Patents

Literature

93results about How to "Meet high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloy resin composition and preparation method thereof

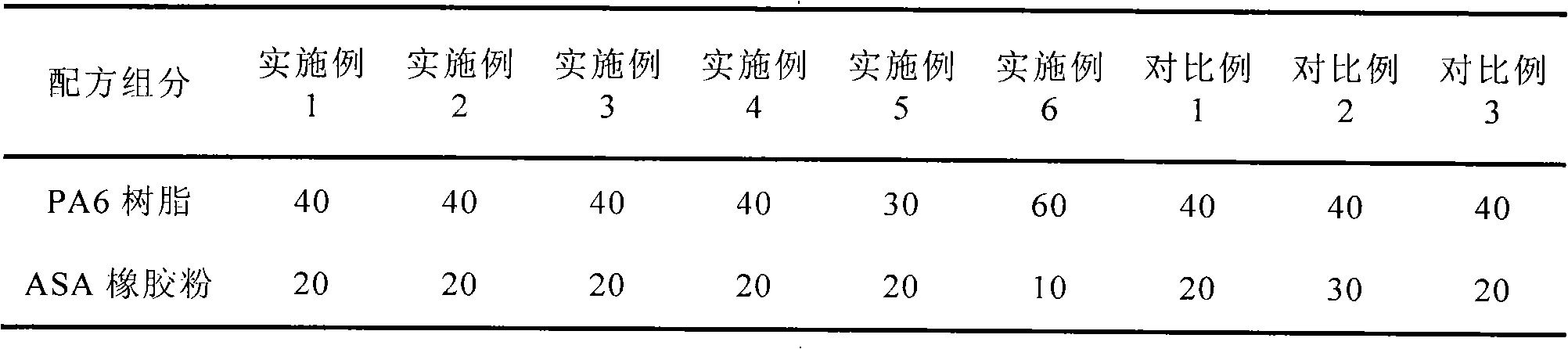

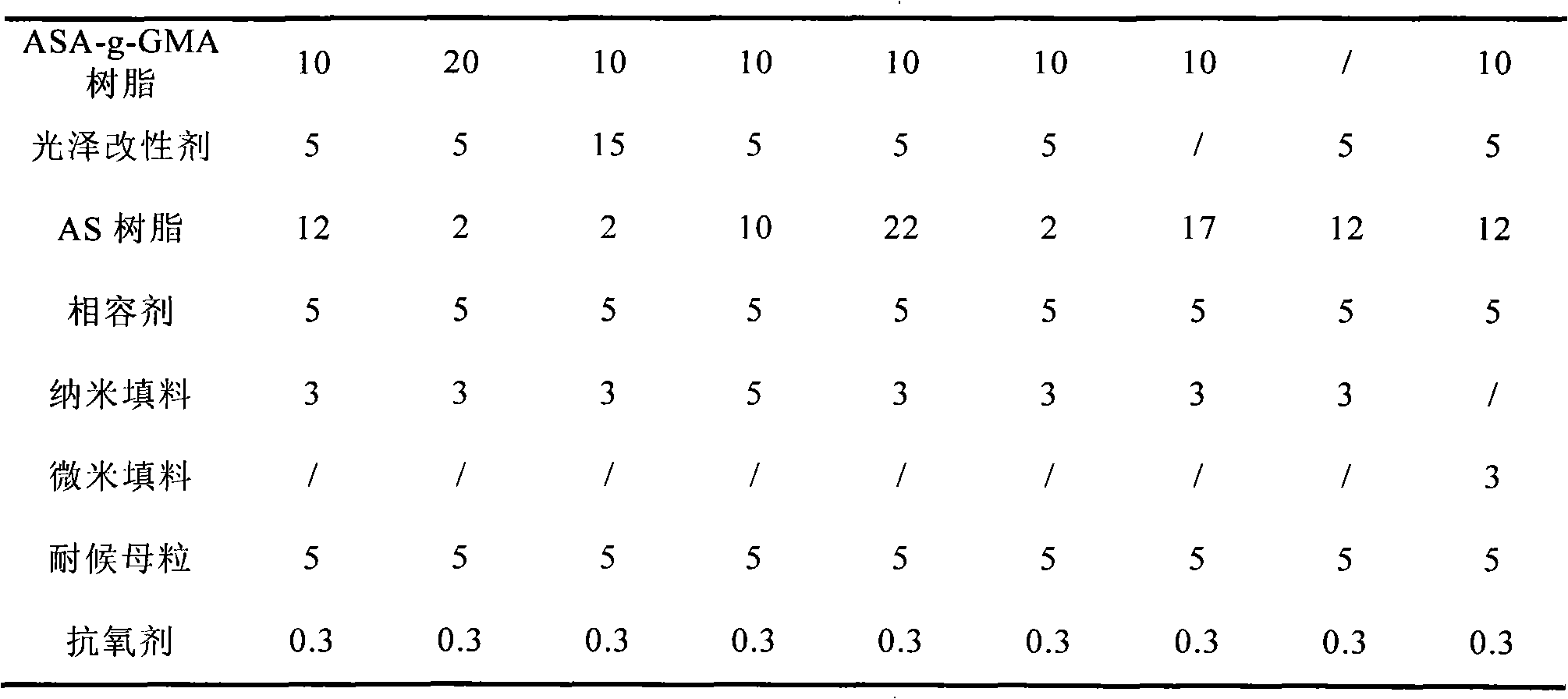

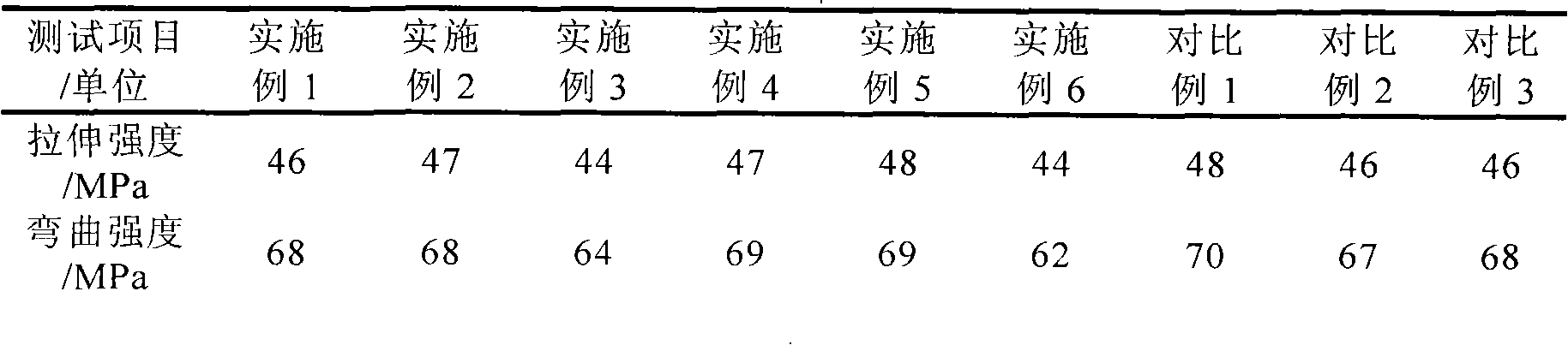

The invention relates to an alloy resin composition and a preparation method thereof. The composition comprises the following components in part by weight: 30-60 parts of polyamide resins, 15-50 parts of ASA (Acetylsalicylic Acid) rubber powder, 10-20 parts of ASA-g-GMA (Glycidyl Methacrylate) resins, 5-15 parts of glossy modifiers, 0-30 parts of AS (Arsenic) resins, 1-8 parts of compatilizers, 5-10 parts of weather-resistant master batch, 1-5 parts of nano fillers and 0.05-0.5 part of antioxidant. The preparation method comprises the following steps of: adding the mixture of all raw materials expect for the weather-resistant master batch to a main charging hole of a double-screw extruder, adding the weather-resistant master batch from a side charging hole, and then carrying out extrusion and pelleting to obtain the product. The alloy resin composition obtained in the method has a softer leopard surface matting effect, a more glossy shiny side lighting effect and better low temperature impact resistance and weather resistance, and is especially suitable for automobile interiors and exteriors with high requirements, such as instrument frames, air outlets of air conditioners, storage boxes, doorknobs, cosmetic mirrors, heat-radiating gratings, rearview mirrors, middle post plates, license plates and the like above wasitlines.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

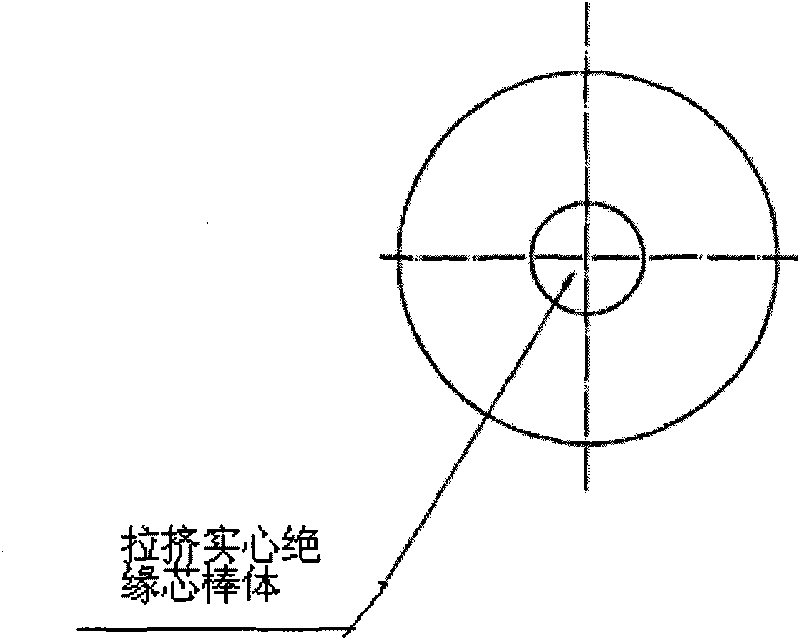

Preparation method of large-diameter composite insulator solid core rod

The invention discloses a preparation method of a large-diameter composite insulator solid core rod. The preparation method comprises the following steps of: selecting a solid pultrusion insulating core rod with a diameter not larger than 130mm; roughly processing the outer surface of the core rod, washing the outer surface by using acetone, then putting the core rod in an oven and keeping temperature constant; coating a 2 percent absolute alcohol solution on the outer surface of the core rod, then putting the core rod in the oven and keeping the temperature constant for 1 hour; weighing resin glue in proportion, pouring the resin glue into a vacuum stirrer, stirring for 20 minutes in vacuum and standing for 50 minutes; mounting the treated solid core rod on a numerical control winding machine and starting winding until the winding machine winds to a design size; vacuumizing and injecting the resin glue; after finishing injecting the resin glue, closing valves at both ends and putting the core rod in a curing oven for heating and stepped curing; and processing the outer surface and determining the size as a required length. The prepared core rod has high bonding strength and small-angle winding, and the content of resin of a secondary winding layer is similar to that of the matrix solid rod. The bonding of interlayer interfaces is firm, and cracks cannot occur, thus the prepared core rod can be widely applied to electric overhead lines.

Owner:陕西泰普瑞电工技术有限公司

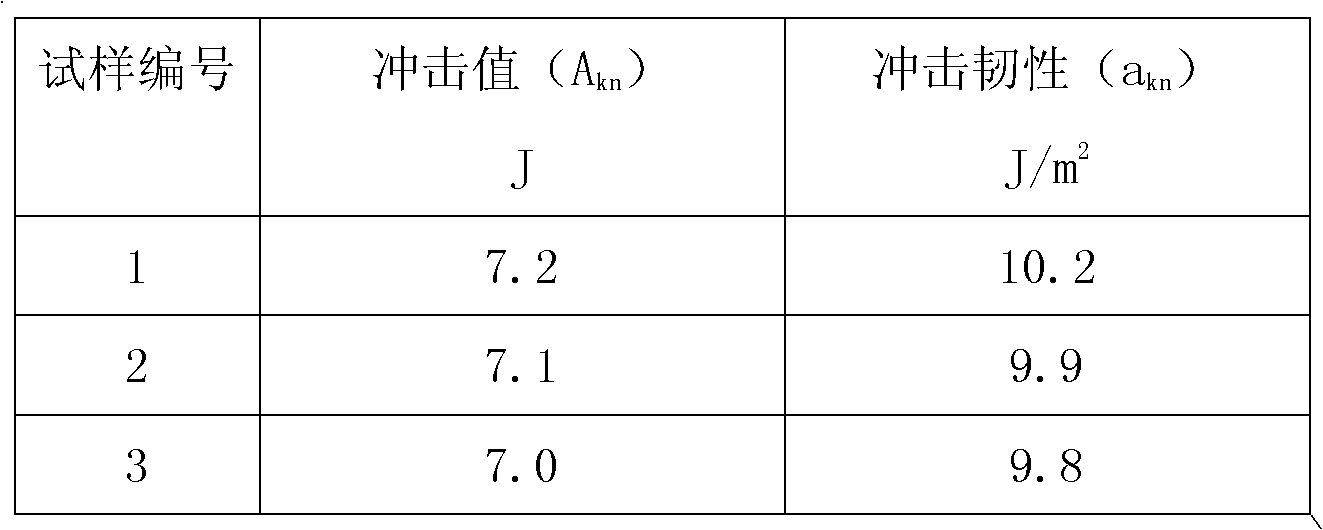

Cobalt-based alloy powder for laser remanufacturing of housing of rolling mill

ActiveCN102220522ALow melting pointSolve and improve formabilityMetallic material coating processesLaser beam welding apparatusRolling millCorrosion

The invention discloses cobalt-based alloy powder for laser remanufacturing of the housing of a rolling mill, which is characterized by comprising the following components in percentage by mass: 0.8 to 1.4 percent of C, 26 to 32 percent of Cr, 3 to 6 percent of W, 0.6 to 1.4 percent of Mo, 1.2 to 1.8 percent of Ni, 0.2 to 0.6 percent of Mn, 0.8 to 2.4 percent of Si, 1.2 to 4.8 percent of Fe, 0.4 to 1.6 percent of B, 0.2 to 0.6 percent of Ce, 0.2 to 0.6 percent of Hf and the balance of Co. The cobalt-based alloy powder is suitable for the laser deposition of large-area ineffective working face of the housing of the rolling mill, and by depositing the alloy powder, the housing of the rolling mill can be reused and the oxidization resistance, corrosion resistance and washing corrosion resistance of the housing of the rolling mill are improved. The online repair problem of the housing of the rolling mill is solved effectively.

