Patents

Literature

34results about How to "Strong fracture toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite-enhanced ultrafine synthetic leather fiber

ActiveCN105463598AHigh breaking strengthAntistaticMelt spinning methodsArtifical filament manufactureLeather industryPolymer science

A graphite-enhanced ultrafine synthetic leather fiber is provided. Graphite nylon 6 master batch is prepared via a twin-screw extrusion way; the nylon 6 master material is added to nylon 6 granules via a metering device for sea-island melt spinning; and graphite-enhanced ultrafine fibers can be achieved after decrement and splitting. The graphite-enhanced ultrafine synthetic leather fiber is characterized by high breaking tenacity, static resistance, bacteria resistance, aging resistant and strong flexibility; ultrafine fiber synthetic leather quality and comprehensive performance can be improved when the graphite-enhanced ultrafine synthetic leather fiber is applied to synthetic leather industry; and traditional sea-island fiber spinning equipment can be employed for production.

Owner:SICHUAN UNIV

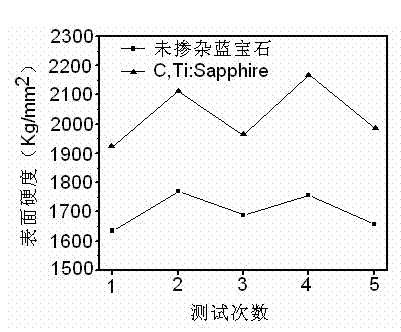

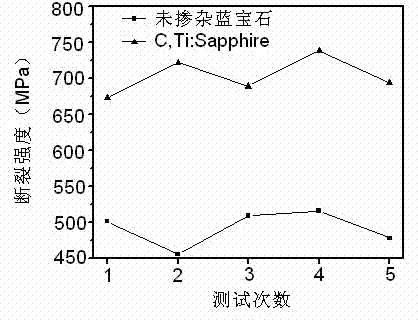

Sapphire crystal with high mechanical property and fabrication method thereof

InactiveCN103046137AIncrease elasticityDoes not impair permeabilityPolycrystalline material growthFrom frozen solutionsTi dopingBreaking strength

The invention relates to a sapphire crystal with a high mechanical property and a fabrication method thereof. The sapphire crystal with the high mechanical property is doped with carbon and titanium; the doping content of the carbon is 1,000-10,000ppm of the total mass of the crystal; and the doping content of the titanium is 500-3,000ppm of the total mass of the crystal. The invention further discloses the fabrication method of the crystal, which comprises the following steps: mixing raw materials at a mixture ratio, grinding, conducting a forming technology, fabricating a crystal growth raw material, and growing the crystal by a temperature gradient method, a descent method or a kyropoulos method. The sapphire crystal doped with the carbon and the titanium is higher in surface hardness, breaking strength and breaking tenacity; and doping ions do not damage optical permeability of the sapphire crystal.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Compact silicon nitride ceramic lift pipe, preparation method and application thereof

The invention relates to a compact silicon nitride ceramic lift pipe and a preparation method thereof. The silicon nitride ceramic lift pipe is prepared from 85-95 parts of silicon nitride and 5-15 parts of a sintering aid. The sintering aid is selected from one or more of aluminum oxide, magnesium oxide, yttrium oxide, cerium oxide and titanium carbide. The silicon nitride ceramic lift pipe provided by the invention has the characteristics of high density, high hardness, high bending strength, and strong fracture toughness, etc., and has long service life, can be used continuously for more than one year on a conventional low pressure aluminum casting machine. Through comprehensive optimization of the raw material composition and the preparation method, the production problem of silicon nitride lift pipes in the aluminum casting industry is solved, the quality of key parts in the domestic aluminum casting industry is enhanced, the aluminum casting production efficiency is greatly improved, the production cost is reduced, the production efficiency is significantly improved, the production cost is reduced, thus being conducive to breaking through the monopoly position of foreign silicon nitride enterprises in the industry, and improving the global awareness of China's silicon nitride ceramic level.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

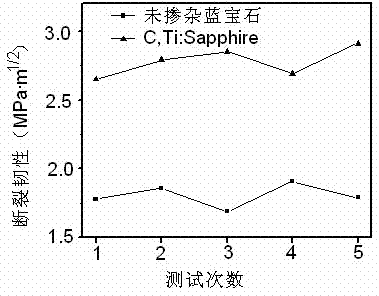

PE pipe production method

The invention discloses a PE pipe production method. The method comprises A, putting PE resin powder, color master batches, a clay nanocomposite material, a flame retardant, nanometer calcium carbonate, a dispersant, an antistatic agent, a coupling agent, a low temperature-resistant plasticizer and an antioxidant into a drying mixer together, and carrying out drying stirring to obtain a raw material, B, adding the raw material into an extractor and carrying out melting extrusion granulation, and C, putting the granulated material into an extruder, carrying out melting and extruding the material through a die outlet. The product is prepared from the PE resin powder, color master batches, clay nanocomposite, flame retardant, nanometer calcium carbonate, dispersant, antistatic agent, coupling agent, low temperature-resistant plasticizer and antioxidant through mixing. The PE pipe has good static resistance, corrosion resistance, flame resistance, flexibility, low temperature resistance, high temperature resistance, good fast crack growth fracture toughness and good pressure resistance and guarantees the safety of the PE pipe in any environments.

Owner:长兴佳能高分子材料有限公司

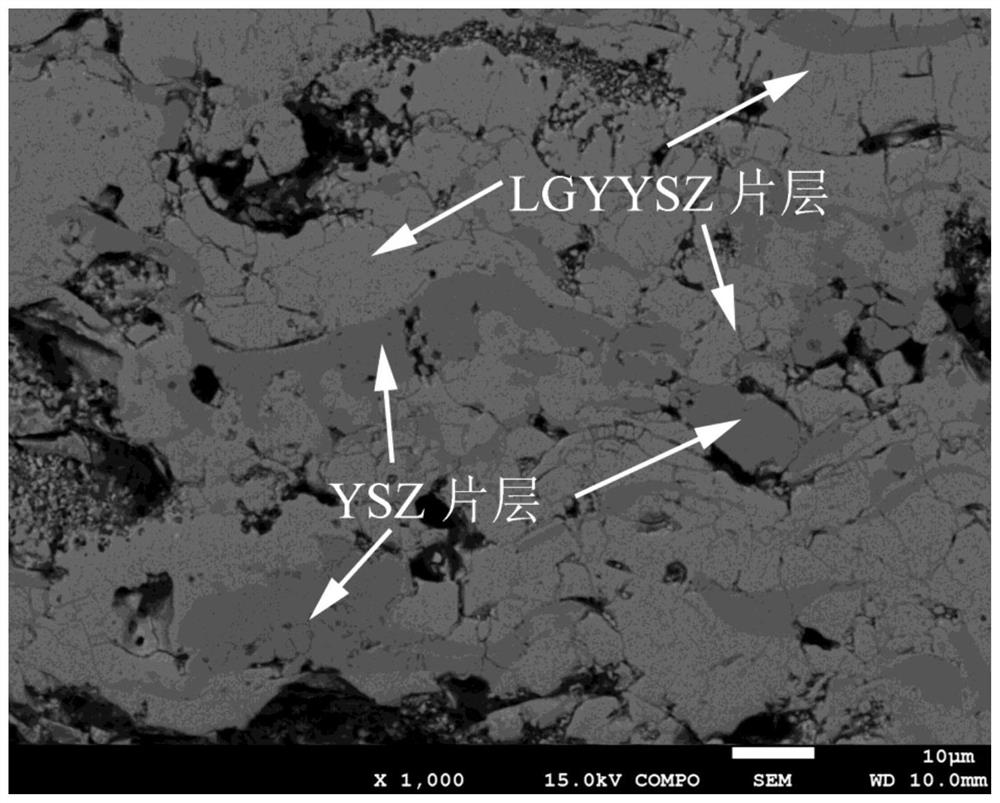

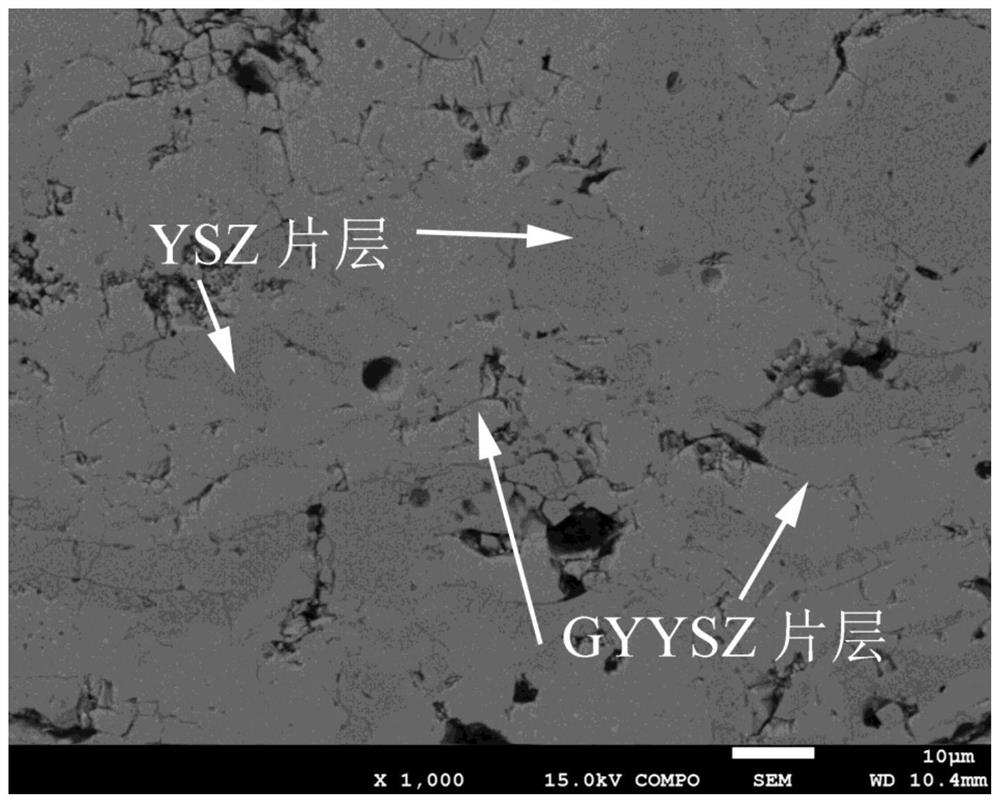

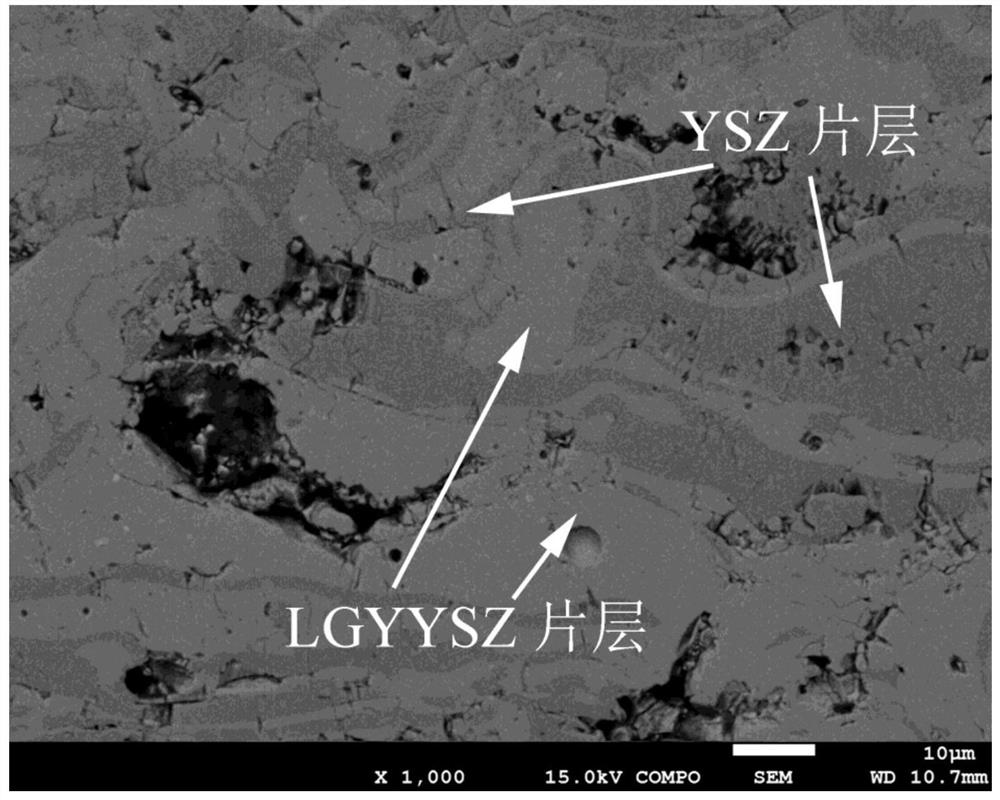

Thermal barrier coating with composite double-ceramic-layer structure and preparation method thereof

PendingCN113388801AHigh thermal conductivityImproved coefficient of thermal expansionMolten spray coatingComposite ceramicThermal barrier coating

The invention relates to a thermal barrier coating with a composite double-ceramic-layer structure and a preparation method thereof, and belongs to the technical field of thermal barrier coating preparation. The thermal barrier coating sequentially comprises a thermal barrier coating bonding layer, a YSZ ceramic layer and a composite ceramic layer from a base body to the top; the composite ceramic layer is composed of a high-toughness ceramic material and a high-rare-earth-content doped zirconium oxide material according to the volume ratio of (1 to 4): (4 to 1); the high-toughness ceramic material is a ceramic material with the fracture toughness being greater than 5MPa. M < 1 / 2 >; and in the high-rare-earth-content doped zirconium oxide material, the sum of the mole fractions of the doped rare earth elements is 16 percent to 30 percent. According to the thermal barrier coating, the thermal barrier coating bonding layer, the YSZ ceramic layer and the composite ceramic layer are sequentially prepared from the base body to the top through a spraying method. The thermal barrier coating can be prevented from cracking in the thermal cycle process, and the service life is long; and cracks are uniformly distributed, the anti-stripping capability is high, and the heat insulation performance is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

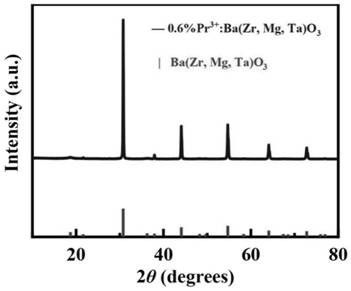

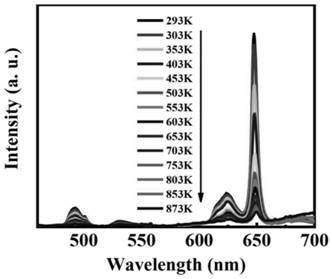

Fluorescence temperature measurement method suitable for ultra-wide temperature measurement range

PendingCN113390529AHigh luminous intensityHigh temperature limitThermometers using physical/chemical changesFluorescence spectraPhysical chemistry

The invention relates to the technical field of fluorescence temperature measurement, in particular to a fluorescence temperature measurement method suitable for an ultra-wide temperature measurement range. The fluorescence temperature measurement method comprises the following steps of: (a) establishing a standard curve of a fluorescence peak intensity ratio of Pr < 3 + >-based 3P1-to-3F2 transition and 3P0-to-3F2 transition of a fluorescence temperature sensing material along with temperature change; and (b) placing the fluorescence temperature sensing material in an environment of which the temperature is to be measured, measuring the fluorescence spectrum of the fluorescence temperature sensing material, calculating the fluorescence peak intensity ratio of Pr < 3 + >-based 3P1-to-3F2 transition and 3P0-to-3F2 transition, substituting the fluorescence peak intensity ratio into the standard curve, and calculating to obtain a temperature measurement value of the to-be-measured environment, the fluorescence temperature sensing material being Pr < 3 + >-doped oxide transparent ceramic, and the molar doping concentration of Pr < 3 + > being 0.1%-10%. According to the temperature measurement method, a higher temperature measurement limit and a wider temperature measurement range can be realized.

