Battery separator, fabrication method thereof

A technology of battery separator and composite separator, which is applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc. resistance increase and other problems, to achieve the effect of good electrical insulation, strong solvent resistance, and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

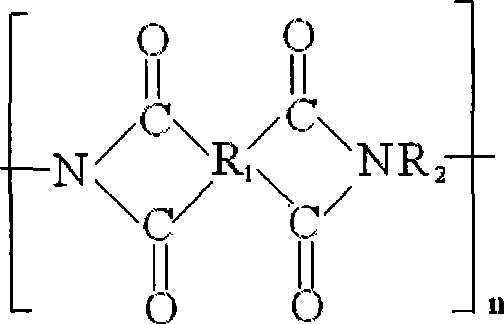

[0052] In step a, dissolve 4,4'-diaminodiphenyl ether (Shanghai Haiqu Chemical Co., Ltd.) and pyromellitic dianhydride (Shanghai Haohua Chemical Co., Ltd.) in organic solvent N, N'-dimethylacetamide (Shanghai Jingwei Chemical Co., Ltd.) to obtain a polyimide precursor solution; wherein the molar ratio of 4,4'-diaminodiphenyl ether and pyromellitic dianhydride is 1:1, and the solvent N,N'- The weight of dimethylacetamide is 12 times of the total weight of 4,4'-diaminodiphenyl ether and pyromellitic dianhydride; the temperature of the solution is controlled at 10-30 DEG C during the preparation process.

[0053] Step b Use a film applicator to coat the polyimide precursor solution prepared in step a on a clean and dry glass plate substrate with a coating thickness of 300 μm, cover with two layers of polyethylene non-woven fabric and soak for 4 minutes, and then apply it to the non-woven fabric A layer of polyimide precursor solution with a thickness of 300 μm was coated on the c...

Embodiment 2

[0057] In step a, dissolve 4,4'-diaminobiphenyl (Shanghai Jiachen Chemical Co., Ltd.) and 3,3',4,4'-biphenyltetracarboxylic dianhydride (Beijing Bomi Technology Co., Ltd.) in an organic solvent N , N'-dimethylacetamide (Shanghai Jingwei Chemical Co., Ltd.) to obtain a polyimide precursor solution; wherein 4,4'-diaminobiphenyl and 3,3',4,4'-biphenyl The molar ratio of tetracarboxylic dianhydride is 1:1.01, the weight of solvent N,N'-dimethylacetamide is 4,4'-diaminobiphenyl and 3,3',4,4'-biphenyl tetra 15 times the total weight of carboxylic dianhydride; the temperature of the solution is controlled at 10-30°C during the preparation process.

[0058] In step b, the polyimide precursor solution prepared in step a is coated on a clean and dry glass plate substrate with a coating thickness of 400 μm, covered with three layers of polypropylene non-woven fabric and then rolled for 1 min to make The polyimide precursor solution can be fully soaked in the polypropylene non-woven fabr...

Embodiment 3

[0061] In step a, 1,2',3,3'-benzophenone tetracarboxylic dianhydride (Beijing Bomi Technology Co., Ltd.) and 3,3'-dimethyl-4,4'-diaminobenzidine Ketone (Shanghai Jiachen Chemical Co., Ltd.) was dissolved in the organic solvent N, N'-dimethylacetamide (Shanghai Jingwei Chemical Co., Ltd.) to obtain a polyimide precursor solution; wherein 1,2', 3,3' -The molar ratio of benzophenone tetracarboxylic dianhydride and 3,3'-dimethyl-4,4'-diaminobenzophenone is 1:0.99, solvent N,N'-dimethylacetamide The weight is 10 times of the total weight of 1,2',3,3'-benzophenone tetracarboxylic dianhydride and 3,3'-dimethyl-4,4'-diaminobenzophenone; preparation During the process, the temperature of the control solution is 10-30°C.

[0062] In step b, a layer of polyester non-woven fabric is covered on the clean and dry glass plate substrate, and the polyimide precursor solution prepared in step a is coated on the polyester non-woven fabric with a film applicator to a thickness of 500 μm to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com