Owner:SHENYANG DALU LASER TECH

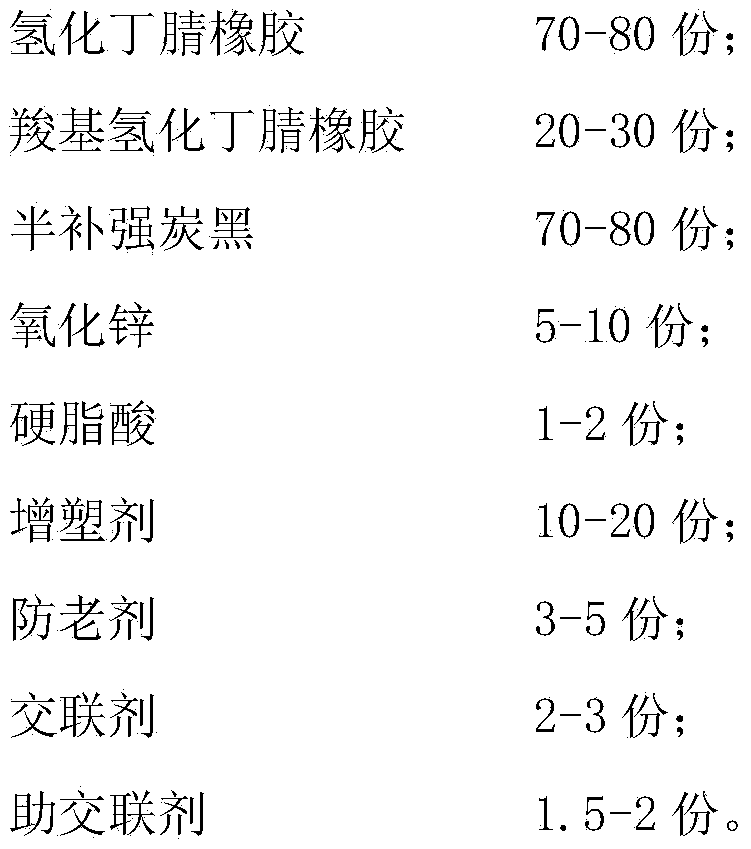

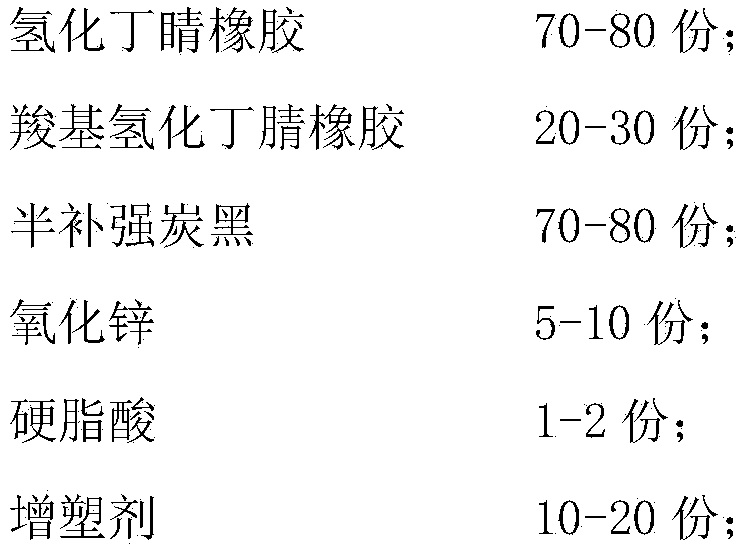

High-temperature stator rubber material and preparation method thereof

The invention discloses a high-temperature stator rubber material and a preparation method thereof and belongs to the field of the rubber material and the preparation method thereof. The rubber material is prepared from, in parts by weight, 70-80 parts of hydrogenated butadiene-acrylonitrile rubber, 20-30 parts of carboxyl hydrogenated butadiene-acrylonitrile rubber, 70-80 parts of semi-reinforcing carbon black, 5-10 parts of zinc oxide, 1-2 parts of stearic acid, 10-20 parts of plasticizer, 3-5 parts of anti-aging agent, 2-3 parts of cross-linking agent and 1.5-2 parts of auxiliary cross-linking agent. The high-temperature stator rubber material is prepared from hydrogenated butadiene-acrylonitrile rubber and carboxyl hydrogenated butadiene-acrylonitrile rubber, the hydrogenated butadiene-acrylonitrile rubber and carboxyl hydrogenated butadiene-acrylonitrile rubber are co-vulcanized so that the high-temperature stator rubber material is capable of meeting the requirement on high temperature resistance, the hydrogenated butadiene-acrylonitrile rubber which is vulcanized by a sulfur-free vulcanization system is capable of resisting the high temperature of 180 DEG C at most, and the vulcanized product has excellent heat resistance, chemical stability and bonding strength, and furthermore, the rubber material has excellent bonding strength.

Owner:南京金三力橡塑有限公司

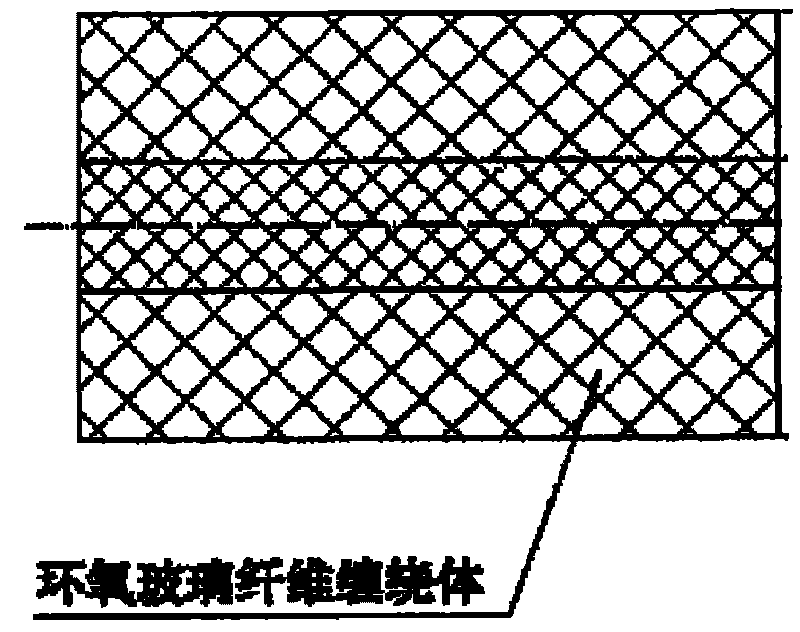

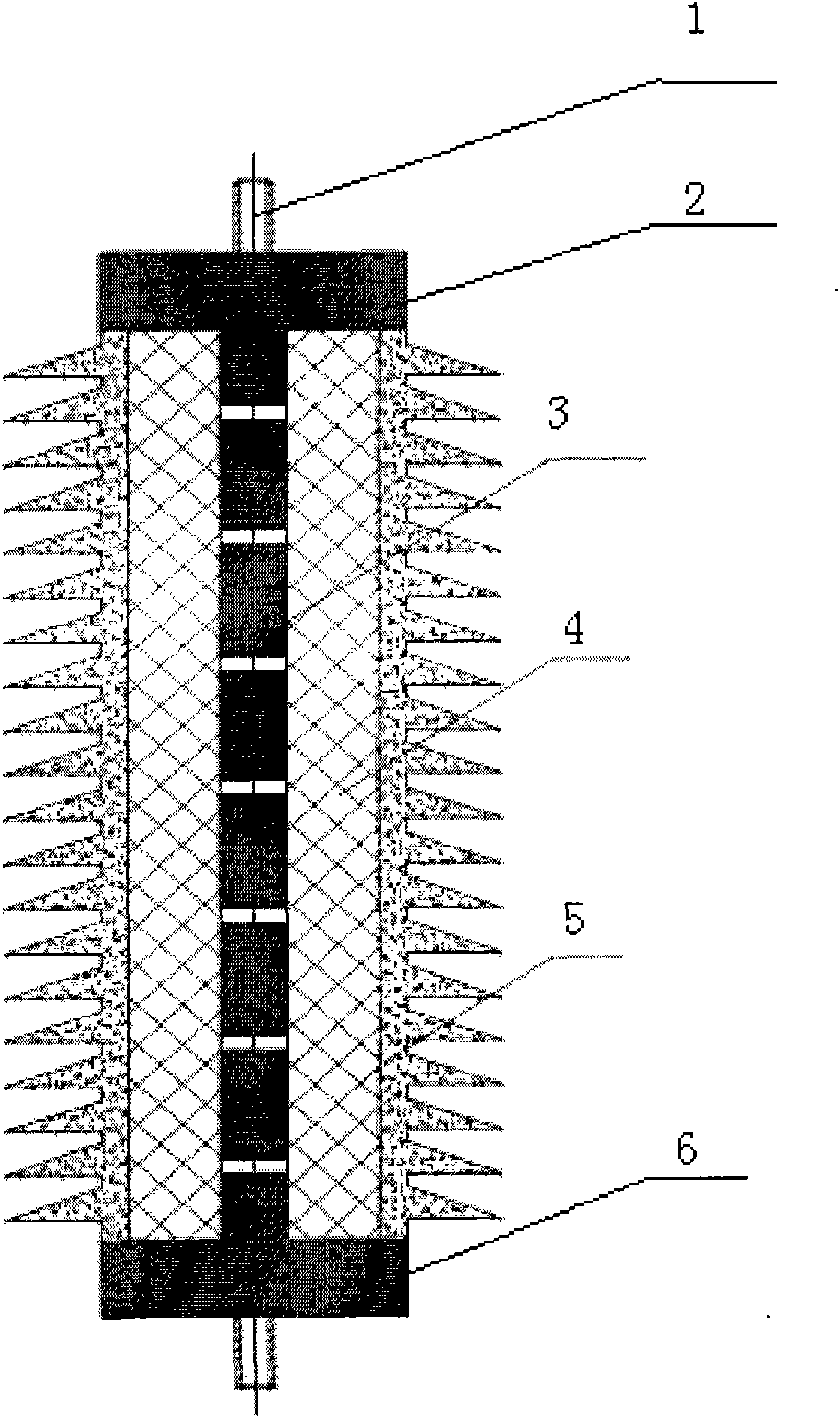

Polymeric housed arrester and method for preparing no-local-discharge compound-glass fiber winding pipe

InactiveCN101866731AImprove impact resistanceReduce weightSparking plugsRigid pipesEpoxyNumerical control

The invention discloses a method for preparing a no-local-discharge compound-glass fiber winding pipe. The preparation method comprises the following steps of: coating a release agent on the surface of a core module; arranging the core module on a numerical-control winding machine; automatically completing a winding process controlled by a microcomputer; winding fiber or alkali-free Worland clothes on the core module; preparing a resin adhesive, wherein the resin adhesive comprises epoxide resin, a curing agent, a toughener, silicon dioxide and a defoaming agent; injecting the resin adhesive in vacuum, stopping injecting the resin adhesive, closing a valve ladder and heating for solidifying and molding. The polymeric housed arrester has simple structure, light weight, good toughness, strong shock resistance capability, high tensile strength, high bending resistance, high twist resistance and more precise fiber distribution and is widely used for a power electric network, a transformer station and a communication device.

Owner:陕西泰普瑞电工技术有限公司

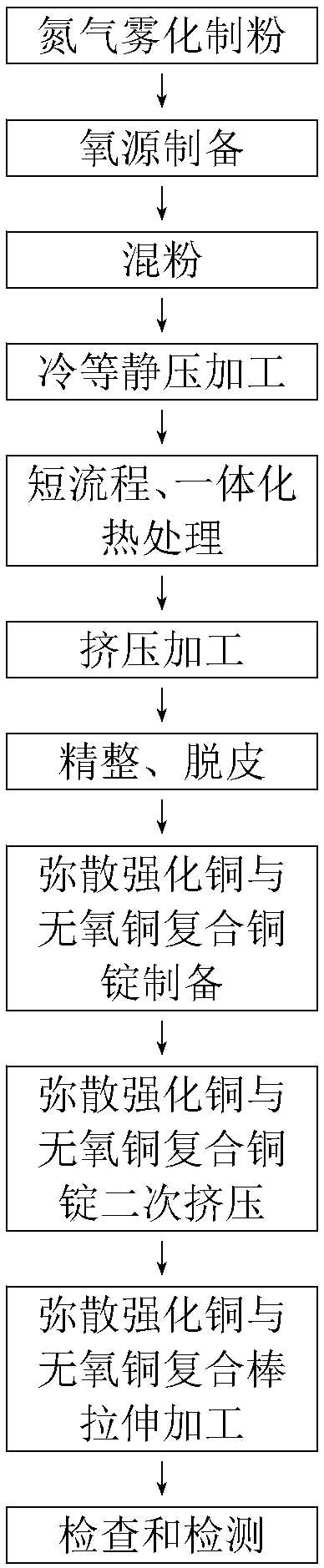

Preparation method of dispersion strengthened copper and oxygen-free copper composite bars

ActiveCN108057732AStrong resistance to high temperature softening abilityImprove high temperature resistanceTransportation and packagingMetal-working apparatusElectronic informationOxygen

The invention relates to a preparation method of dispersion strengthened copper and oxygen-free copper composite bars. The preparation method comprises the preparation process steps of nitrogen atomizing powdering, oxygen source preparation, powder mixing, cold isostatic pressing machining, the short flow path, integrated heat treatment, squeezing machining, finishing and decrustation, preparationof dispersion strengthened copper and oxygen-free copper composite copper ingots, secondary squeezing of the dispersion strengthened copper and oxygen-free copper composite copper ingots, stretchingmachining of the dispersion strengthened copper and oxygen-free copper composite bars, and checking and detecting. Through a powder metallurgy and pressure machining technology, Cu-Al2O3 nano dispersion strengthened copper and oxygen-free copper are composited to be prepared into the Cu-Al2O3 nano dispersion strengthened copper and oxygen-free copper composite bars, through the high-temperature, high-strength and high-grade oxygen-free copper characteristic of the Cu-Al2O3 nano dispersion strengthened copper, the requirements of large-power microwave tubes in the electronic information industry, large-current high-voltage relays in the electrical industry and the like for key materials are met.

Owner:中铝洛阳铜加工有限公司

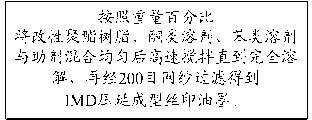

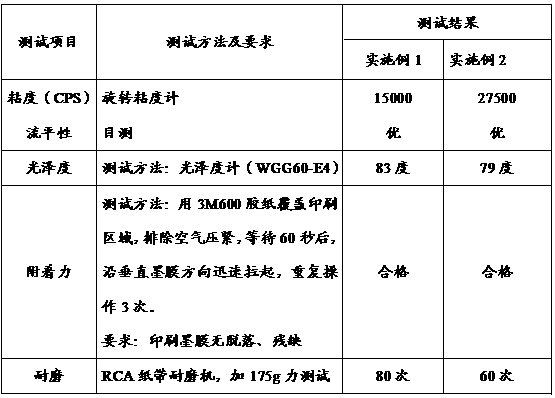

IMD (In-Mold Decoration) calendaring silk-screen printing ink

The invention discloses IMD (In-Mold Decoration) calendaring silk-screen printing ink which comprises the following components in percentage by weight: 40-50% of modified polyester resin, 25-30% of ketone solvent, 20-25% of benzene solvent and 1-5% of assistant. The printing ink solves the problems that existing IMD calendaring is poor in draying effect and the printing process is too fussy. The printing time is reduced, and the extremely strong inner binding force is improved, so that the printing ink has excellent using performance and has the effects of good leveling performance and excellent adhesion force on the printing surfaces of PC (Poly Carbonate) and PET (Polyethylene Terephthalate) materials. The printing oil is bright in color and high-temperature resistance, and the demands of clients on high temperature resistance, high ductility, high adhesive force and high adhesion of products are met.

