Patents

Literature

72 results about "Membrane porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

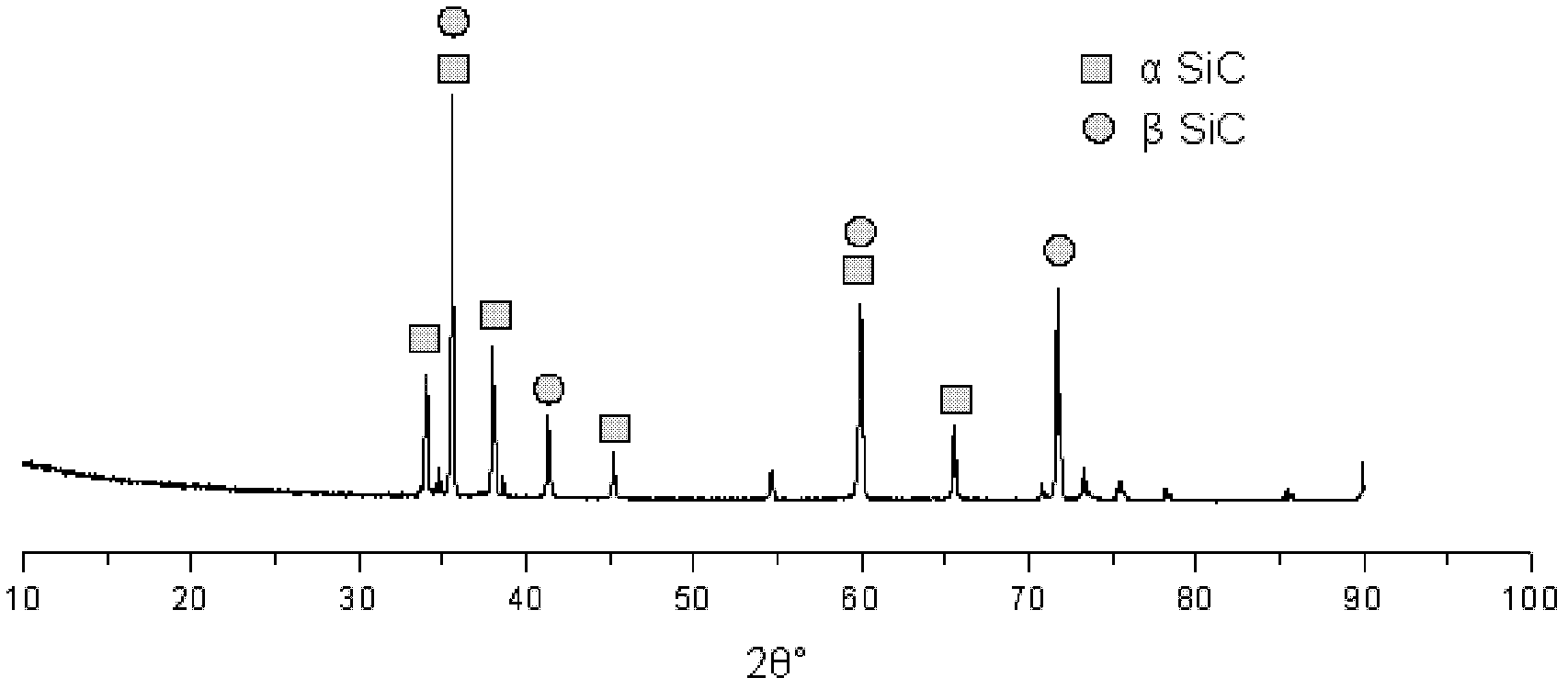

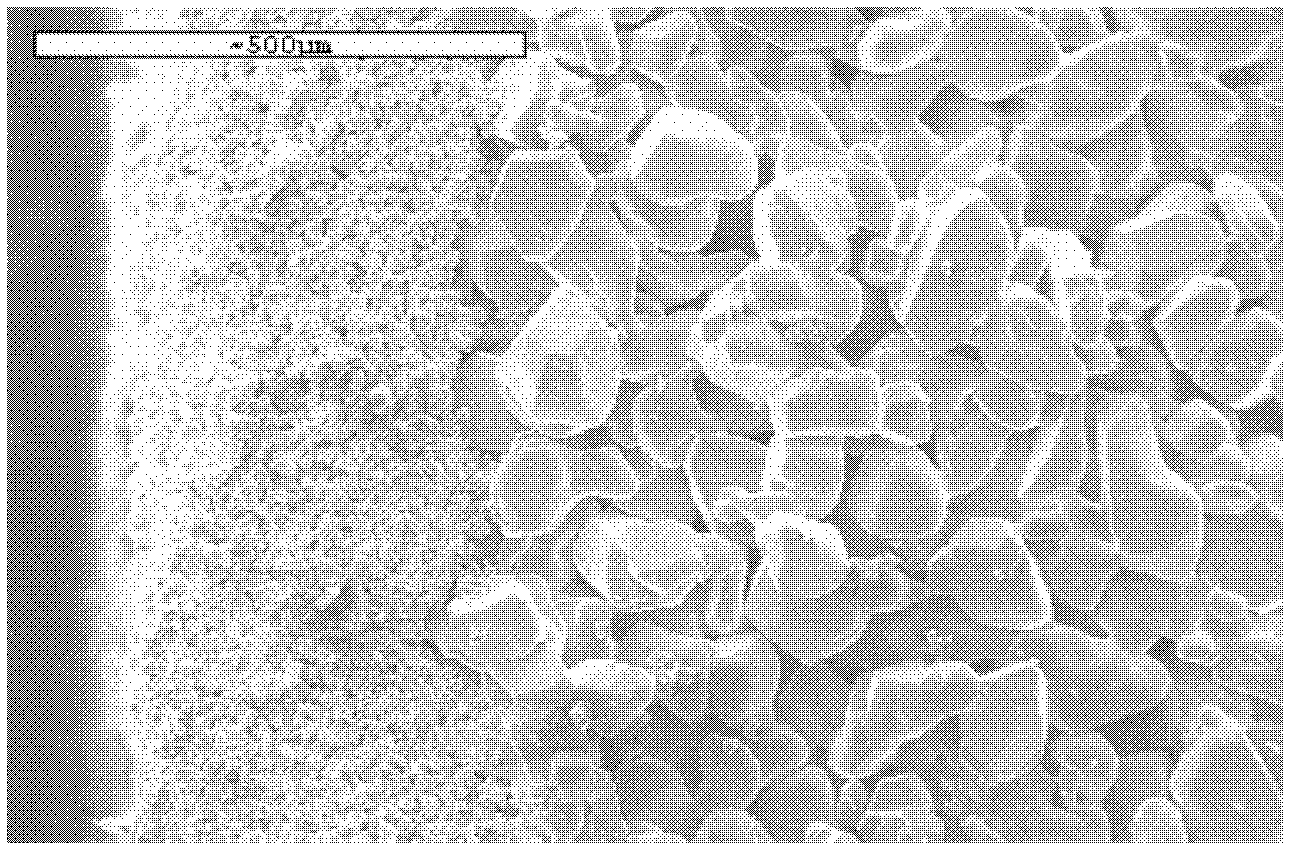

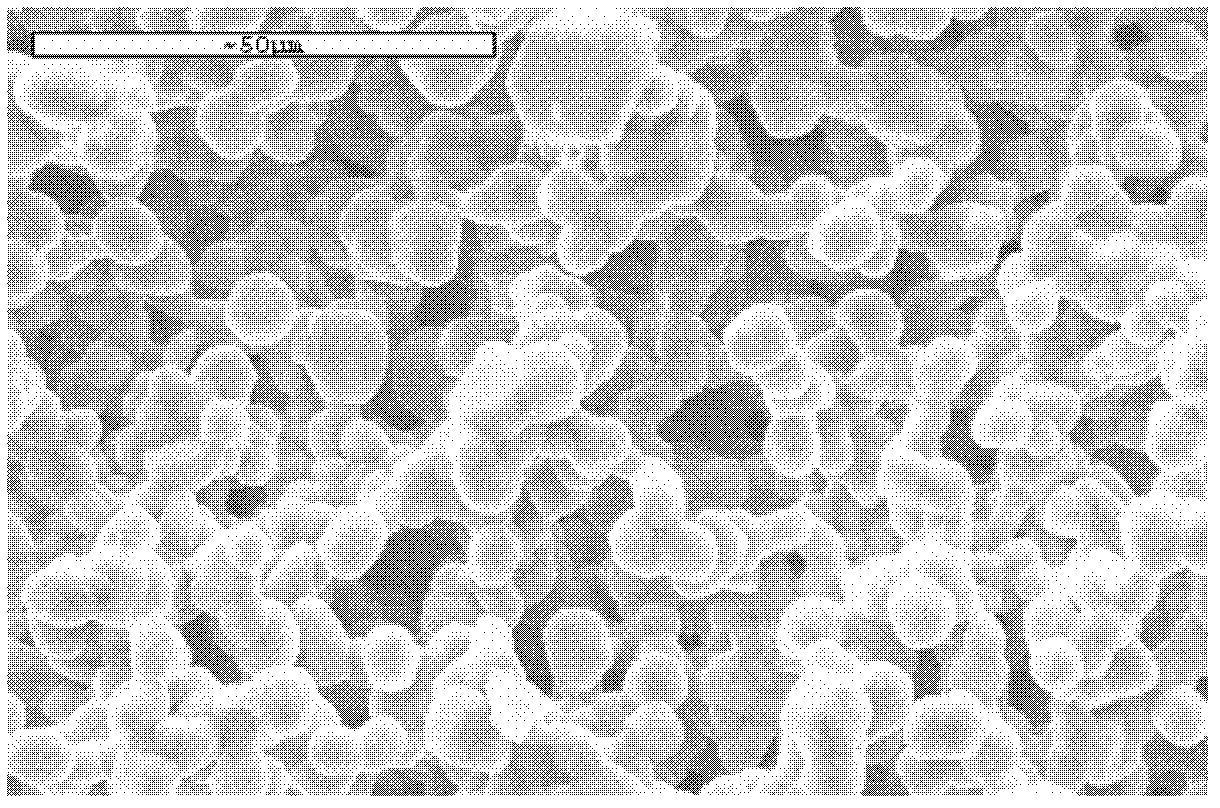

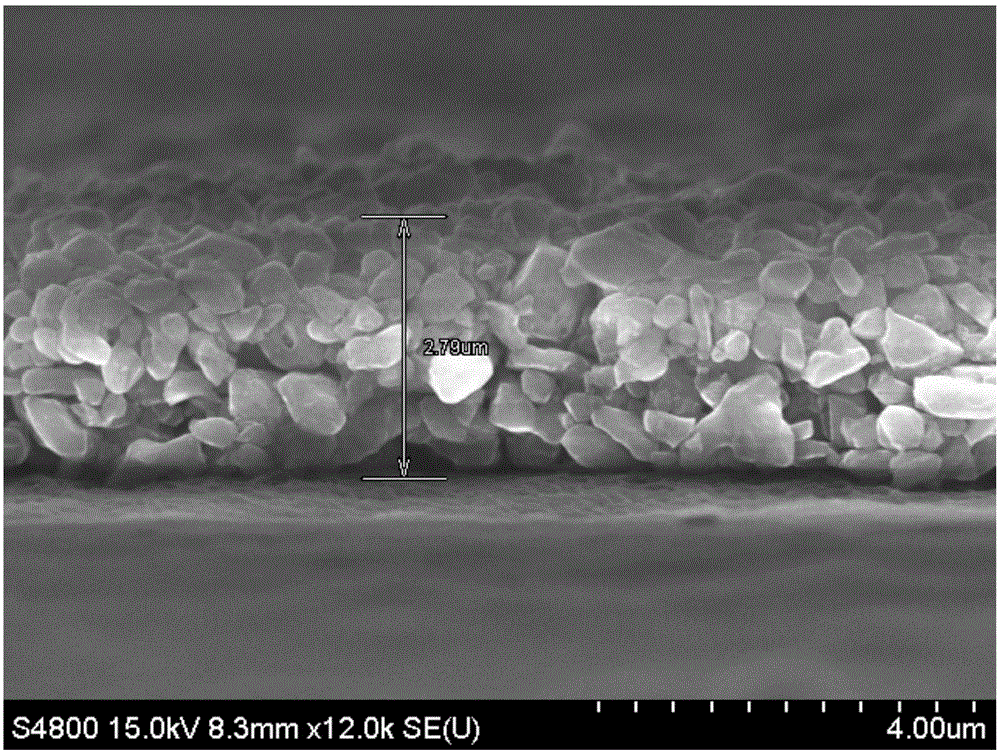

Pure silicon carbide filtering membrane and preparation method thereof

ActiveCN102659447AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

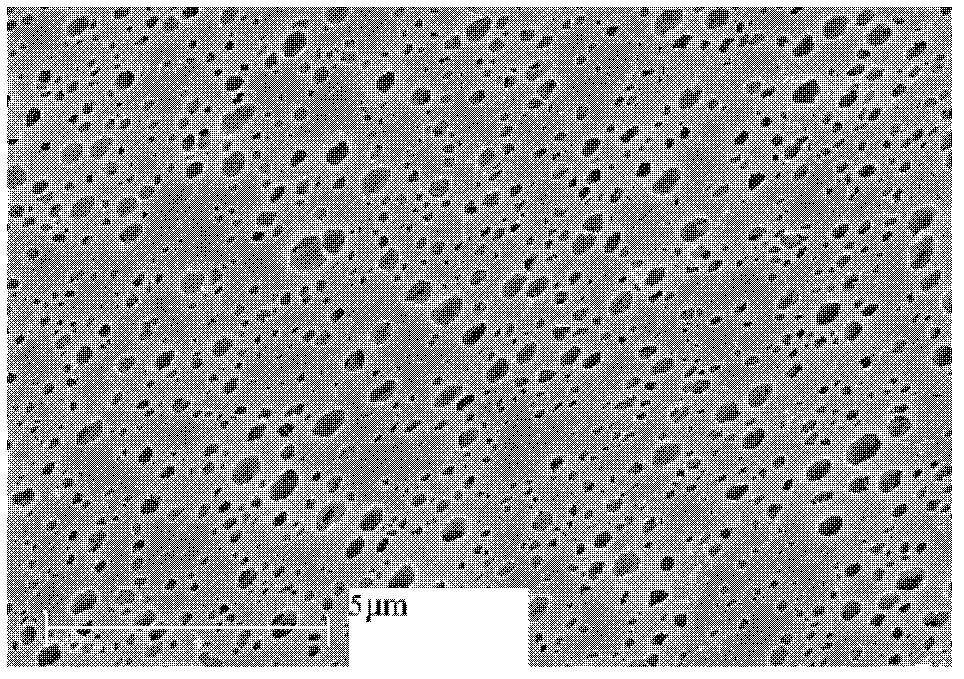

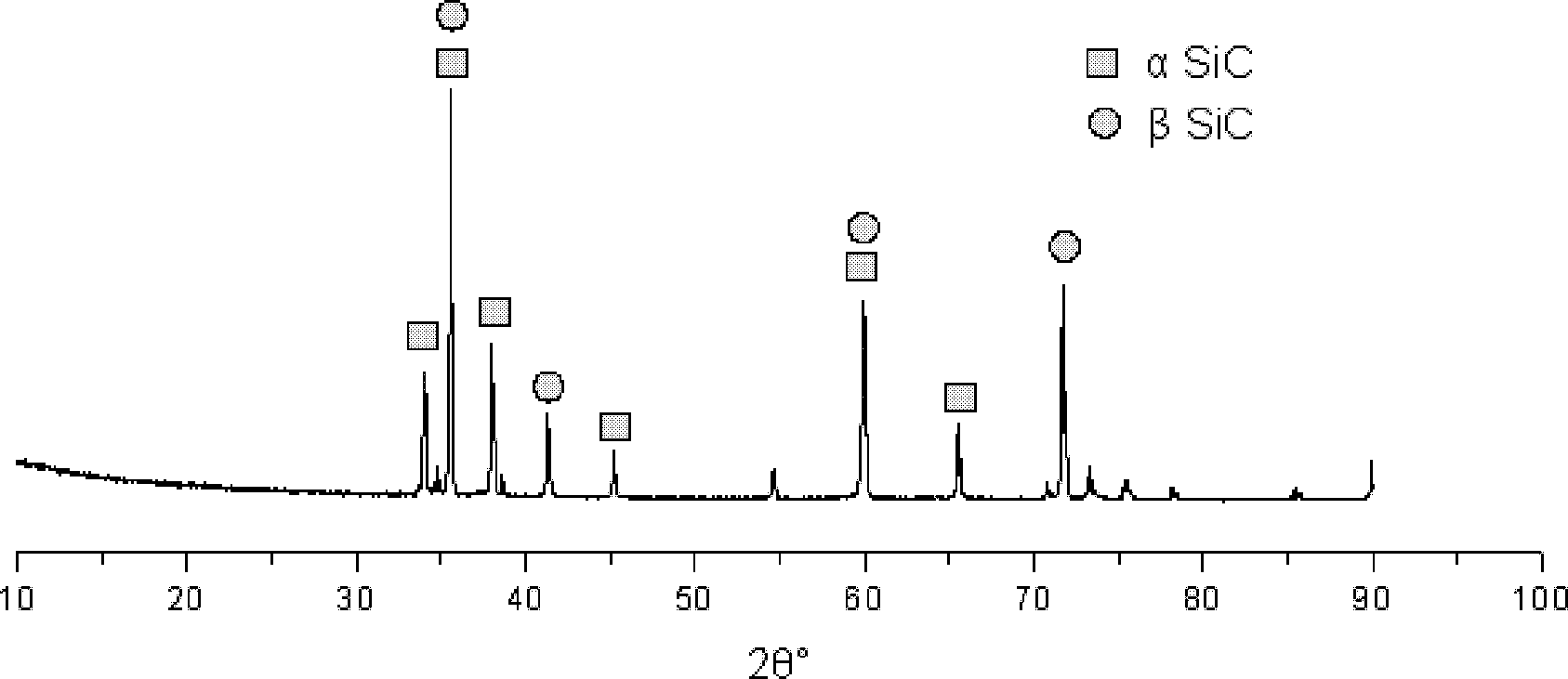

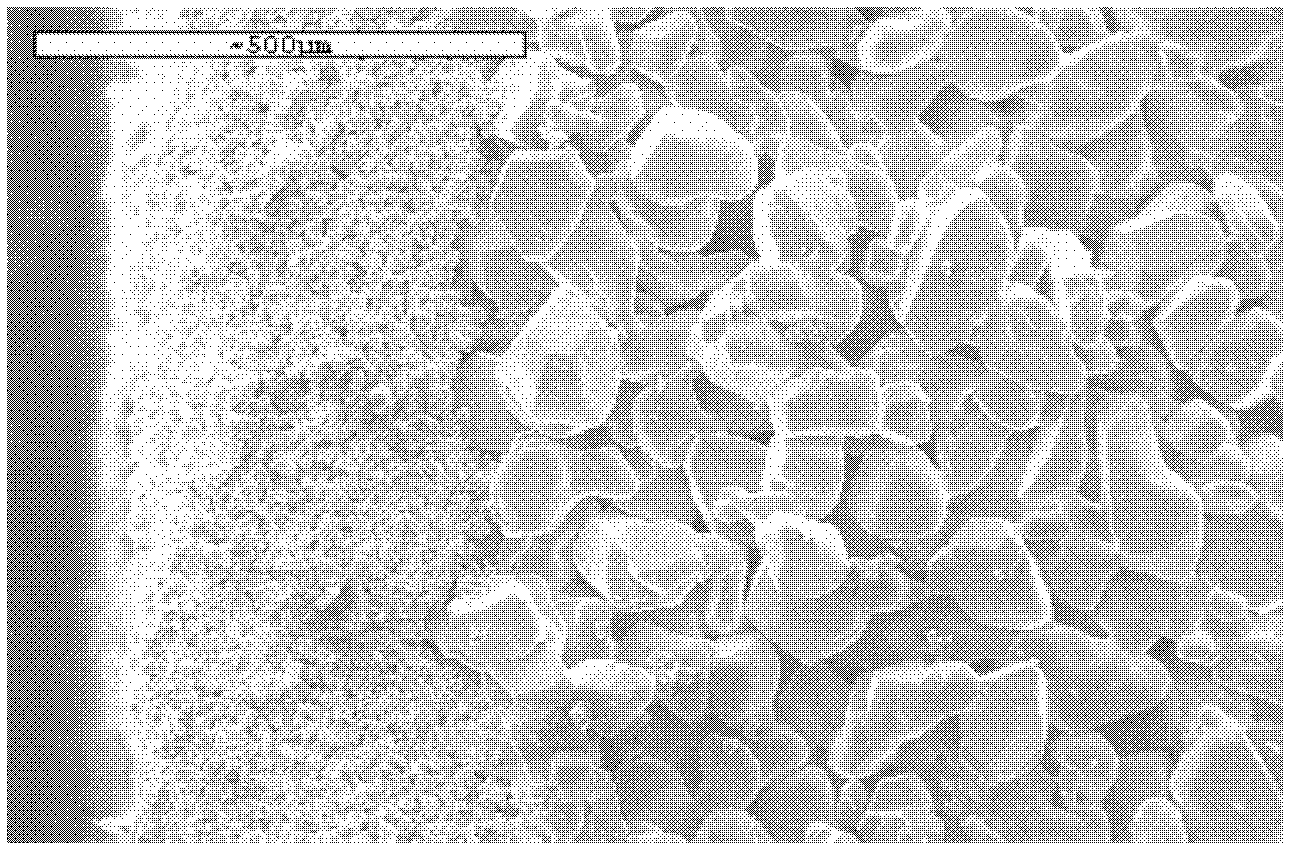

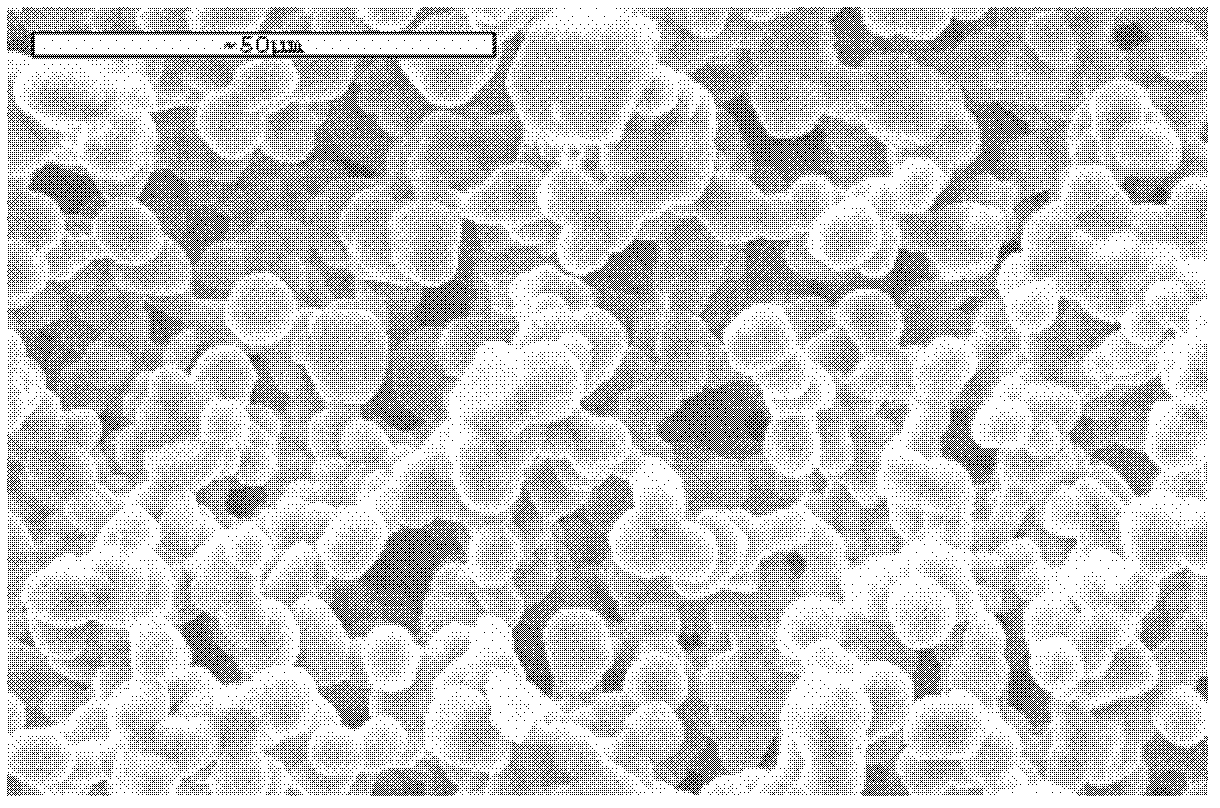

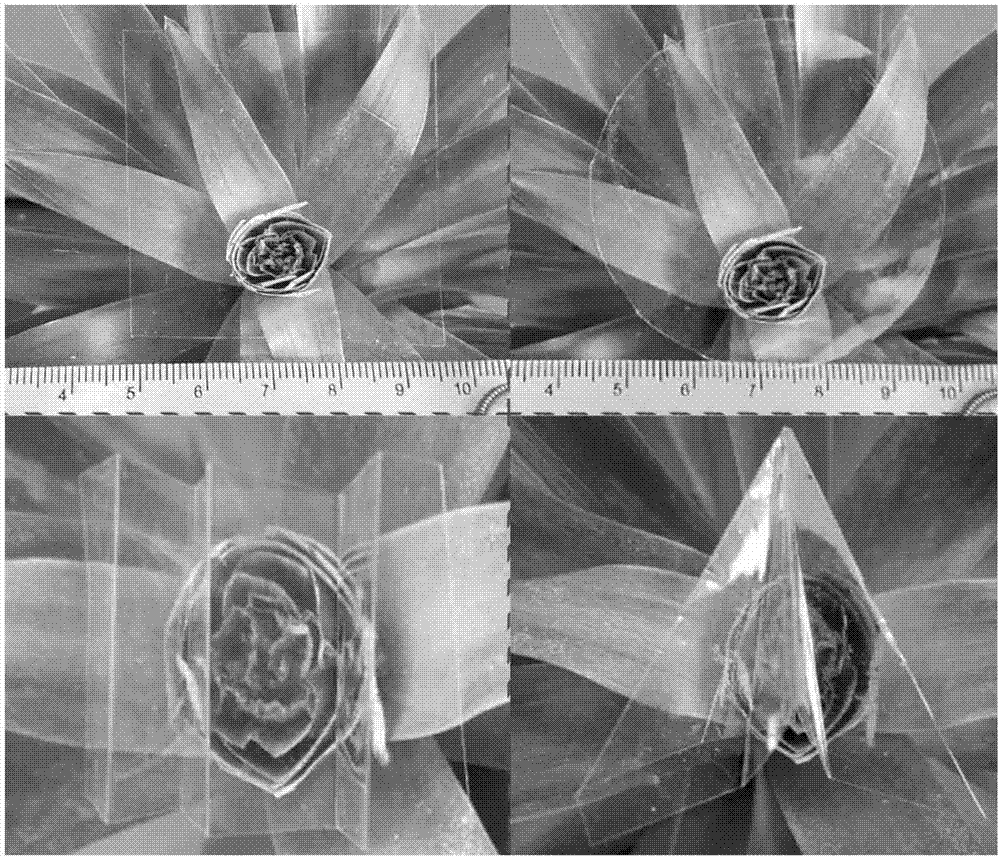

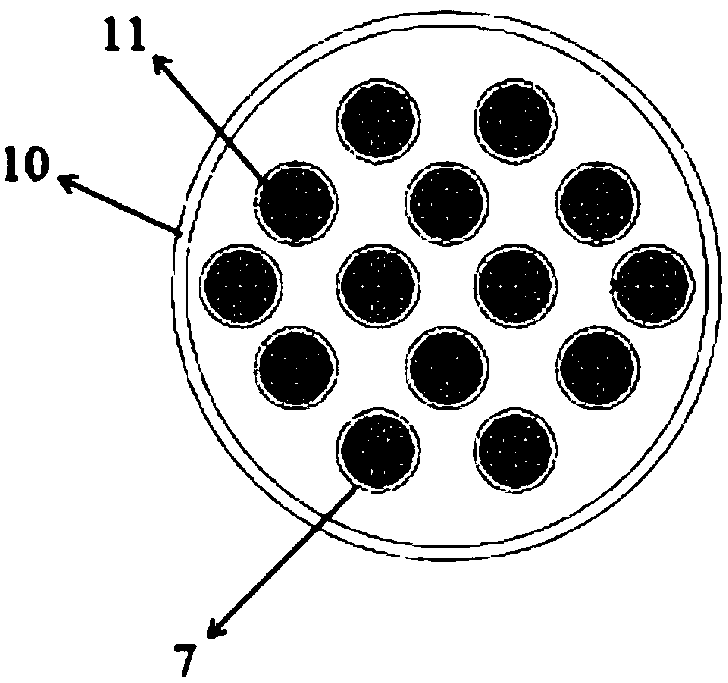

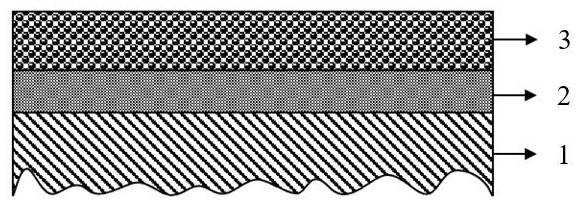

The invention belongs to the technical field of porous ceramic materials and their preparation and especially discloses a pure silicon carbide filtering membrane and a preparation method thereof. The pure silicon carbide filtering membrane has a high porosity, a low pressure drop, high strength, good thermal shock resistance and a high use temperature. The preparation method can be realized easily and can guarantee product performances. The pure silicon carbide filtering membrane comprises pure SiC, is a surface membrane layer obtained by pile-up and binding of fine SiC particles and has aperture sizes of 0.1 to 20 microns and membrane porosity of 25 to 50%. Fine SiC particles, silicon powder, a pore-forming additive and one or more organic resins as raw materials are prepared into a surface membrane layer by spraying or dipping and the surface membrane layer is dried and sintered to form the pure silicon carbide filtering membrane. The pure silicon carbide filtering membrane can be used in an oxidation atmosphere and in a reducing atmosphere, has strong acid corrosion and alkaline corrosion resistance, and can be used for various high / low temperature fluid filtering purification fields such as coal gasification chemical engineering, integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) coal gasification power generation, and high temperature flue gas, automobile exhaust and water purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