Owner:SONGSHAN LAKE MATERIALS LAB +1

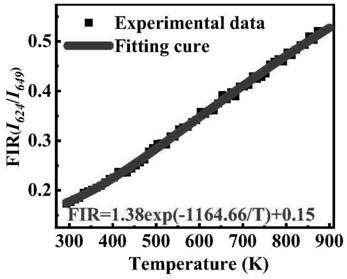

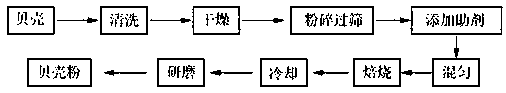

Novel shell-based concrete fish shelter

InactiveCN107667941AReduce manufacturing costImprove adsorption capacityClimate change adaptationPisciculture and aquariaRestoration deviceNatural sand

The invention discloses a novel shell-based concrete fish shelter, and belongs to the field of marine environment restoration device. A preparation process of the fish shelter comprises the steps of preparing coarse broken shells, preparing shell powder and preparing the concrete fish shelter; according to the preparation process, the concrete fish shelter is prepared by adopting the discarded shells to replace natural sand and partial cement as main materials, the resources are recycled, the environmental protection is facilitated, the prepared fish shelter is high in fracture toughness and stability and good in hydrodynamic performance, and the structure of the prepared fish shelter can improve the distribution of nutrients in seawater.