Owner:深圳市美丽华科技股份有限公司

High-temperature resistant insulated thermally conductive paint with low expansion coefficient

The invention relates to a high-temperature resistant insulated thermally conductive paint with a low expansion coefficient. The paint is characterized in that shell powder is used to provide the high-temperature resistance and the insulating property, cubic boron nitride is used to provide the thermal conductivity and the insulating property, molybdenum disulfide is used to fill in the gas holes, high-temperature resistant resin is used to provide the high-temperature resistance and the binding property; and the thermally conductive paint comprises the following components by weight percent: 25-45% of shell powder, 30-50% of high-temperature resistant resin, 1-10% of cubic boron nitride, 1-5% of molybdenum disulfide, 0-5% of curing agent and 1-5% of diluent. The raw material shell powder of the insulated thermally conductive paint has wide resources and low price, thus reducing the cost of the insulated thermally conductive paint; the product has good thermal conductivity, the coefficient of thermal conduction is more than 8W / m.K, the expansion coefficient is less than 5*10<-6> / K; the paint can be sprayed, coated or soaked on the surface of an electronic circuit substrate; and the paint can satisfy the high-temperature resistant, insulating and thermally conductive demands of the electronic circuit substrate.

Owner:耿世达

Laser cladding repair method for breast roll

InactiveCN109722662AAchieving wear resistanceMeet wear resistanceMetallic material coating processesOptoelectronicsHigh pressure water

The invention discloses a laser cladding repair method for a breast roll. The laser cladding repair method comprises the following steps of removing a fatigue layer, performing overlaying to restore the size, performing annealing, performing outer diameter turning, performing low carbon overlaying, performing preheating, performing laser cladding, performing slow cooling and performing argon arc welding repair. For re-repairing, it is presented that re-repairing is performed when a laser cladding layer is worn away by 0.8-1.2 mm; and according to the laser cladding repair method, the repair ofthe breast roll is realized, meanwhile, the requirements for impact resistance, wear resistance, oxidation corrosion resistance, high temperature resistance and high-pressure water erosion resistanceof the breast roll are met, and the service life reaches 2 years or more.

Owner:鞍山大陆激光技术有限公司

Special cobalt-based wear-resistant alloy powder for laser remanufacture of drilling jar

ActiveCN102220580AImprove performanceHigh hardnessMetallic material coating processesLaser beam welding apparatusWear resistantAlloy

The invention relates to special cobalt-based wear-resistant alloy powder for laser remanufacture of a drilling jar. The powder is characterized by comprising the following components in percentage by weight: 0.6-1.0% of C, 32-36% of Cr, 7.5-9.5% of W, 3.0-3.6% of Mo, 0.8-1.2% of Ni, 0.2-0.6% of Mn, 2.0-2.4% of Si, 1.2-2.0% of Fe, 1.6-2.2% of B, 0.1-0.2% of Ce, 0.25-0.4% of Hf, 0.06-0.1% of Zr and the balance of Co. The cobalt-based wear-resistant alloy powder provided by the present invention is exclusively used in laser-cladding large-area failure working surfaces of the shaft journal of the drilling jar; and by cladding the alloy powder material, the drilling jar is restored to use, and the oxidation resistance, corrosion resistance and erosion and wear resistance are improved, thus effectively solving the difficulty in the repair of the failure shaft journal of the drilling jar.

Owner:上海大陆天瑞激光表面工程有限公司

Manometer aqueous high-temperature-resistant metal-baking coating

ActiveCN101619197AHigh temperature resistantGood chemical resistanceCoatingsLow speedTemperature resistance

The invention relates to an aqueous coating, in particular to a nanometer aqueous high-temperature-resistant metal-baking coating which can be used for decorating the surfaces of building materials and household kitchenware, such as electric irons, cookers, high-temperature lamps, ceramic products, and the like and has high temperature (600-700 DEG C) resistance, weatherability longer than 30 years and high rigidity. The preparation process comprises the following steps: mixing aqueous aluminum paste or aqueous pearlescent pigment, water and a dispersant at a low speed to prepare a semi-finished product of aqueous aluminum paste or aqueous pearlescent pigment; sequentially adding aqueous high-temperature-resistant nanometer resin, a flatting agent, a film-forming additive and a pH value regulator at a medium speed; and filtering and packaging after the semi-finished product is detected to be qualified to obtain the nanometer aqueous high-temperature-resistant metal-baking coating. The invention contains no toxic organic solvent, is pollution-free and has the advantages of high temperature resistance, weatherability longer than 30 years, high rigidity, wide suitability, and the like.

Owner:SKSHU PAINT

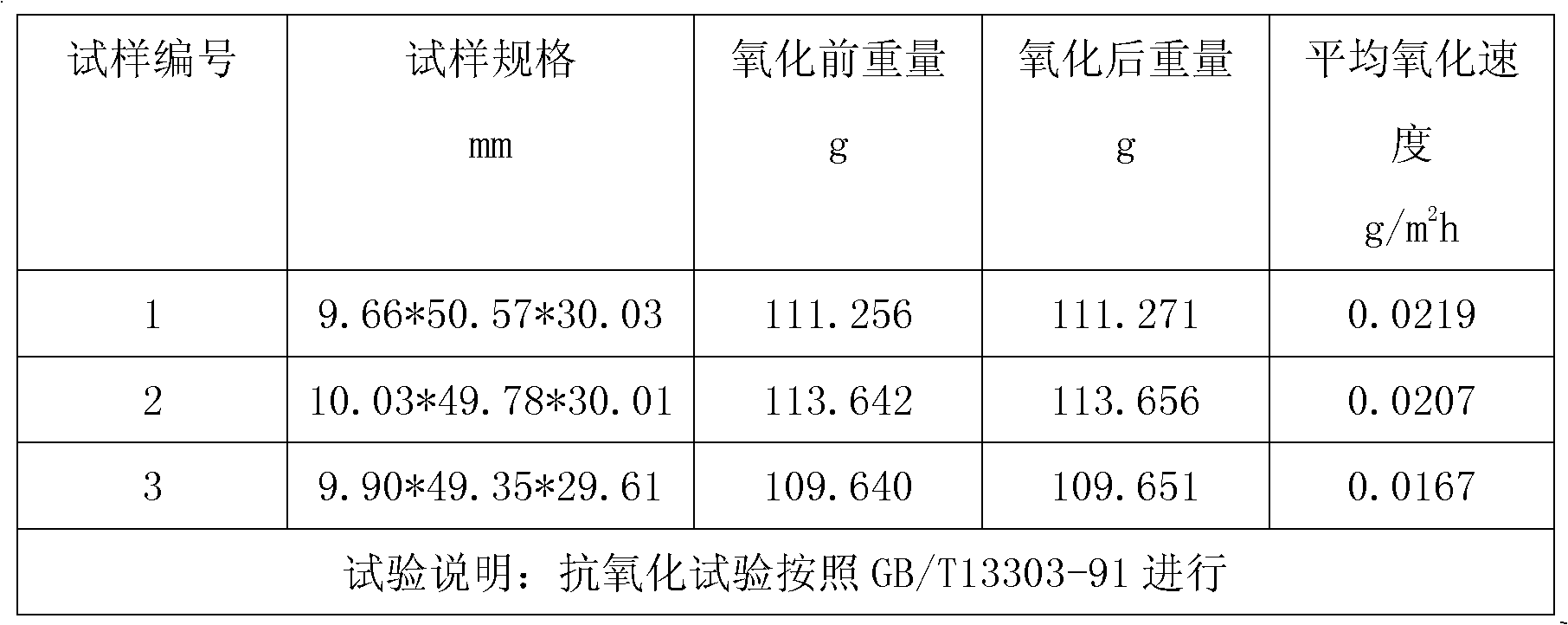

A kind of preparation method of porous foamed iron-nickel-chromium alloy material

InactiveCN102277486APreparation method scienceProcess parameters are reasonablePorosityConductive paste

The present invention is a preparation method of a porous foamed iron-nickel-chromium alloy material, which is characterized in that: the steps include: selecting a porous material, immersing a water-based polymer adhesive at normal temperature; spraying nano-chromium powder evenly on the Immersion on the surface of porous material with water-based polymer adhesive; drying; separating excess chromium powder from porous material matrix; dip-coating conductive adhesive on chromium porous material; electrodepositing iron-nickel alloy after heating and curing treatment on chromium porous material ; Oxidation-reduction treatment; Carrying out secondary diffusion treatment of chromium to obtain porous foamed iron-nickel-chromium alloy material. Its preparation method is scientific, the selected process parameters are reasonable, the quality is easy to control, the cost is low, and it can be produced with light weight, large specific surface area, super thickness, thickness of 5-100mm, high porosity of 96-99.9%, high temperature resistance and corrosion resistance. Excellent, able to meet the requirements of high temperature resistance, corrosion resistance and other harsh working conditions. It is especially suitable as high-temperature filtration, chemical catalysis, carrier, burner gas distribution and high-temperature flame-retardant materials.

Owner:JILIN ZHUOER TECH

Guide roller and preparation technique thereof

The invention discloses a guide roller and a preparation technique thereof. The guide roller comprises the raw material components by weight percent: 3.1-3.45% of C, 0.1-0.9% of Si, 0.1-0.4% of Mn, 0.01-0.03% of P, 0.01-0.03% of S, 24-25% of Cr, 0.4-0.6% of Mo, 0.9-1% of V, 2-3% of W, 0.05-0.1% of rare earth and the balance of Fe. The preparation technique of the guide roller comprises the steps of: firstly, making the guide roller by precision casting, treating by the guide roller by annealing, rough machining, quenching, tempering and finish machining, and obtaining the finished product. The prepared guide roller is low in cost, long in service life and good in high-temperature oxidation resistance, and has the advantages of high-temperature strength, shock resistance, high-temperature toughness and high-temperature frictional wear resistance.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

Novel aluminum alloy material and production process thereof

The invention relates to the technical field of aluminum alloy production, in particular to a novel aluminum alloy material and a production process thereof. The novel aluminum alloy material comprises, by mass percentage, 0.05-0.22 wt% of nickel, 0.8-1.6 wt% of chromium, 0.024-0.032 wt% of manganese, 0.78-1.5 wt% of magnesium, 0.66-1.65 wt% of silicon, 0.45-1.2 wt% of iron, 3.5-5.8 wt% of copper, 4.8-6.5 wt% of zinc, and the balance aluminum and other inevitable impurities. The mechanical property and mechanics property of the novel aluminum alloy material are excellent, and the surface of an aluminum alloy profile can be effectively protected against scratches; and in addition, the process is simple and reasonable, and the production efficiency is high.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

Castable for grid wall of casting residue basin, and preparation method and application method of castable

InactiveCN103396135AHigh strengthHigh bulk densityRecycling and recovery technologiesPolymer scienceAdhesive

The invention discloses a castable for a grid wall of a casting residue basin, and a preparation method and an application method of the castable. The castable is composed of 65-85wt% of steel slag, 3-10wt% of silica fume and 10-30wt% of adhesive. The preparation method comprises the following steps: mixing all the raw materials, adding water to the mixture, stirring and pouring into a grid wall formwork, vibrating and maintaining, thus obtaining the grid wall which can be used. The castable provided by the invention is low in cost and high temperature resistant, cannot burst, and can be widely used in various grid walls of casting residue basins.

Owner:莱芜钢铁集团泰东实业有限公司

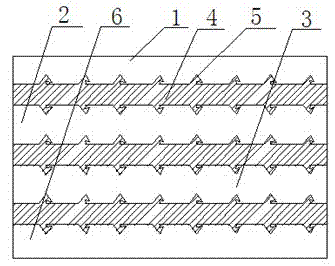

A kind of composite flexible graphite sealing material and sealing gasket manufacturing method

InactiveCN102285164AAvoid sex changeMeet high temperature resistanceLaminationLamination apparatusGraphiteElectromagnetic heating

The invention relates to a method for manufacturing a composite flexible graphite sealing material and a sealing gasket. The sealing material is manufactured by superposing and combining a plurality of flexible graphite. The method is characterized in that a layer of a metal mesh, of which two faces are provided with barbs, is arranged between every two layers of the flexible graphite; the metal meshes are rapidly heated by using an electromagnetic heating manner; composite layers of the flexible graphite and the metal meshes are pressurized when the metal meshes are heated to 850-950 DEG C; the pressed pressure per unit of area can be selected between 200 kg / cm<2> and 500 kg / cm<2>, so that the barbs on the metal meshes can hook surface layers of the graphite layers which are close to the metal meshes to form a whole sealing material; and the whole sealing material is naturally cooled to normal temperature, i.e. the sealing material manufactured by superposing and combining a plurality of flexible graphite is made.

Owner:株洲博尔密封材料有限公司

Quartz glass tube silicon chip bracket component

ActiveCN102032777AHigh strengthMeet the intensityFinal product manufactureFurnace typesCeramic coatingTemperature resistance

The invention provides a quartz glass tube silicon chip bracket component for a mesh belt-free silicon chip sintering furnace. The component comprises a quartz glass tube, metal sleeves, support legs and limiting screws, wherein the support legs are fixed on the metal sleeves; the metal sleeves are provided with threaded holes and are fixed on the quartz glass tube at equal intervals through the limiting screws; the support legs are made of steel wires; and the surfaces of the steel wires are coated with ceramic coatings. The quartz glass tube has the advantages of high intensity, high temperature resistance, low expansion coefficient, thermal shock resistance, acid resistance, chemical stability, high electrical insulating property, small heat absorption capacity and the like and is very suitable to be taken as a silicon chip bracket. The support legs are made of steel wires and the surfaces of the steel wires are coated with ceramic coatings, so that the requirements on intensity, high temperature resistance and wearing resistance of the support leg are met and metal ion pollution of a silicon chip caused by metal contact in a sintering process is reduced. Each metal sleeve is provided with an opening and a threaded hole, so that the metal sleeve is convenient to fix on the quartz glass tube.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

