Preparation method of super-amphiphobic nano cellulose aerogel

A nanocellulose, airgel technology, applied in the direction of coating, etc., to achieve the effect of enhancing successful and effective deposition, high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

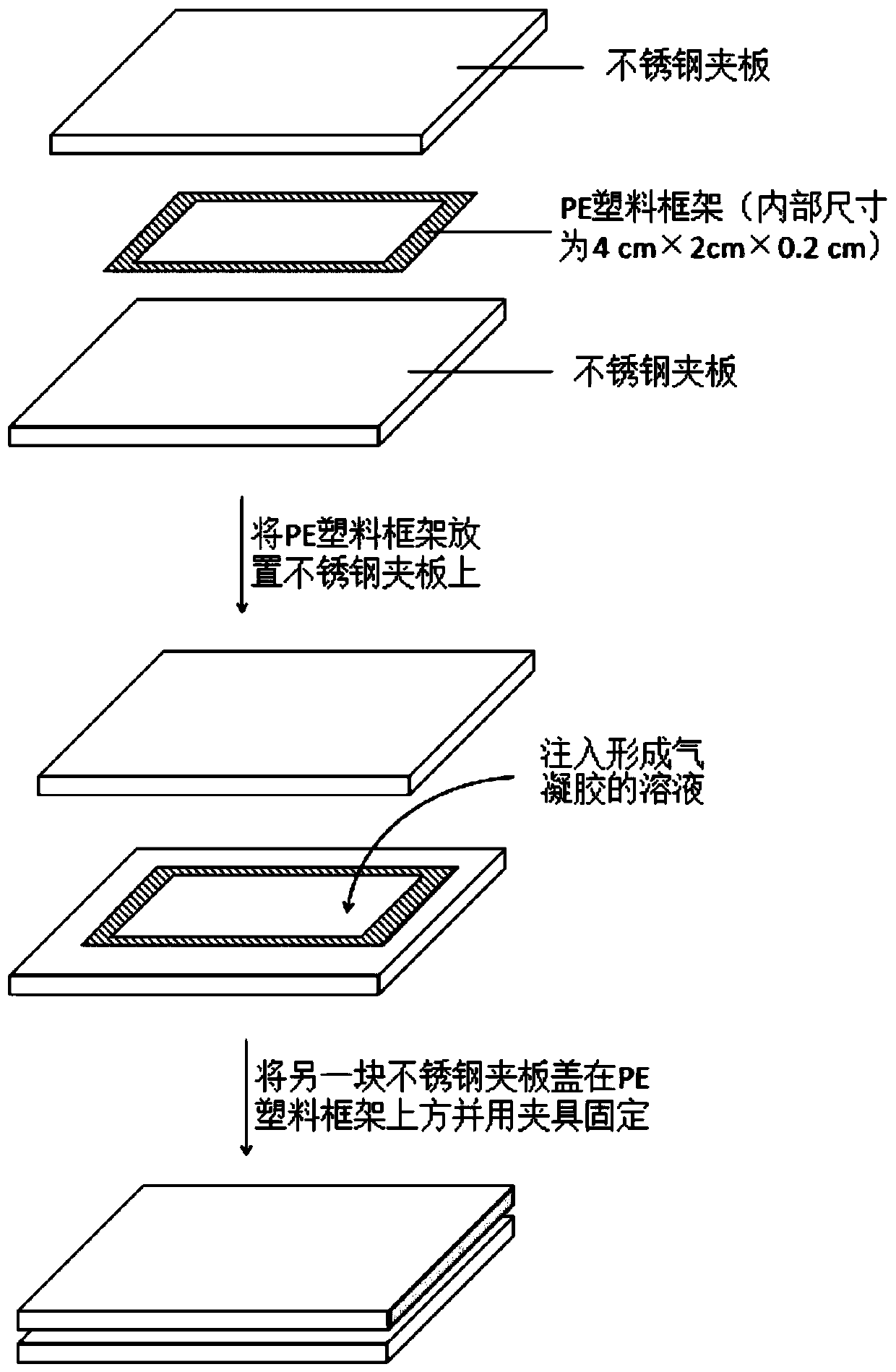

[0033] Embodiment 1: the preparation of nanocellulose airgel

[0034] (1) Nanocellulose (NFC) prepared by TEMPO oxidation: Nanocellulose is prepared by TEMPO oxidation. First soak the pulp board in water to obtain the slurry after thawing, take 10g of absolute dry fiber slurry and soak it in 500mL of deionized water, add TEMPO (0.16g), NaBr (1.6g) successively, and continuously mechanically stir at room temperature. It mixes well. Then 120 mL of NaClO (6.6 wt%) solution was added to start the oxidation reaction. During the reaction process, 2mol / L NaOH was used to adjust the pH value to maintain the pH value of the entire reaction system between 10-10.5 until the pH value no longer decreased, and 50 mL of ethanol was added to terminate the reaction. The slurry after the reaction was first suction filtered, then soaked in 0.1mol / L HCl solution to acidify and wash, and the steps of washing and suction filtration were repeated three times. The washed slurry was quantified to 1...