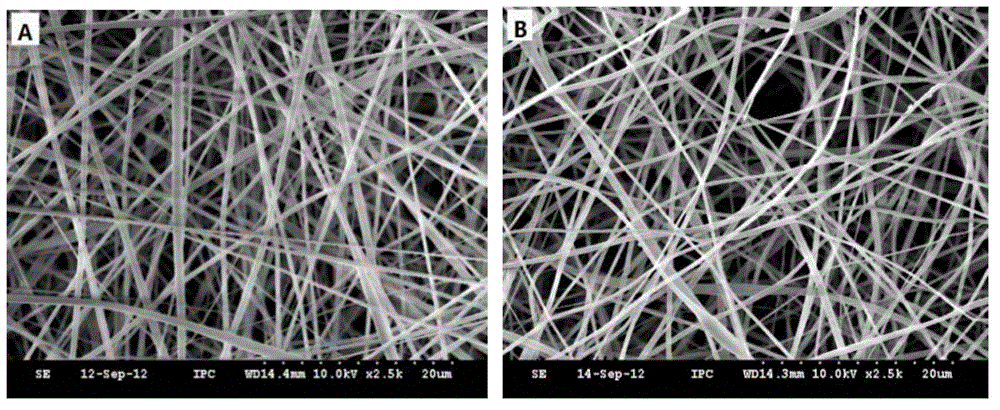

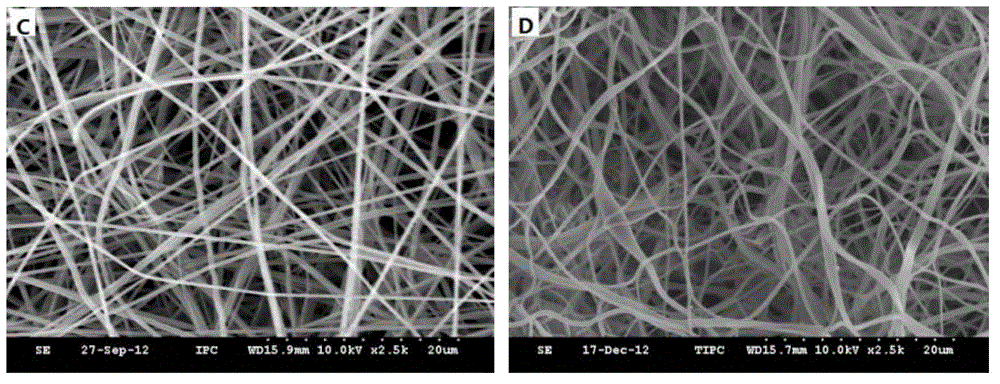

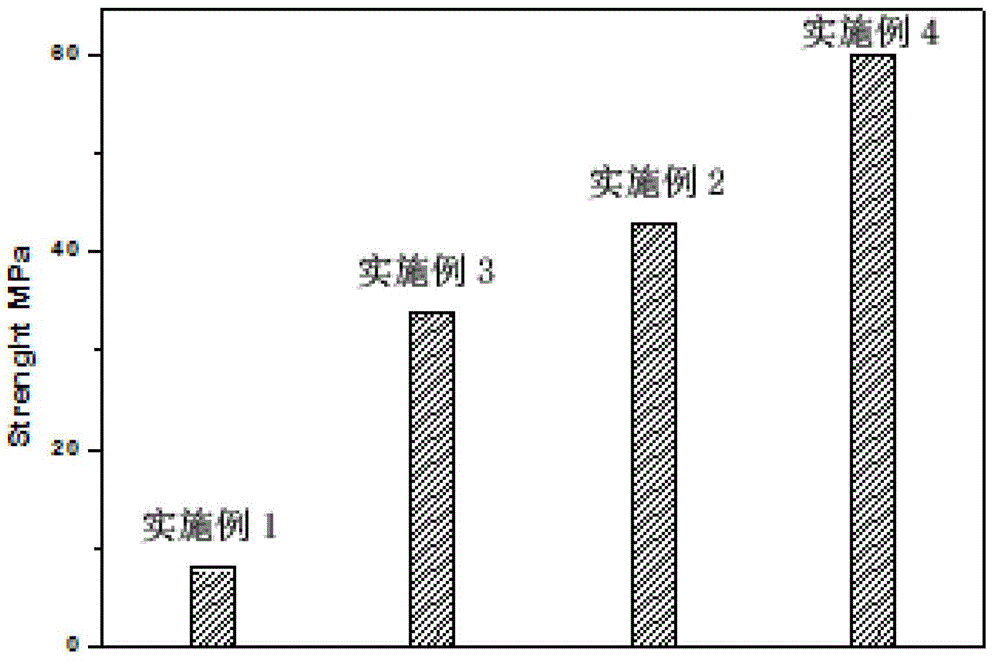

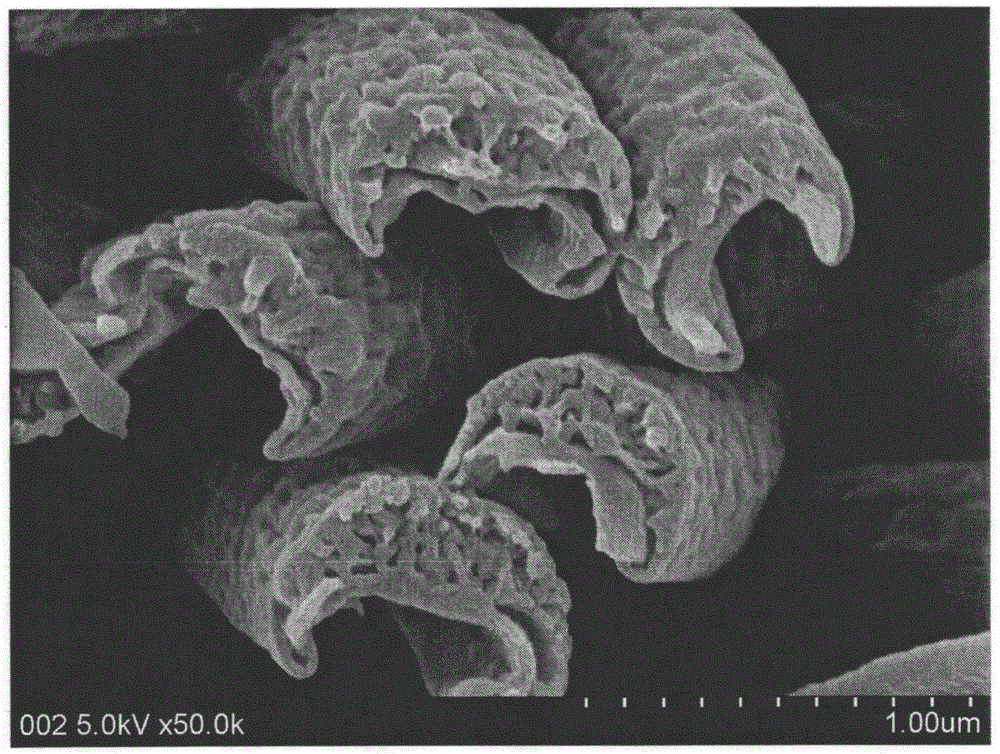

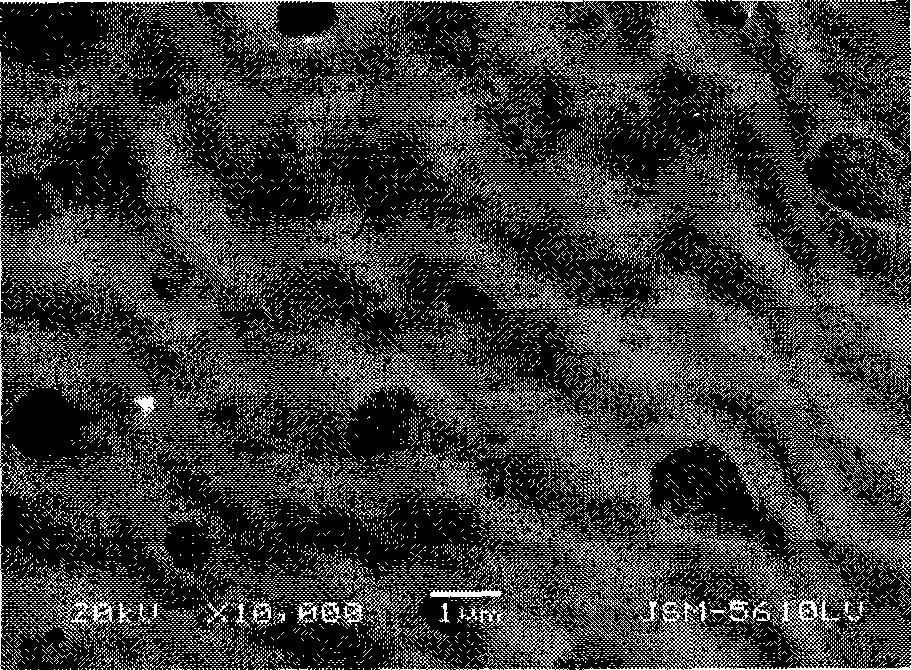

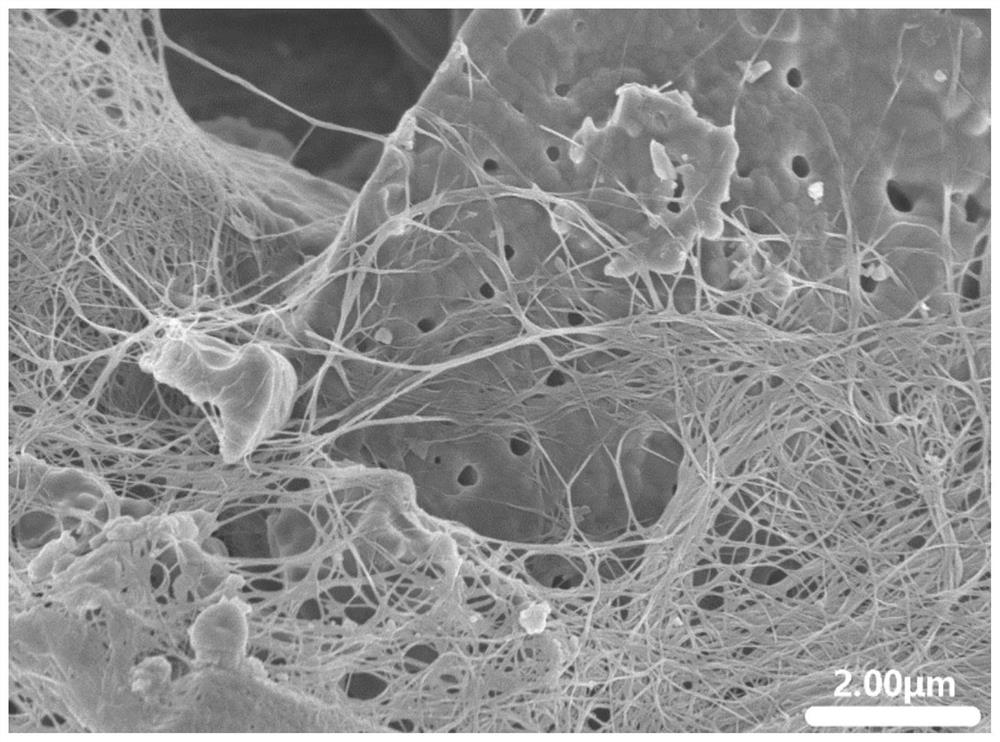

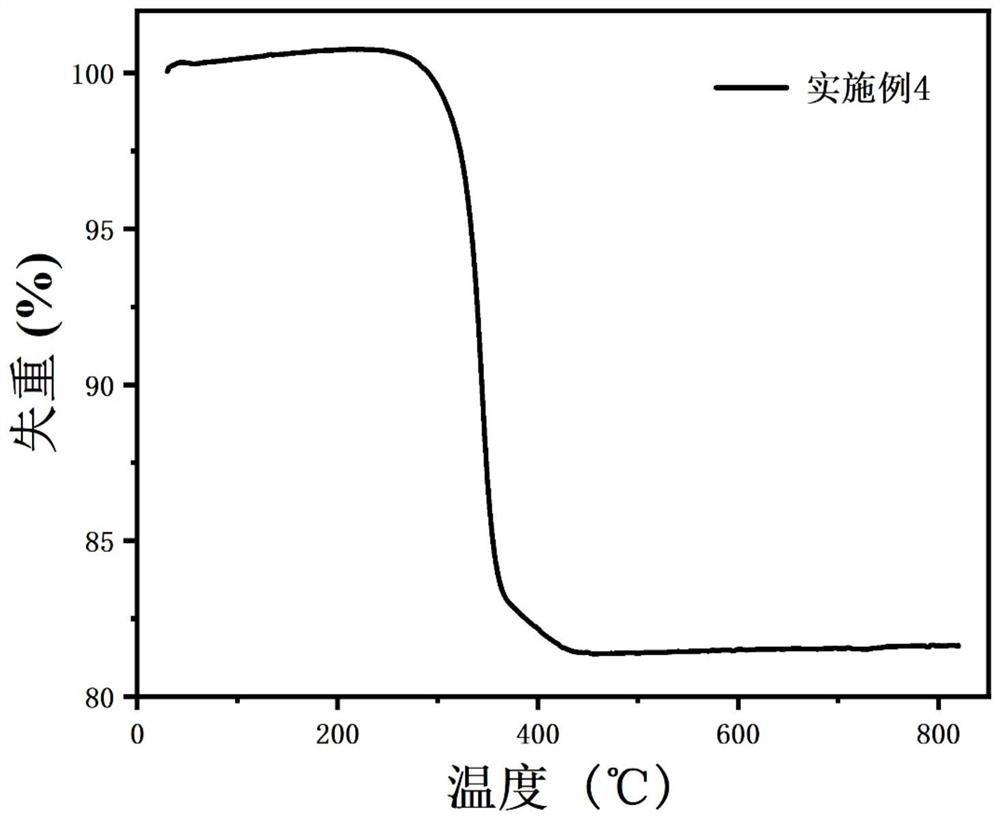

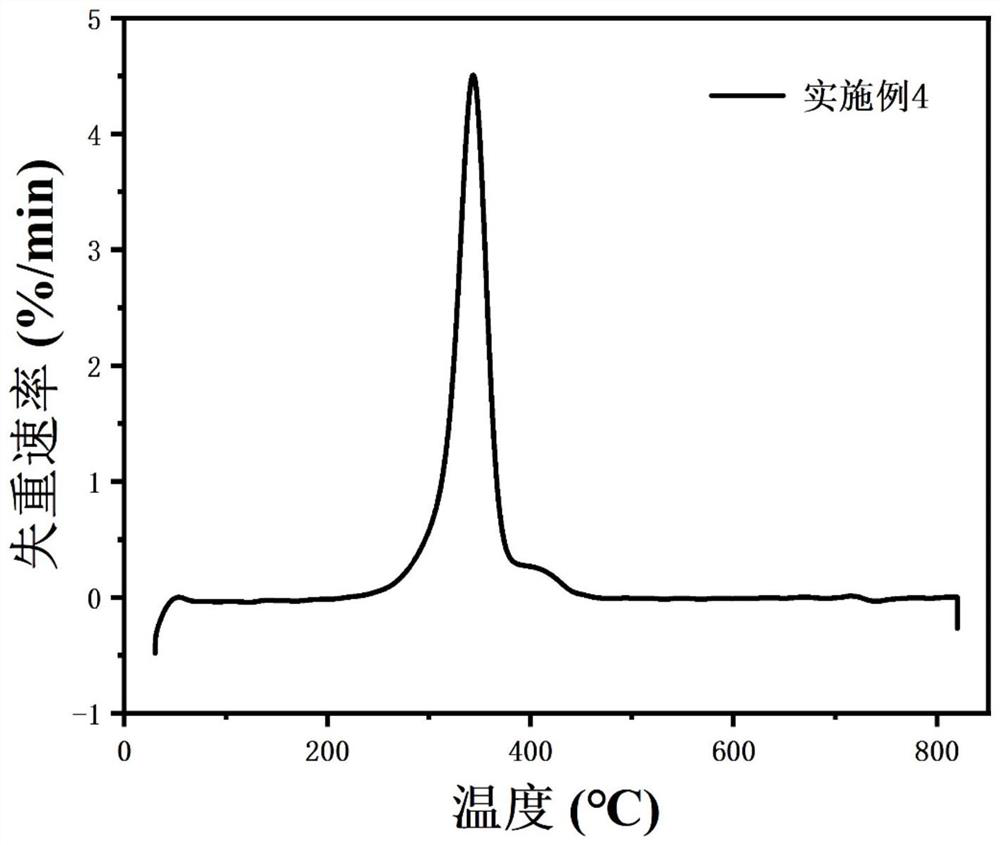

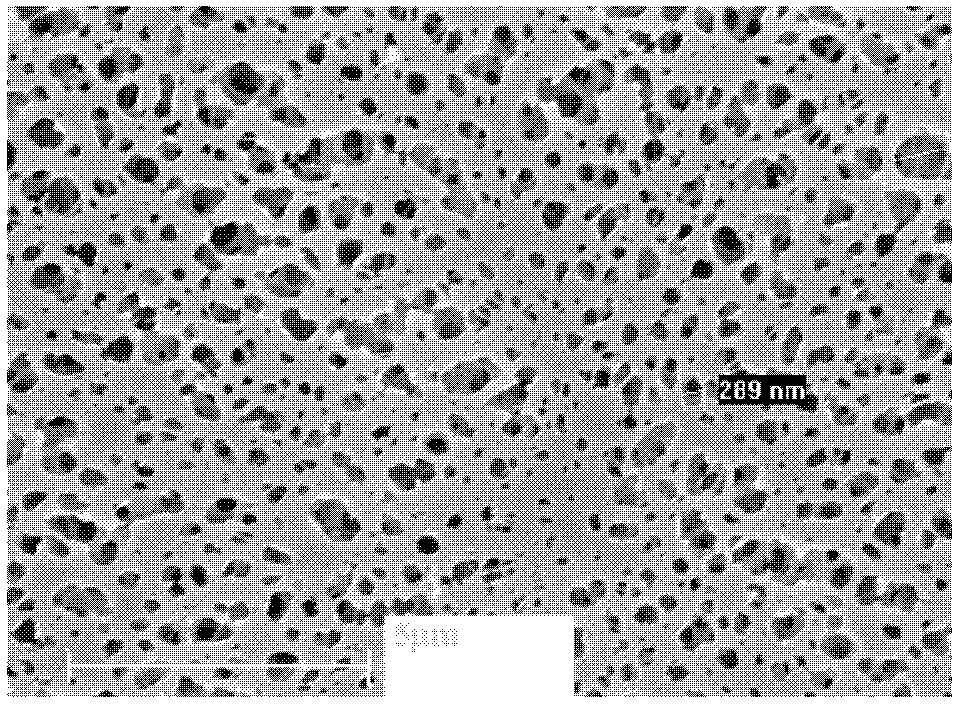

High-strength polyimide nano fiber porous membrane, and preparation method and application thereof

InactiveCN103147253AHigh porosityImprove mechanical propertiesHeating/cooling textile fabricsNon-woven fabricsFiberChemical composition

The invention discloses a high-strength polyimide nano fiber porous membrane. The porosity of the polyimide nano fiber porous membrane is 70-85%, the average pore diameter is 100-250 nm, the glass transition temperature is 260-400 DEG C, the tensile strength is 8-70 MPa, and the dimensional shrinkage after high-temperature 200 DEG C heat treatment for 1 hour is less than 0.3%. The chemical composition of the polyimide nano fiber porous membrane is copolymerized polyimide or blended polyimide. The invention also discloses a preparation method and application of the polyimide nano fiber porous membrane. The polyimide nano fibrous membrane disclosed by the invention is a membrane material having the advantages of high strength, low dimensional change rate, high porosity and favorable thermal properties.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

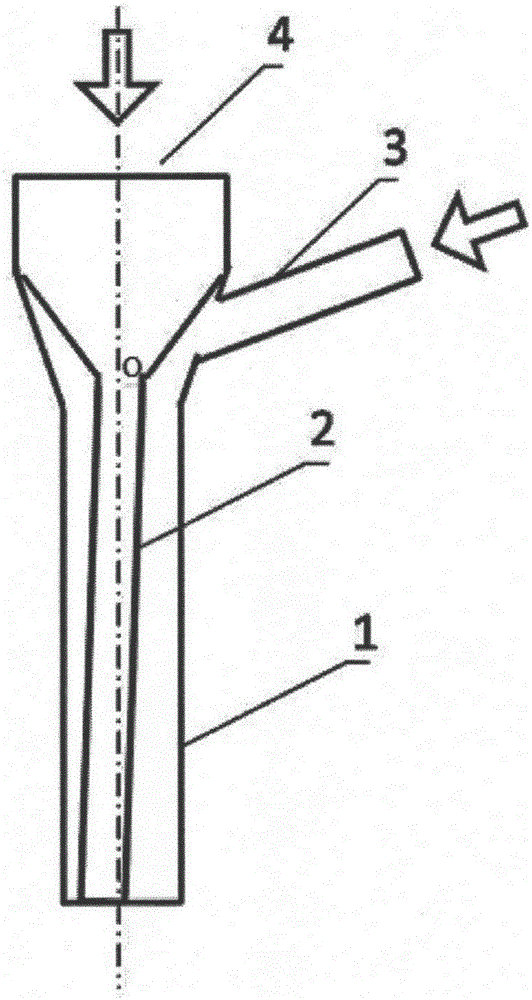

Porous membrane and pore-forming method thereof

InactiveCN103706259AUniform porous structureSemi-permeable membranesHollow fibre membranePorous membrane

The invention discloses a porous membrane and a pore-forming method of the porous membrane. According to a preparation method, a foaming pore-forming agent is introduced into a membrane-forming system and can generate uniformly distributed trace air bubbles through reaction so as to form a porous structure; therefore, the porosity of the membrane is improved, and macropore defects of the membrane can be avoided. The pore-forming method is applicable to membrane preparation by a solution method and a melting method. The pore-forming method specifically comprises the steps of (1) membrane preparation by the solution method: uniformly mixing a membrane-forming polymer and the foaming pore-forming agent, dissolving the mixture in a solvent to obtain a membrane casting solution containing the foaming pore-forming agent, wherein the membrane casting liquid enters an acidic coagulating bath after being subjected to scraping or is spun through a hollow fiber spinning head, so that the membrane casting liquid is solidified and formed to obtain the porous membrane when the foaming pore-forming agent reacts to form the air bubbles; (2) membrane preparation by the melting method: uniformly mixing the membrane-forming polymer and the foaming pore-forming agent, and obtaining an initial hollow fiber containing the foaming pore-forming agent through conventional hollow fiber membrane melting spinning, and putting the obtained initial hollow fiber into the acidic coagulating bath, wherein the hollow fiber is solidified and formed to obtain the porous membrane when the foaming pore-forming agent reacts to form the air bubbles.

Owner:TIANJIN POLYTECHNIC UNIV

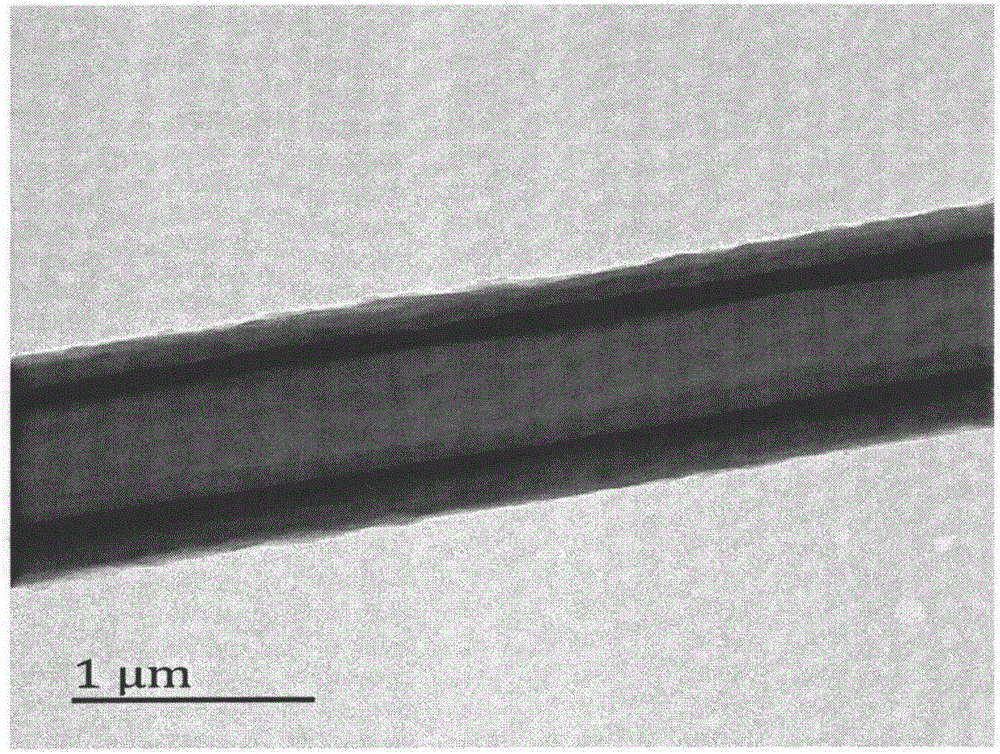

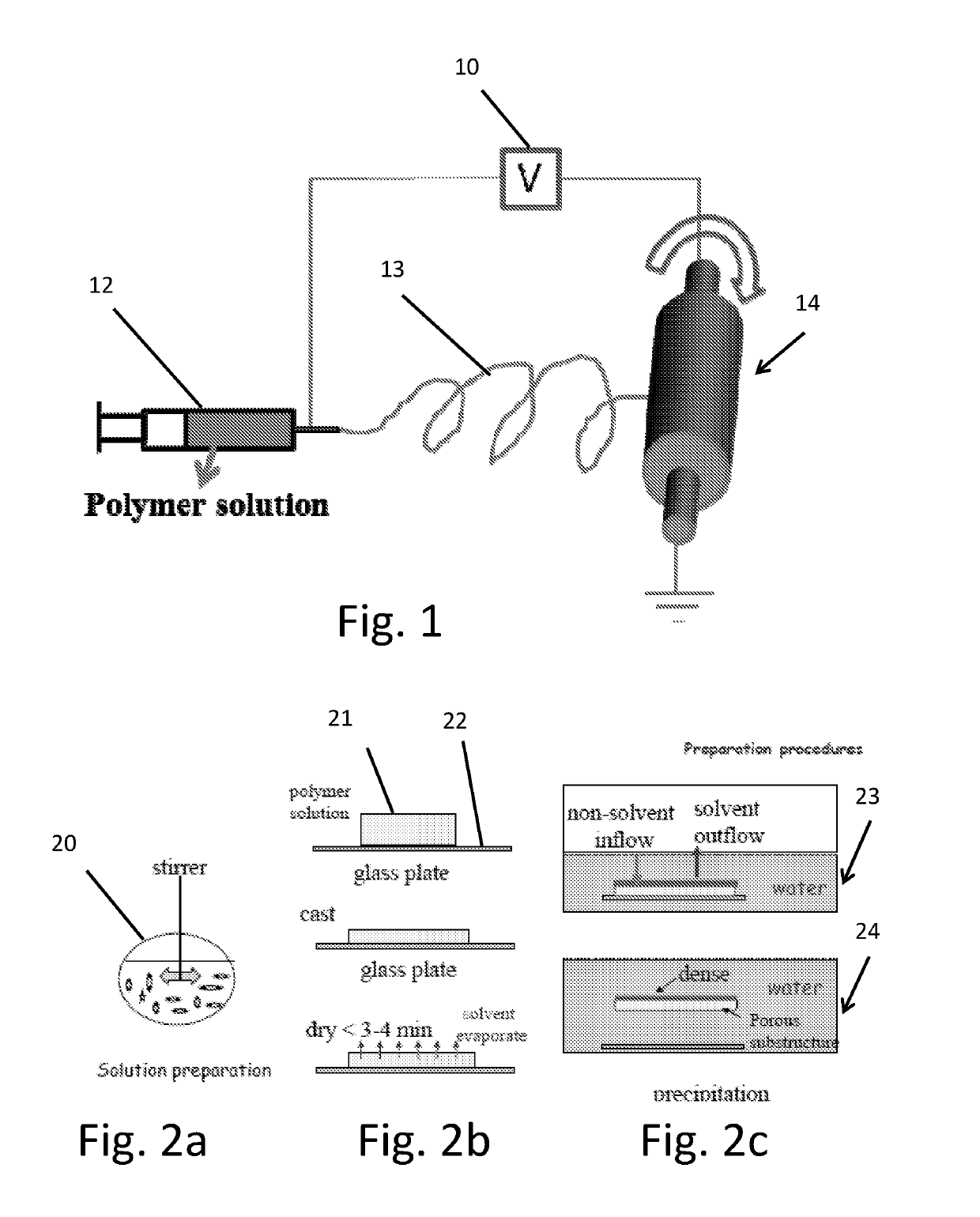

Type-C core-shell nanofiber membrane and eccentric-shaft electrostatic spinning preparation method thereof

InactiveCN105696197ASimple manufacturing methodEasy to realize the operation of large-scale productionSemi-permeable membranesElectro-spinningFiberDistillation

