Patents

Literature

33results about How to "High temperature limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

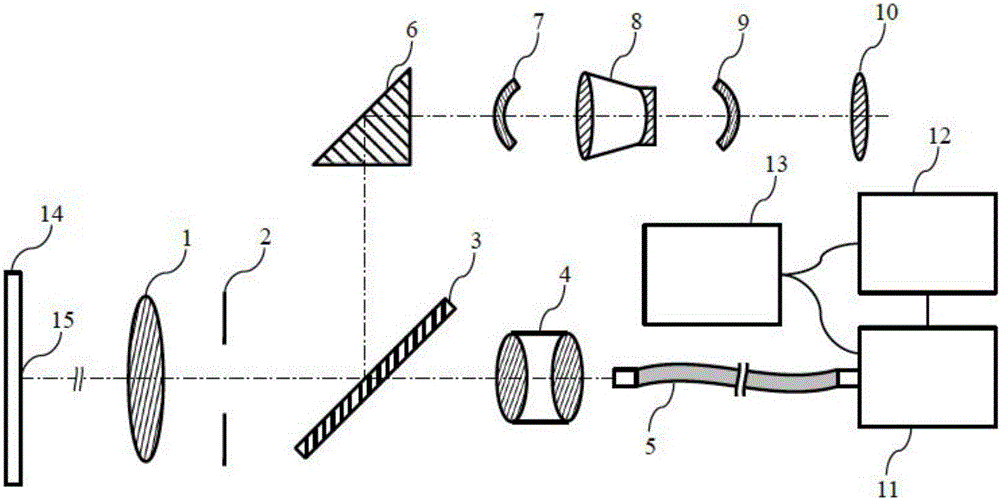

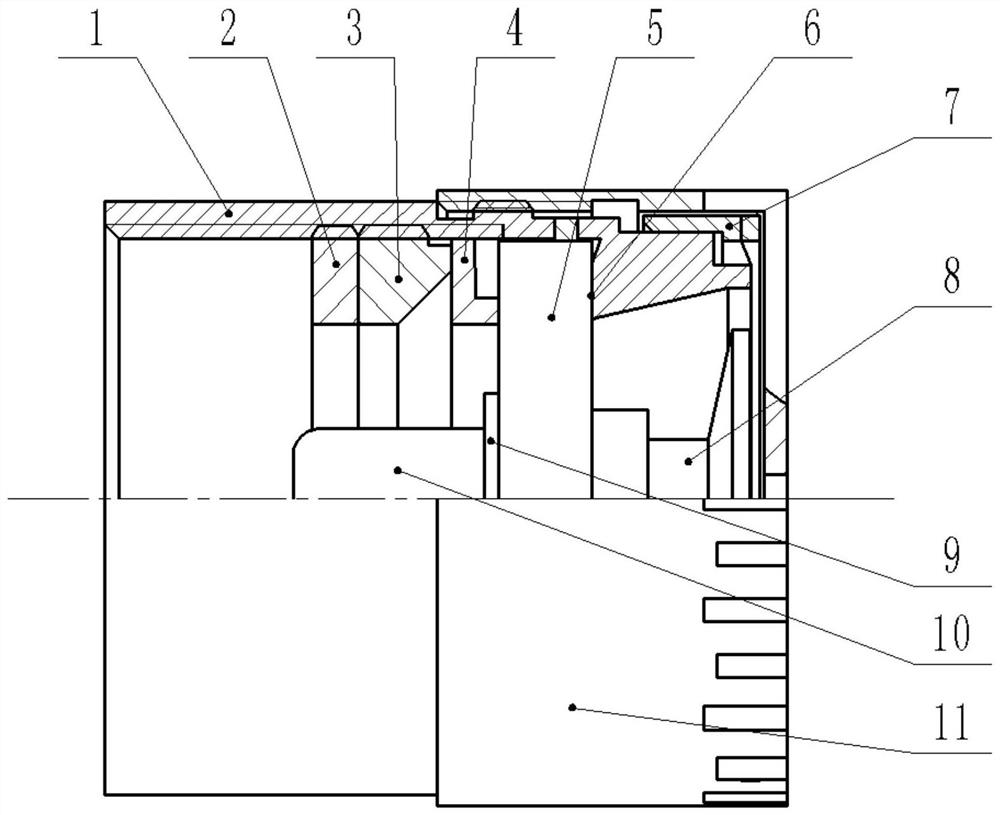

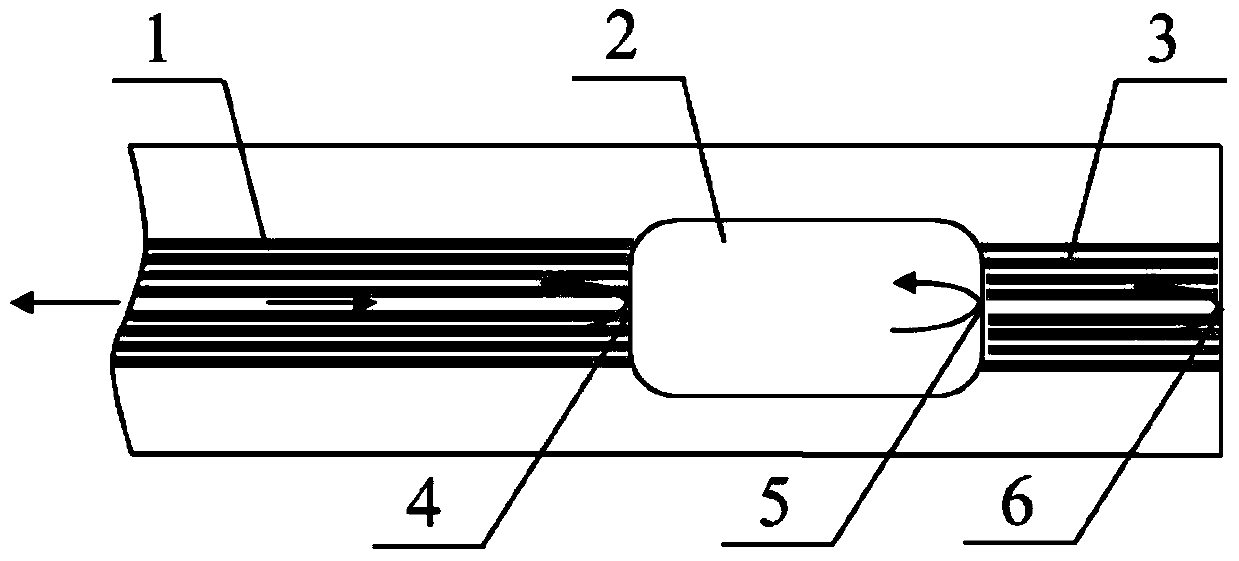

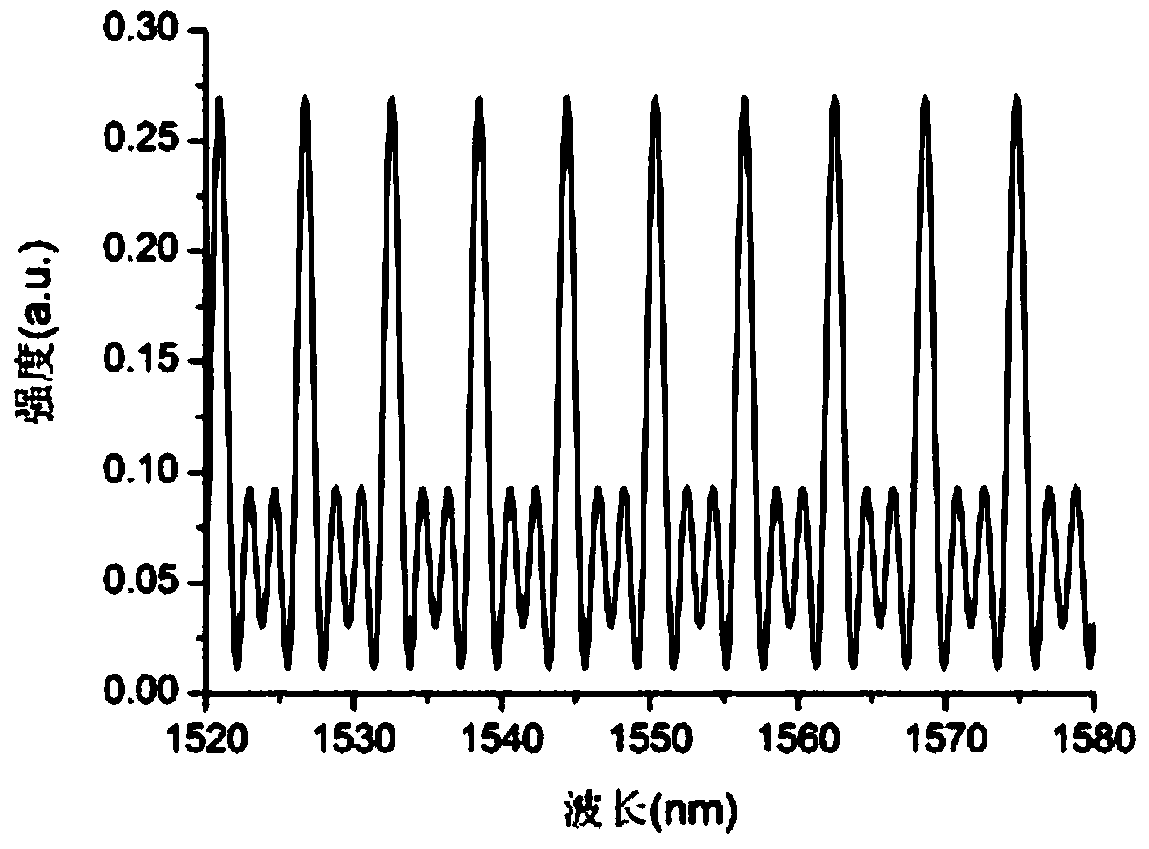

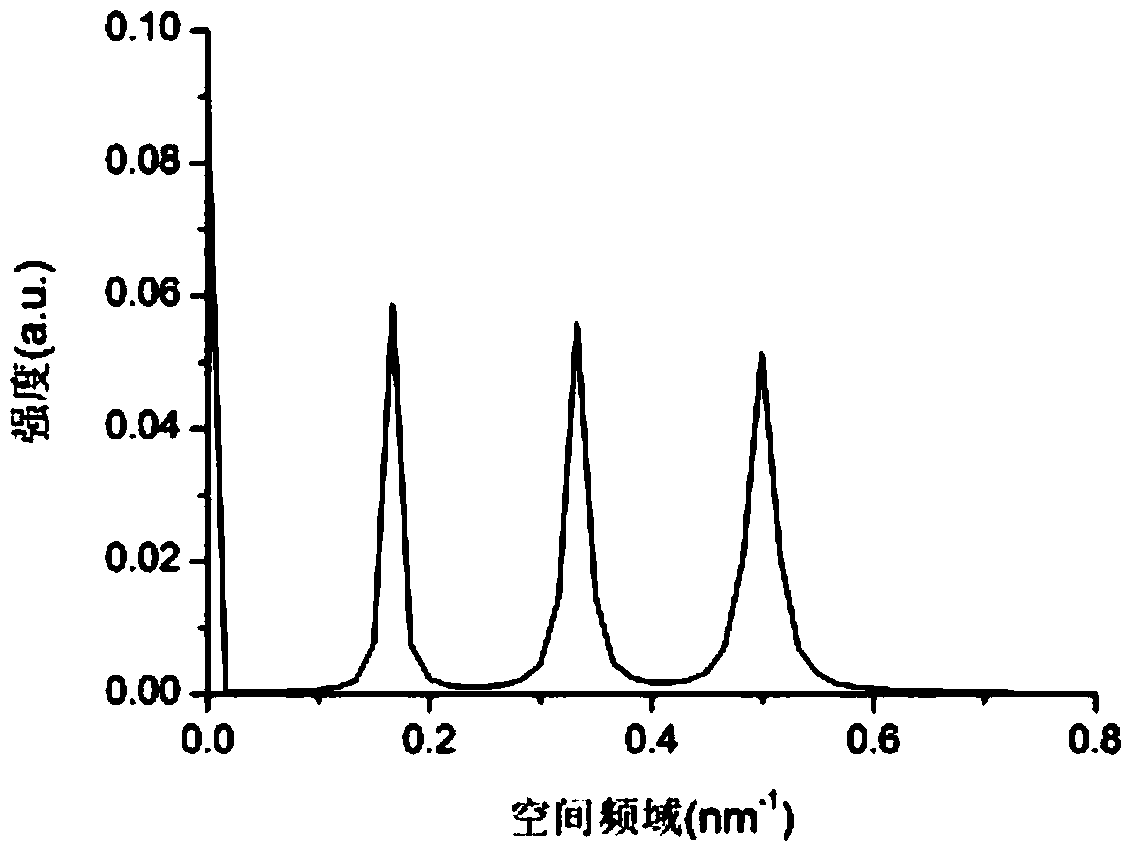

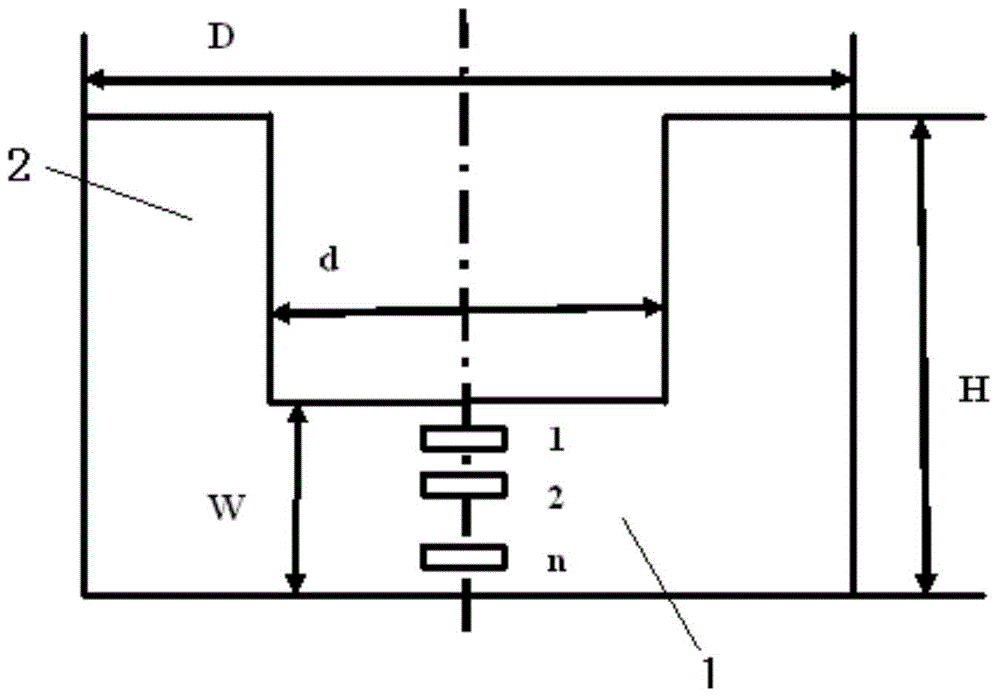

High-temperature Fabry-Perot (FP) composite micro/nano fiber temperature and pressure sensor

ActiveCN105043588AHigh temperature limitSmall structure sizeThermometers using physical/chemical changesFluid pressure measurement by optical meansCross sensitivityEngineering

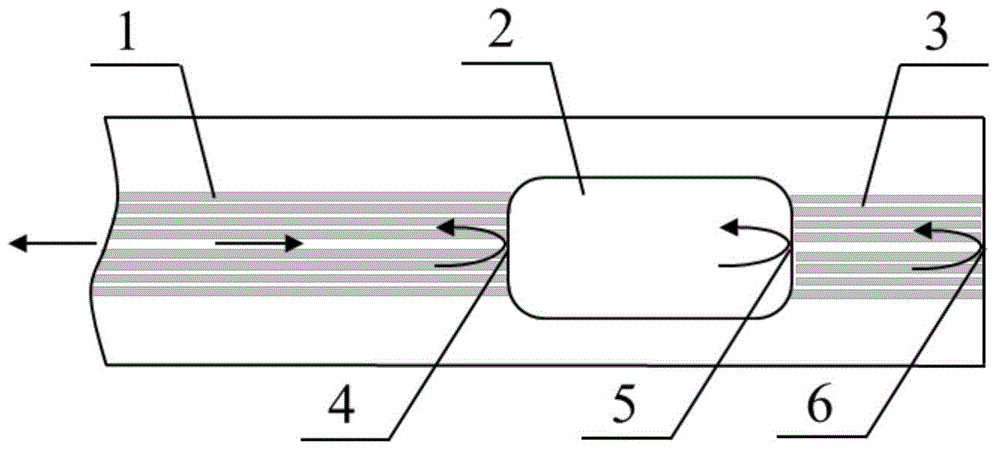

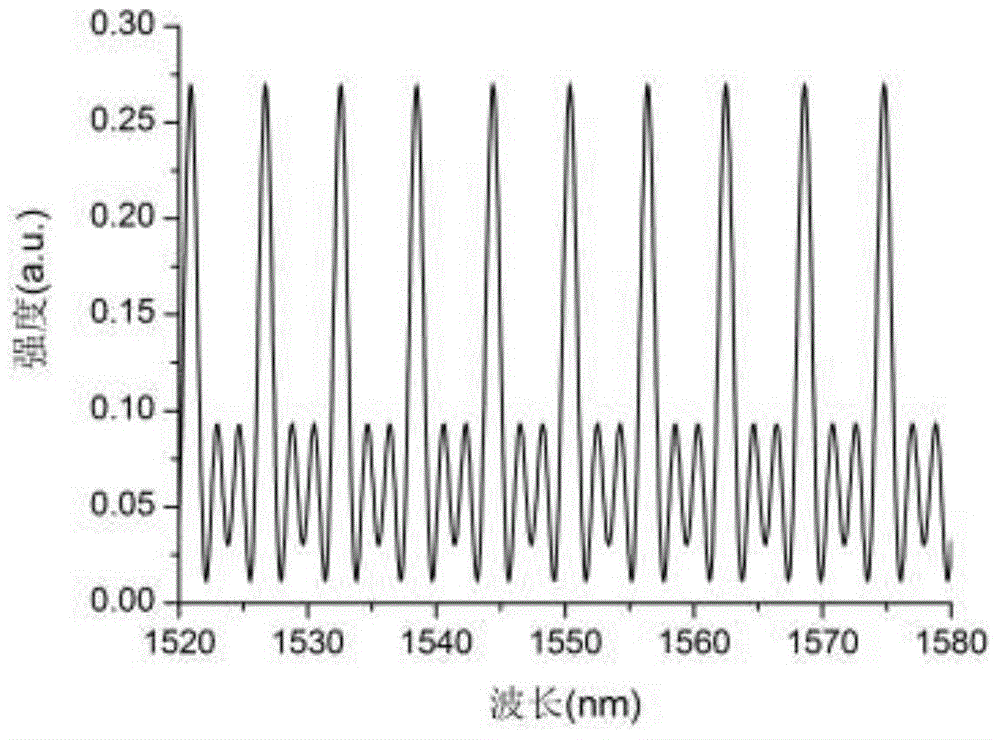

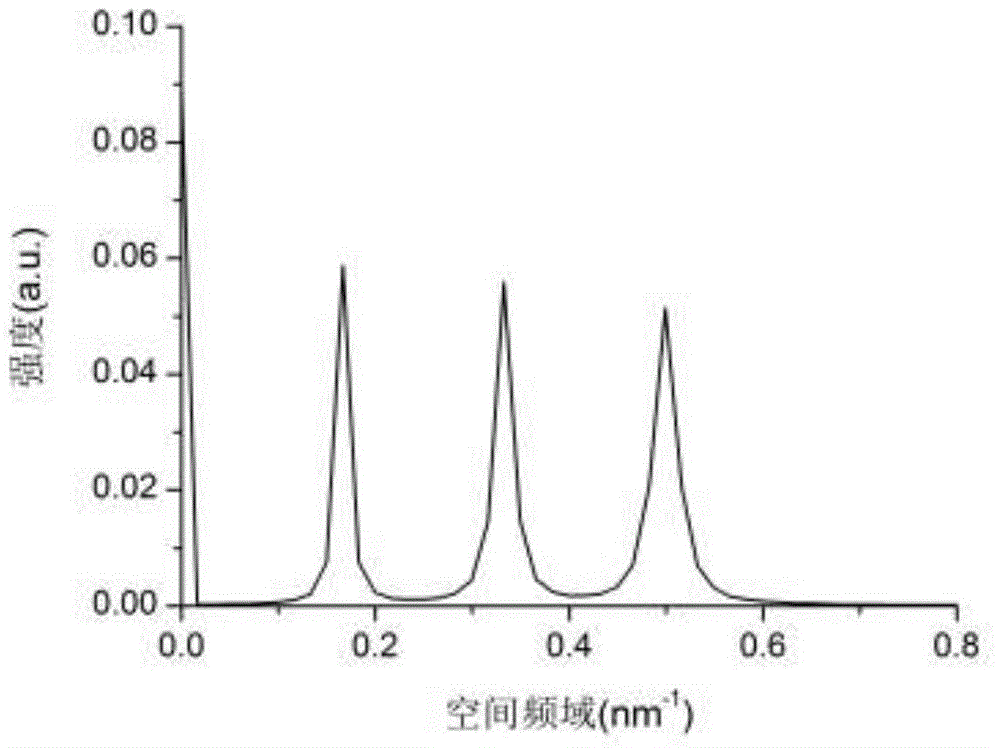

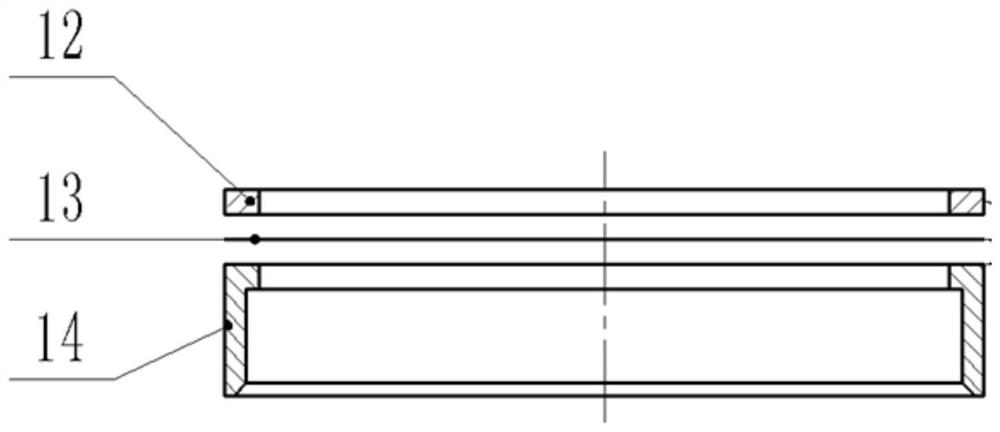

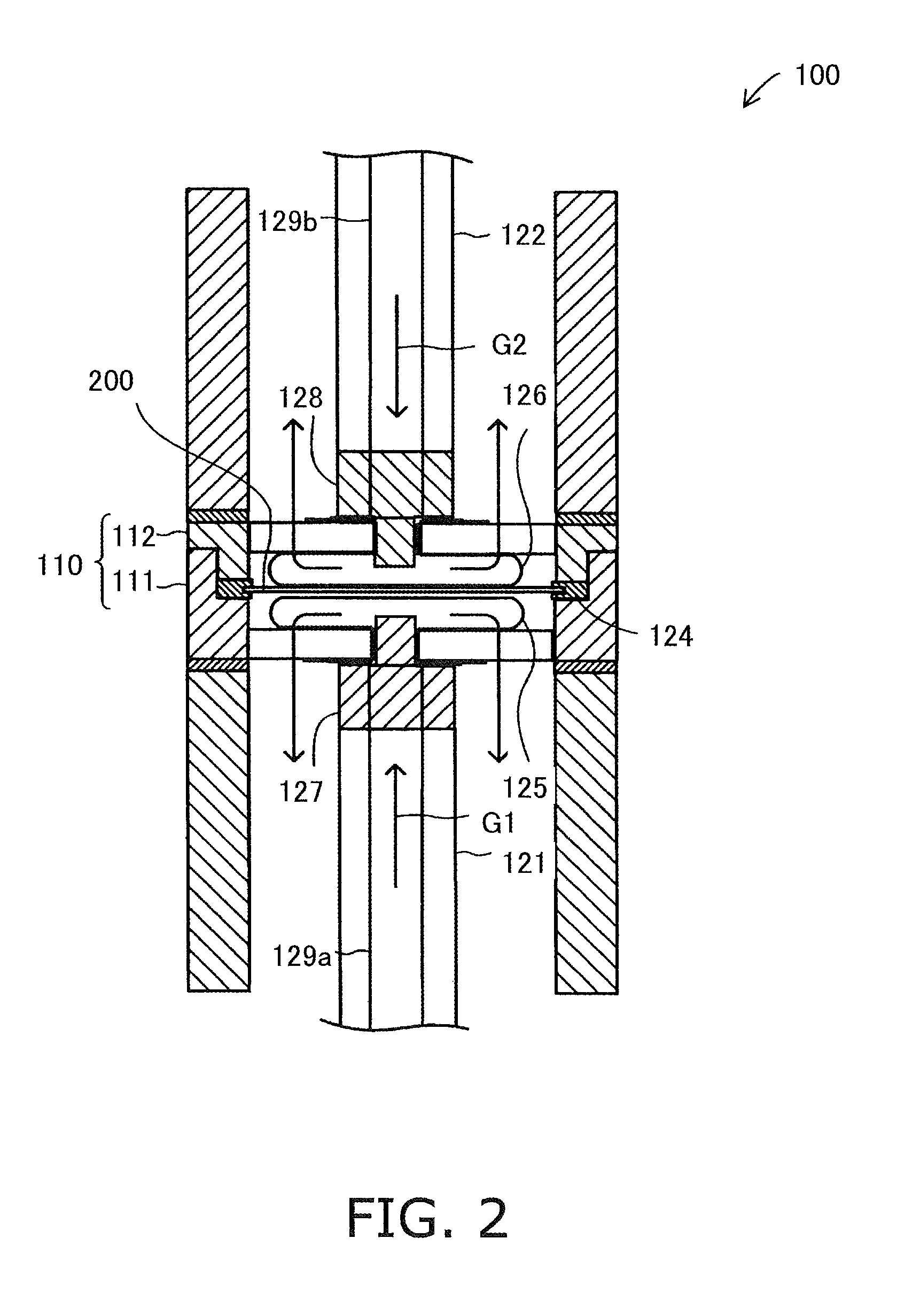

The invention relates to a high-temperature Fabry-Perot composite micro / nano fiber temperature and pressure sensor, and belongs to the technical field of fiber sensors. The sensor comprises a fiber access segment, a pressure sensor segment and a temperature sensor segment, wherein the fiber access segment includes a solid fiber, the pressure sensor includes a hollow thin-wall fiber, and the temperature sensor includes another solid fiber. Cylindrical holes are formed in the end portions of the two solid fibers respectively in a femtosecond second processing method, and then welded to form an FP interference type pressure cavity, one fiber serves as the fiber access segment, the other fiber is cut and ground to the solid fiber of certain thickness, a temperature sensor is thus formed, and the difference between the cavities lengths of the temperature sensor and the pressure sensor is controlled to decouple double-parameter measurement. Compared with the prior art, the sensor of the invention is small in structural size, resistant to high temperature, capable of measure the temperature and pressure at the same time, and free of cross sensitivity of the two parameters.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