Embodiment 2

[0040] Example 2: Characterization of nanocellulose aerogels

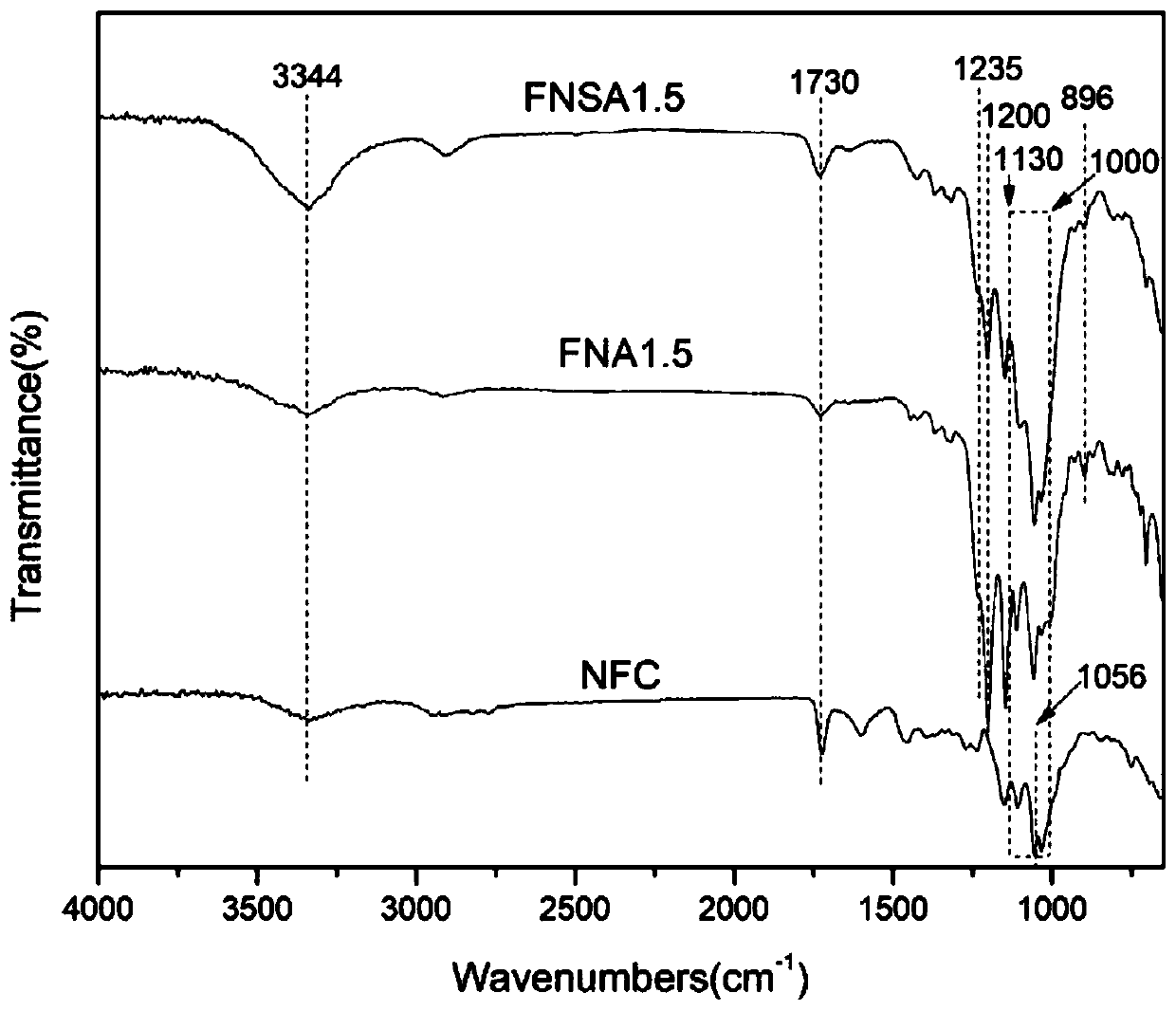

[0041] (1) FTIR analysis: the fully dried airgel sample was pressed into thin slices in a tablet press. The FTIR spectrum of the airgel recorded by the total reflection infrared spectrometer FTIR-650, the measurement wavelength range is 4000-650cm -1 . Pure NFC was used as the control group of the experiment.

