Sapphire crystal with high mechanical property and fabrication method thereof

A sapphire crystal and crystal technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as insufficient mechanical properties of sapphire crystals, improve fracture surface energy, improve elastic modulus and fracture surface energy, wide space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

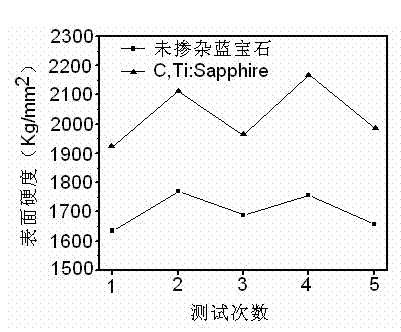

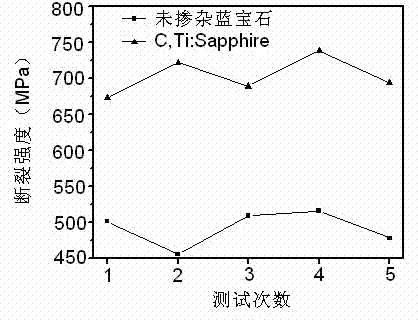

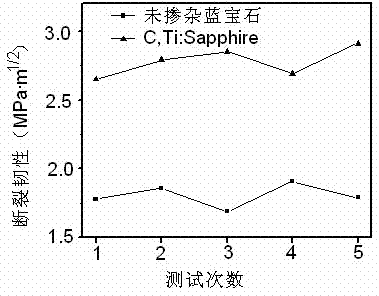

[0033] Embodiment 1: temperature gradient method growth doping amount is 5000ppm graphitic carbon and 1000ppmTiO 2 C,Ti:sapphire crystals

[0034] Weigh the α-Al with a purity of 99.999% 2 o 3 Raw material 3Kg, 1000ppm spectroscopically pure TiO 2(ie 3g), and 5000ppm spectroscopically pure graphite carbon (ie 15g), mixed and ground on a planetary ball mill for 24 hours, and then cold-dried and pressed into blocks for later use.

[0035] The temperature gradient method is used to grow C, Ti: sapphire crystals. The specific steps are: select a-oriented [11-20] pure sapphire as the seed crystal, put the pure sapphire seed crystal in the molybdenum crucible seed crystal tank, and uniformly press the block material Put it into the crucible, cover the crucible lid, and install the furnace. Vacuum to furnace pressure -3 Pa, continue to heat up to 2333K, keep the temperature for 3 hours after the raw material is melted, and after the melt is completely melted and stabilized,...

Embodiment 2

[0038] Embodiment 2: temperature gradient method growth doping amount is 1000ppm graphitic carbon and 500ppmTiO 2 C,Ti:sapphire crystals

[0039] Except that the added doped graphitic carbon is 1000ppm (ie 3g), and the doped TiO 2 Except for 500ppm (that is, 1.5g), the other ingredients are the same as in Example 1, mixed and ground on a planetary ball mill for 24 hours, taken out, cold-dried and pressed into blocks for future use.

[0040] The temperature gradient method is used to grow C, Ti: sapphire crystals. The specific steps are: select a-oriented [11-20] pure sapphire as the seed crystal, put the sapphire seed crystal in the seed crystal groove of the molybdenum crucible, and uniformly press the block material Put it into the crucible, cover the crucible lid, and install the furnace. Vacuum to furnace pressure -3 Pa, continue to heat up to 2363K, keep the temperature for 1h after the raw material is melted, and after the melt is completely melted and stabilized...

Embodiment 3

[0041] Embodiment 3: temperature gradient method growth doping amount is 10000ppm graphitic carbon and 3000ppmTiO 2 C,Ti:sapphire crystals

[0042] Except that the added doped graphitic carbon is 10000ppm (ie 30g), and the doped TiO 2 Except for 3000ppm (that is, 9g), other ingredients are the same as in Example 1, mixed and ground on a planetary ball mill for 24 hours, taken out, cold-dried and pressed into blocks for later use.

[0043] C, Ti: sapphire crystals are grown by the temperature gradient method. The specific steps are: select a-oriented [11-20] pure sapphire as the seed crystal, put the Sapphire seed crystal in the seed crystal tank of the molybdenum crucible, and uniformly press the block material Put it into the crucible, cover the crucible lid, and install the furnace. Vacuum to furnace pressure -3 Pa, continue to heat up to 2348K, keep the temperature for 2 hours after the raw material is melted, and after the melt is completely melted and stabilized, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com