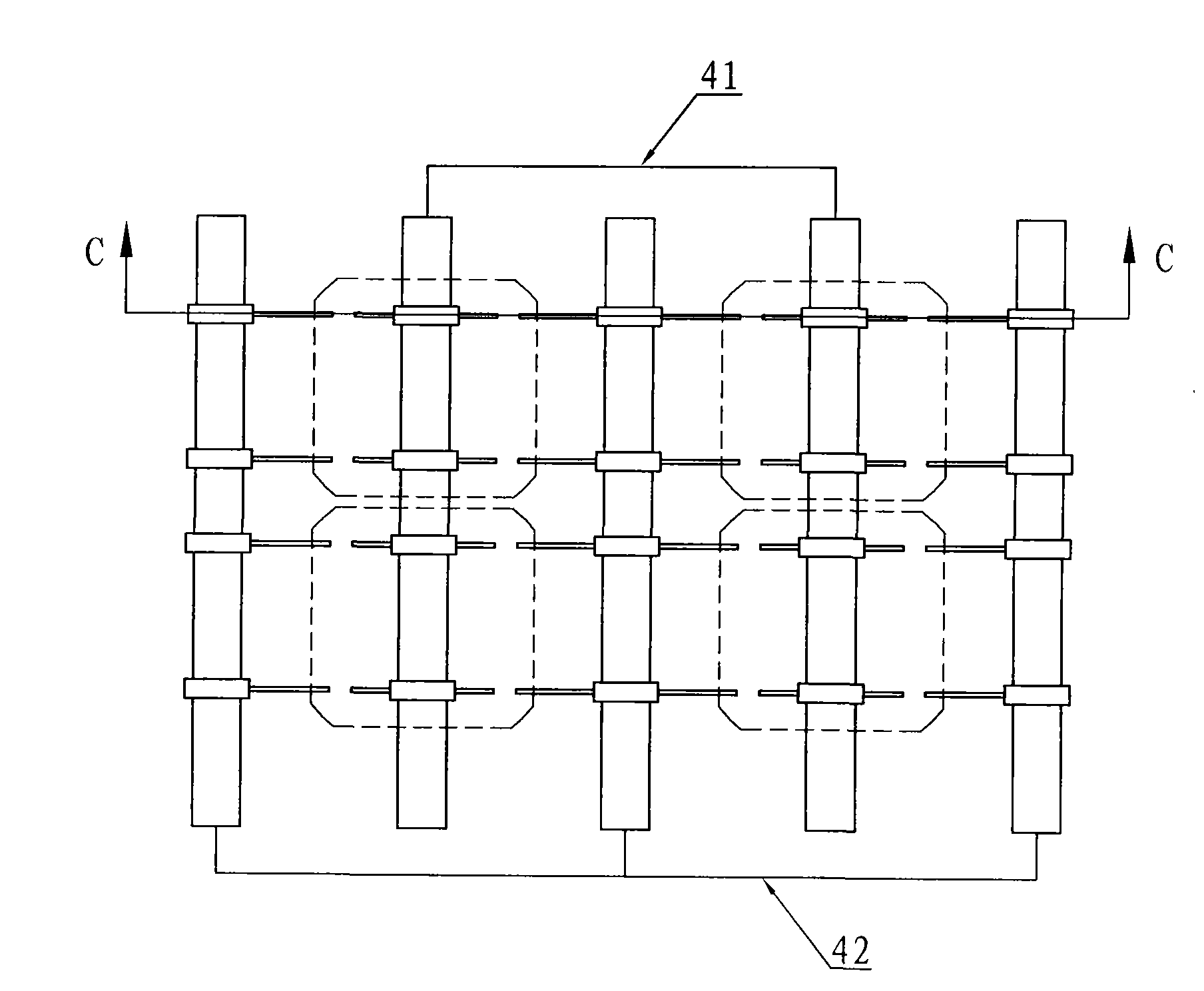

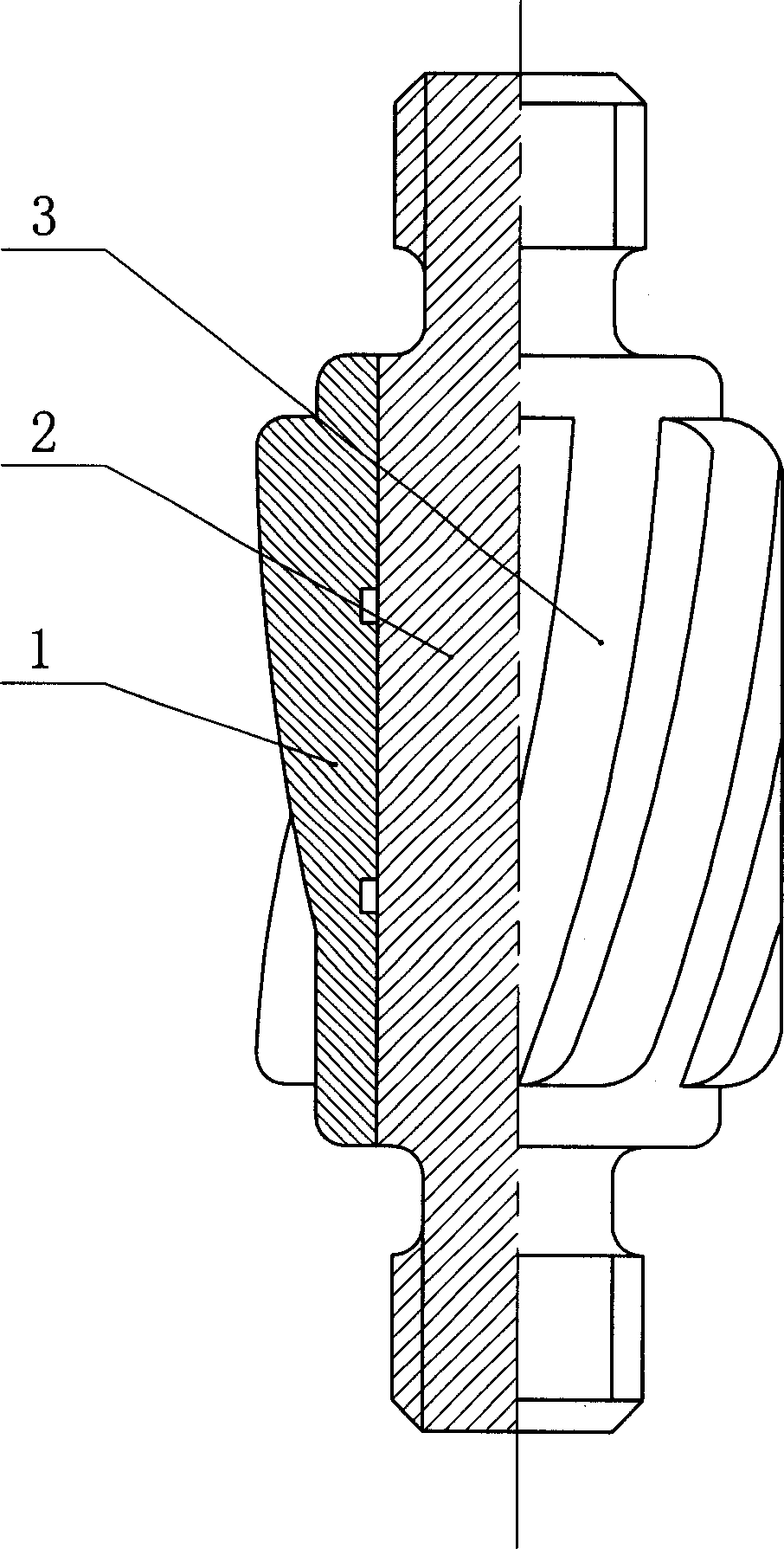

Centralizer and its manufacturing method

InactiveCN1755062AGood processing performanceUnique wear-resistantDrilling rodsCeramic shaping apparatusCeramicSilicon nitride

The invention discloses a stabilizer and making method for supplying an uneasy abrasive, long lifespan, long replacing period, high product efficient stabilizer, which comprises the following parts: stable block (1), short rob (2) and diagonal pilot channel (3), wherein the stable block (1) is encased around the peripheral short rob (2); several diagonal pilot channels (3) are set around the stable block (1) and each channel forms a certain critical angle to the stable block (1); the stable block (1) is made of silicon nitride ceramics material which comprises the following peculiar advantages: abrasion-proof, corrosion-resisting, high temperature-resistant and light quality. The making method of the stabilizer comprises the following steps: loading the silicon nitride ceramics power in the preparing stabilizer mould; compressing the mould by 1800kg / cm2 pressure to form a pattern; finishing the stabilizer by agglomeration in 1100-1300 Deg.C. The making method contains simple process and low cost, which can be applied in the domain of oil exploitation.

Owner:王敬东

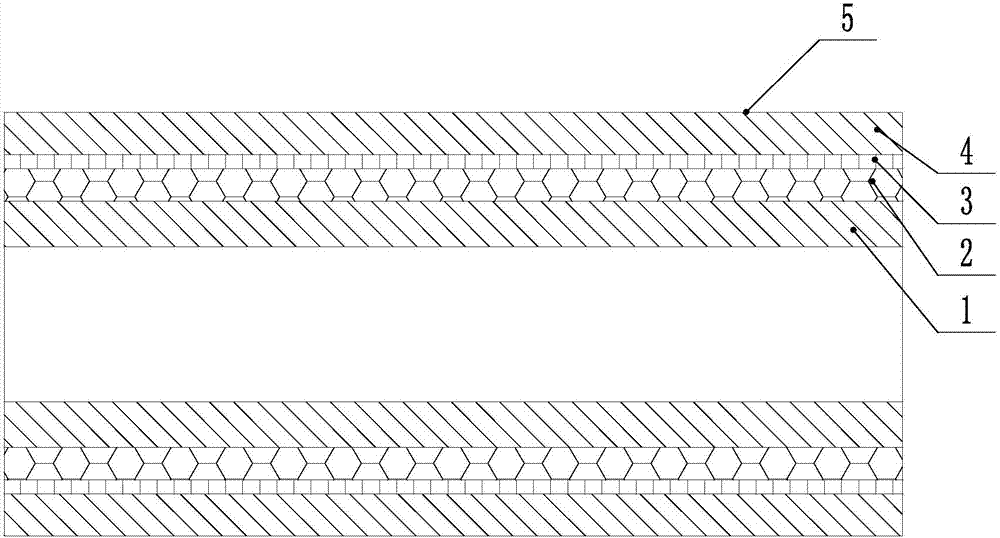

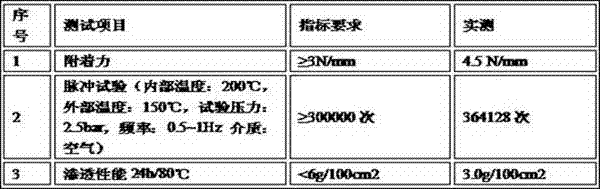

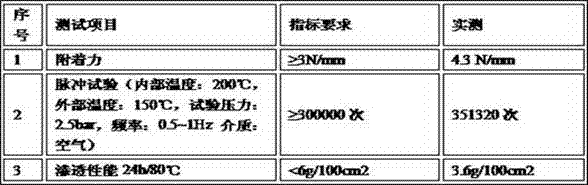

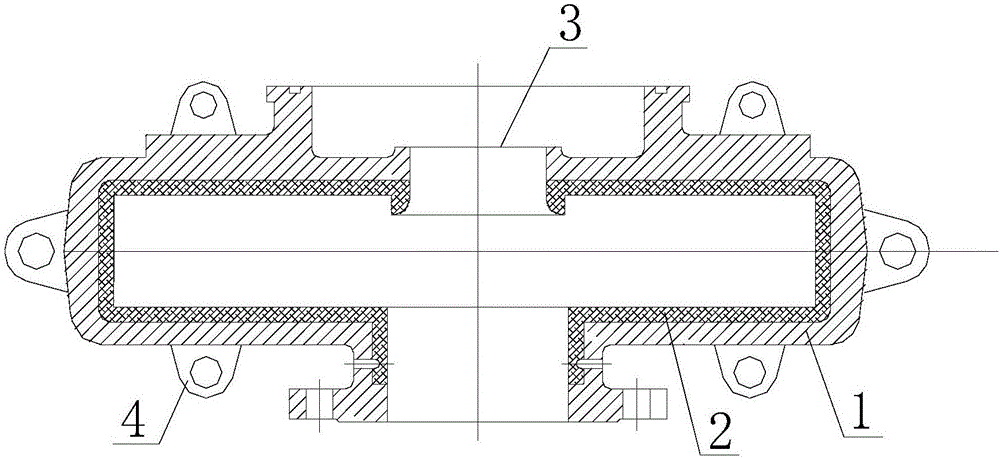

Ethylene-acrylic elastomer turbocharging rubber hose and manufacturing method thereof

InactiveCN107084285AMeet the use requirementsMeet high temperature resistanceSynthetic resin layered productsFlexible pipesElastomerEngineering

The invention discloses an ethylene-acrylic elastomer turbocharging rubber hose and a manufacturing method thereof. The ethylene-acrylic elastomer turbocharging rubber hose comprises a rubber hose body and is characterized in that the rubber hose body is composed of an inner fluororubber layer, a middle ethylene-acrylic elastomer layer, an aramid cord layer and an outer ethylene-acrylic elastomer layer; and the thickness of the inner fluororubber layer is 0.4mm-1.0mm, the thickness of the middle ethylene-acrylic elastomer layer is 1mm-4mm, the thickness of the aramid cord layer is 0.1mm-2mm, and the thickness of the outer ethylene-acrylic elastomer layer is 1mm-4mm. The ethylene-acrylic elastomer turbocharging rubber hose has the following beneficial effects that the fluororubber and ethylene-acrylic elastomer as well as ethylene-acrylic elastomer turbocharging rubber hose of the structure can meet the using requirements of being resistant to fuel oil, permeation and high temperatures, the bursting pressure is high, the using requirements of an automobile engine system can be met, and the adhesive force between the wall layers of the hose is higher than or equal to 3N / mm.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

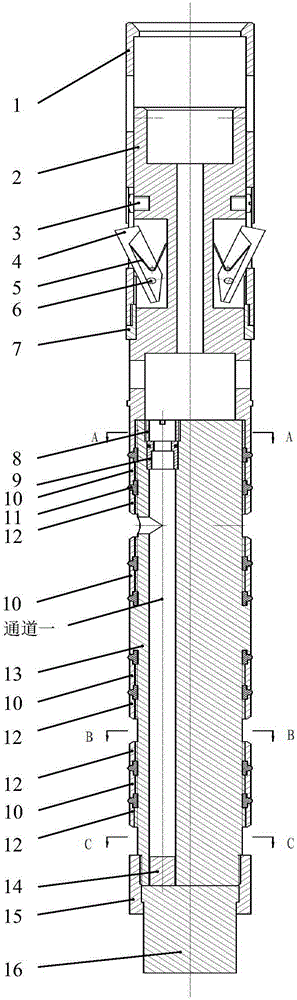

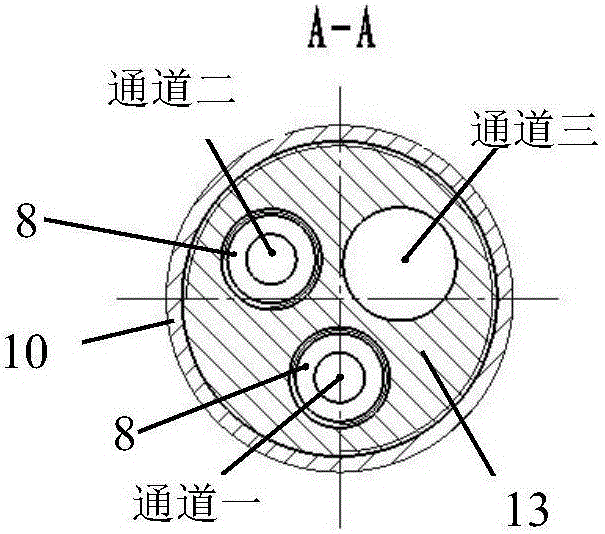

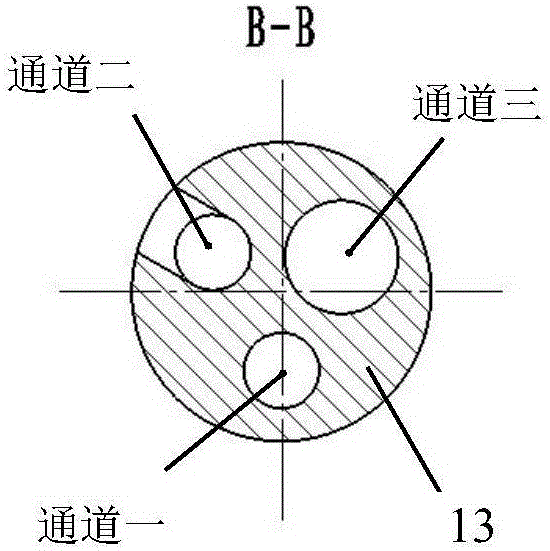

Gas well storage type integrated layered production allocation pressure gauge

ActiveCN105888650ASimple structureAvoid interlayer interferenceSurveyFluid removalOil productionProcess engineering

The invention relates to the technical field of oil production engineering, and belongs to a gas well storage type integrated layered production allocation pressure gauge, which solves the problem in the prior art that long-term pressure monitoring and productivity allocation during a dynamic production process of two gas producing zones cannot be realized at the same time. The gas well storage type integrated layering and production allocating pressure gauge is formed by a salvaging connector (1), a positioning main body (2), anti-rotation pins (3), positioning scissors (4), torsion springs (5), scissor pins (6), regulating sleeves (7), a pressing cap (8), an air faucet (9), regulating rings (10), sealing packings (11), pressing rings (12), a production allocation main body (13), a sensor (14), a back-up nut (15) and a pressure gauge cabin (16). The gas well storage type integrated layered production allocation pressure gauge disclosed by the invention has the advantages that the structure is simple and reliable, static and dynamic production of two kinds of gas producing zones and long-term monitoring on pressure in a shaft can be realized at the same time, and the like.

