Porous membrane and pore-forming method thereof

A porous membrane and pore-forming technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems that have not been reported in the literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] In the preparation method of the porous membrane according to the present invention, the solution method for membrane formation, the membrane-forming system includes 15-30wt% polymer, 15-30wt% water-soluble porogen, 40-70wt% organic solvent, each The sum of the components is 100wt%, and the proportion of the foaming pore-forming agent in the casting liquid is 0.1-5wt%.

[0009] In the formula of the present invention, the film-forming polymer is a film-forming material that can be dissolved in a conventional solvent, including polyacrylonitrile (PAN), polyvinylidene fluoride (PVDF), polysulfone (PS), polyethersulfone (PES );

[0010] The water-soluble porogen is polyethylene glycol (PEG) of different molecular weights, polyvinylpyrrolidone (PVP) or a mixture thereof with a certain mass ratio;

[0011] Described organic solvent is the organic solvent that does not react with foaming pore-forming agent, comprises N, N dimethylformamide (DMF), N, N dimethylacetamide (DMAc...

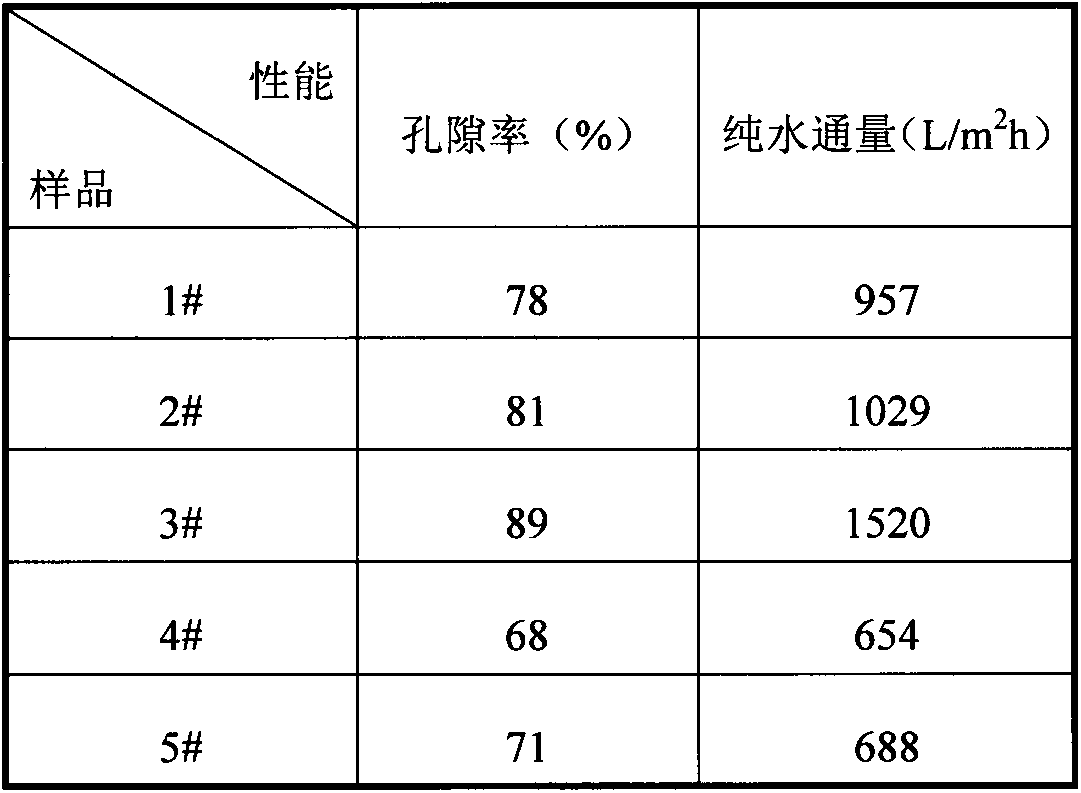

Embodiment 1

[0016] Polyvinylidene fluoride (PVDF) is used as a film-forming polymer with a content of 20wt%; the water-soluble porogen is PEG with an average molecular weight of 4000, and the content is 25wt%; the organic solvent is DMAc, and the content is 55wt%; Sodium borohydride is selected as the porosity agent, and the content is 5wt‰ of the mass of the entire casting solution; PVDF, PEG and sodium borohydride weighed in proportion are dispersed and dissolved in DMAc to obtain a uniform casting solution. The dry-wet spinning hollow fiber spinning head enters the coagulation bath after being solidified and stretched to obtain the hollow fiber membrane of the present invention, and the obtained membrane is correspondingly marked as 1#. Test the porosity, pure water flux (working pressure 0.1Mpa) and mechanical strength of the membrane.

Embodiment 2

[0018] Take polyacrylonitrile (PAN) as the film-forming polymer, the content is 20wt%; the water-soluble porogen is selected as PEG with an average molecular weight of 4000, and the content is 25wt%; the organic solvent is DMAc, and the content is 55wt%; foaming Sodium borohydride is selected as the agent, and the content is 5wt‰ of the whole casting solution quality; PVDF, PEG and sodium borohydride weighed in proportion are dispersed and dissolved in DMAc to obtain a uniform casting solution, and the casting solution is subjected to conventional After the dry-wet spinning hollow fiber spinneret enters the coagulation bath, solidifies and draws to obtain the hollow fiber membrane of the present invention, the obtained membrane is correspondingly marked as 2#. Test the porosity and pure water flux of the membrane (working pressure 0.1Mpa).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com