High-temperature anti-explosion signal cable for new energy automobiles

A new energy vehicle and signal cable technology, applied in the cable field, can solve problems such as endangering the life safety of passengers, personal injury, damage to vehicles, etc., and achieve the effect of ensuring personal safety and protecting the smooth flow of lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

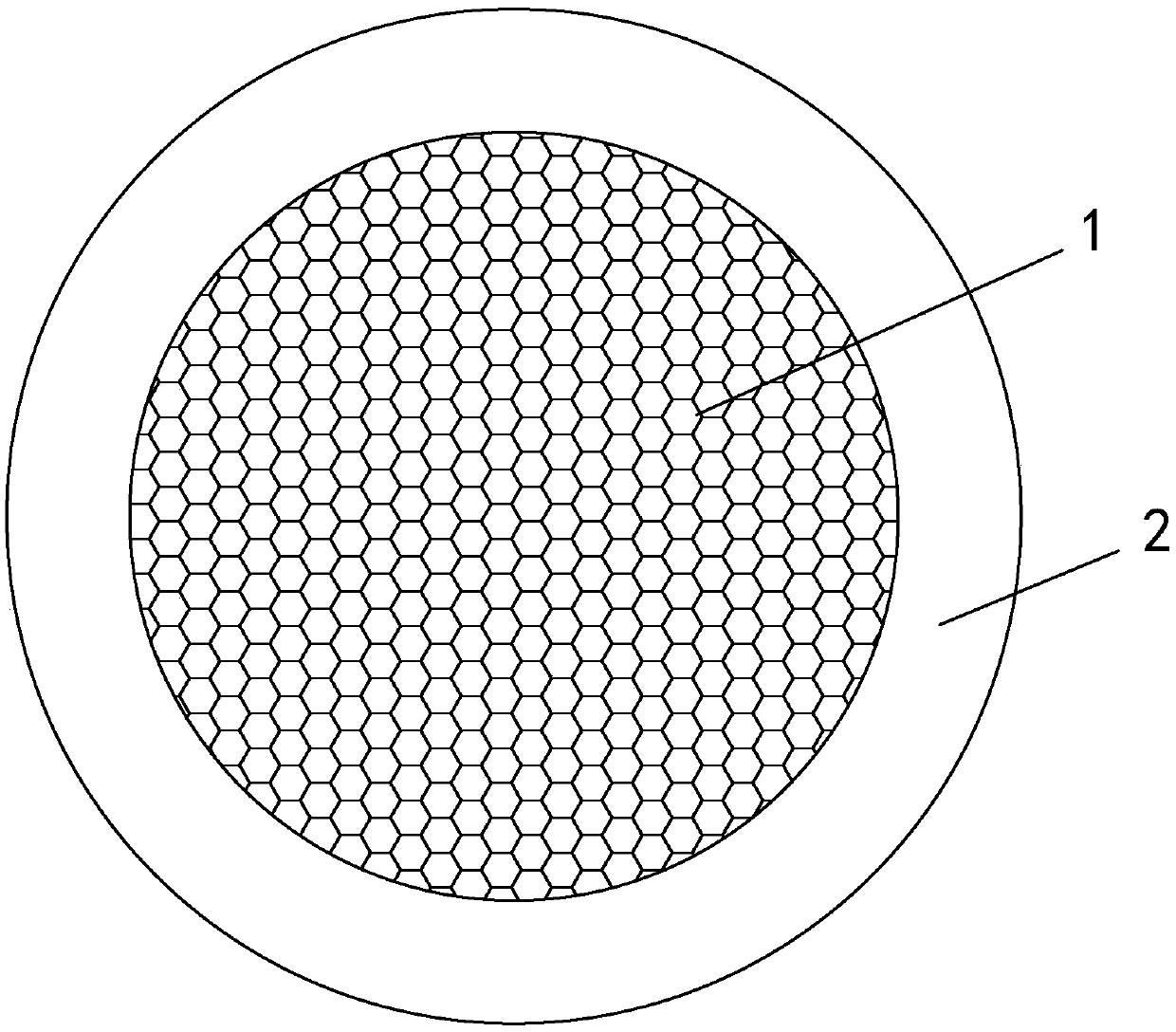

[0066] Example: such as figure 1 As shown, a high-temperature explosion-proof signal cable for new energy vehicles, including a central conductor 1 and a special high-temperature-resistant silicone rubber ceramic insulating layer 2;

[0067] The central conductor 1 is an annealed bare copper or tin-plated stranded conductor formed by cross regular stranding, and is a Class 6 annealed conductor meeting the requirements of GB / T3956; the outer periphery of the central conductor 1 is tightly covered with the Special high temperature resistant silicone rubber ceramic insulation layer 2.

[0068] The special high temperature resistant silicon rubber ceramic insulating layer 2 is made of special high temperature resistant silicon rubber ceramic material;

[0069] The raw materials of the special high-temperature-resistant silicone rubber ceramic material include the following components by weight:

[0070] 3~15 parts of methyl silicone rubber;

[0071] Methyl vinyl silicone rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com