Patents

Literature

77results about How to "Uniform porous structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Straw fiber reinforced foam concrete and preparation method thereof

ActiveCN104130006AUniform porous structureReduce voidsSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses straw fiber reinforced foam concrete and a preparation method thereof, and belongs to the technical field of building materials. The straw fiber reinforced foam concrete comprises the following components by mass: 40-80 parts of a cementitious material; 1-20 parts of a fine lightweight aggregate; 0.05-0.6 part of straw fiber; 2-8 parts of a chemical foaming agent; 0.5-4 parts of a physical foaming agent; 0.02-0.14 part of a foam stabilizing agent; 0.1-0.8 part of a catalyst; 0.05-0.6 part of a thickening agent and 15-30 parts of water. The preparation method is as follows: mixing and stirring the cementitious material, the straw fiber and the thickening agent, then adding the water, the chemical foaming agent, the foam stabilizing agent and the catalyst, stirring to obtain a slurry mixture, then adding expanded vermiculite, stirring to obtain chemically foamed foam concrete; adding the physical foaming agent into the chemically foamed foam concrete, stirring, pouring into a mould, and demoulding after concrete is solidified and hardened to prepare the straw fiber reinforced foam concrete. The straw fiber reinforced foam concrete has a more uniform multihole structure, and the water proof, sound insulation and heat insulation effects are better than that of foam concrete in the prior art.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

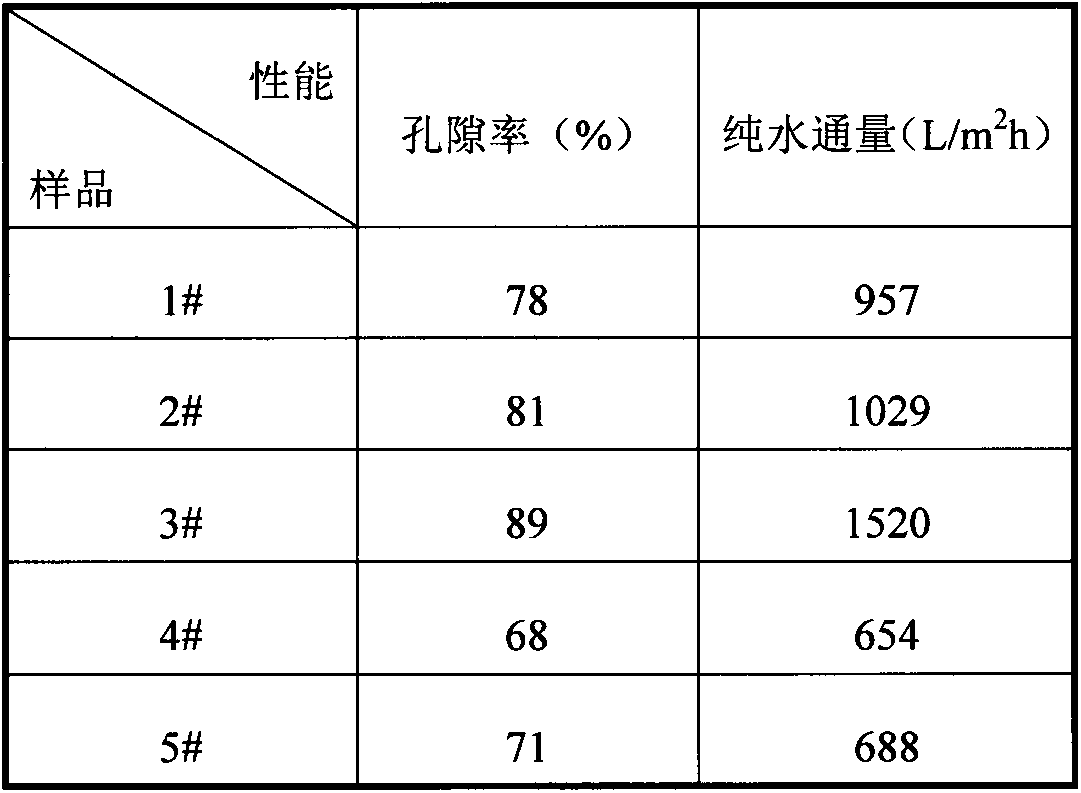

Porous membrane and pore-forming method thereof

InactiveCN103706259AUniform porous structureSemi-permeable membranesHollow fibre membranePorous membrane

The invention discloses a porous membrane and a pore-forming method of the porous membrane. According to a preparation method, a foaming pore-forming agent is introduced into a membrane-forming system and can generate uniformly distributed trace air bubbles through reaction so as to form a porous structure; therefore, the porosity of the membrane is improved, and macropore defects of the membrane can be avoided. The pore-forming method is applicable to membrane preparation by a solution method and a melting method. The pore-forming method specifically comprises the steps of (1) membrane preparation by the solution method: uniformly mixing a membrane-forming polymer and the foaming pore-forming agent, dissolving the mixture in a solvent to obtain a membrane casting solution containing the foaming pore-forming agent, wherein the membrane casting liquid enters an acidic coagulating bath after being subjected to scraping or is spun through a hollow fiber spinning head, so that the membrane casting liquid is solidified and formed to obtain the porous membrane when the foaming pore-forming agent reacts to form the air bubbles; (2) membrane preparation by the melting method: uniformly mixing the membrane-forming polymer and the foaming pore-forming agent, and obtaining an initial hollow fiber containing the foaming pore-forming agent through conventional hollow fiber membrane melting spinning, and putting the obtained initial hollow fiber into the acidic coagulating bath, wherein the hollow fiber is solidified and formed to obtain the porous membrane when the foaming pore-forming agent reacts to form the air bubbles.

Owner:TIANJIN POLYTECHNIC UNIV

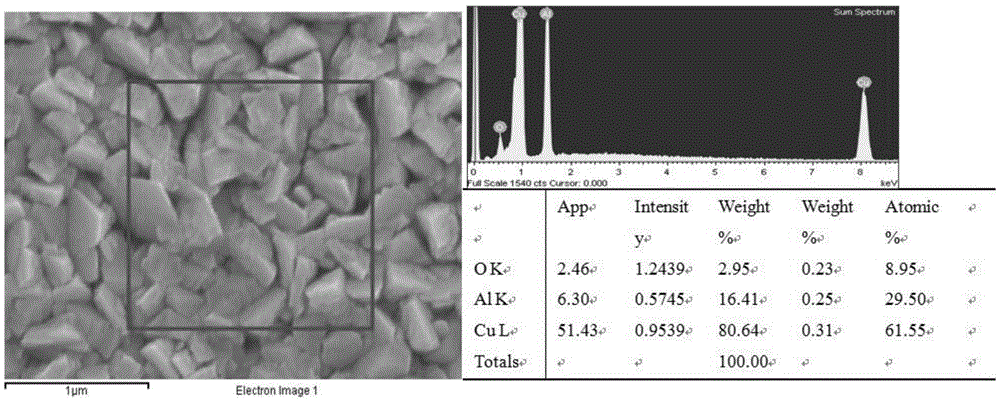

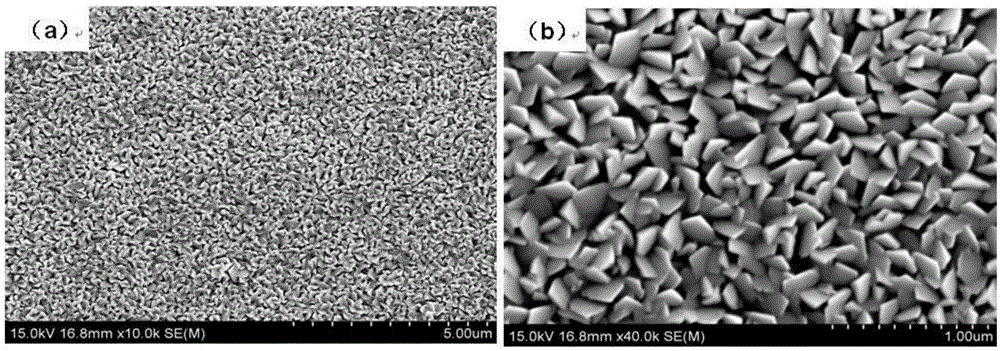

Method for preparing nano porous copper thin film material by magnetron sputtering

ActiveCN105543796AStructural continuityMeet the areaVacuum evaporation coatingSputtering coatingAlloyCopper foil

The invention relates to a method for preparing a nano porous copper thin film material by magnetron sputtering. The method takes a commercial copper foil as a base body material and takes high-purity copper target and aluminum target as sputtering materials; magnetron sputtering equipment is a preparation tool; a nano porous copper thin film is obtained by sputtering a copper-aluminum thin film through a glow discharge principle, and dealloying and corroding to remove an active component aluminum after annealing and alloying. The method provided by the invention is a two-step reaction method, the problems in the prior art that steps for carrying out smelting, ball milling and melt spinning on alloy auxiliary materials are complicated and consumed time is long are solved, and steps of a preparation process are simplified; a nano porous structure of nano porous copper is obtained and the size of the thin film is controllable; the obtained structure is better than a nano porous copper powder sample obtained by a traditional method; furthermore, an application range of the nano porous copper is enlarged and the nano porous copper has a commercial prospect.

Owner:SHANDONG UNIV

Method of preparing magnesium-doped hydroxyapatite/titania active film on surface of medical titanium alloy

ActiveCN102747403AUniform film thicknessCompact structureSurgerySurface reaction electrolytic coatingMicro arc oxidationTitanium oxide

The invention discloses a method of preparing a magnesium-doped hydroxyapatite / titania active film on the surface of medical titanium alloy. According to the invention, the technology of microarc oxidation is used for synthesis of the magnesium-doped hydroxyapatite / titania active film on the surface of titanium alloy in phosphate electrolyte containing magnesium ions and calcium ions. The film prepared by using the preparation method provided by the invention has a porous structure, high binding strength with a titanium alloy substrate and good biological activity and cellular affinity.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Self-heat-insulation light weight wallboard containing hollow ceramsites and preparation method thereof

ActiveCN104129959AUniform porous structureReduce voidsSolid waste managementCeramicwareFiberFoaming agent

The invention discloses a self-heat-insulation light weight wallboard containing hollow ceramsites and a preparation method thereof, and belongs to the technical field of building materials. The self-heat-insulation light weight wallboard comprises the following components by mass: 20-60 parts of a cementitious material, 5-30 parts of a lightweight aggregate, 0.05-0.5 part of a composite early strength agent, 2-8 parts of a foaming agent, 0.02-0.14 part of a foam stabilizing agent, 0.1-0.8 part of a catalyst, 0.05-0.6 part of a binder, 0.05-0.6 part of straw fiber and 15-30 parts of water. The preparation method is as follows: putting the cementitious materials, the straw fiber and the binder together, then mixing, then orderly adding the water, the foaming agent, the stabilizer and the catalyst, stirring to obtain a slurry mixture, adding hollow ceramsites, obturator perlite and expanded vermiculite in saturated surface-dry condition, stirring, then using an injection pump to inject into a wallboard forming machine for molding, and 3-5 hours after the concrete is solidified and hardened, demoulding to obtain the self-heat-insulation light weight wallboard containing the hollow ceramsites. The self-heat-insulation light weight wallboard containing the hollow ceramsites has energy saving, environmentally-friendly, fire insulating, sound-insulation, high-strength, lightweight, waterproof, thermal-insulation, corrosion-resistant, durable and other characteristics.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Separator for a non-aqueous secondary battery and non-aqueous secondary battery

ActiveUS20140255754A1Excellent ion permeabilityUniform porous structureJackets/cases materialsLi-accumulatorsPolyvinylidene fluorideStructural unit

The present invention provides a separator for a non-aqueous secondary battery including a porous substrate, and an adhesive porous layer that is formed at one or both sides of the porous substrate, contains (1) polyvinylidene fluoride resin A and (2) polyvinylidene fluoride resin B described below, and has a porosity of from 30% to 60% and an average pore size of from 20 nm to 100 nm:(1) polyvinylidene fluoride resin A is selected from the group consisting of vinylidene fluoride homopolymers and DVF copolymers containing structural units derived from vinylidene fluoride (VDF) and structural units derived from hexafluoropropylene (HFP), a total content of structural unit derived from HFP in each of the VDF copolymers being 1.5 mol % or less of a total content of structural unit in each of the VDF copolymers; and(2) polyvinylidene fluoride resin B selected from the group consisting of VDF copolymers containing a structural unit derived from VDF and a structural unit derived from hexafluoropropylene, a total content of structural unit derived from HFP in each of the VDF copolymers being greater than 1.5 mol % of a total content of structural unit in each of the VDF copolymers