The invention provides a type-C core-shell nanofiber membrane and an eccentric-shaft electrostatic spinning preparation method thereof.The preparation method is characterized by comprising the steps that a hydrophobic polymer is dissolved in a solvent to obtain a shell-layer solution; a hydrophilic polymer is dissolved in a solvent to obtain a core-layer solution, the shell-layer solution and the core-layer solution are respectively injected into an outer needle and an inner needle of an eccentric-shaft electrostatic spinning needle at a certain flowing speed, and meanwhile a high-voltage electrostatic generator is connected with the eccentric-shaft electrostatic spinning needle to perform electrostatic spinning so as to obtain the core-shell nanofiber membrane.The hydrophobic type-C grooved core-shell nanofibers obtained by means of the preparation method and used for membrane distillation can remarkably improve the defects of low membrane porosity, low heat conversion efficiency, low water vapor flux and membrane pore wetting of a traditional distillation membrane based on the particular structural characteristics, the porosity, heat conversion efficiency and water vapor flux of a common electrostatic spinning membrane can be improved, a membrane distillation technology can compete with a reverse osmosis technology in the field of seawater desalination.

Owner:DONGHUA UNIV

Environment-friendly high-performance ceramic coating lithium ion battery diaphragm and preparation method thereof

ActiveCN104638220AGuaranteed adhesionIncrease capacityCell seperators/membranes/diaphragms/spacersPolyolefinCeramic coating

The invention discloses an environment-friendly high-performance ceramic coating lithium ion battery diaphragm and a preparation method thereof. The environment-friendly high-performance ceramic coating lithium battery diaphragm comprises a polyolefin matrix microporous membrane and a ceramic coating which is composited on the upper surface or on the upper surface and the lower surface of the polyolefin matrix microporous membrane; the overall thickness of the environment-friendly high-performance ceramic coating lithium battery diaphragm is 8 to 40 micrometers; the thickness of the ceramic coating is 2 to 5 micrometers; the porosity of the polyolefin matrix microporous membrane is 42 to 52 percent, the aperture of the polyolefin matrix microporous membrane is 0.15 to 1.5 micrometers, and the axial cross section of each hole in the polyolefin matrix microporous membrane is in a wavy shape. A lithium ion battery prepared by adopting the environment-friendly high-performance ceramic coating lithium ion battery diaphragm is relatively good in safety, and the problems of dropping and no temperature resistance of an existing lithium battery diaphragm ceramic coating and the safety problem caused by the diaphragm of a lithium ion battery can be effectively solved; the lithium ion battery diaphragm provided by the invention is high in porosity and good in electrolyte wetting property, mechanical property and temperature resistance and also has high-temperature turn-off performance.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

Battery separator, fabrication method thereof

ActiveCN101393976ASignificant progressCell seperators/membranes/diaphragms/spacersElectrical batteryPhysical chemistry

The invention discloses a battery diaphragm and a preparation method thereof. The battery diaphragm is a porous battery septum and comprises polyimide and non-woven fabric. The porosity of the battery diaphragm provided by the invention is 30 to 50 percent, and the average pore diameter is 0.01-0.1 Mum, thereby ensuring that lithium ions pass through the battery diaphragm smoothly, and reducing hole resistance in a battery. When the battery is used, even if in abnormal situations such as local high temperature and the like, because the polyimide and the non-woven fabric are directly combined, the polyimide does not fall off from the non-woven fabric, the short circuit of the battery is not caused, and the safety performance of the battery is improved.