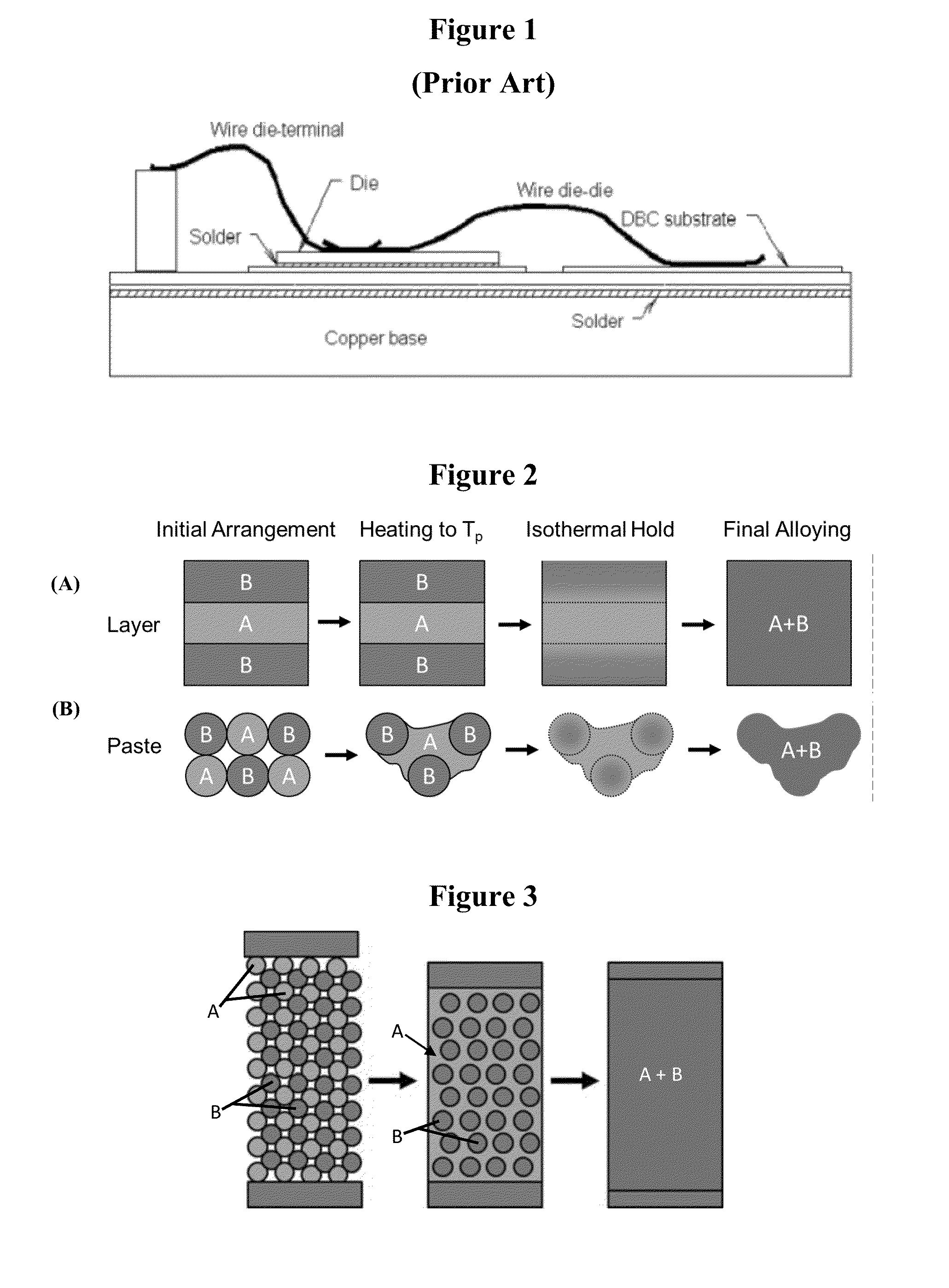

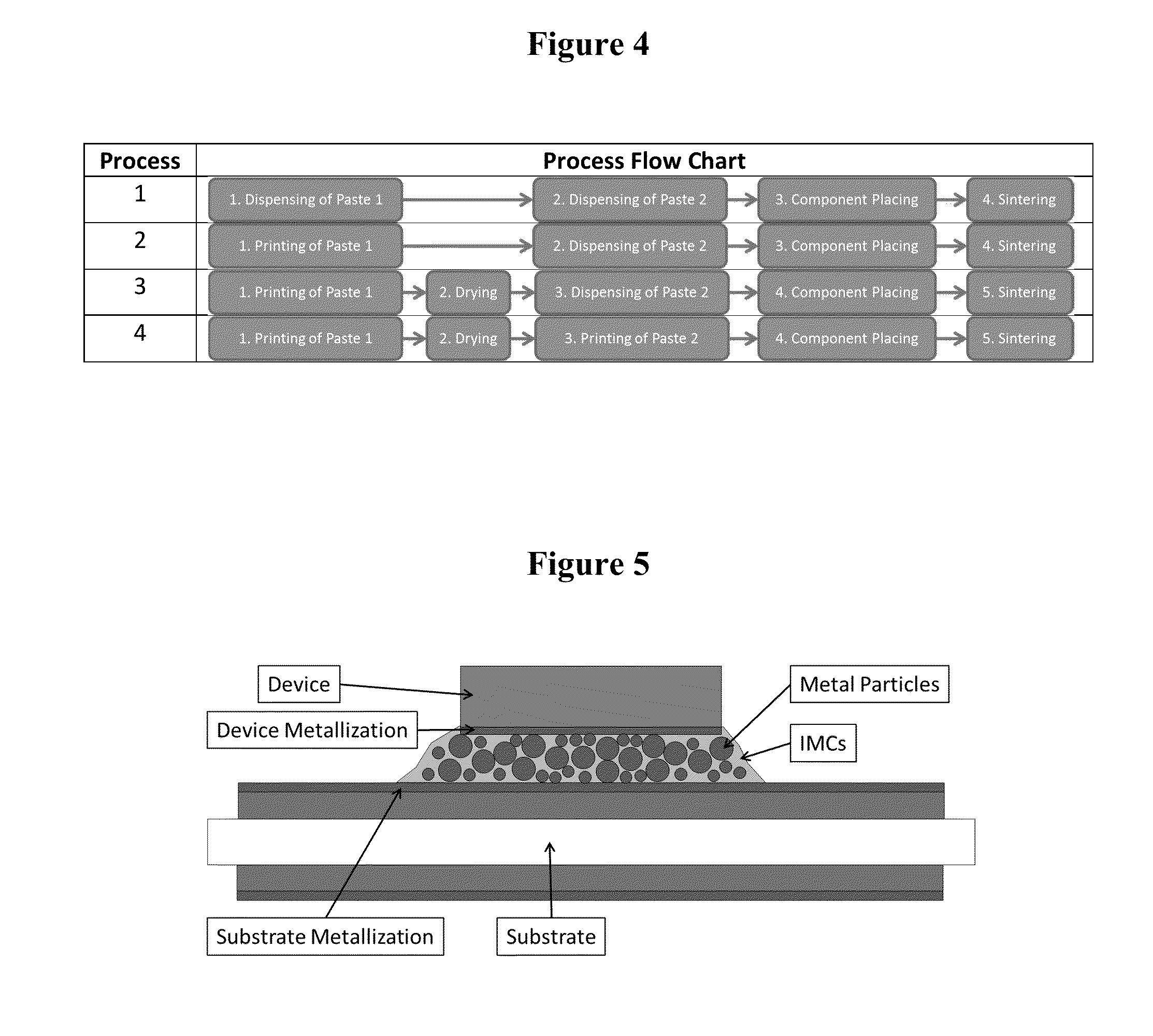

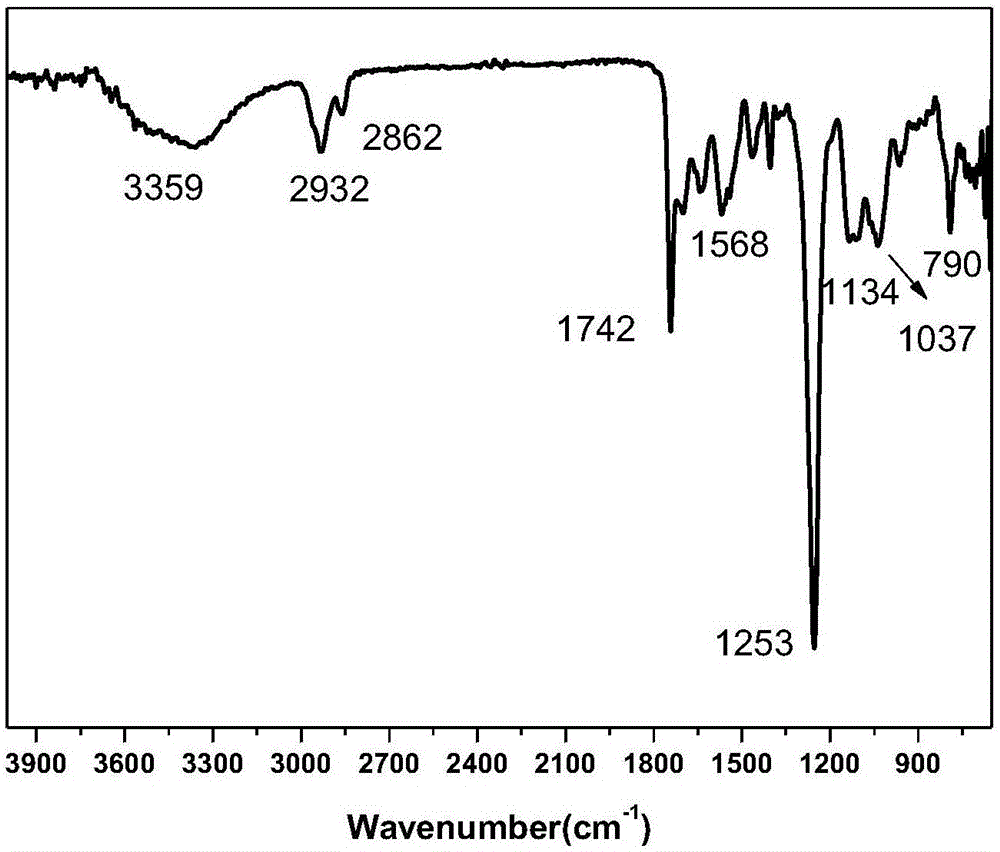

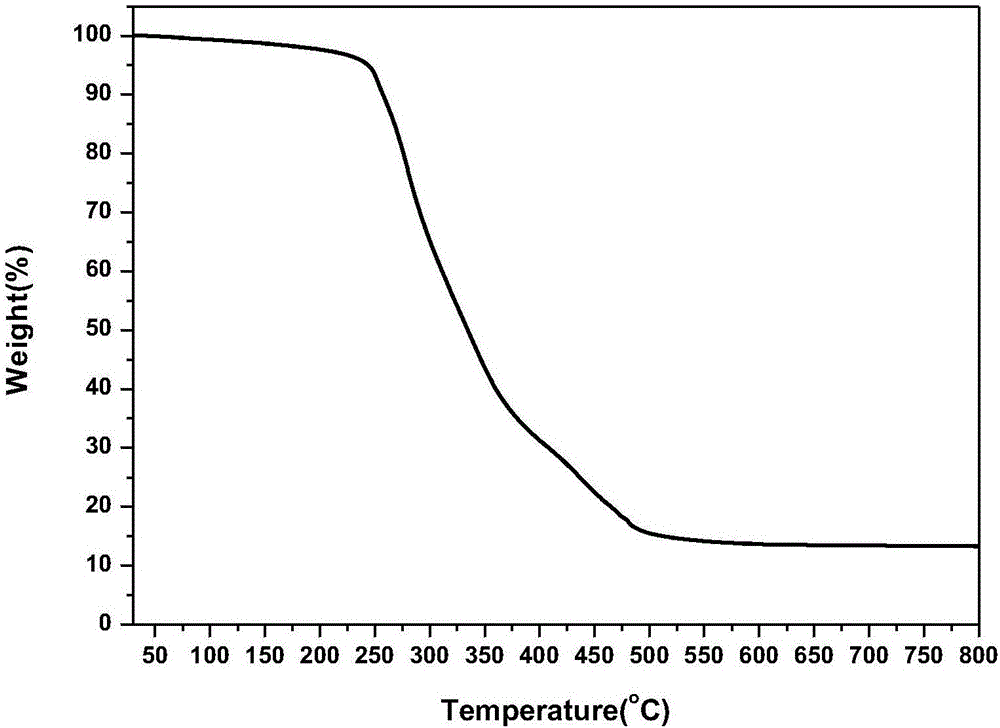

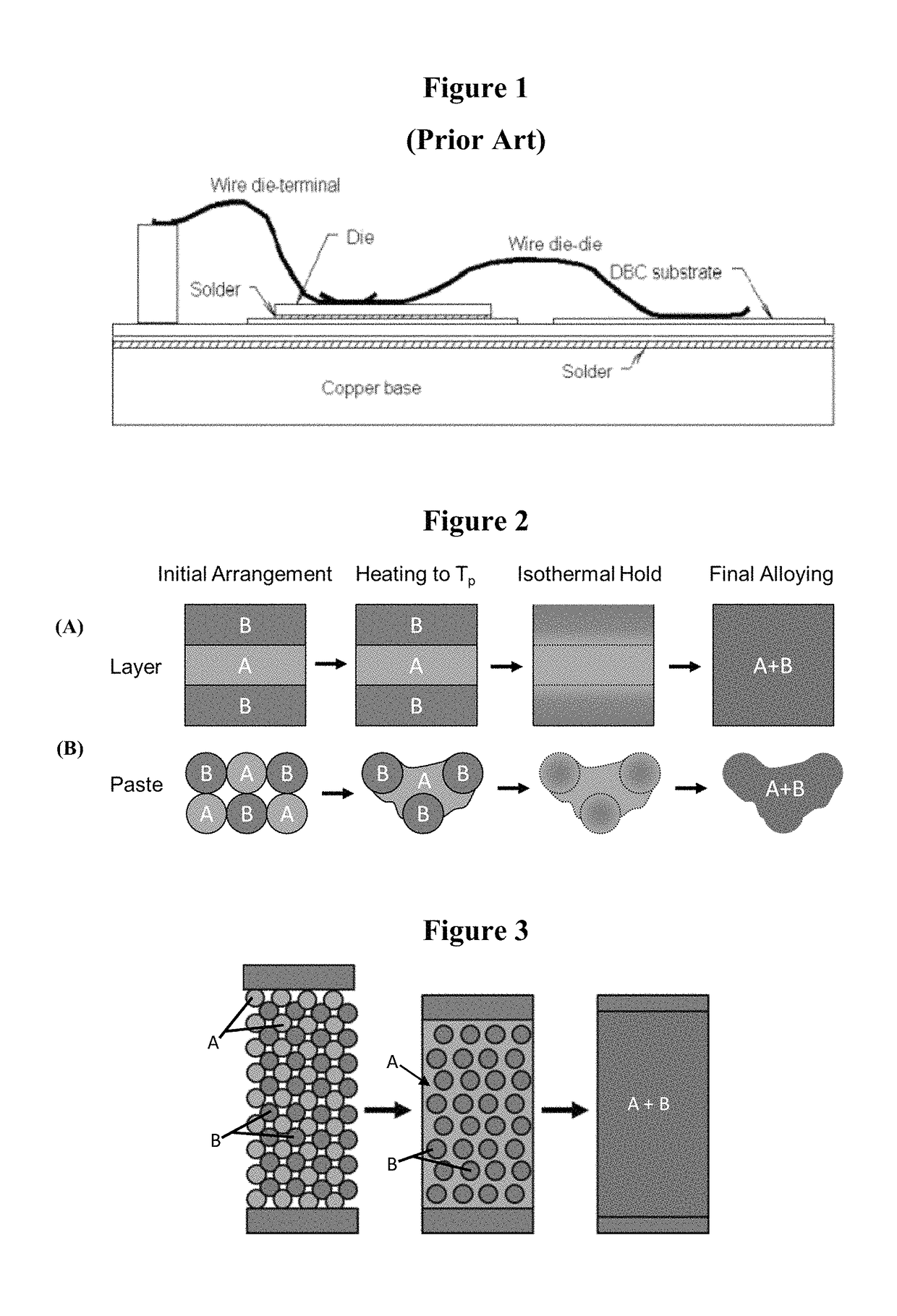

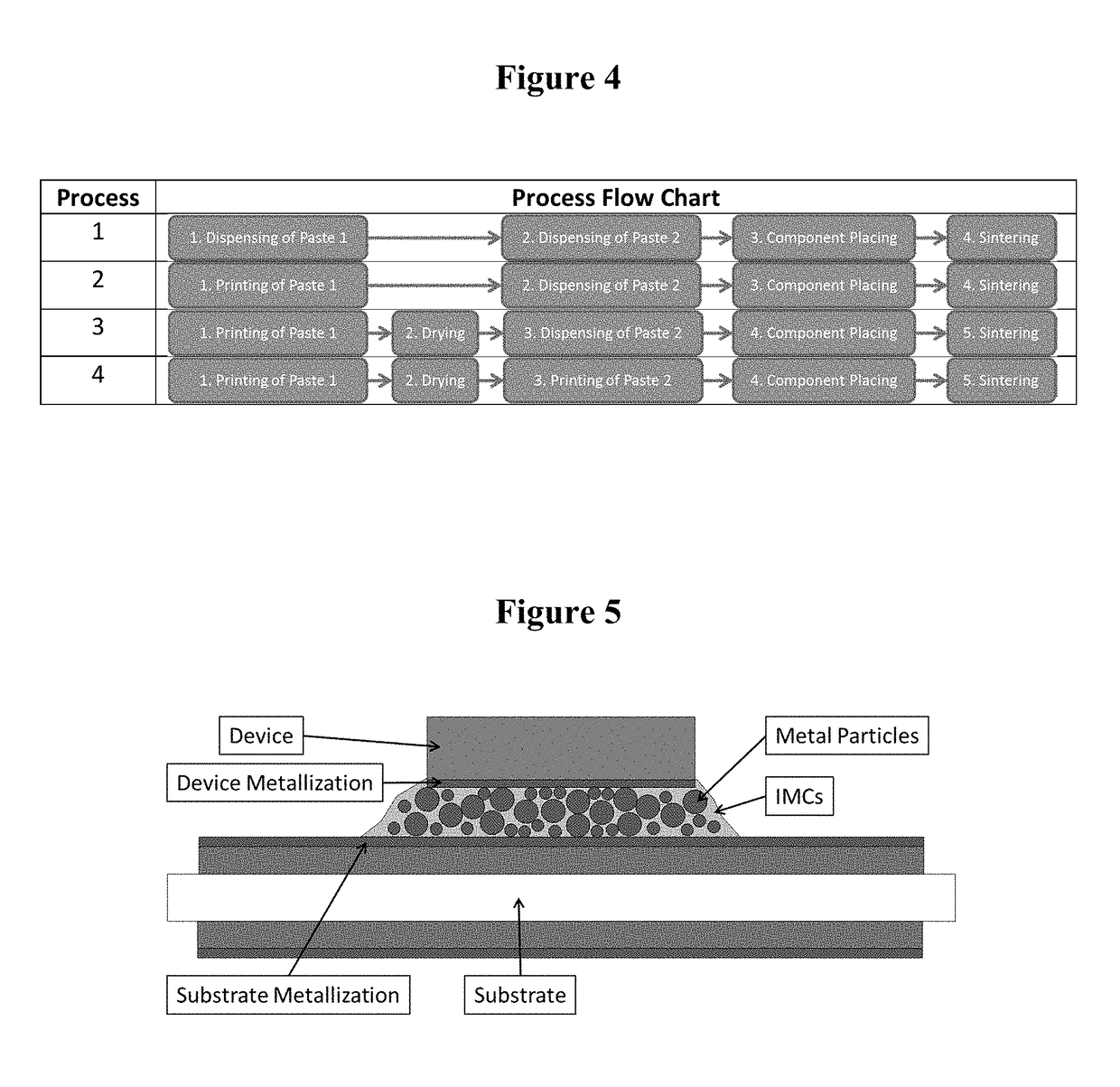

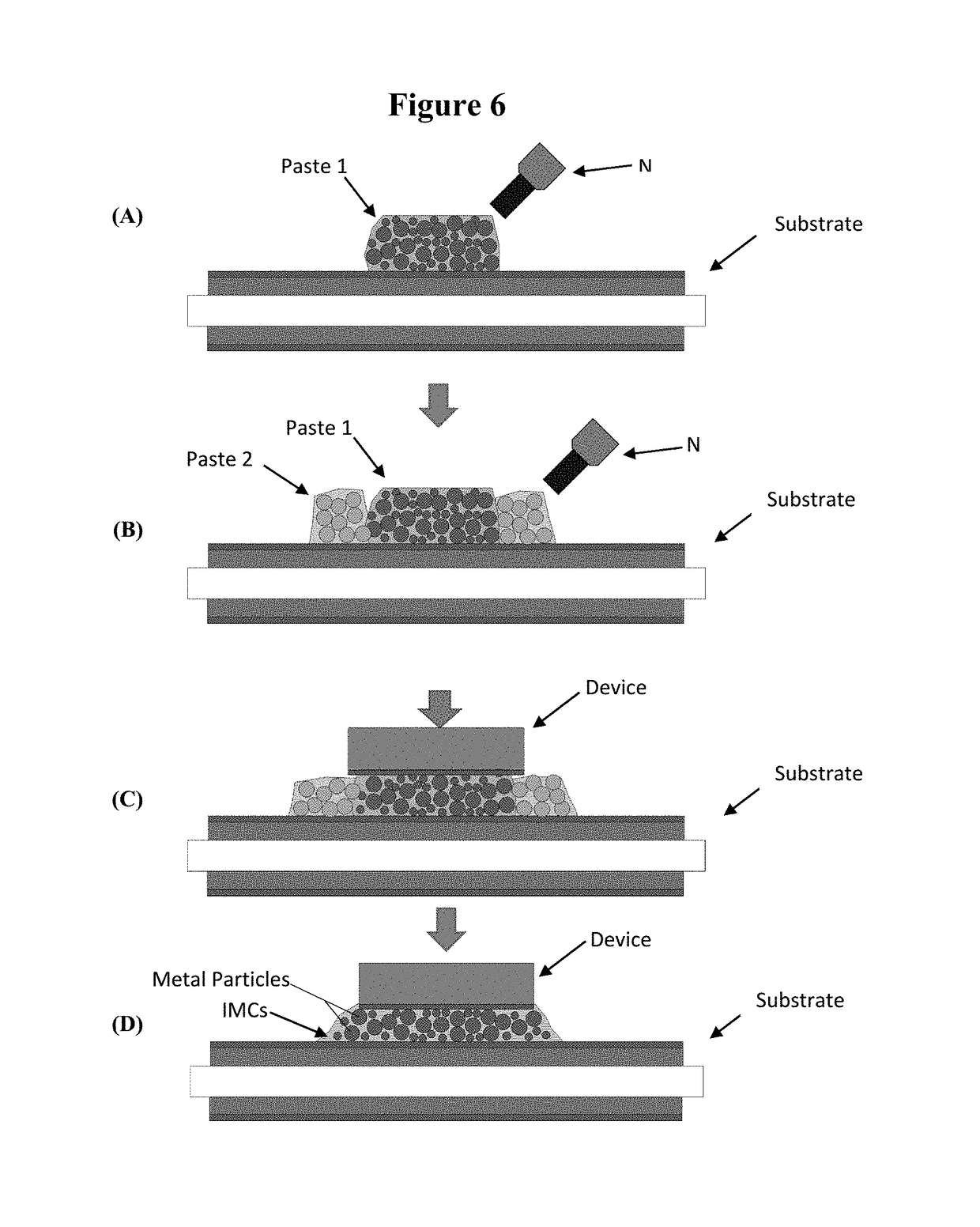

Transient Liquid Phase Sinter Pastes and Application and Processing Methods Relating Thereto

ActiveUS20160129530A1Improve microstructureIncreased durabilitySolid-state devicesWelding/cutting media/materialsElectronMaterials science

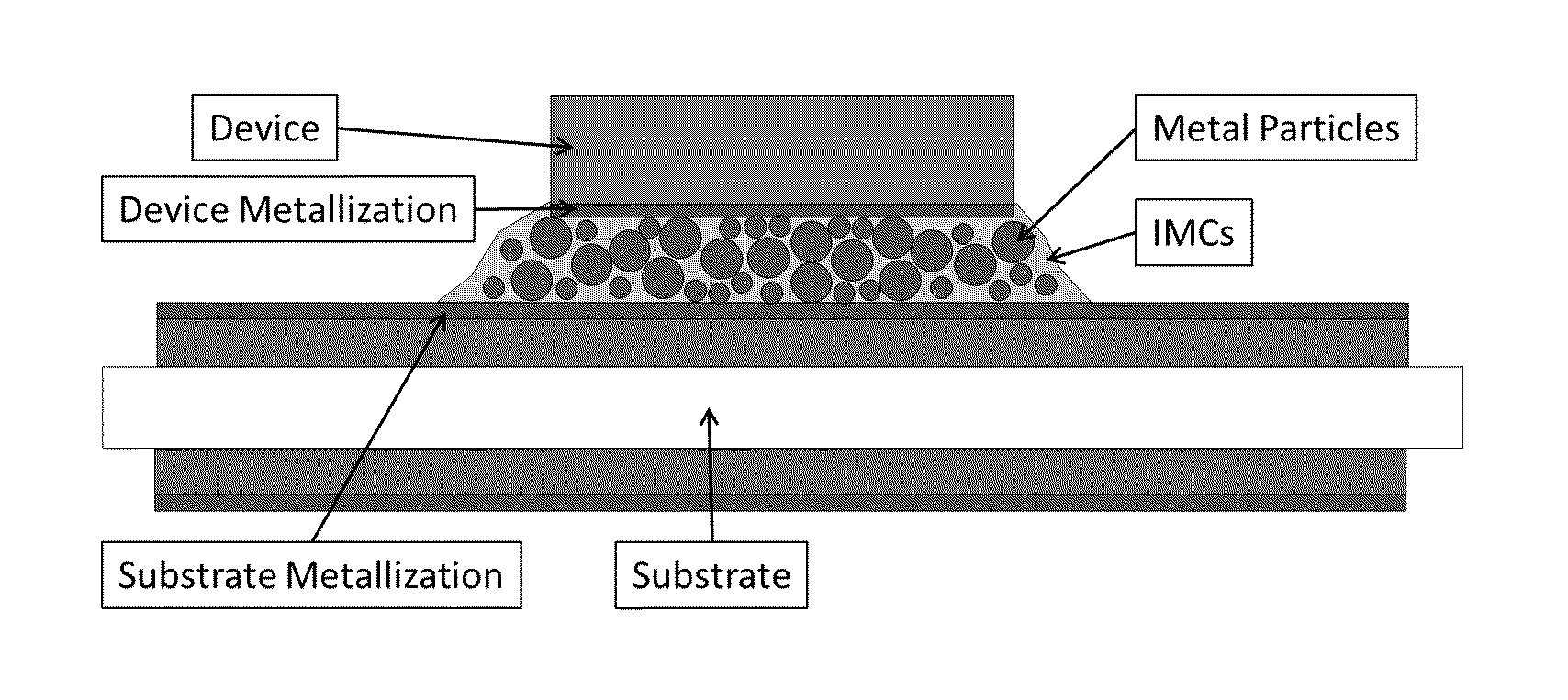

The present invention relates to transient liquid phase sinter pastes for electronic interconnects, and sinter paste application and processing methods.