Owner:TEIJIN LTD

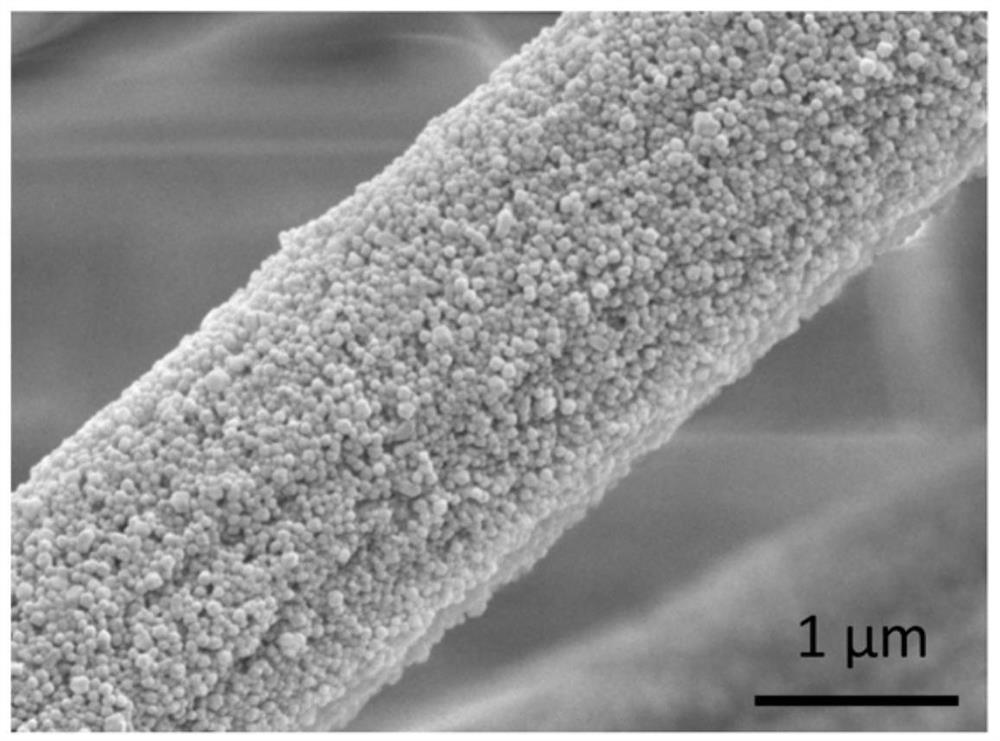

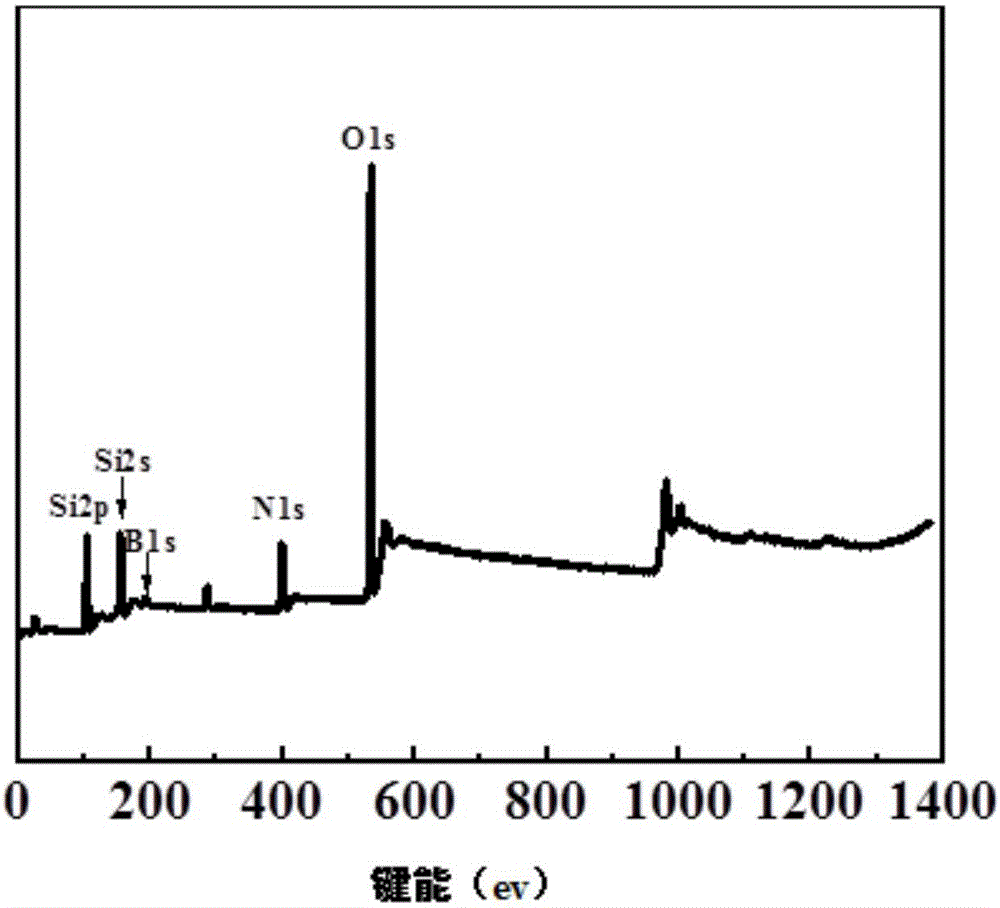

Porous electrode for flow battery and preparation method of porous electrode

ActiveCN111785978ALarge specific surface areaIncrease active areaCell electrodesHeating/cooling textile fabricsChemistryAcetamide

The invention provides a porous electrode for a flow battery and a preparation method of the porous electrode, and relates to the field of flow batteries. The preparation method comprises the following steps: S1, adding polyacrylonitrile and a metal salt into N, N-dimethylformamide or N, N-dimethylacetamide, carrying out heating and mixing until polyacrylonitrile and the metal salt are dissolved,so as to obtain an electrospinning stock solution; S2, carrying out electrostatic spinning by using the electrospinning stock solution to obtain an electrospun fiber membrane; S3, dissolving an organic ligand in a solvent to obtain an organic ligand solution, soaking the electrospun fibrous membrane in the organic ligand solution for a period of time, and generating MOF particles in situ on the surface of the electrospun fibrous yarn; and S4, carrying out pre-oxidation on the fibers with the MOF particles deposited on the surfaces, and then carrying out carbonization in an inert gas atmosphereto obtain the porous electrode. The porous electrode prepared in the invention has a large specific surface area, is helpful for reducing the activation loss of the battery and improving the performance of the battery, and can be suitable for various flow batteries.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Diaphragm paper, and preparation method and application thereof

ActiveUS20160049627A1Small apertureImprove isolationNatural cellulose pulp/paperSpecial paperEngineeringElectrolyte

Diaphragm paper, and a preparation method and an application thereof. The diaphragm paper comprises a first layer, a second layer, and a third layer, wherein the second layer is located between the first layer and the third layer; the first layer and the third layer are loose layers, of which the average aperture is larger than 10 μm and the basis weight is 5 to 30 g / m2; and the second layer is a compact layer, of which the average aperture is smaller than 5 μm and the basis weight is 2 to 15 g / m2. The compact layer has small aperture and good insulating performance, and is capable of effectively insulating a positive electrode and a negative electrode. The loose layers have good liquid permeability and electrolyte absorptivity, and can guarantee the discharge performance of a battery. The material is further advantageous in having good dimensional stability and being thin, so that a battery can achieve high capacity.

Owner:SOUTH CHINA UNIV OF TECH

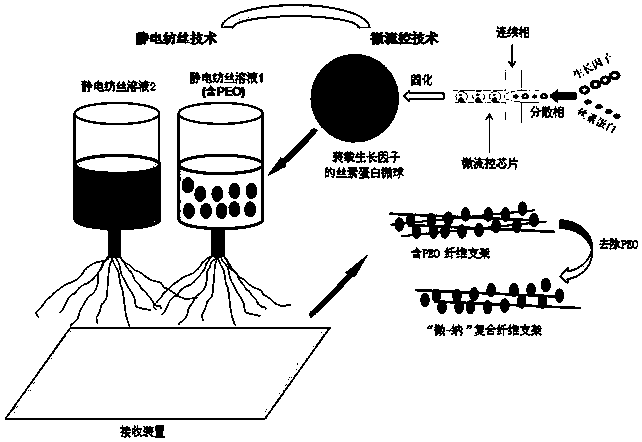

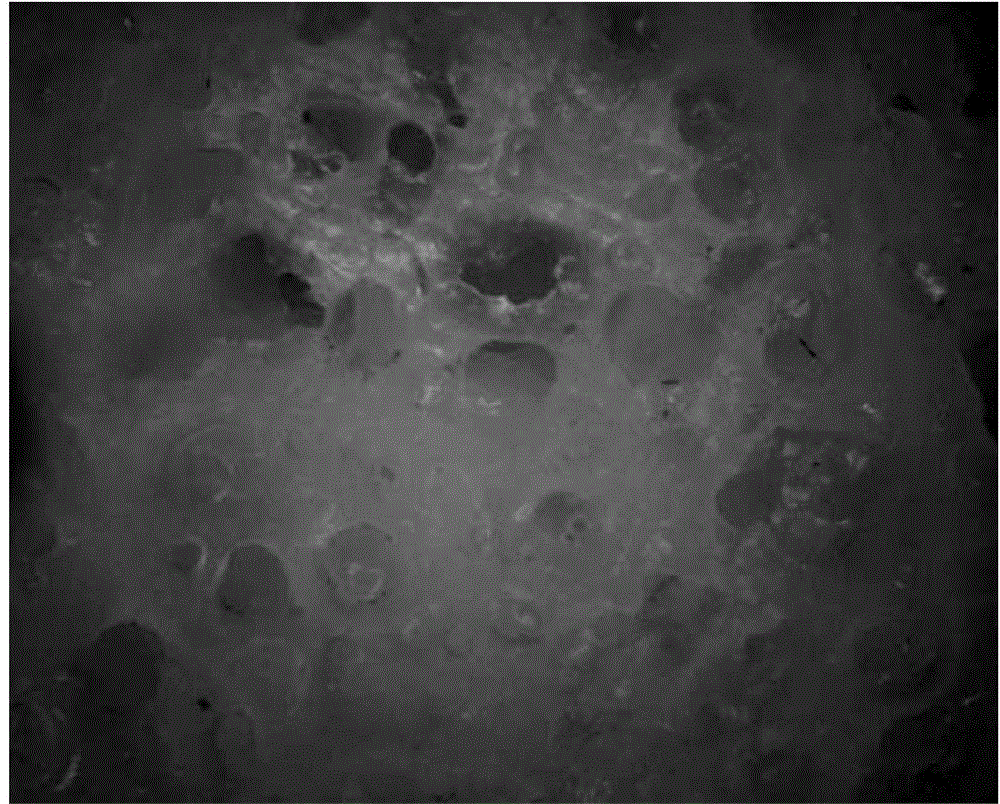

Three-dimensional nanofiber stent based on microfluidic technology and electrospinning technology and preparation method thereof

InactiveCN107865979AGood biocompatibilityImprove mechanical propertiesPharmaceutical delivery mechanismElectro-spinningPorosityFiber

The invention relates to the fields of a microfluidic technology and an electrospinning technology, and provides a method for preparing a three-dimensional nanofiber stent with a micro-nanometer composite structure. By the microfluidic technology, monodisperse silk fibroin microspheres with a uniform dimension are prepared; growth factors are slowly and stably released along with the silk microsphere degradation, so that the biological effect is fully achieved; and the burst release problem and the peak valley phenomenon generated by nonuniform microspheres prepared through mechanical stirring, oscillation, ultrasonic homogenate and the like in the prior art are solved. In addition, double spray heads or a single spray head is used for performing electrostatic spinning on an ethanol solution of the silk fibroin microspheres containing growth factors and PEO (Polyethylene Oxide), and a hexafluoroisopropanol solution of silk fibroin; then, PEO fiber in the solution is dissolved; and themicro-nanometer composite three-dimensional nanofiber stent with the uniform porous structure and the proper porosity is prepared. The stent has good biocompatibility and certain mechanical performance; the inward growth of cells is facilitated; the increase and the migration of the cells are promoted; the double functions of improving the small-caliber artificial blood vessel forward patency rateand remodeling the blood vessel wall are realized; and the stent is applicable to the restoration or the replacement of injury or lesion small-caliber blood vessel tissues.

Owner:BEIHANG UNIV

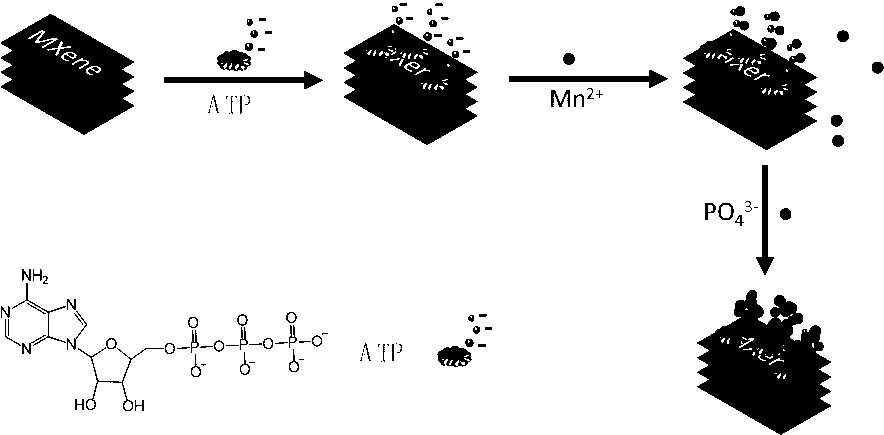

Preparation and application of Mxene-Mn3(PO4)2 composite electrode material

InactiveCN108614023AUniform porous structureHigh economic valueMaterial electrochemical variablesMedical diagnosisNanocomposite

The invention discloses preparation and application of an Mxene-Mn3(PO4)2 composite electrode material. The preparation is characterized in that two-dimensional Ti3C2 nanosheets are synthesized from aTi3AlC2 ceramic material as a raw material, and ATP (adenosine triphosphate) is used as a template to induce synthesis of Mn3(PO4)2 nanoparticles. The Ti3C2 / Mn3(PO4)2 nanocomposite synthesized with the method integrates good conductivity of Ti3C2 and biological mimetic enzyme activity of Mn3(PO4)2, and the composite material has excellent conductivity and catalytic performance by complementary advantages of the two raw materials, and is the excellent electrode material for preparing superoxide dismutase. The composite material can be used for constructing biosensors and has excellent application prospects in the fields of medical diagnosis, medical research and the like.