Owner:BYD CO LTD

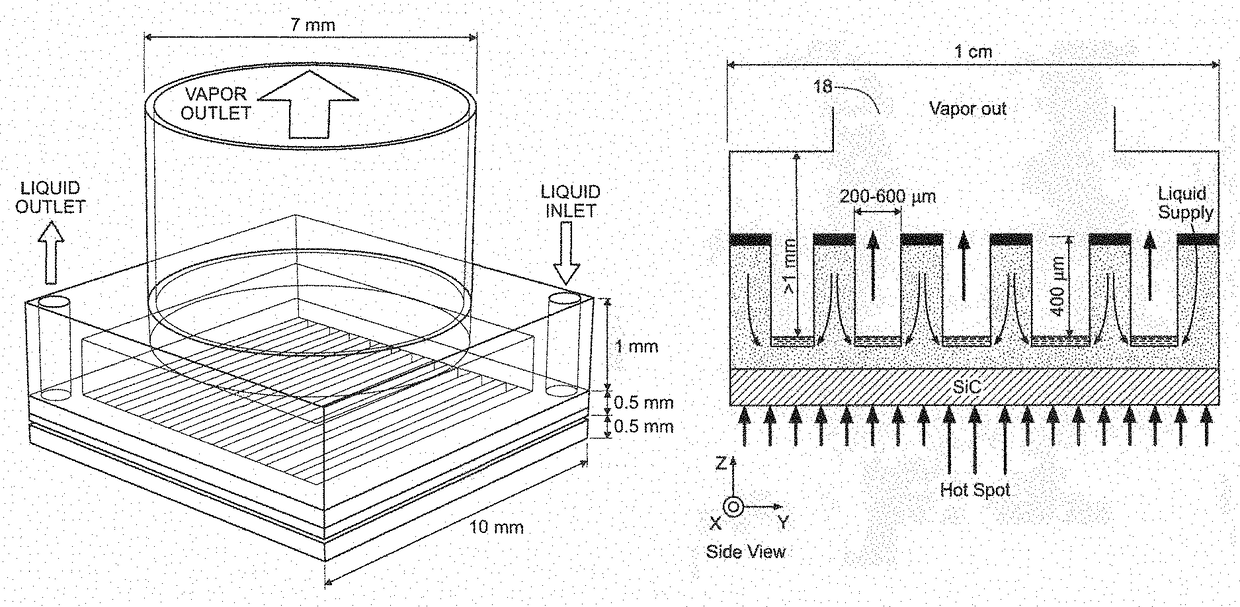

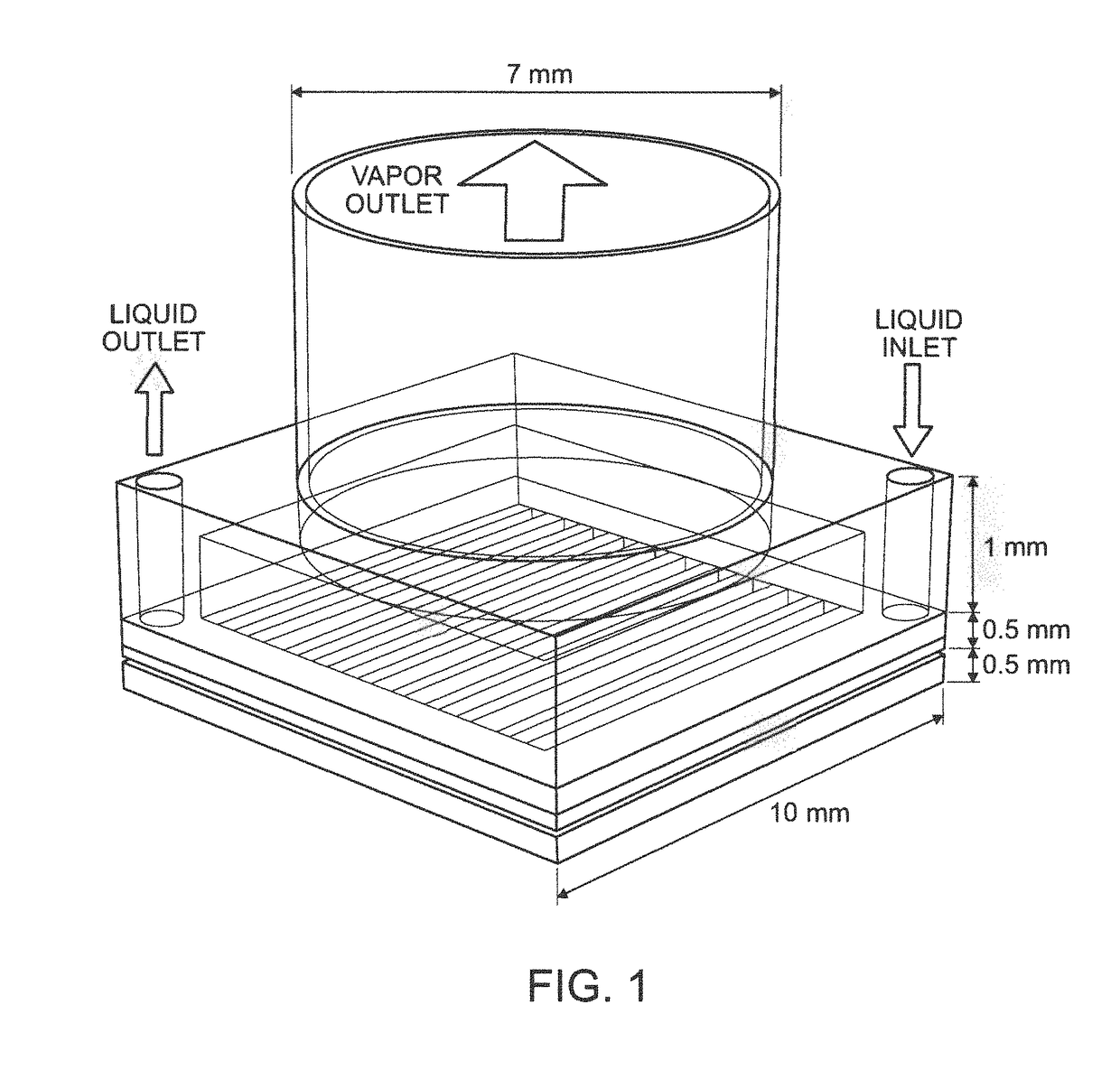

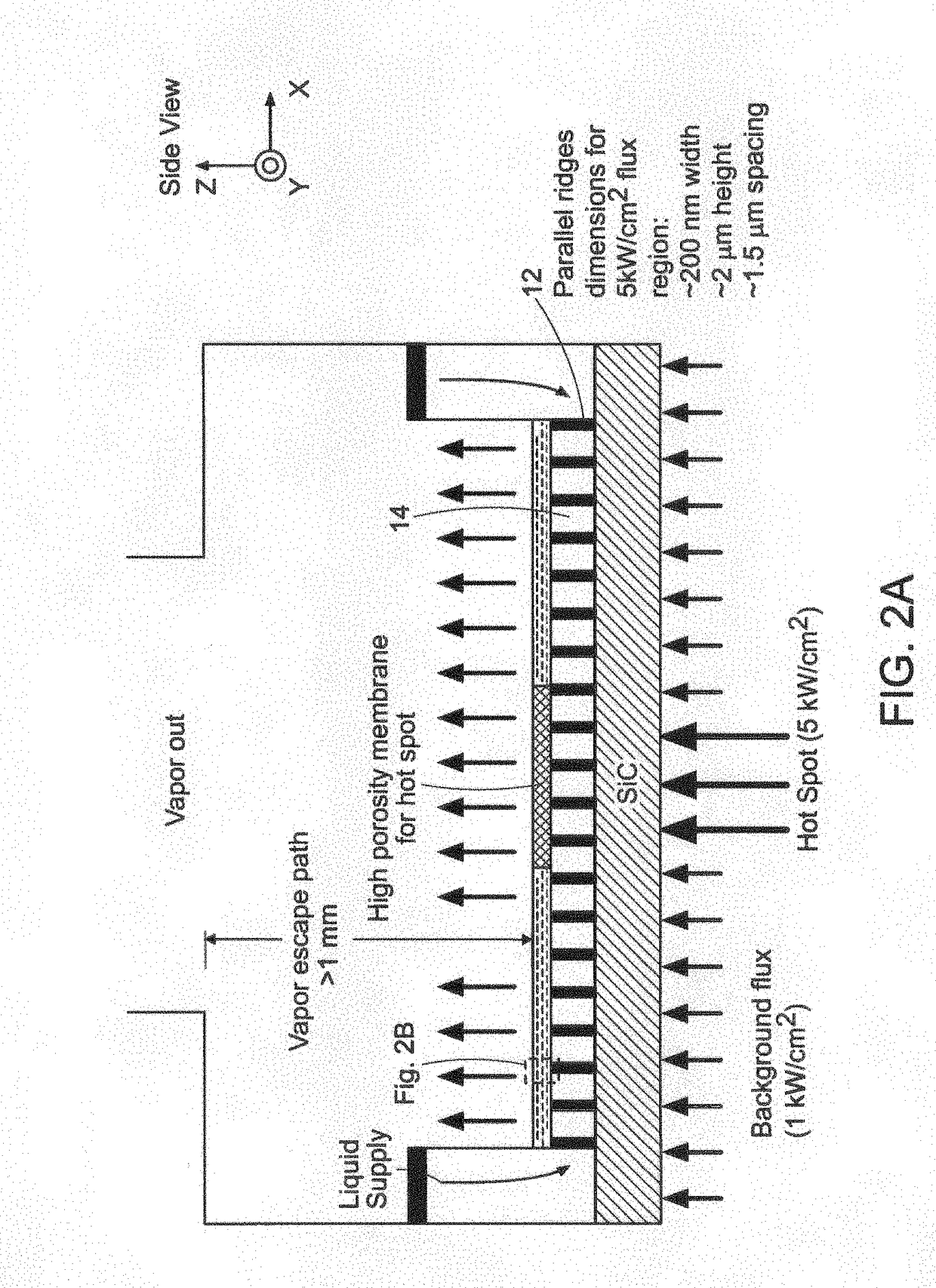

Evaporative Heat Transfer System

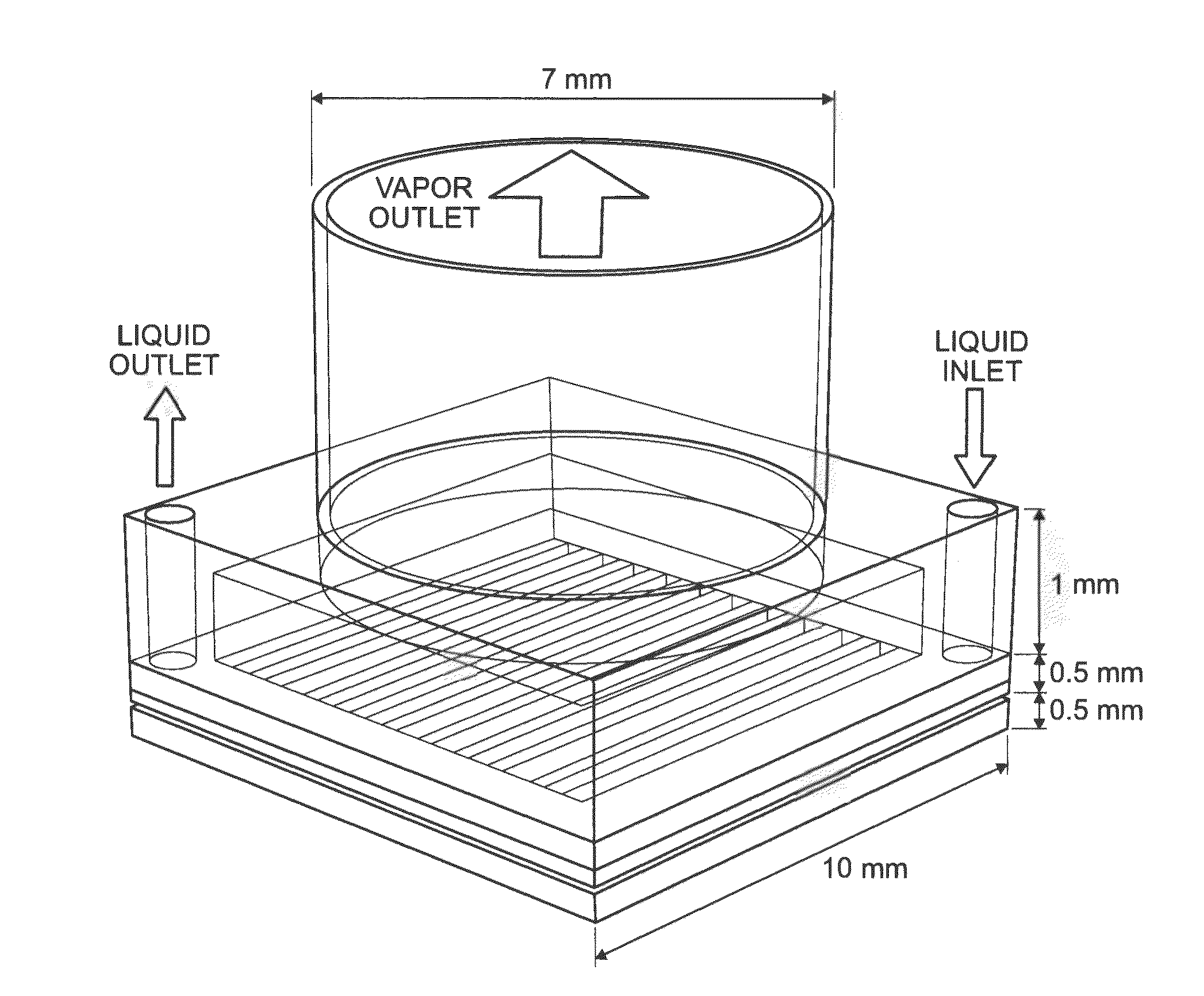

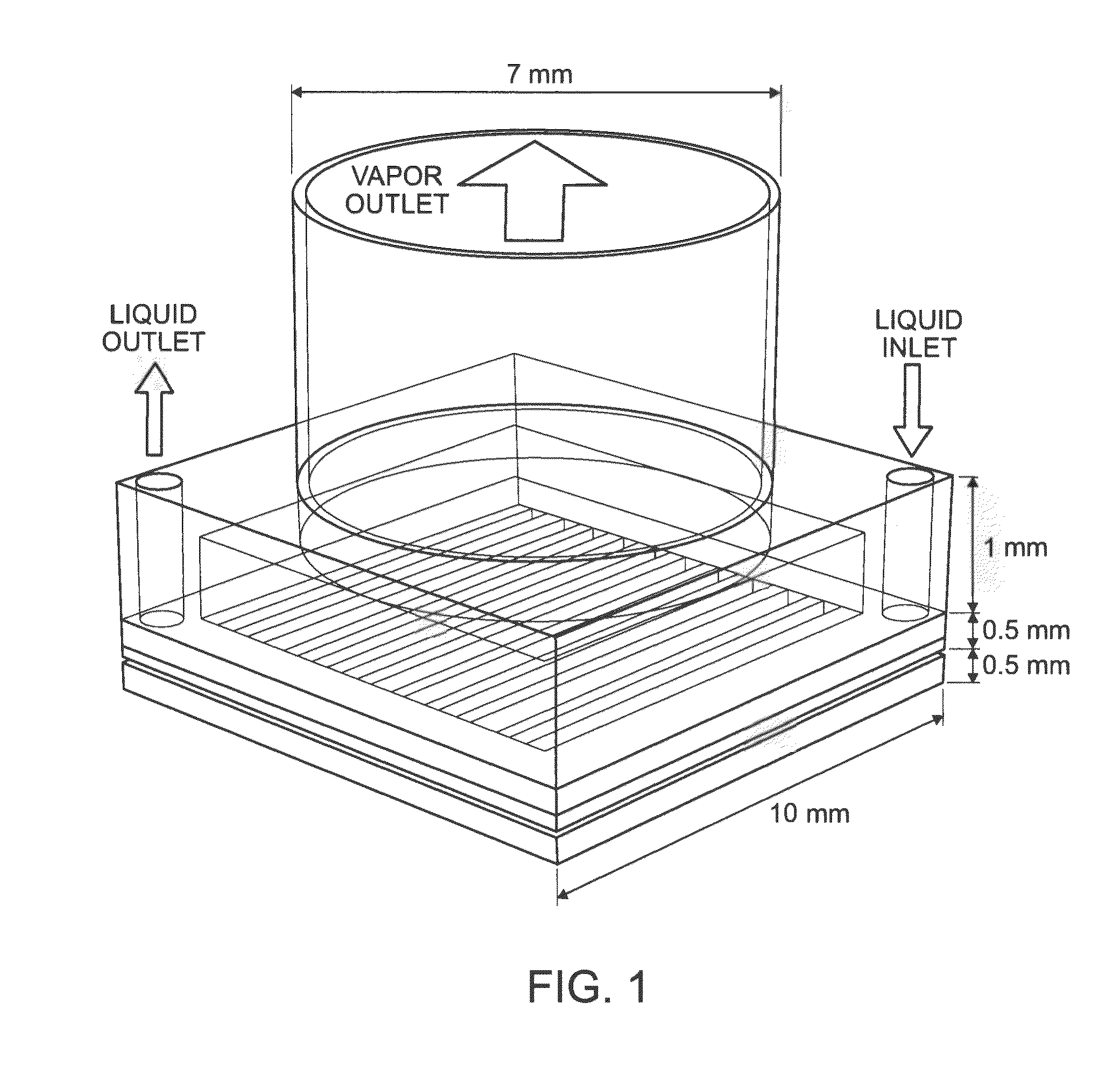

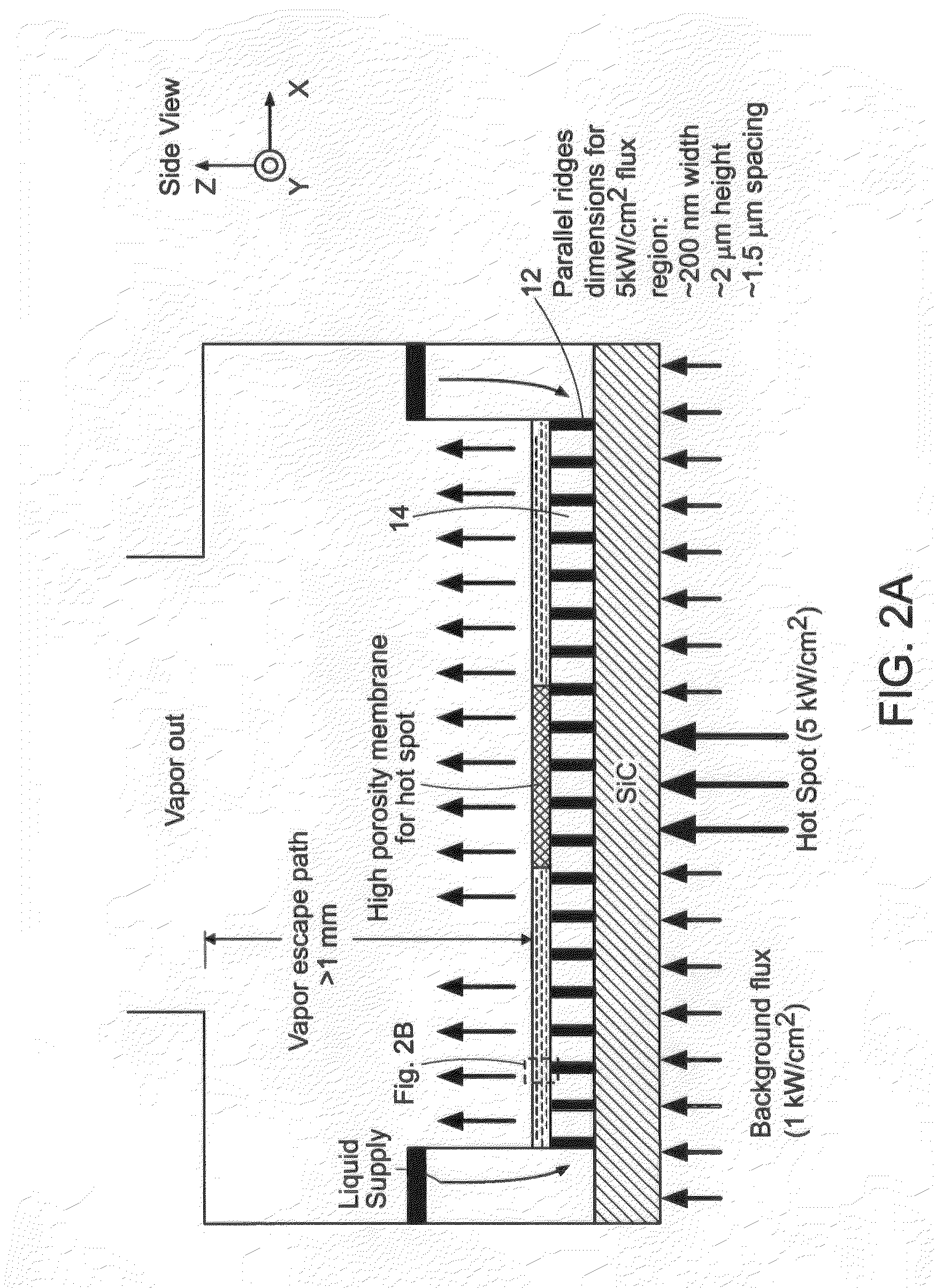

ActiveUS20140196498A1High capillary pressureHeat dissipationSemiconductor/solid-state device detailsEvaporators/condensersEvaporation heat transferNanoporous membrane

Evaporative heat transfer system. The system includes a substrate and a plurality of substantially parallel, spaced-apart ridges extending from the substrate forming vertical liquid manifolds therebetween. A nanoporous membrane is supported on the ridges and a pump delivers a dielectric fluid across the ridges. The fluid is drawn through the liquid manifolds via capillarity provided by the nanoporous membrane and evaporates to dissipate heat flux through the substrate. A preferred dielectric fluid is pentane. It is preferred that membrane porosity vary across the membrane to tailor thermal resistances to limit temperature rises.

