Novel shell-based concrete fish shelter

A technology of concrete and fish reefs, applied in fish farming, application, climate change adaptation, etc., can solve the problem of uneven fish and reef effects, protect marine biodiversity and recreational fisheries, and prevent destructive fishing of marine organisms , the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

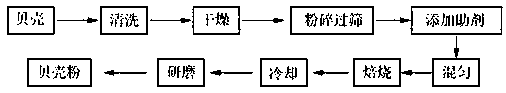

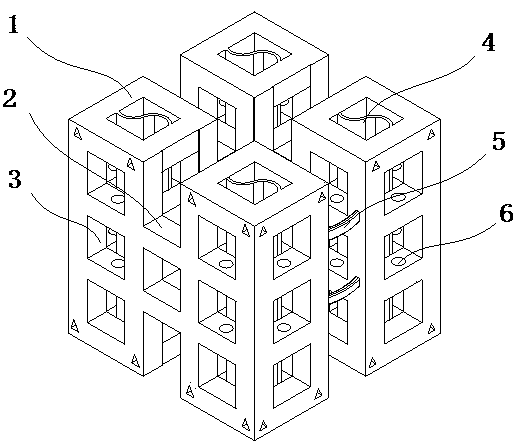

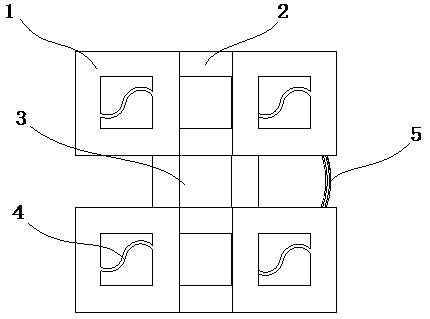

[0025] Such as Figure 1-3 As shown, a new type of shell-based concrete fish reef, the preparation process of the fish reef is as follows, the preparation of coarse shells, the preparation of shell powder, the preparation of concrete fish reef, the specific steps are as follows:

[0026] 1) Preparation of coarsely crushed shells: wash the discarded shells with cleaning solution for 3 times, dry them at 150°C for 1.5 hours, grind them into 5mm particles, and sieve to obtain coarsely crushed shell powder. The cleaning solution consists of the following ingredients and Composition in parts by weight: 12 parts of disodium edetate, 18 parts of octadecyl dihydroxyethyl amine oxide, 17 parts of dipotassium glycyrrhizinate, 0.05 part of p-dimethylaminobenzaldehyde, dodecylbenzenesulfonic acid 20 parts of sodium, 8 parts of sodium metasilicate pentahydrate, 12 parts of coconut oil fatty acid diethanolamide, 13 parts of fatty alcohol polyoxyethylene ether, 42 parts of deionized water; ...

Embodiment 2

[0032] Such as Figure 1-5 As shown, a novel shell-based concrete fish reef, the preparation process of the fish reef is as follows, the preparation of coarse shells, the preparation of shell powder, the preparation of concrete fish reef, the specific preferred steps are as follows:

[0033] 1) Preparation of coarsely crushed shells: wash the discarded shells with cleaning solution for 3 times, dry them at 150°C for 2 hours, grind them into 10mm particles, and sieve to obtain coarsely crushed shell powder. The cleaning solution consists of the following components and weight: Ingredients: 14 parts of disodium edetate, 18 parts of octadecyl dihydroxyethyl amine oxide, 22 parts of dipotassium glycyrrhizinate, 0.05 parts of p-dimethylaminobenzaldehyde, sodium dodecylbenzenesulfonate 21 parts, 10 parts of sodium metasilicate pentahydrate, 15 parts of coconut oil fatty acid diethanolamide, 12 parts of fatty alcohol polyoxyethylene ether, 40 parts of deionized water;

[0034] 2) Pr...

Embodiment 3

[0040] Such as figure 1 As shown, a new type of shell-based concrete fish reef, the preparation process of the fish reef is as follows, the preparation of coarse shells, the preparation of shell powder, the preparation of concrete fish reef, the specific steps are as follows:

[0041] 1) Preparation of coarsely crushed shells: wash the discarded shells with cleaning solution for 3 times, dry them at 200°C for 1.5 hours, grind them into 16mm particles, and sieve to obtain coarsely crushed shell powder. The cleaning solution consists of the following ingredients and Composition in parts by weight: 14 parts of disodium edetate, 15 parts of octadecyl dihydroxyethyl amine oxide, 16 parts of dipotassium glycyrrhizinate, 0.07 part of p-dimethylaminobenzaldehyde, dodecylbenzenesulfonic acid 13 parts of sodium, 6 parts of sodium metasilicate pentahydrate, 4 parts of coconut oil fatty acid diethanolamide, 15 parts of fatty alcohol polyoxyethylene ether, 50 parts of deionized water;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com