Owner:SOUTHWEST UNIVERSITY

Process to make synthetic leather and synthetic leather made therefrom

ActiveUS7306825B2Good handNice appearanceLayered productsPretreated surfacesPolyurethane dispersionOrganic acid

A synthetic leather is made by a impregnating a non-woven or woven textile with an aqueous polyurethane dispersion comprised of a nonionizable polyurethane and an external stabilizing surfactant. The impregnated textile is then exposed to water containing a coagulant for a coagulation time sufficient to coagulate the dispersion. The method may be used to form a synthetic leather having excellent wet ply adhesion and may contain an insoluble multivalent cation organic acid.

Owner:DOW EURO

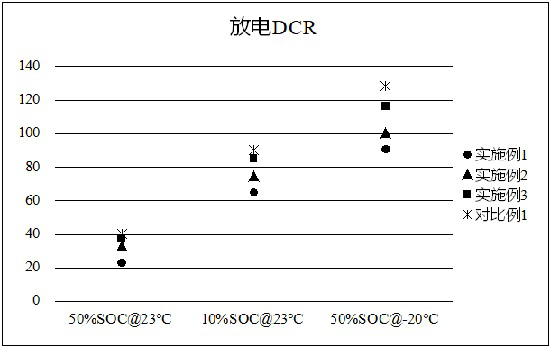

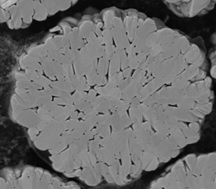

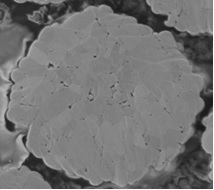

Anode material with uniform porous structure and preparation method thereof

InactiveCN113651373AImprove structural stabilityUniform porous structureSecondary cellsPositive electrodesOxalateManganate

The invention discloses a positive electrode material with a uniform porous structure. The morphology of the positive electrode material is the uniform porous structure, the secondary particle D50 of the material is 2-15 [mu] m, and the porosity of the positive electrode material is 1.5-5%. The preparation method comprises the following steps: synthesizing a nickel-cobalt-manganese oxalate precursor with a compact structure by adopting a coprecipitation method, subjecting the oxalate precursor with the compact structure and a metal oxide doped with elements to mixing and presintering to obtain a doped nickel-cobalt-manganese oxide precursor with a uniform porous structure; and uniformly mixing the doped nickel-cobalt-manganese oxide precursor having the uniform porous structure with a lithium salt, carrying out primary sintering, carrying out mixing with a coating compound, and carrying out secondary sintering to finally obtain the doped and coated nickel-cobalt-lithium manganate positive electrode material with the uniform porous structure. The process of the method is simple, cost is relatively low, the performance of the material is obviously improved, and the prepared nickel-cobalt-lithium manganate positive electrode material with the uniform porous structure still has excellent rate capability and output power under the condition of low cobalt content.

Owner:HENAN KELONG NEW ENERGY CO LTD

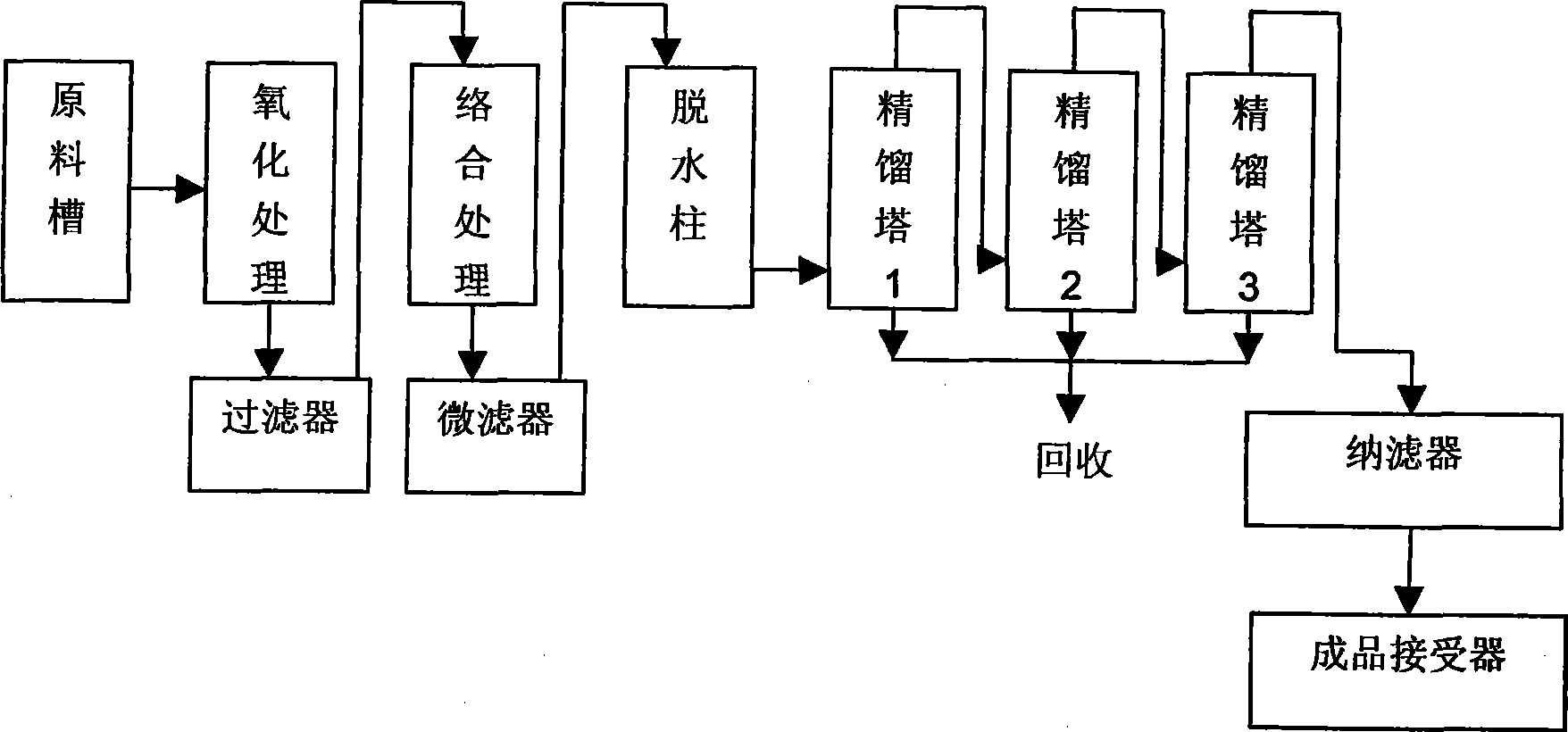

Method for preparing super-clean and high-purity acetic acid and apparatus thereof

ActiveCN101362683AEfficient removalUniform porous structureCarboxylic compound separation/purificationFiltrationSmall footprint

The invention relates to a method for preparing super-clean high-purity acetic acid, and the high-purity acetic acid is mainly suitable for cleaning and corrosion in the manufacture industry of large scale integrated circuit semiconductor devices in the microelectronic industry. The method is as follows: firstly, the industrial grade acetic acid (99.0 percent) material is mixed with potassium permanganate with 0.1-0.5 percent of the weight of the acetic acid material in an oxidation processor; the mixture is filtered after 30-60 minutes under the normal temperature and pressure; the filtrate and a silicone polymer complexing agent of the bi-allyl 18-coronary-6 ether are mixed in a complexing processor for 30-120 minutes, and then the mixture is filtered by the microfiltration membrane of a microstrainer under the operation pressure of 0.1-0.2MPa; the filtrate passes through a 2,000mm dehydration column, and then enters a multi-level rectification tower with the speed of 0.05-0.20mm / s, and the semi-finished product yielded from the tower enters a product acceptor after the filtration by the nanofiltration membrane of a nanofiltration device under the operation pressure of 0.5-0.8MPa. The method has the advantages of simple process, low production cost, high product purity and low content of impurity ion. The device has the advantages of small occupied area, convenient automatic operation, stable quality and continuous production.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

