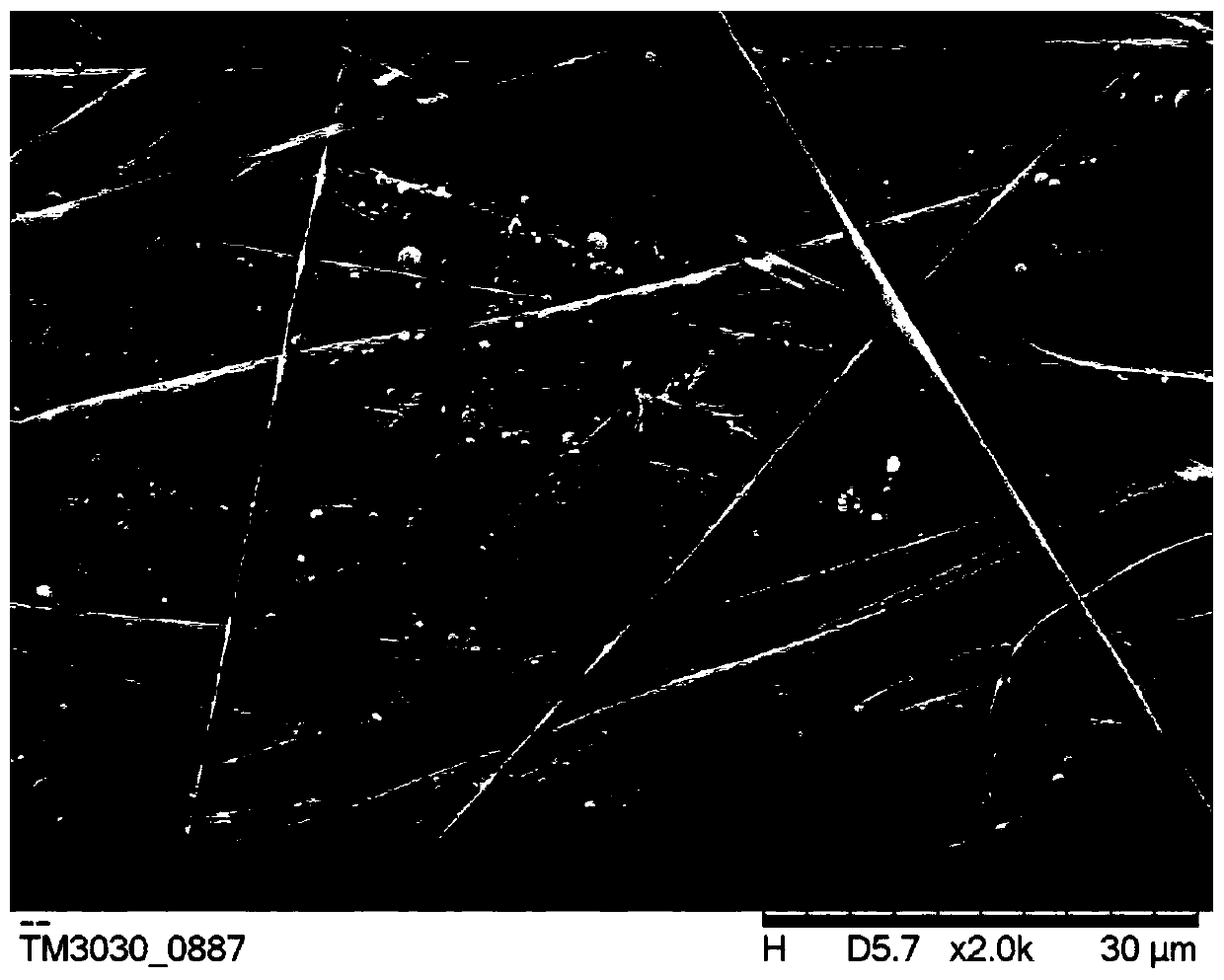

Preparation method of three-dimensional hydrophobic tubular nanofiber membrane

A nanofiber membrane and hydrophobic nanotechnology, which is applied in the field of preparation of three-dimensional hydrophobic tubular nanofiber membranes, can solve the problems of complex fabrication process of hydrophobic membranes, poor mechanical properties of hydrophobic membranes, and low self-supporting ability, so as to improve the anti-wetting effect , High hydrophobic performance, high self-supporting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) In terms of mass fraction, the formula of the first casting solution is: 13% of polyvinyl chloride, 52.2% of N,N-dimethylformamide, and 34.8% of tetrahydrofuran; the formula of the second casting solution is: 4 % SiO 2 , 57.6% of N,N-dimethylformamide, 38.4% of tetrahydrofuran.

[0033] The first casting solution preparation step is: adding polyvinyl chloride to a mixed solvent of N,N-dimethylformamide and tetrahydrofuran (V / V=3:2), stirring for 3 hours at a temperature of 40°C, Obtain a uniform casting solution;

[0034] The second casting solution preparation step is: first SiO 2 (40nm) was added into a mixed solvent of N,N-dimethylformamide and tetrahydrofuran (V / V=3:2) and mechanically stirred for 0.5h, then stirred and dissolved at a temperature of 40°C for 3h to obtain Uniform casting solution;

[0035] 2) The casting solution obtained in step 1) is left to defoam at room temperature;

[0036] 3) Turn on the temperature and humidity controller of the elect...

Embodiment 2

[0040] 1) In terms of mass fraction, the formula of the first casting solution is: 13% of polyvinyl chloride, 52.2% of N,N-dimethylformamide, 34.8% of tetrahydrofuran (the formula is the same as in Example 1); component two The formulation is: 2% SiO 2 , 58.8% of N,N-dimethylformamide, 39.2% of tetrahydrofuran.

[0041]The preparation step of the first casting solution is: add polyvinyl chloride to the mixed solvent (3:2) of N,N-dimethylformamide and tetrahydrofuran, stir and dissolve at a temperature of 40°C, and the stirring time is 3h , to obtain a uniform casting solution;

[0042] The second casting solution preparation step is: SiO 2 (40nm) into a mixed solvent of N,N-dimethylformamide and tetrahydrofuran (3:2) and mechanically stirred for 0.5h, then stirred and dissolved at a temperature of 40°C for 3h to obtain a uniform casting solution ;

[0043] 2) The casting solution obtained in step 1) is left to defoam at room temperature;

[0044] 3) Turn on the temperatur...

Embodiment 3

[0048] 1) In terms of mass fraction, the formula of the first casting solution is: 15% polyvinylidene fluoride, 0.05% anhydrous lithium chloride, 42.5% N,N-dimethylacetamide, 42.5% acetone; The formula of the second casting liquid is: 60wt% polytetrafluoroethylene emulsion (aqueous solution).

[0049] The preparation step of the first casting solution is: adding polyvinylidene fluoride and anhydrous lithium chloride to a mixed solvent (1:1) of N,N-dimethylacetamide and acetone, and at a temperature of 40°C Stir to dissolve, and the stirring time is 3 hours to obtain a uniform casting solution;

[0050] 2) The casting solution obtained in step 1) is left to defoam at room temperature;

[0051] 3) Turn on the temperature and humidity controller of the electrospinning machine, and control the temperature at 30° C. and the humidity at 60%.

[0052] Put the polyester braided tube on the roller, and then set the relevant parameters of electrospinning. Pour the two components into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com