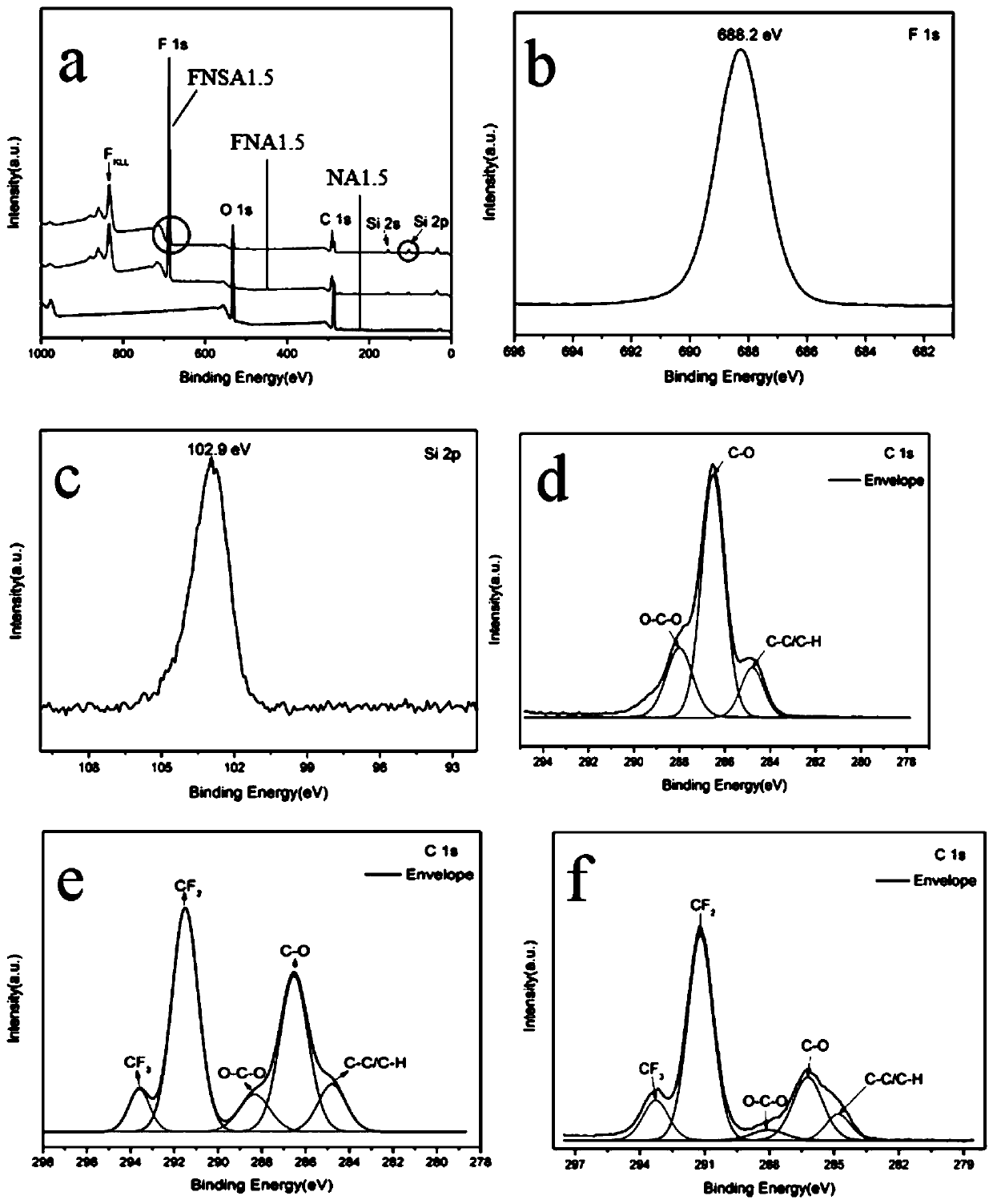

[0042] FT-IR spectra of NFC, FNA1.5 and FNSA1.5 as figure 2 shown. The aerogels prepared under different NFC concentrations had similar FTIR spectra, which were analyzed with FNA1.5 as a representative. Airgel NFC samples showed significant differences before and after CVD. at 3344cm -1 and 1730cm -1 The peaks at can be attributed to the stretching vibrations of cellulose-OH and -COOH, respectively. The C-O stretching vibration peak of NFC appears at 1056cm -1 place. The typical absorption peaks of the Si-O-Si bond of FNA1.5 and FNSA1.5 and the cellulose C-O bond are at 1130-1000 cm -1 The absorp...

Embodiment 3

[0048] Example 3: Factors Affecting the Lyophobic Properties of Nanocellulose Airgel

[0049] SEM analysis method: Spray gold on the surface of the thoroughly dried airgel sample and observe the surface morphology of the sample through a JSM-7600F field emission scanning electron microscope and take pictures. The operating voltage of the electron microscope is 5kV, and each sample selects five different The location is scanned and observed, and photos with repeated features are selected for analysis.

[0050]Contact angle measurement method: use the T200-Auto3 Plus optical contact angle tester to measure the wettability of the sample. The software of the instrument automatically calculates the contact angle value according to Young's equation. In a static mode at room temperature, 4 μL of water droplets, glycerol, ethylene glycol, castor oil, and hexadecane were dropped on the surface of the fluorinated airgel samples, and the contact angles of each sample were measured at fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com