Owner:ZHEJIANG OCEAN UNIV

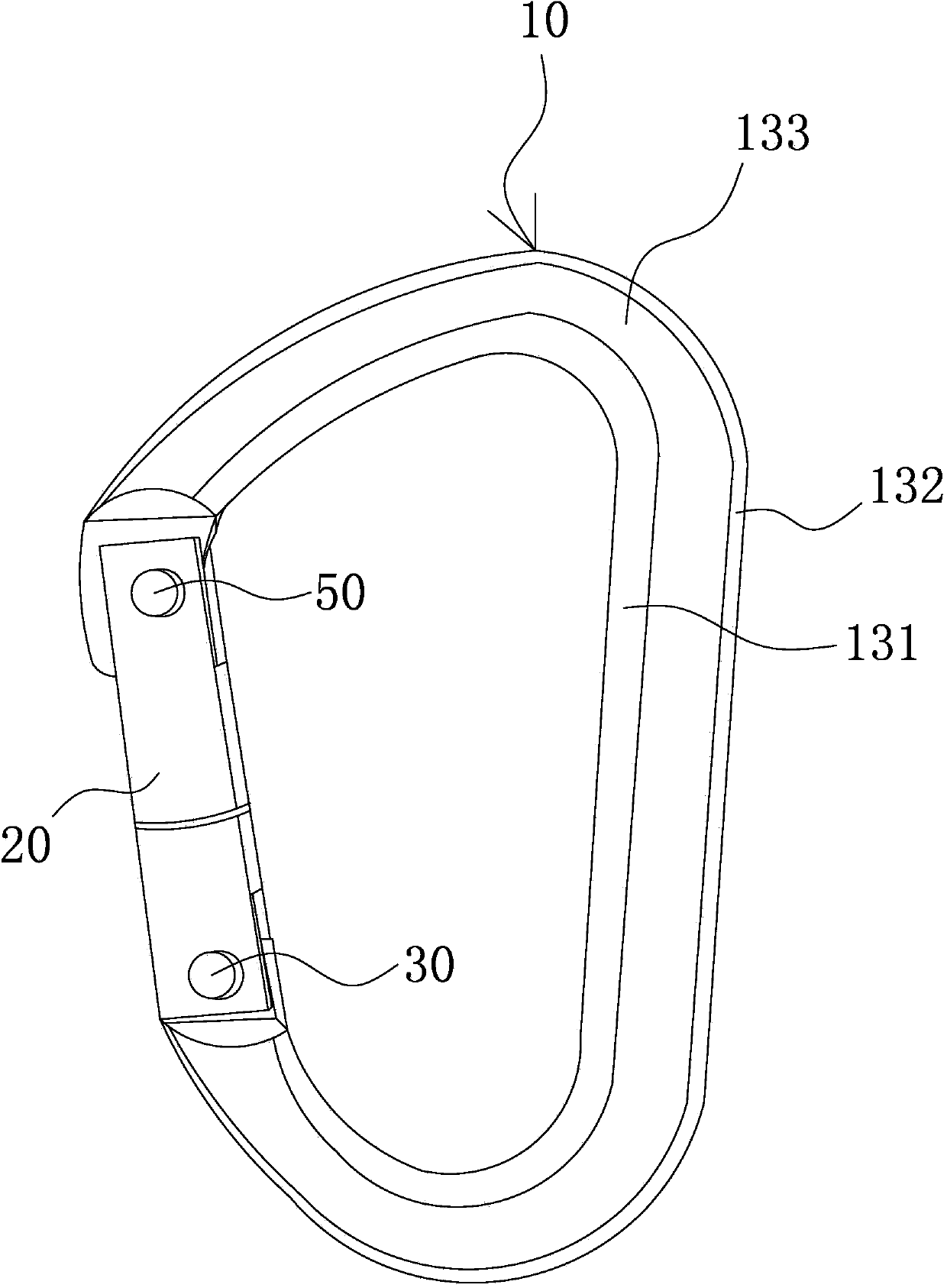

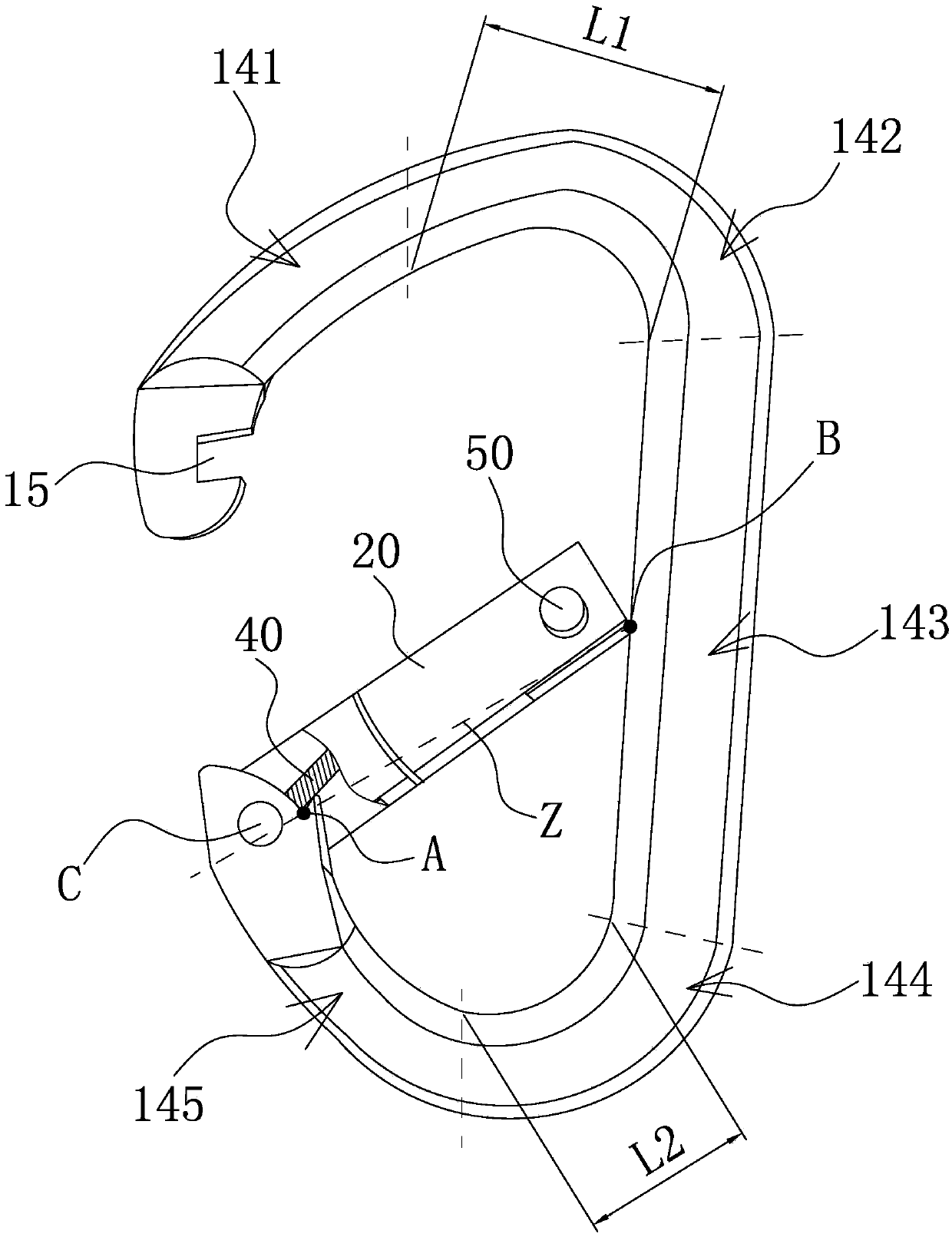

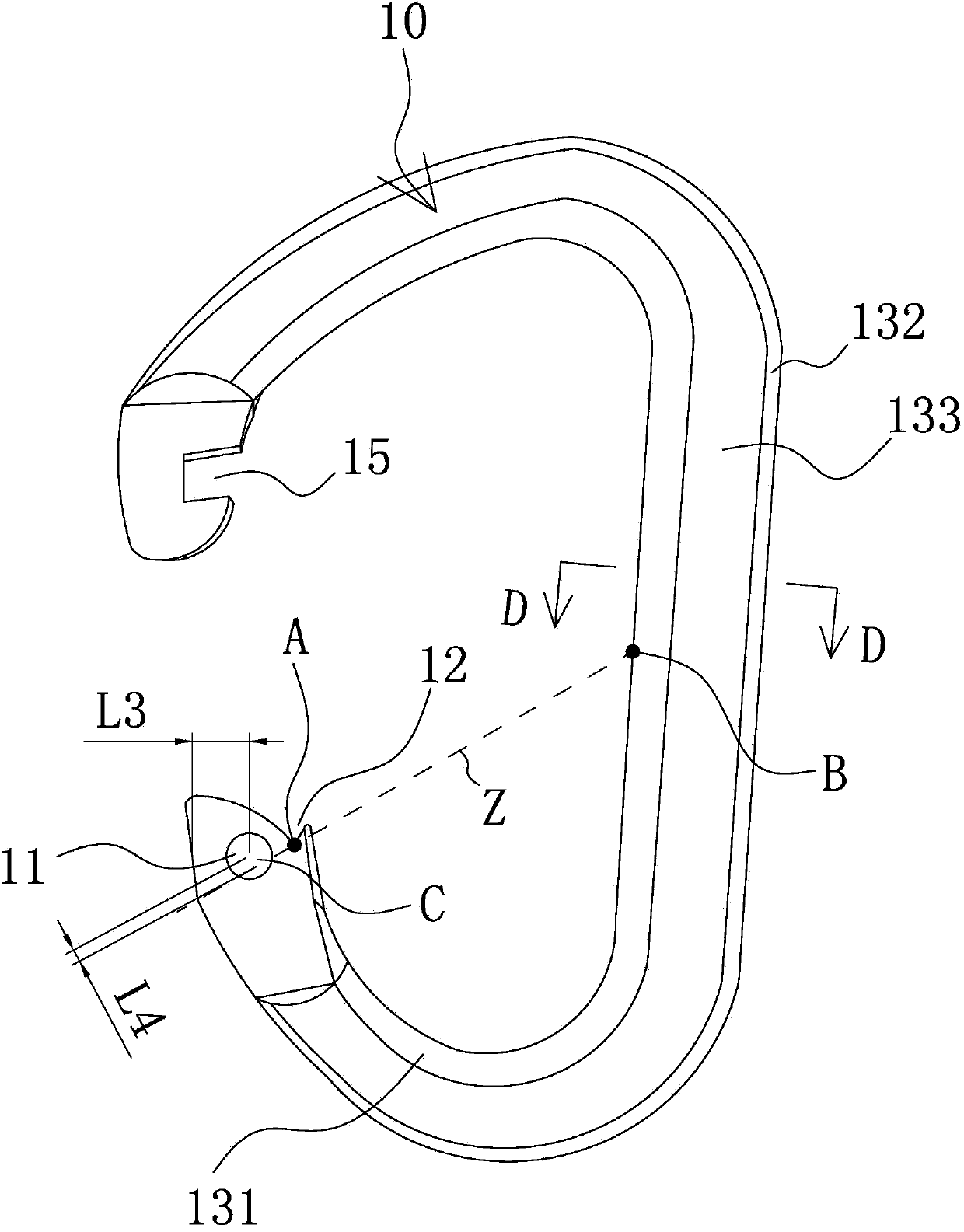

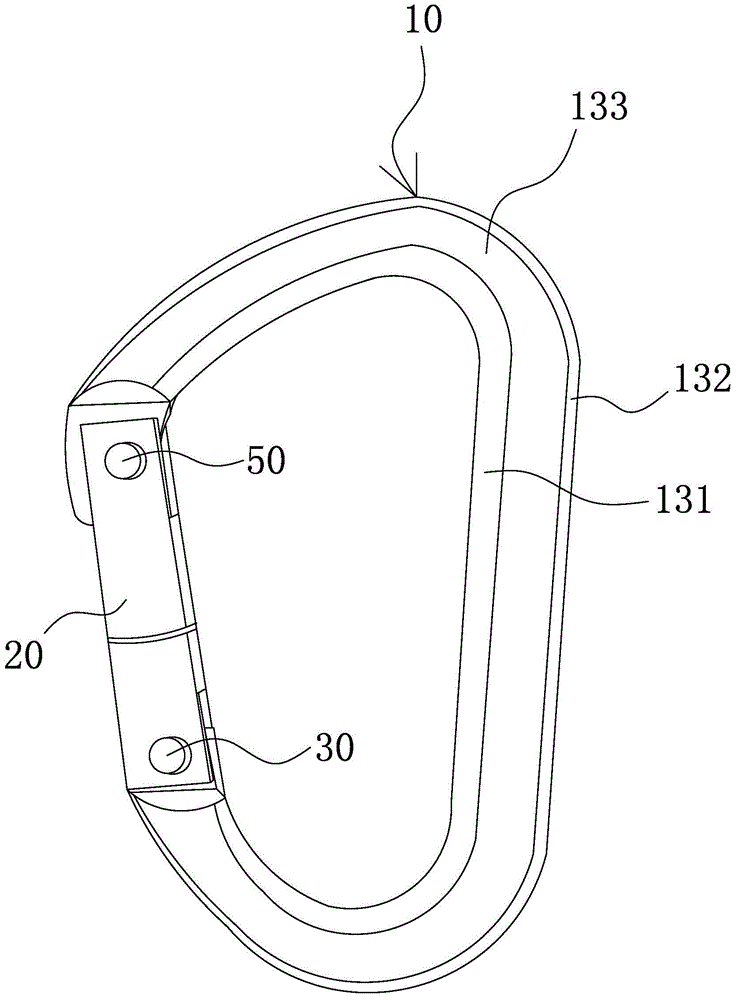

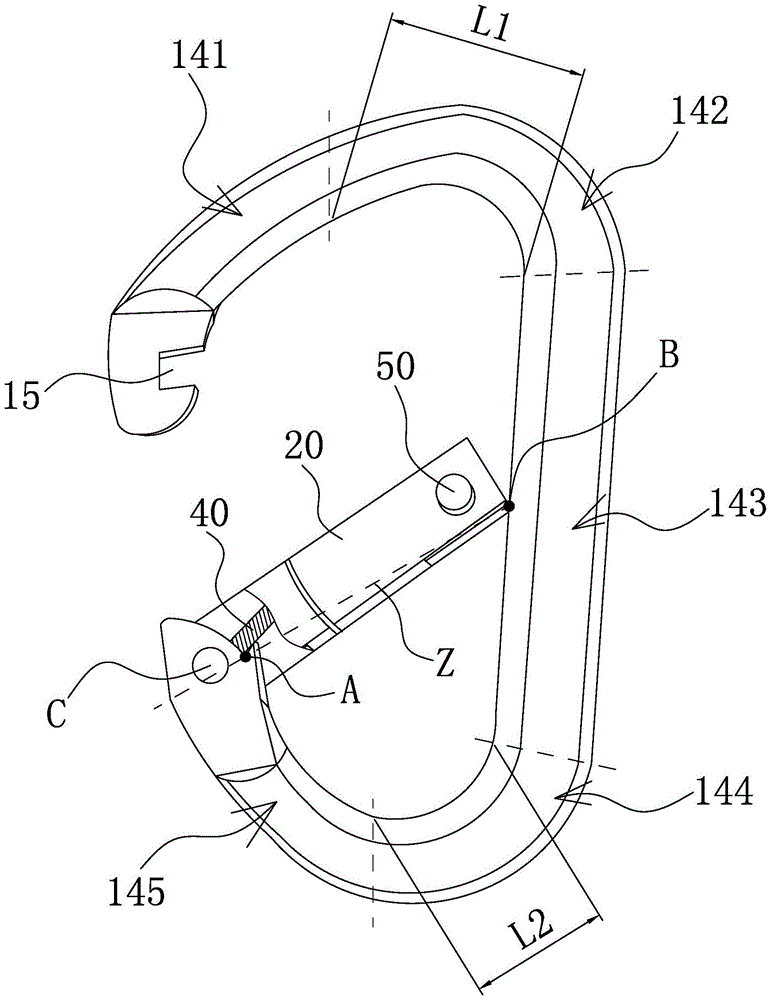

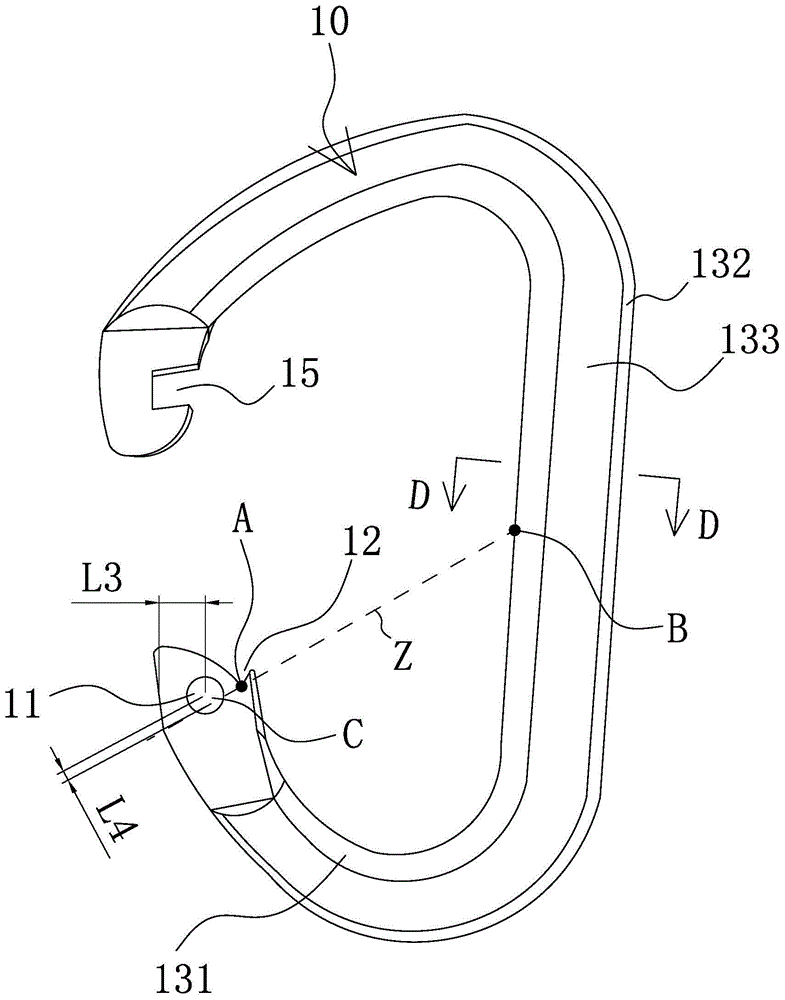

Mountain-climbing hook and processing technology thereof

InactiveCN103740991AUniform structure and mechanical propertiesReduce extrusion pressureMountaineeringCorrosionEngineering

The invention relates to a mountain-climbing hook and a processing technology thereof. The mountain-climbing hook comprises a movable rod and a hook body with an articulation hole, wherein the outer peripheral surface of the hook body is encircled by an inner arc-shaped surface, an outer arc-shaped surface and two flat planes; the cross section abutting against the bottom of a gap and the cross section at the lower end of a mounting plate are intersected at a point A; when the movable rod is rotated, the upper end of the movable rod and the inner arc-shaped surface are intersected at a point B, the point A and the point B are connected to form a straight line Z, the shortest straight-line distance between a central point C of the cross section of the articulation hole and the outer arc-shaped surface is L3, and the shortest straight-line distance between the point C and the straight line Z is L4. The processing technology of the mountain-climbing hook is specifically as follows: smelting a well prepared alloy into an aluminum solution, degassing, refining, standing, skimming, and then casting into an aluminum alloy round cast bar; performing extrusion forming in a reverse direction; and performing heat treatment on a cast piece to obtain the mountain-climbing hook. The mountain-climbing hook provided by the invention has the advantages of relatively high tensile strength, corrosion resistance and fracture toughness, as well as long service life.

Owner:NINGBO YINZHOU TIANYING ALUMINUM PROD

PVC (polyvinyl chloride) silencing water drainage pipe and production method thereof

InactiveCN107778691AImprove stabilityGood dimensional stabilityTubular articlesAnhydrous Calcium SulfateAntioxidant

The invention relates to a PVC (polyvinyl chloride) silencing water drainage pipe and a production method thereof. The PVC silencing water drainage pipe is prepared from being prepared from the following raw materials in parts by weight: 80 to 100 parts of polyvinyl chloride resin, 100 to 130 parts of nano anhydrous calcium sulfate, 5 to 8 parts of a stabilizer, 2 to 5 parts of a modifier, 0.5 to2.0 parts of PE (polyethylene) wax, 0.5 to 2 parts of an aluminate coupling agent and 0.2 to 0.5 part of a compound antioxidant. The raw materials of the PVC silencing water drainage pipe are simple and easy to obtain, so that the PVC silencing water drainage pipe is low in cost, extremely high in aging resistance, flexibility, low-temperature resistance and high-temperature resistance; by the adding of a methyl methacrylate-butadiene-styrene copolymer, the PVC silencing water drainage pipe achieves a silencing effect; the low-temperature toughness and the impact resistance are improved; the PVC silencing water drainage pipe has a shock absorption function.