Owner:MASSACHUSETTS INST OF TECH

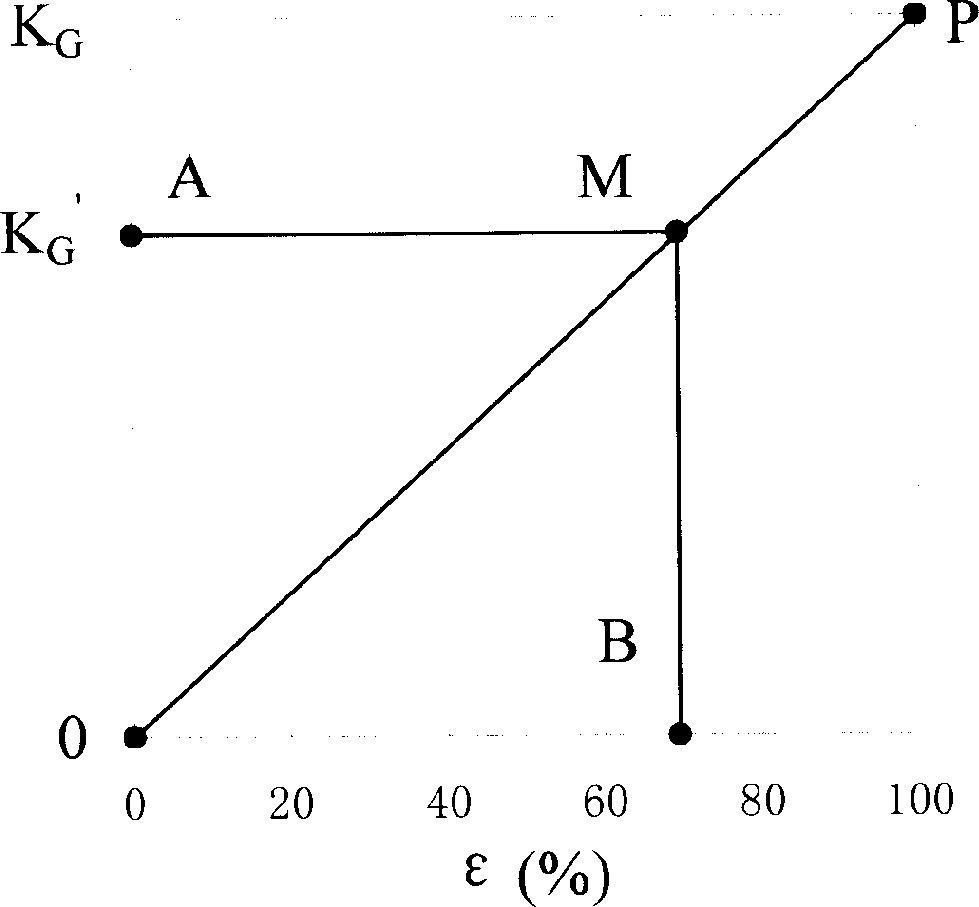

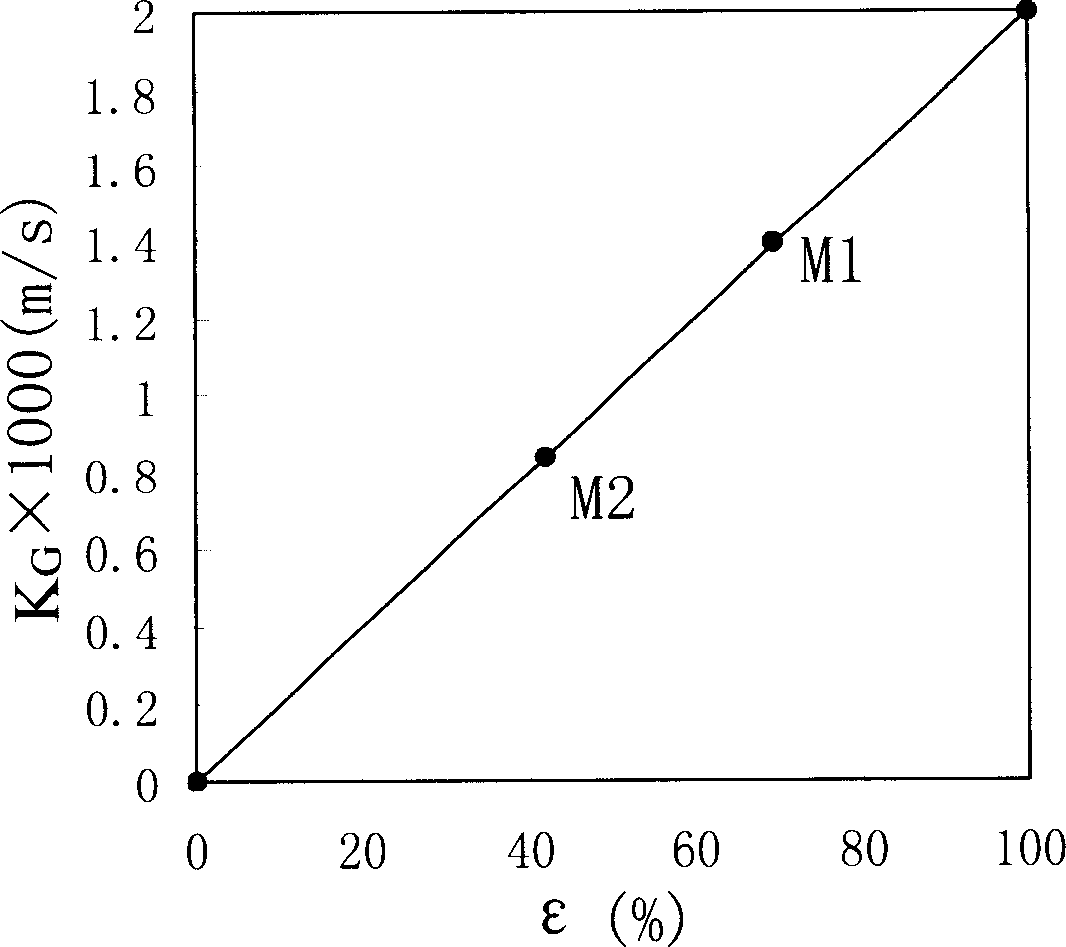

Method for measuring microcellular plate-type membrane porosity

A method utilizes strict linear relationship features between film porosity and overall mass transfer in film absorption course to determine and calculate overall mass transfer coefficient Kg value in advance under condition of the used mass transfer system without film through film absorption test so drawing of relationship between the porosity and the system overall mass transfer coefficient can be drawn out. Under the same system and the same test condition, film to be tested is added on to determine and calculate out mass transfer Kg value under condition with film so the porosity value of film to be tested can be read out from relationship drawing of mass transfer coefficient to porosity.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for porous superhydrophobic membrane with structural gradient changes

The invention belongs to the technical field of membrane science and provides a preparation method for a porous superhydrophobic membrane with structural gradient changes. The preparation method includes the following steps: utilizing a plasma technology to modify a basement membrane so that the porosity of the membrane can be increased; respectively adopting a coating method and an in-situ sol-gel method to prepare composite membranes with gradient changes of micron and nanoscale structures; and utilizing the surface chemical reaction of a low surface energy substance to obtain a superhydrophobic membrane through modification. The method utilizes plasma treatment to increase the surface porosity of the basement membrane; the basement membrane is coated with micron-sized particles; nanoscale particles can be generated on the surface of the basement membrane and the micron-sized particles in-situ; and the prepared superhydrophobic membrane can have characteristics of porousness and structural gradient changes by regulating the sizes and load capacity of the microparticles and nanoparticles on the surface of the basement membrane. The preparation method solves the problem of membranehole blockage caused by the direct coating method; new ideas of constructing multi-level rough structures can also be provided; and the preparation method is simple and low in cost, so that the preparation method has wide application prospects in the field of membrane separation.

Owner:DALIAN UNIV OF TECH

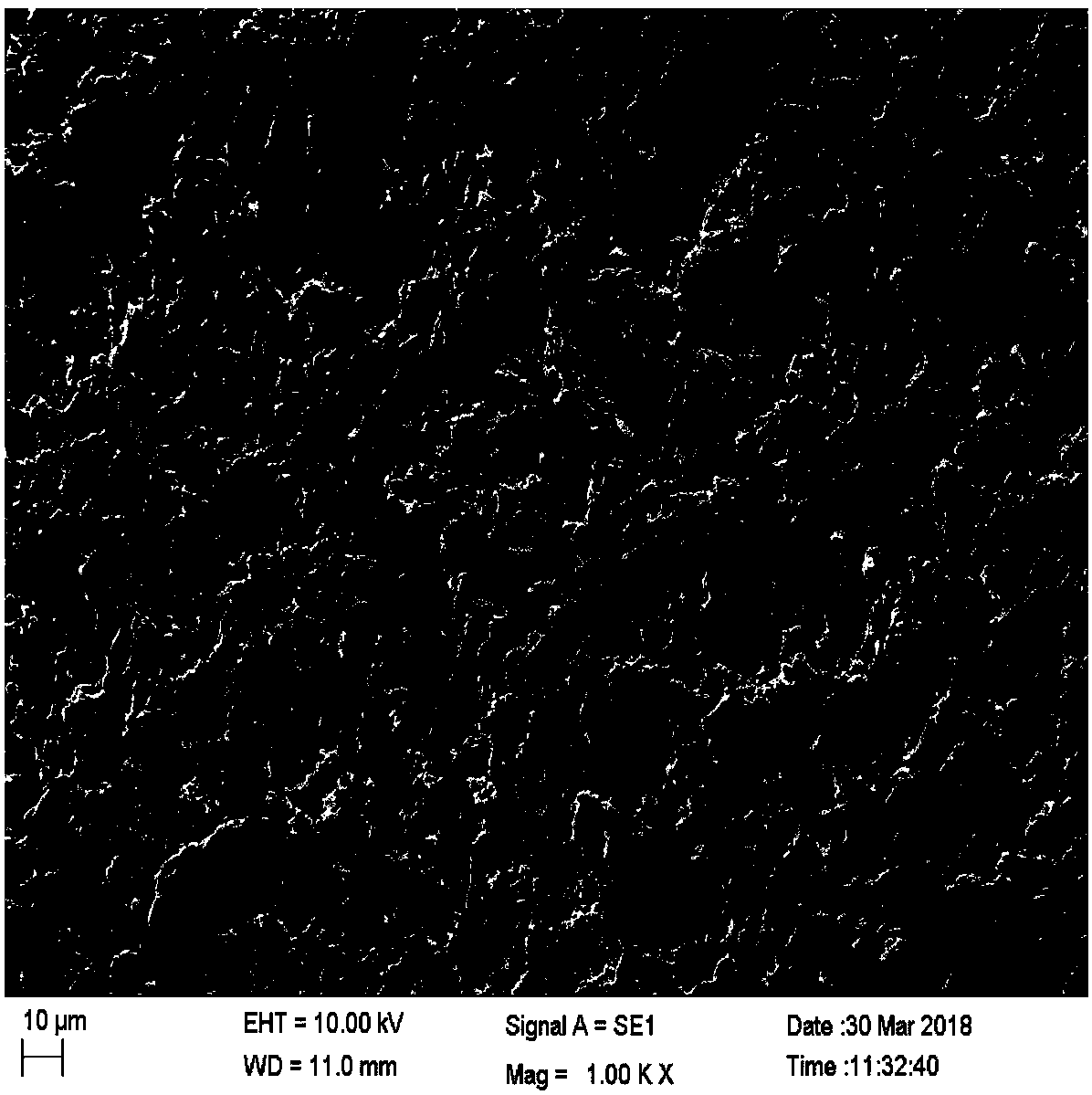

Structure control method of outer surface of polypropylene separation membrane

The invention relates to a structure control method of the outer surface of a polypropylene separation membrane. The method comprises the steps that: (1) polypropylene and a diluent are added into a kettle with a stirring device; the mixture is heated and stirred, such that a membrane casting solution is prepared; (2) the membrane casting solution is filtered by using a filter; an inner core liquid is introduced into a spinning nozzle; the inner core liquid and the membrane casting solution are extruded by the spinning nozzle; the mixture is cooled and cured through 0-20 DEG C coagulation bath, such that a hollow fiber membrane is obtained; (3) the hollow fiber membrane is wound by using a winding machine, and is extracted in one or a plurality of extraction agents; and (4) the extracted membrane is fetched and dried; and the extraction agent is removed, such that the polypropylene hollow fiber separation membrane is obtained. According to the invention, variety and temperature conditions of the coagulation bath are improved, such that a problem of polypropylene separation membrane outer surface compact skin is solved. Polypropylene separation membrane porosity is improved from 44% to approximately 70%, and polypropylene separation membrane pore size is reduced from 0.45 to approximately 0.25. The increasing of porosity and the reduction of pore size show that the membrane pores are more uniform, and the probability of large pores is reduced or eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

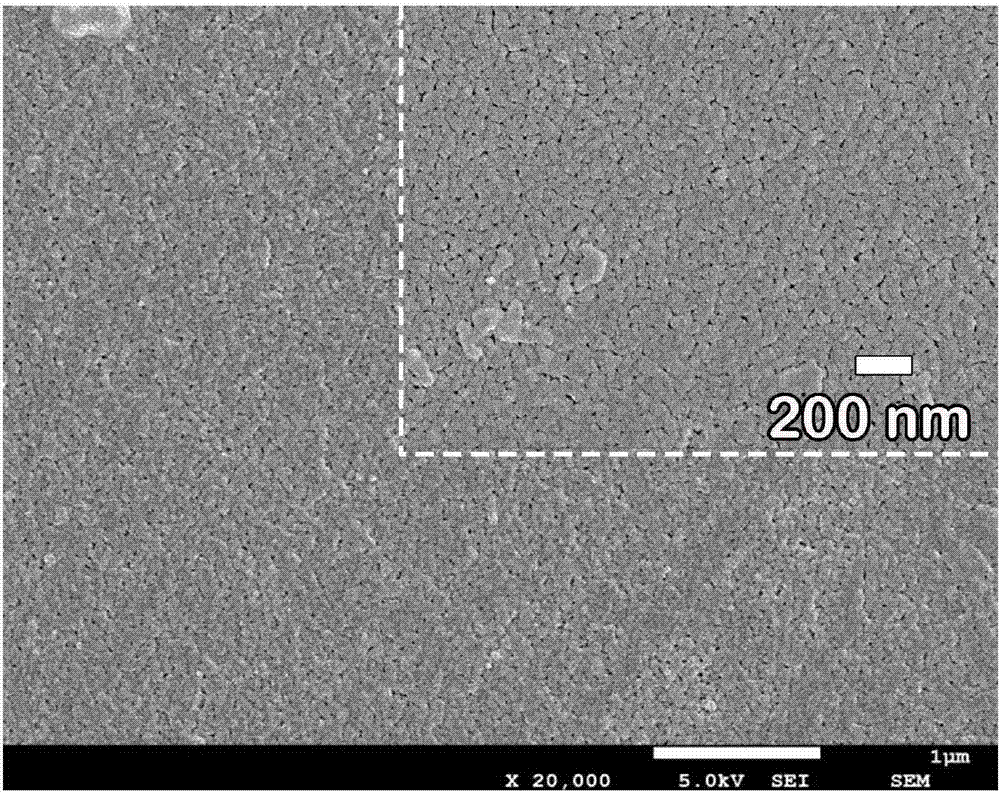

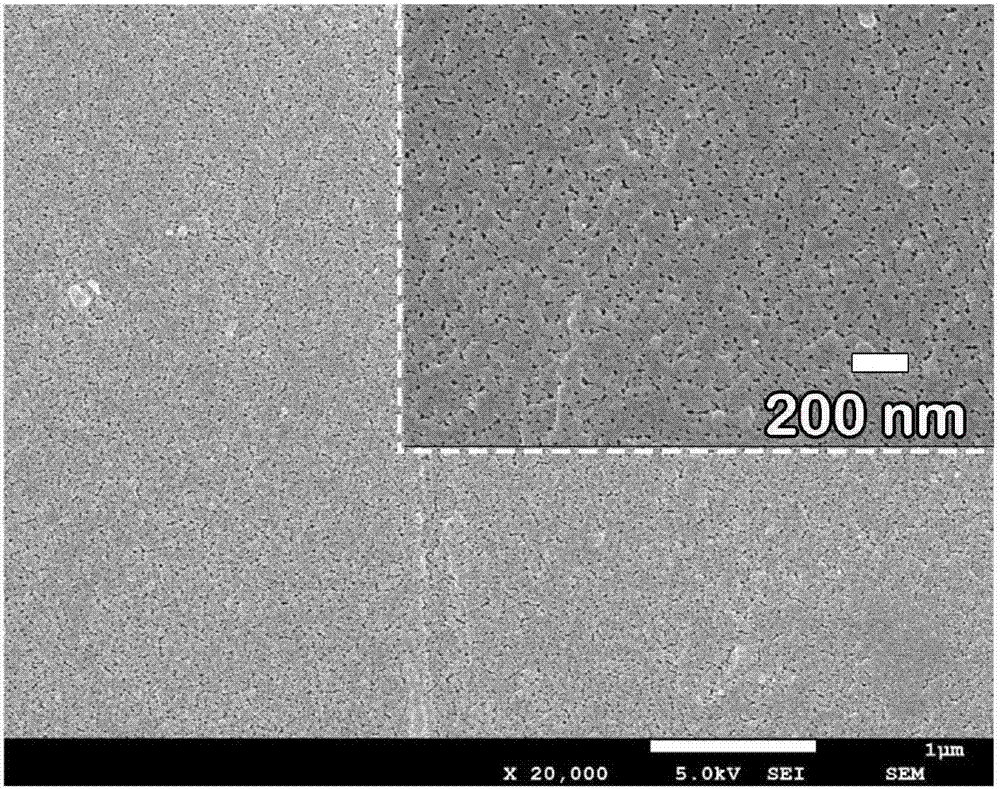

Method for synthesizing nano silicon dioxide modified PVDF (polyvinylidene fluoride) hydrophobic microporous membrane in situ

InactiveCN108499363AGood dispersionAvoid reunionMembranesUltrafiltrationSilicon dioxideChemical stability

The invention discloses a method for synthesizing a nano silicon dioxide modified PVDF (polyvinylidene fluoride) hydrophobic microporous membrane in situ. The method comprises: preparing a PVDF solution, preparing a solution containing nano silicon dioxide, preparing a casting solution, casting, forming a membrane, drying and the like. According to the invention, the excellent characteristics of the PVDF hydrophobic microporous membrane are maintained, at the same time, the microstructure of the PVDF hydrophobic microporous membrane is improved, the membrane pore size, the membrane porosity and the membrane hydrophobicity are increased, the agglomeration of nanoparticles in the casting solution is overcome, the dispersibility of the nano silicon dioxide in the casting solution is improved,the hydrophobicity, membrane flux, chemical stability and membrane strength of the PVDF hydrophobic microporous membrane are enhanced, and the problem of reduction of the membrane flux caused by poordispersibility, prone agglomeration and easy blockage of membrane pores of the nanoparticles in the casting solution when inorganic nanoparticles are modified in the preparation of the PVDF hydrophobic microporous membrane is solved, so that the membrane is endowed with the characteristics of large water flux, high membrane flux, high hydrophobicity, high mechanical strength, and stable chemicalproperties.

