Aluminosilicate auxiliary deposition silver coating planting abutment ceramic material and preparation method thereof

A technique of aluminosilicate and assisted deposition, which is applied in the fields of implantology, medical science, dentistry, etc., can solve the problems of antibacterial treatment of non-ceramic abutments, and achieve the effect of low cost, high safety, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment discloses the investigation of the sintering conditions of the aluminosilicate of the present invention, specifically:

[0047] Step 1. Use CAD / CAM technology to cut VITA In-Ceram 2000YZ porcelain blocks into ceramic pieces with a thickness of 1mm, a length of 21mm, and a width of 10mm. After sandblasting, they are cleaned with plasma water for 5 minutes, and placed in a VITA Zyrcomat porcelain furnace at 1000°C Roast for 15 minutes, take it out from the porcelain furnace and let it stand for 5 minutes to obtain zirconia porcelain pieces, which are set aside;

[0048]Step 2. Apply a thin (<0.5mm) layer of VITA VM9 adhesive effect porcelain powder mixed with VITA VM9 adhesive effect porcelain special liquid on the surface of the zirconia ceramic sheet treated in step 1, and then apply ceramic The firing bracket is placed in a ceramic furnace, and the temperature in the furnace is pre-fired to 500°C, and then kept for 6 minutes, then the temperature is rai...

Embodiment 2

[0053] This embodiment provides the preparation method of the aluminosilicate-assisted deposition of the silver-containing coating of the planting abutment ceramic material of the present invention, specifically:

[0054] Step 1. Use CAD / CAM technology to cut VITA In-Ceram 2000YZ porcelain blocks into ceramic pieces with a thickness of 1mm, a length of 21mm, and a width of 10mm. After sandblasting, they are cleaned with plasma water for 5 minutes, and placed in a VITA Zyrcomat porcelain furnace at 1000°C Roast for 15 minutes, take it out from the porcelain furnace and let it stand for 5 minutes to obtain zirconia porcelain pieces, which are set aside;

[0055] Step 2. Apply a thin (<0.5mm) layer of VITA VM9 adhesive effect porcelain powder mixed with VITA VM9 adhesive effect porcelain special liquid on the surface of the zirconia ceramic sheet treated in step 1, and then apply ceramic The firing bracket is placed in a ceramic furnace, and the temperature in the furnace is pre-...

Embodiment 3

[0060] Compared with Example 2 in this example, in step 2, the porcelain furnace is heated to 980°C and kept for 1 minute, and then kept under vacuum for 6 minutes to obtain a sintered aluminosilicate-coated tile; the rest of the conditions are same. For sample 1.

[0061] The implant abutment ceramic material impregnated with 1mol / l silver nitrate is marked as sample 1-1, and the implant abutment ceramic material impregnated with 5mol / l silver nitrate is marked as sample 1-5.