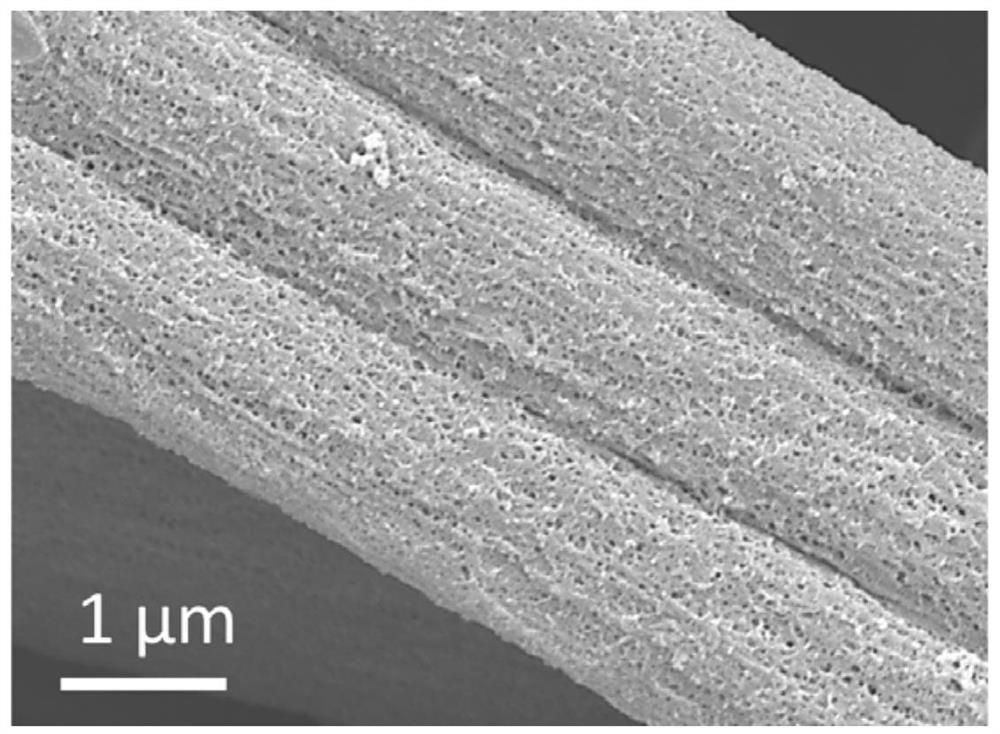

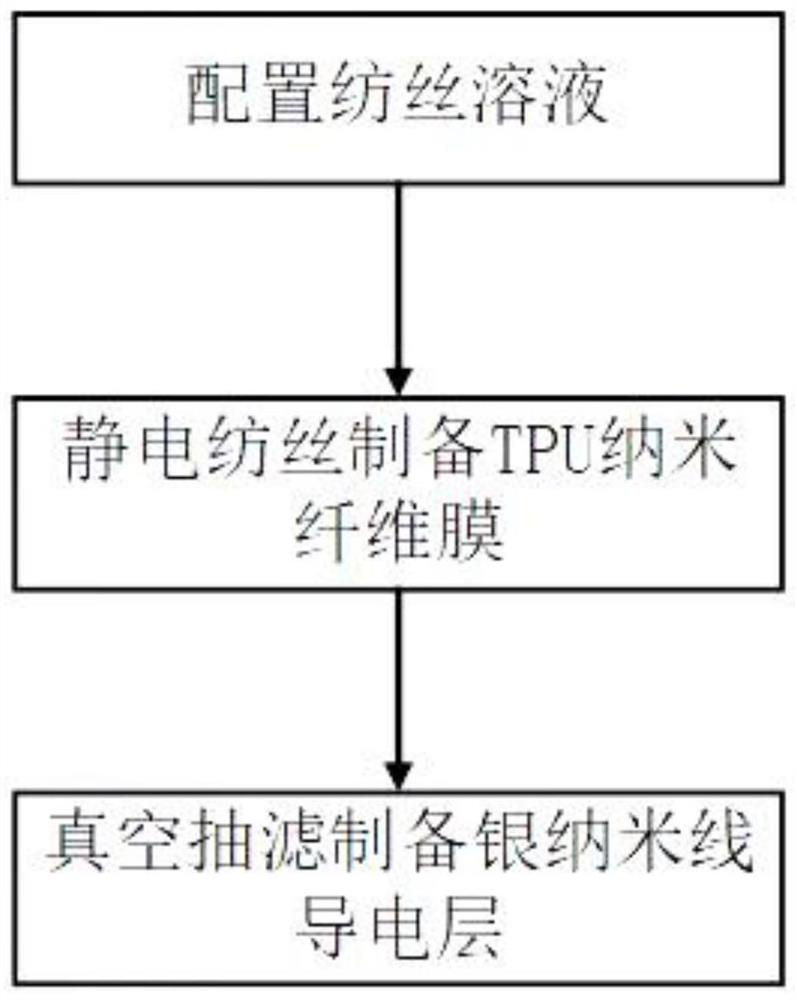

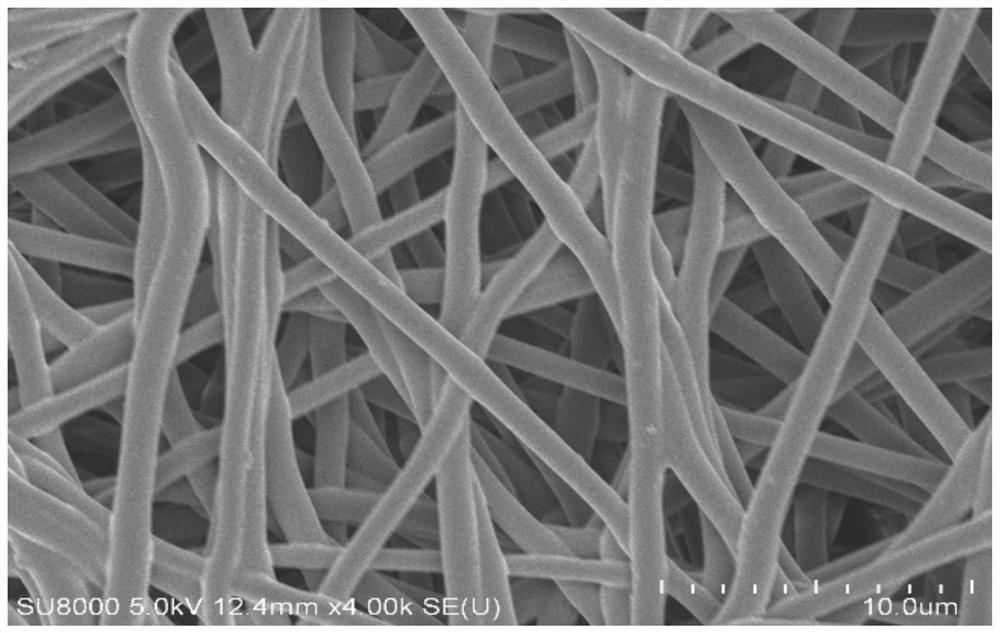

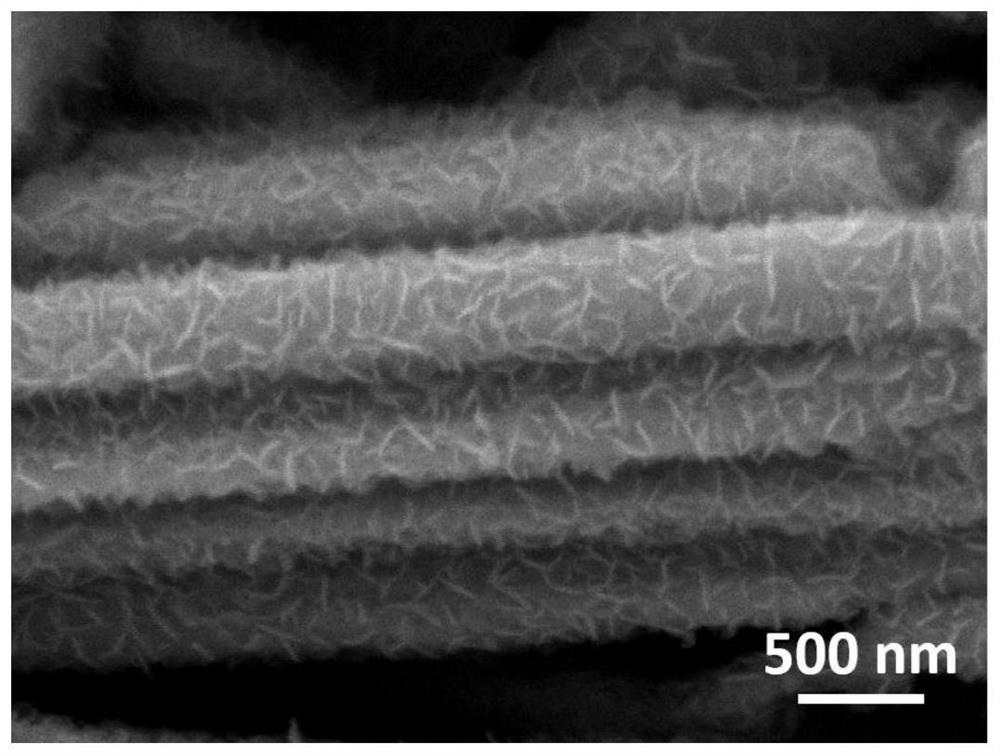

Preparation methods for composite nanofiber membrane and flexible strain sensor

ActiveCN112900080APromote formationAvoid damageMonocomponent polyurethanes artificial filamentFibre typesPolymer scienceSpinning

The invention discloses preparation methods for a composite nanofiber membrane and a flexible strain sensor. The preparation method for the composite nanofiber membrane comprises the following steps of firstly dissolving polymer particles in an organic solvent to prepare a spinning solution; transferring the spinning solution into an injector, extruding the spinning solution through the injector, and adjusting relevant parameters of electrostatic spinning to enable jet flow to be stable so as to collect a nanofiber membrane on a collecting plate; after silver nanowire dispersion liquid is diluted and subjected to water bath ultrasonic dispersion, depositing a metal nanowire layer on the pre-stretched nanofiber membrane through a vacuum-assisted suction filtration method; and increasing the binding force between nanowires and the binding force between the nanowires and an elastic substrate through high-temperature annealing. The prepared flexible strain sensor has a large sensing range and can be used for detecting deformation such as bending, stretching and twisting.

Owner:XI AN JIAOTONG UNIV

Preparation method and driving method of shape-memory polycaprolactone foam

The invention relates to a preparation method and a driving method of shape-memory polycaprolactone foam. The invention relates to the field of functional polymer materials, in particular to the preparation method and the driving method of the shape-memory polycaprolactone foam. The invention is intended to solve the problems of complex process, low production efficiency, high cost and uneasy control existing in conventional preparation methods. The preparation method includes the following steps: (1) polycaprolactone is dissolved into dichloromethane, stirring is performed at room temperature until the polycaprolactone is dissolved completely, benzamide peroxide is then added, stirring is performed at room temperature until the benzamide peroxide is dispersed uniformly, and thereby polycaprolactone solution is obtained; (2) the polycaprolactone solution obtained in step 1 is poured into a mold, and is then put into a microwave oven to be heated, and thereby the shape-memory polycaprolactone foam is obtained. The driving method is as follows: under the condition of microwave heating, the shape-memory polycaprolactone foam can be restored to an initial shape within 98s.

Owner:HARBIN INST OF TECH

Composite modified aqueous acrylic resin emulsion coating-containing pearlescent flame retardation wallpaper

InactiveCN105295626AStable performanceImprove breathabilityCovering/liningsFlame-proof filament manufactureEmulsionFire retardant

The invention discloses a composite modified aqueous acrylic resin emulsion coating-containing pearlescent flame retardation wallpaper. A resin adhesive adopted in a coating slurry used by the wallpaper is a cellulose acetate copolymer modified aqueous acrylic resin emulsion, the emulsion has stable performances and contains no formaldehyde or other chronic volatile toxic compounds, a coating formed by the emulsion is smooth and elastic and has water resistance, antifouling and antibiosis functions, pearl powder-polylactic acid porous fibers added to the slurry have a uniform porous structure, and a flame retardation agent is uniformly dispersed in the resin emulsion, has coating permeability and flame retardation improvement efficacy, endows the coating with multi-angle pearlescent color, and increases the ornamental effect.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Double-metal loaded titanium dioxide nano porous ceramic catalyst as well as preparation method and application thereof

InactiveCN108187692AImprove hydrodynamic propertiesHigh catalytic activityMaterial nanotechnologyOrganic compound preparationPtru catalystMetal particle

The invention relates to a double-metal loaded titanium dioxide nano porous ceramic catalyst as well as a preparation method and application thereof. The catalyst takes a titanium dioxide nano porousceramic membrane as a carrier and gold and copper double-metal nanoparticles as an active component; the preparation method of the catalyst comprises the following steps: 1) carrying out press filtering and sintering on a titanic acid nano-ribbon to obtain the titanium dioxide nano porous ceramic membrane; 2) loading the gold and copper double-metal nanoparticles on the ceramic membrane by adopting a one-step deposition-precipitation method; reducing through H2 to prepare the gold and copper double-metal loaded titanium dioxide nano porous ceramic catalyst. The double-metal loaded titanium dioxide nano porous ceramic catalyst prepared by the preparation method has the advantages that catalytic active metal particles are uniformly distributed and the component composition is quantified andcontrollable; the catalyst has a uniform porous structure and high porosity and has the advantages of high catalytic activity, selectivity and stability; the catalyst is easy to recycle and repeatedlyused and is suitable for large-scale industrial application.

Owner:SHANDONG UNIV

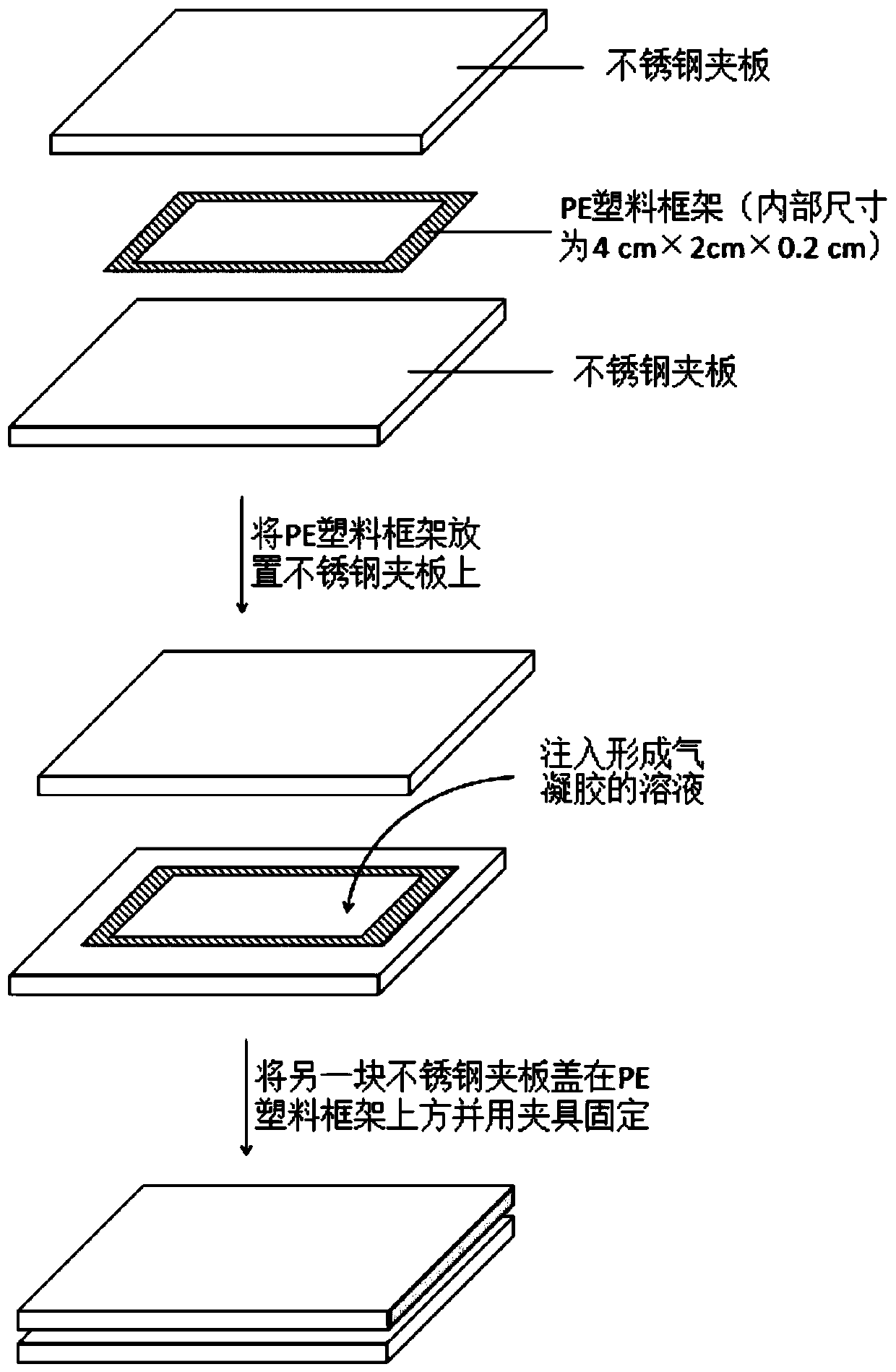

Preparation method for preparing porous gelatin film from GO (graphene oxide) stabilized Pickering emulsion

The invention discloses a preparation method for preparing a porous gelatin film from a GO (graphene oxide) stabilized Pickering emulsion. The method comprises the steps as follows: a proper amount ofGO is added to deionized water, a GO suspended dispersion liquid is prepared, and ultrasonic treatment is performed; a gelatin solution is dissolved in the GO suspension, benzoate is added to serve as an oil phase, and ultrasonic treatment is performed; a sample in placed in a water bath, then casting is performed, and a non-crosslinked film is obtained; the non-crosslinked film is impregnated ina solution containing a crosslinking agent for a period to be crosslinked, then, the film is washed with ethanol and deionized water, finally, the film is dried, and the gelatin film adopting a porous structure is obtained. The preparation process for preparing the porous gelatin film from the Pickering emulsion is simple, green, environmentally friendly, has low equipment requirement, high aqueous solution stability and uniform porous structure, is prone to large-scale production and has wide application prospects in wastewater separation, gas separation, food emulsification, catalysis, heavy metal ion detection and other fields.

