistance, limited materials, etc., and achieve good thermal cracking effect and meet the needs of transportation and layout, to meet the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

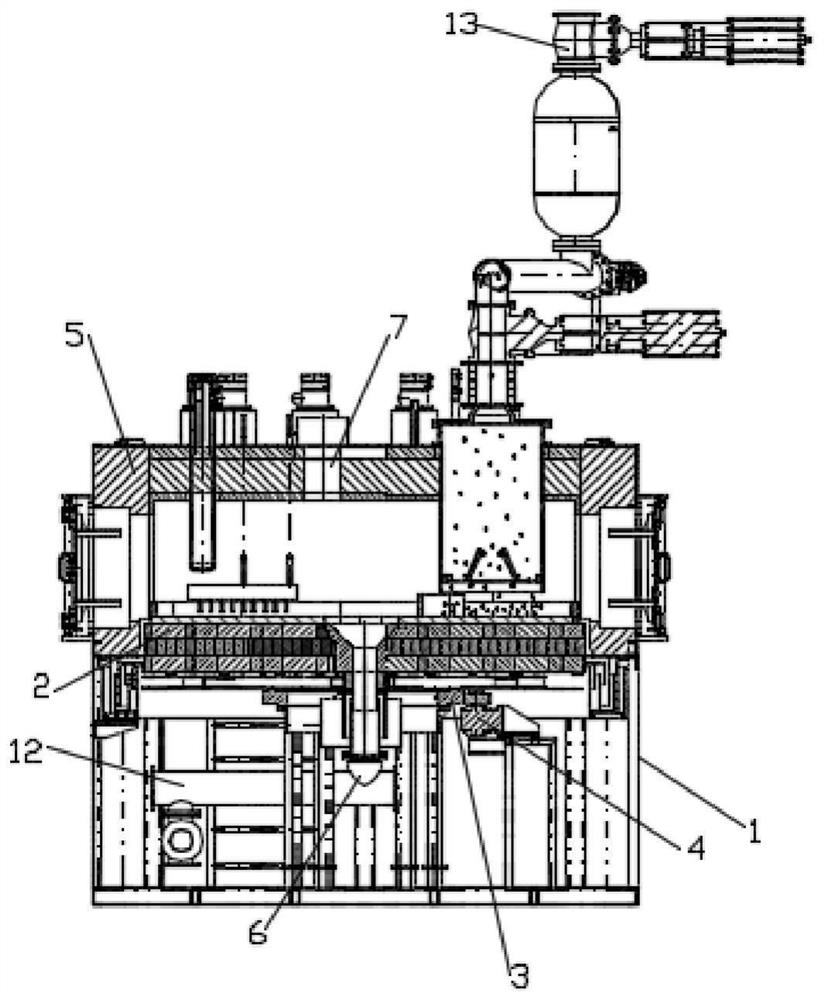

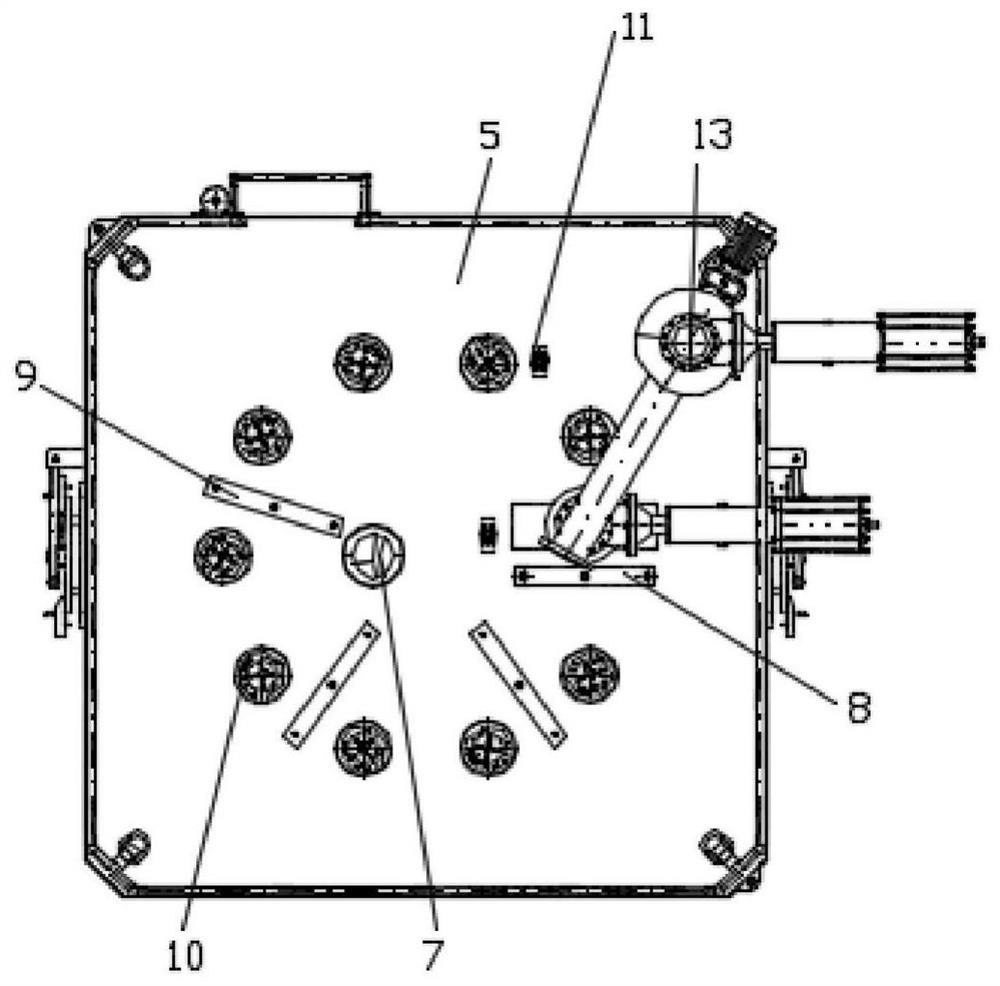

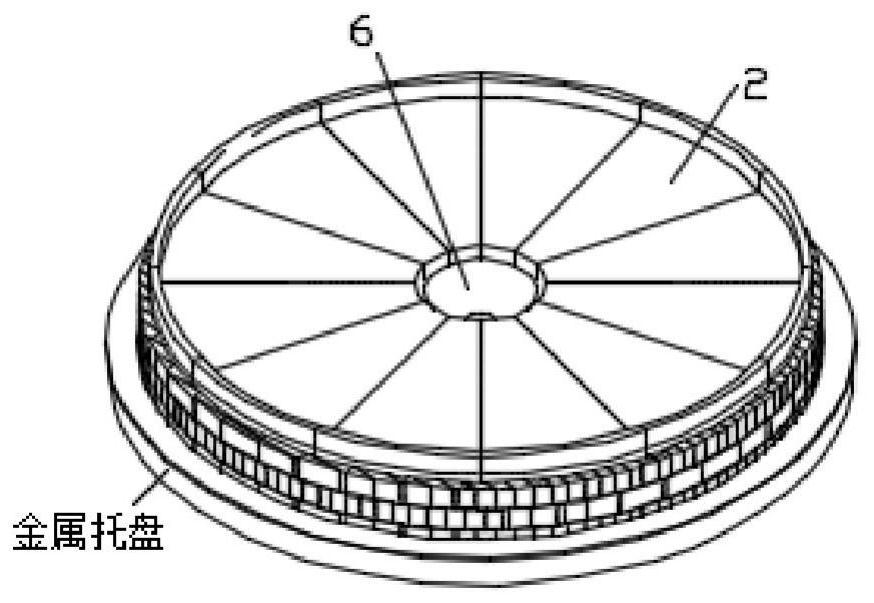

[0032] The present invention provides a technical solution: please refer to figure 1 and Figure 6 , a furnace platform rotary thermal cracker, including a fixed bracket 1, the fixed bracket 1 is the main load-bearing component of the furnace platform rotary thermal cracker, which is used to carry its upper parts, the fixed bracket 1 is a metal bracket, The upper end of the fixed bracket 1 is provided with a rotary hearth 2, please refer to image 3 and Figure 4 , the table top of the rotary hearth 2 is made of high temperature resistant and corrosion resistant material at high temperature, the rotary hearth 2 can accept the solid waste that is thermally cracked in the pyrolyzer, and the high temperature resistant and corrosion resistant material is successively provided with heat resistant Insulation material layer and metal tray, the lower end of the rotary hearth 2 and the fixed support 1 are connected with a toothed turntable bearing 3, one side of the toothed turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com