Owner:GUANGXI UNIV FOR NATITIES

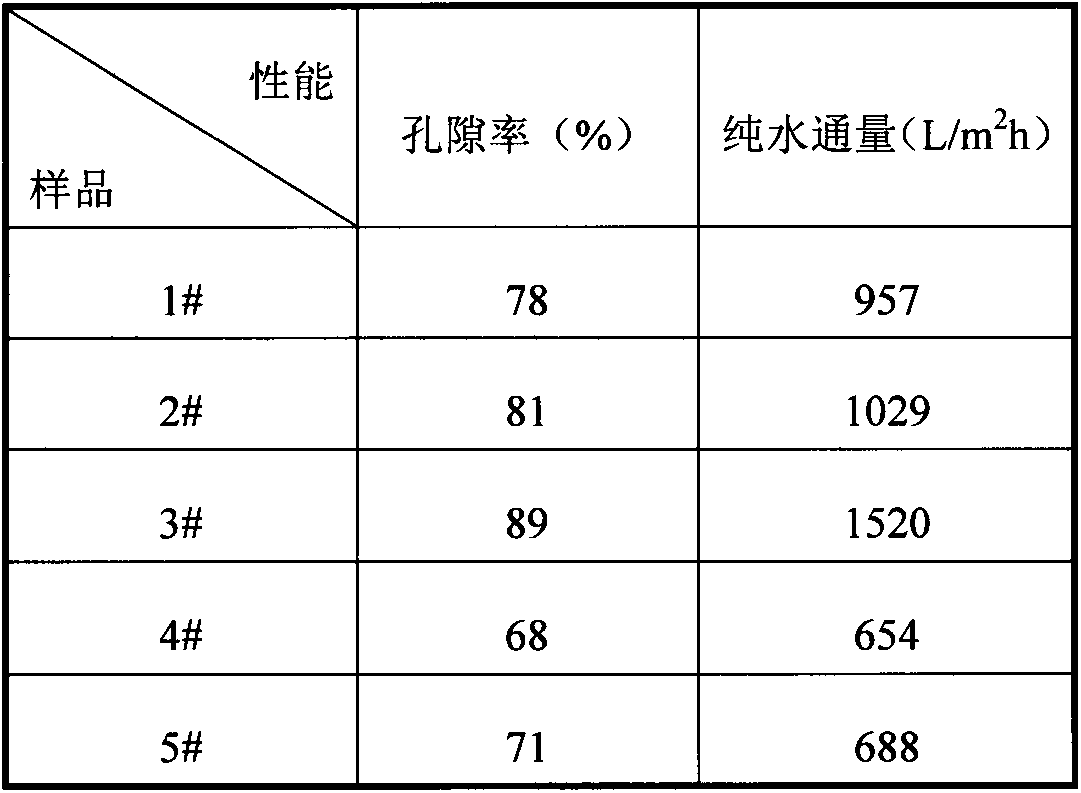

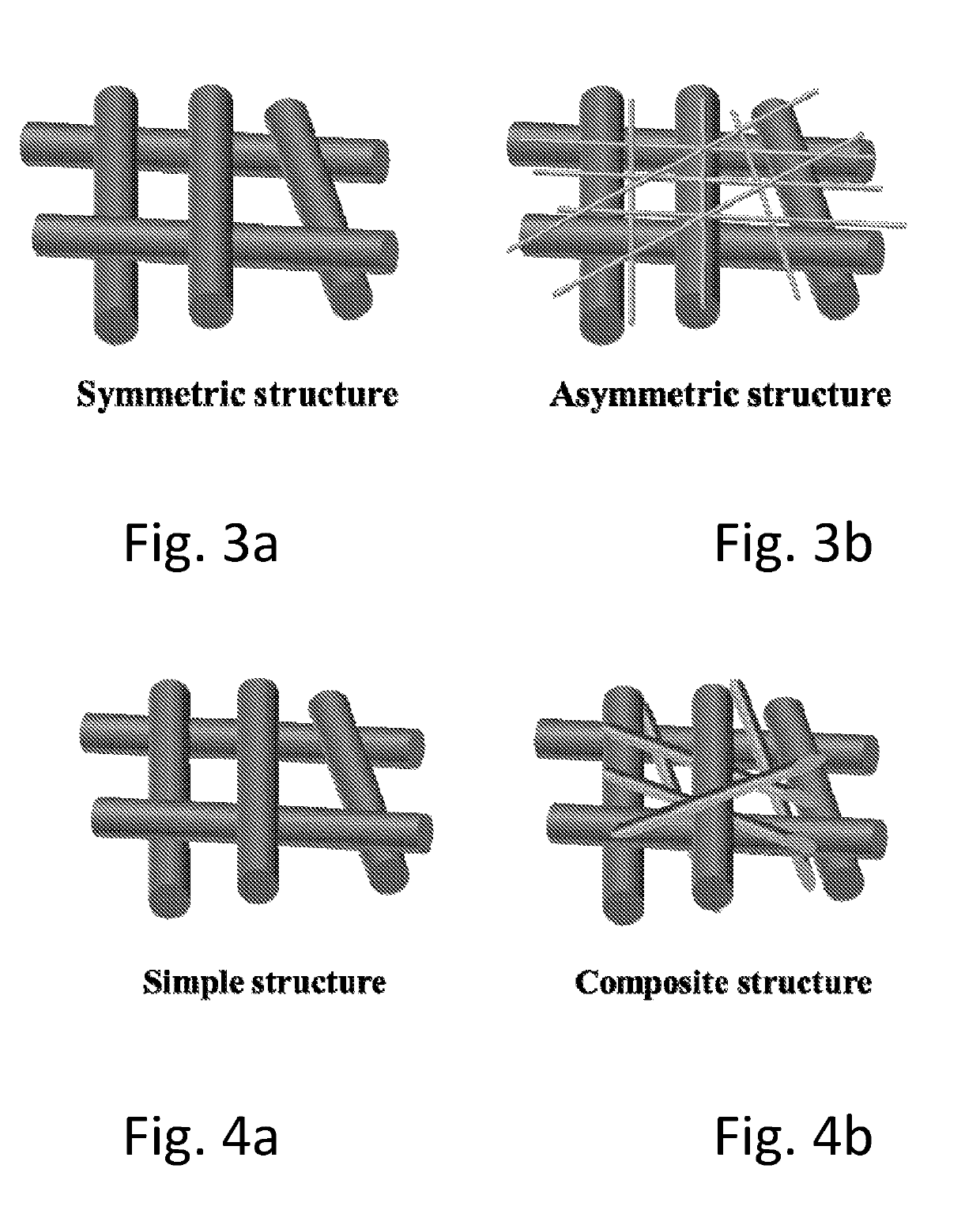

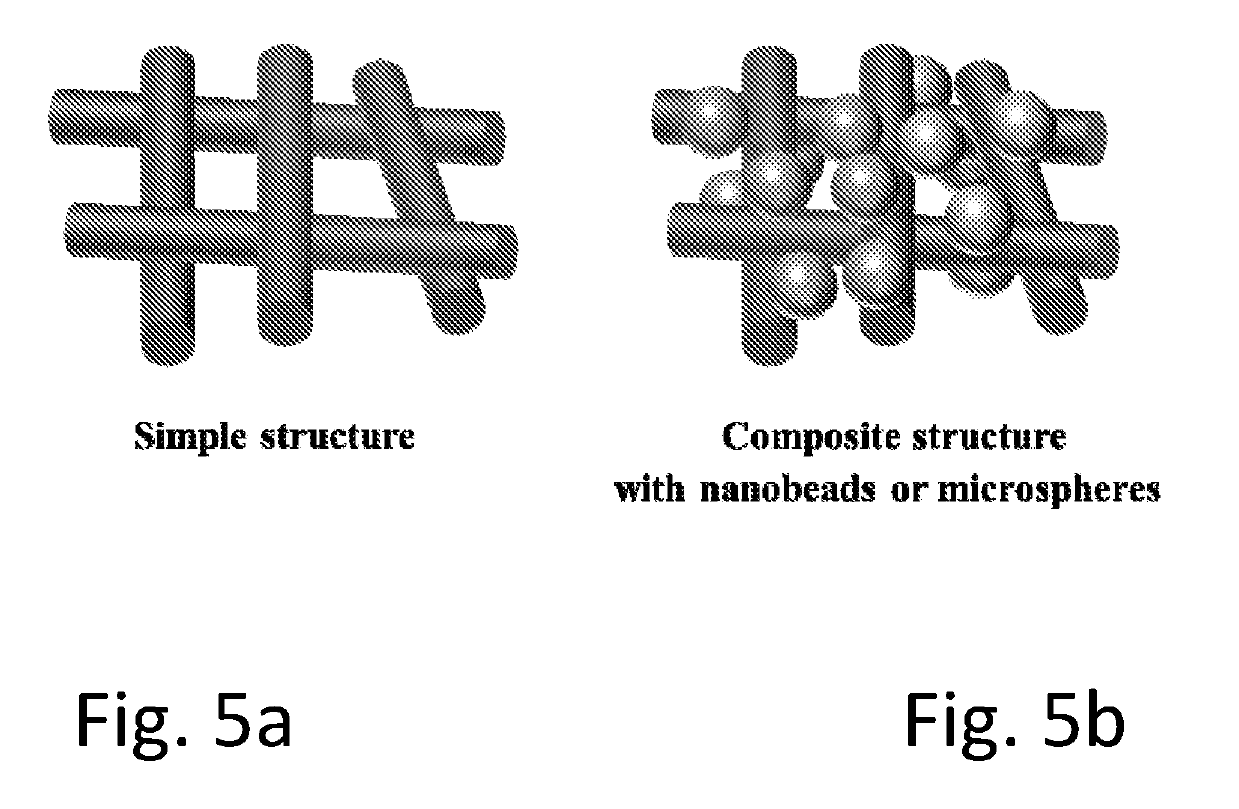

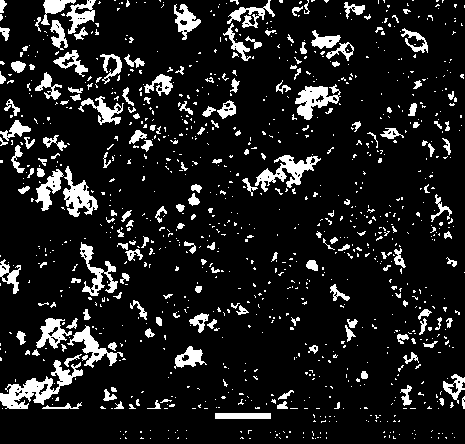

Preparation of hand-carry gravity-driven water filter with high throughput and water disinfection performance

ActiveUS20190168172A1Improve antifouling performancePromote regenerationMembranesSemi-permeable membranesNon solventSpinning

A hand-carry gravity-driven water filter with high throughput and water disinfection performance is formed. Membranes used for this water filter can be fabricated using electrospun method and non-solvent induced phase inversion method. A novel composite membrane structure (interwoven composite structure) was designed for further enhances water permeability and mechanical strength. The composite membrane can be composed of nanofibers with different diameter from the same polymer or different polymers. Membrane porosity and surface pore size can be controlled. Silver nanoparticles can be in-situ loaded on the surface of the membranes. The developed filter is effective for removal of a wide range of contaminants (e.g., pathogens, suspended solids and heavy metals). The purification process can be carried out under the drive of gravity (with an option for mechanically-enhanced filtration) without electricity.

Owner:VERSITECH LTD

Low-shielding large-area perovskite solar cell and preparation method thereof

InactiveCN106252518AHigh light transmittanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideHole transport layer

The invention relates to a low-shielding large-area perovskite solar cell which has component photoelectric conversion efficiency of 14% to 15%. According to the perovskite solar cell, a light absorption layer porous skeleton is a porous skeleton thin film formed by doping tin oxide transparent conductive nano particles and transparent nonconductive nano particles Al2O3, ZrO2 or SiO2 and carrying out high-temperature sintering, a porosity of the thin film is 30% to 50%, a porosity diameter is 5 to 20nm, a thickness of the thin film is 400 to 800nm, light transmittance is 80% to 95%, and a surface square resistance is 102 to 103ohm; a perovskite absorbing material is a smooth and uniform CH3NH2PbI3 crystallized film; and a hole transmission layer is a smooth and uniform molybdenum trioxide-silicon dioxide gel film. According to the low-shielding large-area perovskite solar cell disclosed by the invention, by regulating and controlling light transmittance, the porosity and the surface square resistance of the light absorption layer porous skeleton, shielding of the porous skeleton for the sunlight is reduced, light transmission is improved, electrical conductivity is improved, and photoelectric conversion efficiency of the large-area perovskite solar cell is improved.

Owner:TIANJIN VOCATIONAL INST

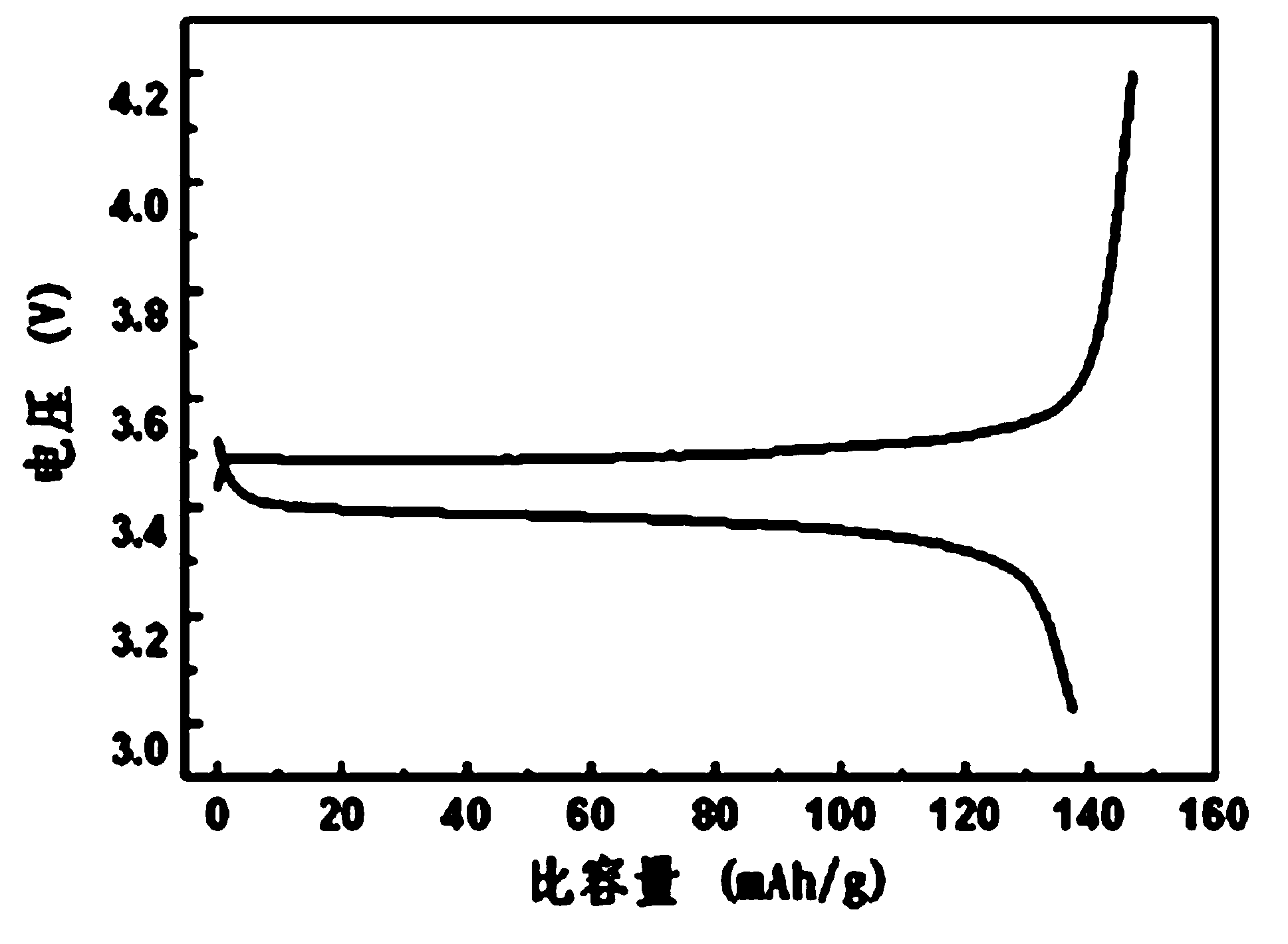

Lithium ion battery and its preparation method

ActiveCN103794814AImprove securityHigh porosityCell electrodesFinal product manufactureLithium-ion batteryCharge and discharge

The invention provides a lithium ion battery and its preparation method. The lithium ion battery comprises a housing, an electrode group and an electrolyte, and the electrode group and the electrolyte are sealed in the housing, the electrode group comprises a positive electrode, a negative electrode and an inorganic membrane arranged between the positive electrode and the negative electrode, the inorganic membrane includes lithium manganese phosphate and a binder, in relative to 100 parts by weight of the lithium manganese phosphate, the content of the binder is 1-15 parts by weight; and the inorganic membrane porosity is 30-80%. The prepared lithium ion battery has the advantage of inorganic membrane safety performance, the charge and discharge capacity of the battery is higher, and the cycling performance is better.

Owner:BYD CO LTD

Preparation method of three-dimensional hydrophobic tubular nanofiber membrane

ActiveCN110975640ASimple processNo workabilitySemi-permeable membranesMembranesPolymer scienceSpinning

The invention discloses a preparation method of a three-dimensional hydrophobic tubular nanofiber membrane. The preparation method comprises the following steps: uniformly dissolving a hydrophobic polymer in a mixed solvent to form a first membrane casting solution; taking a solution of hydrophobic nanoparticles as a second membrane casting solution; respectively putting the first membrane castingsolution and the second membrane casting solution into a first spinning injector and a second spinning injector, and collecting nanofibers on a receiver filled with a tubular support material under certain conditions; and taking down a tubular braided tube after spinning, and volatilizing solvents to obtain the nanofiber membrane, wherein the first spinning injector and the second spinning injector are located on the front upper portion and the rear upper portion of the receiver respectively and located in a plane which passes through the center of the receiver in the width direction and is perpendicular to the axis of the receiver. The membrane prepared by using the method is high in porosity, high in mechanical strength, good in thermal stability, good in lipophilicity and hydrophobicity and excellent in separation stability and reusability, and has long-time separation efficiency of greater than 95%.

Owner:TIANJIN POLYTECHNIC UNIV

Pure silicon carbide filtering membrane

ActiveCN102659447BGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cellulose polymer electrolyte membrane, and preparation method and application thereof

ActiveCN107129592AGood flexibilityImprove electrochemical performanceHybrid capacitor electrolytesHybrid/EDL manufacturePliabilityElectrochemistry

The invention provides a cellulose polymer electrolyte membrane, and a preparation method and application thereof. According to the invention, cellulose is used as a raw material, so the membrane has high porosity, electrolyte absorption performance and electrolyte retention performance due to reassembling of molecular structures of cellulose and a great amount of mesoporous structures among the molecular structures and is thus improved in ionic conductivity; and the membrane has good mechanical properties due to action of a great number of hydrogen bonds among the molecular chains of cellulose and formation of a three-dimensional homogeneous system. The cellulose polymer electrolyte membrane provided by the invention can be repeatedly folded, has good surface flexibility and transparency, abundant mesoporous structures and adjustable pore diameters; the pore diameters become larger and more uniform with prolongation of humidification time; the cellulose polymer electrolyte membrane porosity of 71.78%, ionic conductivity of 0.325 s / cm and good mechanical properties. As the cellulose polymer electrolyte membrane provided by the invention is applied to a flexible all-solid-state supercapacitor and a minisized supercapacitor, the membrane has good electrochemical performance and the prepared supercapacitors have scalability.

Owner:NORTHEAST FORESTRY UNIVERSITY

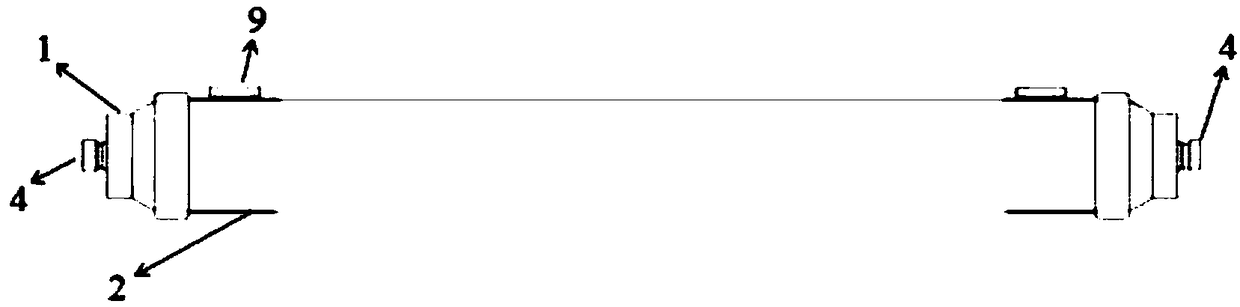

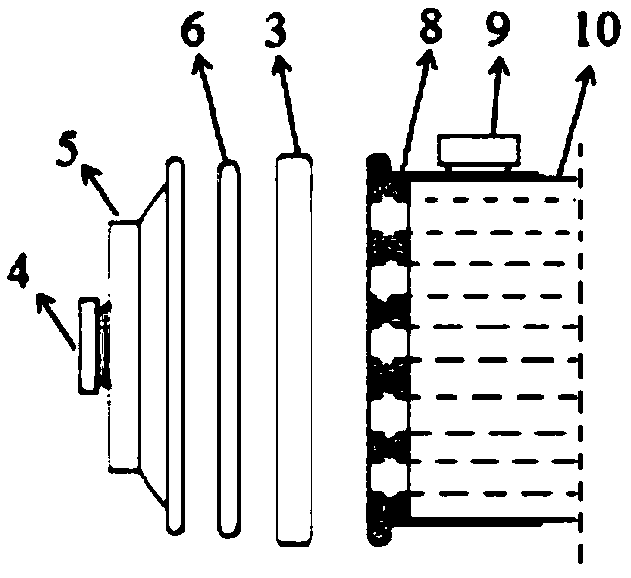

No-rinse pipe type membrane assembly for water treatment

PendingCN108579441AEasy to produceQuality is not easy to controlSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUnit massVolumetric Mass Density

The invention provides a no-rinse pipe type membrane assembly for water treatment and relates to a no-rinse pipe type membrane assembly for water treatment. The invention aims to solve the problems that the existing inlet no-rinse DF membrane has large diameter and thick wall, the membrane prepared from raw materials with unit mass has small filtering area, low membrane silk filling density, low membrane porosity and high operation pressure, and the energy consumption is increased. The no-rinse pipe type membrane assembly for water treatment consists of a sealing head, a membrane pipe and a metal hoop; the sealing head consists of a water flow port, a sealing head screw cap and a sealing ring; and the membrane pipe consists of a plurality of core pipes, a sealing head screw cylinder, a clean water port, a membrane shell cylinder and pipe type membrane silk. The DF membrane assembly at the inlet can be replaced, and application in the fields of waste water treatment and recycling as well as material separation and concentration instead of the traditional settling pool or filtering pool.