Owner:JIANGNAN UNIV

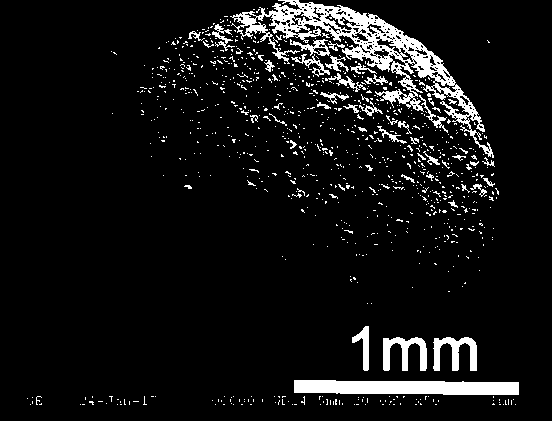

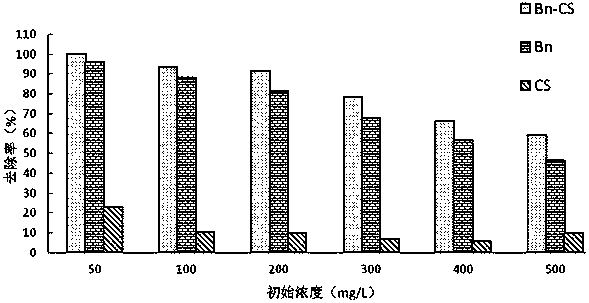

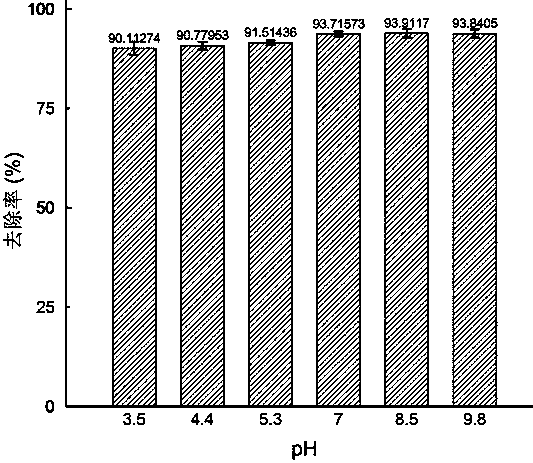

Magnetic porous bentonite chitosan composite microsphere and preparation method thereof

ActiveCN108355621AIncreased porous structureHas a porous structureOther chemical processesRadioactive contaminantsPorosityMagnetic media

The invention discloses a magnetic porous bentonite chitosan composite microsphere. The magnetic porous bentonite chitosan composite microsphere is characterized by being prepared from the following raw materials in parts by weight: 1-10 parts of bentonite, 1-5 parts of acetic acid, 1-3 parts of chitosan, 1-6 parts of ferric chloride hexahydrate, 1-3 parts of ferrous chloride tetrahydrate, 10-15 parts of sodium hydroxide, 5-10 parts of sodium citrate and 200-250 parts of water. High-porosity chitosan hydrogel microsphere is modified and led into a magnetic medium, and bentonite is loaded intothe microsphere to successfully prepare the magnetic porous bentonite chitosan composite microsphere with relatively strong cesium-ion adsorption ability and ability of utilizing a magnetic technologyto recycle. The magnetic porous bentonite chitosan composite microsphere has the characteristics of being high in adsorption rate, great in adsorption capacity, insensitive to pH and wide in scope ofapplication; and the magnetic porous bentonite chitosan composite microsphere can be gathered through external magnetic fields, solid-solution separation is easily realized, and recycling is convenient; and the whole preparation process is simple, operation time is short, and control is easy.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

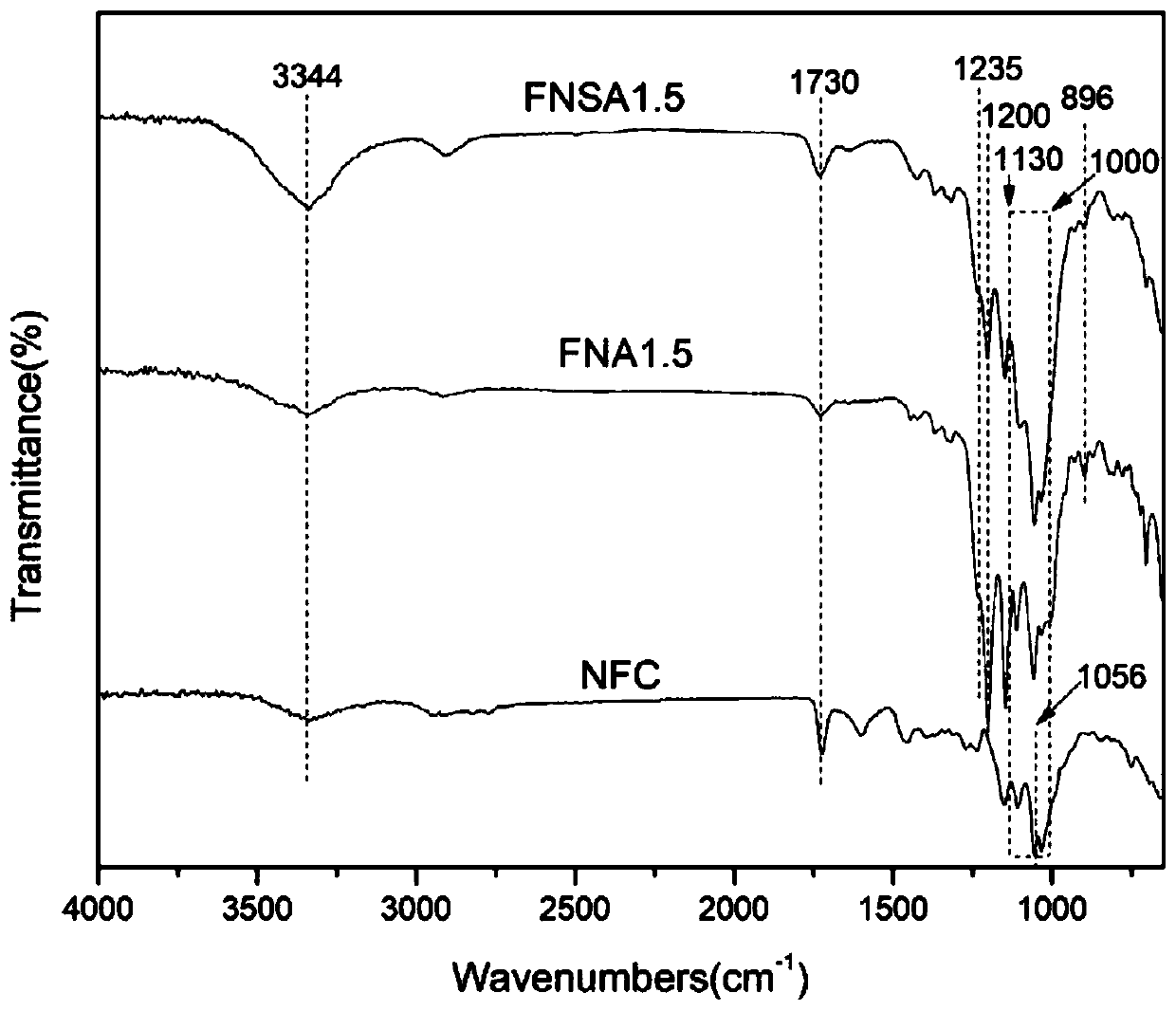

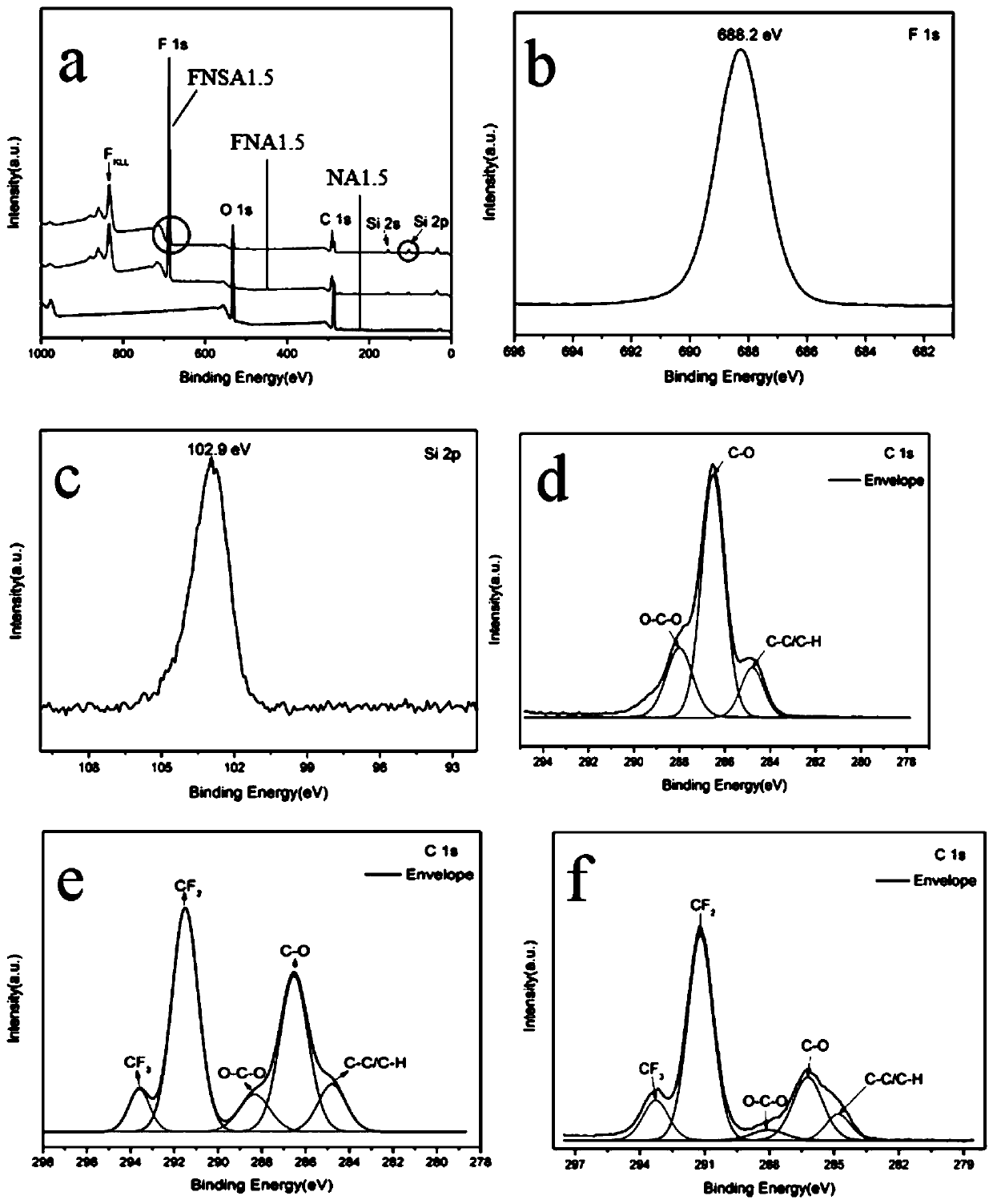

Preparation method of super-amphiphobic nano cellulose aerogel

ActiveCN110669249AHigh reactivityEnhances successful and efficient depositionCoatingsHigh polymerCastor oil

The invention discloses a preparation method of a super-amphiphobic nano cellulose aerogel, and belongs to the technical field of high polymer materials. The preparation method comprises the followingsteps: by taking nanocellulose prepared by TEMPO oxidation method and nano-SiO2 particles prepared by Stober method as raw materials, preparing a mixed suspension, injecting the mixed suspension intoa mold, freezing in liquid nitrogen, and then freeze-drying under a low-temperature condition to obtain nanocellulose aerogel; adopting a chemical vapor deposition method; carrying out amphiphobic modification on the surface of the obtained nanocellulose aerogel with THFOS so as to obtain the super-amphiphobic nano cellulose aerogel. The average contact angle of the super-amphiphobic nano cellulose aerogel with water, castor oil, and hexadecane reaches 166 degrees, 157 degrees and 150 degrees, and the super-amphiphobic nano cellulose aerogel has the common characteristics of super-amphiphobicmaterials such as water resistance, and oil repellency, and has a good industrial application prospect.

