Lithium ion battery and its preparation method

A lithium-ion battery and battery technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of unsatisfactory battery safety performance, reduced battery quality and capacity, etc., and achieves improved production efficiency, small thickness, simplified roll The effect of the winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also provides a preparation method for the above-mentioned battery, the steps include: S1, preparation of the electrode group: the electrode group is prepared by winding or stacking the negative electrode / inorganic separator / positive electrode, and the inorganic separator is attached to the surface of the positive electrode and / or the negative electrode On the surface, the inorganic diaphragm includes lithium manganese phosphate and a binder, and the content of the binder is 1-15 parts by weight relative to 100 parts by weight of lithium manganese phosphate; the porosity of the inorganic diaphragm is 30-80 %. The aforementioned lithium manganese phosphate and binder are commercially available. The method for forming the electrode group by winding or stacking has no special requirements in the present invention, and can be carried out with reference to the prior art, and will not be repeated here.

[0020] The inorganic separator between the positi...

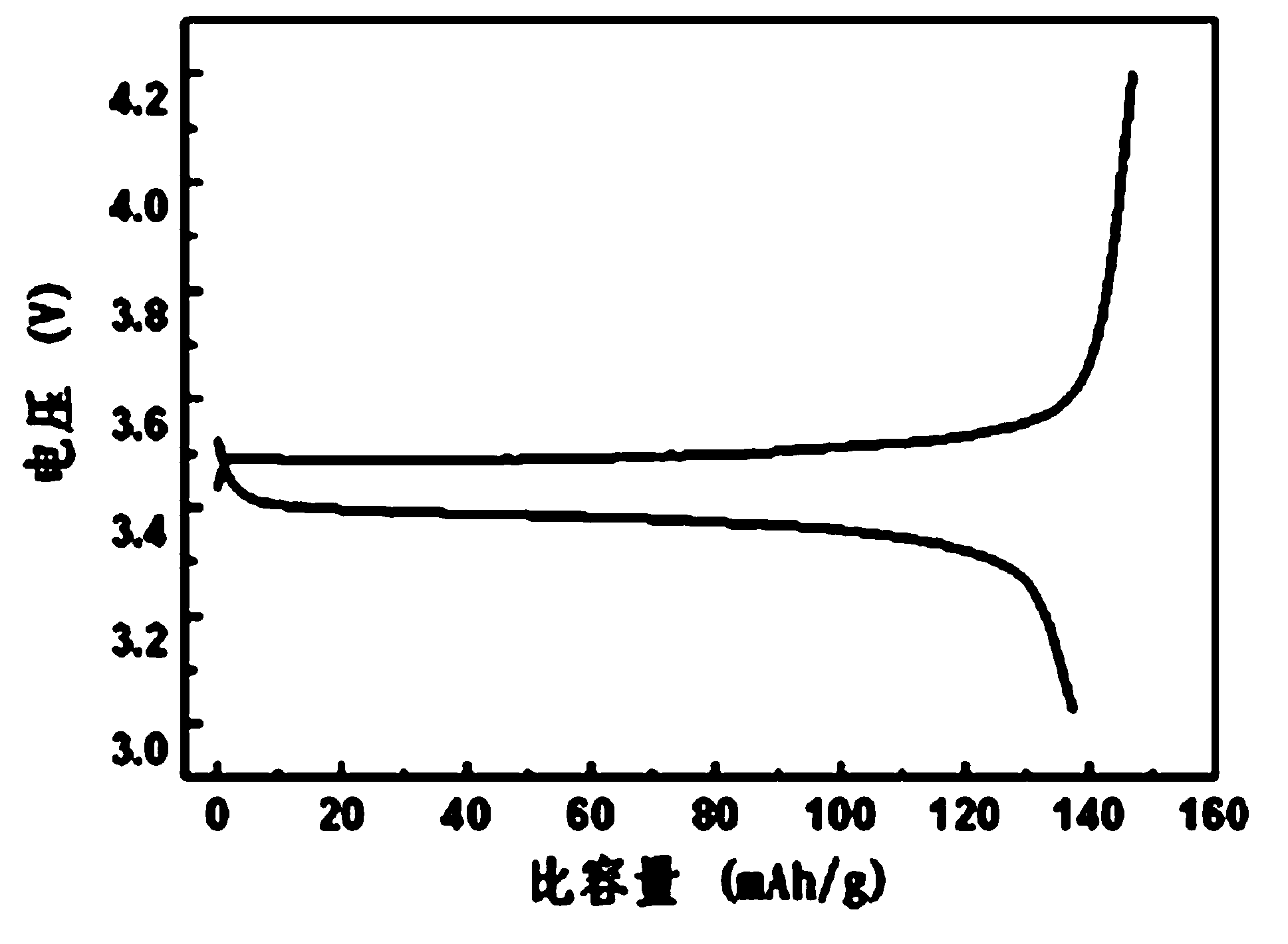

Embodiment 1

[0042] (1) Preparation of positive electrode sheet

[0043] Weigh lithium iron phosphate (LiFePO 4 ), acetylene black, polyvinylidene fluoride (PVDF), N-methylpyrrolidone (NMP) according to the weight ratio of LiFePO 4 : Acetylene black:PVDF:NMP=85:10:5:50 Prepare the positive electrode slurry, stir it evenly, coat it on a 12μm thick aluminum foil, then dry it at 120℃ for 5h, then press it with a tablet machine, and finally slice it , to obtain a lithium-ion battery positive electrode with length×width×thickness=551mm×44mm×130 μm.

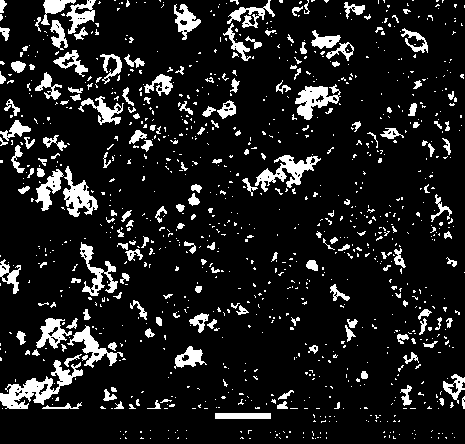

[0044] (2) Preparation of inorganic separator

[0045] Stir and dissolve 0.5g of polyvinylidene fluoride in 5g of N-methylpyrrolidone, add 8.6g of lithium manganese phosphate powder with a particle size of 50nm, and stir with an electric stirrer (at a speed of 1000rpm) for 20min to obtain an inorganic slurry with a solid content of Controlled at 61wt%. A coating machine was used to coat the surface of the positive electrode sheet with a coating...

Embodiment 2

[0052] The battery sample S2 was prepared by the same method as in Example 1, except that the coating thickness of the inorganic slurry was 5 μm.

[0053] The same method as in Example 1 was used to measure the porosity of the inorganic separator to be 52%, and the liquid absorption rate to be 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com