Method for preparing FeAl-based intermetallic compound flexible film through Al infiltration

A flexible film and compound technology, applied in the field of inorganic porous film material preparation, can solve the problems of difficult processing, insufficient corrosion resistance, high aluminum content alloys, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

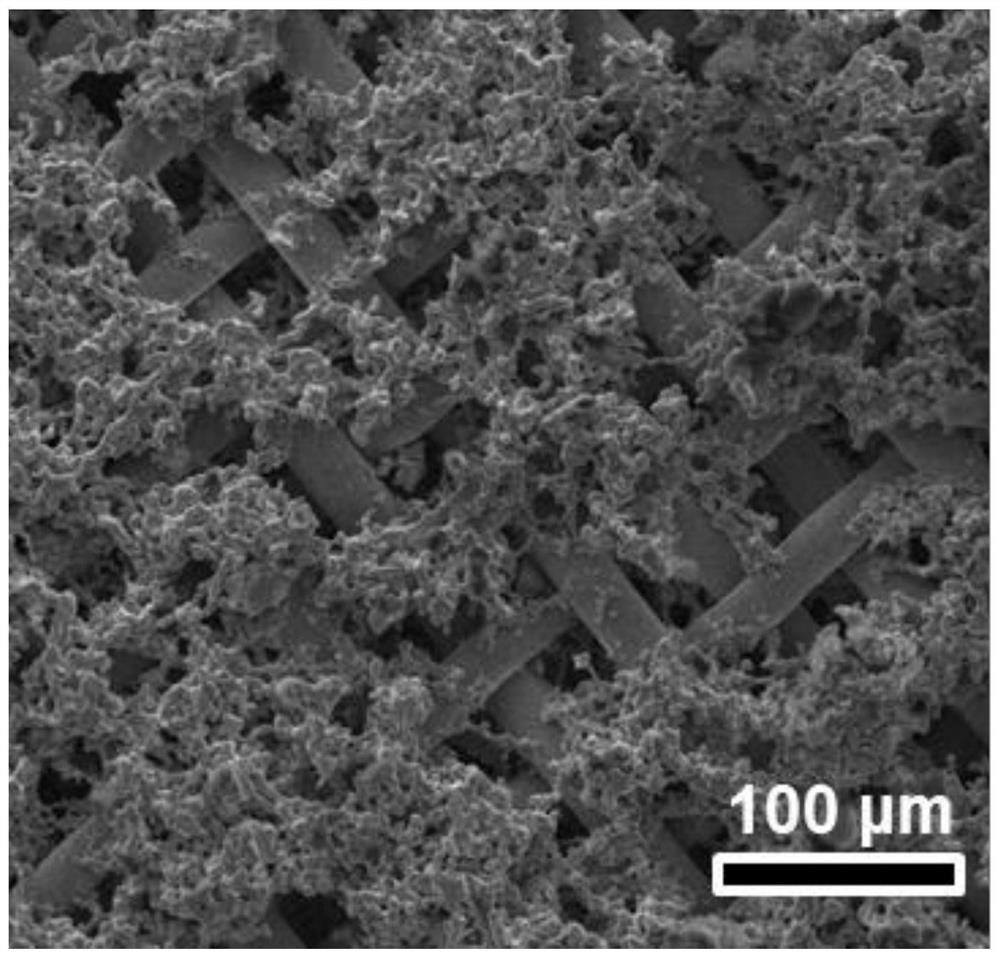

[0039] 1. Preparation of Fe-based alloy flexible film by sintering process:

[0040] (1) Ingredients: According to the national standard composition ratio of 304 stainless steel (the mass percentage is Ni 11%, Cr 18%, Si1%, Mn 2%, P 0.045%, S 0.03%, C 0.08%, and the balance is Fe). Take each element powder, and add 0.5% of C powder additionally, the total weight of ingredients is 100g, to obtain pre-alloy powder; then add 30g of ethanol as wet grinding medium, 5g of binder PEG, and mix;

[0041] (2) Ball milling: after grinding for 24 hours in a planetary ball mill, pre-alloyed powder slurry is obtained;

[0042](3) Spraying and sizing: adopt a spray gun to spray the slurry on the 80-order 304 stainless steel wire mesh substrate, and the amount of sizing is 250g per square stainless steel wire mesh in terms of the pre-alloyed powder mass;

[0043] (4) Drying: put the wire mesh sprayed with the pre-alloyed powder in an oven to dry, the drying temperature is 80°C, and the dryin...