Owner:UNIV OF MARYLAND

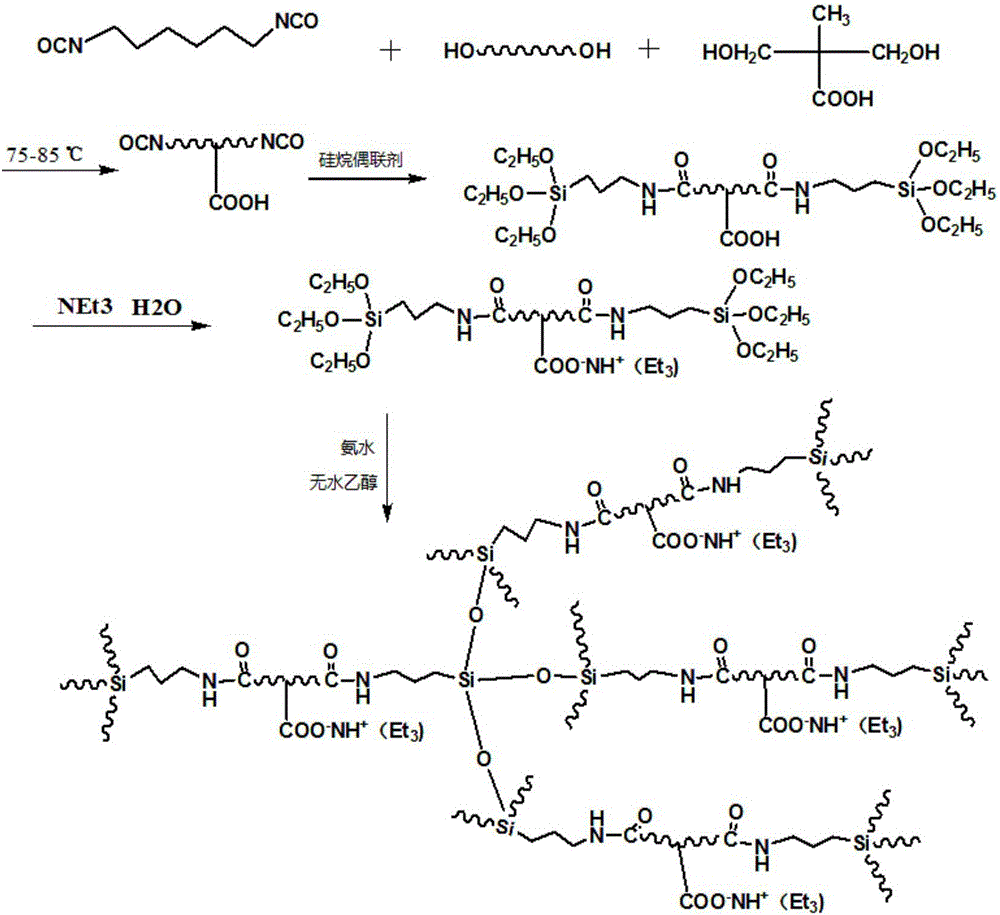

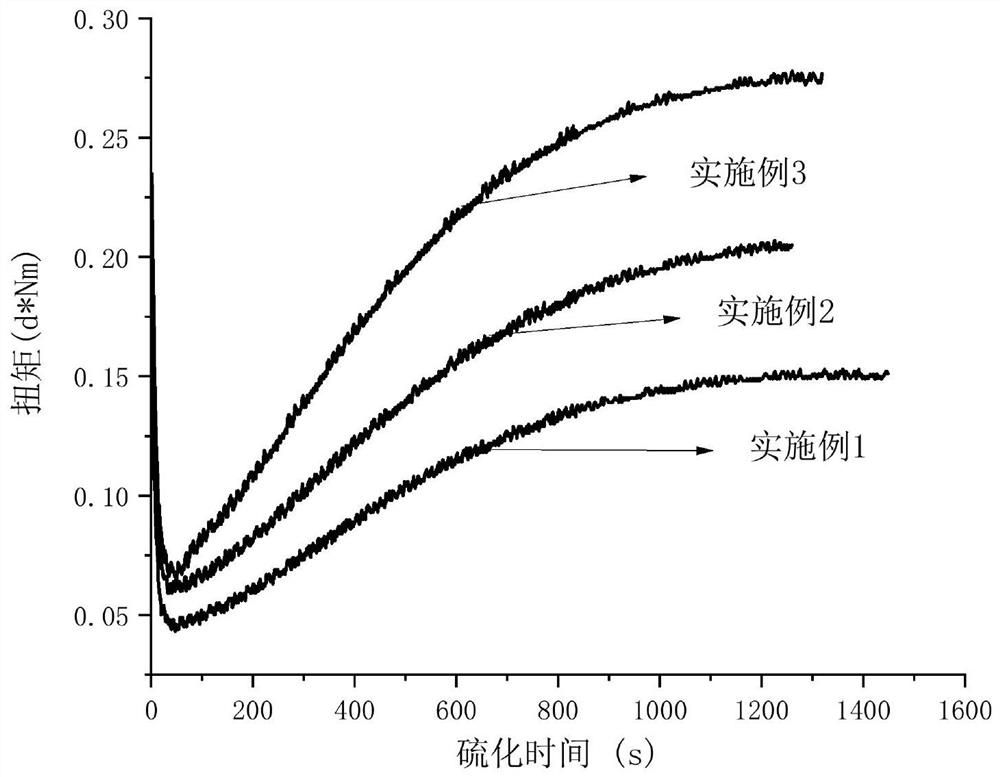

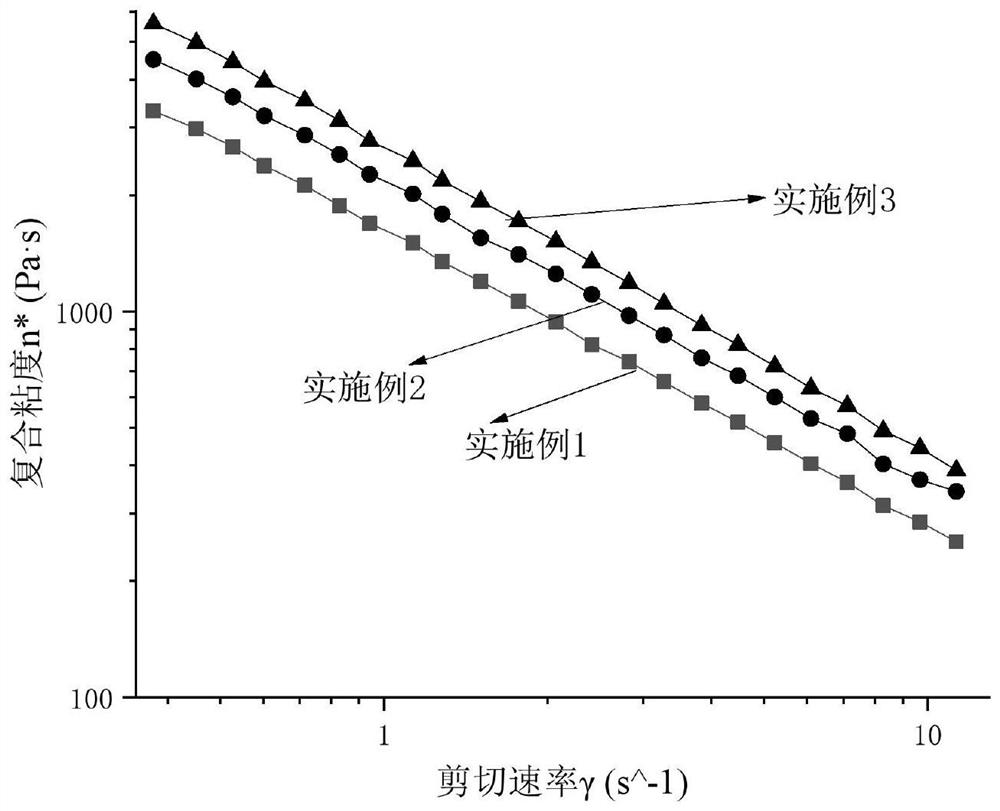

Silicon-modified hyperbranched polyurethane and preparation method thereof

The invention belongs to the field of polymer materials, and in particular relates to silicon-modified hyperbranched polyurethane and a preparation method thereof. The preparation method is as follows: first, isocyanato-terminated linear polyurethane is synthesized and then reacted with a silane coupling agent to obtain siloxane-terminated linear polyurethane, then triethylamine and deionized water are added to obtain aqueous polyurethane, finally, ammonia and absolute ethanol are added for crosslinking under alkaline conditions to obtain the silicon-modified hyperbranched polyurethane. Compared with the prior art, the method has the beneficial effects that the aqueous hyperbranched polyurethane using silicon atoms as a crosslinking center can be obtained by relying on silane coupling agent molecules to modify the polyurethane, hyperbranched reaction is performed in an aqueous phase, use of a volatile organic solvent is avoided, the use amount of the organic solvent is reduced, the method is environmentally-friendly and energy saving, by the introduction of organic silicon, the heat resistance of the polyurethane is greatly improved, the use temperature limit of the polyurethane is improved, and the expansion field of the polyurethane is facilitated.

Owner:HUBEI UNIV

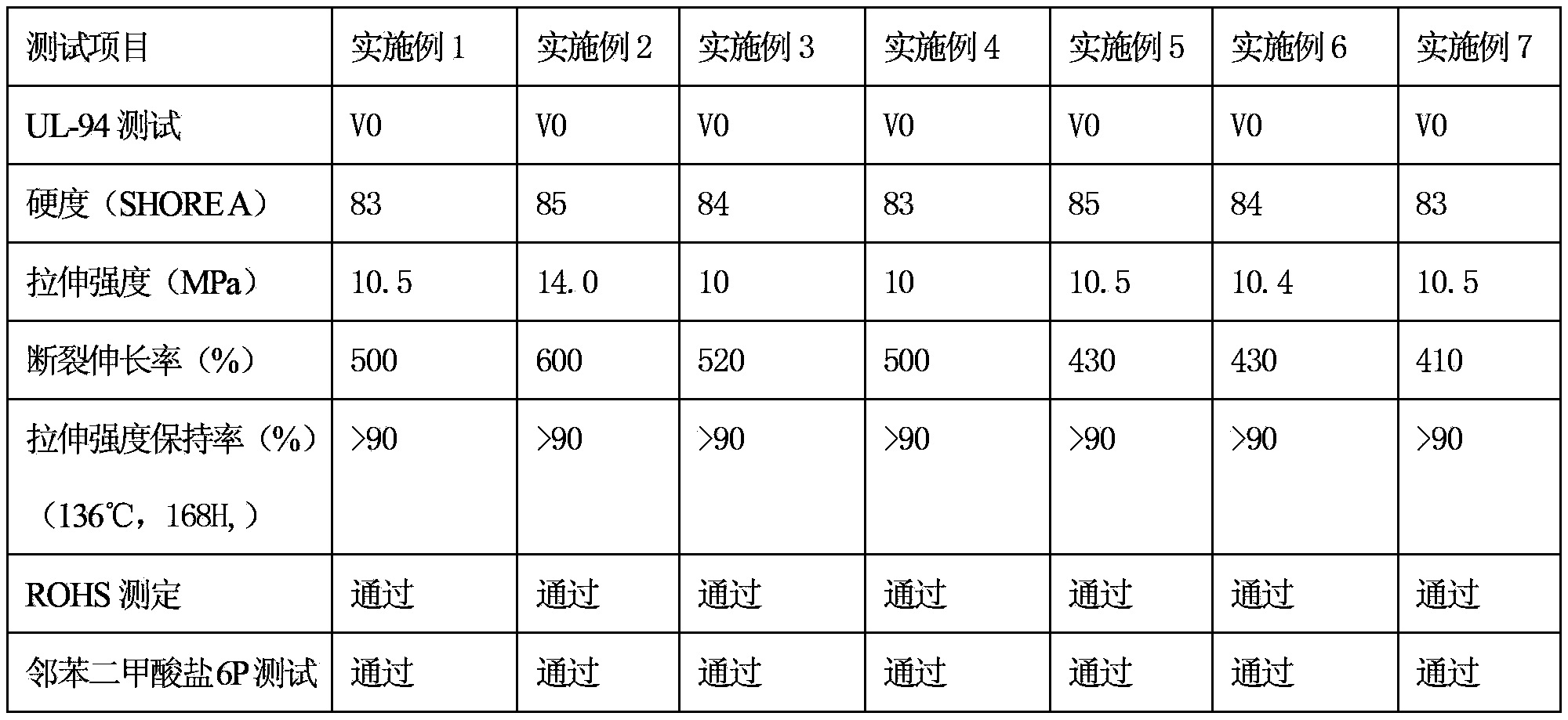

Weather-proof environment-friendly flame-retardant polymer material for flexible cable and preparation method thereof

InactiveCN104059321AWon't releaseEasy to processInsulated cablesInsulated conductorsTetrabromobisphenol AAntimony trioxide

The invention discloses a weather-proof environment-friendly flame-retardant polymer material for a flexible cable and a preparation method thereof. The polymer material comprises the following components by weight: 100 parts of a component A, 20 to 200 parts of a component B and 50 to 130 parts of a component C, wherein the component A is TPE, the component B is TPV, the component C is a fire retardant and comprises C1 and C2, C1 is one selected from the group consisting of decabromodiphenylethane, 1,2-bis(tribromophenoxy)ethane, tetrabromobisphenol A, tetrabromo-benzene anhydride, octabromo-ether, bis(tetrabromo-o-benzene-dimethyl ether imide)ethane and hexabromocyclododecane and has a particle size in a range of 10 to 30 mu m, and C2 is one selected from the group consisting of antimony trioxide, zinc borate and zinc oxide. The polymer material provided by the invention has improved processing performance and tensile strength, high usage temperature and excellent weatherability, environmental protection performance and flame resistance and is especially applicable to outdoor usage in a severe environment.

Owner:SINOTEX INVESTMENT & DEV CO LTD

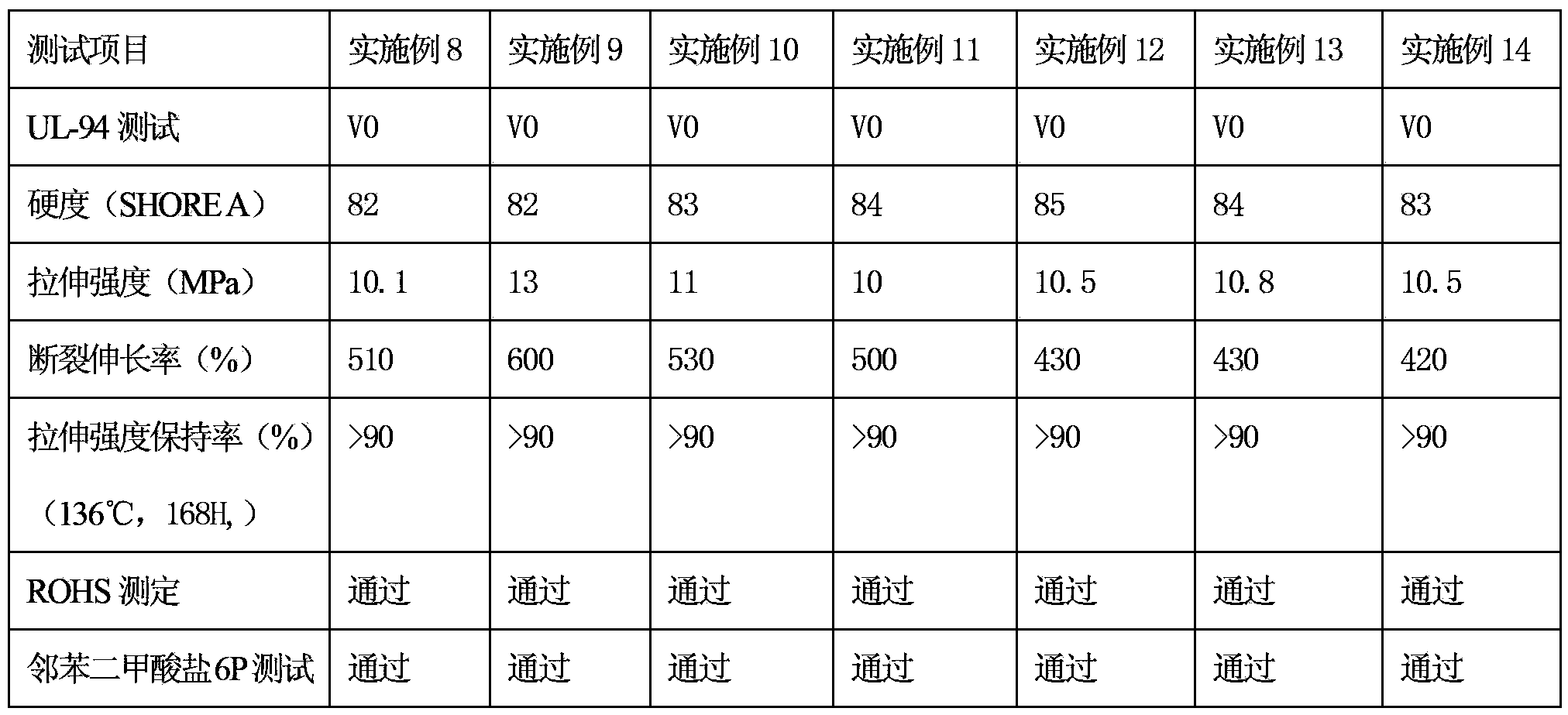

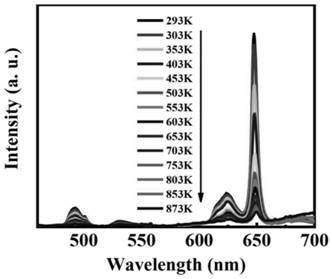

Fluorescence temperature measurement method suitable for ultra-wide temperature measurement range

PendingCN113390529AHigh luminous intensityHigh temperature limitThermometers using physical/chemical changesFluorescence spectraPhysical chemistry

The invention relates to the technical field of fluorescence temperature measurement, in particular to a fluorescence temperature measurement method suitable for an ultra-wide temperature measurement range. The fluorescence temperature measurement method comprises the following steps of: (a) establishing a standard curve of a fluorescence peak intensity ratio of Pr < 3 + >-based 3P1-to-3F2 transition and 3P0-to-3F2 transition of a fluorescence temperature sensing material along with temperature change; and (b) placing the fluorescence temperature sensing material in an environment of which the temperature is to be measured, measuring the fluorescence spectrum of the fluorescence temperature sensing material, calculating the fluorescence peak intensity ratio of Pr < 3 + >-based 3P1-to-3F2 transition and 3P0-to-3F2 transition, substituting the fluorescence peak intensity ratio into the standard curve, and calculating to obtain a temperature measurement value of the to-be-measured environment, the fluorescence temperature sensing material being Pr < 3 + >-doped oxide transparent ceramic, and the molar doping concentration of Pr < 3 + > being 0.1%-10%. According to the temperature measurement method, a higher temperature measurement limit and a wider temperature measurement range can be realized.

Owner:SONGSHAN LAKE MATERIALS LAB +1

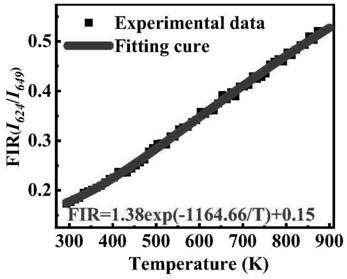

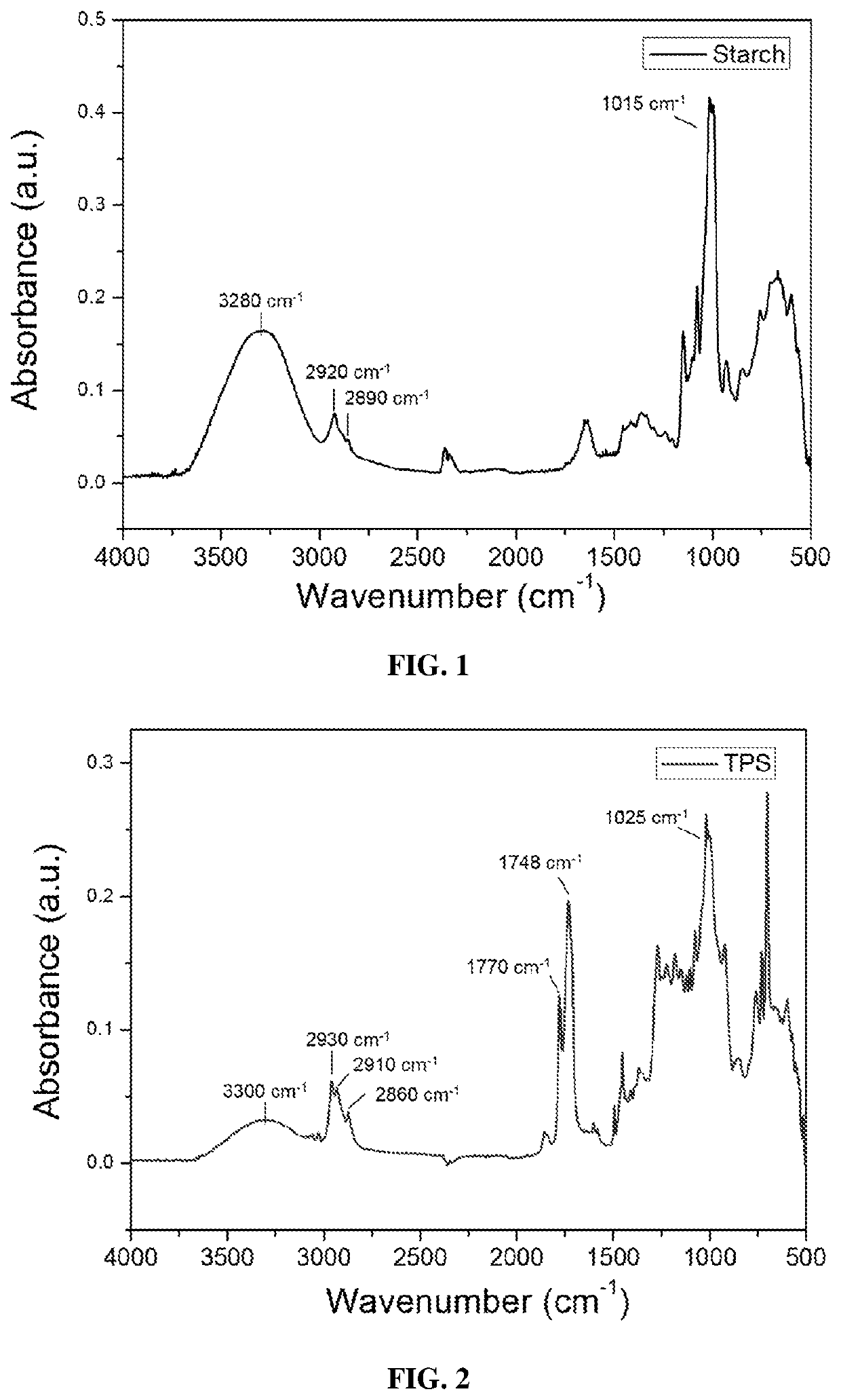

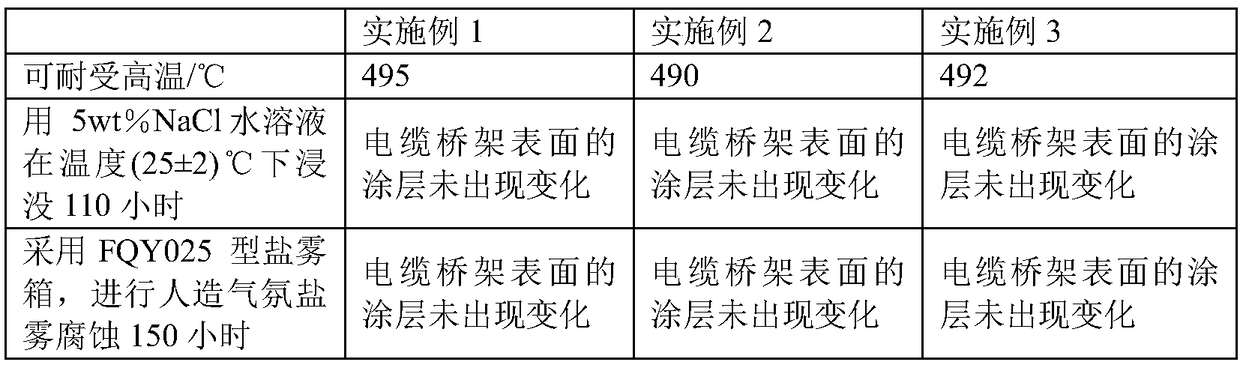

Hydrophobic thermoplastic starch composite and method for manufacturing the same

The present invention provides a hydrophobic thermoplastic starch and method for manufacturing the same, to be used as granules for making biodegradable composites. The hydrophobic thermoplastic Starch of the invention is in a granule type, has the melt flow index in the range of 0.2˜6 g / 10 min at 160° C. and has 60˜80 wt % of starch and the water content less than 9%.