Owner:GUANGXI JINTAN PIPE IND TECH CO LTD

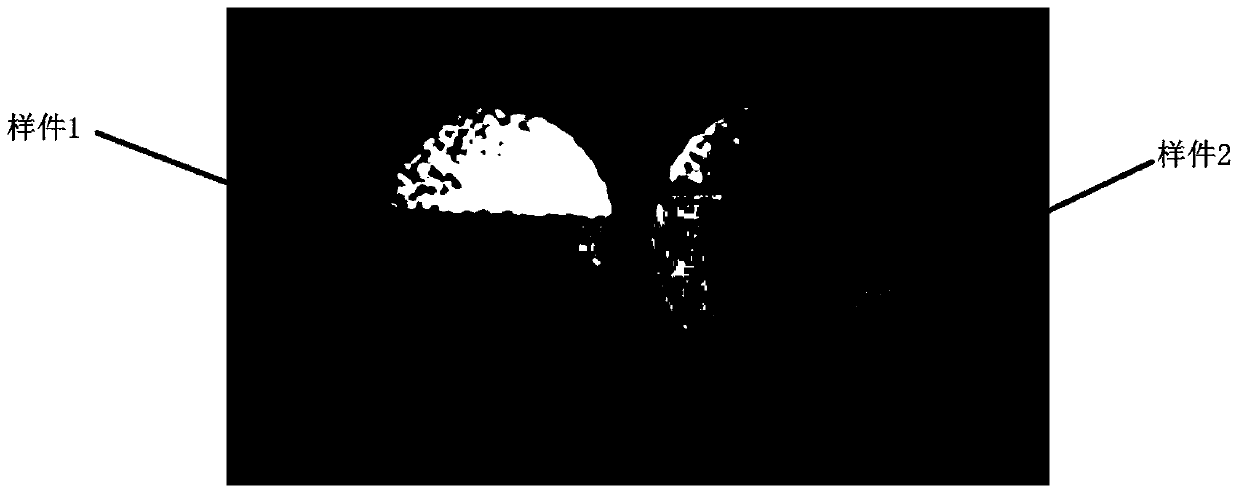

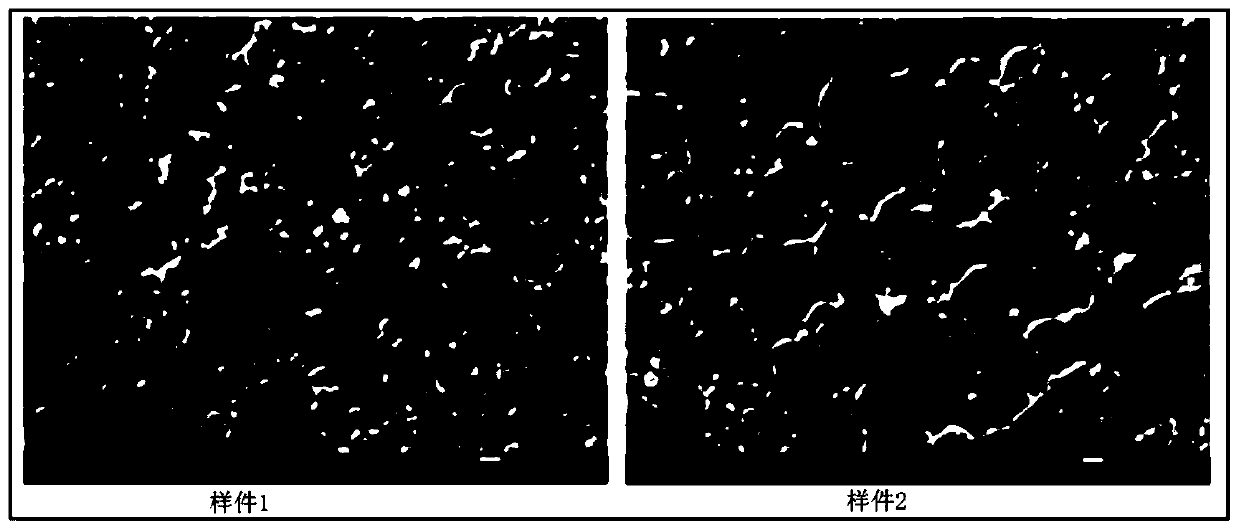

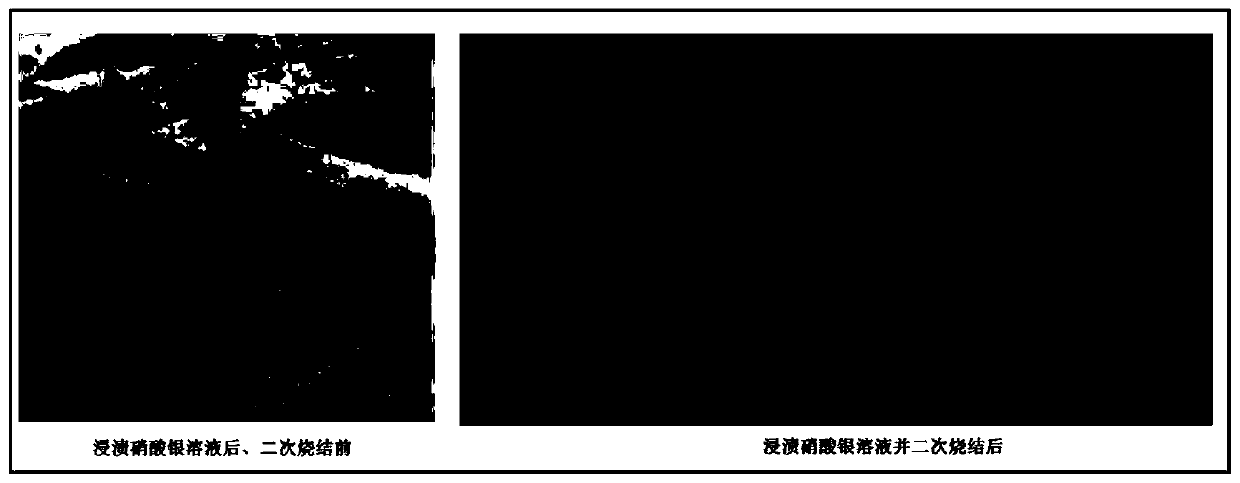

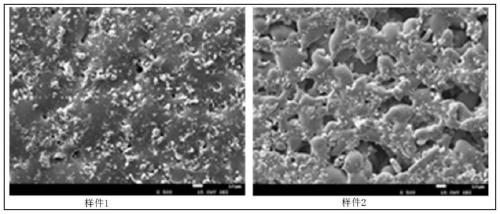

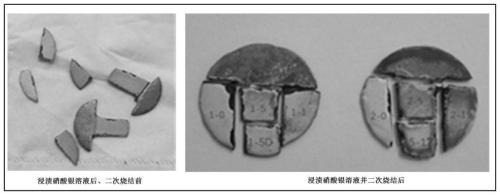

Aluminosilicate auxiliary deposition silver coating planting abutment ceramic material and preparation method thereof

The invention discloses an aluminosilicate auxiliary deposition silver coating planting abutment ceramic material and a preparation method thereof to solve the problem in the prior art that a ceramicabutment is not subjected to antibacterial treatment. The preparation method comprises the steps of coating a layer of aluminosilicate on the surface of a zirconia ceramic sheet and baking to obtain asintered aluminosilicate coated ceramic sheet; immersing the sheet in a silver nitrate solution for ultrasonic water bath impregnation away from light; after the impregnation, taking out the aluminosilicate coated ceramic sheet and baking to reduce the silver nitrate impregnated on a coating of the aluminosilicate coated ceramic sheet in situ to obtain the aluminosilicate auxiliary deposition silver coating planting abutment ceramic material. The material has the advantages of being scientific in design and convenient to operate, has both aesthetics and antibacterial property, and can stablyexert the antibacterial action for a long period. The preparation method is simple, low in cost and high in safety.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

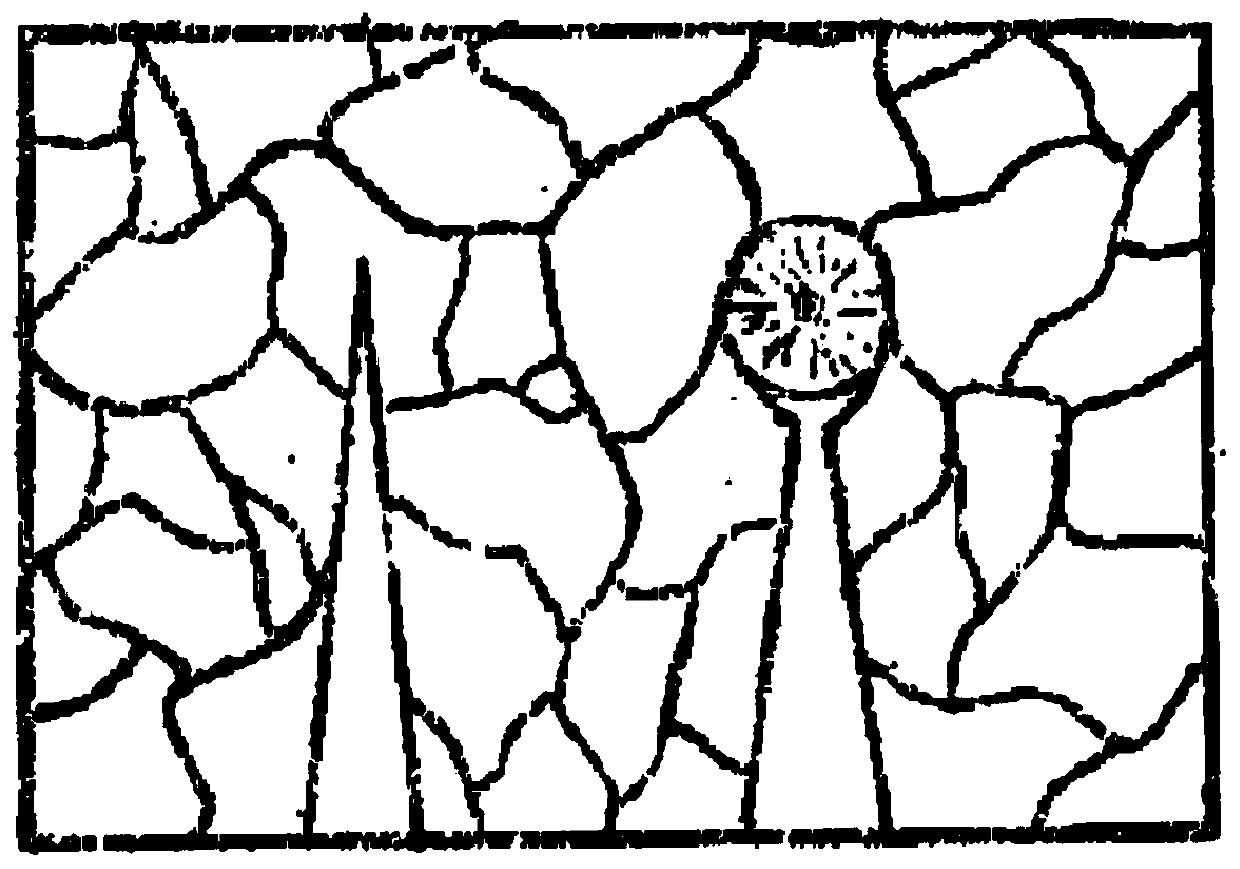

Nodular cast iron section bar capable of improving fracture toughness and technology

InactiveCN110343944AWith relaxation stressA large amountProcess efficiency improvementSulfurManganese

The invention discloses a nodular cast iron section bar capable of improving the fracture toughness. The nodular cast iron section bar comprises, by mass, 3.45%-3.55% of carbon, 2.55%-2.65% of silicon, 0.15%-0.25% of manganese, 0.009%-0.011% of sulphur, 0.030%-0.034% of phosphorus, 0.009%-0.0011% of bismuth and the balance iron. Graphite nodules in the section bar structure are small, large in quantity and high in roundness, the round and small graphite nodules have the relaxation stress and have the effect of delaying crack propagation, and the effect of preventing cracks from being generatedis achieved. The invention further discloses a technology for the nodular cast iron section bar capable of improving the fracture toughness. The metal bismuth is added into iron liquid, therefore, the quantity of the graphite nodules is increased, the declination speed in the inoculation process is decreased, abnormal graphite generated in the quick cooling process is eliminated, and the roundness of the graphite nodules can be improved. Meanwhile, size grading of the graphite nodules is improved, the plasticity of the nodular cast iron is obviously improved on the condition that the strengthof the nodular cast iron is invariable, and then the nodular cast iron has the good fracture toughness.

