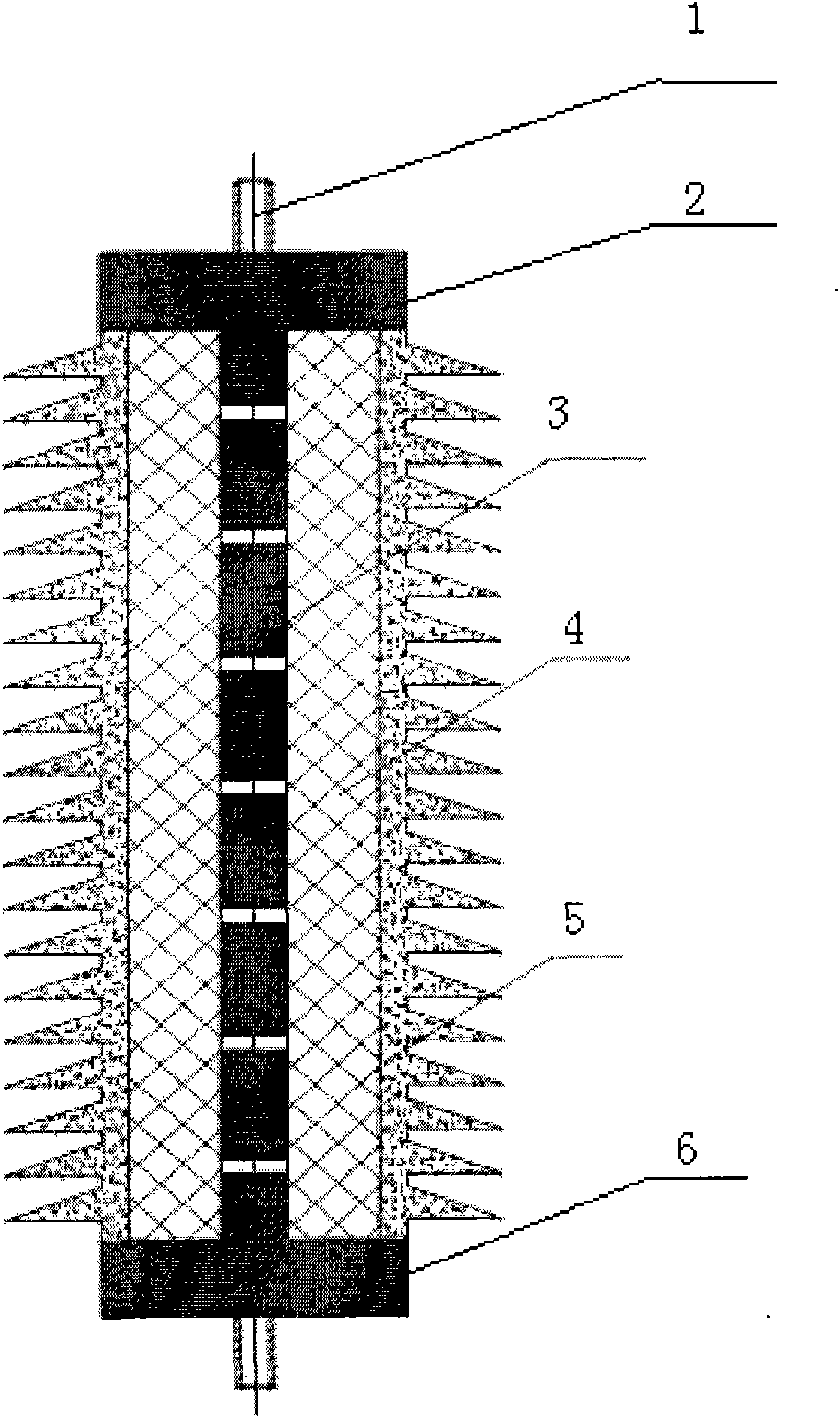

Polymeric housed arrester and method for preparing no-local-discharge compound-glass fiber winding pipe

A glass fiber, composite jacket technology, applied in the field of arresters, can solve the problems of poor impact resistance, poor twist resistance, low tensile strength, etc., to achieve strong impact resistance, strong twist resistance, high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a composite glass fiber wound pipe without partial discharge, carried out according to the following steps:

[0025] (1) Select the core mold according to the customer's requirements, and coat the surface of the core mold with a release agent;

[0026] (2), mandrel is installed on the numerical control winding machine, input relevant parameter, and described relevant parameter refers to winding length, external diameter, winding layer number, winding angle, and its winding process is automatically completed by microcomputer control;

[0027] (3) The material wound on the mandrel is acid-resistant ECR-2400 Tex fiber or WBL-0.14 alkali-free Wolan cloth treated with Wolan;

[0028] (4), the preparation of resin glue, the composition ratio of resin glue is TDE-85 epoxy resin: curing agent: toughening agent: nano silicon dioxide: defoamer=90~100 parts: 110 parts~120 parts: 1.5 Parts to 2.5 parts: 1.5 parts to 2.5 parts: 1.0 parts to 3.0 parts; the cur...

Embodiment 2

[0036] The preparation of resin glue for high-strength glass fiber wound pipe, the composition ratio of resin glue is TDE-85 epoxy resin: curing agent: toughening agent: nano silicon dioxide: defoaming agent = 92-98 parts: 112-118 parts : 1.7 parts to 2.3 parts: 1.7 parts to 2.3 parts: 1.5 parts to 2.5 parts; the curing agent is methyl hexahydrophthalic anhydride or methyl tetrahydrophthalic anhydride, and the toughening agent is nitrile rubber or Qishi epoxy Toughening agent, the 550 or 500, the above-mentioned varieties are weighed in proportion and poured into a vacuum mixer for vacuum stirring for 20 minutes, and left to stand for 1 hour. The other steps of the preparation method are the same as in Example 1.

Embodiment 3

[0038] The preparation of resin glue for high-strength glass fiber wound pipe, the composition ratio of resin glue is TDE-85 epoxy resin: curing agent: toughening agent: nano silicon dioxide: defoaming agent = 94 to 96 parts: 114 to 116 parts : 1.8 parts to 2.2 parts: 1.9 parts to 2.2 parts: 1.8 parts to 2.3 parts; the curing agent is methyl hexahydrophthalic anhydride or methyl tetrahydrophthalic anhydride, and the toughening agent is nitrile rubber or Qishi epoxy For the toughening agent, the defoamer 550 or 500, the above-mentioned varieties are weighed in proportion and poured into a vacuum mixer for vacuum stirring for 20 minutes, and left to stand for 1 hour. The other steps of the preparation method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com