Owner:GREEN WORLD BIOTECH MATERIALS CO LTD

Method for manufacturing high-temp PTC thermosensitive resistor

ActiveCN1624817AGood compatibilityIncrease the degree of cross-linkingPositive temperature coefficient thermistorsPhysical chemistryElectronic component

A manufacturing method of high temperature macromolecule PTC thermal resistor relates to manufacturing method of the electronic component whose material mainly is crystalline hypo-crystalline high polymer and its mixture. A manufacturing method of high temperature PTC thermal resistor is that after the chip is forming, the chip is set in the heating equipment whose high polymer melting point is more than from five centigrade degree to thirty centigrade degree for from five minutes to fifty minutes, then slowly cooled to room temperature, later irradiated, and irradiation dosage range is 0.2- 0.7 times of which is from 20KGy to 5000KGy; after the irradiation , the chip is again set in the heating equipment whose high polymer melting point is more than from five centigrade degree to thirty centigrade degree for from five minutes to fifty minutes, then slowly cooled to room temperature, do the second irradiation, and the irradiation dosage range is 0.4- 0.8 times which is from 20KGy to 5000KGy.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

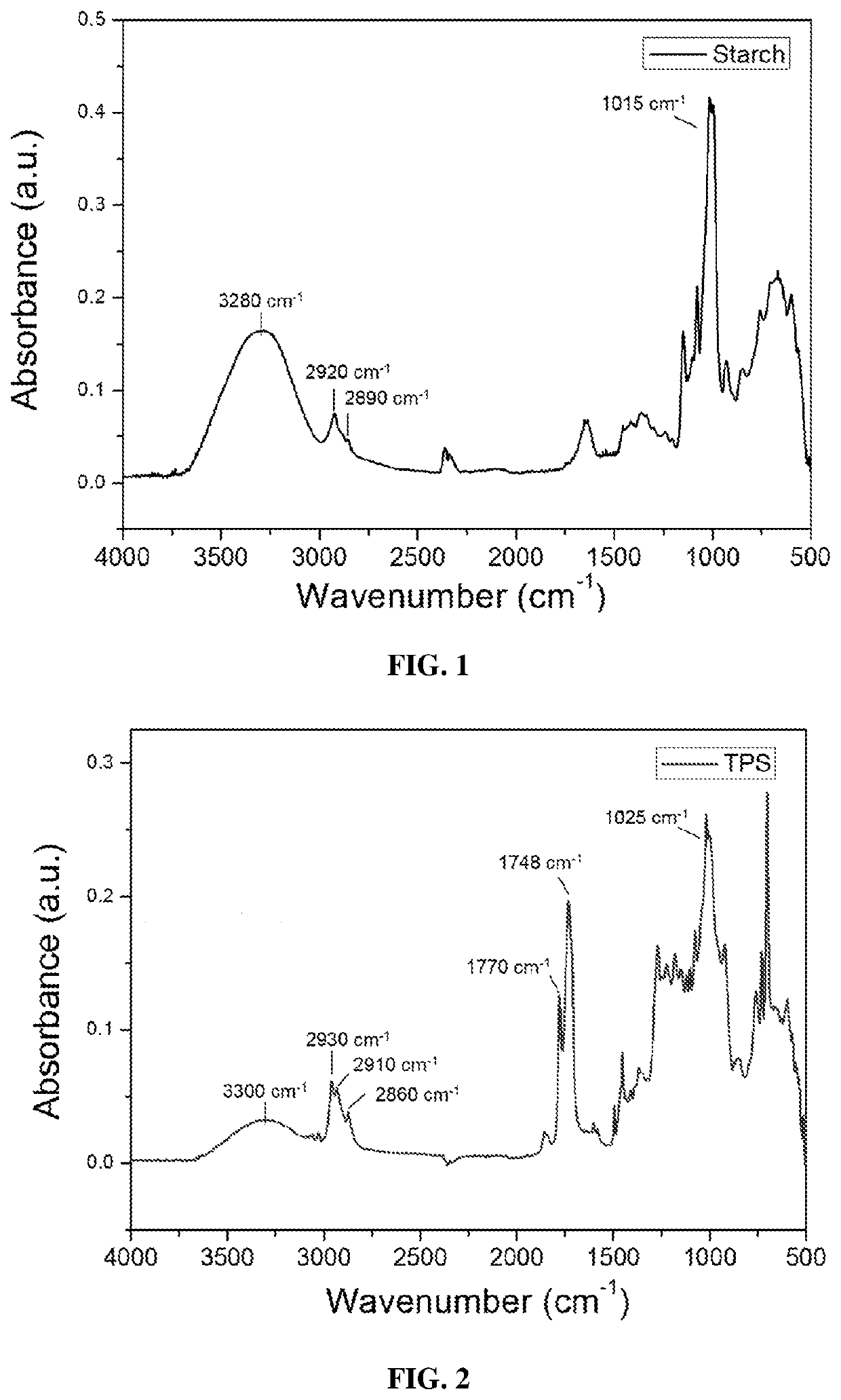

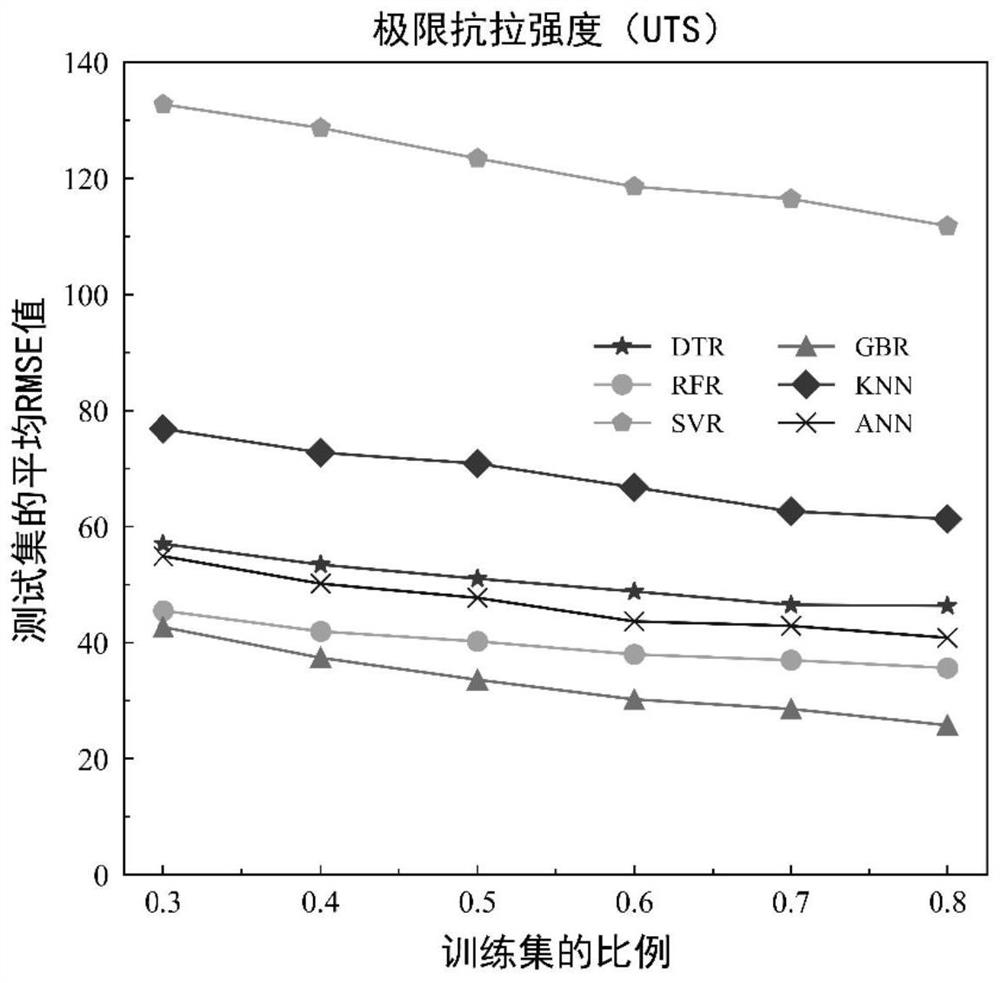

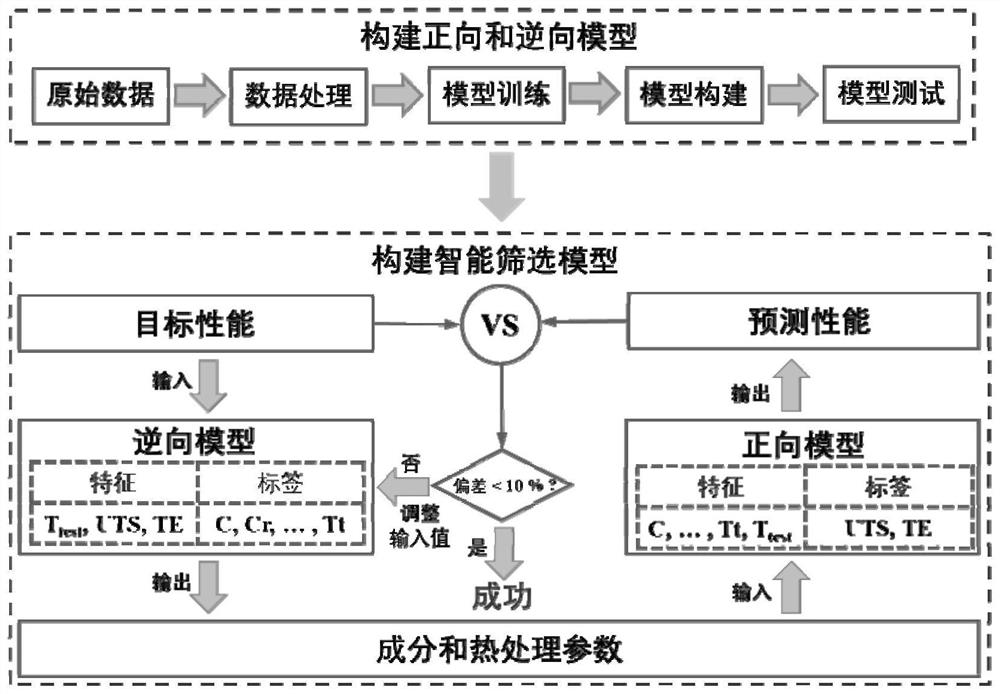

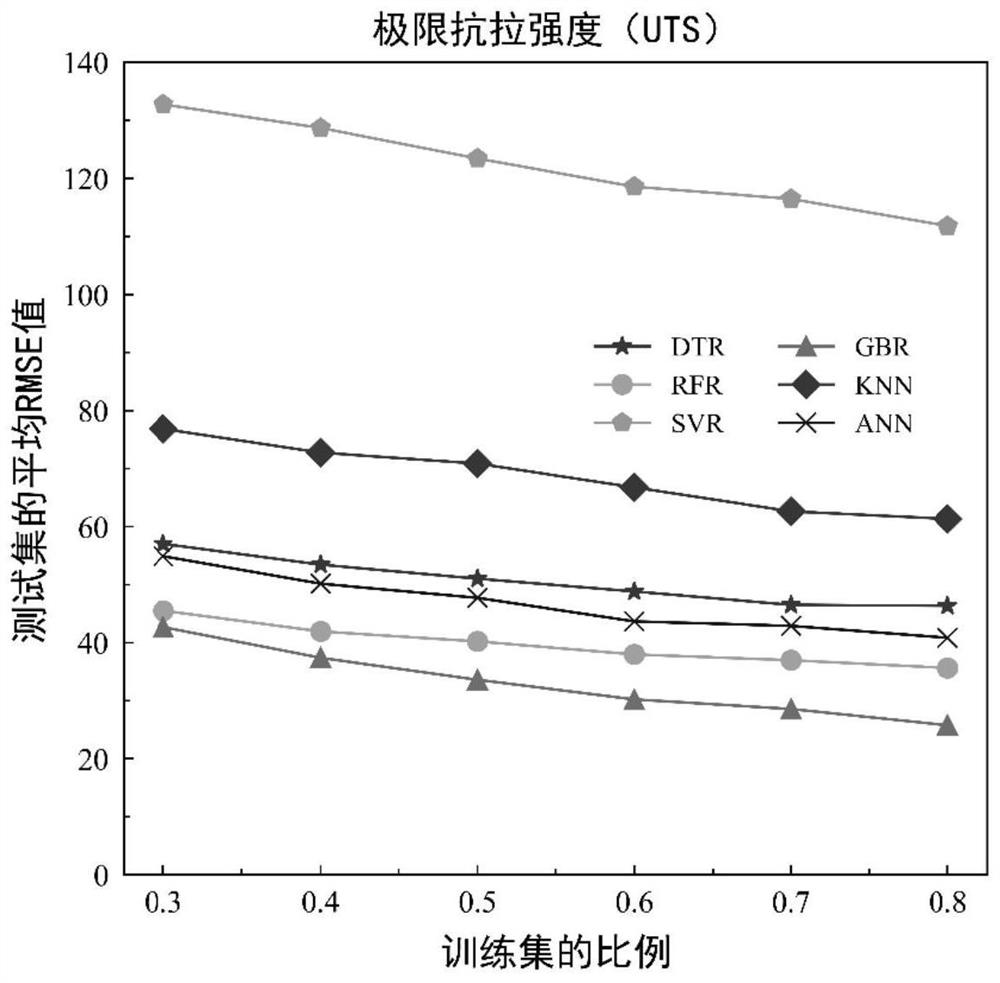

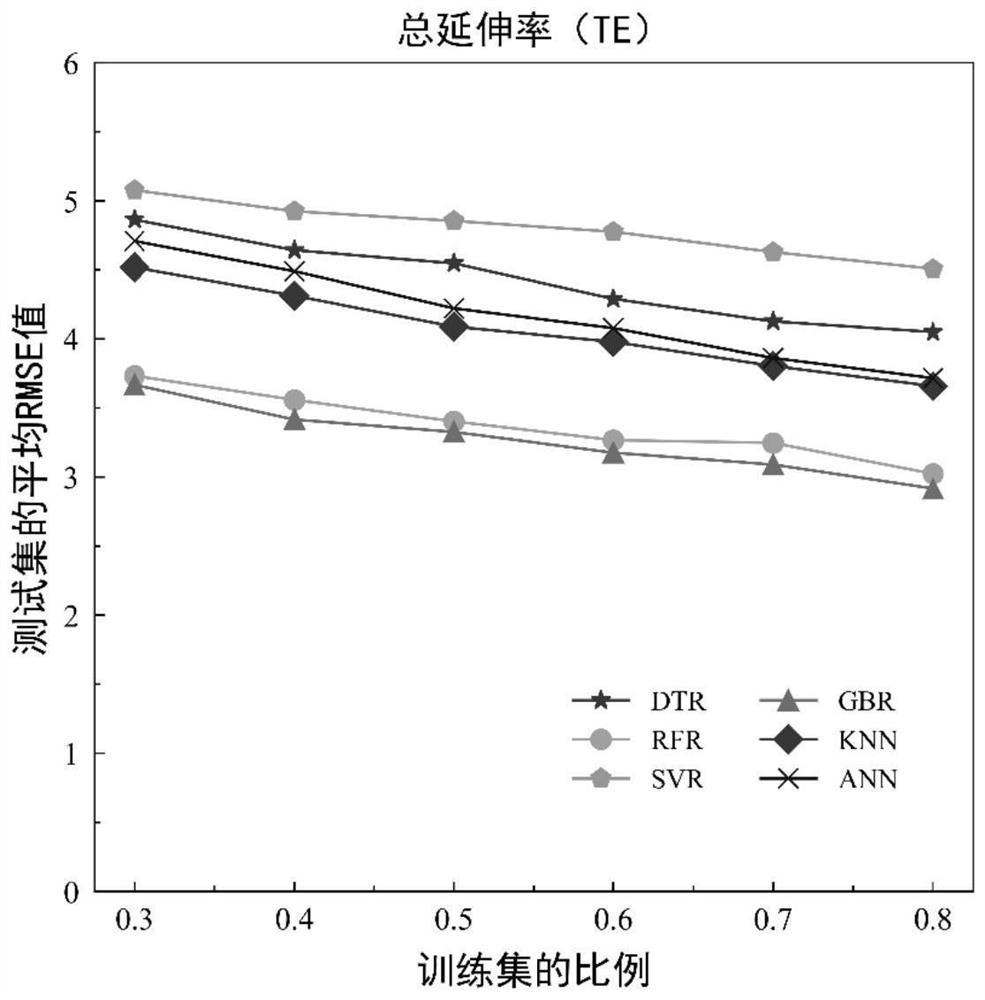

High-toughness high-temperature-resistant RAFM steel and design method thereof based on machine learning

ActiveCN113073267AHigh temperature limitEasy to stretchChemical property predictionEnsemble learningTemperingChemical composition

The invention provides high-toughness high-temperature-resistant RAFM steel which comprises the following chemical components: 0.12 to 0.16 percent of C, 9.5 to 10.5 percent of Cr, 1.6 to 1.8 percent of W, 0.48 to 0.52 percent of Si, 0.6 to 0.7 percent of Mn, 0.23 to 0.27 percent of V, 0.10 to 0.26 percent of Ta, 0.001 to 0.005 percent of Zr and the like. The heat treatment parameters are as follows: the normalizing temperature is 1010-1050 DEG C, the normalizing time is 20-55 minutes, the tempering temperature is 600-720 DEG C, and the tempering time is 50-90 minutes. The invention further provides a machine learning-based design method of the steel. The RAFM steel disclosed by the invention has a relatively high use temperature upper limit and also has a relatively good tensile property at a high temperature; and meanwhile, the machine learning method constructed by the invention is high in generalization ability, and reasonable components and heat treatment parameters can be quickly and efficiently designed.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

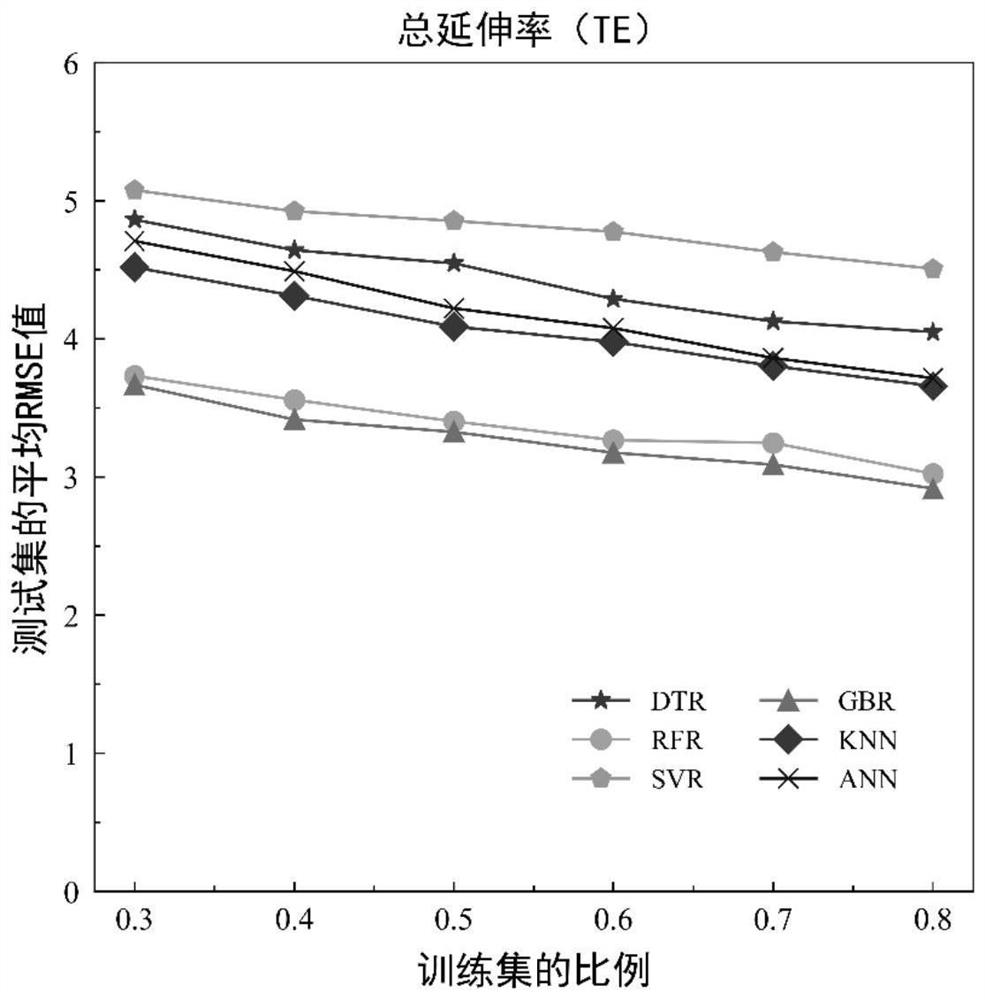

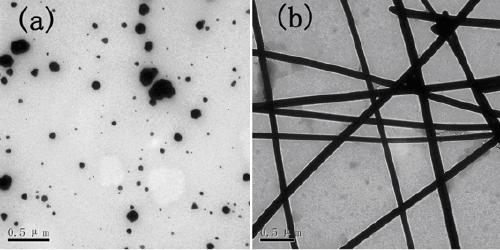

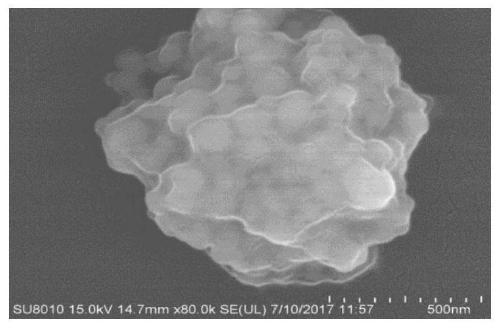

Preparing method of silver nanoparticle mixed filler modified silicone rubber conductive composite material

The invention relates to the technical field of nanocomposite material. A preparing method of a silver nanoparticle mixed filler modified silicone rubber conductive composite material is provided, and aims to solve the problems that silver nanoparticles prepared through a regular method have high surface energy which is prone to agglomeration, compatibility between the silver nanoparticles and a silicone rubber basal body is poor, and thus the silver nanoparticles is so hard to be evenly dispersed in the basal body that comprehensive performance of the composite material is affected. The preparing method comprises the steps of preparing silver nanoparticles by adopting a chemical reduction method and conducting surface modification by using a silane coupling agent so as to make the silver nanoparticles evenly disperse in an organic solvent, and with a combination of a silver nanowire, dispersing the silver nanoparticles and mixed filler of the silver nanoparticles into a silicone rubber basal body by adopting a solution blended process so as to prepare an elastic silicone rubber composite material with excellent electrical conductivity. The composite material not only has the advantages of being stable in resistance time property, high in temperature limit, controllable in resistance temperature coefficient and the like, but also has high elasticity of a rubber material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

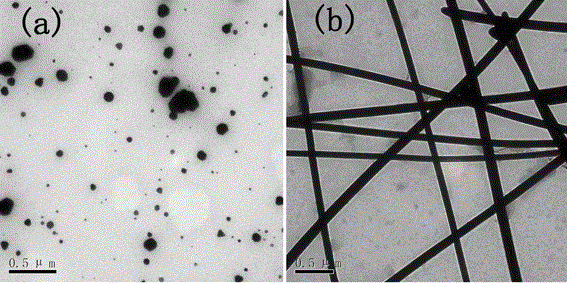

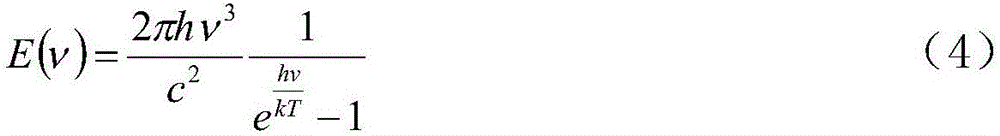

Method and device for measuring high temperature through micro spectrometer

The invention discloses a method and device for measuring high temperature through a micro spectrometer. According to the method, the micro spectrometer is used for measuring thermal radiation energy intensity of an object in the wave band range of 200-1000 nm, certain conversion and fitting are conducted on a thermal radiation energy intensity curve, and the temperature of the measured object can be calculated. The measurement temperature range of the method is 1000-10000 K. The method has the advantages of being high in temperature measurement upper limit, high in speed, high in measuring precision, good in stability and not limited by material surface appearance, emissivity and other factors. The device mainly comprises an optical system, a CCD spectrometer and a data processing unit, and has the advantages of being simple in structure, low in cost, small in size, low in weight, convenient to carry and the like.

Owner:HANGZHOU DIANZI UNIV

Micro-crosslinking self-repairing sealant as well as preparation method and application thereof

ActiveCN114456745AStrong stickinessIncrease stickinessNon-macromolecular adhesive additivesMacromolecular adhesive additivesForeign matterPolymer science

According to the micro-crosslinking tire self-repairing sealant and the preparation method thereof, the sealant has extremely low modulus and extremely high self-adhesion and has certain elasticity, and when a tire is punctured by foreign matter, the sealant can immerse into gaps under the action of tire pressure to bond cracks, so that the tire pressure is guaranteed. The sealant main body is preferably selected from butyl rubber, brominated butyl rubber and medium-molecular-weight polyisobutene, the softening agent is preferably selected from low-molecular-weight polyisobutene, the low-molecular-weight polyisobutene has excellent compatibility with the medium-molecular-weight polyisobutene and the butyl rubber and is not easy to migrate out, and the sealant is endowed with extremely strong viscosity while the modulus of the sealant is reduced.