Owner:HANDAN HENGGONG METALLURGICAL MACHINERY CO LTD

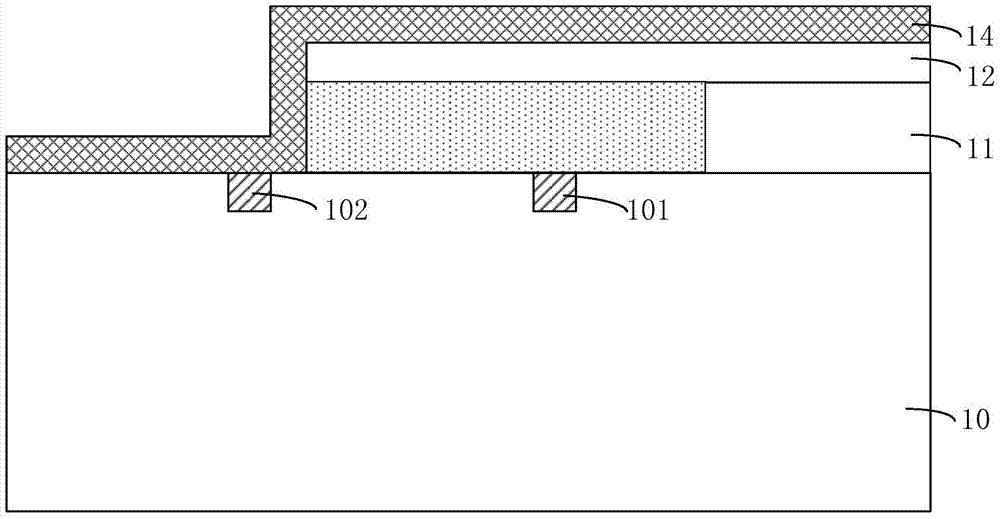

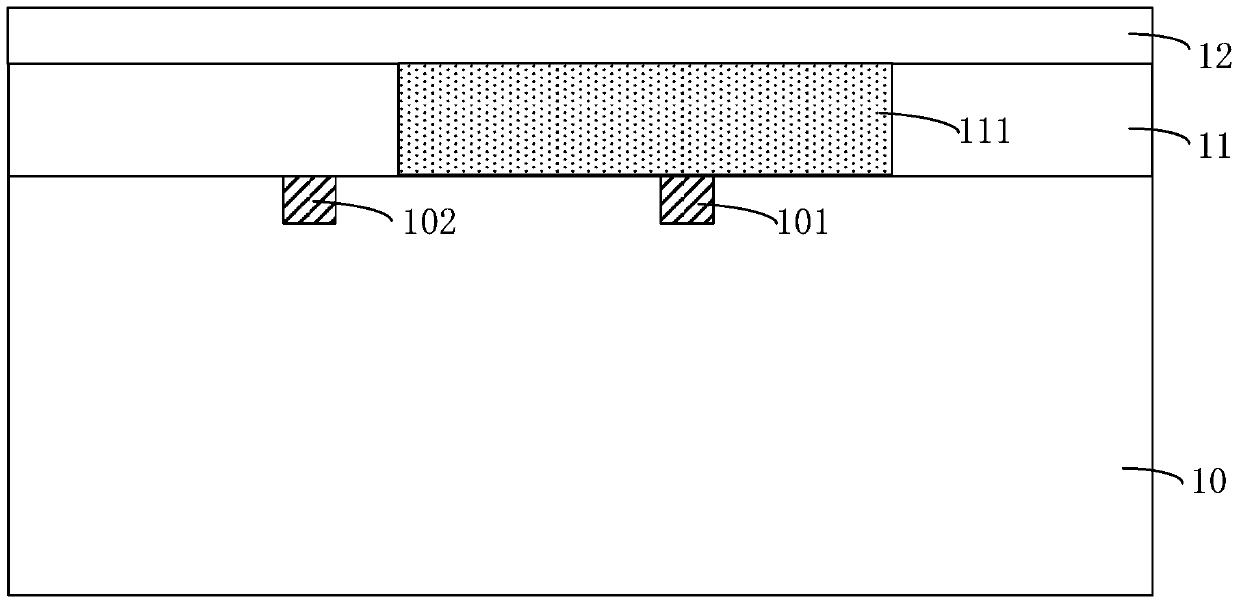

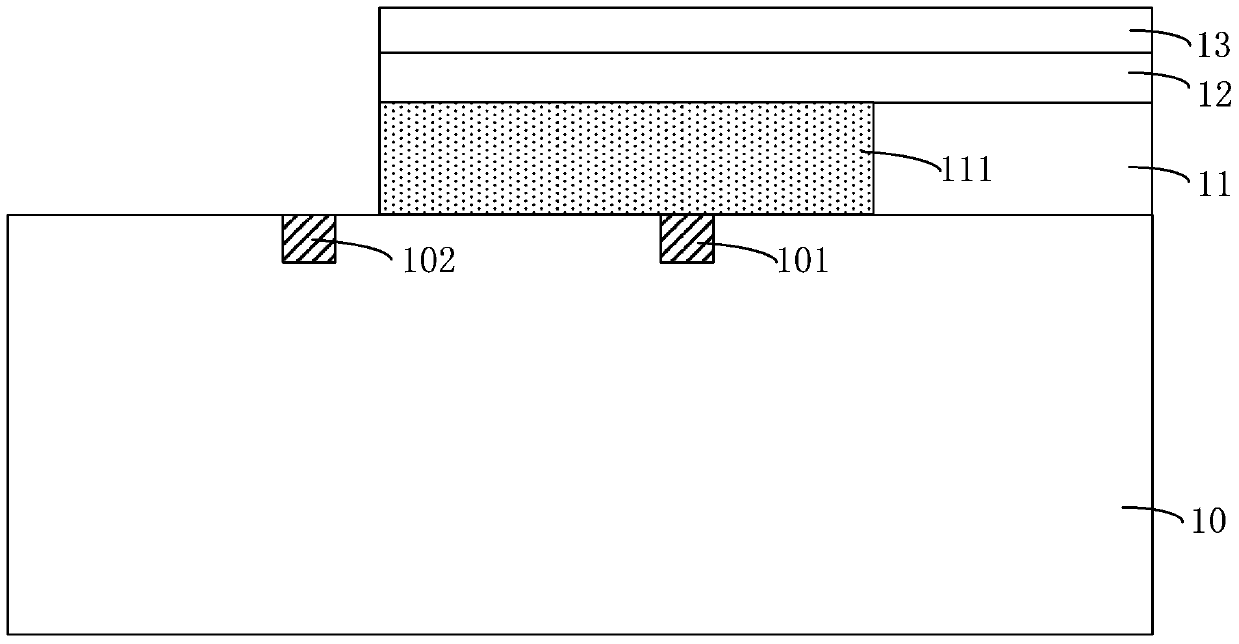

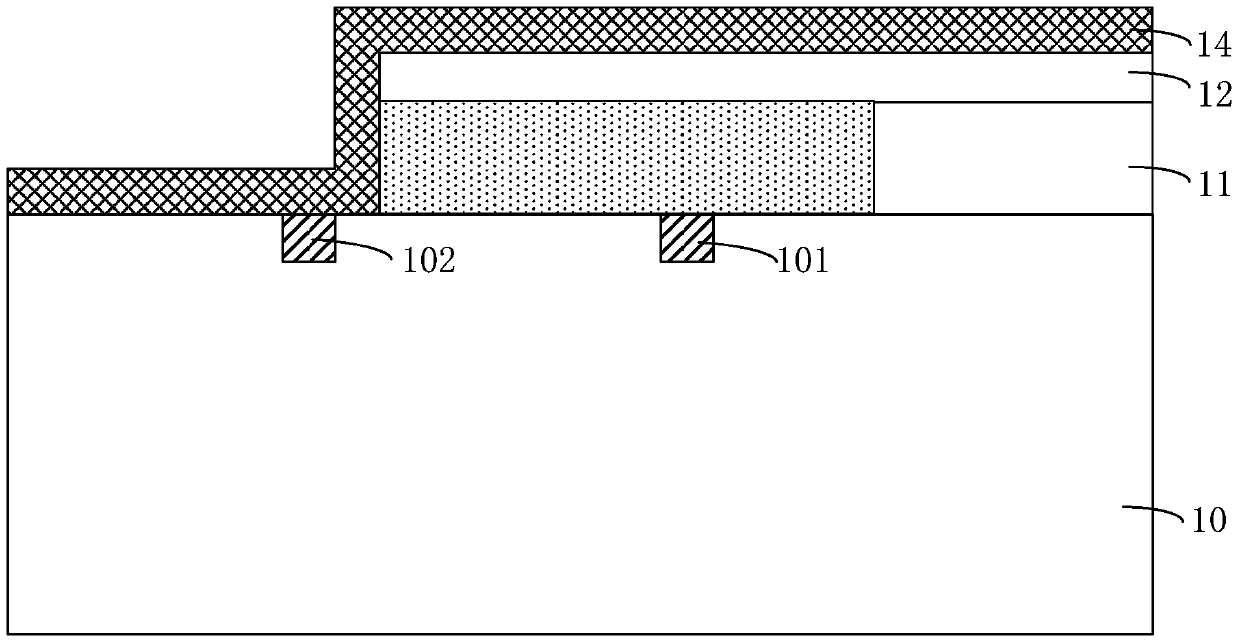

MEMS (Micro-Electro-Mechanical-System) device and manufacturing method thereof and MEMS temperature sensor and manufacturing method thereof

ActiveCN106918397AAdd folding structureAvoid breakingDecorative surface effectsThermometers using material expansion/contactionCantilevered beamCapacitance

The invention relates to an MEMS (Micro-Electro-Mechanical-System) device and a manufacturing method thereof so as to improve the reliability of a cantilever beam of the existing MEMS device, and relates to an MEMS temperature sensor and a manufacturing method thereof so as to improve the process and structure of the existing MEMS temperature sensor. For the MEMS device, a zigzag structure is additionally arranged at a connecting part of a movable portion and a fixed portion of the cantilever beam, and the connecting part is reinforced so as to avoid the connecting part from being broken. For the MEMS temperature sensor, the lower surface or the upper surface of the movable portion of the cantilever beam is provided with a strain gauge with the thermal expansion coefficient being different from that of the movable portion of the cantilever beam, so that the movable portion of the cantilever beam is warped and deformed in the measuring process because the thermal expansion coefficient is different from that of the strain gauge, capacitance between the movable portion of the cantilever beam and a fixed electrode changes, and thus the temperature is detected.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