Owner:HEILONGJIANG UNIV

Multifunctional load type nanometer multilayer composite membrane, and preparation method and application thereof

ActiveCN113019157AImprove multi-functionFunction increaseSemi-permeable membranesMembranesPolymer scienceNano hybrid

The invention discloses a multifunctional load type nano multilayer composite membrane, and a preparation method and application thereof. The composite membrane comprises a polymer microporous supporting layer, an amination cross-linked transition layer and a nano-hybridized multifunctional skin layer. The preparation method comprises the following steps: preparing and generating the polymer microporous support layer on a super-hydrophobic rough substrate, and then preparing the aminated cross-linked transition layer and the nano-hybridized multi-skin layer in sequence. The polymer microporous membrane in the multifunctional load type nano multilayer composite membrane is high in porosity, large in aperture and high in water molecule permeation rate, and meanwhile, the super-hydrophobic rough surface prevents reverse circulation of water molecules; the aminated cross-linked transition layer is compact and has no defect, so that the separation performance of the membrane material is improved, and active sites are provided for loading of the nano material; and the nano-hybridized multifunctional skin layer can catalytically degrade small molecular substances, has a sterilization / bacteriostasis effect, prolongs the service life of the membrane material, complements advantages of multiple layers, couples multiple functions, and can realize seawater desalination, sewage purification, oil-water separation and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

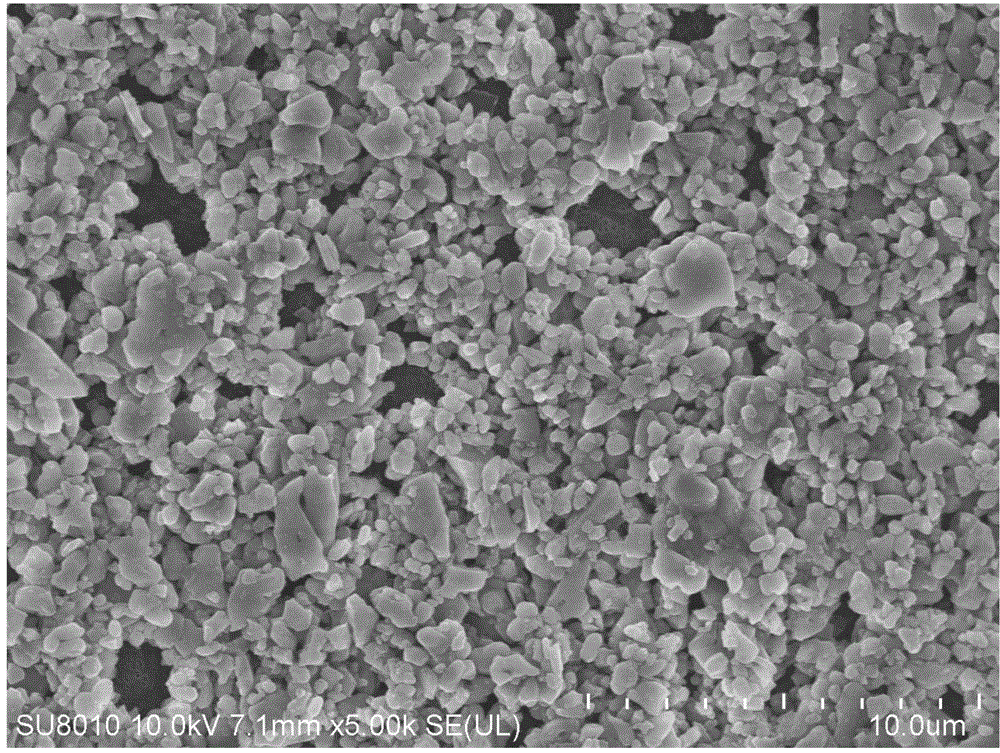

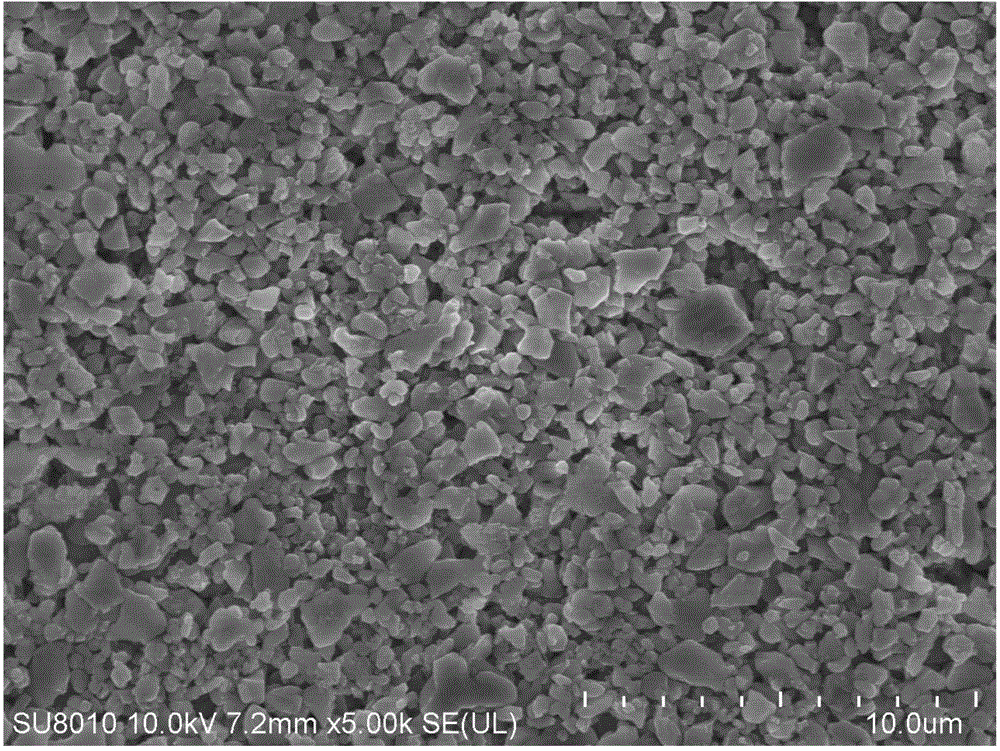

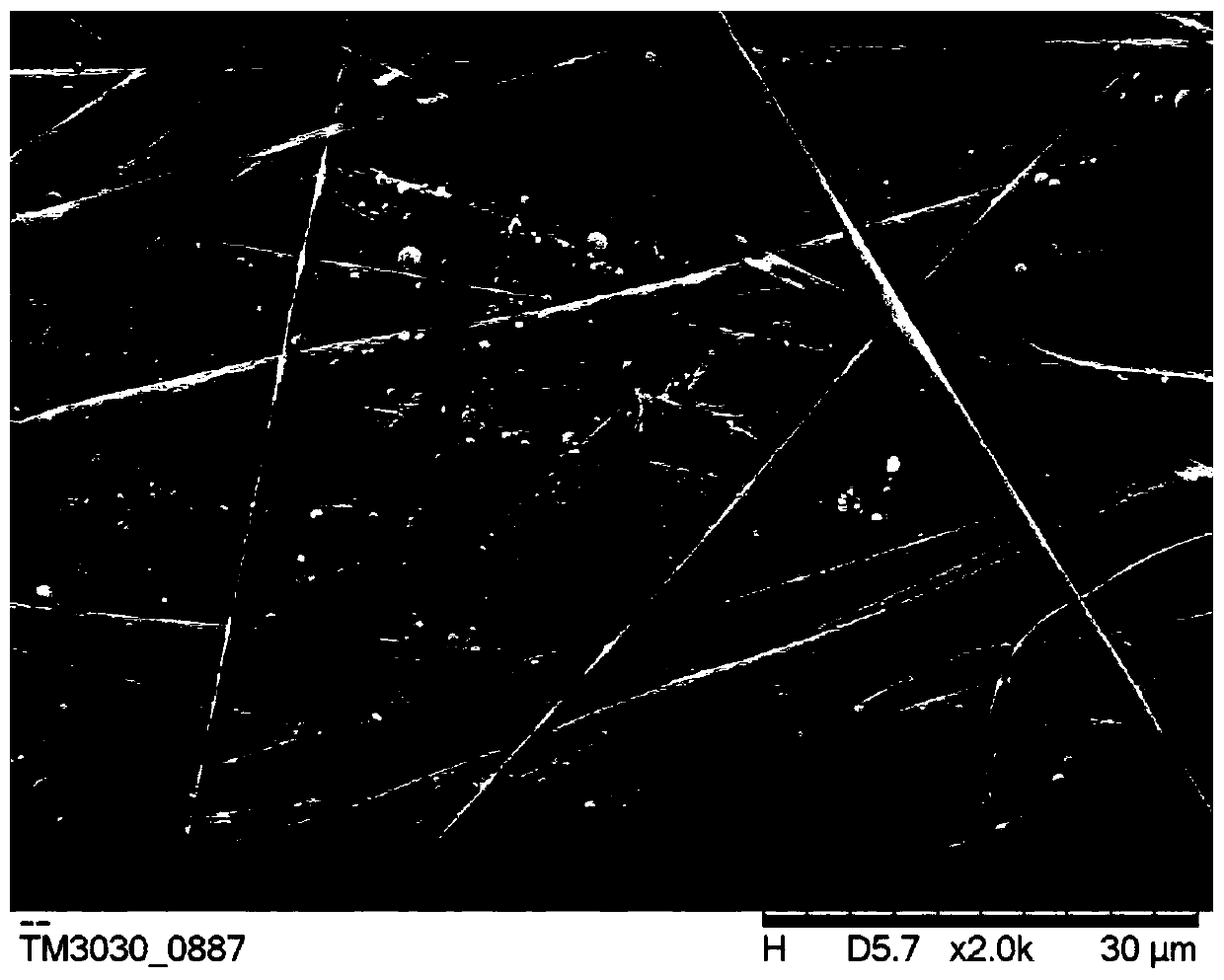

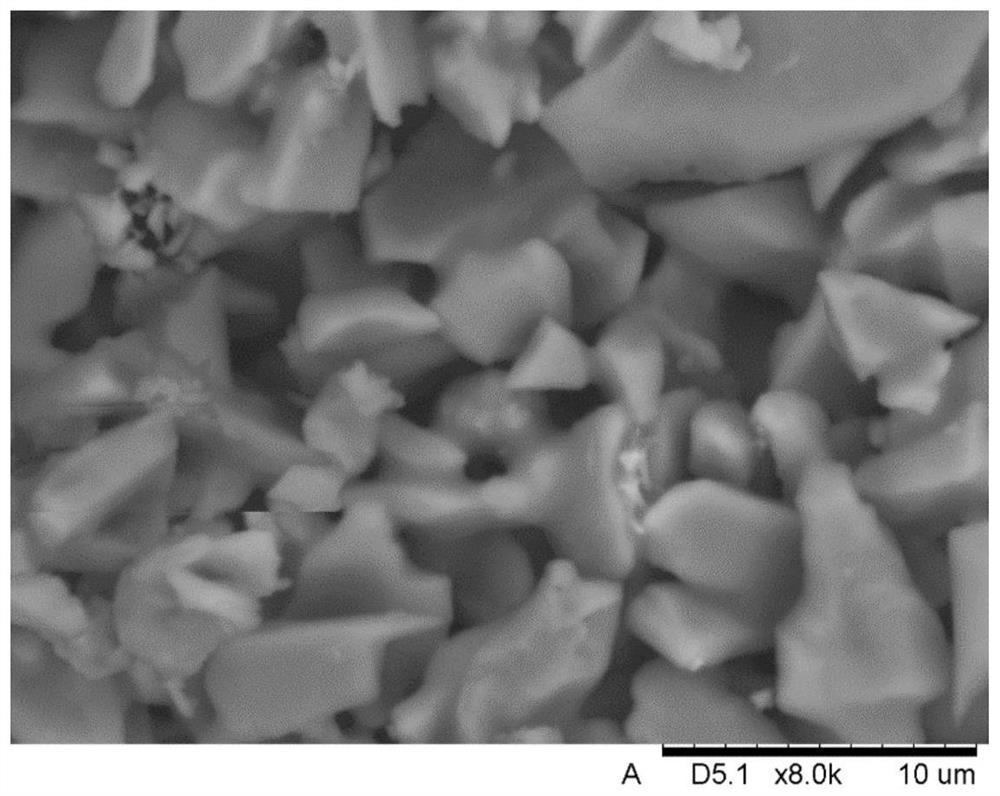

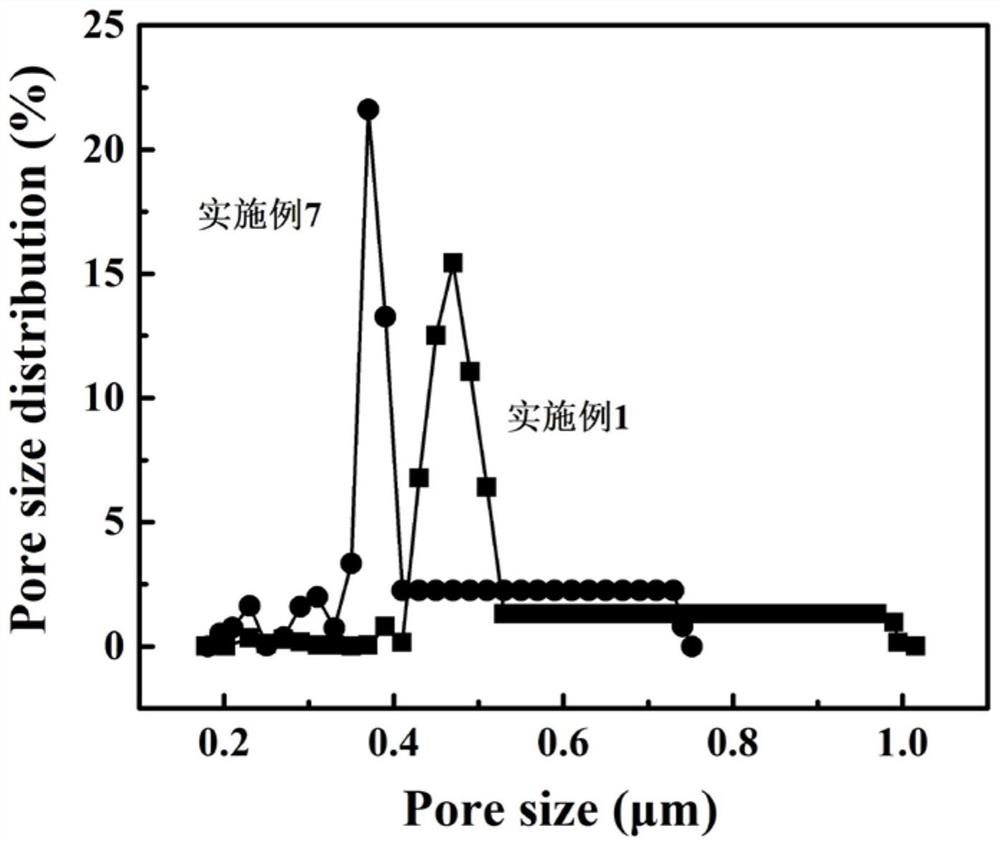

Method for regulating and controlling pore structure and surface property of silicon carbide film in one step

ActiveCN114315363ALower firing temperatureReduce manufacturing costSemi-permeable membranesFatty/oily/floating substances removal devicesCarbide siliconPhysical chemistry

The invention relates to a method for regulating and controlling the pore structure and the surface property of a silicon carbide film in one step, which comprises the following steps: firstly, sufficiently mixing SiC powder with a sintering aid, and then cooperatively regulating and controlling the pore structure and the surface wetting property of the SiC film by controlling the forming pressure and the sintering condition. And by controlling the amount of SiO2 generated by oxidizing SiC, in-situ reaction of the SiO2 and the sintering aid is promoted to generate neck connection, so that the sintering temperature of the SiC film can be reduced, and the strength and corrosion resistance of the silicon carbide film can be improved. The sintering degree of the SiC film is effectively controlled by regulating and controlling the forming pressure and the sintering temperature, and the method is a simple method for regulating and controlling the pore structure and the surface property of the SiC film in one step. The porosity of the prepared SiC membrane is adjustable in a range of 13%-48%, the aperture is adjustable in a range of 0.17 [mu] m-1 [mu] m, the dynamic water initial contact angle of the SiC membrane is 12.01-66.8 degrees, and the underwater oil contact angle is adjustable in a range of 120.3-155.1 degrees; the prepared SiC film has high bending strength and pure water permeability, and has wide application prospects in the fields of oil-water separation and emulsion preparation.

Owner:NANJING UNIV OF TECH

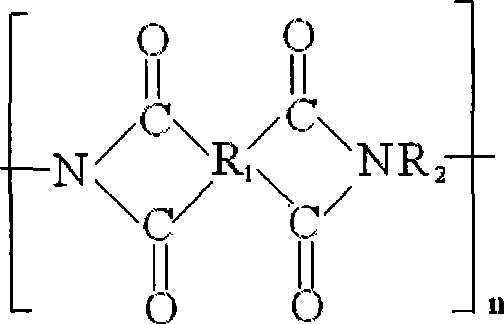

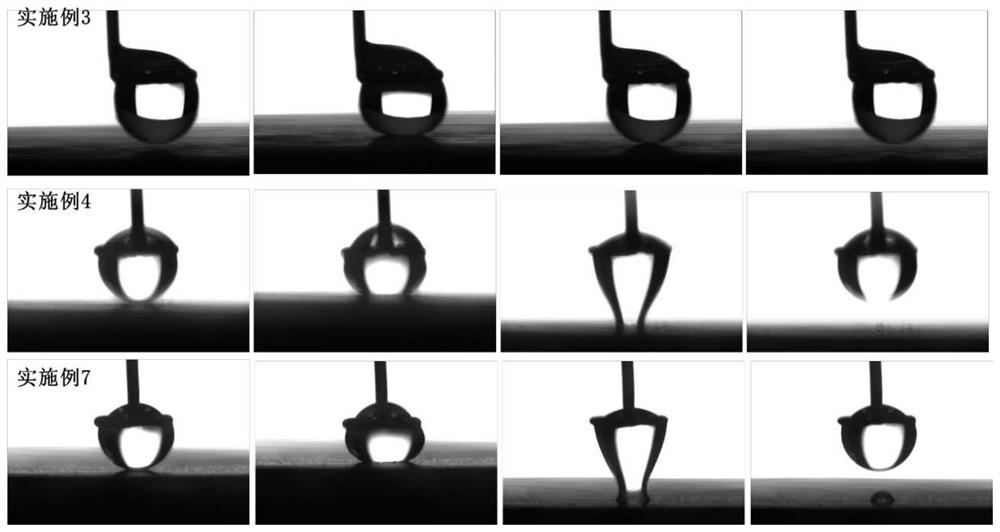

Lithium battery polyimide diaphragm and preparation method thereof

InactiveCN111192993AHigh porosityReduce manufacturing costSecondary cellsCell component detailsSodium bicarbonateImide

The invention discloses a lithium battery polyimide diaphragm and a preparation method thereof. According to the invention, the porosity of the polyimide battery diaphragm is increased by utilizing the nano sodium bicarbonate pore-forming agent; and meanwhile, diethylenetriamine is used for crosslinking the polyimide battery diaphragm, the strength of the polyimide battery diaphragm is improved, and the thermal decomposition temperature of sodium bicarbonate coincides with the temperature interval of polyamic acid imidization, so that the polyamic acid imidization can be performed while thermal decomposition is performed, and the polyimide diaphragm with high porosity is prepared under the condition of high production efficiency. The polyimide diaphragm prepared by the method is high in porosity; the decomposition gas is environment-friendly, tail gas treatment measures are not needed, diaphragm strength is high, and production cost is low; and the lithium battery polyimide diaphragm has unique combined balance performance of electrical performance, thermal performance, chemical performance and mechanical performance, retains respective characteristics of the above performances, and is a high-end lithium battery diaphragm.

Owner:王美岭

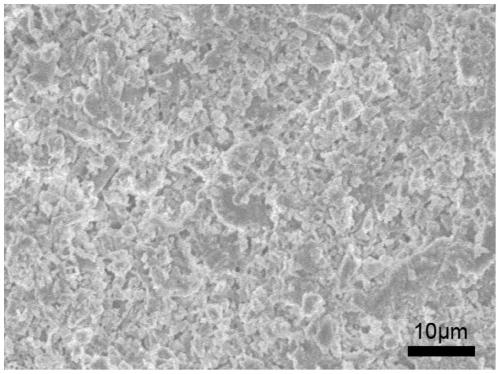

Production method of thermoplastic high-molecular material hollow fiber micro-pore membrane

The invention relates to a production method of a thermoplastic high-molecular material hollow fiber micro-pore membrane and belongs to the technical field of membrane separation. The method includes the following steps: 1) mixing a thermoplastic high-molecular material and CAB, of which the melting points are similar; 2) spinning the mixture through melt spinning method at 180-240 DEG C to prepare untwisted yarns; 3) drafting the untwisted yarns at 80-130 DEG C; 4) performing thermal treatment at 140-180 DEG C to obtain thermoplastic high-molecular material / CAB blended hollow fibers; and 5) placing the blended hollow fibers in acetone to dissolve the CAB phase to prepare the thermoplastic high-molecular material hollow fiber micro-pore membrane which is 30-45% in hollowness degree and 40-55% in porosity. The hollow fiber micro-pore membrane is high in porosity, is uniform in pore size distribution, is strong in mechanical performance and excellent in filtering performance, is low in processing cost, has a high additional value, is environment-friendly, and is an excellent basic material for the field of membrane separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method using metal hydroxide nano fibers to prepare high-throughput PVDF porous film

InactiveCN107008164AImprove throughputLarge specific surface areaSemi-permeable membranesFiberNanofiber

The invention relates to a method using metal hydroxide nano fibers to prepare a high-throughput polyvinylidene difluoride (PVDF) porous film. The method includes the steps of firstly, adding the metal hydroxide nano fibers into a solvent, and stirring to prepare metal hydroxide nano fiber dispersion liquid; secondly, adding PVDF and a pore-forming agent into the metal hydroxide nano fiber dispersion liquid, evenly stirring, and ultrasonically defoaming to obtain film casting liquid; thirdly, using an immersion precipitation phase inversion process to scrape the prepared film casting liquid to obtain a flat PVDF film; fourthly, placing the flat PVDF film into an acetic acid solution to remove the metal hydroxide nano fibers, washing with deionized water, and airing to obtain the high-throughput PVDF porous film. Compared with a traditional method for preparing a teflon film, the method has the advantages that the porosity of the prepared polyvinylidene difluoride film is increased evidently, and the throughput of the film is increased evidently.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

Non-medical nano-film filtering mask

InactiveCN111616450AImprove reliabilityImprove durabilityProtective garmentSpecial outerwear garmentsMedicineEngineering

The invention discloses a non-medical nano-film filtering mask, and specifically relates to a mask for filtering air by using a nano-film. The mask of the invention overcomes the defects that a melt-blown cloth filtering mask in the prior art is low in use reliability and durability and poor in protection effect. The mask comprises a mask body, a left ear hanging belt and a right ear hanging belt,wherein the mask body is composed of a nano-film layer, an outer-layer non-woven fabric and an inner-layer non-woven fabric, the outer-layer non-woven fabric and the inner-layer non-woven fabric arefixed into a whole through stamping lines, the nano-film layer is attached to the outer surface of the outer-layer non-woven fabric, and the thickness of the nano-film layer is 0.2 mm. The nano-film layer is a PTFE film, wherein the porosity of the PTFE film is 85% or above, 14 billion micropores are formed in each square centimeter of the PTFE film, pore diameters are in a range of 0.02-15 microns, the PTFE film is mainly made of polytetrafluoroethylene resin, the content of the polytetrafluoroethylene resin is not lower than 90%, and the balance is impurities. The interception rate of 0.3 micron particles by the mask can reach 99% or above.