Embodiment 2

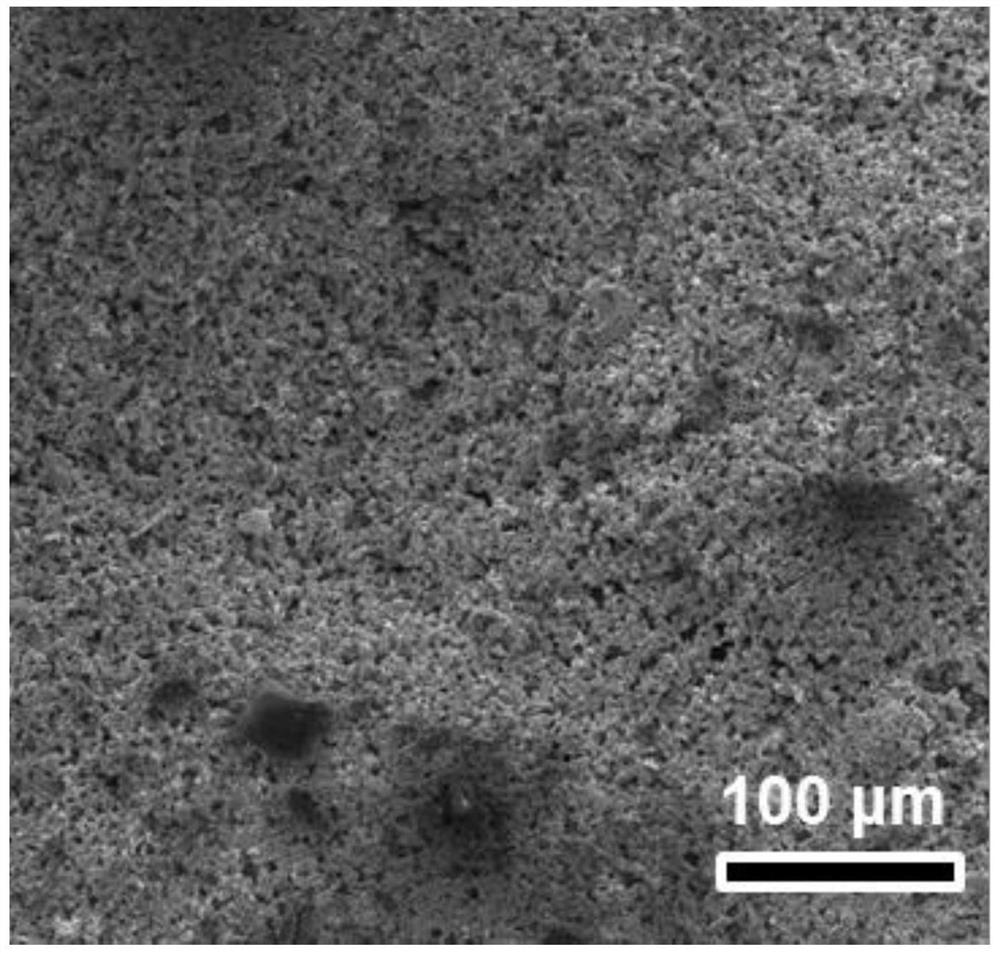

[0049] 1. Preparation of Fe-based alloy flexible film by sintering process:

[0050] (1) Ingredients: According to the national standard composition ratio of 316L stainless steel (in which mass percentage Ni 13%, Cr 18%, Si1%, Mn 2%, P 0.045%, S 0.03%, Mo 2%, C 0.03%, the balance Weigh each element powder for Fe), and additionally add 0.8% C powder, the total mass of the ingredients is 100g, to obtain pre-alloyed powder; then add 35g of wet grinding medium ethanol, 10g of binder PVA, and mix;

[0051] (2) Ball milling: after grinding for 30 hours in a planetary ball mill, a pre-alloyed powder slurry is obtained;

[0052] (3) Spraying and sizing: use a spray gun to spray the slurry on the 60-purpose 316L stainless steel wire mesh substrate, and the amount of sizing is 300g per square stainless steel wire mesh based on the pre-alloyed powder mass;

[0053] (4) Drying: put the wire mesh sprayed with the pre-alloyed powder in an oven to dry, the drying temperature is 80°C, and th...