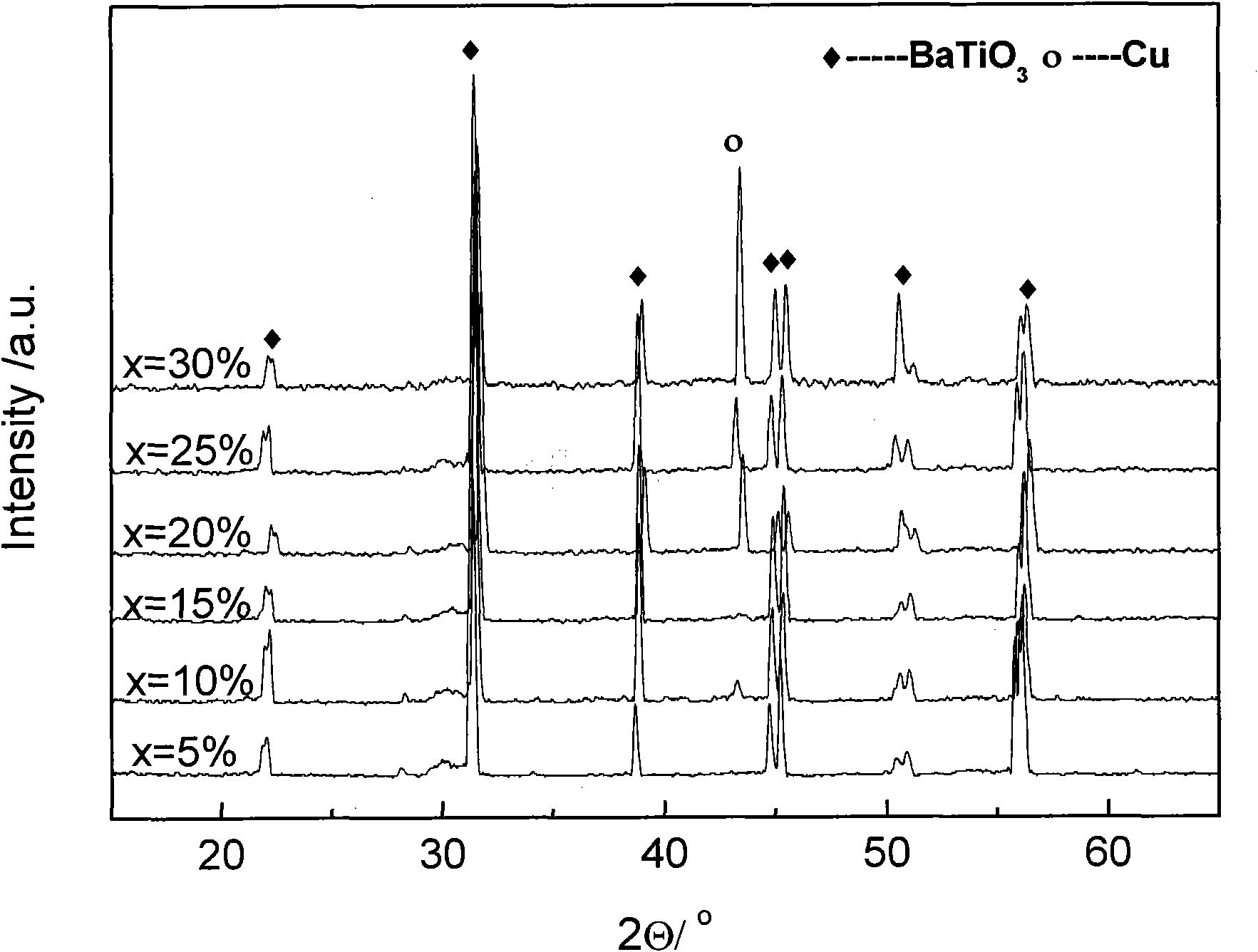

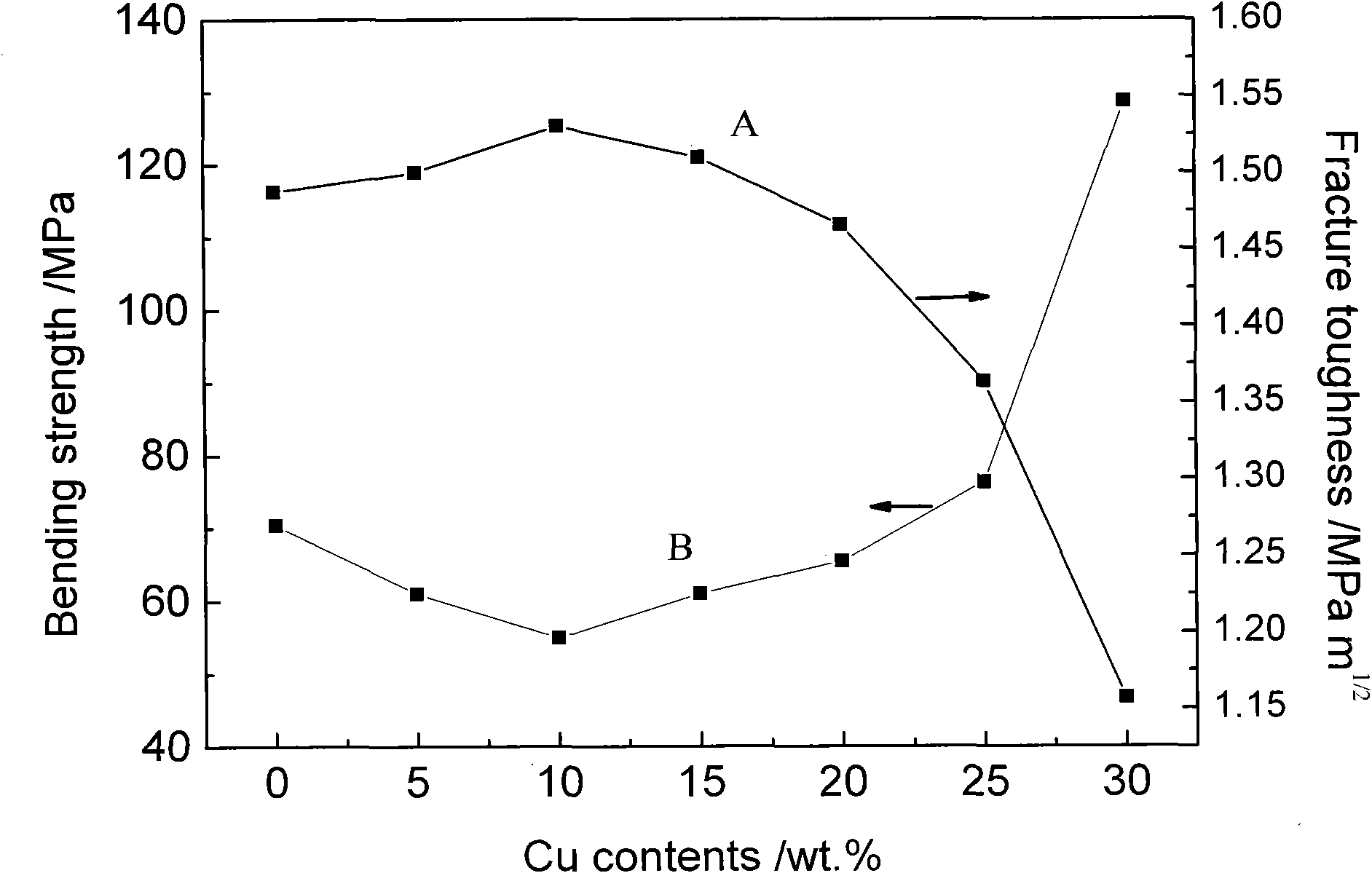

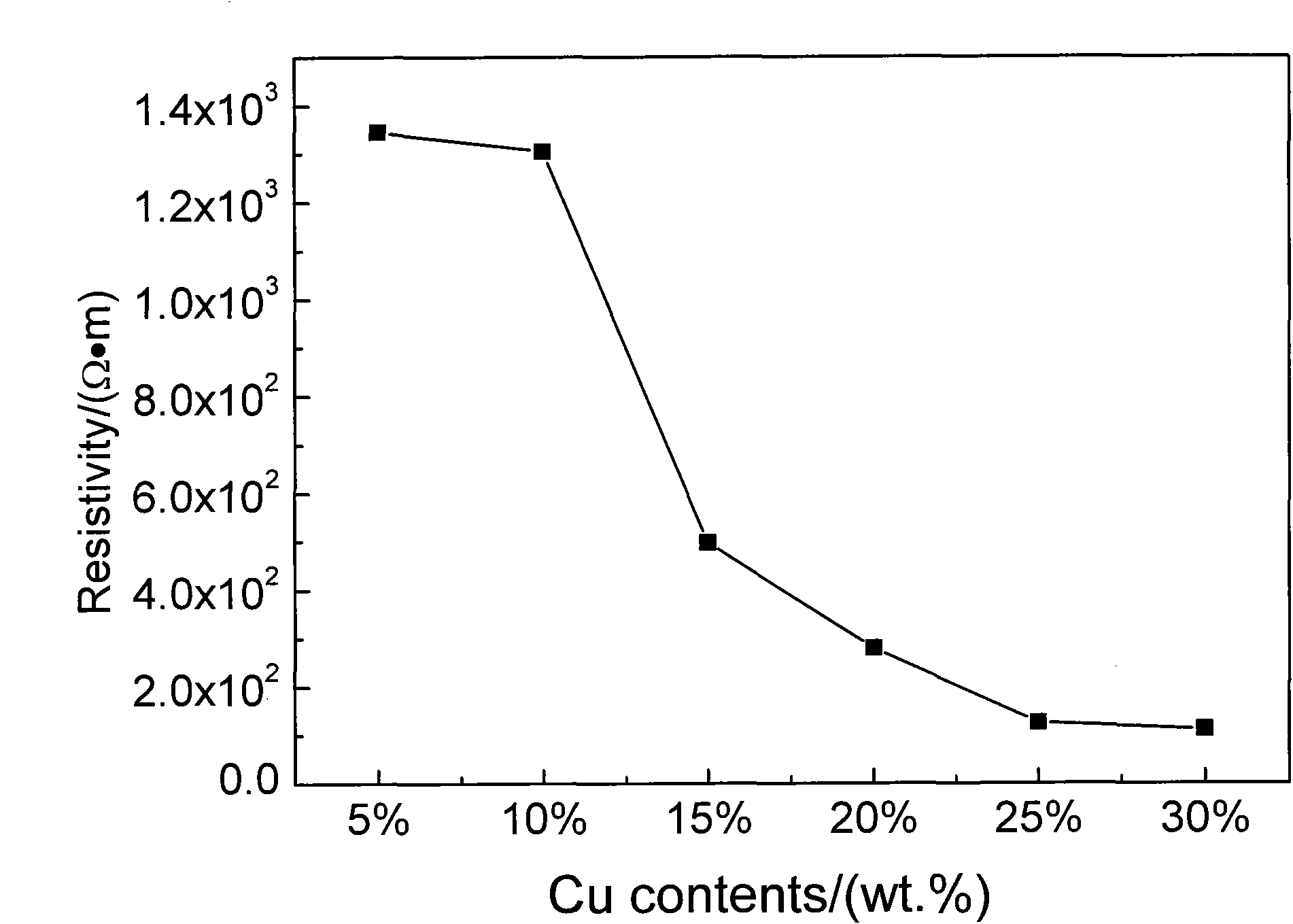

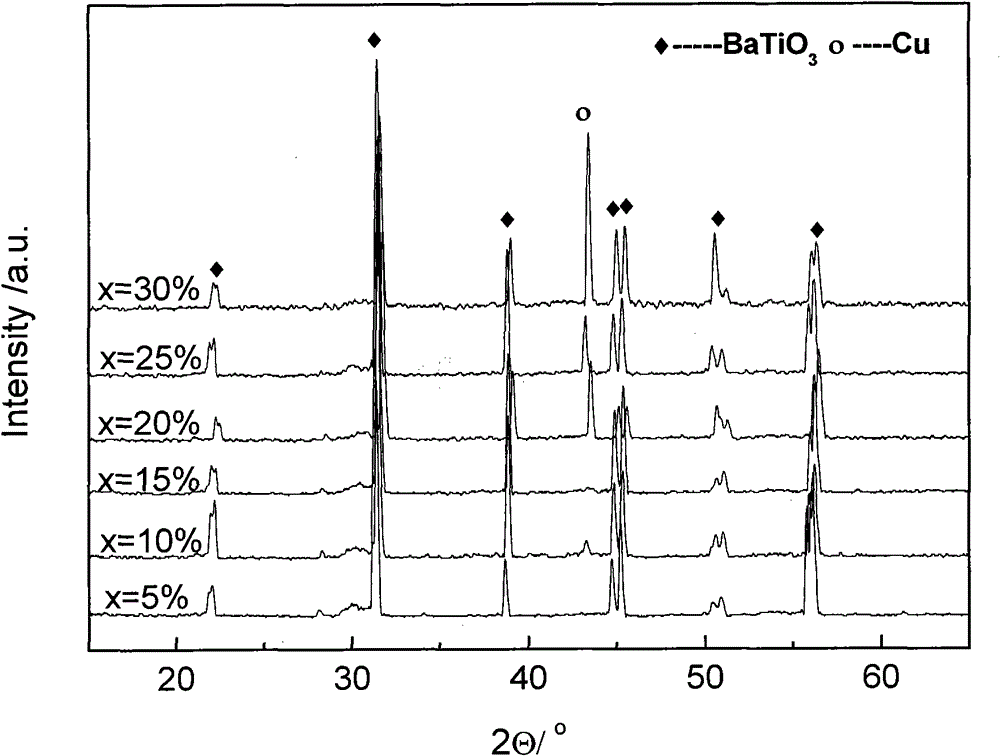

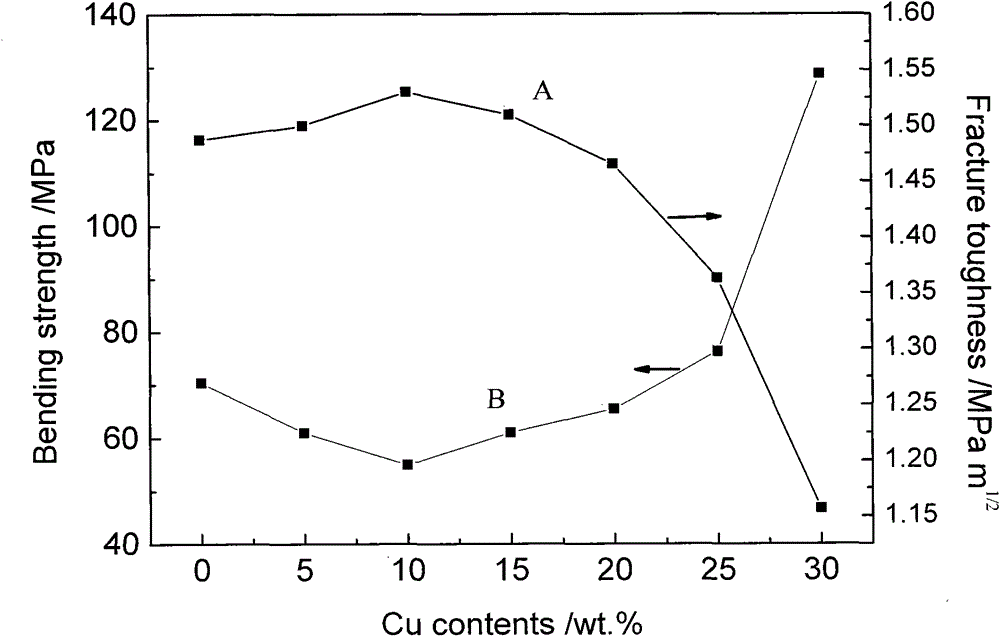

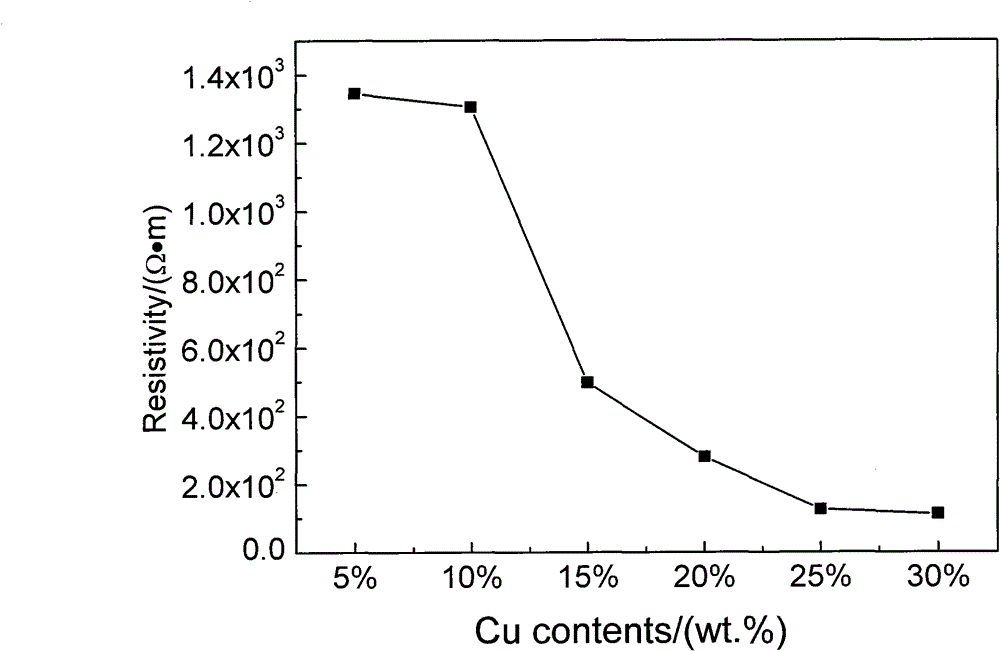

Composite material with high dielectric constant and preparation method thereof

The invention provides a composite material with a high dielectric constant. The composition of the composite material is expressed as BaTiO3 / xCu, wherein x is 0 to 30 weight percent. The invention also provides a preparation method of the material, which comprises: mixing barium strontium titanate powder and copper powder, which serve as raw materials, according to a BaTiO3 to Cu ratio of 1:x, wherein the x is 0 to 30 weight percent; mixing the mixture with a ball milling medium and ballstone; and ball milling, drying granulating, aging, pressing to form a film, sintering and cooling to obtain BaTiO3 / xCu. In the invention, the preparation process is simple and has the characteristics of low cost and no pollution.

Owner:YANCHENG LANBANG TECHN FIBER

PPR water supply pipe tubular product

The invention provides a PPR water supply pipe tubular product which comprises the following raw materials: polypropylene resin powder, a polypropylene random copolymer, color master batch, a clay nano composite material, color masterbatch ash and an adjuvant, wherein the adjuvant comprises an antioxidant and crosslinked high density propylene; the color masterbatch ash comprises calcium carbonate and a talcum powder filler; the melt flow rate of the raw materials is 0.2-0.22 g / 10 minutes, the melt density is 0.8-0.96 g / cm3, the oxidation induction time is 110-130 minutes, the tensile strength is 35MPa, and the fracture depth rate is 600%. The PPR water supply pipe tubular product provided by the invention has good anti-pressure ability, flexibility, low-temperature resistance, high-temperature resistance and strong rapid crack propagation breaking tenacity, and the PPR water supply pipe tubular product is better in pressure resistance as a result of the added color masterbatch ash and the clay nano composite material.

Owner:GUANGXI JINTAN PIPE IND TECH CO LTD

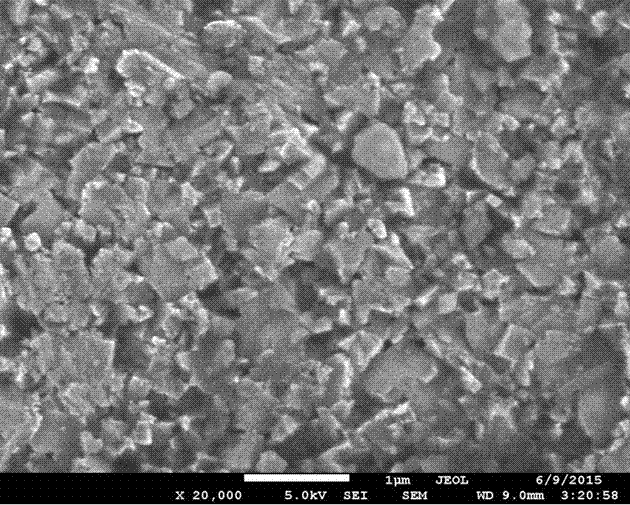

A kind of sintering method of cobalt-free tungsten carbide

The invention discloses a sintering method of cobalt-free tungsten carbide. The sintering method comprises: 1, respectively weighing graphene and nanometer WC powder, uniformly mixing, and drying; and 2, placing the dried graphene and nanometer WC powder mixture into a graphite mold, compacting, sintering at a temperature of 1500-1700 DEG C with a discharge plasma sintering device, carrying out thermal insulation for 5 min, cooling, and taking out the sample. According to the sintering method of the present invention, the high toughness and the high breaking strength of the graphene are utilized to enhance the fracture toughness of the sample; and the graphene is electrically conductive, such that the sintering performance can be changed during the use of the discharge plasma sintering. With the method of the present invention, the sintering temperature is substantially reduced, the sintering time is short, the thermal insulation time is short, and the obtained tungsten carbide has the superfine structure.

Owner:SHANGHAI MARITIME UNIVERSITY

Production method for PVC-U drainage pipe

The invention provides a production method for a PVC-U drainage pipe. The method comprises the following steps: step 1, adding raw materials into a mixer and carrying out stirring and drying so as to form a mixture; step 2, adding the mixture into an extractor and carrying out melting, extruding and granulating; and step 3, adding an obtained granulated material into an extruder, then carrying out melting and die extrusion, and carrying out spray cooling through a cooling water tank so as to obtain the PVC-U drainage pipe, wherein a principle in the step 1 is as follows: a weight of an aluminum-free stabilizer accounts for 4% of the weight of the raw materials; the weight of chlorinated polyethylene accounts for 6% of the weight of the raw materials; the weight of titanium dioxide accounts for 1.4% of the weight of the raw materials; the weight of paraffin accounts for 0.2% of the weight of the raw materials; and the weight of stearin accounts for 0.2% of the weight of the raw materials; and a clay nanometer composite material is a layered silicate nanometer material. The PVC-U drainage pipe provided by the invention has ageing resistance, flexibility, low-temperature resistance, high-temperature resistance, rapid crack propagation and strong fracture toughness.

Owner:GUANGXI JINTAN PIPE IND TECH CO LTD

Sintering method of low-Co WC

The invention discloses a sintering method of low-Co WC. The sintering method comprises steps as follows: step 1, nano-WC powder, TiB2 and Co powder are subjected to ball mill mixing uniformly and are dried, mixed powder is obtained, wherein the content of TiB2 is 0.1w%-0.7w%, and the content of Co powder is 0.2w%-0.8w%; step 2, the mixed powder is put in a graphite die and compacted, then the mixed powder and the die are both put between an upper electrode and a lower electrode of an SPS (spark plasma sintering) device, subjected to vacuum pumping, powered-on, heated at a speed of 200 DEG C / min and pressurized, a product is subjected to heat preservation for 5-10 min after sintering temperature reaches 1,500-1,700 DEG C and axial pressure reaches 50 MPa, and a sample is taken out after power-off cooling; step 3, the product out of the furnace is polished and cleaned, and a finished product is obtained. Co is added during sintering of WC, so that fracture toughness of a hard alloy can be enhanced; then TiB2 is added, the hardness of the hard alloy is not affected by Co by the aid of the characteristic of high hardness of TiB2, and TiB2 can also change electrical conductivity of the powder and change sintering performance; under the synergy with the SPS technology, the sintering effect is better, crystalline grains cannot grow up, and the density and the hardness are higher.