Owner:NANJING FORESTRY UNIV

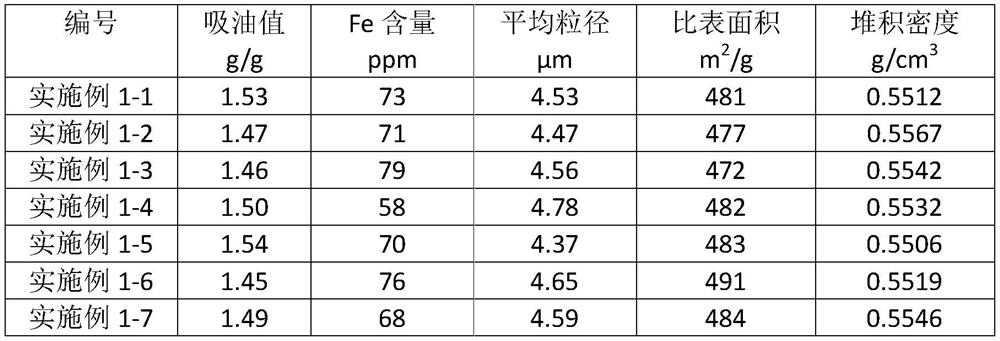

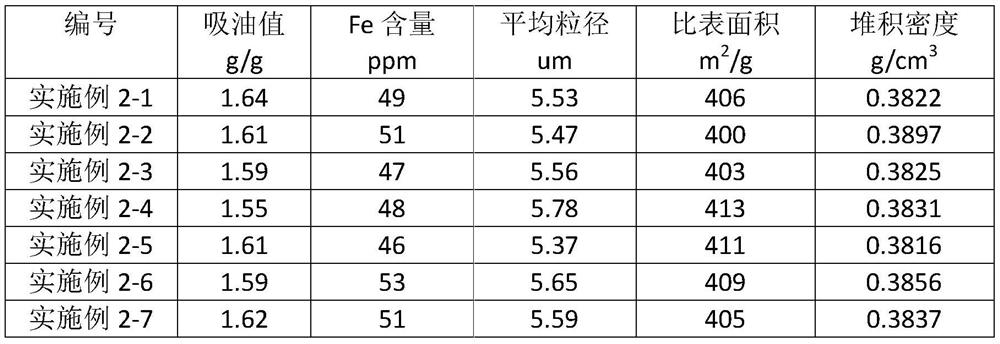

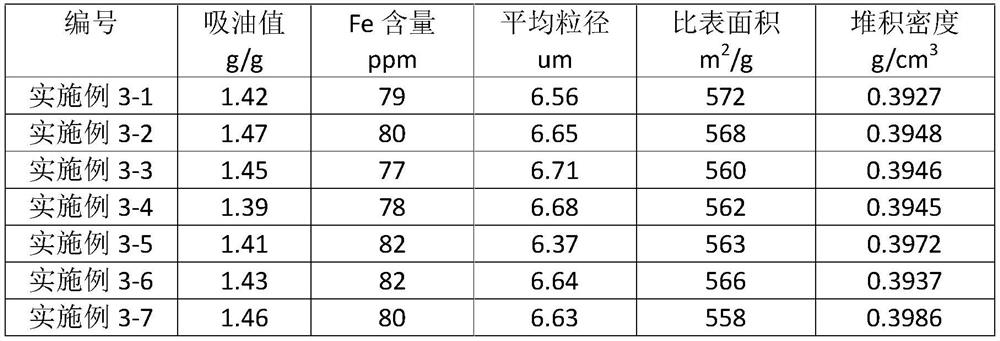

Preparation method of silicon-aluminum film opening agent and film opening agent

The invention discloses a preparation method of a silicon-aluminum film opening agent. The preparation method comprises the following steps: S1, preparing porous silicon-aluminum oxide by utilizing water glass and an aluminum salt solution; S2, adding dilute sulfuric acid into the porous silicon-aluminum oxide, adjusting the pH value, and conducting aging, cooling and filtering to obtain a filtercake; S3, washing the filter cake with dilute sulfuric acid and water in sequence, re-dispersing the washed filter cake in water, adding an organosilane dispersing agent, and conducting uniform dispersing to obtain slurry; and S4, carrying out spray drying on the slurry, and carrying out jet milling to obtain the silicon-aluminum film opening agent. According to the preparation method of the silicon-aluminum film opening agent, the silicon-aluminum film opening agent product with good smoothness, fluidity, dispersity and filterability is obtained, and the silicon-aluminum film opening agent product has good processing performance in plastic film production.

Owner:广州凌玮科技股份有限公司

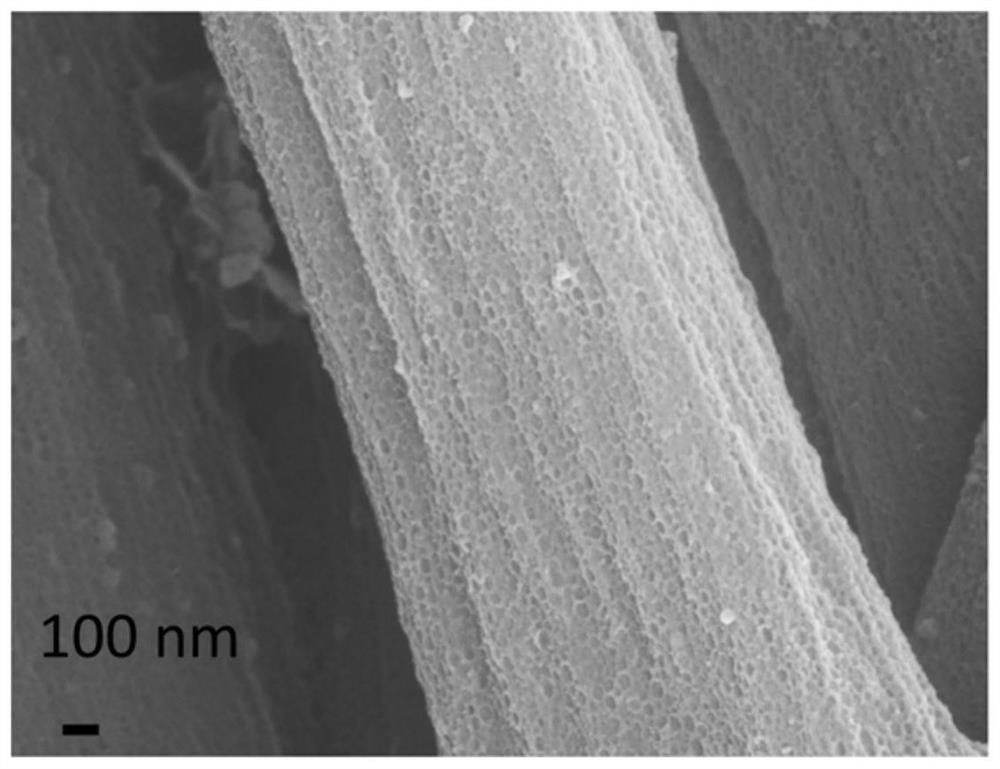

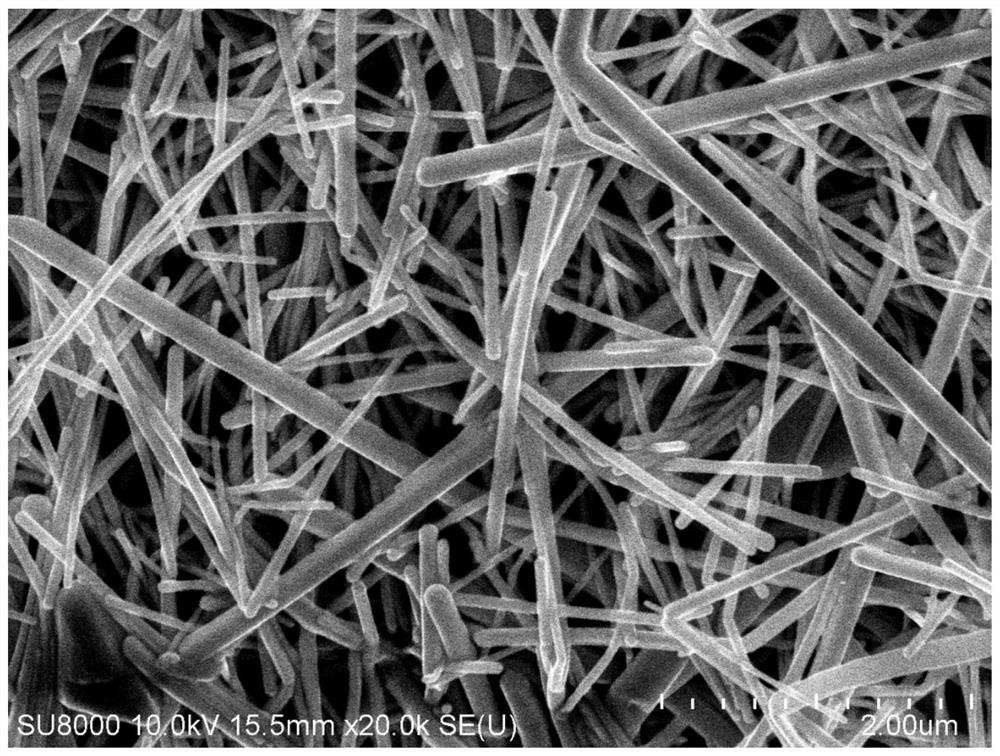

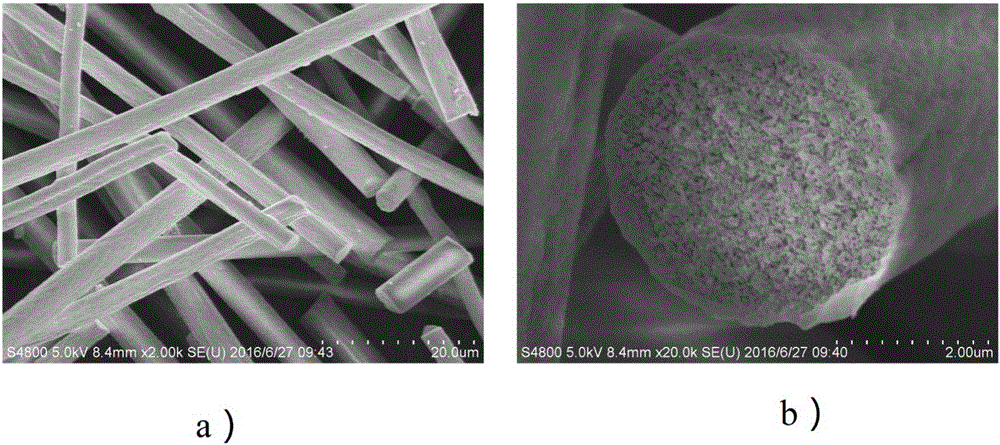

Porous Si-B-N-O ultra-fine fiber preparation method

ActiveCN106337217AUniform porous structureLow costInorganic material artificial filamentsFiberUltra fine

A porous Si-B-N-O ultra-fine fiber preparation method includes the steps that 1, a micromolecular boron source, siloxane and modified siloxane serve as solutes, dilute acid and alcohol serve as solvents, a spinning additive is added to prepare a spinning solution, and electrostatic spinning is performed to prepare PBSO (polyborosiloxane) fibrils; 2, the fibrils are put in a drying oven for processing before drying, the dried fibrils are put in a high-temperature furnace in in the atmosphere of NH3 and / or N2 mixed gas for high temperature firing, and porous Si-B-N-O ultra-fine fibers with the diameter of 0.5-5 microns are obtained after the room temperature is reached after cooling. The prepared porous Si-B-N-O ultra-fine fibers are in shapes of fiber felt, are uniform in diameter and have uniform pores internally, the residual carbon content inside the material is low, and the pore range is 2-50 nm. The porous Si-B-N-O ultra-fine fibers have excellent dielectric properties and high temperature resistant performance and have the wide application prospect in aerospace.