Embodiment 3

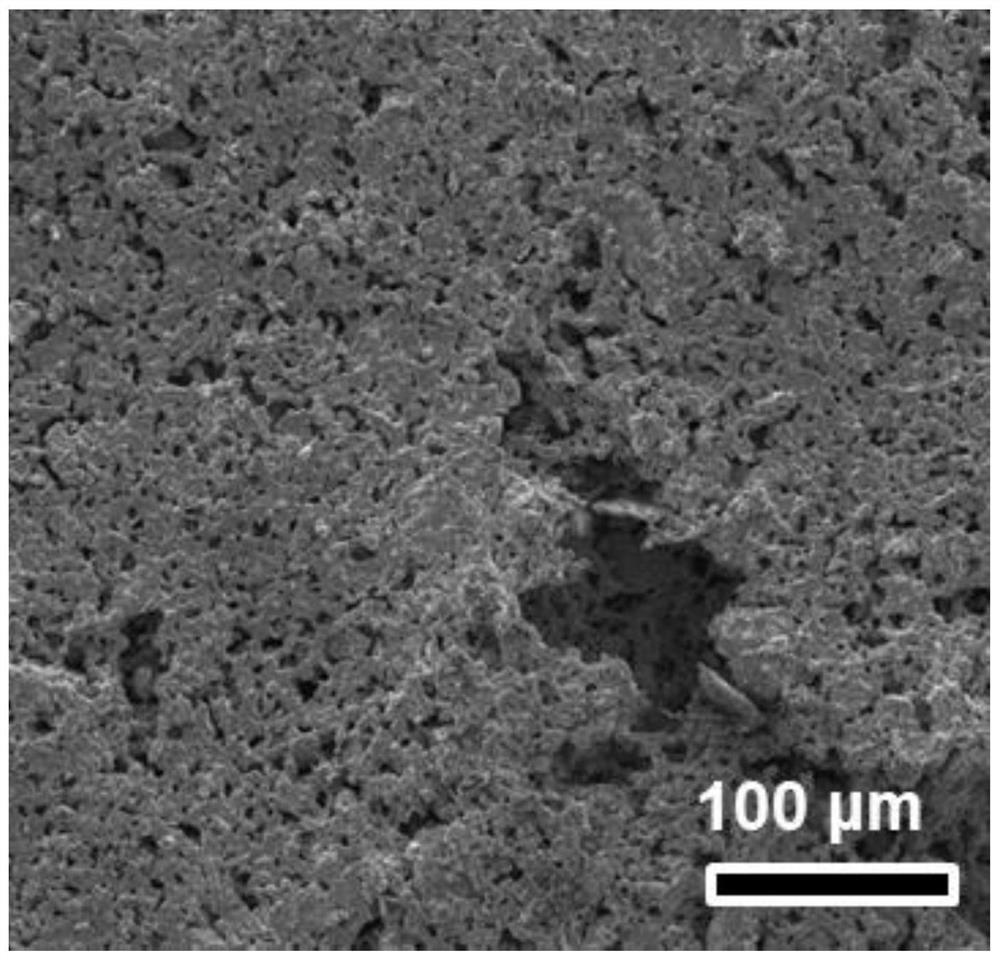

[0059] 1. Preparation of Fe-based alloy flexible film by sintering process:

[0060] (1) Ingredients: According to the national standard composition ratio of 310s stainless steel (the mass percentage is Ni 22%, Cr 26%, Si 1.5%, Mn 2%, P 0.045%, S 0.03%, C 0.08%, and the balance is Fe ) Weigh each element powder, and additionally add 0.5% C powder, the total mass of ingredients is 100g, to obtain pre-alloy powder; then add 40g of wet grinding medium ethanol, binder PVB 5g, and mix;

[0061] (2) Ball milling: after grinding for 36 hours in a planetary ball mill, a pre-alloyed powder slurry is obtained;

[0062] (3) Spraying and sizing: use a spray gun to spray the slurry on the 80-order 310s stainless steel wire mesh substrate, and the amount of sizing is 350g per square stainless steel wire mesh in terms of the pre-alloyed powder mass;

[0063] (4) Drying: put the wire mesh sprayed with the pre-alloyed powder in an oven to dry, the drying temperature is 80°C, and the drying ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com