Owner:PETROCHINA CO LTD +1

Transmission belt material and preparation method thereof

InactiveCN107325349AImprove mechanical propertiesEasy to processStearic acidButadiene-styrene rubber

The invention discloses a transmission belt material. A formula of the material comprises the following components in parts by mass: 10 to 25 parts of natural rubber, 25 to 40 parts of styrene butadiene rubber, 60 to 75 parts of nitrile rubber, 1 to 4 parts of sulfur, 5 to 8 parts of plasticizer, 2 to 5 parts of bonding agent, 7 to 11 parts of zinc oxide, 2 to 4 parts of anti-aging agent RD, 1.5 to 3 parts of anti-aging agent NBC, 0.5 to 2 parts of anti-aging agent DNP, 15 to 18 parts of carbon black, 5 to 6 parts of white carbon black, 1 to 3 parts of N-cyclohexyl-2-benzothiazolesulfenamide, 1 to 2 parts of 2,2'-dibenzothiazyl disulfide, 3 to 5 parts of stearic acid, 10 to 11 parts of coumatone resin, and 3.5 to 5 parts of pine tar. A preparation method comprises the following steps: (1), putting the natural rubber, the styrene butadiene rubber and the nitrile rubber into a banbury mixer, heating to the temperature of 110 to 120 DEG C; (2), adding half of the carbon black and rising the temperature to be 145 to 155 DEG C for milling for 4 to 6min, sequentially adding the zinc oxide, the white carbon black, the coumatone resin, an accelerator and the anti-aging agents for milling; (3), adding the rest carbon black, the plasticizer, the sulfur and the pine tar into a open mill for carrying out milling for 6 to 9min to obtain masterbatch; (4), putting the masterbatch into a vulcanizing mold for carrying out vulcanization treatment.

Owner:ANYANG INST OF TECH

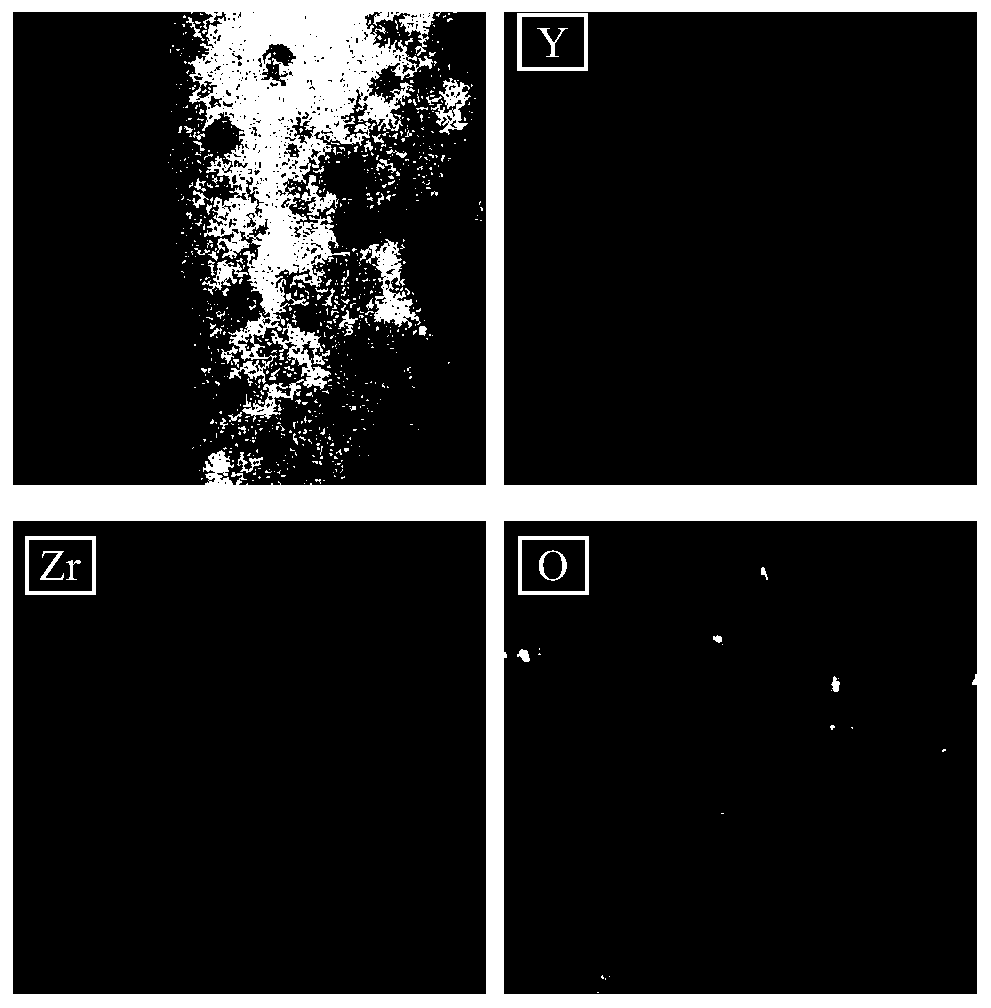

Nanometer structure oxide dispersion strengthening vanadium alloy and preparation method thereof

ActiveCN110499441AGood thermal stability at high temperatureMeet high temperature resistanceSolid solutionNanostructure

The invention discloses a nanometer structure oxide dispersion strengthening vanadium alloy and a preparation method thereof. Components of the alloy comprise, by mass part, 3.9%-4.1% of Cr, 3.9%-4.1%of Ti, 0.05%-5% of Zr, 0.1%-4% of Y and the balance V and inevitable impurity. V base, V-Cr base and V-Cr-Ti base alloy powder, or pure metal element powder is used for being mixed with metal Zr powder and YH2 powder; ball milling is carried out after mixing, the ratio of balls to materials is 5:1-10:1, the rotating speed of a ball milling machine is 200-260 turns per minute, the diameter of themilling balls is 5-10 mm, and ball milling time is 50-60 h; solid solution alloy powder obtained after ball milling is subjected to solidifying sintering, the sintering temperature is 950-1450 DEG C,heat preserving time is 1-15 min, and sintering pressure is 10-100 MPa; and the sintered alloy is subjected to vacuum annealing for 0.5-2 h on the vacuum condition at the temperature of 1050-1200 DEGC, and the oxide dispersion strengthening vanadium alloy is obtained.