Owner:哈尔滨飞诺科技有限责任公司

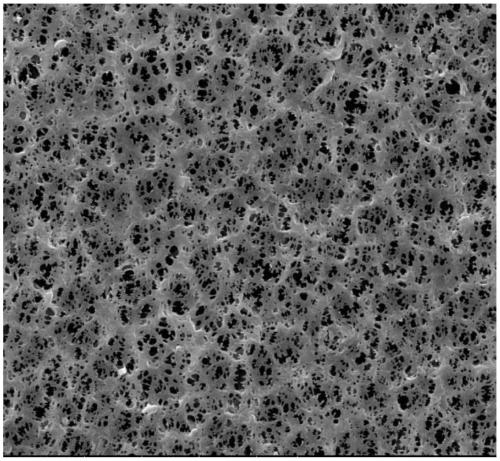

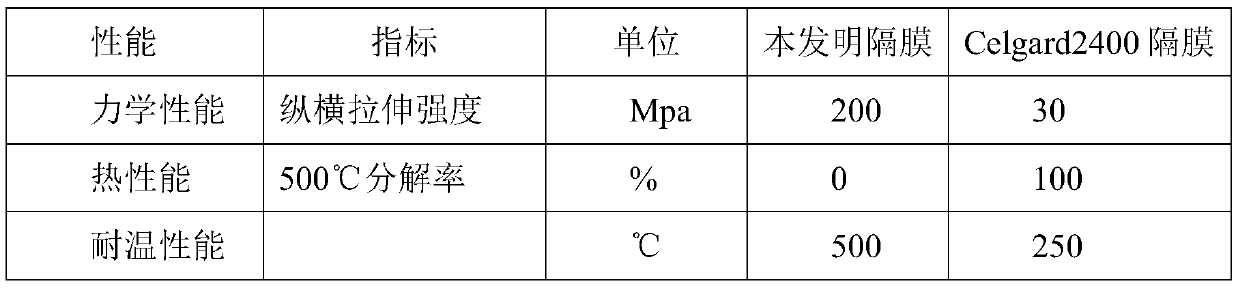

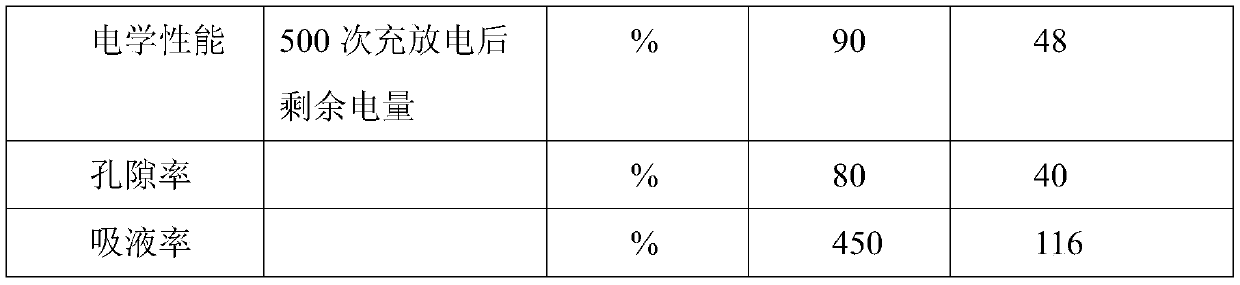

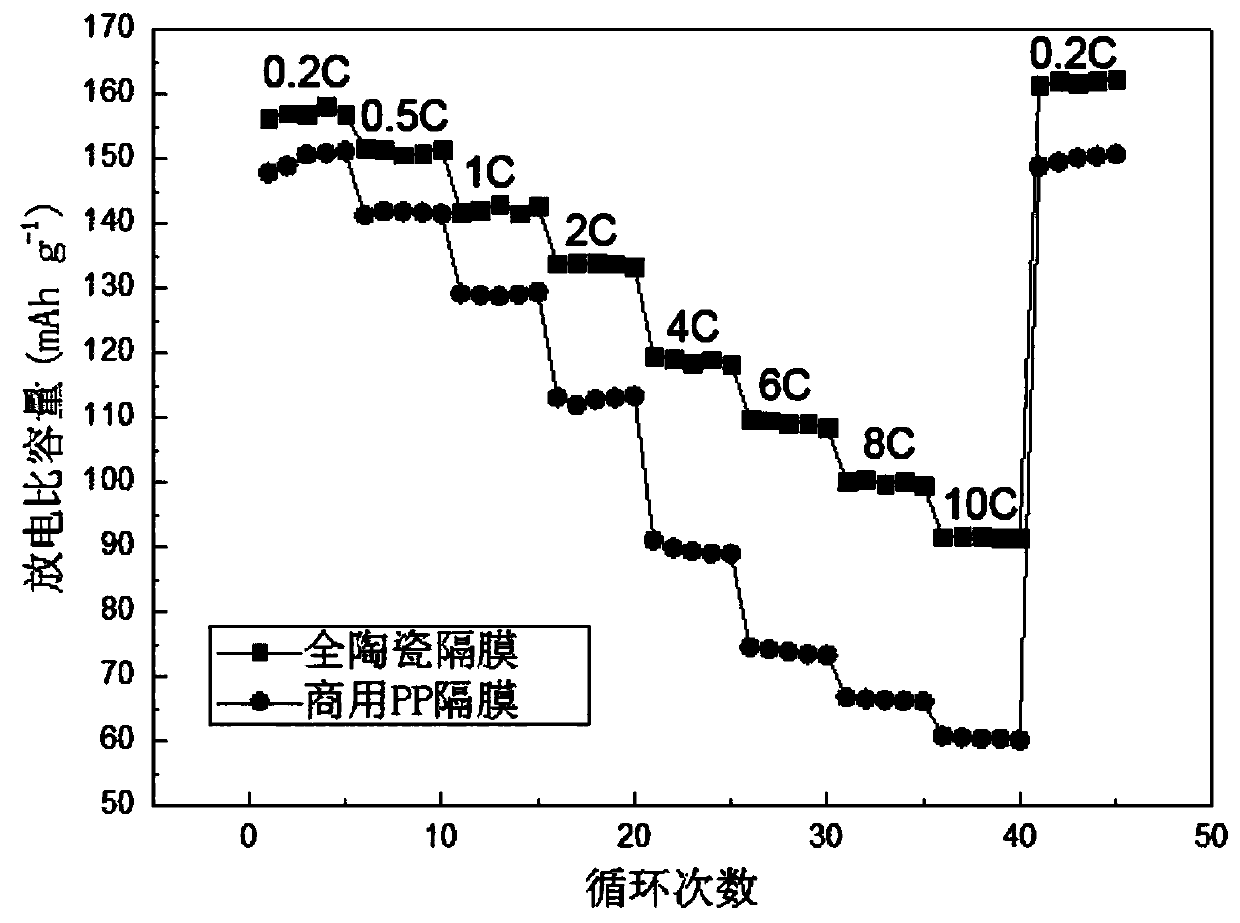

Full-ceramic diaphragm for lithium ion battery and preparation method thereof

ActiveCN111477819AHigh porosityGases from pyrolysis help increase porositySecondary cellsCell component detailsPhysical chemistryAll ceramic

The invention relates to a full-ceramic diaphragm for a lithium ion battery and a preparation method thereof, and belongs to the field of diaphragm materials. According to the method, natural porous mineral diatomite is used as a main raw material, lithium carbonate and a small amount of titanium dioxide are added, a small amount of binder is used, high-temperature calcination is performed after compression molding, and the full-ceramic diaphragm for the lithium ion battery taking titanium-doped lithium silicate as the main component can be obtained. The thermal stability temperature of the full-ceramic diaphragm exceeds 800 DEG C, so that the problem of short circuit and fire in the battery caused by thermal shrinkage deformation of the diaphragm of the traditional lithium ion battery iseffectively avoided, and the safety of the lithium ion battery is remarkably improved. The full-ceramic diaphragm is high in porosity and large in liquid absorption rate, the titanium-doped lithium silicate component in the diaphragm can promote dissociation of lithium salt in electrolyte of the lithium ion battery, lithium ion transmission is promoted, and the capacity retention ratio of the battery during large-current charging and discharging and long-time operation is increased.

Owner:JILIN UNIV

Evaporative heat transfer system

ActiveUS9835363B2Semiconductor/solid-state device detailsEvaporators/condensersEvaporation heat transferNanoporous membrane

Evaporative heat transfer system. The system includes a substrate and a plurality of substantially parallel, spaced-apart ridges extending from the substrate forming vertical liquid manifolds therebetween. A nanoporous membrane is supported on the ridges and a pump delivers a dielectric fluid across the ridges. The fluid is drawn through the liquid manifolds via capillarity provided by the nanoporous membrane and evaporates to dissipate heat flux through the substrate. A preferred dielectric fluid is pentane. It is preferred that membrane porosity vary across the membrane to tailor thermal resistances to limit temperature rises.

Owner:MASSACHUSETTS INST OF TECH

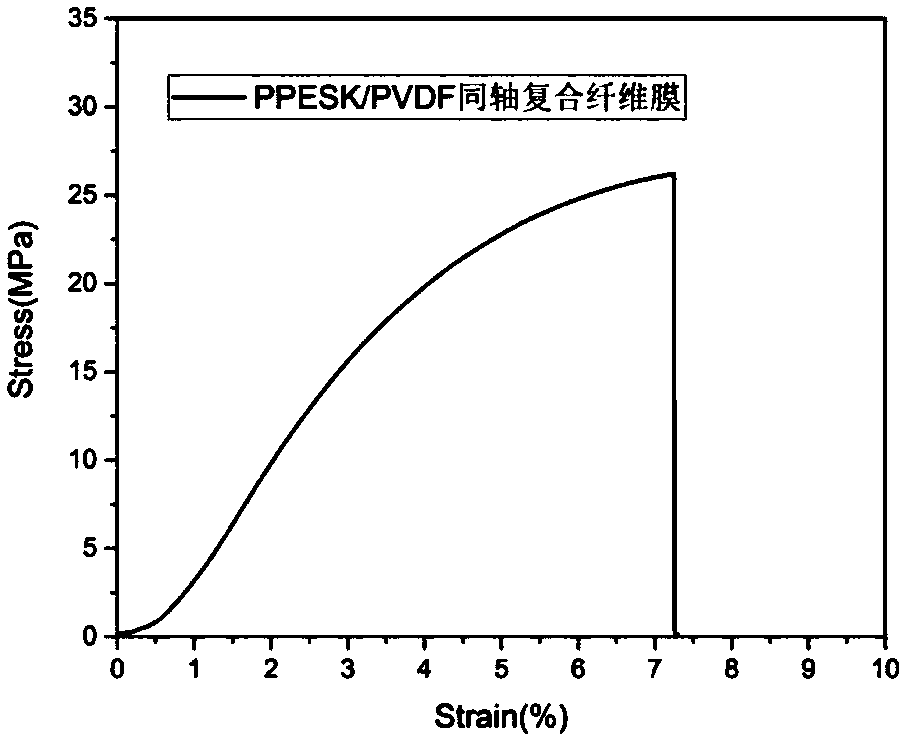

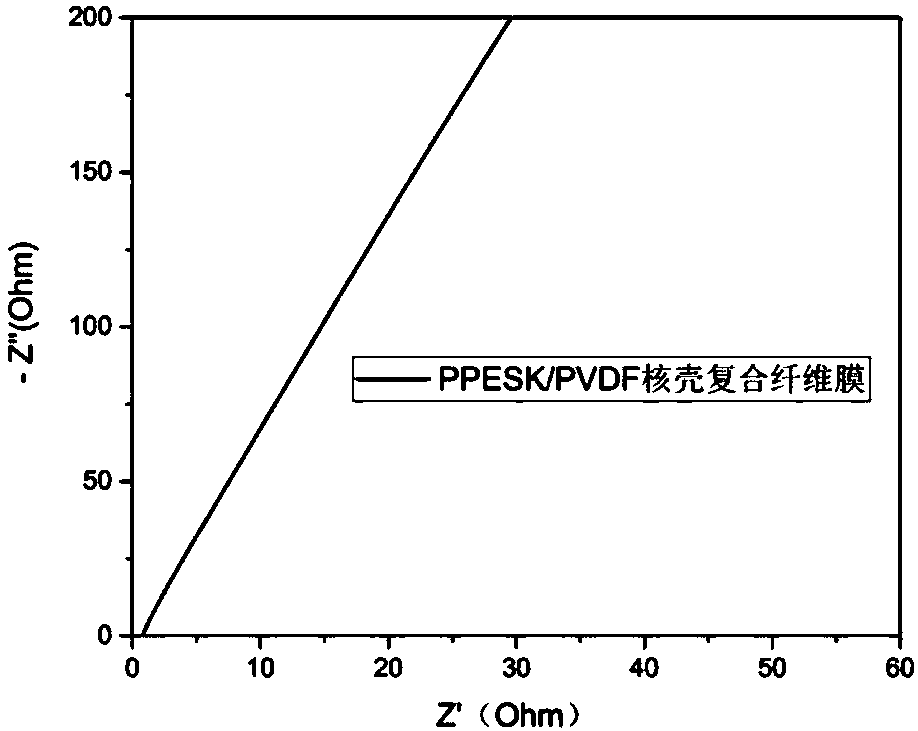

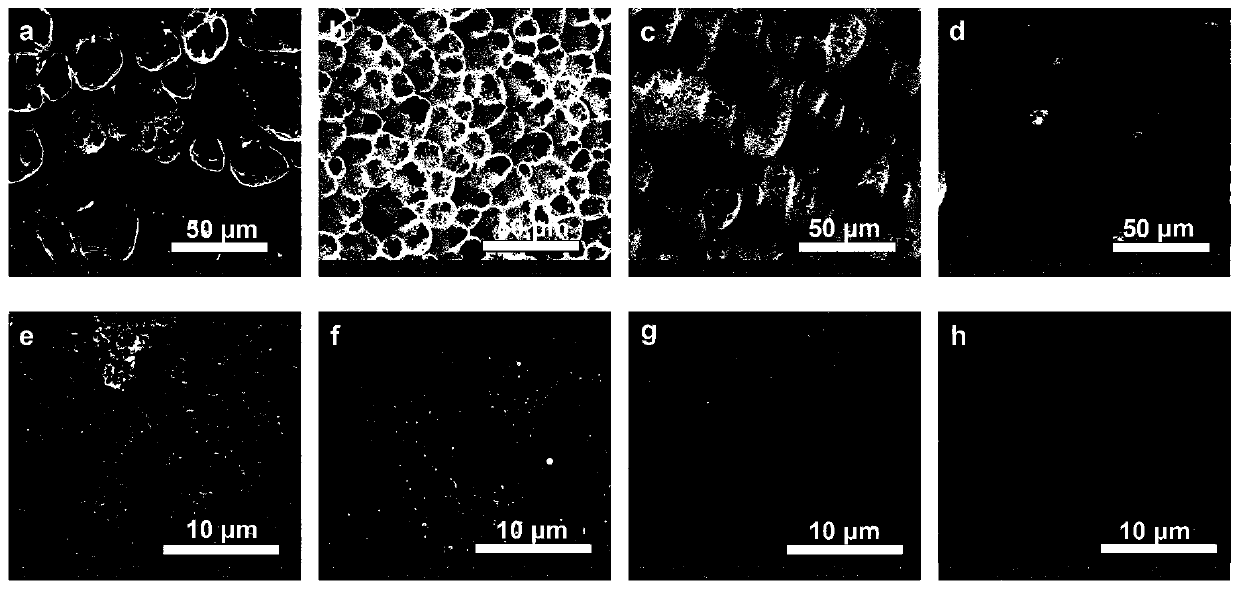

A method for preparing lithium battery separators by coaxial electrospinning

ActiveCN106450101BGood chemical resistanceImprove high temperature resistanceElectro-spinningCell component detailsFiberElectrolytic agent

The invention provides a method for preparing a lithium battery separator by coaxial electrospinning, belonging to the technical field of lithium battery separators. The lithium battery separator is a composite fiber membrane with a core / shell structure prepared by coaxial electrospinning technology. The core and shell layers of the composite fiber membrane are concentric, and the core layer is made of polyarylether sulfone ketone nanofibers with high melting point. Composition, the shell layer is composed of polyvinylidene fluoride nanofibers with low melting point, especially the coaxial composite film is hot-pressed at a certain temperature and pressure, and the shell layer fibers are micro-melted or melted to make the bonding between the fibers The tensile strength of the composite film in all directions is greatly improved. The lithium battery separator has a porosity of more than 75%, an electrolyte absorption rate of more than 550%, and can withstand high temperatures of 180°C. Therefore, the separator prepared by this method has good electrochemical properties and thermal and mechanical properties. And electric vehicles and other fields have high application value.

Owner:DALIAN UNIV OF TECH

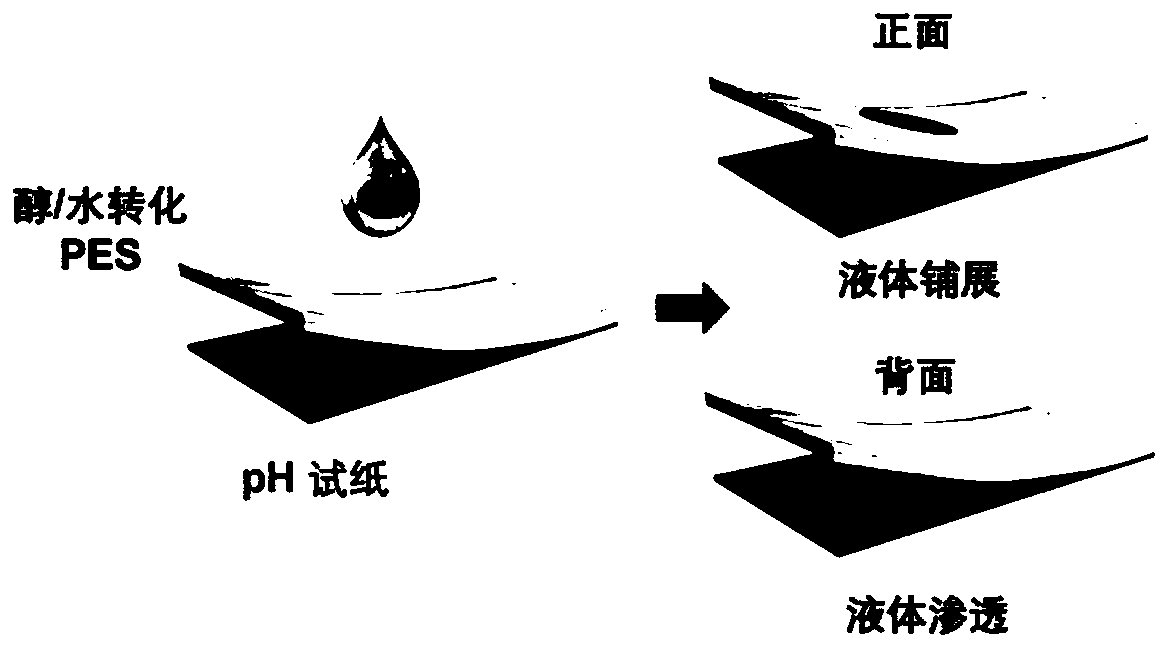

Hydrophilic single-layer porous membrane as well as preparation method and application thereof

ActiveCN111004508AControl osmotic stateImprove featuresMembranesSemi-permeable membranesMicro nanoPolymer science

The invention discloses a hydrophilic single-layer porous membrane as well as a preparation method and application thereof, and belongs to the technical field of functional material preparation. The hydrophilic single-layer polymer porous membrane is finally prepared by preparing a membrane casting solution, scraping the membrane and utilizing a phase inversion method in sequence; by changing theinitial concentration of the membrane casting solution, the thickness of membrane scraping, the composition of a phase inversion solvent and the proportion of a mixed phase inversion solvent, asymmetric micro-nano holes with different pore sizes are controlled to be prepared in the opposite surfaces of the single-layer polymeric membrane, so that intelligent control on different permeation statesof the liquid is realized. The preparation method of the hydrophilic single-layer porous membrane disclosed by the invention is simple and feasible; the thickness, porosity and pore size of the prepared porous membrane are easy to control, and the porous membrane is low in cost, environment-friendly, safe, reliable and easy for industrial large-scale production, and can be well applied to the fields of liquid one-way permeation, dressings or functional textiles for quickly drying wounds and directional transportation.

Owner:BEIHANG UNIV

Cellulose inorganic composite membrane, high-temperature-resistant battery diaphragm as well as preparation method and application of high-temperature-resistant battery diaphragm

PendingCN114256560ADoes not affect normalityAdjustable thicknessSecondary cellsCell component detailsPhysical chemistryLithium-ion battery

The invention provides a cellulose inorganic composite membrane, a high-temperature-resistant battery diaphragm as well as a preparation method and application of the high-temperature-resistant battery diaphragm, and belongs to the field of lithium ion battery manufacturing. The cellulose inorganic composite membrane comprises bacterial cellulose and composite powder. The composite powder comprises an organic high-molecular compound and an inorganic substance; the mass ratio of the bacterial cellulose to the composite powder is (5-50): (25-200); the mass ratio of the organic high-molecular compound to the inorganic matter is (10-300): (100-300). The preparation method of the battery diaphragm is simple, pollution-free in process and low in commercialization cost. The battery diaphragm is high in porosity and liquid absorption rate, and electrolyte infiltration and ion migration are facilitated; the thermal stability is excellent, so that the safety performance of the lithium ion battery is greatly improved; and when being applied to the lithium ion battery diaphragm, the lithium ion battery diaphragm shows better long cycle performance and rate cycle performance, and is a lithium ion battery diaphragm with great potential.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Structure control method of outer surface of polypropylene separation membrane

The invention relates to a structure control method of the outer surface of a polypropylene separation membrane. The method comprises the steps that: (1) polypropylene and a diluent are added into a kettle with a stirring device; the mixture is heated and stirred, such that a membrane casting solution is prepared; (2) the membrane casting solution is filtered by using a filter; an inner core liquid is introduced into a spinning nozzle; the inner core liquid and the membrane casting solution are extruded by the spinning nozzle; the mixture is cooled and cured through 0-20 DEG C coagulation bath, such that a hollow fiber membrane is obtained; (3) the hollow fiber membrane is wound by using a winding machine, and is extracted in one or a plurality of extraction agents; and (4) the extracted membrane is fetched and dried; and the extraction agent is removed, such that the polypropylene hollow fiber separation membrane is obtained. According to the invention, variety and temperature conditions of the coagulation bath are improved, such that a problem of polypropylene separation membrane outer surface compact skin is solved. Polypropylene separation membrane porosity is improved from 44% to approximately 70%, and polypropylene separation membrane pore size is reduced from 0.45 to approximately 0.25. The increasing of porosity and the reduction of pore size show that the membrane pores are more uniform, and the probability of large pores is reduced or eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com