Workbench bedplate

A workbench and platen technology, which is applied to workbenches, manufacturing tools, etc., can solve the problems of difficult cleaning, low strength and impact resistance, and difficult installation, so as to improve temperature uniformity, improve impact resistance, and light weight installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

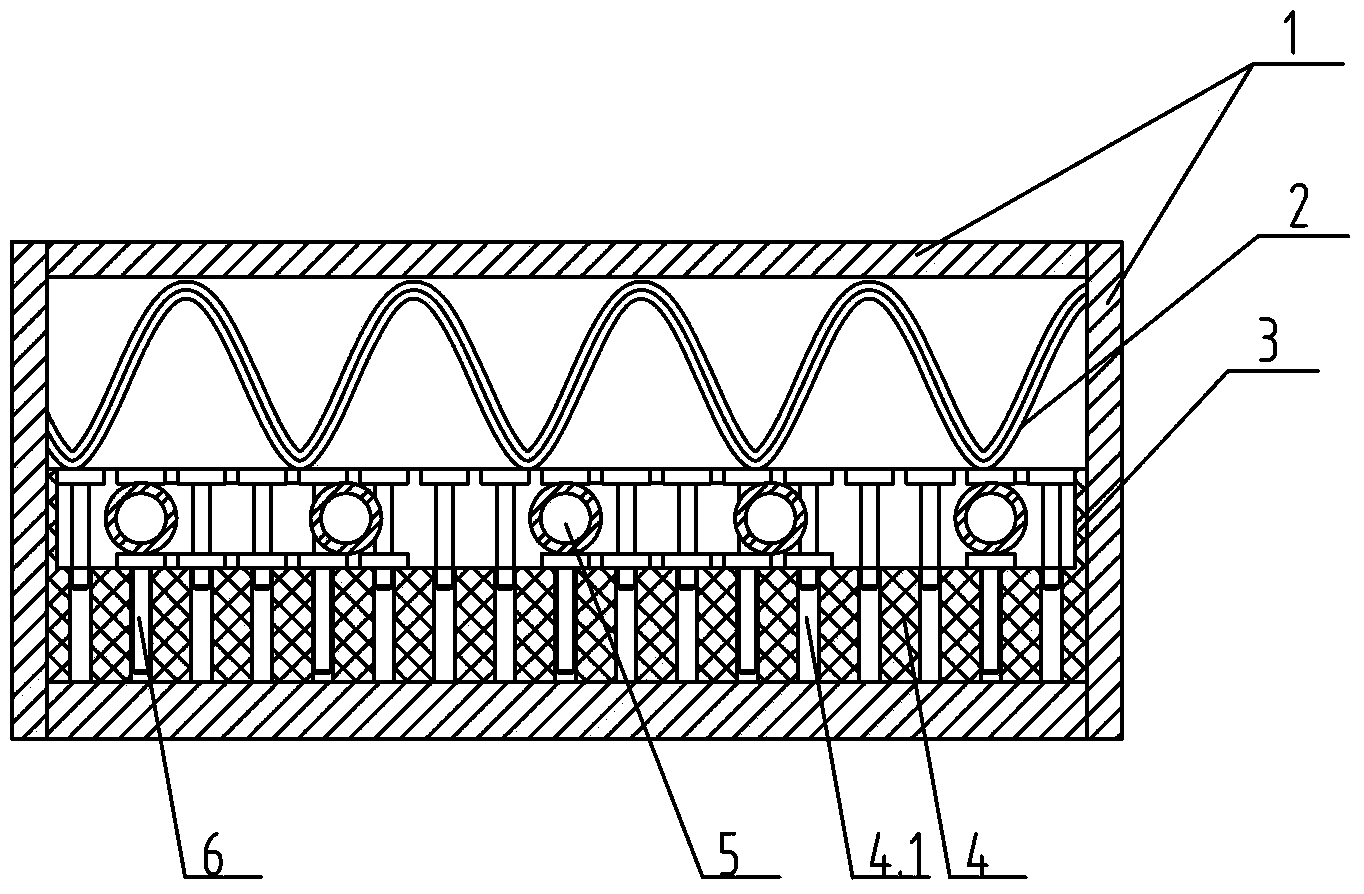

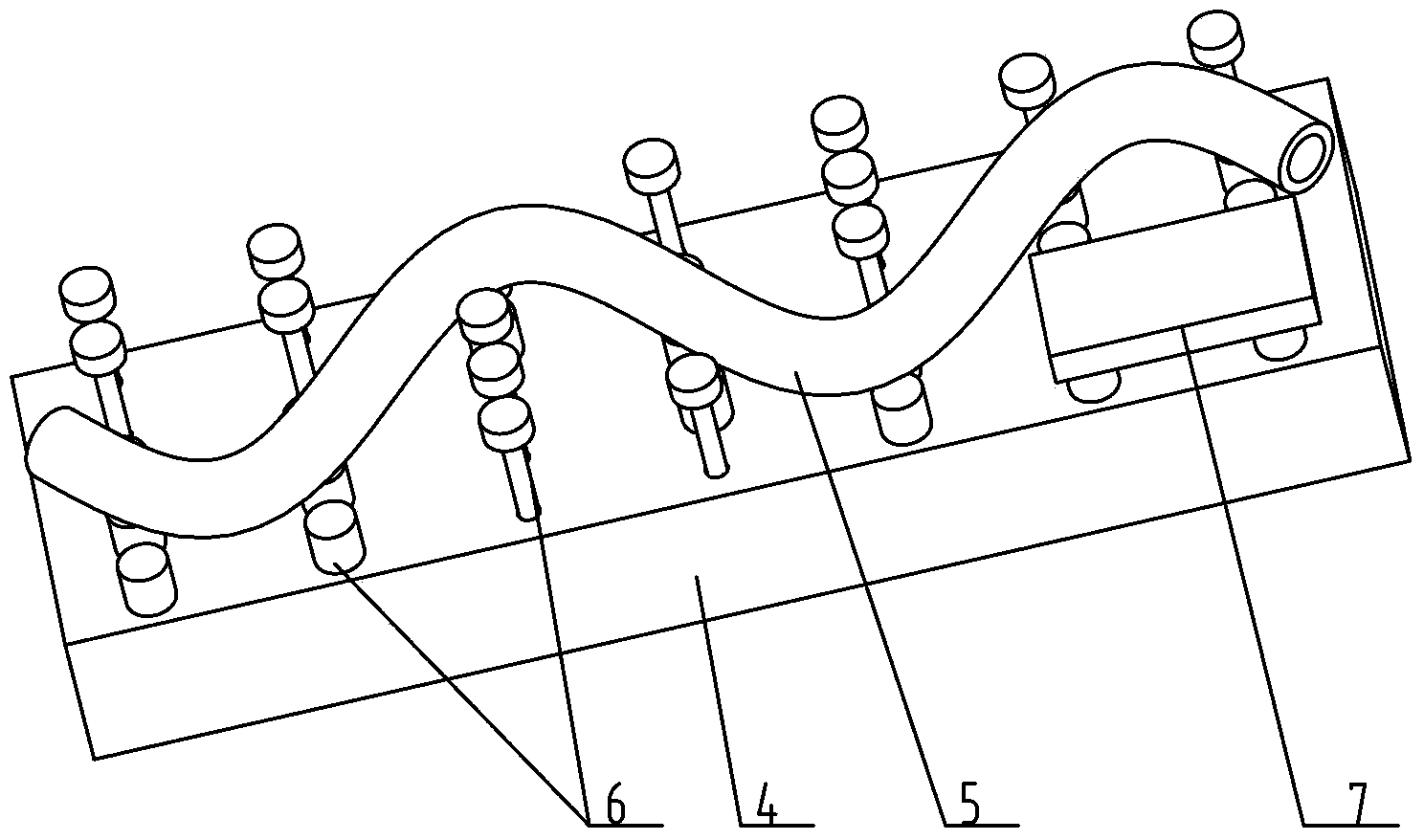

[0014] Such as figure 1 , 2 As shown, a workbench platen includes a stainless steel plate 1, an inner core plate 2 disposed in the inner cavity of the stainless steel plate 1, and a drawable temperature-regulating layer 3 disposed on the lower surface of the inner core plate 2. The inner core board 2 is formed by stacking multiple layers of parallel corrugated metal meshes. The temperature regulation layer 3 includes a fixed plate 4 with grooves and a plurality of pin holes 4.1 at the bottom of the grooves. The open water and air pipe 5, the pin 6 matched with the pin hole 4.1, the side of the stainless steel plate 1 is provided with the inlet and outlet connected with the water and air pipe 5. The withdrawable temperature-regulating layer 3 adopts a drawer structure. The grids of the upper and lower wavy metal meshes are staggered, which can further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com