Owner:ANGANG STEEL CO LTD

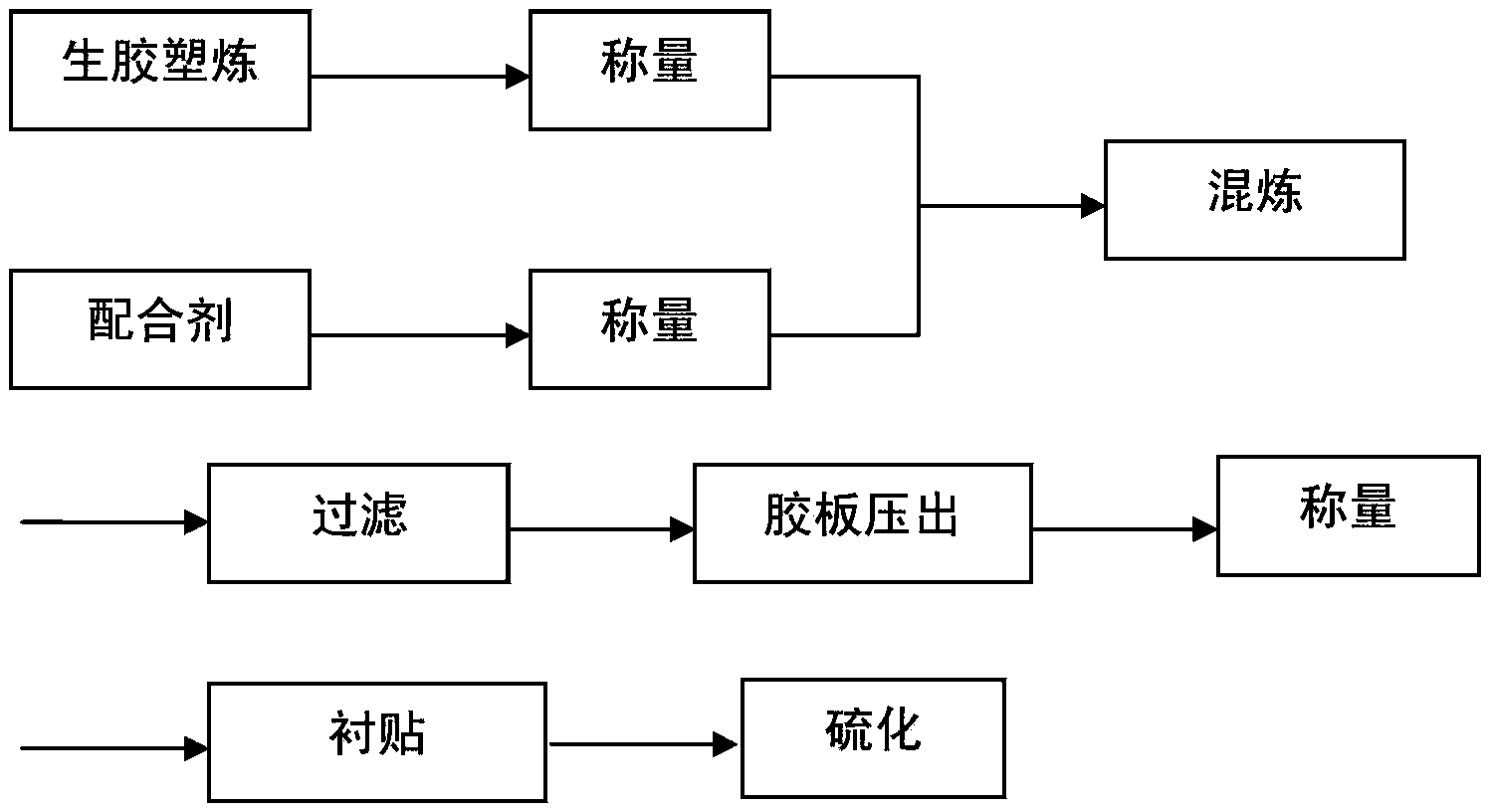

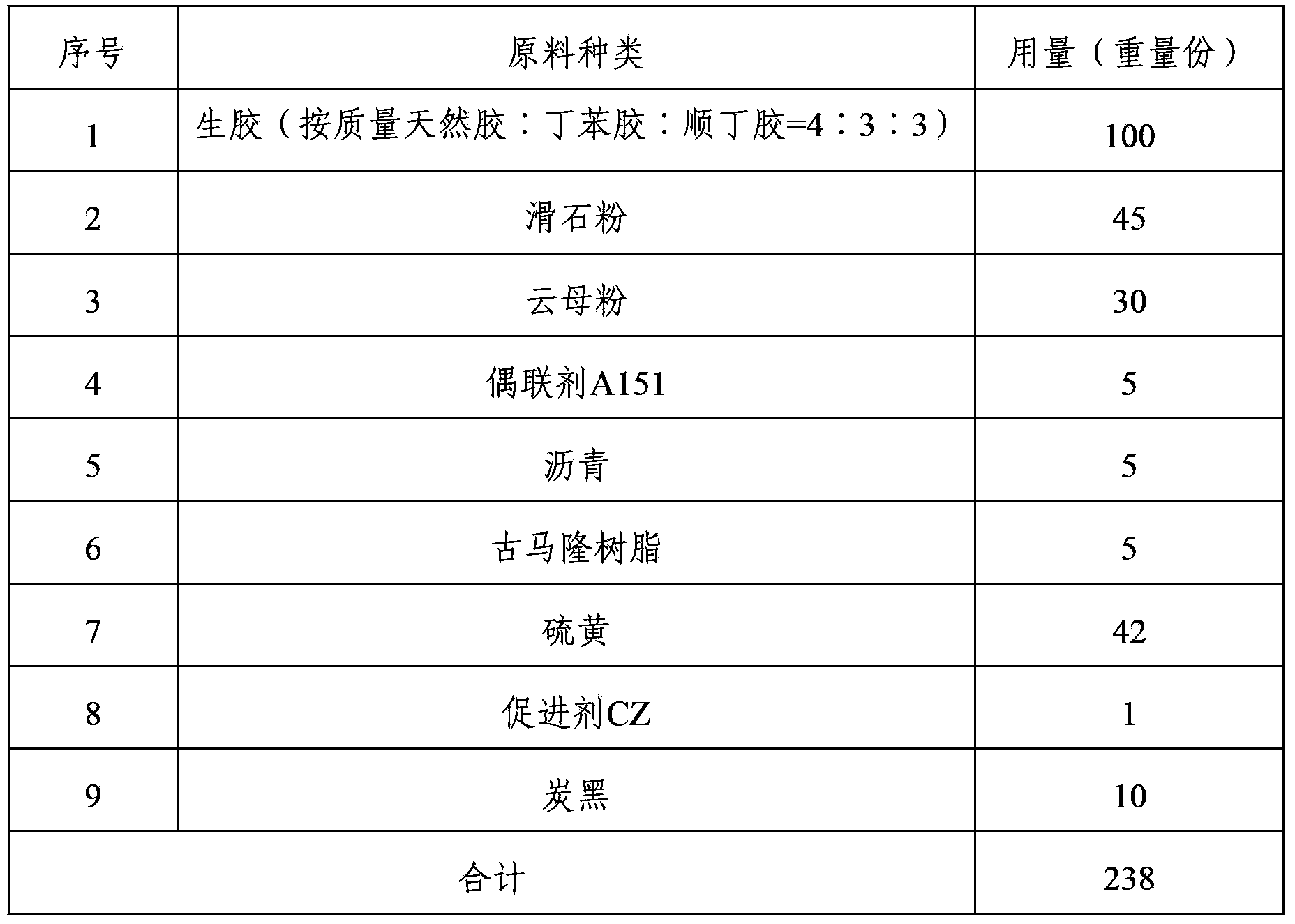

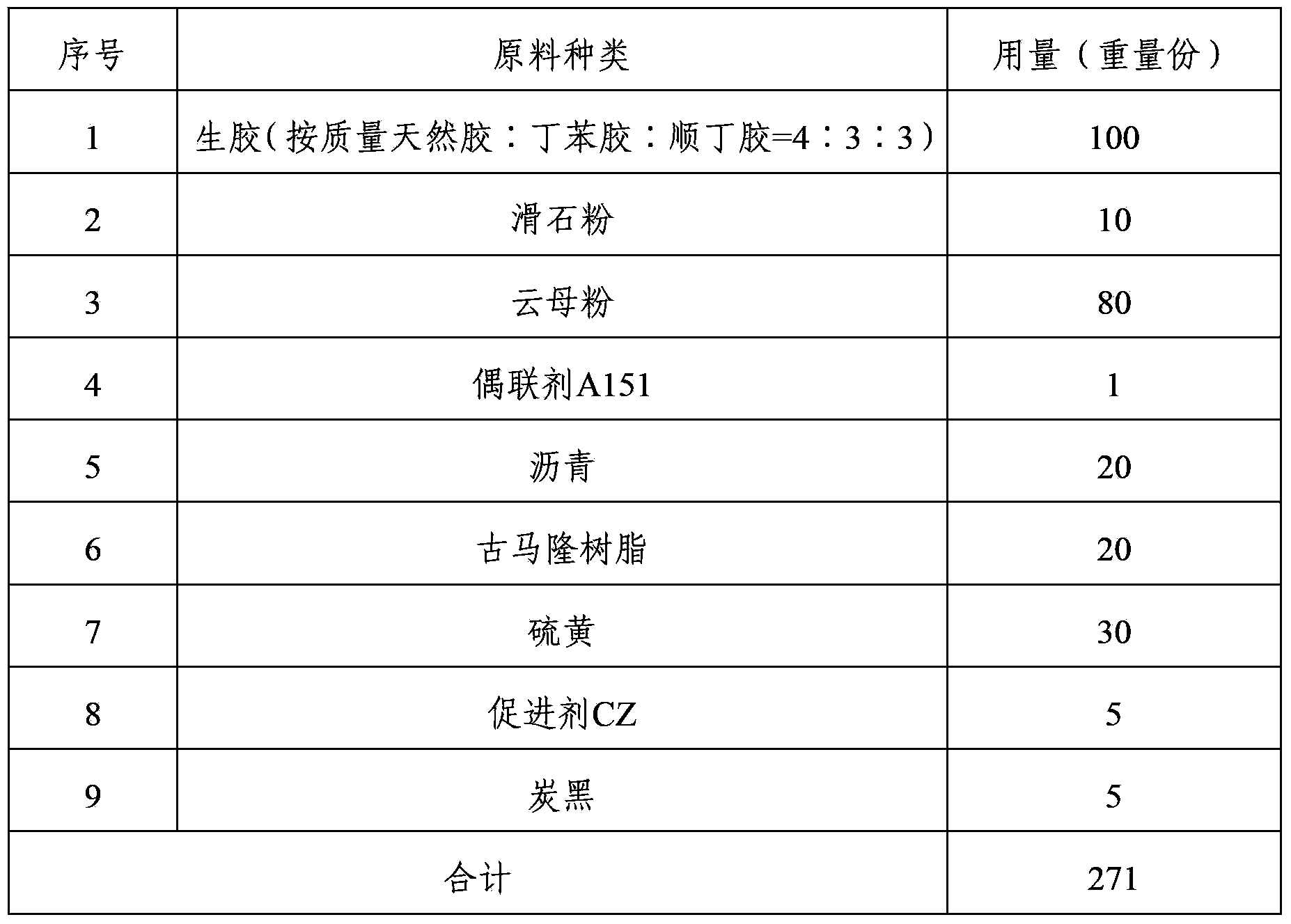

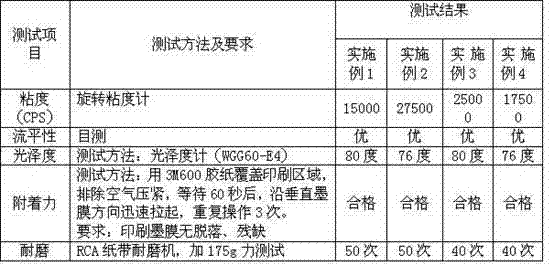

Anti-corrosion rubber composition and anti-corrosion rubber lining

The invention relates to an anti-corrosion rubber composition. The anti-corrosion rubber composition comprises the components of, by weight, 100 parts of raw rubber, 20-80 parts of talcum powder, 10-60 parts of mica powder, 0.5-10 parts of coupling agent, 0.5-15 parts of pitch, 1-20 parts of coumarone resin, 30-60 parts of sulphur, 0.1-5 parts of accelerant and 1-20 parts of dyeing agent. The invention also relates to an anti-corrosion rubber lining. The rubber lining produced through the anti-corrosion rubber composition provided in the invention can bear a working temperature of 130 DEG C under a high vacuum degree, is acid and alkali resistant at high temperatures and is applicable to a 11-stage flash device of an adhesive production line.

Owner:XIANYANG SAIFU ANTICORROSION EQUIP

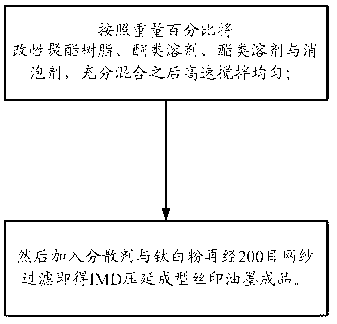

Silk-screen printing ink and application thereof

The invention discloses silk-screen printing ink and an application thereof. The silk-screen printing ink is applied to thermoplastic polyurethane (TPU) calendaring molding. The silk-screen printing ink comprises the following components in percentage by weight: 30 to 40 percent of polyurethane (PU) resin, 30 to 45 percent of ketone solvent, 10 to 25 percent of benzene solvent and 1 to 5 percent of aid. According to the silk-screen printing ink for calendaring molding of the TPU material, the problems of light leakage, breakage and degumming after the conventional printing oil is printed and molded on the TPU are effectively solved. The silk-screen printing ink mainly comprises the PU resin and a proper amount of aids, so that the silk-screen printing ink has excellent using performance, can achieve the effects of good leveling and excellent adhesive force on the printing surface of the TPU material, and can meet the requirements of clients on wear resistance, high temperature resistance, punching resistance and the like of products.

Owner:深圳市美丽华科技股份有限公司

High-temperature anti-explosion signal cable for new energy automobiles

A high-temperature anti-explosion signal cable for new energy automobiles comprises a center conductor and a special high-temperature-resistant silicon rubber ceramic insulating layer. The center conductor is an annealed bare copper or tinned stranded conductor formed by standard cross stranding and is peripherally and closely coated with the special high-temperature-resistant silicon rubber ceramic insulating layer. The high-temperature anti-explosion signal cable has the advantages that performance requirements on high temperature resistance, super softness and the like can be met; after direct flame impact on the cable, the cable surface is turned into a ceramic shell with excellent flame-retardant, fireproof, fire insulation and fire prevention functions, and accordingly line smoothness is effectively protected, signal transmission is unaffected, signals can be transmitted quickly and accurately to enable people in automobiles to response timely, and personal safety is guaranteed.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

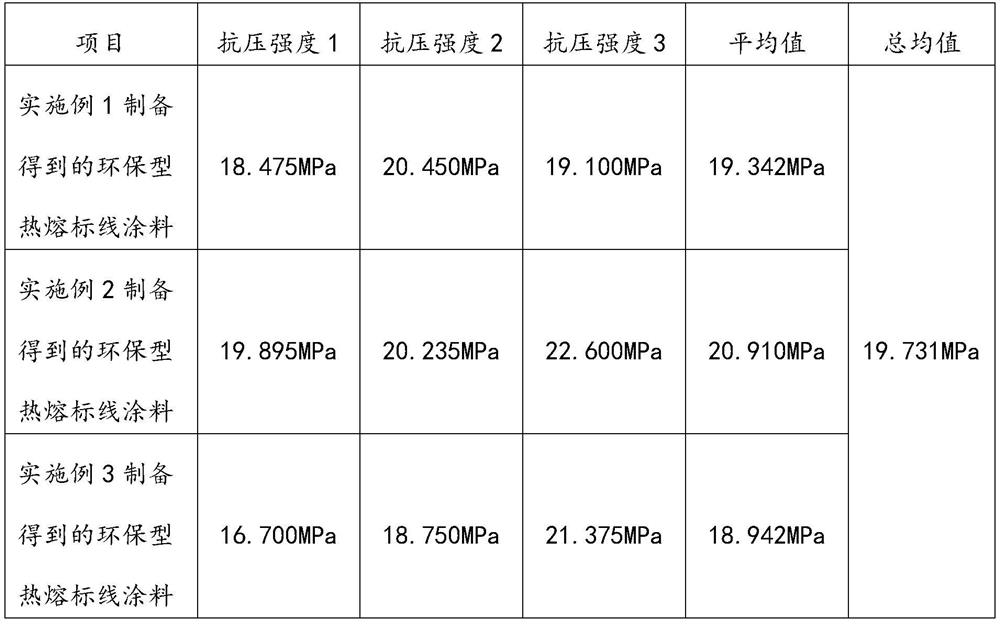

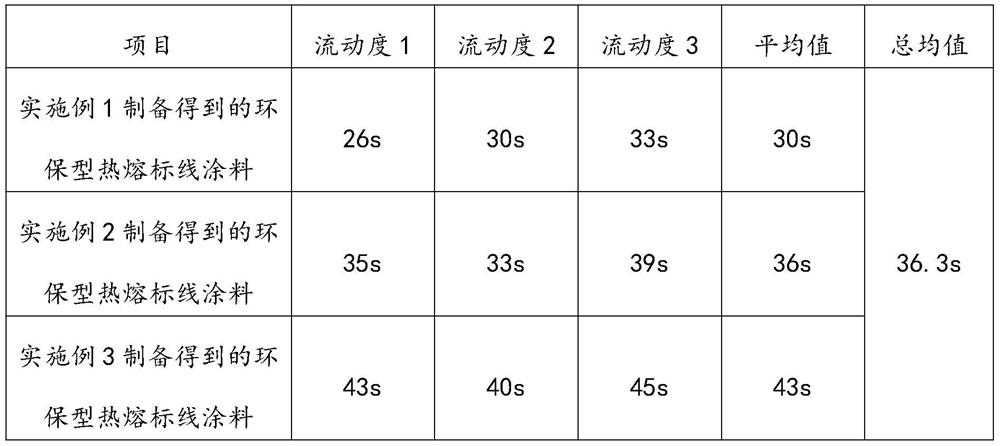

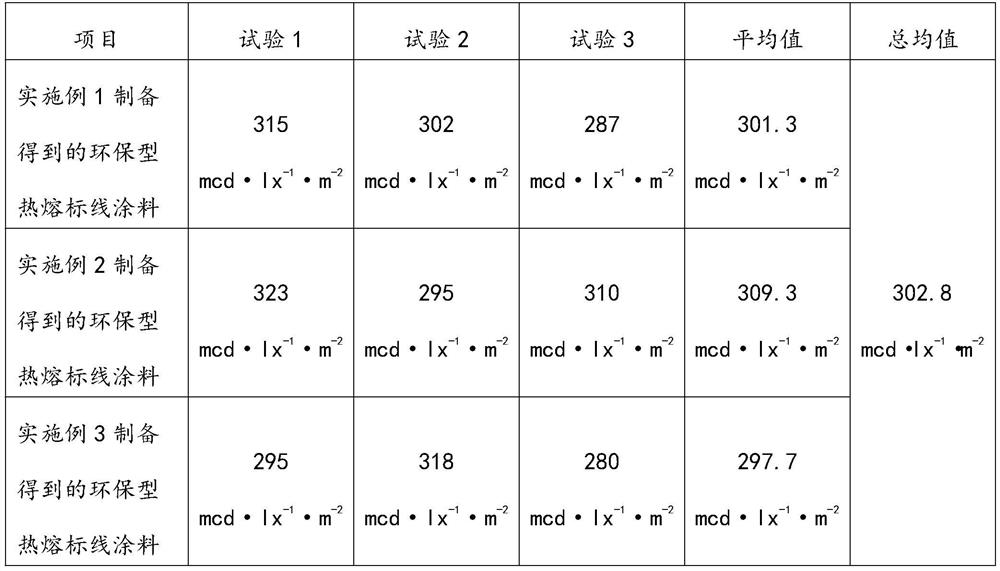

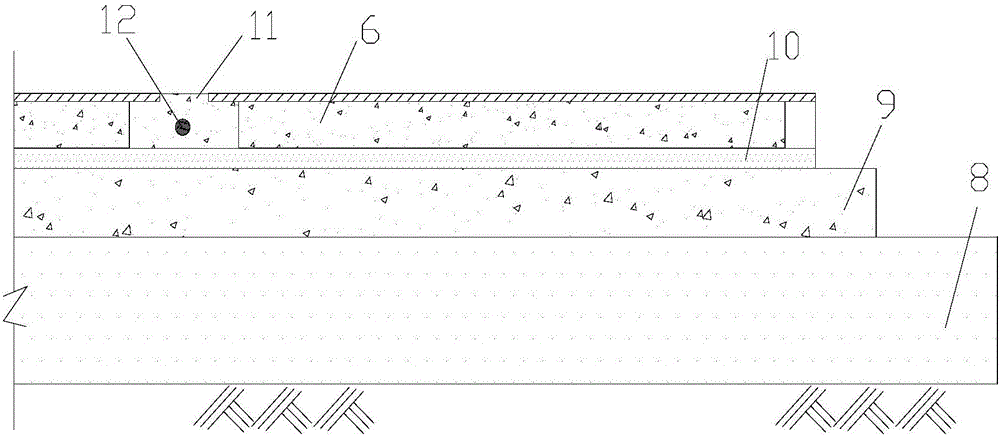

Environment-friendly hot-melt marking coating and preparation method thereof

InactiveCN111635688AImprove liquidityHigh compressive strengthConjugated diene hydrocarbon coatingsReflecting/signal paintsCompressive resistanceNitrile rubber

The invention discloses an environment-friendly hot-melt marking coating and a preparation method thereof, and belongs to the technical field of environment-friendly hot-melt marking coatings. The environment-friendly hot-melt marking coating is prepared from, by weight, 13-15 parts of modified C5 petroleum resin, 6-8 parts of a pigment, 27-29 parts of quartz sand, 26-28 parts of ground calcium carbonate, 1-3 parts of castor oil, 2-4 parts of polyethylene wax, 1-3 parts of powdered acrylonitrile-butadiene rubber and 20-23 parts of glass beads. The invention also discloses a preparation methodof the environment-friendly hot-melt marking coating. The environment-friendly hot-melt marking coating has the advantages of good fluidity, high compressive strength, short drying time, high softening point, good flexibility, water resistance, acid and alkali resistance, good light reflection performance and the like.