Owner:SHANGHAI MARITIME UNIVERSITY

a climbing hook

The invention relates to a mountain-climbing hook and a processing technology thereof. The mountain-climbing hook comprises a movable rod and a hook body with an articulation hole, wherein the outer peripheral surface of the hook body is encircled by an inner arc-shaped surface, an outer arc-shaped surface and two flat planes; the cross section abutting against the bottom of a gap and the cross section at the lower end of a mounting plate are intersected at a point A; when the movable rod is rotated, the upper end of the movable rod and the inner arc-shaped surface are intersected at a point B, the point A and the point B are connected to form a straight line Z, the shortest straight-line distance between a central point C of the cross section of the articulation hole and the outer arc-shaped surface is L3, and the shortest straight-line distance between the point C and the straight line Z is L4. The processing technology of the mountain-climbing hook is specifically as follows: smelting a well prepared alloy into an aluminum solution, degassing, refining, standing, skimming, and then casting into an aluminum alloy round cast bar; performing extrusion forming in a reverse direction; and performing heat treatment on a cast piece to obtain the mountain-climbing hook. The mountain-climbing hook provided by the invention has the advantages of relatively high tensile strength, corrosion resistance and fracture toughness, as well as long service life.

Owner:NINGBO YINZHOU TIANYING ALUMINUM PROD

Application method of ceramic nano material for preventing ring formation in rotary cement kiln

InactiveCN106699232AHigh vibration frequencyImprove fracture toughnessRotary drum furnacesCeramic coatingCement kiln

The invention relates to an application method of a ceramic nano material for preventing ring formation in a rotary cement kiln. The application method is characterized in that the ceramic nano material is an RSI-X-HT 700-1910 high temperature nano ceramic material, and the application method comprises the following concrete steps: checking and confirming positions of crust and formed rings before construction, soaking a nano ceramic coating material and hydrating, cleaning the surface of a to-be-sprayed part, carrying out nano ceramic spraying operation, maintaining, checking and accepting. The application method has the beneficial effects that the RSI-X-HT 700-1910 high temperature nano ceramic material is adopted for preheating and decomposing a transitional zone, at which ring formation and crust attachment can be easily caused, of a cement kiln, the difficult problem that the ring formation and crust attachment can be easily caused in the traditional zone cannot be solved after a preheating and decomposing kiln appears is solved, and inferior coal can be better used and garbage can be better burned without producing great influence on a kiln system, so that yield and quality of the kiln system are stable, and the application method has broad prospect and is worthy of popularization.

Owner:ANHUI WUHU CONCH CONSTR & INSTALLATION ENG

A dense silicon nitride ceramic liquid riser and its preparation method and application

The invention relates to a compact silicon nitride ceramic lift pipe and a preparation method thereof. The silicon nitride ceramic lift pipe is prepared from 85-95 parts of silicon nitride and 5-15 parts of a sintering aid. The sintering aid is selected from one or more of aluminum oxide, magnesium oxide, yttrium oxide, cerium oxide and titanium carbide. The silicon nitride ceramic lift pipe provided by the invention has the characteristics of high density, high hardness, high bending strength, and strong fracture toughness, etc., and has long service life, can be used continuously for more than one year on a conventional low pressure aluminum casting machine. Through comprehensive optimization of the raw material composition and the preparation method, the production problem of silicon nitride lift pipes in the aluminum casting industry is solved, the quality of key parts in the domestic aluminum casting industry is enhanced, the aluminum casting production efficiency is greatly improved, the production cost is reduced, the production efficiency is significantly improved, the production cost is reduced, thus being conducive to breaking through the monopoly position of foreign silicon nitride enterprises in the industry, and improving the global awareness of China's silicon nitride ceramic level.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

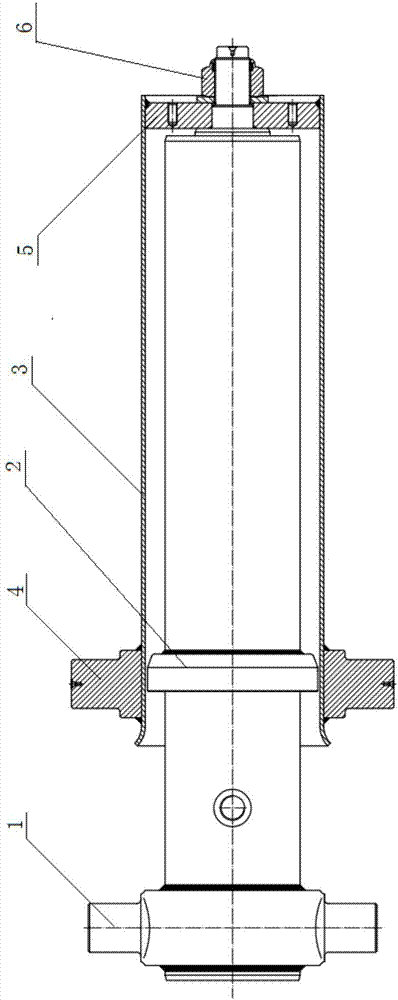

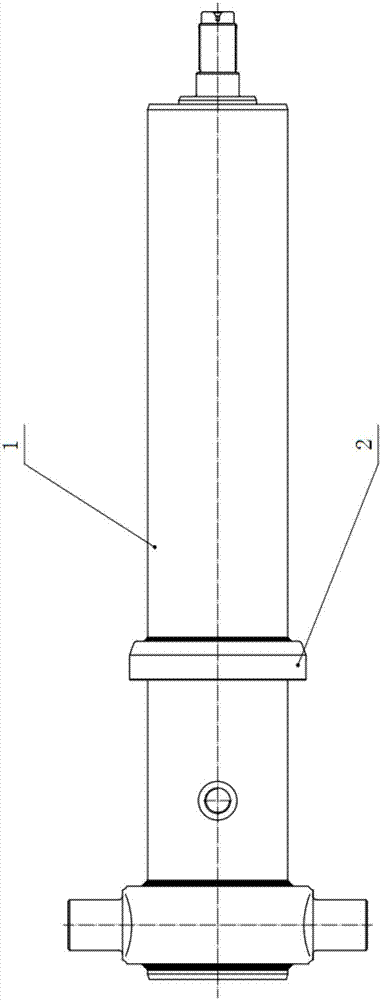

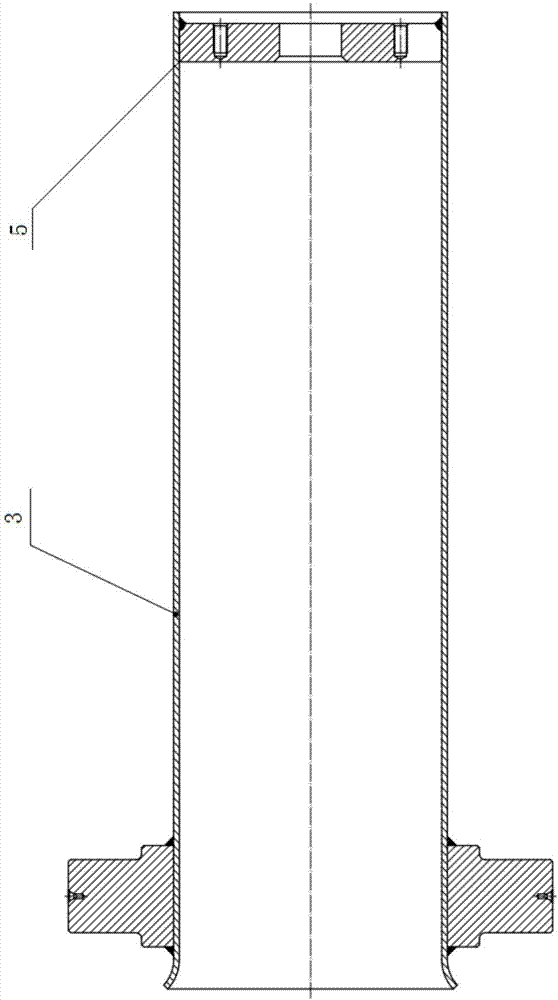

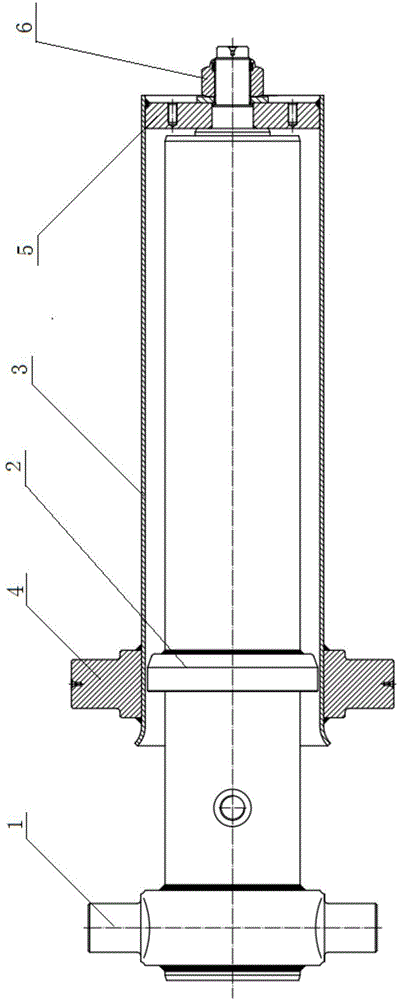

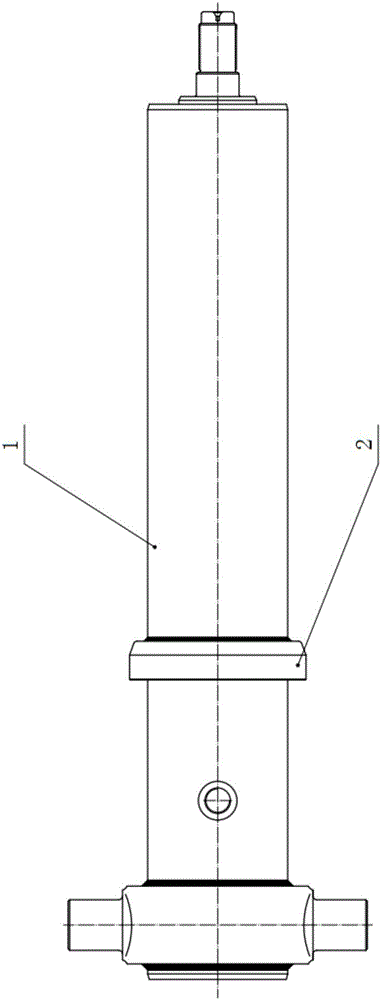

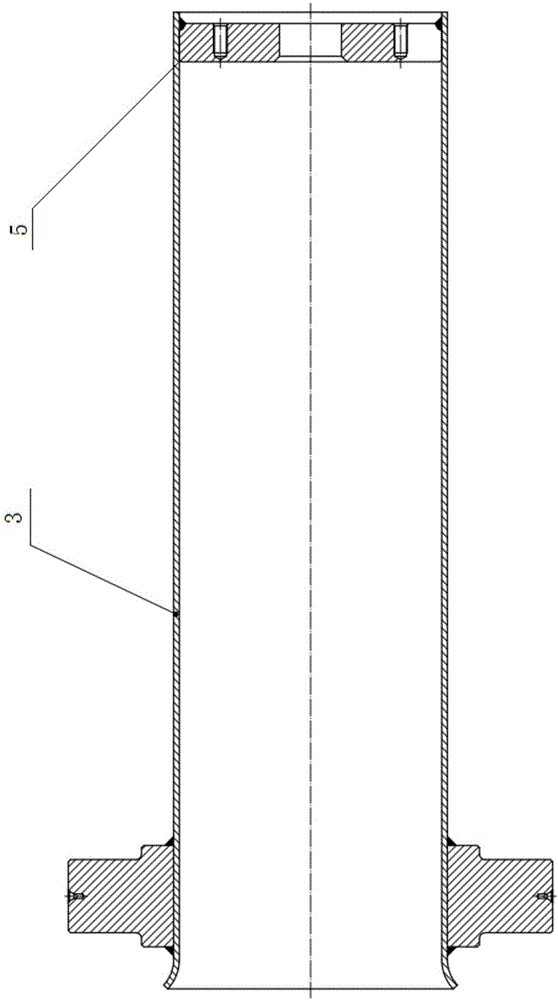

A front telescopic sleeve hydraulic cylinder for a dump truck

ActiveCN106351914BReduce manufacturing costAbnormal sound will not occurFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

A front telescopic sleeve hydraulic cylinder for novel self-dumping trunk relates to the technical field of hydraulic cylinder. The front telescopic sleeve hydraulic cylinder for novel self-dumping trunk comprises a cylinder assembly and housing welded parts. The front end of the housing welded parts is provided an opening, and the rear end of the housing welded parts is provided with an end cap, and the lateral wall near the front end position of the housing welded parts is provided with an upper hinge axis. The cylinder assembly is inserted into the housing welded parts through the opening, and the end portion of the cylinder assembly is locked by a large nut outside the end cap after passing through the end cap. The lateral wall of the cylinder assembly is provided with a supporting ring which is evenly provided with at least three supporting nails. The front telescopic sleeve hydraulic cylinder for novel self-dumping trunk has the advantages of low manufacturing cost and short maintenance time.