Owner:NAT UNIV OF DEFENSE TECH

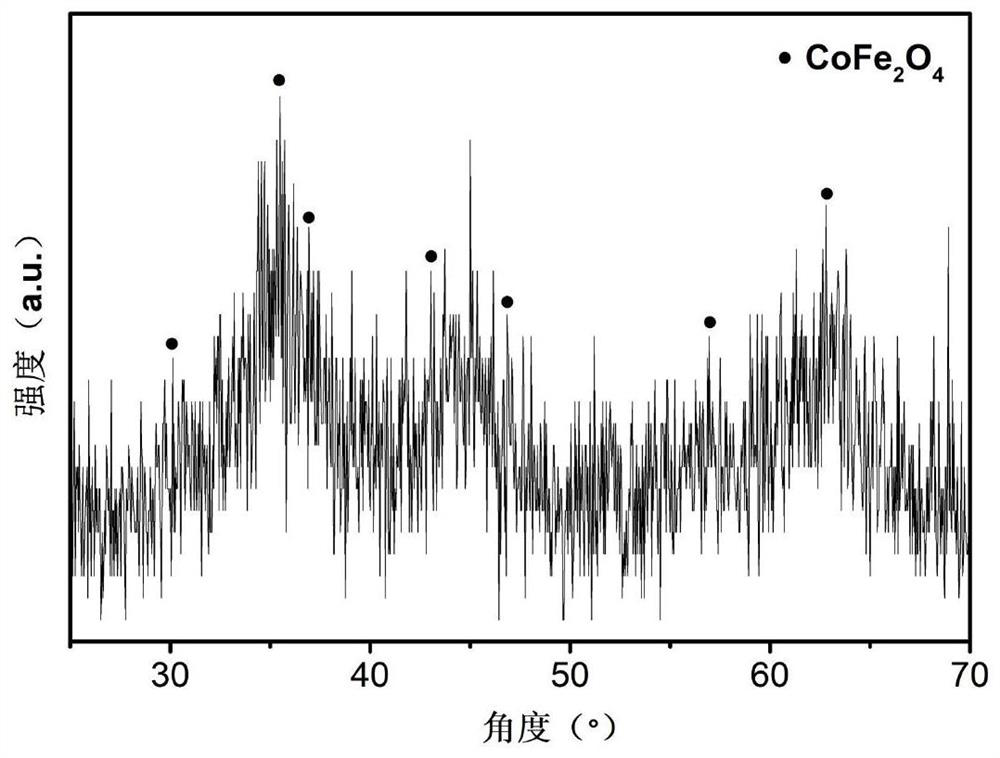

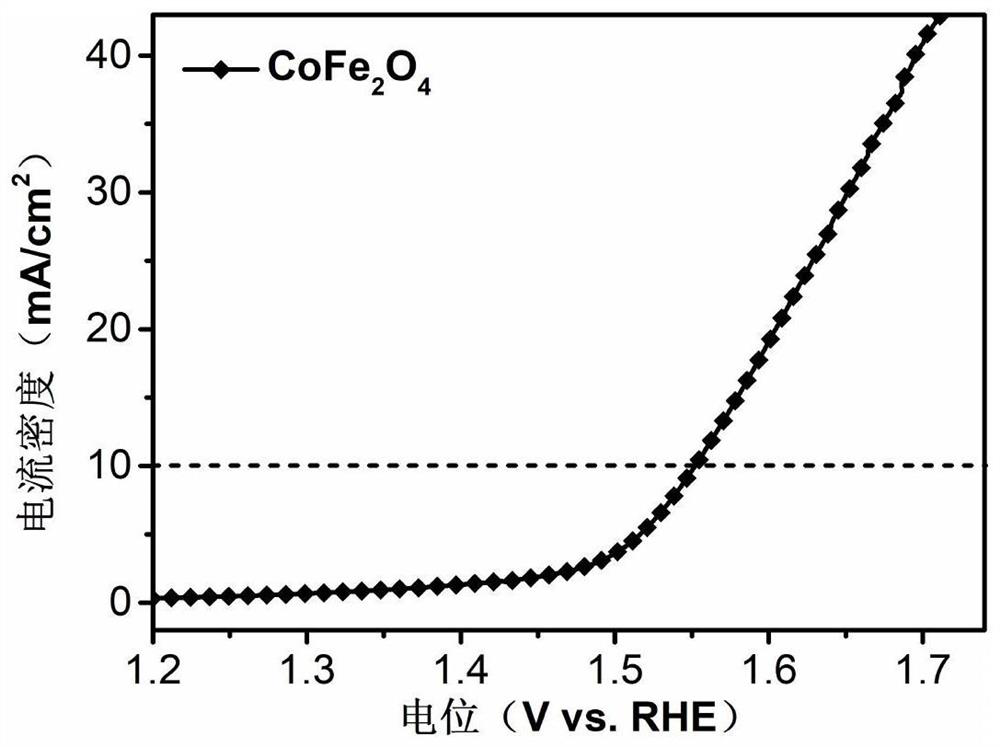

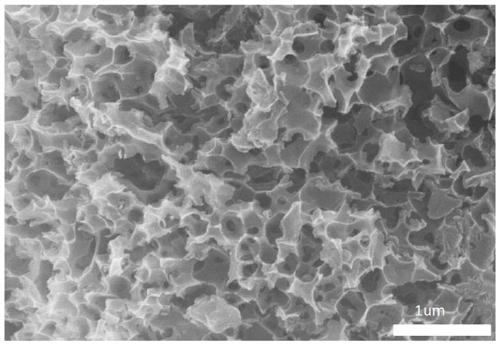

Preparation method and application of spinel type oxide catalyst

PendingCN111841543AReduce manufacturing costRapid coolingMetal/metal-oxides/metal-hydroxide catalystsElectrodesAir atmospherePtru catalyst

The invention discloses a preparation method of a spinel type oxide catalyst. One or two transition metals of cobalt, iron, nickel, manganese, copper, chromium and zinc and aluminum are jointly heatedto a molten state by adopting a vacuum induction melting furnace, cooling is performed to obtain a rod-shaped alloy ingot, a vacuum melt-spinning device is employed for melting for blow casting intoa corresponding alloy strip, carrying out dealloying treatment on the alloy strip in an alkaline solution to obtain a dealloyed product, and in order to improve the crystallinity and stability of thematerial, the dealloyed product is placed in a tubular furnace for high-temperature annealing treatment in an air atmosphere, thus obtaining the spinel type oxide catalyst. The invention also relatesto application of the electrode material. The obtained catalyst has a multi-metal mixed valence state, can significantly enhance the conductivity of the material, shows good electrocatalytic activityto oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) in an alkaline environment, has good stability, and can be used as a cathode catalyst of a chargeable and dischargeable metal-airbattery.