Owner:杨三强 +5

Preparation technique for steel plate terrace of industrial workshop

InactiveCN105926899AHigh bearing pressureMeet high temperature resistanceFlooringSurface layerSheet steel

The invention provides a preparation technique for a steel plate terrace of an industrial workshop. The preparation method comprises the steps that modular steel plate concrete elements are adopted, and the modular steel plate concrete elements are laid on a concrete cushion which is prepared in advance; and then long lacing bars are arranged between all the steel plate concrete elements, gaps are filled and compacted with fine aggregate concrete, and the integrity of the whole surface layer is guaranteed. By the adoption of the preparation technique, pits and sunken parts of a traditional steel plate terrace can be eliminated, and the phenomena of desoldering and upwarping of the connection portion at the ends of a steel plate are also eliminated; the effect that a steel plate ground is smooth in the user condition is guaranteed, and the integrity is firm; in addition, through the modular laying, no large hoisting equipment is needed, the labor is greatly saved, and the laying construction speed is high; multiple functional technical requirements for the bearing capacity, abrasion resistance, high-temperature resistance and the like of the cast terrace can be met; and the preparation technique has extremely high practical value.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

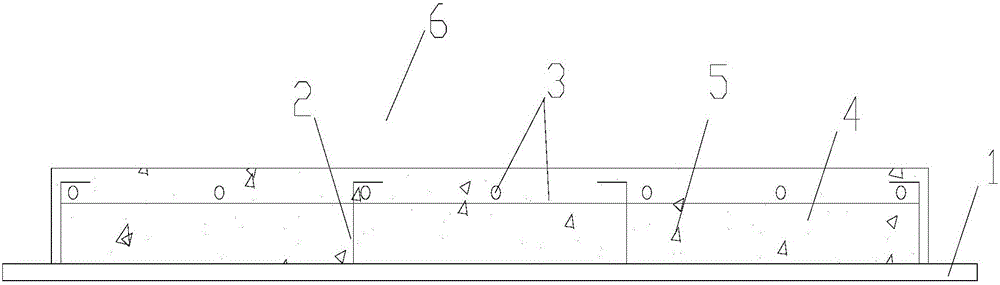

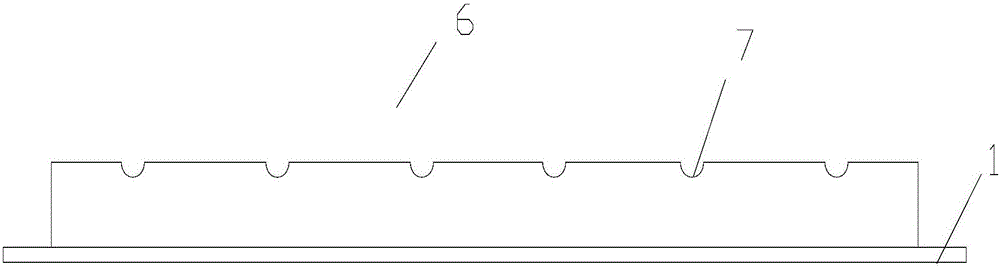

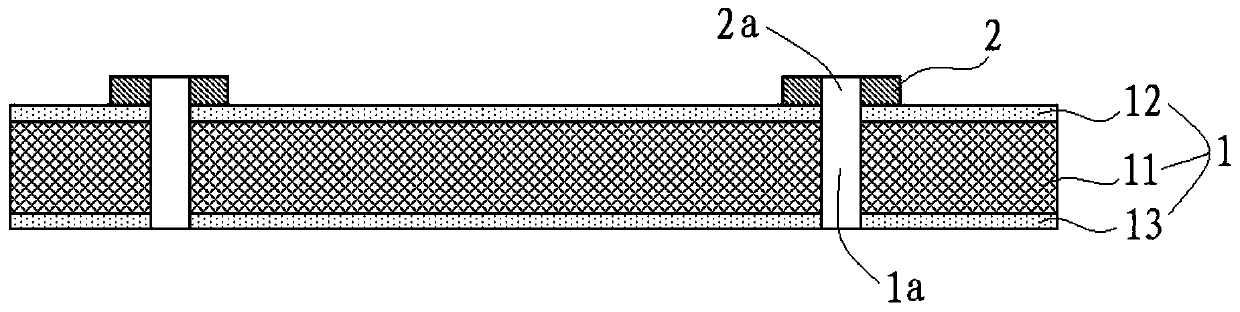

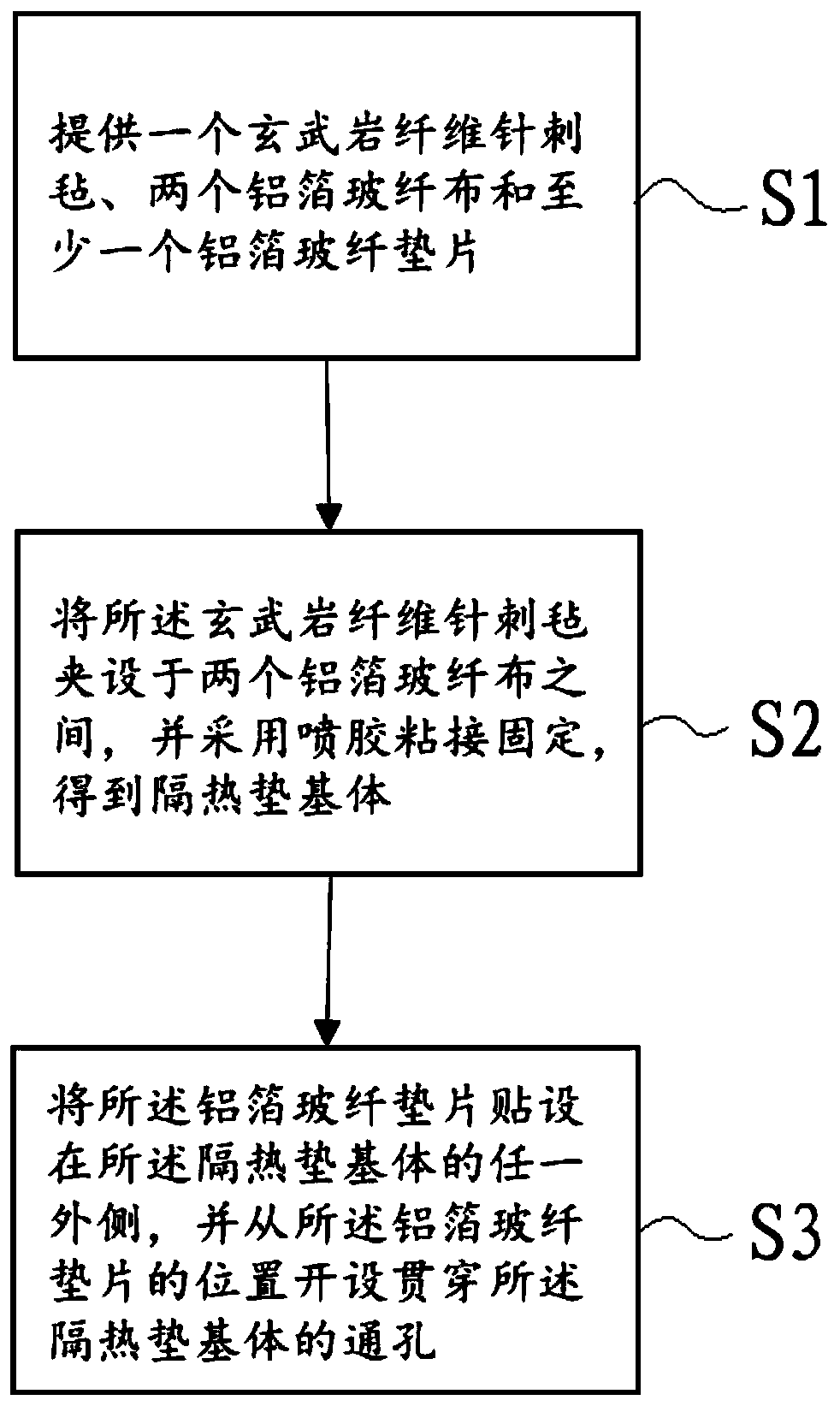

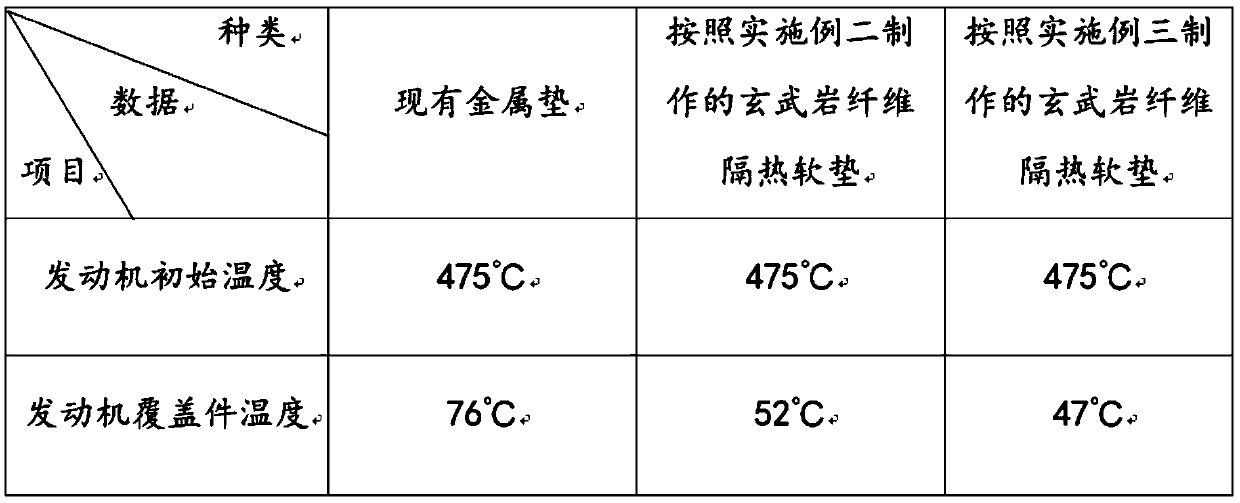

Basalt fiber heat insulation cushion and preparation method thereof

ActiveCN110549700AHigh temperature resistantCorrosion resistantLamination ancillary operationsLaminationGlass fiberThermal insulation

The invention provides a basalt fiber heat insulation cushion, and aims to solve the technical problems that an existing metal cushion has poor heat insulation performance and rusting of an engine cover part is not effectively improved. The basalt fiber heat insulation cushion comprises a heat insulation cushion base body and at least one aluminum foil glass fiber gasket; the base body comprises abasalt fiber needled felt and two aluminum foil glass fiber cloths; the two aluminum foil glass fiber cloths are respectively attached to two outer side surfaces of the basalt fiber needled felt; thealuminum foil glass fiber gasket is attached to any outer side surface of the heat insulation cushion base body; the aluminum foil glass fiber gasket is provided with a mounting hole; and a through hole communicating with the mounting hole and penetrating through the heat insulation cushion base body is formed in the heat insulation cushion base body. The invention also provides a manufacturing method of the basalt fiber thermal insulation cushion.

Owner:东实(武汉)实业有限公司

High-technology ceramic pump body used for pump and manufacturing method thereof

InactiveCN106337831AWon't fall offWon't leakPump componentsCeramic shaping apparatusCeramic metalCorrosion

The invention provides a high-technology ceramic pump body used for a centrifugal pump and a manufacturing method thereof. The high-technology ceramic pump body is mainly composed of a ceramic lining and a metal shell, wherein the ceramic lining is formed by combining two semicircular ceramic pieces and is provided with a feeding inlet and a discharging outlet; the metal shell is also composed of two semicircular metal pieces, the structure of the metal shell is matched with ceramic, and the ceramic and metal are bonded with high-temperature glue; and two semicircular parts are connected through bolts, the connection surface is subjected to flexible sealing, and the integrated pump body is formed. The manufacturing method of the high-technology ceramic pump body comprises the steps of ceramic lining manufacturing, ceramic-metal assembly assembling and forming machining. Compared with existing stainless steel and macromolecular pump bodies, the ceramic pump body can simultaneously meet the requirements for corrosion resistance, abrasion resistance, high-temperature resistance, good sealing performance, safety and reliability, and the life of the pump shell is prolonged by 5-10 times. Compared with pump shells inlaid with ceramic blocks, the ceramic of the pump shell of the high-technology ceramic pump body is not disengaged, leakage does not occur, and the reliability is improved.

