Nano-calcium plastic fiber felt composite automobile inner decoratire lining board and its manufacturing method

A technology for automotive interior and nano-calcium, which is applied in the field of nano-calcium-plastic fiber felt composite automotive interior lining and manufacturing, which can solve the problems of single function and achieve the effect of high weight, low density and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

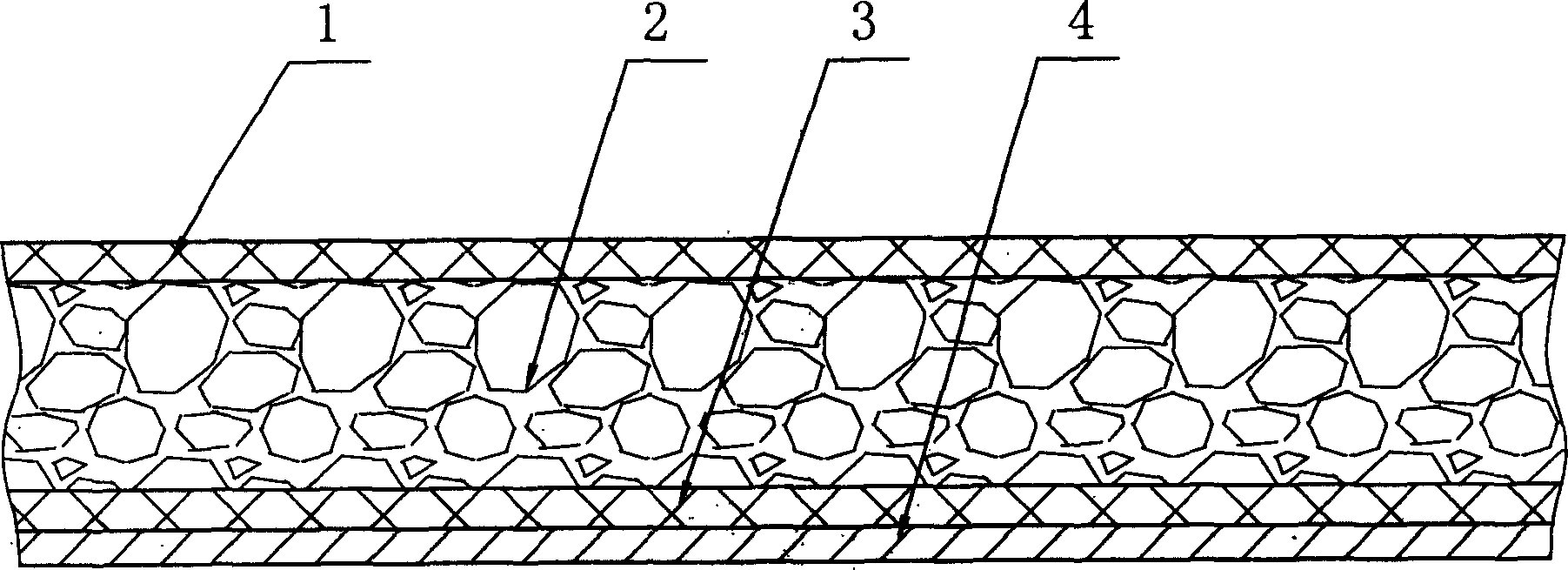

[0013] like figure 1 The nano-calcium-plastic fiber felt composite automotive interior lining board shown is composed of four layers of materials. The surface layer is nano-calcium plastic 1, the second layer is thermoplastic fiber felt 2, the third layer is nano-calcium plastic 3, and the bottom layer is Non-woven fabric4. The nano-calcium plastic on the surface layer and the nano-calcium-plastic component on the third layer, in parts by weight, are: 100 parts of waste plastics, 5-30 parts of nano-calcium carbonate, an appropriate amount of plastic modifiers, stabilizers and flame retardants; The components of the thermoplastic fiber mat are, by weight percentage: 55-70% of hemp fiber or brown fiber or glass fiber or polyester fiber, 30-45% of polypropylene fiber or polyethylene fiber. The calcium plastic content per unit area of nano-calcium-plastic layers 1 and 3 is 300-500g / m 2 , the mass per unit area of thermoplastic fiber mat 2 is 500-800g / m 2 , the weight per un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com