Owner:BEIJING UNIV OF CHEM TECH

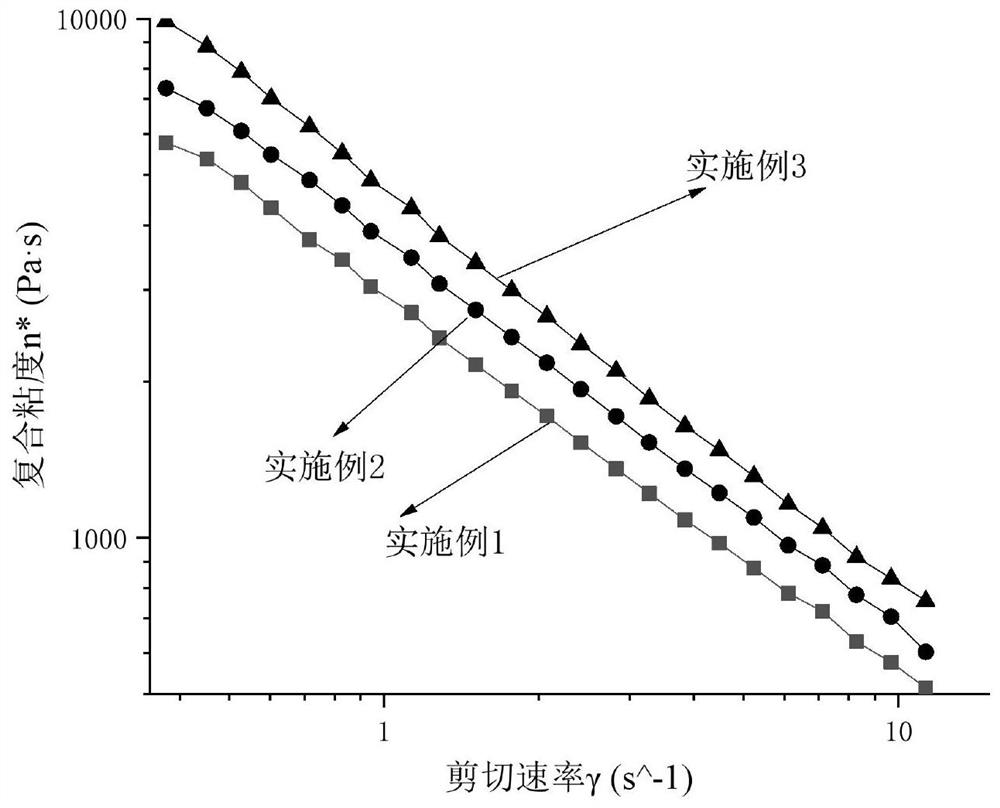

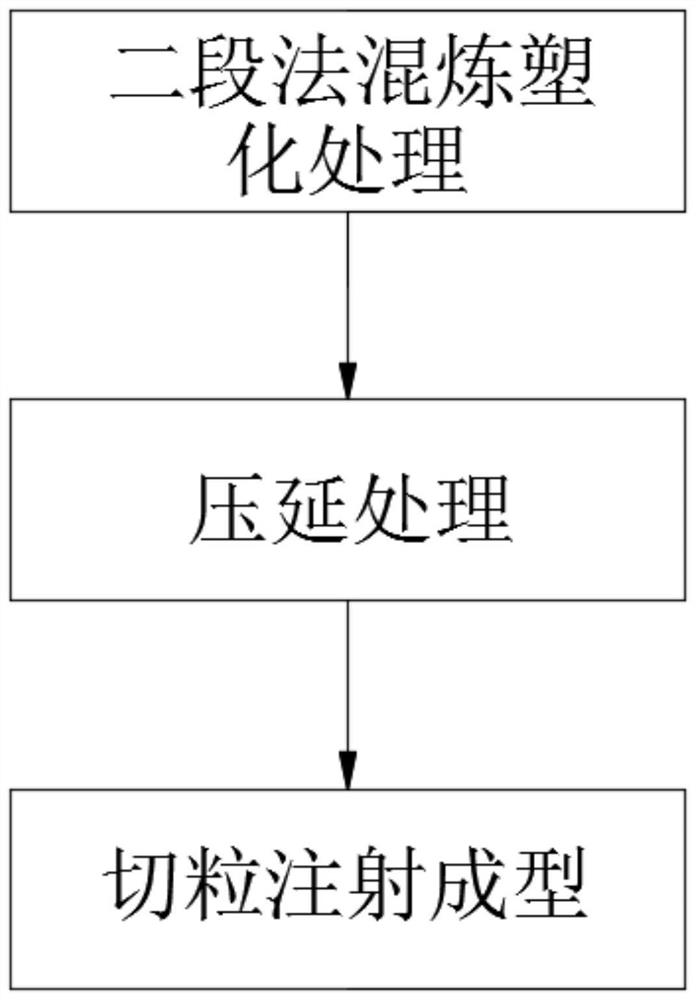

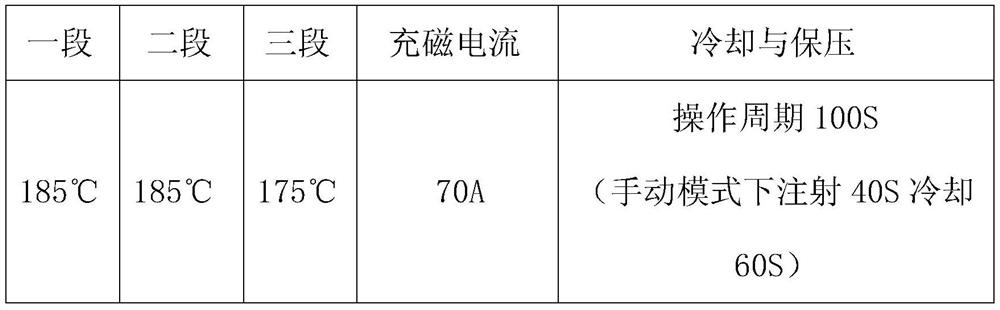

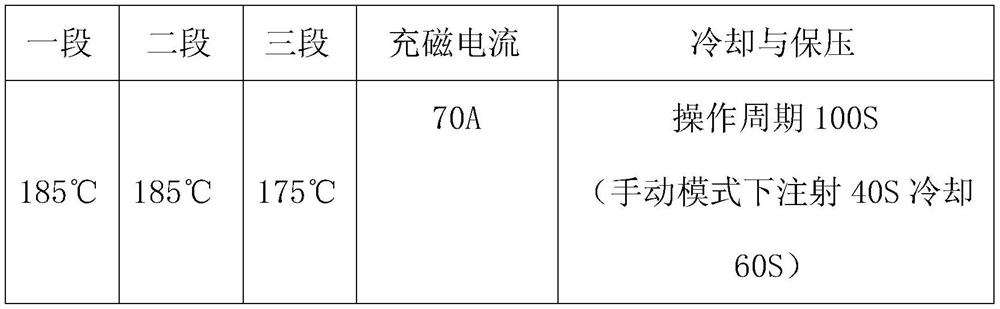

High-fluidity samarium-iron-nitrogen flexible bonded permanent magnet for injection molding and preparation method thereof

ActiveCN111667967AHigh temperature limitHave the conditions to earn foreign exchange through exportInorganic material magnetismInductances/transformers/magnets manufacturePlasticizerSamarium

The invention discloses a high-fluidity samarium-iron-nitrogen flexible bonded permanent magnet for injection molding and a preparation method thereof. The high-fluidity samarium-iron-nitrogen flexible bonded permanent magnet comprises the following components: 90-94 parts by weight of samarium-iron-nitrogen magnetic powder, 3-5 parts by weight of a rubber binder, 2-3 parts by weight of a plasticizer, 0.5-1 part by weight of a heat stabilizer and 0.5-1 part by weight of a lubricant. According to the invention, the samarium-iron-nitrogen flexible bonded permanent magnet meets the latest ROHS2.0standard certification standard, and has export and foreign exchange earning conditions; the injection-molded flexible samarium-iron-nitrogen magnet fills up the blank of a high-fluidity area of theinjection-molded flexible samarium-iron-nitrogen magnet, improves the upper limit of the use temperature of the current flexible bonded magnet from 80 DEG C to 120 DEG C, widens the use field, and improves the stability and reliability thereof.

Owner:BGRIMM TECH CO LTD

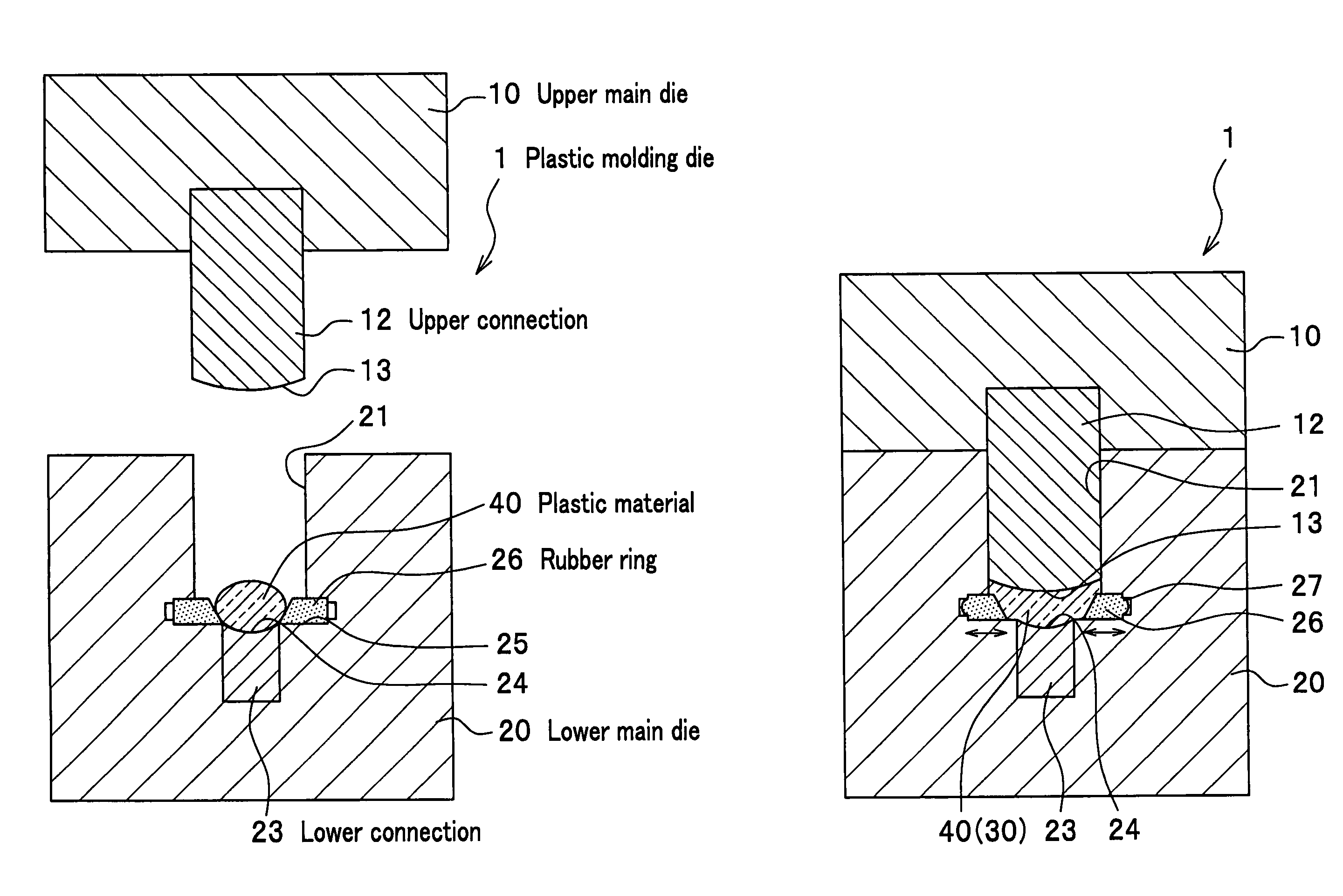

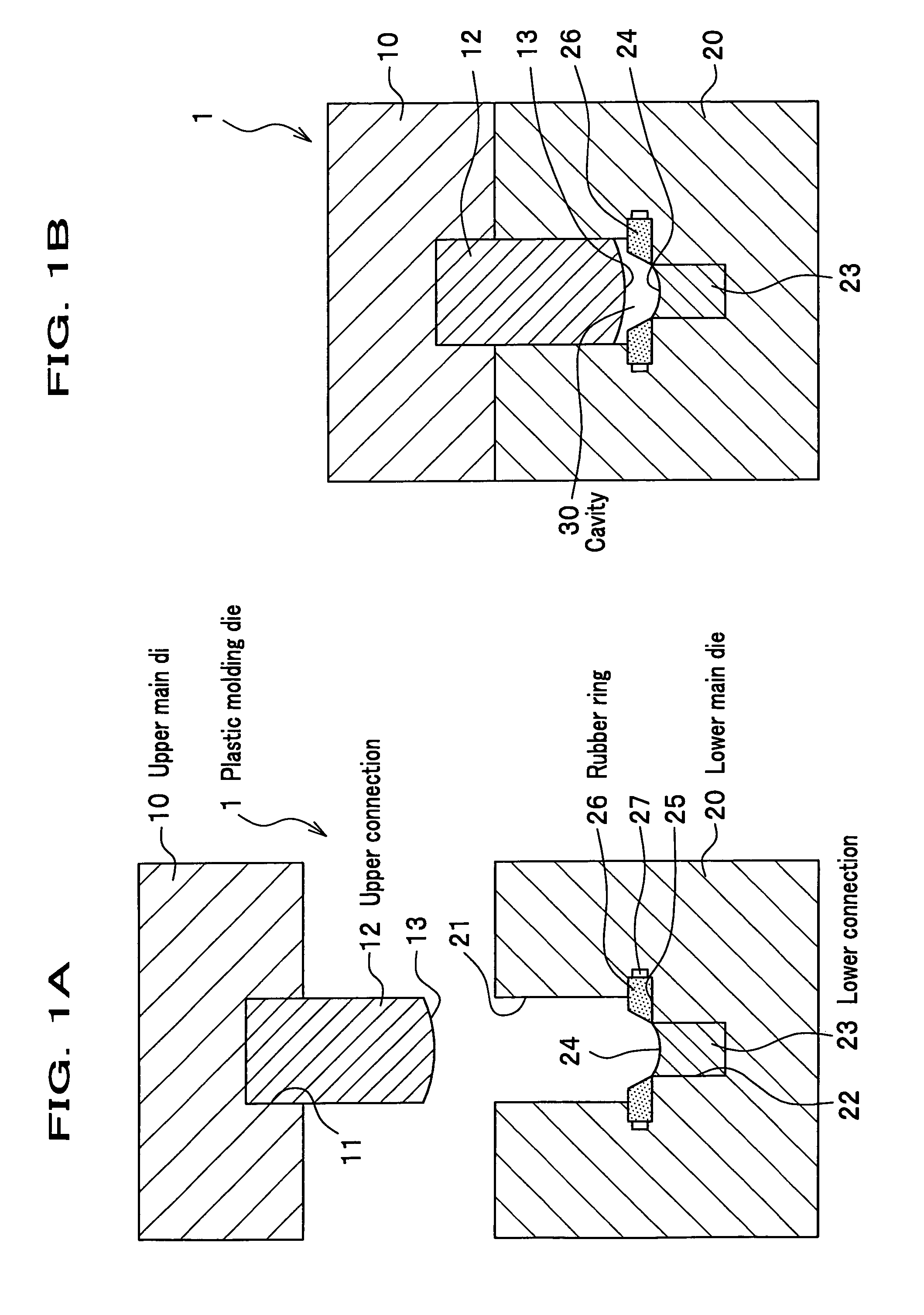

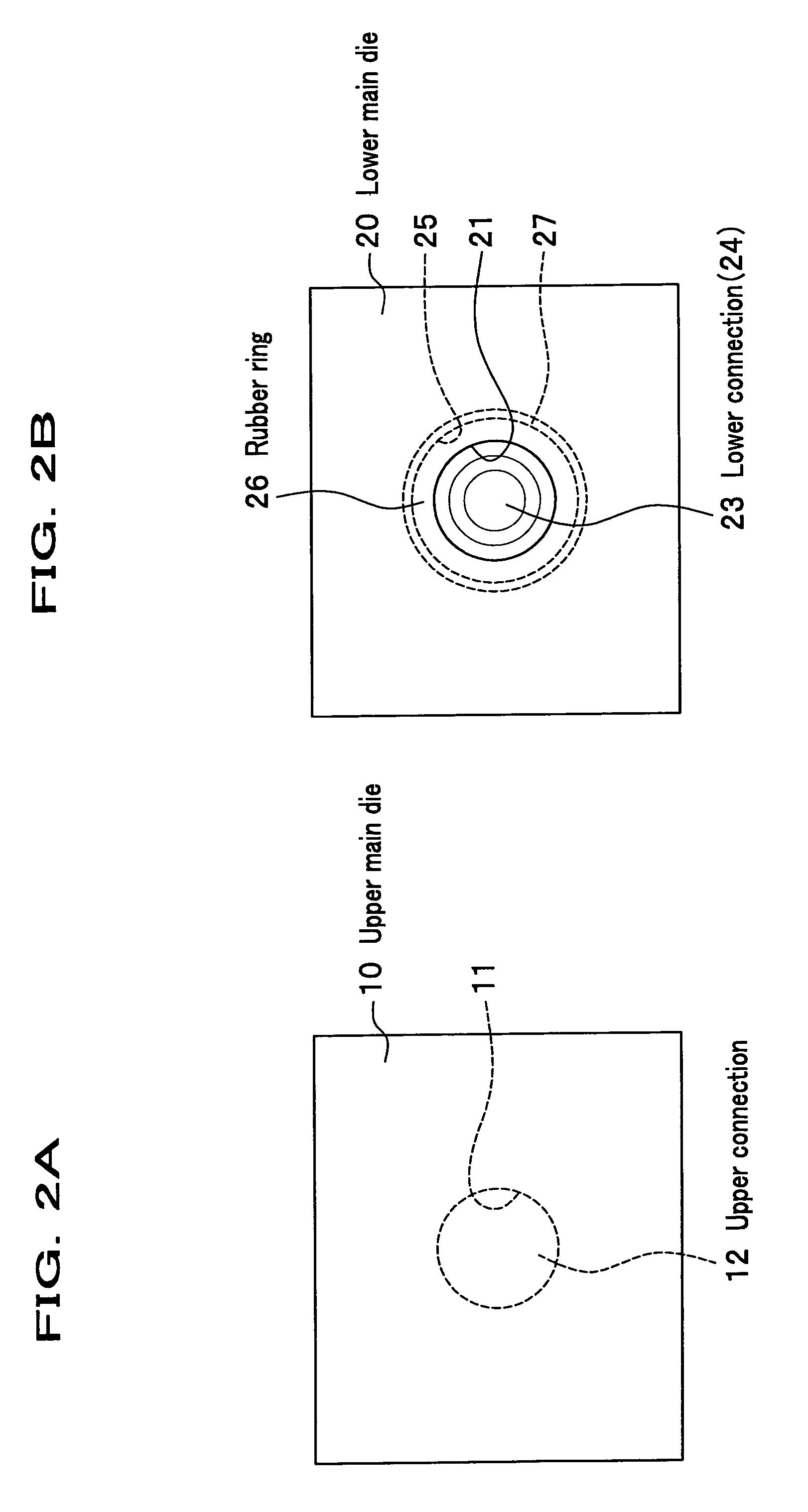

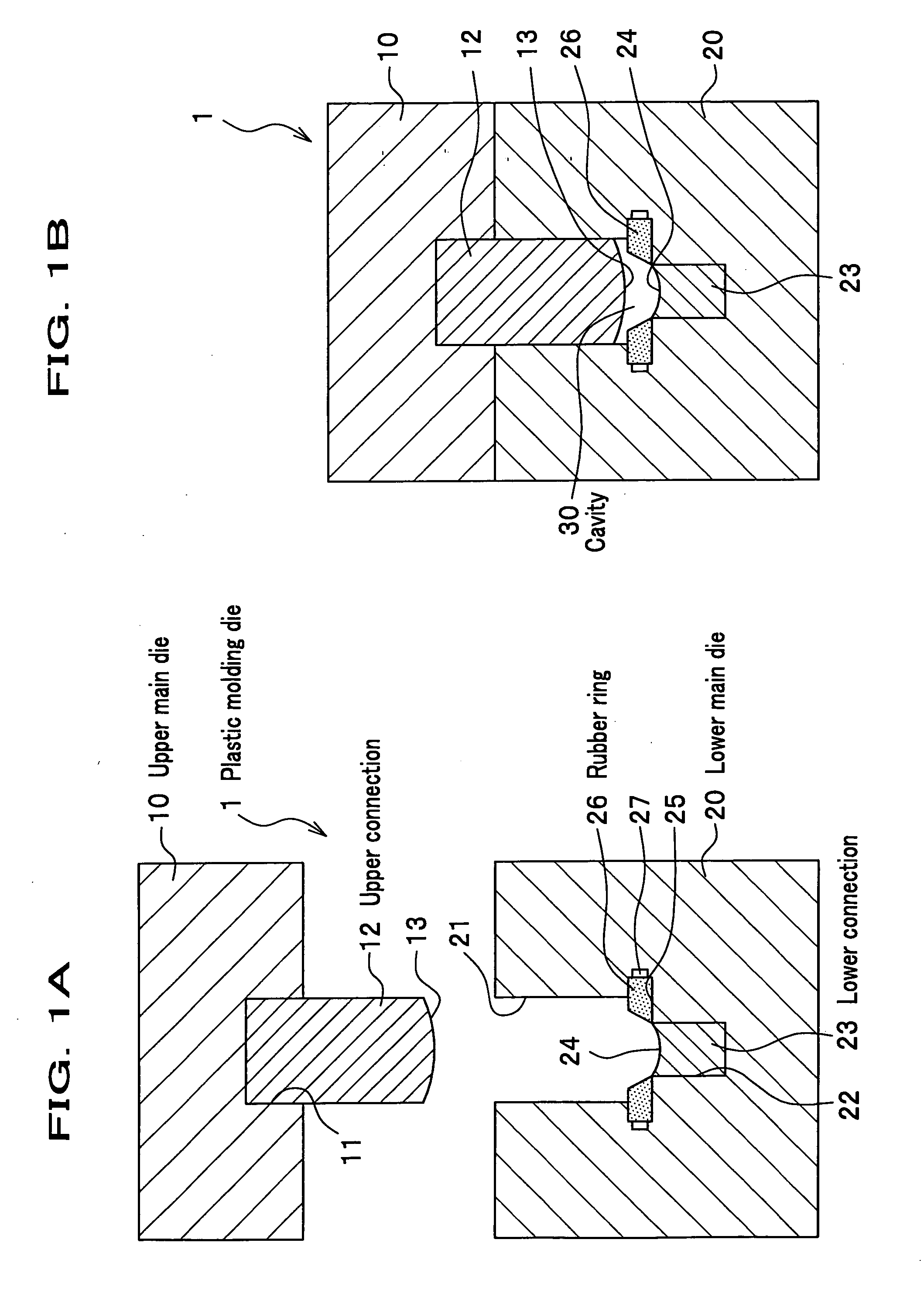

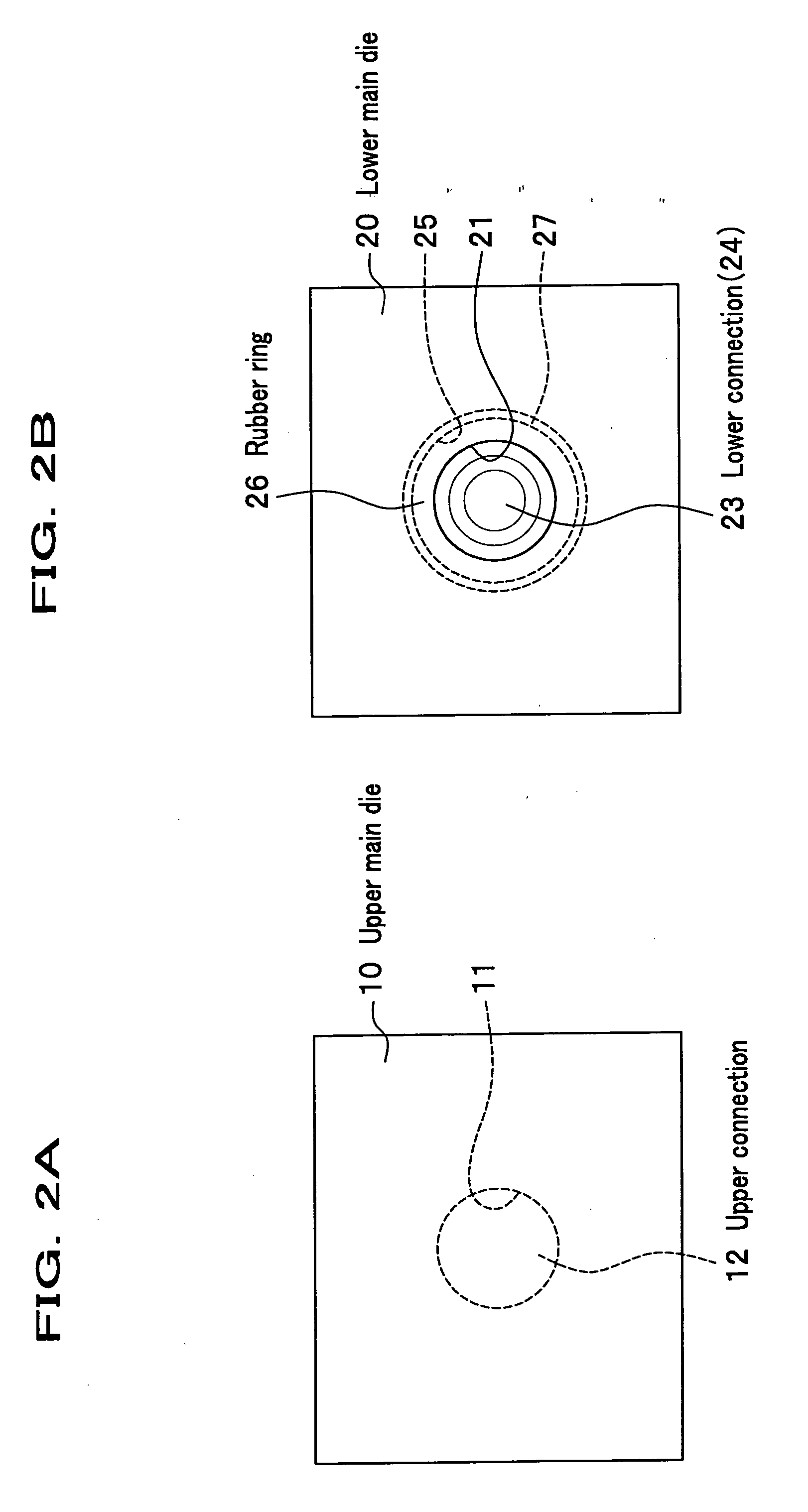

Plastic molding die

InactiveUS7845934B2Reduce cavity volumeKeep in touchSemiconductor/solid-state device detailsConfectioneryCompression moldingElastomer

A plastic molding die provided with a cavity where a plastic material is put in, wherein a part of an inner surface of the cavity is configured with an elastic body. A molding portion corresponding to a molding surface of a molded product is disposed on the inner surface of the cavity, and the elastic body is arranged on a portion other than the molding portion of the inner surface of the cavity. The plastic molding die may be a molding die for compression molding. The elastic body is made of rubber, and has an upper temperature limit higher than a glass-transition temperature of the plastic material. The degree of rubber hardness of the elastic body is from 50 to 100.