Owner:湖北万邦液压装备有限公司

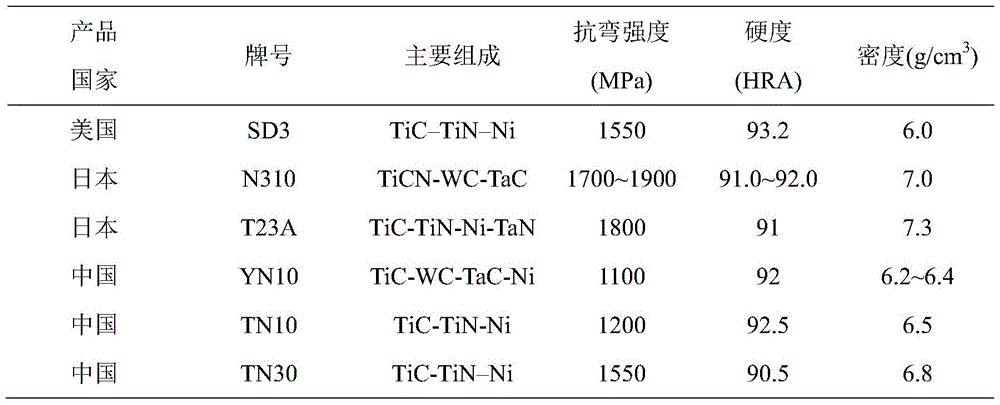

Ti(c,n)-based cermet reinforced and toughened by strip-shaped ternary boride and preparation method thereof

Owner:SHAREATE TOOLS

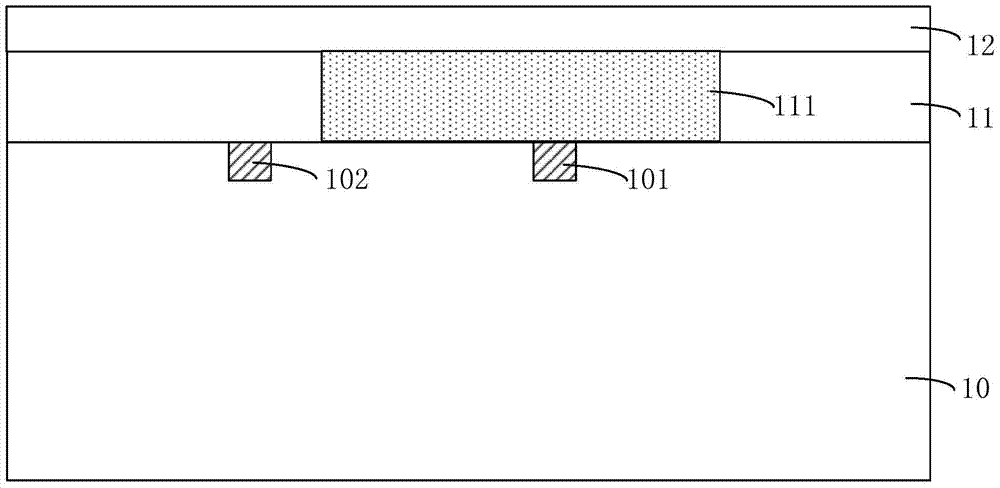

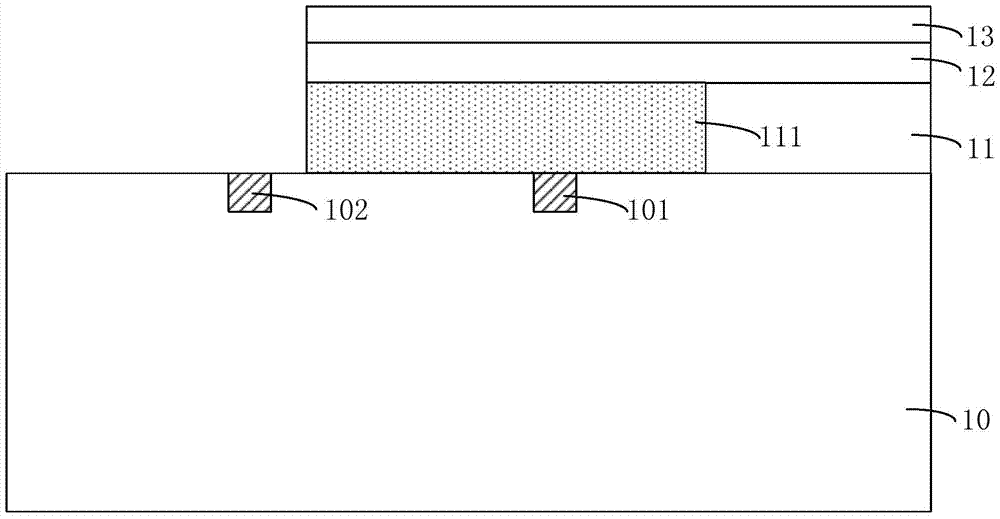

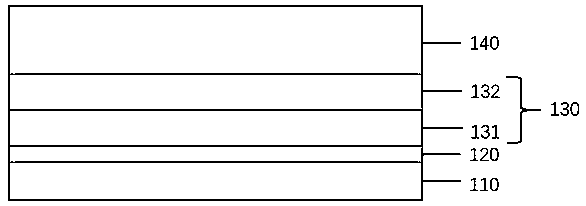

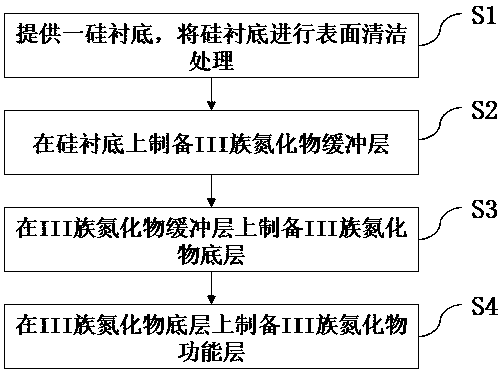

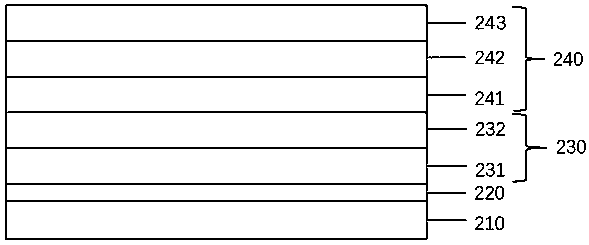

III-group nitride layer on silicon substrate

PendingCN109887997AMaximum critical fracture thicknessLarge bond strength critical fracture thicknessLaser active region structureSemiconductor devicesSiliconBond strength

The invention discloses an III-group nitride layer on a silicon substrate. The III-group nitride layer comprises a silicon substrate, and an III-group nitride buffer layer, an III-group nitride bottomlayer and an III-group nitride functional layer which are arranged on the silicon substrate in sequence, wherein the III-group nitride bottom layer comprises a middle layer and a substrate layer; themiddle layer comprises the components of BxAlyGa1-x-yN, wherein x is greater than or equal to 0.05 and less than or equal to 1, y is greater than or equal to 0 and less than or equal to 1, and x+ y is greater than or equal to 0 and less than or equal to 1; and the substrate layer comprises the components of AlzGa1-zN, wherein z is greater than or equal to 0 and less than or equal to 1. The III-group nitride layer has the following advantages that compared with a traditional AlGaN middle layer which is used when the III-group nitride layer grows on a silicon substrate, due to the fact that theB-N bond has higher bond strength and stronger fracture toughness than Al-N bond, more compressive stress can be accumulated in the growth process of the invention, the III-group nitride layer with alarger critical fracture thickness can be realized, and the performance of the III-group nitride semiconductor device is further improved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

mems device, mems temperature sensor and respective manufacturing methods

ActiveCN106918397BAdd folding structureAvoid breakingDecorative surface effectsThermometers using material expansion/contactionCapacitanceCantilevered beam

The invention relates to an MEMS (Micro-Electro-Mechanical-System) device and a manufacturing method thereof so as to improve the reliability of a cantilever beam of the existing MEMS device, and relates to an MEMS temperature sensor and a manufacturing method thereof so as to improve the process and structure of the existing MEMS temperature sensor. For the MEMS device, a zigzag structure is additionally arranged at a connecting part of a movable portion and a fixed portion of the cantilever beam, and the connecting part is reinforced so as to avoid the connecting part from being broken. For the MEMS temperature sensor, the lower surface or the upper surface of the movable portion of the cantilever beam is provided with a strain gauge with the thermal expansion coefficient being different from that of the movable portion of the cantilever beam, so that the movable portion of the cantilever beam is warped and deformed in the measuring process because the thermal expansion coefficient is different from that of the strain gauge, capacitance between the movable portion of the cantilever beam and a fixed electrode changes, and thus the temperature is detected.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A graphene-reinforced ultrafine synthetic leather fiber

ActiveCN105463598BHigh breaking strengthAntistaticMelt spinning methodsArtifical filament manufactureLeather industryMasterbatch

A graphite-enhanced ultrafine synthetic leather fiber is provided. Graphite nylon 6 master batch is prepared via a twin-screw extrusion way; the nylon 6 master material is added to nylon 6 granules via a metering device for sea-island melt spinning; and graphite-enhanced ultrafine fibers can be achieved after decrement and splitting. The graphite-enhanced ultrafine synthetic leather fiber is characterized by high breaking tenacity, static resistance, bacteria resistance, aging resistant and strong flexibility; ultrafine fiber synthetic leather quality and comprehensive performance can be improved when the graphite-enhanced ultrafine synthetic leather fiber is applied to synthetic leather industry; and traditional sea-island fiber spinning equipment can be employed for production.

Owner:SICHUAN UNIV

Composite material with high dielectric constant and preparation method thereof

The invention provides a composite material with a high dielectric constant. The composition of the composite material is expressed as BaTiO3 / xCu, wherein x is 0 to 30 weight percent. The invention also provides a preparation method of the material, which comprises: mixing barium strontium titanate powder and copper powder, which serve as raw materials, according to a BaTiO3 to Cu ratio of 1:x, wherein the x is 0 to 30 weight percent; mixing the mixture with a ball milling medium and ballstone; and ball milling, drying granulating, aging, pressing to form a film, sintering and cooling to obtain BaTiO3 / xCu. In the invention, the preparation process is simple and has the characteristics of low cost and no pollution.

Owner:YANCHENG LANBANG TECHN FIBER

Front telescopic sleeve hydraulic cylinder for novel self-dumping trunk

ActiveCN106351914AReduce manufacturing costAbnormal sound will not occurFluid-pressure actuatorsHydraulic cylinderEngineering

A front telescopic sleeve hydraulic cylinder for novel self-dumping trunk relates to the technical field of hydraulic cylinder. The front telescopic sleeve hydraulic cylinder for novel self-dumping trunk comprises a cylinder assembly and housing welded parts. The front end of the housing welded parts is provided an opening, and the rear end of the housing welded parts is provided with an end cap, and the lateral wall near the front end position of the housing welded parts is provided with an upper hinge axis. The cylinder assembly is inserted into the housing welded parts through the opening, and the end portion of the cylinder assembly is locked by a large nut outside the end cap after passing through the end cap. The lateral wall of the cylinder assembly is provided with a supporting ring which is evenly provided with at least three supporting nails. The front telescopic sleeve hydraulic cylinder for novel self-dumping trunk has the advantages of low manufacturing cost and short maintenance time.

Owner:湖北万邦液压装备有限公司

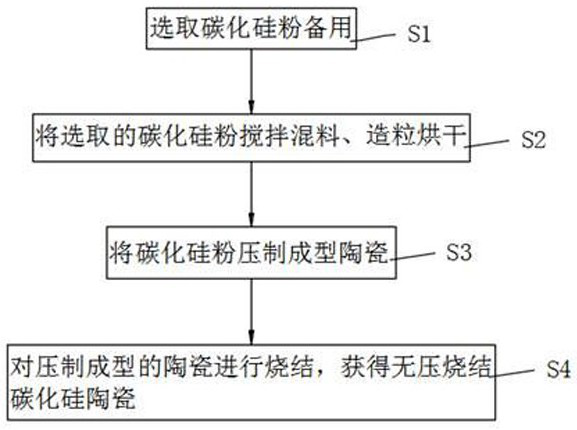

Preparation process of large-size pressureless sintered silicon carbide ceramic material

The invention discloses a preparation process of a large-size pressureless sintered silicon carbide ceramic material, and belongs to the technical field of ceramics. The method comprises the following steps of: S1, selecting silicon carbide powder for later use, S2, stirring, mixing, granulating and drying the selected silicon carbide powder, S3, isostatically pressing the silicon carbide powder to form ceramic, S4, sintering the pressed and formed ceramic to obtain the pressureless sintered silicon carbide ceramic. According to the invention, the traditional sintering process is broken through, the 99.9% silicon carbide micro powder is sintered at a high temperature of 22000 DEG C under a non-pressure condition and in an argon atmosphere, the density reaches 3.15 g / cm < 3 >, the thermal conductivity is good, the thermal conductivity reaches 74 W / m.k, the Knoop hardness is 2600 kg / mm < 2 >, and the sintered non-pressure silicon carbide material has super-strong fracture toughness, relatively high fracture strength, zero porosity, density of 3.15 g / cm < 2 >, better wear resistance and corrosion resistance, and the highest working temperature of 16100 DEG C.

Owner:山东君道高温材料有限公司

A preparation method for sintering zirconium-aluminum composite eutectic ceramics using flash firing technology

ActiveCN107188544BImprove high temperature stabilityStrong fracture toughnessCompression moldingAluminum composites

The invention belongs to the technical field of ceramic preparation and particularly relates to a preparation method of sintering zirconium-aluminum composite eutectic ceramic through the flash sintering technology. The preparation method comprises proportionally and uniformly mixing Al2O3 and YSE, adding in ethanol and performing ball-milling and drying to obtain precursor powder; adding bonding agent into the precursor power for uniform grinding, after the mixture is dried, performing compression molding to obtain an eutectic ceramic precursor; sintering the eutectic ceramic precursor through the flash sintering technology to prepare the Al2O3-YSE eutectic ceramic. According to the preparation method, the flash sintering technology is applied to preparation of the Al2O3-YSE eutectic ceramic, the prepared Al2O3-YSE eutectic ceramic have a rod-like eutectic morphology and is high in high-temperature stability, breaking tenacity and bending strength, and the eutectic morphology is relatively uniform. Compared with other eutectic ceramic preparation methods, the preparation method of sintering the zirconium-aluminum composite eutectic ceramic through the flash sintering technology has the advantages of being simple in equipment, high in controllability during preparation, short in preparation time, energy-efficient and the like.

Owner:WUHAN UNIV OF TECH

Aluminosilicate-assisted deposition of silver-containing coating implant abutment ceramic material and its preparation method

InactiveCN110051446BDesign scienceSimple and fast operationDental implantsCeramic abutmentsAnti bacteria

The invention discloses an aluminosilicate-assisted deposition of a silver-containing coating ceramic material and a manufacturing method for a planting abutment, which solves the problem that there is no antibacterial treatment of the ceramic abutment in the prior art. The preparation method of the present invention comprises the following steps: after coating a layer of aluminosilicate on the surface of zirconia tiles, firing to obtain sintered aluminosilicate coated tiles; immersion in an ultrasonic water bath; after the immersion, take out the aluminosilicate-coated tiles and bake them to reduce the silver nitrate impregnated on the coating of the aluminosilicate-coated tiles in situ to obtain aluminosilicate-assisted deposition Implant abutment ceramic material with silver coating. The invention has scientific design, simple operation, aesthetics and antibacterial properties, can continuously and stably exert antibacterial effect for a long time, and has simple preparation method, low cost and high safety.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com