Owner:ZHONGBEI UNIV

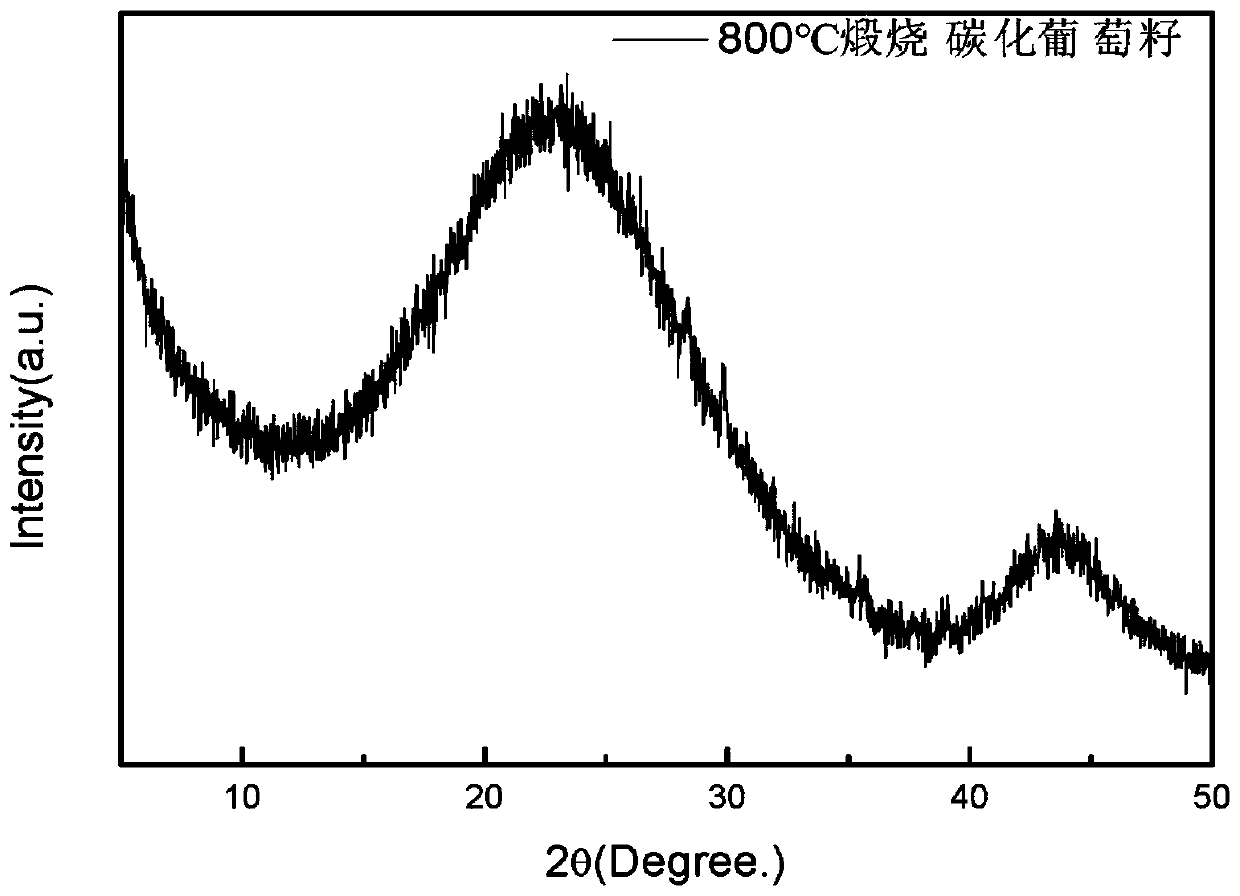

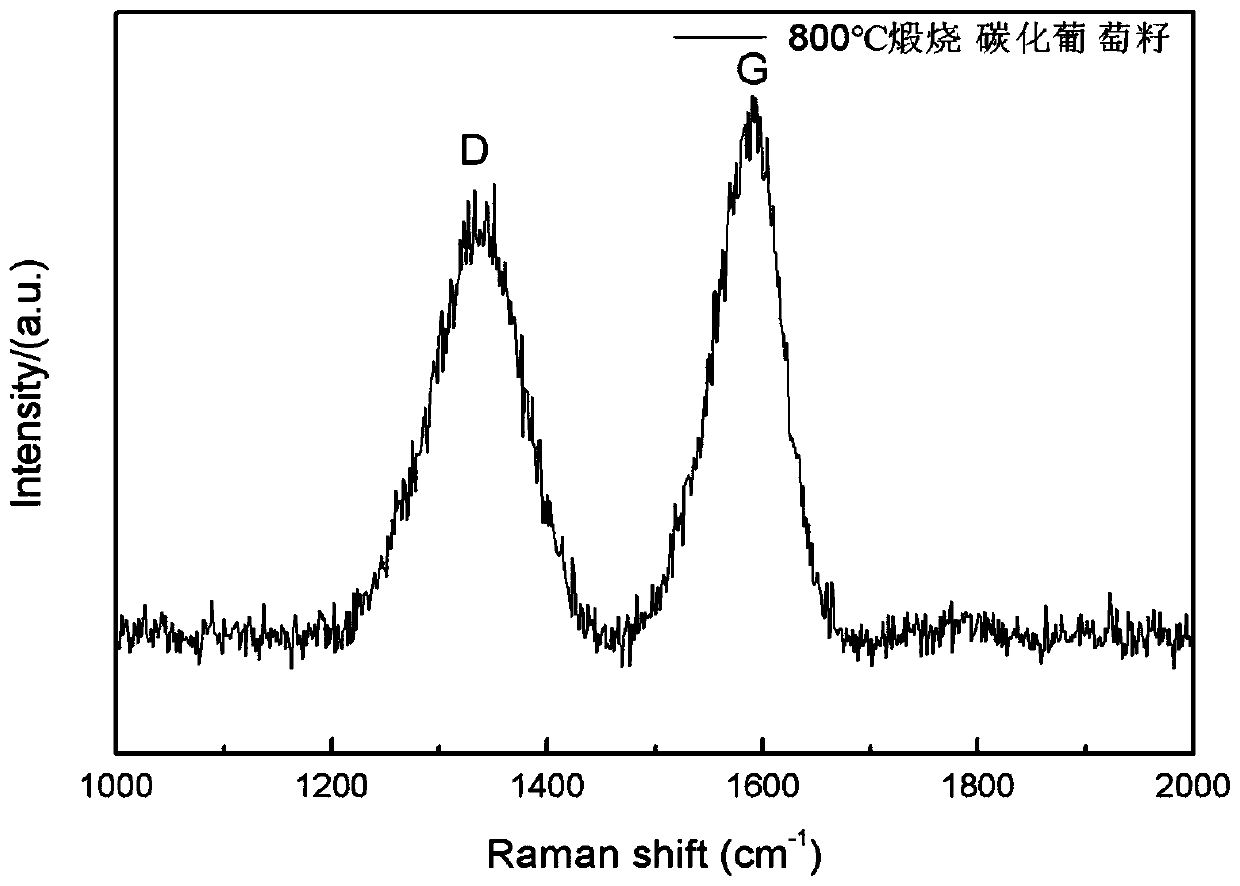

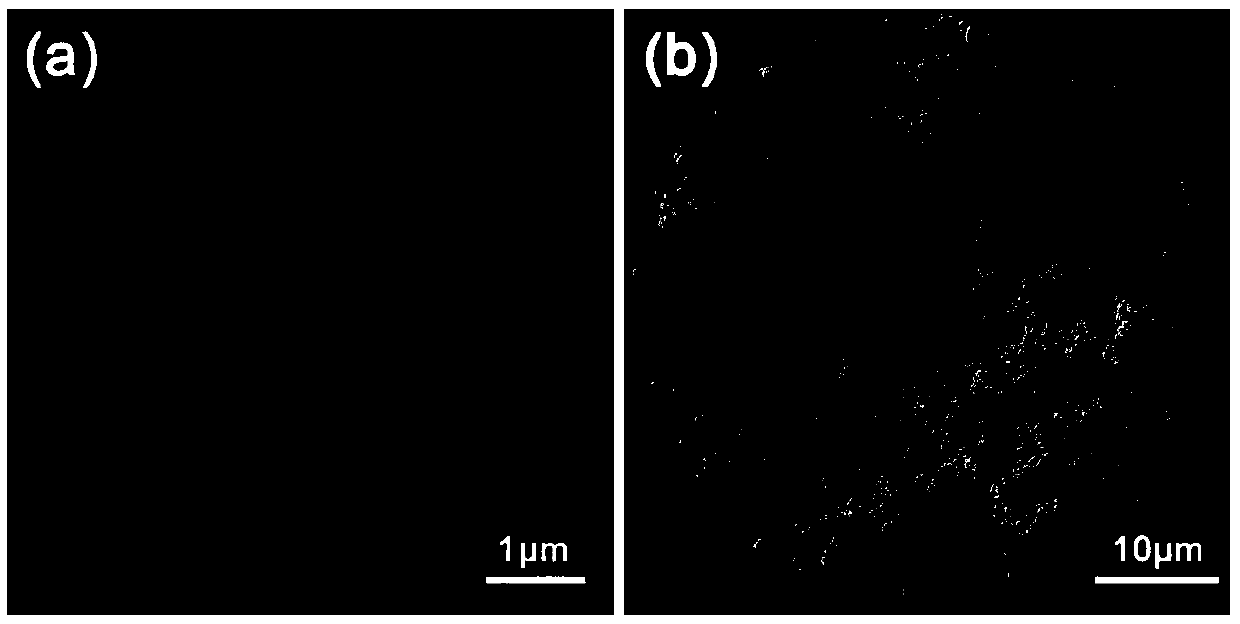

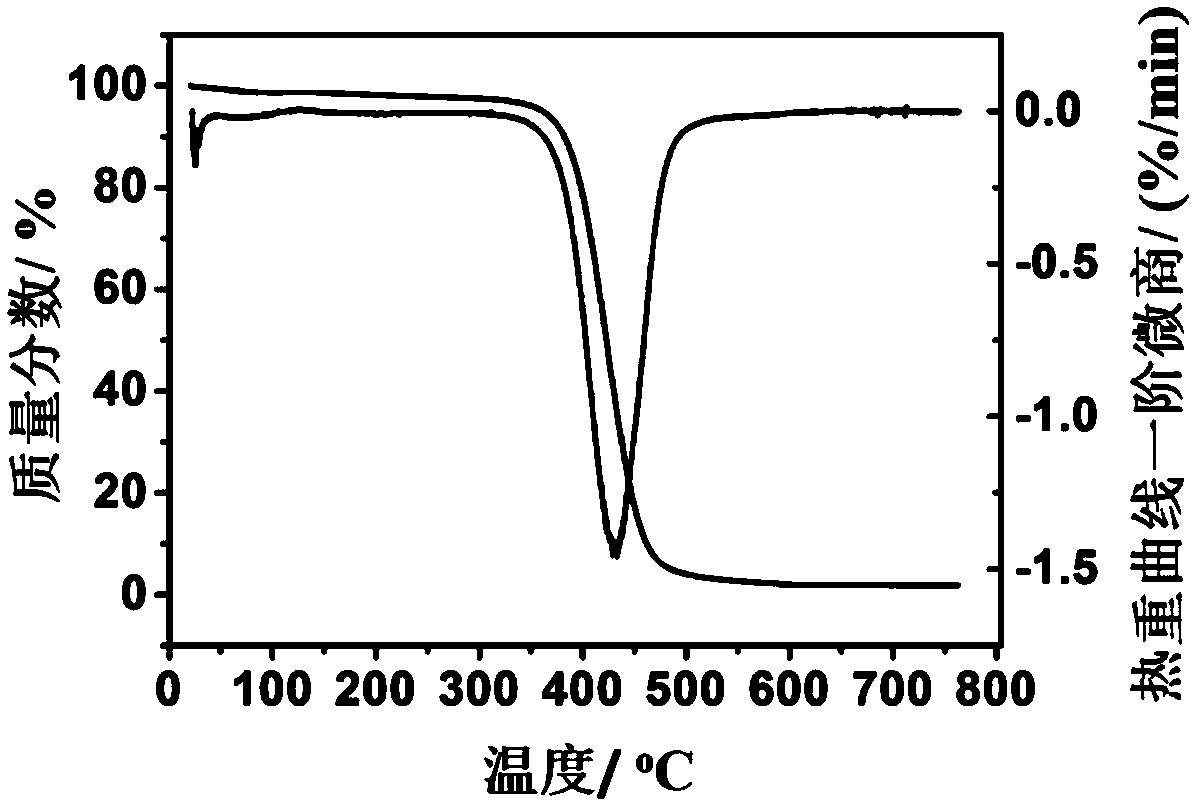

Preparation method and application of novel lithium ion battery negative electrode material carbonized grape seed

InactiveCN111268677ASynthesis conditions are easy to controlEasy to operateCarbon compoundsNegative electrodesGrape seedArgon atmosphere

The invention discloses a preparation method and application of a novel lithium ion battery negative electrode material carbonized grape seed. The preparation method comprises the following steps: drying grape seeds, grinding into powder, soaking in an activator solution, and magnetically stirring the solution at 80 DEG C for 4 hours; and filtering the solution, carrying out vacuum drying on the soaked grape seed powder at 80 DEG C for 12 hours, putting the dried grape seed powder into a tubular furnace, calcining the grape seed powder at 700-900 DEG C for 2-6 hours in an argon atmosphere, cooling the grape seed powder to room temperature, sequentially carrying out centrifugal washing with hydrochloric acid and distilled water to neutrality, carrying out vacuum drying, and grinding the grape seed powder to obtain the target product carbonized grape seeds. The carbonized grape seeds are used as the negative electrode material of the lithium ion battery, so that the raw materials are easy to obtain and are environment-friendly; secondly, the carbonized grape seeds have a porous structure, so that the reaction active sites are increased, the conductivity of the material can be improved, and the electrochemical performance of the material is improved.

Owner:LIAONING UNIVERSITY

Method for preparing foam concrete by secondary foaming

The invention discloses a method for preparing foam concrete by secondary foaming, and belongs to the technical field of foam concrete preparation. The method includes: modifying polyester fibers and pearl fibers by water glass and hexadecyl trimethyl ammonium bromide to obtain mixed modified fibers, adding the mixed modified fibers into cement, adding coal ash, coal gangue and the like and water into the cement, stirring to mix, performing ball milling to obtain concrete pulp, preparing a foaming liquid from water, sodium dodecyl benzene sulfonate, triethanolamine and arachidonic acid, adding egg white into the cement and grinding for primary foaming, adding the foaming liquid into the cement for secondary foaming so as to obtain foam concrete pulp, shaping and maintaining to obtain the foam concrete. The prepared foam concrete is provided with a uniform porous structure, a water absorption rate of the foam concrete is lower than 8%, so that high anti-permeability is realized; in addition, the foam concrete has the advantages of low shrink, no cracking and high compressive strength, and is wide in application space.

Owner:TRUSYN CHEM TECH

Carboxylated porous polystyrene microspheres and preparation method thereof

The invention provides carboxylated porous polystyrene microspheres and a preparation method thereof. The preparation method of the carboxylated porous polystyrene microspheres comprises steps as follows: 1), seed microspheres are swollen by cyclohexane; 2), the seed microspheres obtained in the step 1) are subjected to further swelling by styrene monomers, functional acrylic monomers, a crosslinking agent and a pore-foaming agent; a protective agent and an aqueous phase polymerization inhibitor are added to a system obtained after swelling in the step 2), and then a polymerization reaction isperformed; the seed microspheres are polystyrene microspheres. The carboxylated porous polystyrene microspheres obtained with the preparation method of the carboxylated porous polystyrene microspheres are not only uniform in size, but also contain rich and uniform carboxyl functional groups on the surfaces, and are of a uniform porous structure.

Owner:湖北新纵科病毒疾病工程技术有限公司

Hybrid porous monolithic material, and preparation method and application thereof

ActiveCN110575824AEasy to makeShort manufacturing timeOther chemical processesChromatographic separationChemical reaction

The invention relates to a preparation method of a polyacrylate hybrid monolithic material containing a polyhedral oligomeric silsesquioxane (POSS) reagent. The preparation method comprises the following steps: mixing the polyhedral oligomeric silsesquioxane reagent containing a thiol group with other two acrylate monomers, adding a pore-foaming solvent, and performing ultrasonic dissolution; andinitiating an in-situ acrylate self-polymerization reaction and a thiol-acrylate click chemical reaction with ultraviolet light to obtain the hybrid monolithic material. The preparation method of themonolithic material has the advantages of simple and rapid preparation process and mild reaction conditions, and the monolithic material has a uniform pore structure and a good thermal stability, andcan be applied to high performance chromatographic separation analysis of small molecular compounds and complex biological samples.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

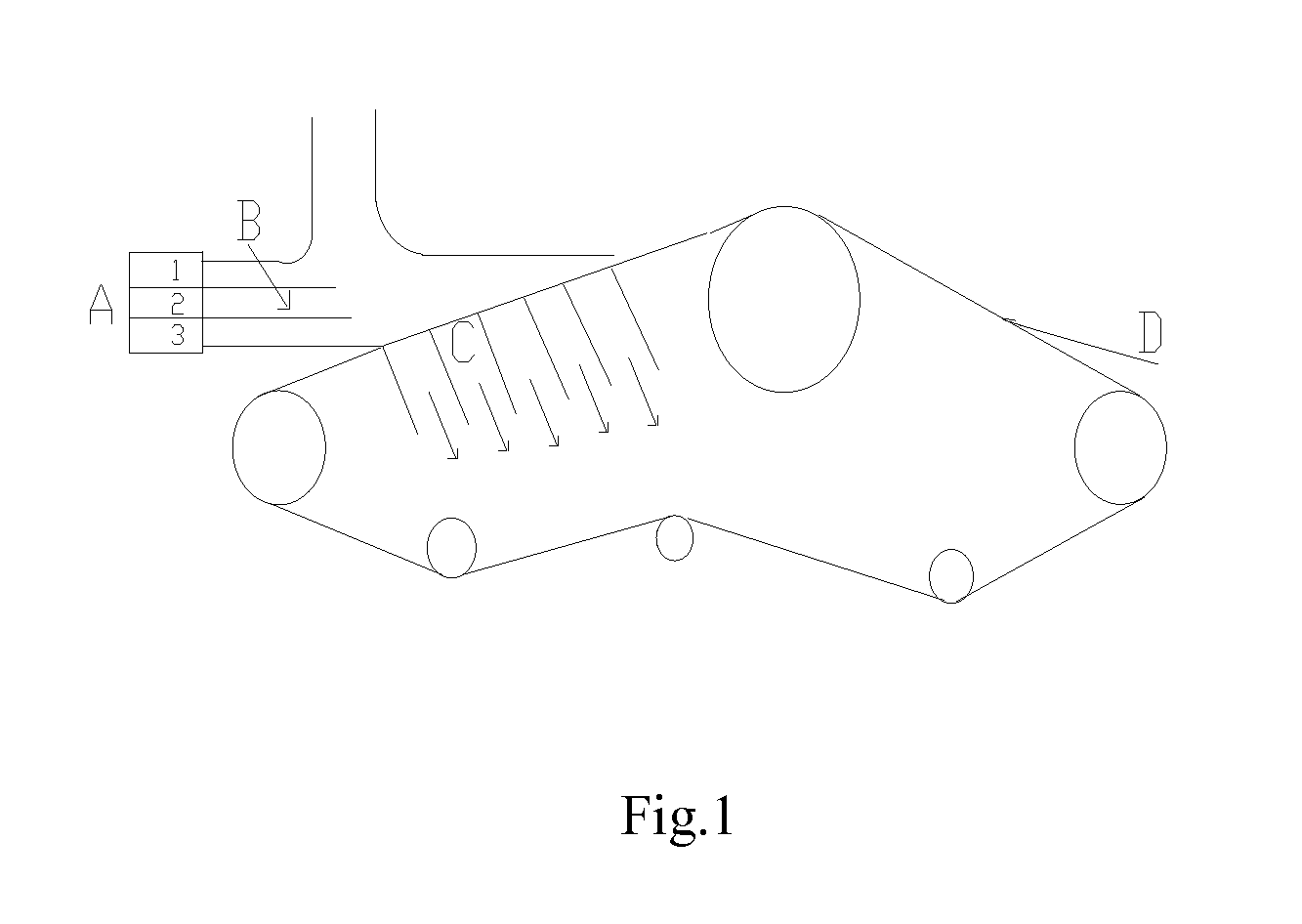

Method for continuously preparing lithium battery diaphragm by utilizing melt spinning process

InactiveCN112421183AUniform porosityImprove wettabilityFibre typesCell component detailsLithium oxideLithium hydroxide

The invention belongs to the technical field of lithium battery diaphragms, and particularly relates to a method for continuously preparing a lithium battery diaphragm by utilizing a melt spinning process. The method comprises the steps: mixing TEOS, absolute ethyl alcohol, deionized water and hydrochloric acid with the mass fraction of 28%, reacting at the temperature of 60-65 DEG C for 10-11 hours, cooling to room temperature, slowly adding a lithium hydroxide aqueous solution, adding an inorganic filler after the pH value of the solution system is alkaline, continuously adding the lithium hydroxide aqueous solution, stirring to react for 4-6 hours, standing and aging for 24 hours or more, centrifugally separating, and drying in vacuum to obtain porous silicon dioxide gel powder loaded with the inorganic filler; uniformly mixing PP granules with the porous silicon dioxide gel powder loaded with the inorganic filler and a coupling agent, heating, melt-blowing and spinning to form a film at the temperature of 200-230 DEG C, soaking the film material obtained by spinning in diluted hydrochloric acid, washing with deionized water, and drying to obtain the product. The diaphragm obtained by the method provided by the invention has uniform pores.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

B05-grade autoclaved aerated concrete block and preparation method thereof

The invention discloses a B05-grade autoclaved aerated concrete block and a preparation method thereof. The B05-grade autoclaved aerated concrete block comprises the following raw materials in percentby weight: 77-78% of fly ash, 13.5-14.5% of lime, 6-7% of cement, 2-2.5% of gypsum and 0.061-0.065% of silicon dioxide-coated aluminum powder. A gas-forming agent, namely aluminum powder, is pretreated by a coating method so as to cover a part of the surface thereof with a film layer, so that the contact surface area between the aluminum powder and a slurry is reduced, and thus the stirring timeof the aluminum powder in the slurry is prolonged; after a longer stirring time, the aluminum powder is dispersed in the slurry as uniformly as possible, so that the finally formed aerated concrete block is guaranteed to have relatively high porosity and a uniform porous structure and thus light weight and high strength are achieved.

Owner:SICHUAN UNIV +1

Method for preparing porous chitosan membrane from graphene oxide (GO)-stabilized Pickering emulsion

The invention discloses a method for preparing a porous chitosan membrane from a GO-stabilized Pickering emulsion. The method comprises the following steps: adding a proper amount of GO into deionizedwater so as to prepare a GO suspension dispersion solution and carrying out ultrasonic treatment; dissolving a chitosan solution into the GO suspension dispersion solution, adding benzoic acid esteras an oil phase and then carrying out ultrasonic treatment; placing a sample in a water bath and then carrying out casting to obtain an uncross-linked membrane; impregnating the uncross-linked membrane in a solution containing a cross-linking agent for cross-linking of the membrane for a period of time, then carrying out washing with ethanol and deionized water; and finally drying the membrane soas to obtain the chitosan membrane with a porous structure. The preparation method provided by the invention is simple in preparation process, friendly to environment and low in requirements on equipment; high stability of aqueous solutions is realized; the porous structure is uniform; large-scale production of the membrane can be easily implemented; and the porous chitosan membrane has good application prospects in the fields of food preservation, wastewater treatment, catalysis, heavy metal ion detection and the like.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com