Owner:FUJIFILM CORP +1

Transient liquid phase sinter pastes and application and processing methods relating thereto

ActiveUS10232472B2Improve microstructureIncreased durabilitySolid-state devicesWelding/cutting media/materialsElectronMaterials science

Owner:UNIV OF MARYLAND

A preparation method of silver nano-mixed filler modified silicone rubber conductive composite material

ActiveCN106467670BUniform particle sizeImprove conductivityNanotechnologyRubber materialNano composites

The invention relates to the technical field of nanocomposite material. A preparing method of a silver nanoparticle mixed filler modified silicone rubber conductive composite material is provided, and aims to solve the problems that silver nanoparticles prepared through a regular method have high surface energy which is prone to agglomeration, compatibility between the silver nanoparticles and a silicone rubber basal body is poor, and thus the silver nanoparticles is so hard to be evenly dispersed in the basal body that comprehensive performance of the composite material is affected. The preparing method comprises the steps of preparing silver nanoparticles by adopting a chemical reduction method and conducting surface modification by using a silane coupling agent so as to make the silver nanoparticles evenly disperse in an organic solvent, and with a combination of a silver nanowire, dispersing the silver nanoparticles and mixed filler of the silver nanoparticles into a silicone rubber basal body by adopting a solution blended process so as to prepare an elastic silicone rubber composite material with excellent electrical conductivity. The composite material not only has the advantages of being stable in resistance time property, high in temperature limit, controllable in resistance temperature coefficient and the like, but also has high elasticity of a rubber material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

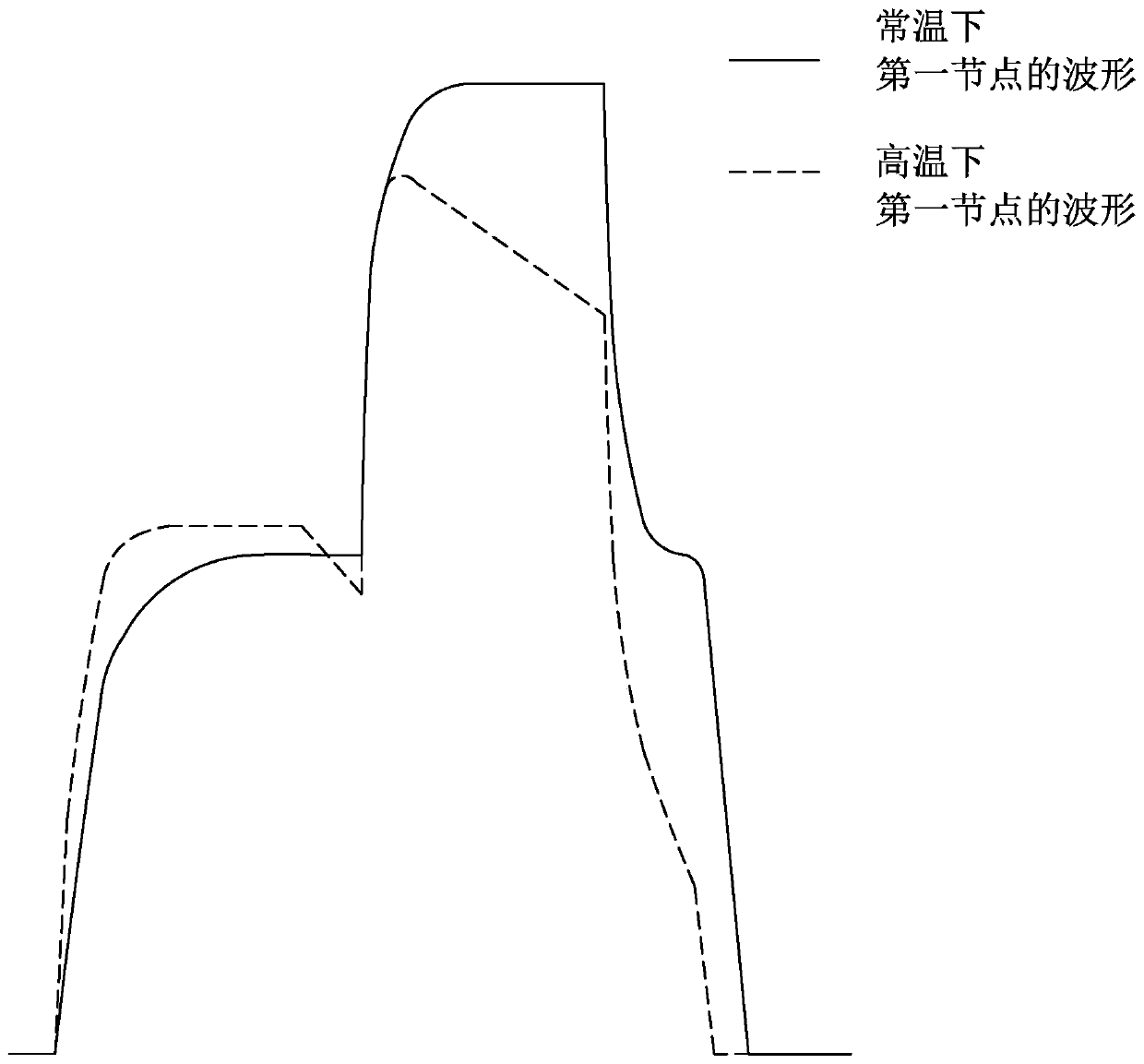

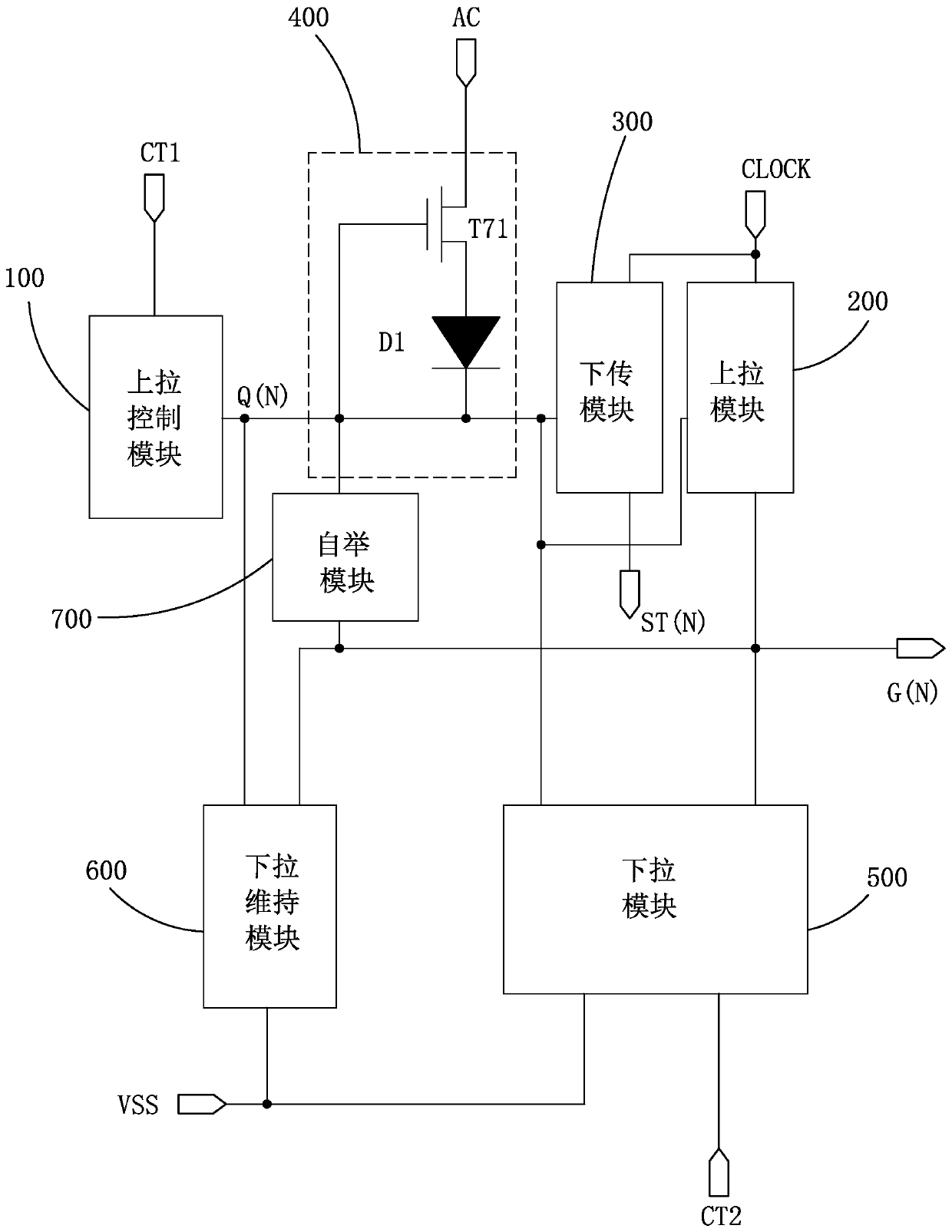

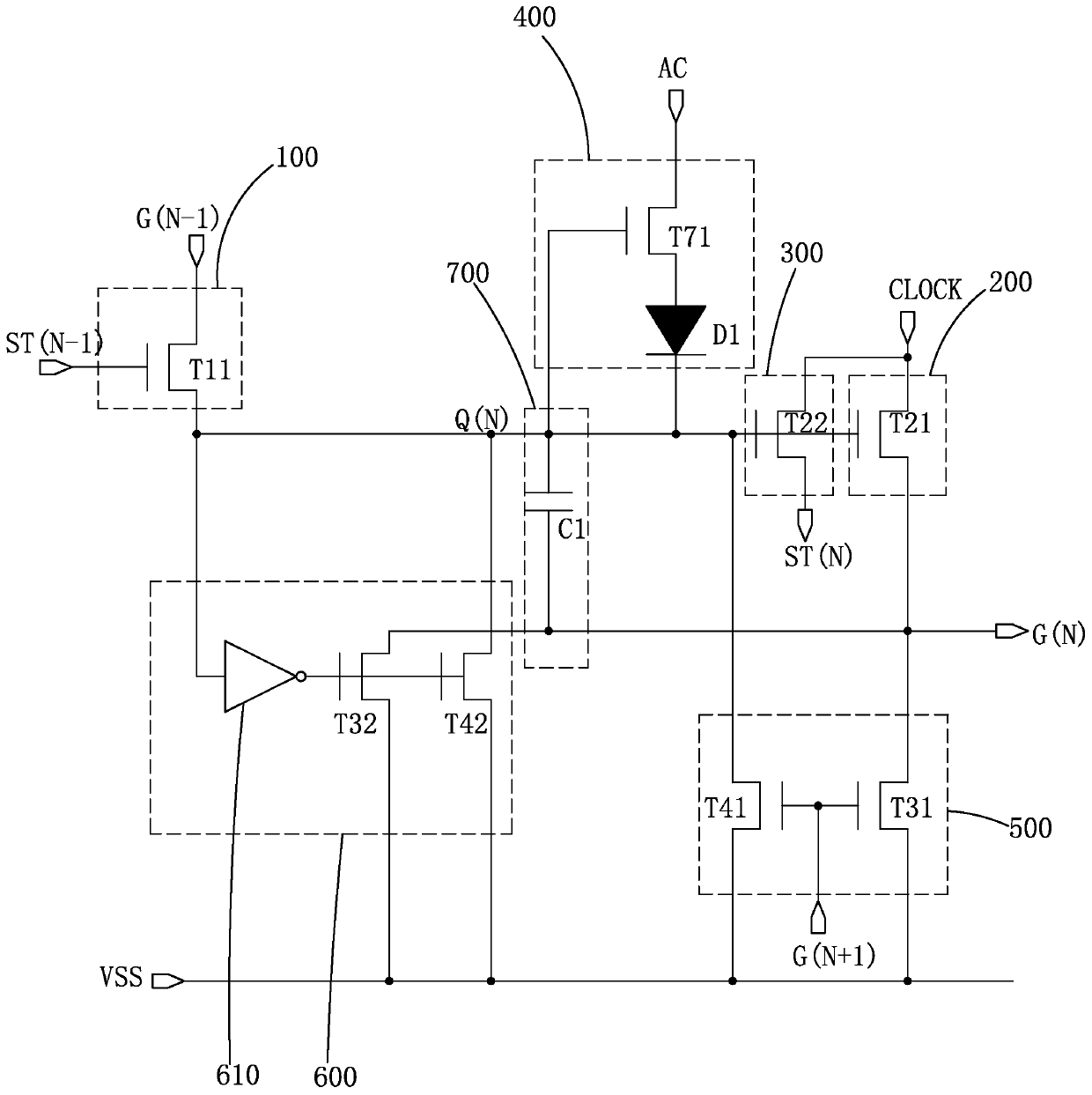

goa circuit and liquid crystal display panel

ActiveCN110021278BHigh temperature limitImprove reliabilityStatic indicating devicesLiquid-crystal displayHemt circuits

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

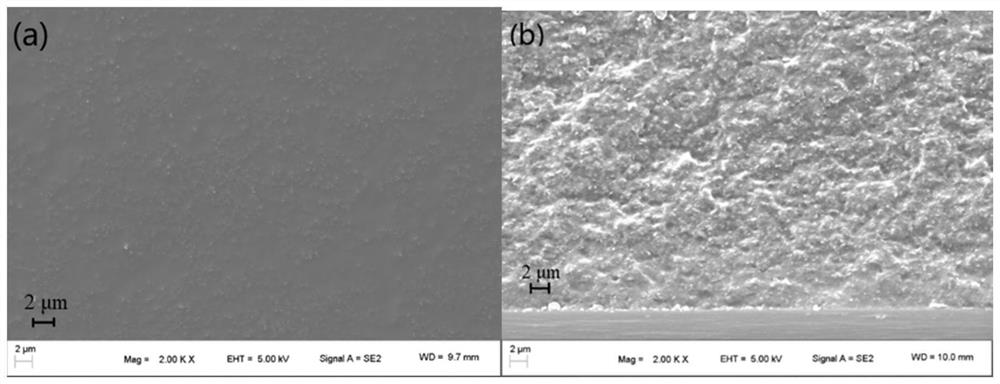

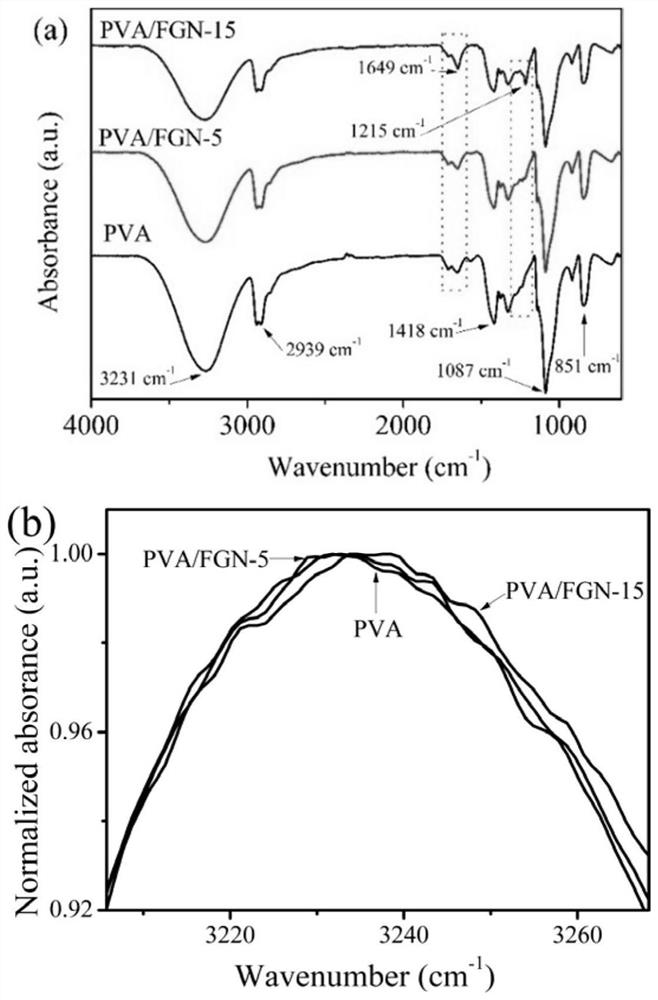

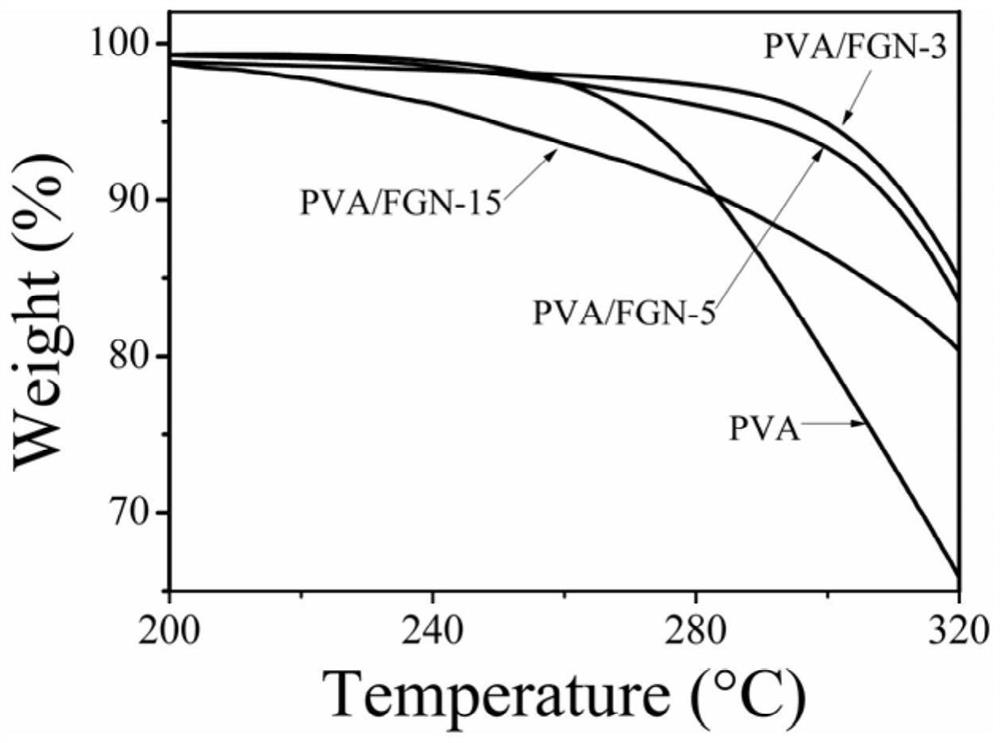

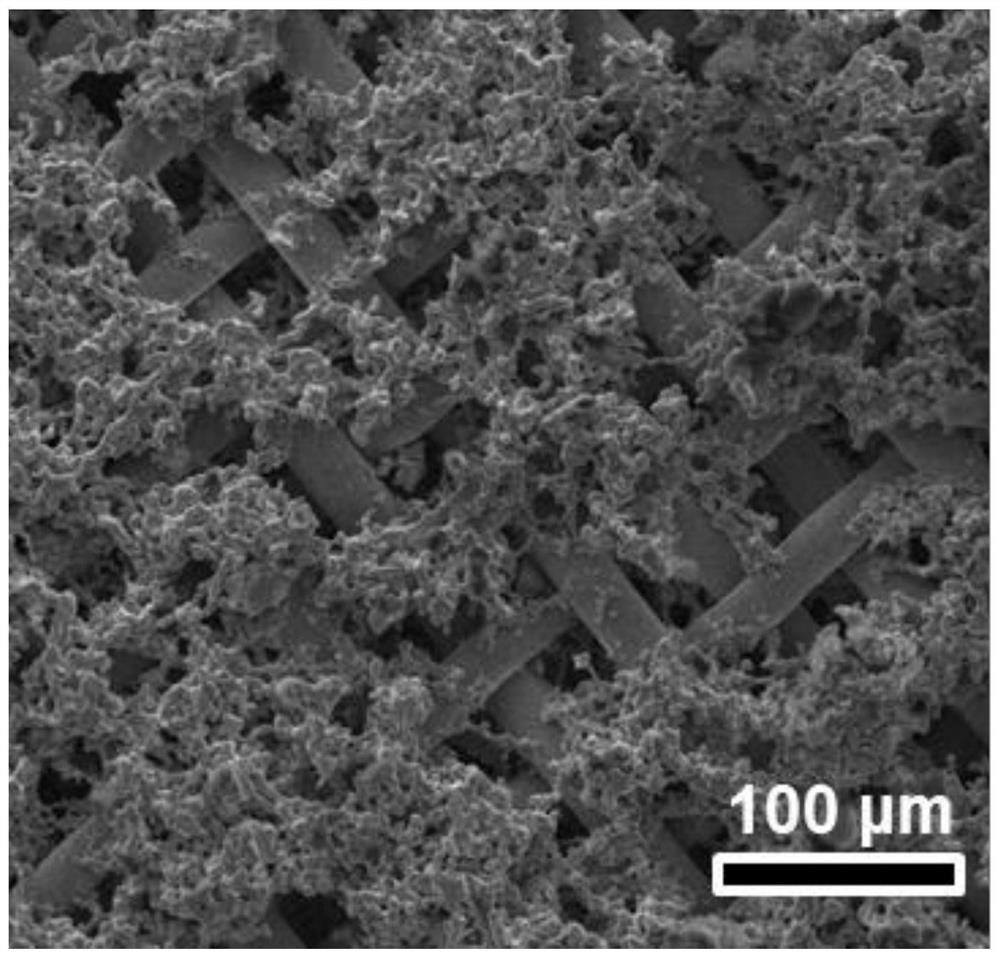

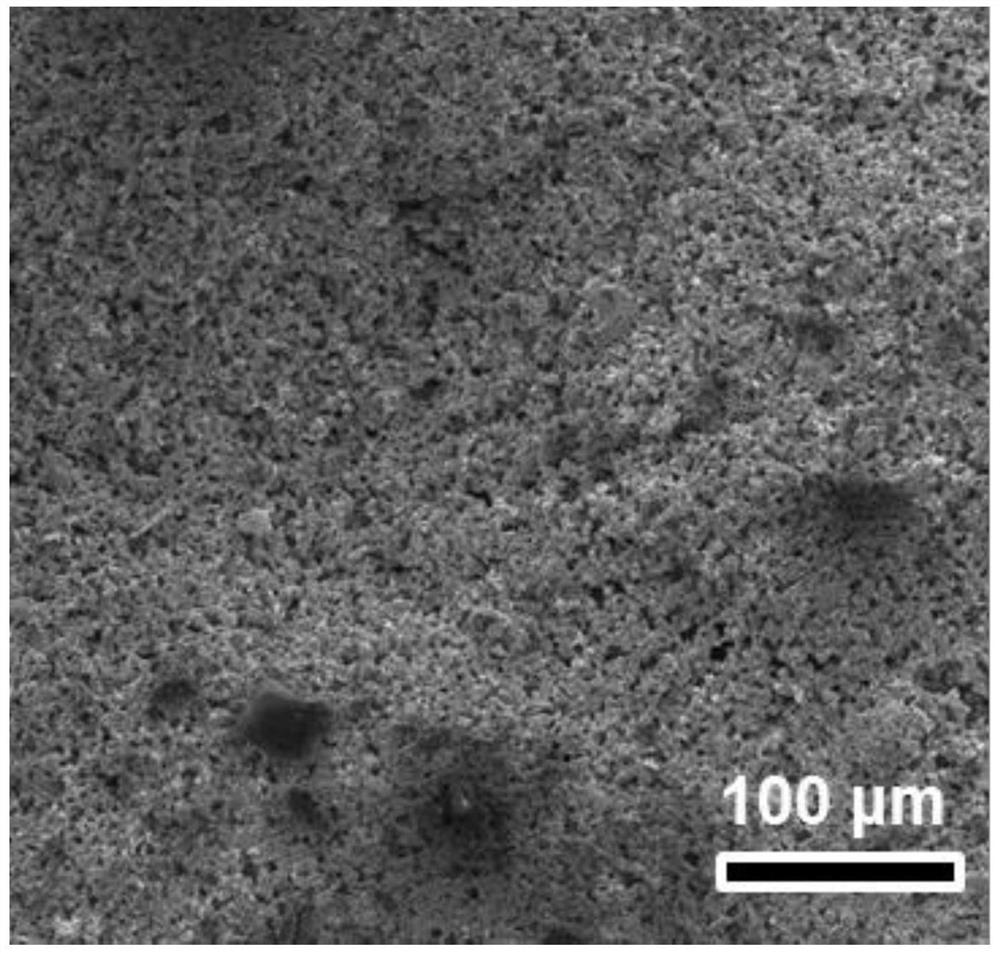

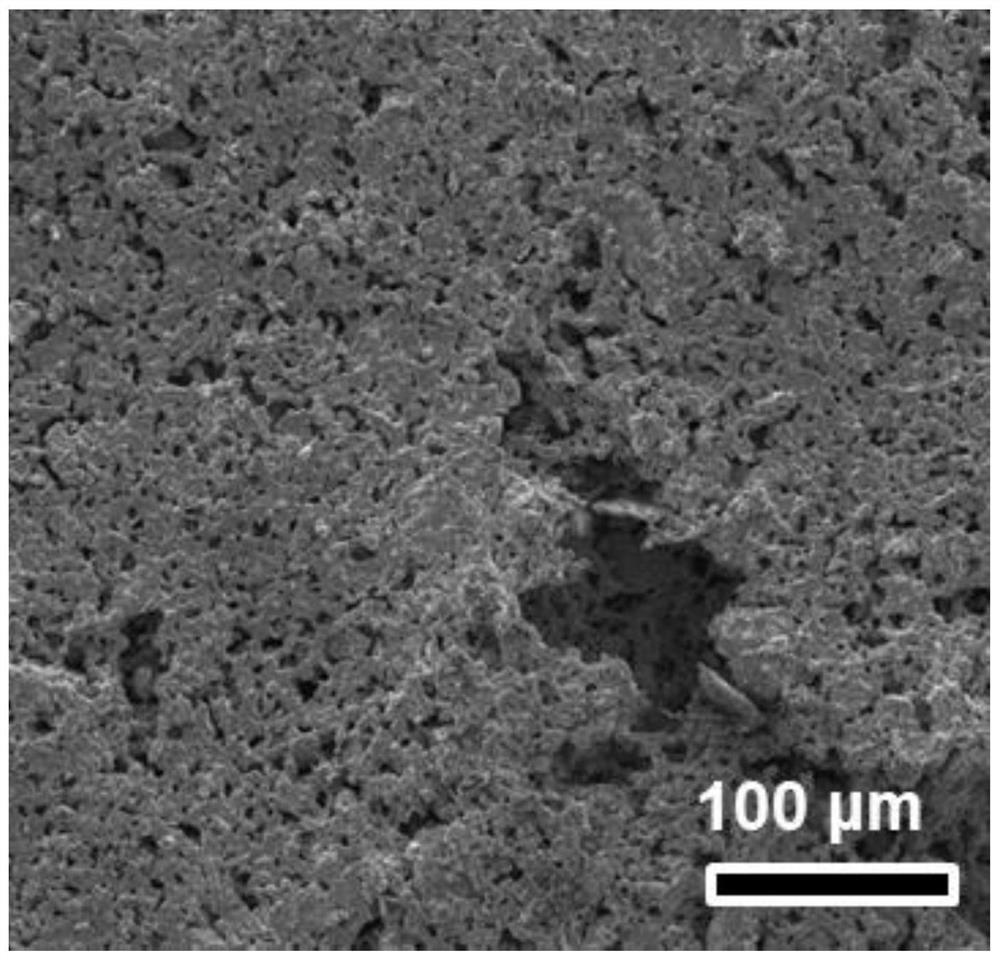

Polymer composite material as well as preparation method and application thereof

ActiveCN114456526AImprove insulation performanceImprove thermal performancePolyvinyl alcoholCrystallinity