Owner:HEFEI JINGCHUANG CERAMIC EQUIP TECH +1

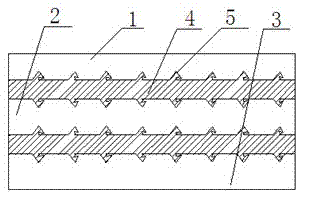

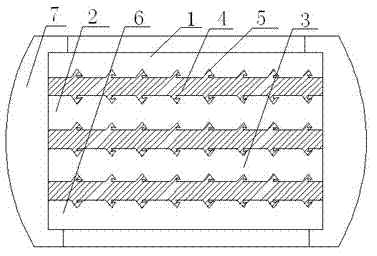

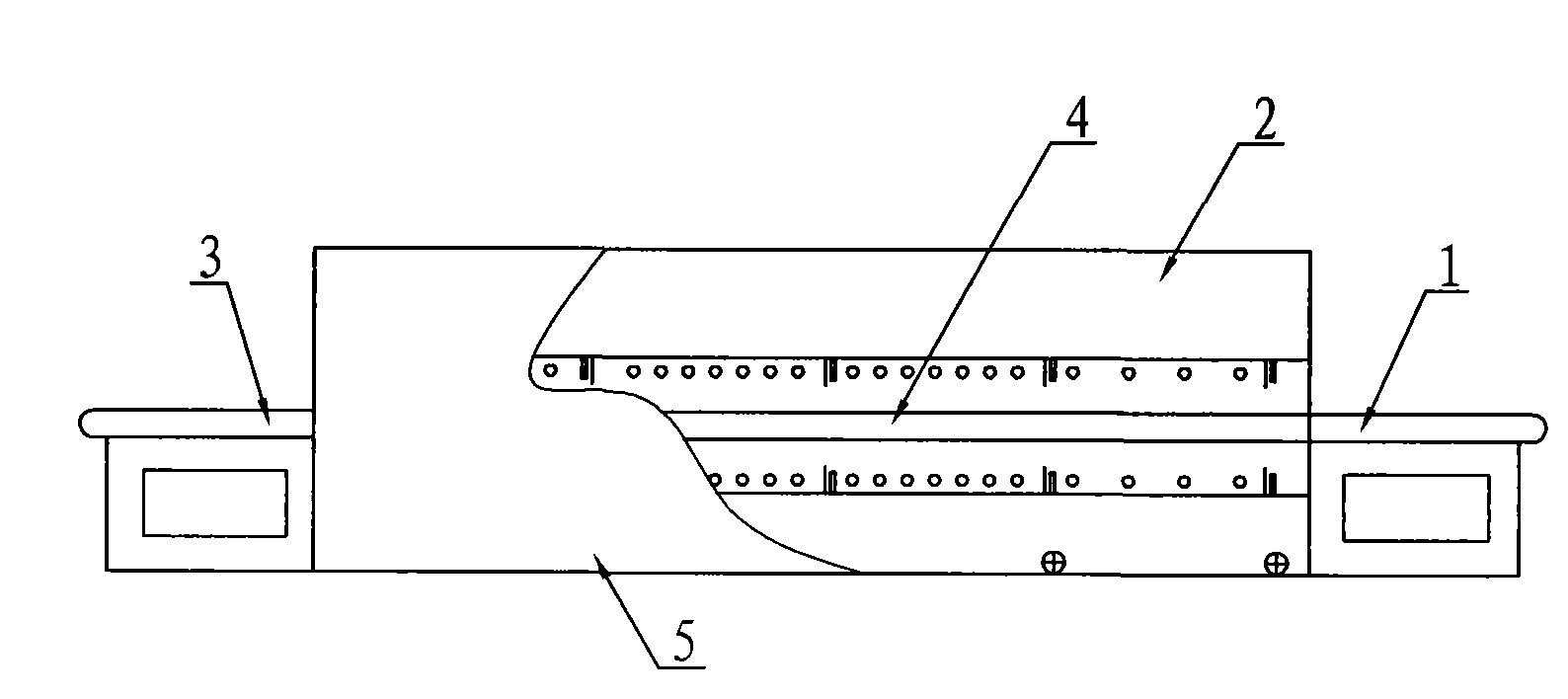

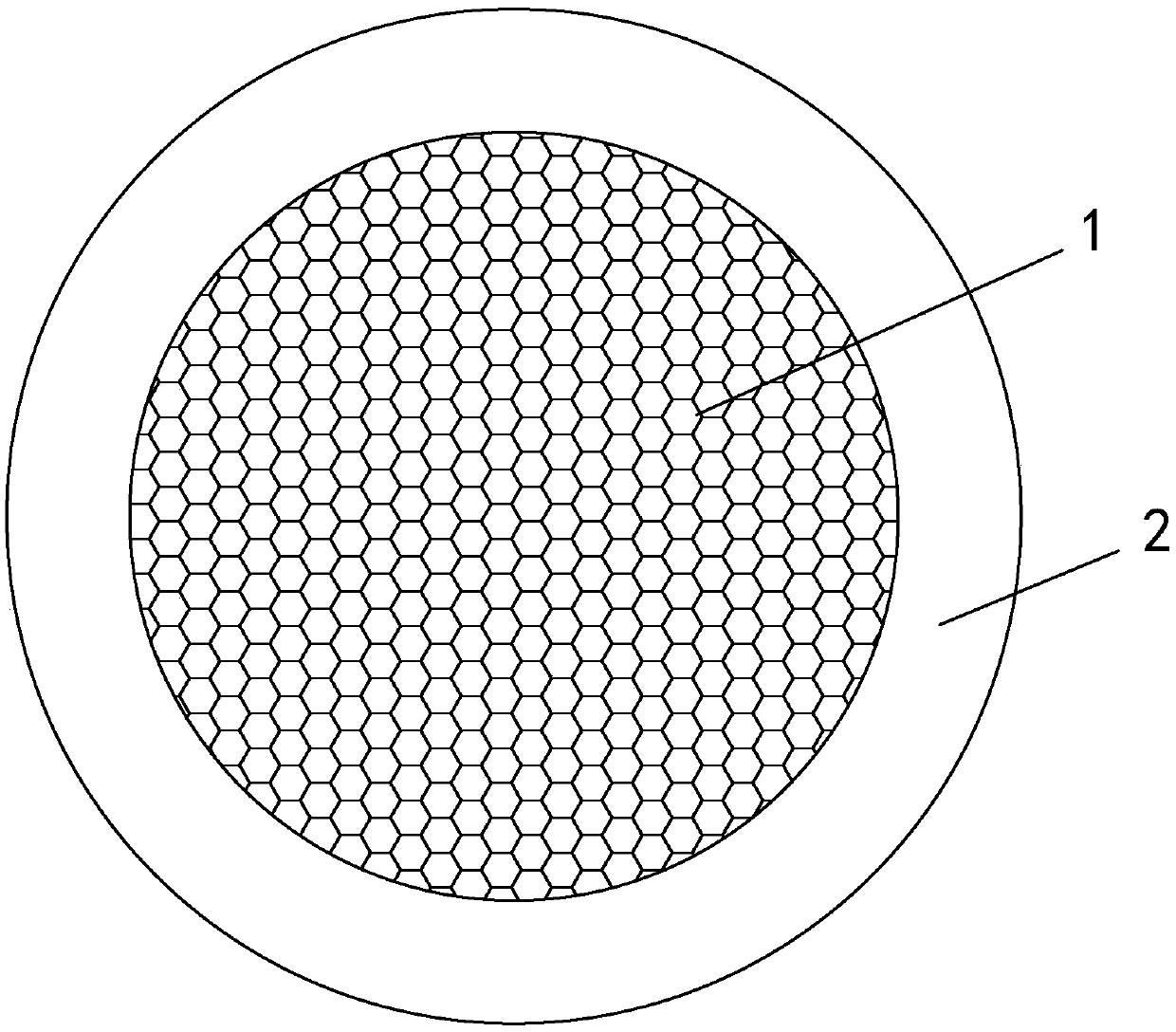

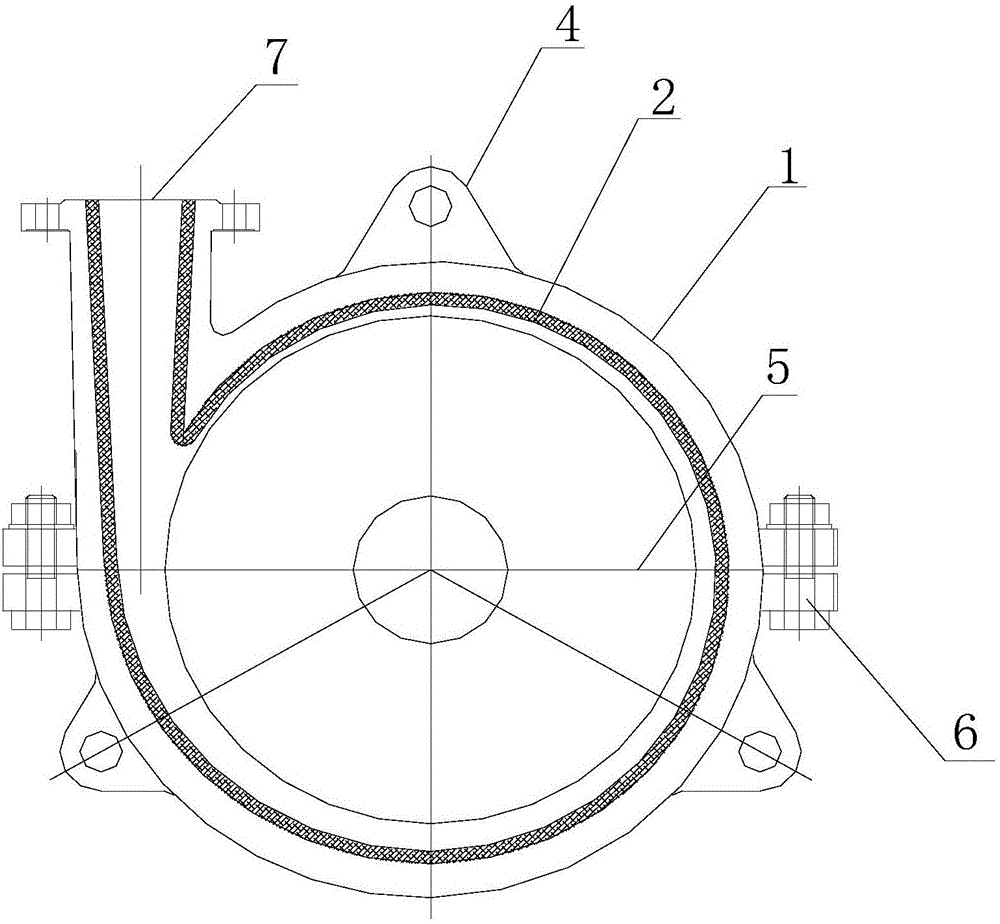

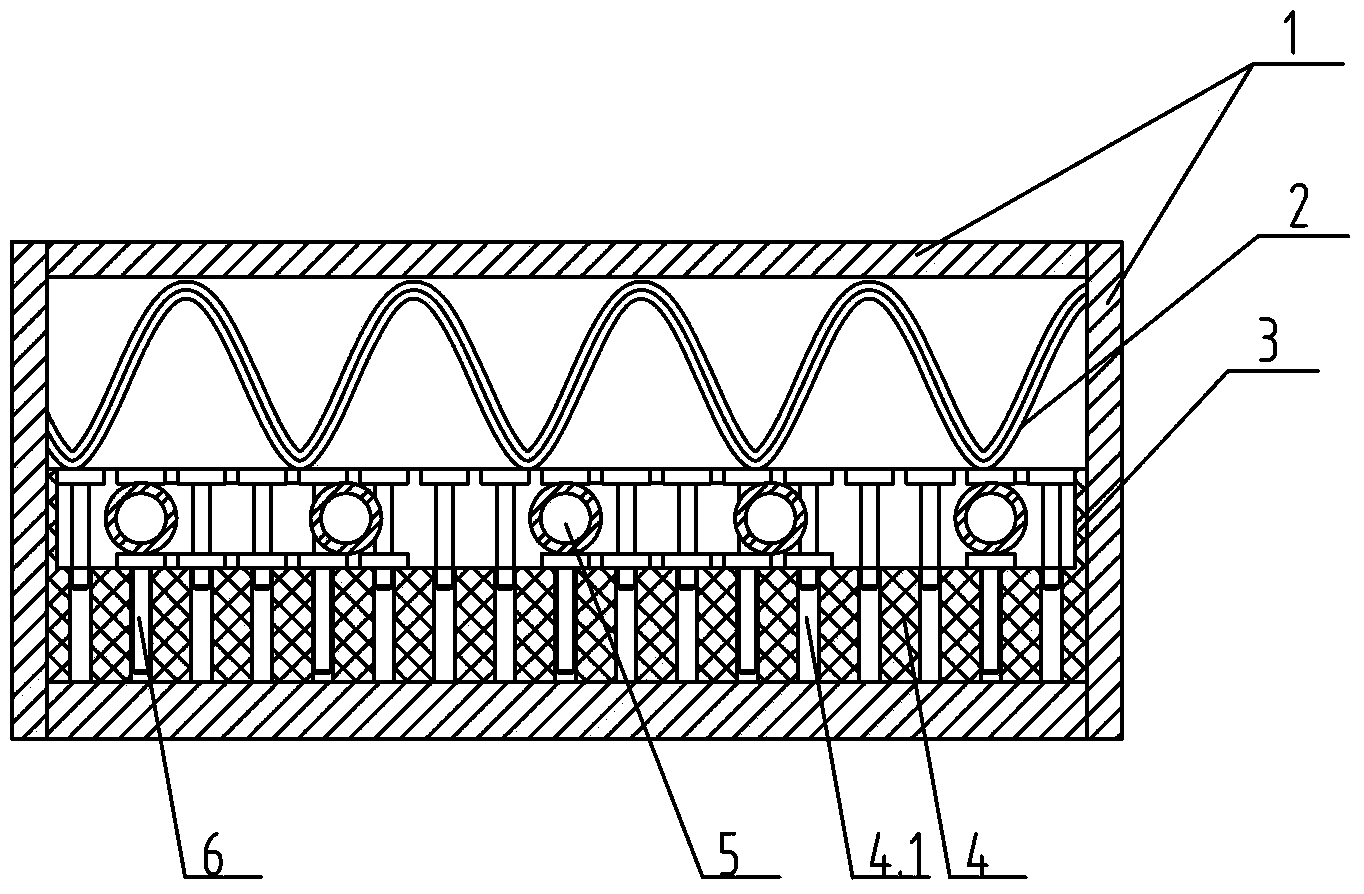

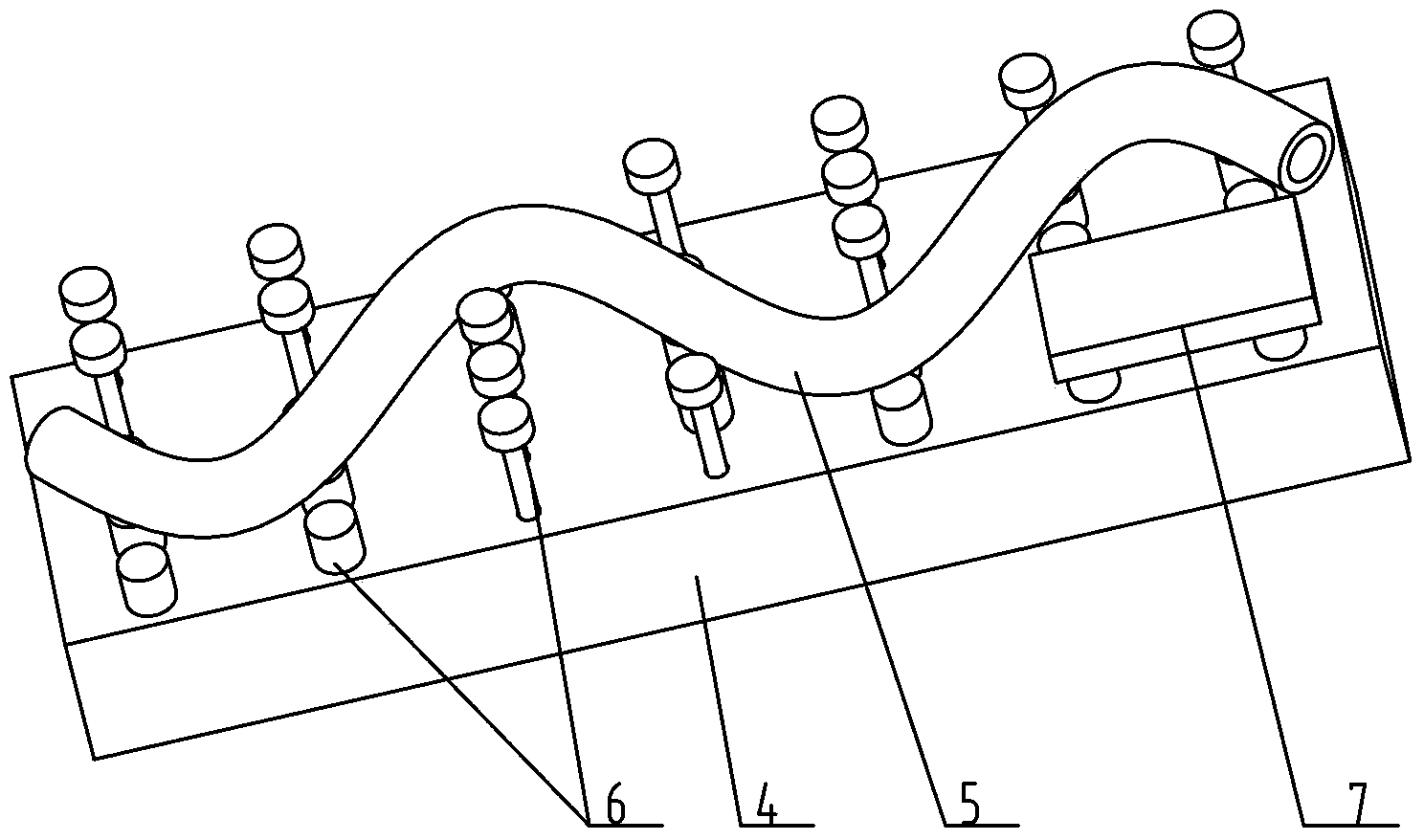

Workbench bedplate

ActiveCN103381592AMeet high temperature resistanceMeet wear resistanceWork benchesShear capacityDual purpose

The invention discloses a workbench bedplate which comprises a stainless steel plate (1), an inner core plate (2) arranged in the inner chamber of the stainless steel plate (1) and a withdrawable temperature-regulating layer (3) arranged on the lower surface of the inner core plate (2), wherein the inner core plate (2) is formed by stacking a plurality of layers of waved metal meshes which are parallel to one another; the temperature-regulating layer (3) comprises a fixing plate (4), a water-gas dual-purpose pipe (5) and pins (6); the fixing plate (4) is provided with a groove; a plurality of pin holes (4.1) are formed in the bottom of the groove; the two ends of the dual-purpose pipe (5) are open; the pins are matched with the pin holes (4.1); an inlet and an outlet which are connected with the water-gas dual-purpose pipe (5) are formed in the side surfaces of the stainless steel plate (1). The workbench bedplate can meet the diversification requirements for high-temperature resistance, wear resistance, convenience in mounting, light weight, impact resistance, high anti-shear capability and capability of heating or cooling products.

Owner:安徽格太信控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com