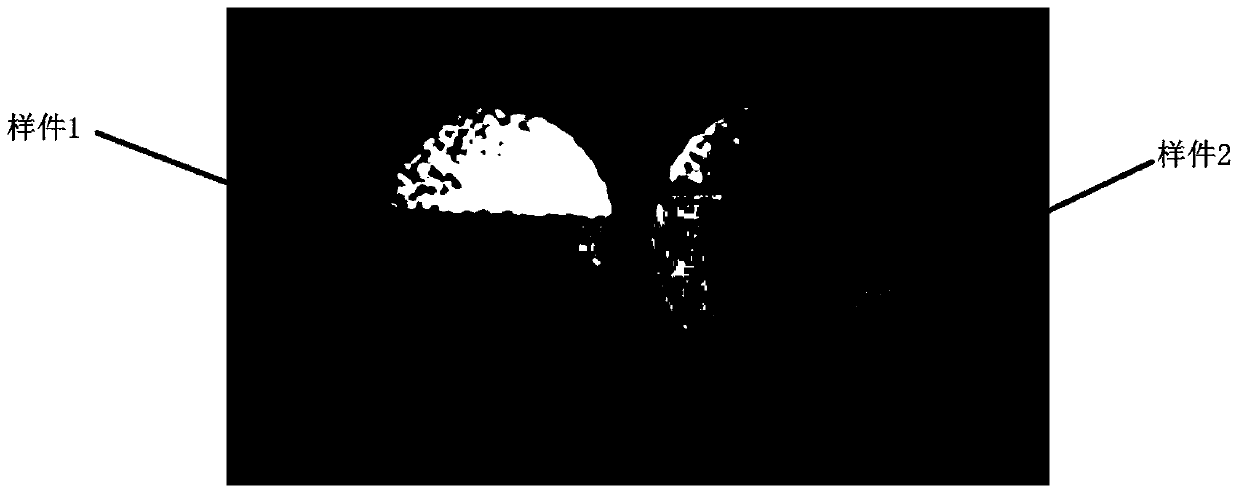

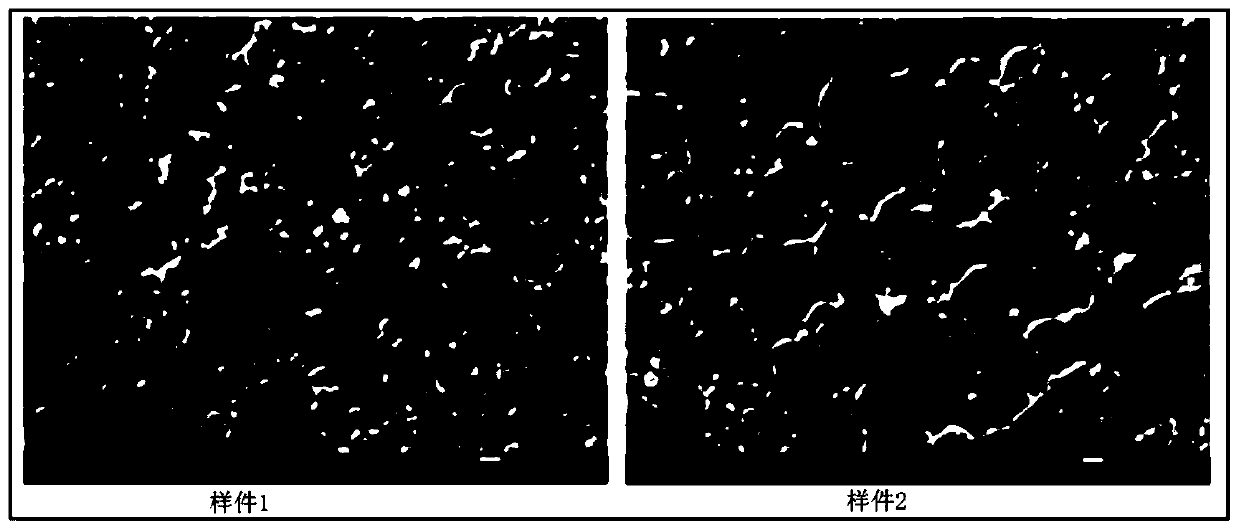

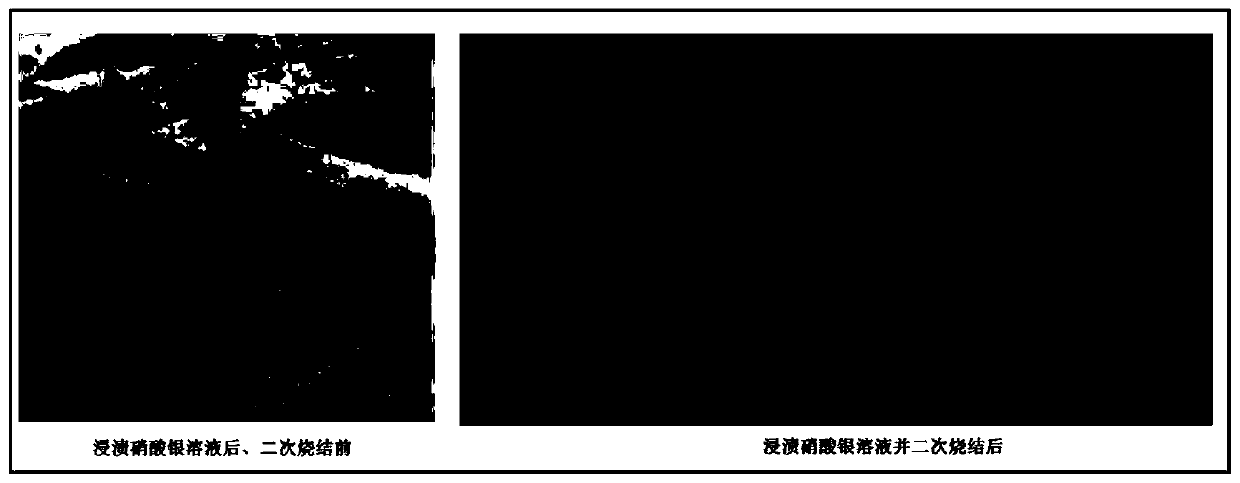

[0062] Compare the appearance of samples 1-1, 2-1, 1-5, and 2-5, and the results are attached image 3 shown. Among them, sample 1-0 represents the part of sample 1 that is not impregnated with silver nitrate, and 2-0 represents the part of sample 2 that is not impregnated with silver nitrate. After the sample was cut and dipped in silver nitrate solution, there was no special color display before the second sintering; after the sample was dipped and second sintered, it showed the color of reduced A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com