The invention discloses a polymer composite material which comprises polyvinyl alcohol and fluorinated graphene nanosheets in a mass ratio of (85-99): (1-15), and the fluorinated graphene nanosheets are connected with polyvinyl alcohol molecules through hydrogen-bond interaction and are uniformly dispersed in the polyvinyl alcohol. The invention also discloses a preparation method and application of the polymer composite material. Compared with the prior art, the polymer composite material provided by the invention takes polyvinyl alcohol as a polymer matrix, modification is realized by a large doping amount of fluorinated graphene nanosheets, stable connection of fluorinated graphene and polyvinyl alcohol is realized through hydrogen-bond interaction between fluorinated graphene and polyvinyl alcohol molecules, and uniform dispersion of fluorinated graphene in polyvinyl alcohol is realized; meanwhile, the polyvinyl alcohol is directionally arranged by taking the fluorinated graphene nanosheet as the center, so that the crystallinity is increased; the composite material disclosed by the invention is biodegradable and has excellent electrical insulation property, thermal property and stability.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for preparing FeAl-based intermetallic compound flexible film through Al infiltration

ActiveCN112080718AHigh temperature limitGood resistance to high temperature oxidationDispersed particle filtrationSolid state diffusion coatingVulcanizationCorrosion

The invention discloses a method for preparing a FeAl-based intermetallic compound flexible film through Al infiltration. According to the method, a Fe-based alloy flexible film is prepared by adopting a sintering process, then the Al infiltration is carried out by adopting a powder embedding method, and an Al infiltration agent is composed of iron-aluminum alloy powder, Al2O3 powder and NH4Cl, sothat the FeAl-based intermetallic compound flexible film is formed. According to the invention, the defects of a traditional filter film are overcome, and the prepared FeAl-based intermetallic compound flexible film is high in porosity, has good high-temperature oxidation resistance, vulcanization performance, mechanical performance and filtering performance, and can be used for filtering, separating and purifying in a high-temperature environment and a strong-corrosion environment.

Owner:向双清

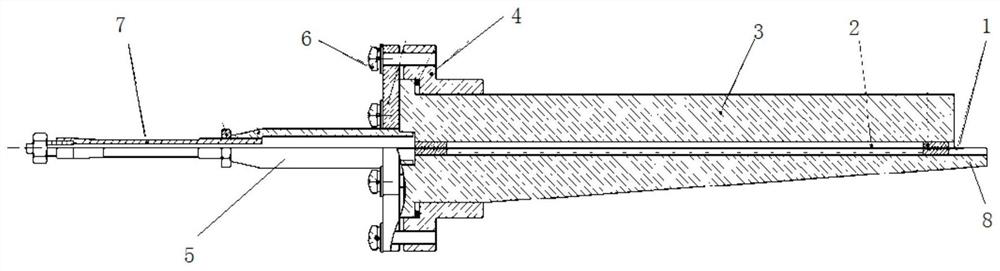

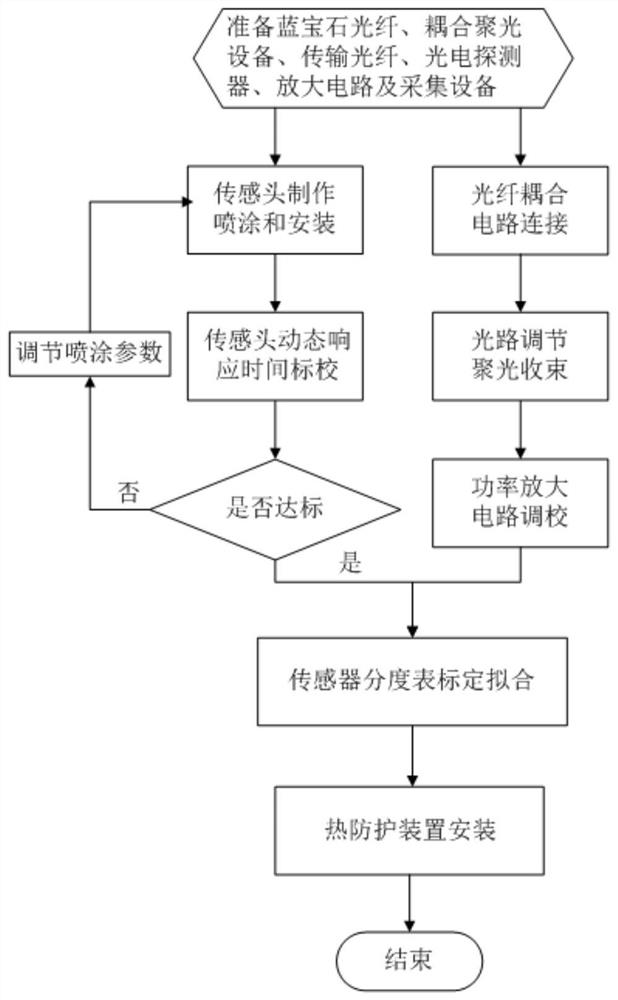

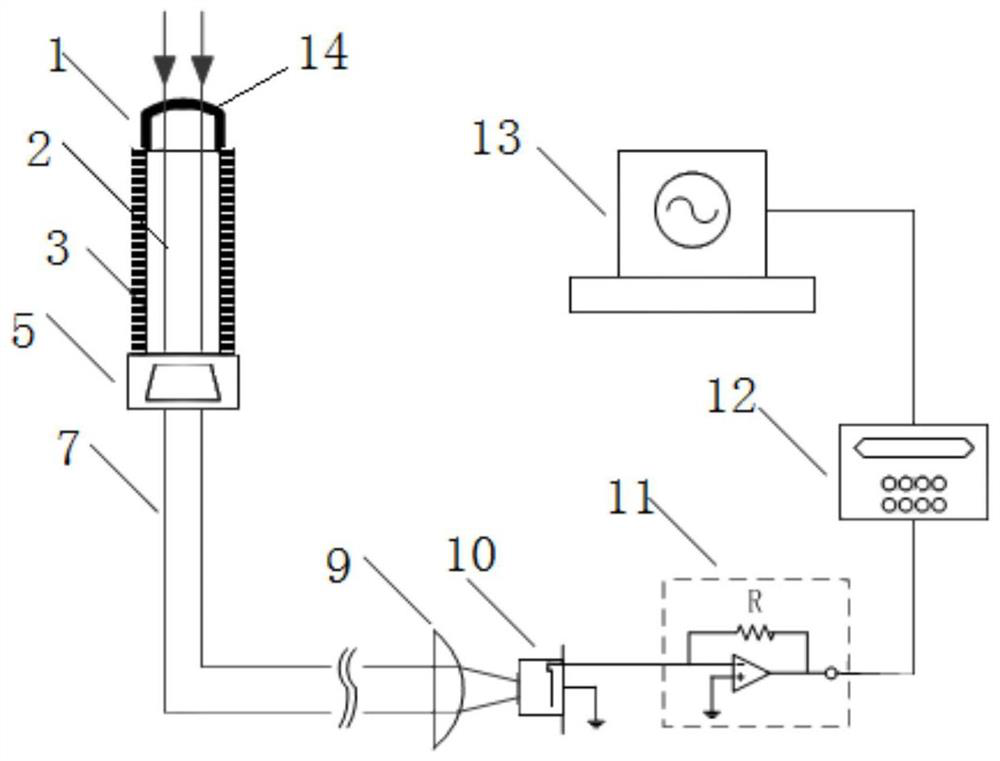

A kind of sapphire temperature sensor and its manufacturing method and temperature measuring system

ActiveCN109489855BWide temperature rangeFast thermal responseThermometers using physical/chemical changesOptical fiber couplerOptical fiber probe

Disclosed are a sapphire temperature sensor, a manufacturing method thereof, and a temperature measurement system. The sapphire temperature sensor includes: a heat protection device, a sapphire fiber probe, and a fiber coupler; one end of the sapphire fiber probe is a sensor head, and the other end is connected to the fiber coupler; the heat protection device is surrounded by the outside of the sapphire fiber; the sensor head is placed At one end of the heat protection device, the other end of the protection device is connected to the fiber coupler; the sensing head is composed of a black body cavity coated on the outer surface of one end of the sapphire optical fiber, and the black body cavity is heated by a variety of temperature-sensitive material particles through a plasma arc to melt state and evenly sprayed on the outer surface of one end of the sapphire fiber. The sapphire fiber optic temperature sensor made by plasma spraying method has the advantages of wide temperature measurement range, fast thermal response, high precision, long life, low cost and intrinsic insulation, and has more prominent advantages than traditional thermometers, such as corrosion resistance, Strong ability to resist electromagnetic interference.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

High-stability working standard microphone used in wide temperature range

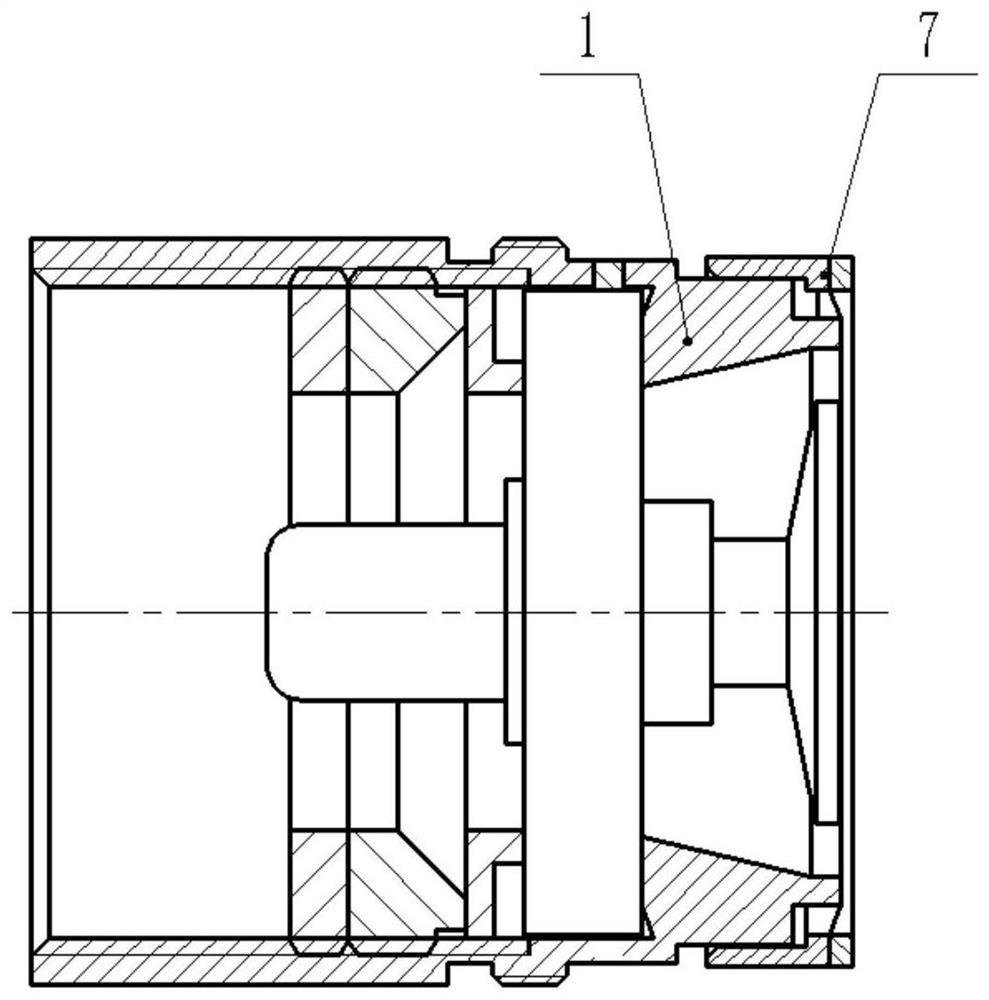

InactiveCN112135228ARealize functionAchieve high temperature performanceNon-planar diaphragms/conesCapacitanceVibrating membrane

The invention discloses a high-stability working standard microphone used in a wide temperature range, which comprises a shell, a vibrating diaphragm, a rear polar plate, a protective cover, an insulator and a signal output mechanism, wherein the protective cover is mounted outside the shell, a cavity is formed in the shell, and the rear polar plate, the insulator and the signal output mechanism are all mounted in the cavity; the vibrating diaphragm is installed at the upper end of the shell, the rear polar plate is located below the vibrating diaphragm, an air gap is formed between the rear polar plate and the vibrating diaphragm, the vibrating diaphragm, the rear polar plate and the air gap form a capacitor, the insulator is connected with the rear polar plate, and the signal output mechanism is connected with the insulator. The upper ring, the nickel alloy vibrating diaphragm and the lower ring are welded into a whole in a laser welding mode, the overall high-temperature resistanceof the microphone is achieved, the use temperature range of the microphone is widened, the shell and the vibrating diaphragm are connected in an interference fit mode and are pressed together, and reliable connection of the microphone shell and the vibrating diaphragm is achieved.

Owner:HANGZHOU AIHUA INSTR

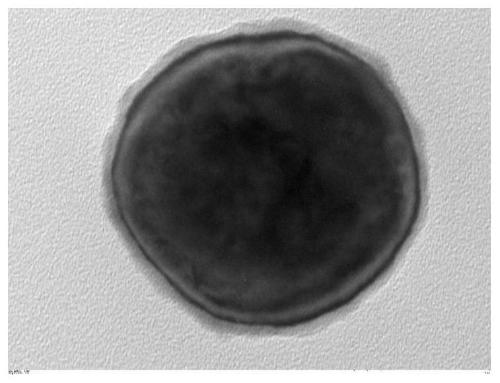

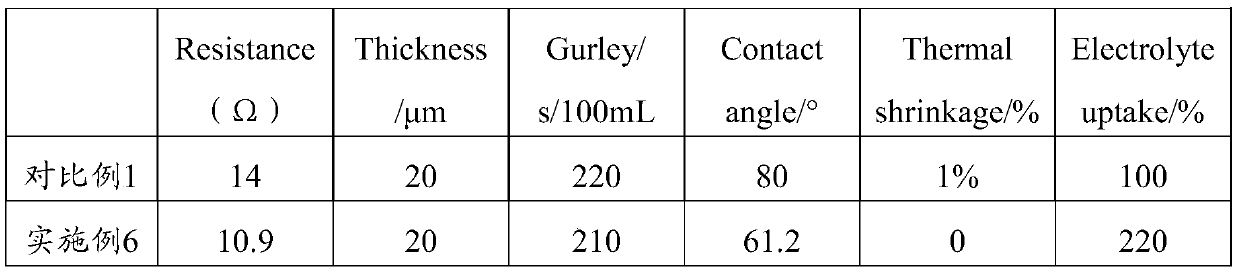

A preparation method of modified barium titanate material, battery diaphragm and lithium ion battery

ActiveCN108822586BReduced polarization effectsNot volatileCell component detailsSecondary cells servicing/maintenanceElectrolytic agentPtru catalyst

The invention belongs to the field of lithium ion batteries, and particularly relates to a preparation method of a modified barium titanate material, and a battery diaphragm and lithium ion battery. The preparation method provided by the invention comprises the following steps: dispersing barium titanate particles, phosphonitrilic chloride trimer, a monomer and a catalyst in a reaction solvent andcarrying out a reaction, wherein the monomer is polyol or polyol sodium. According to the invention, flexible polyphosphazene coats the surfaces of barium titanate particles, so that the modified barium titanate material has the effect of high liquid retention, the electrolyte does not volatilize easily, the increase rate of resistance is slow, the polarization effect of barium titanate is reduced, and the service life of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

Method for manufacturing high-temp PTC thermosensitive resistor

ActiveCN100426424CGood compatibilityIncrease the degree of cross-linkingPositive temperature coefficient thermistorsPhysical chemistryElectronic component

A manufacturing method of high temperature macromolecule PTC thermal resistor relates to manufacturing method of the electronic component whose material mainly is crystalline hypo-crystalline high polymer and its mixture. A manufacturing method of high temperature PTC thermal resistor is that after the chip is forming, the chip is set in the heating equipment whose high polymer melting point is more than from five centigrade degree to thirty centigrade degree for from five minutes to fifty minutes, then slowly cooled to room temperature, later irradiated, and irradiation dosage range is 0.2- 0.7 times of which is from 20KGy to 5000KGy; after the irradiation , the chip is again set in the heating equipment whose high polymer melting point is more than from five centigrade degree to thirty centigrade degree for from five minutes to fifty minutes, then slowly cooled to room temperature, do the second irradiation, and the irradiation dosage range is 0.4- 0.8 times which is from 20KGy to 5000KGy.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

A high-strength, high-temperature-resistant rafm steel and its design method based on machine learning

ActiveCN113073267BHigh temperature limitEasy to stretchChemical property predictionMolecular designTemperingMachine

The invention provides a high-strength, toughness and high-temperature resistant RAFM steel, the chemical composition of which is: C: 0.12-0.16%, Cr: 9.5-10.5%, W: 1.6-1.8%, Si: 0.48-0.52%, Mn: 0.6- 0.7%, V: 0.23~0.27%, Ta: 0.10~0.26%, Zr: 0.001~0.005%, etc.; heat treatment parameters are: normalizing temperature 1010~1050℃, normalizing time 20~55min, tempering temperature 600~720 ℃, tempering time 50 ~ 90min. The present invention also provides a machine learning-based design method for the above-mentioned steel. The RAFM steel of the present invention has a higher service temperature upper limit, and also has better tensile properties at high temperatures; at the same time, the machine learning method constructed by the present invention has strong generalization ability, and can quickly and efficiently design reasonable composition and heat treatment parameter.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Hydrophobic thermoplastic starch composite and method for manufacturing the same

The present invention provides a hydrophobic thermoplastic starch and method for manufacturing the same, to be used as granules for making biodegradable composites. The hydrophobic thermoplastic Starch of the invention is in a granule type, has the melt flow index in the range of 0.2-6 g / 10 min at 160° C. and has 60-80 wt % of starch and the water content less than 9%.

Owner:GREEN WORLD BIOTECH MATERIALS CO LTD

Composite high-temperature-resistant cable bridge, and coating technology

InactiveCN109251662AImprove high temperature resistancePrevent corrosionFireproof paintsAnti-corrosive paintsIron oxidePerlite

The invention discloses a composite high-temperature-resistant cable bridge, and coating technology, and belongs to the technical field of cable bridges. The composite high-temperature-resistant cablebridge comprises a bridge main body; the external surface of the bridge main body is coated with an internal high temperature resistance layer and an external anti-corrosion layer; the external anti-corrosion layer is prepared through coating of an epoxy coating, and the thickness ranges from 1 to 2mm; the internal high temperature resistance layer comprises, by weight, 55 to 65 parts of polycarbosilane, 4 to 9 parts of glass fiber, 9 to 11 parts of m-benzol unsaturated polyester resin, 20 to 25 parts of acrylic resin, 13 to 14 parts of alumina, 12 to 16 parts of iron oxide, 10 to 15 parts ofdioctyl phthalate, 5 to 9 parts of polyacrylamide, 3 to 5 parts of perlite, 2 to 4 parts of acetylene carbon black, and 4 to 7 parts of sodium bicarbonate. The composite high-temperature-resistant cable bridge possesses excellent corrosion resistance and high temperature resistance, and the service life of the composite high-temperature-resistant cable bridge is prolonged.

Owner:镇江朝阳机电科技有限公司

A high-temperature temperature and pressure optical fiber Fabry-Perot composite micro-nano sensor

ActiveCN105043588BHigh temperature limitSmall structure sizeThermometers using physical/chemical changesFluid pressure measurement by optical meansMicro nanoCross sensitivity

The invention relates to a high-temperature temperature and pressure optical fiber Fabry-Perot composite micro-nano sensor, which belongs to the technical field of optical fiber sensors. The sensor of the present invention comprises an optical fiber access section, a pressure sensor section and a temperature sensor section; the optical fiber access section is a solid-core optical fiber, the pressure sensor is a hollow-core thin-walled optical fiber, and the temperature sensor is another section of solid-core optical fiber; the present invention adopts The femtosecond laser processing method processes a cylindrical hole on the end face of two solid-core optical fibers, and then welds them to form a FP interference-type pressure chamber. One of the optical fibers is used as an optical fiber access section, and the other is cut. The optical fiber is ground into a section of solid-core optical fiber with a certain thickness to form a temperature sensor, and the decoupling of the two-parameter measurement is realized by controlling the cavity length difference between the temperature sensor and the pressure sensor. Compared with the prior art, the invention has the advantages of small structure size, high temperature resistance, simultaneous temperature / pressure measurement and no double parameter cross sensitivity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

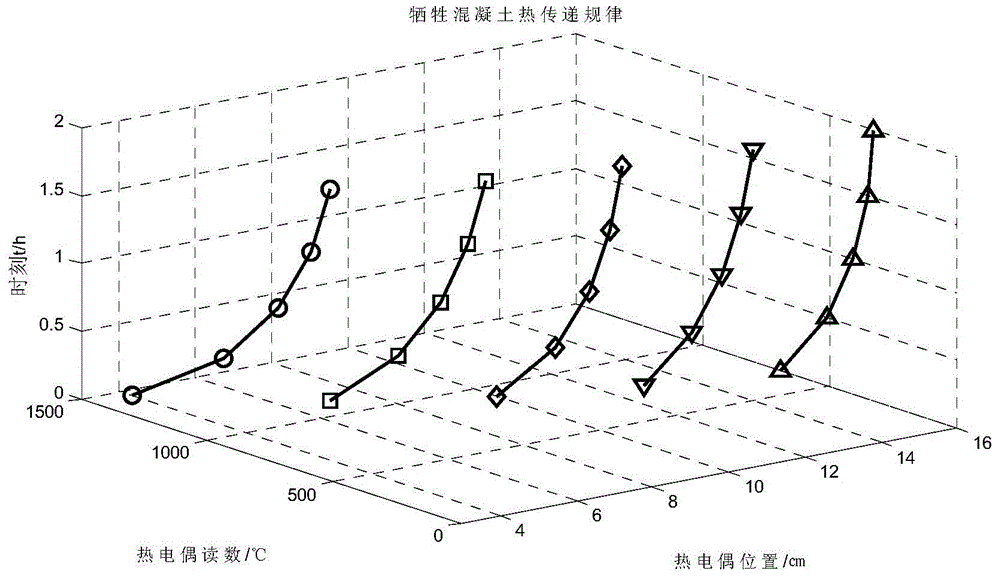

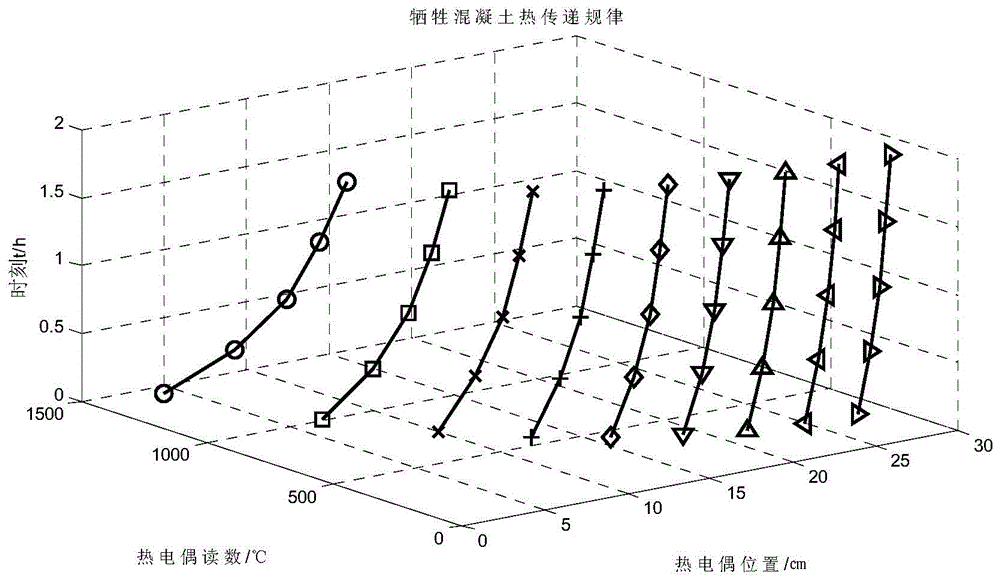

Method for measuring sacrifice concrete heat transfer law

InactiveCN104597074AEasy to operateAccurate measurementMaterial thermal conductivityMeasuring instrumentMathematical software

The invention provides a method for measuring a sacrifice concrete heat transfer law. The method comprises the following steps: preparing a sacrifice concrete sample; connecting kinds of thermocouples and a multi-channel temperature measuring instrument; injecting molten stainless steel into the sacrifice concrete sample, and simultaneously, starting the multi-channel temperature measuring instrument; recording reading numbers of the thermocouples at different moments; building three-dimensional right-angle coordinate systems by employing the positions of the thermocouples as x axes, the reading number of the thermocouples as y axes and different moments t as z axes according to the reading numbers of the thermocouples at the same moment, the reading numbers of the thermocouples at different moments and the positions of the thermocouples in sacrifice concrete; and drawing a relationship function graph by virtue of MATLAB mathematical software so as to obtain the sacrifice concrete heat transfer law. A conventional measurement instrument is adopted, so that the operation is simple and convenient and the measurement result is accurate; and the sacrifice concrete heat transfer law at different time intervals can be measured.

Owner:SOUTHEAST UNIV

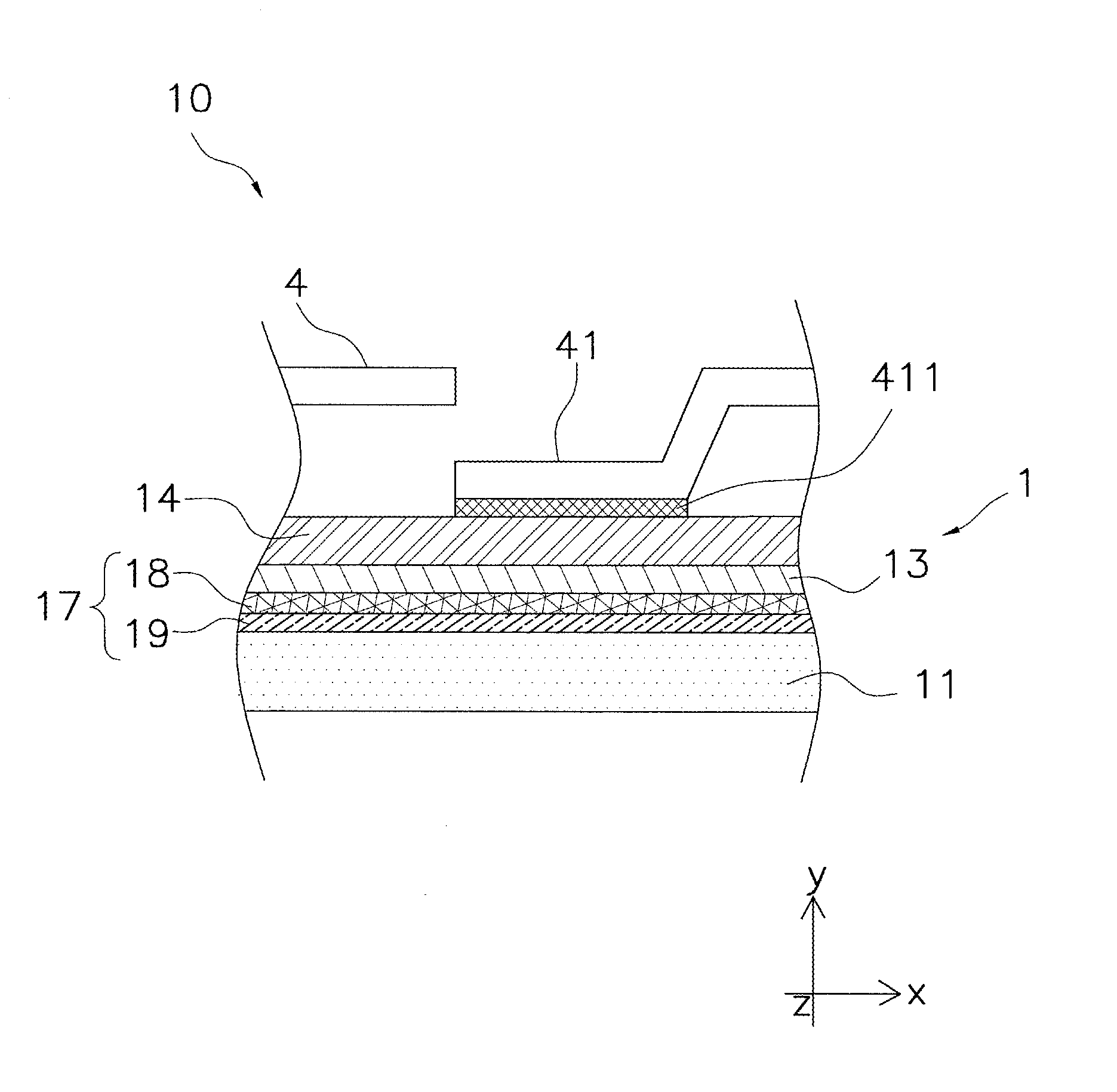

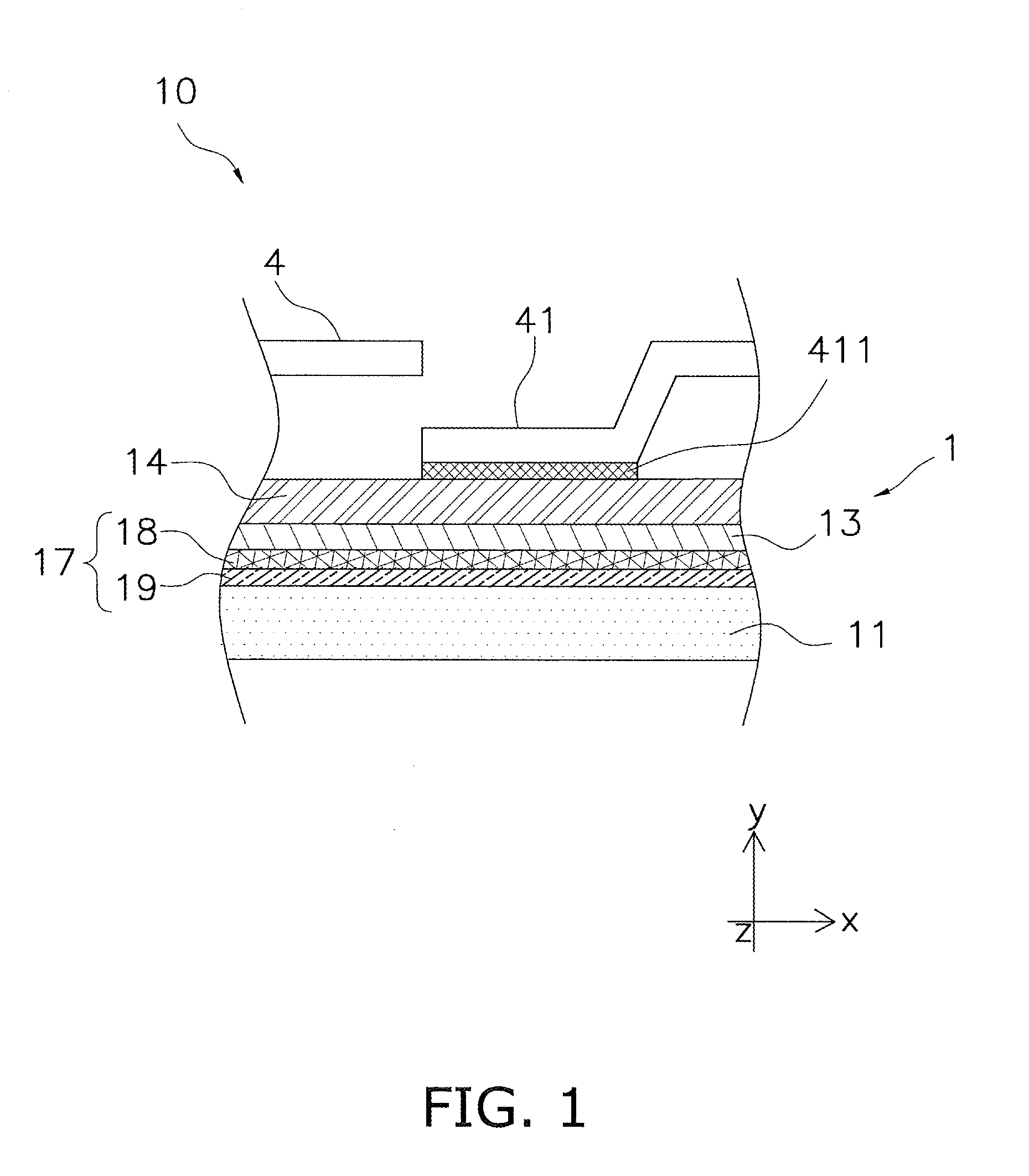

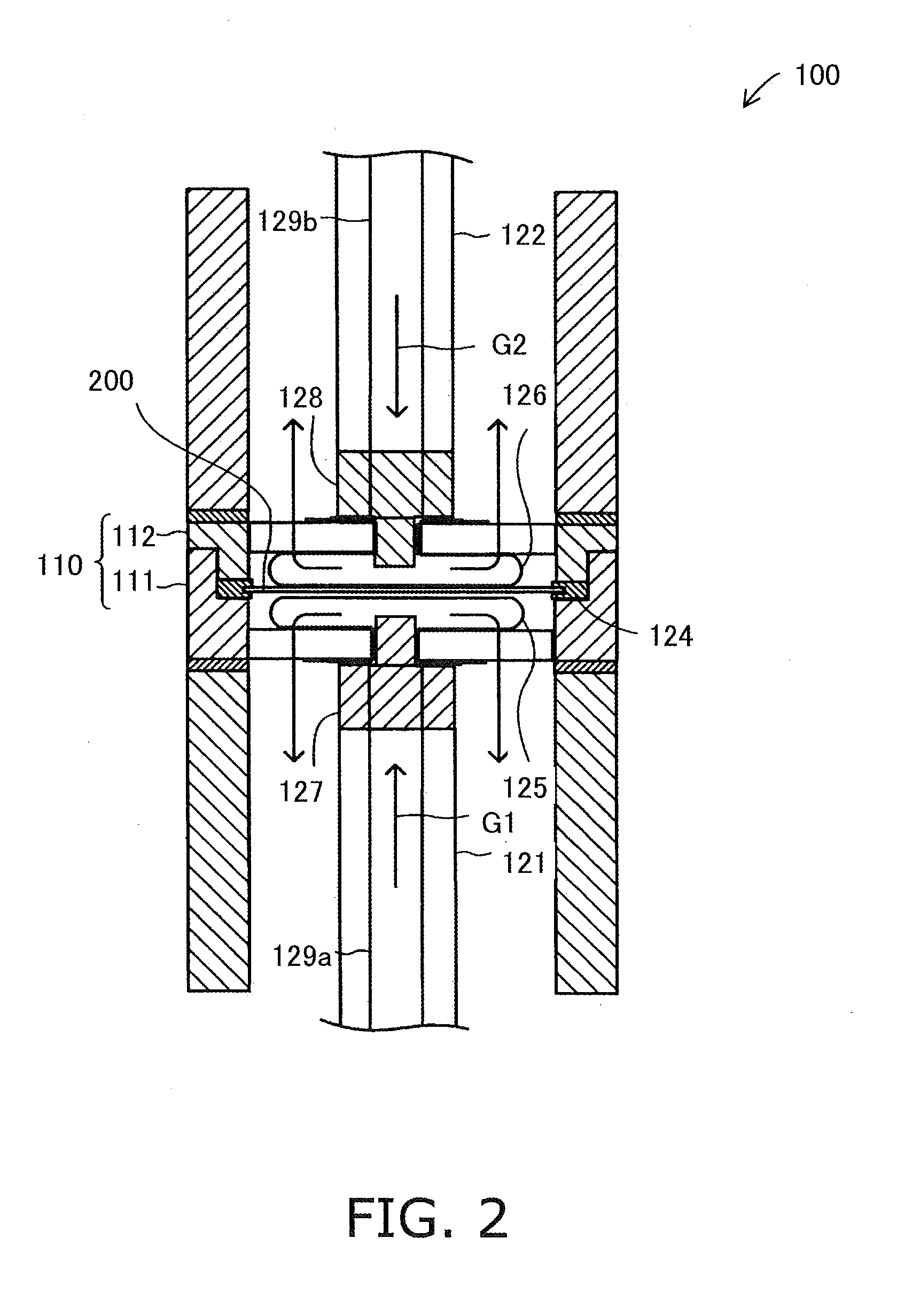

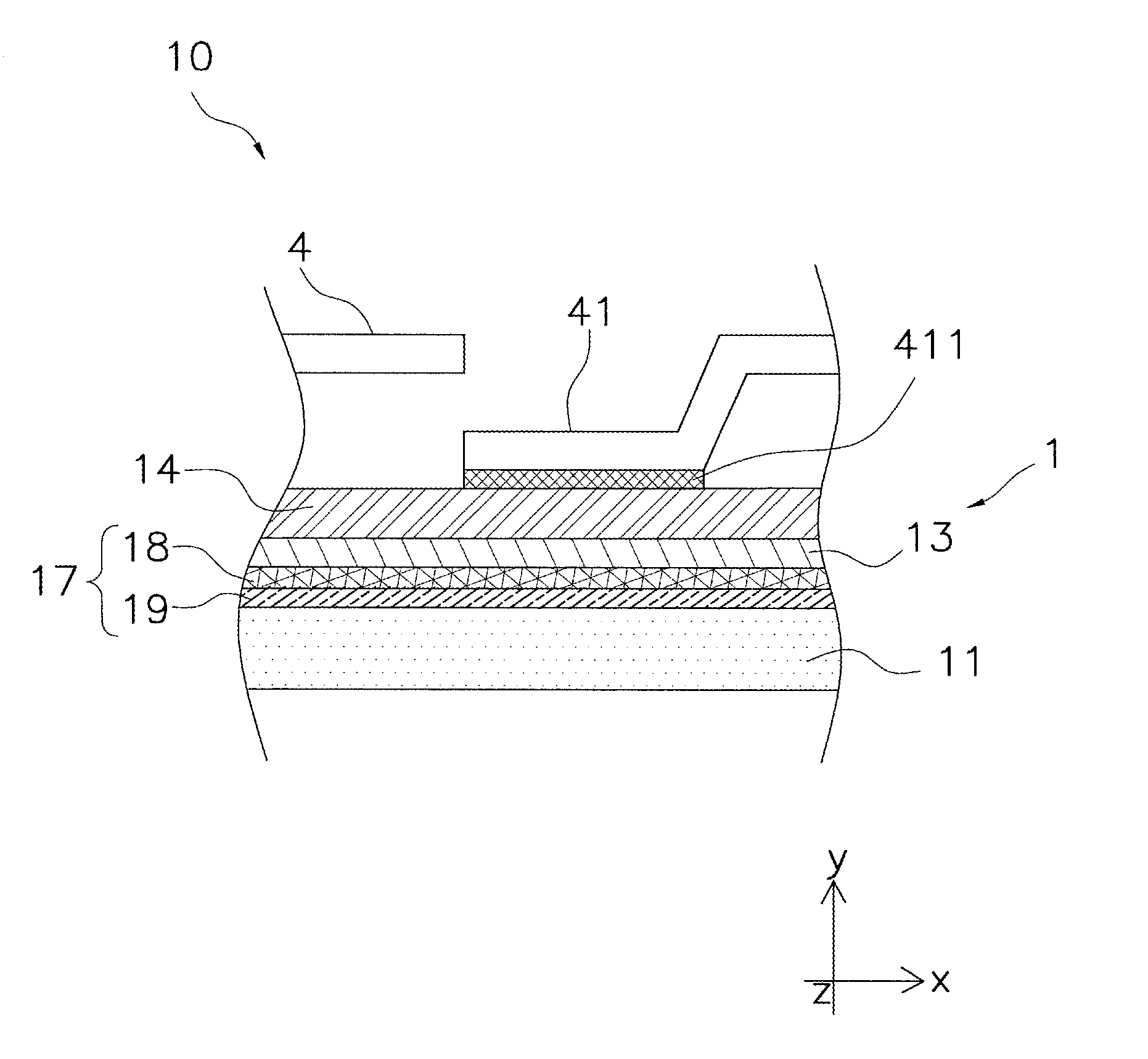

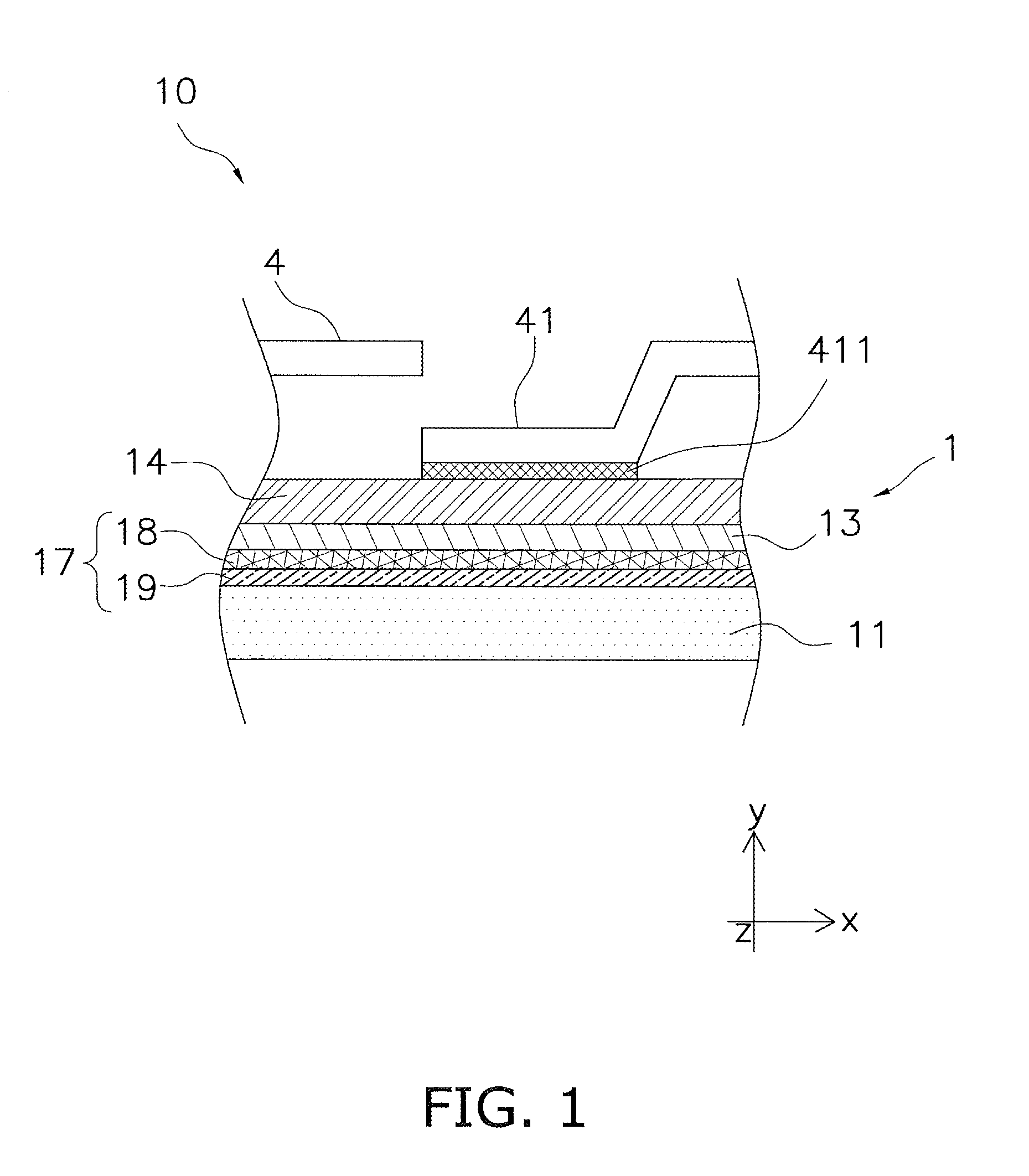

Fuel cell

ActiveUS20120264035A1Enhances upper limitHigh temperature limitFinal product manufactureActive material electrodesFuel cellsOptoelectronics

A fuel cell (1) includes an anode (11), a cathode (14), an electrolyte layer (13) containing ceria and provided between the anode (11) and the cathode (14), and at least two intermediate layers containing zirconia and provided between the electrolyte layer (13) and the anode (11). The at least two intermediate layers include a first intermediate layer (18) that contains ceria and a second intermediate layer (19) that has a higher zirconia concentration than the first intermediate layer and is provided between the first intermediate layer and the anode.

Owner:NGK INSULATORS LTD

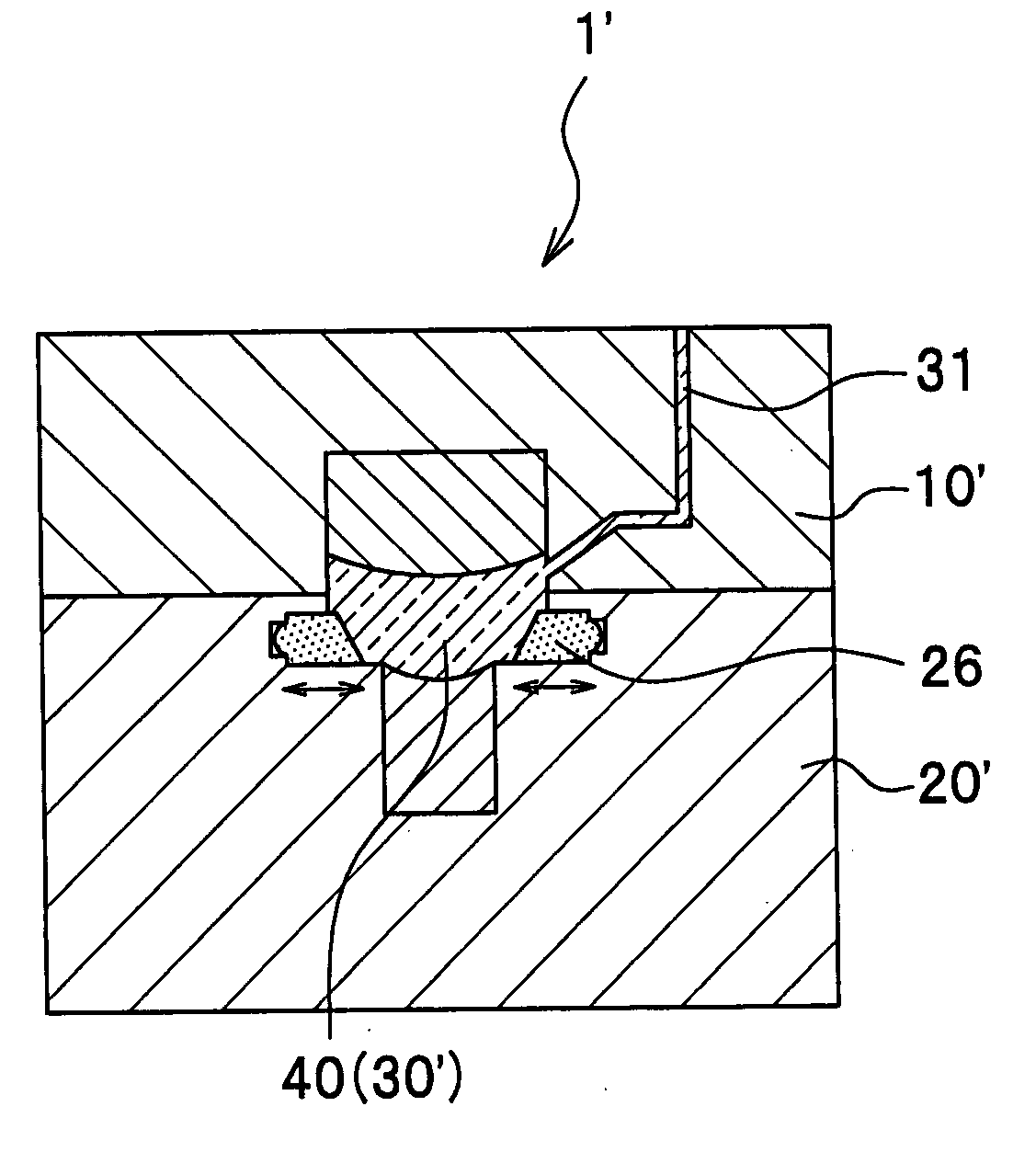

Plastic molding die

InactiveUS20060157834A1Improve molding accuracyReduce cavity volumeSemiconductor/solid-state device detailsConfectioneryPlastic moldingEngineering

A plastic molding die provided with a cavity where a plastic material is put in, wherein a part of an inner surface of the cavity is configured with an elastic body. A molding portion corresponding to a molding surface of a molded product is disposed on the inner surface of the cavity, and the elastic body is arranged on a portion other than the molding portion of the inner surface of the cavity. The plastic molding die may be a molding die for compression molding. The elastic body is made of rubber, and has an upper temperature limit higher than a glass-transition temperature of the plastic material. The degree of rubber hardness of the elastic body is from 50 to 100.

Owner:FUJIFILM CORP +1

Fuel cell

ActiveUS8349522B2High temperature limitFinal product manufactureActive material electrodesFuel cellsOptoelectronics

A fuel cell (1) includes an anode (11), a cathode (14), an electrolyte layer (13) containing ceria and provided between the anode (11) and the cathode (14), and at least two intermediate layers containing zirconia and provided between the electrolyte layer (13) and the anode (11). The at least two intermediate layers include a first intermediate layer (18) that contains ceria and a second intermediate layer (19) that has a higher zirconia concentration than the first intermediate layer and is provided between the first intermediate layer and the anode.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com