Patents

Literature

220 results about "Ftir spectra" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fourier-transform infrared spectroscopy (FTIR) is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. An FTIR spectrometer simultaneously collects high-spectral-resolution data over a wide spectral range.

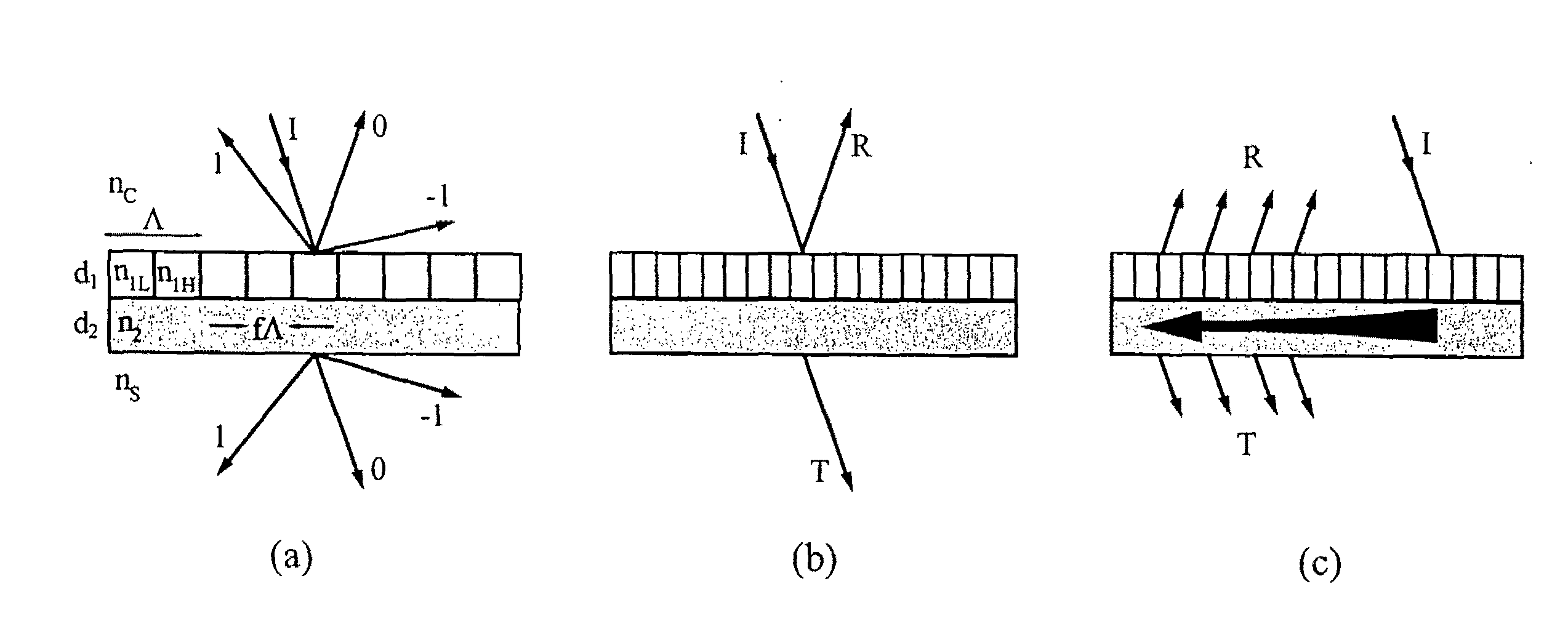

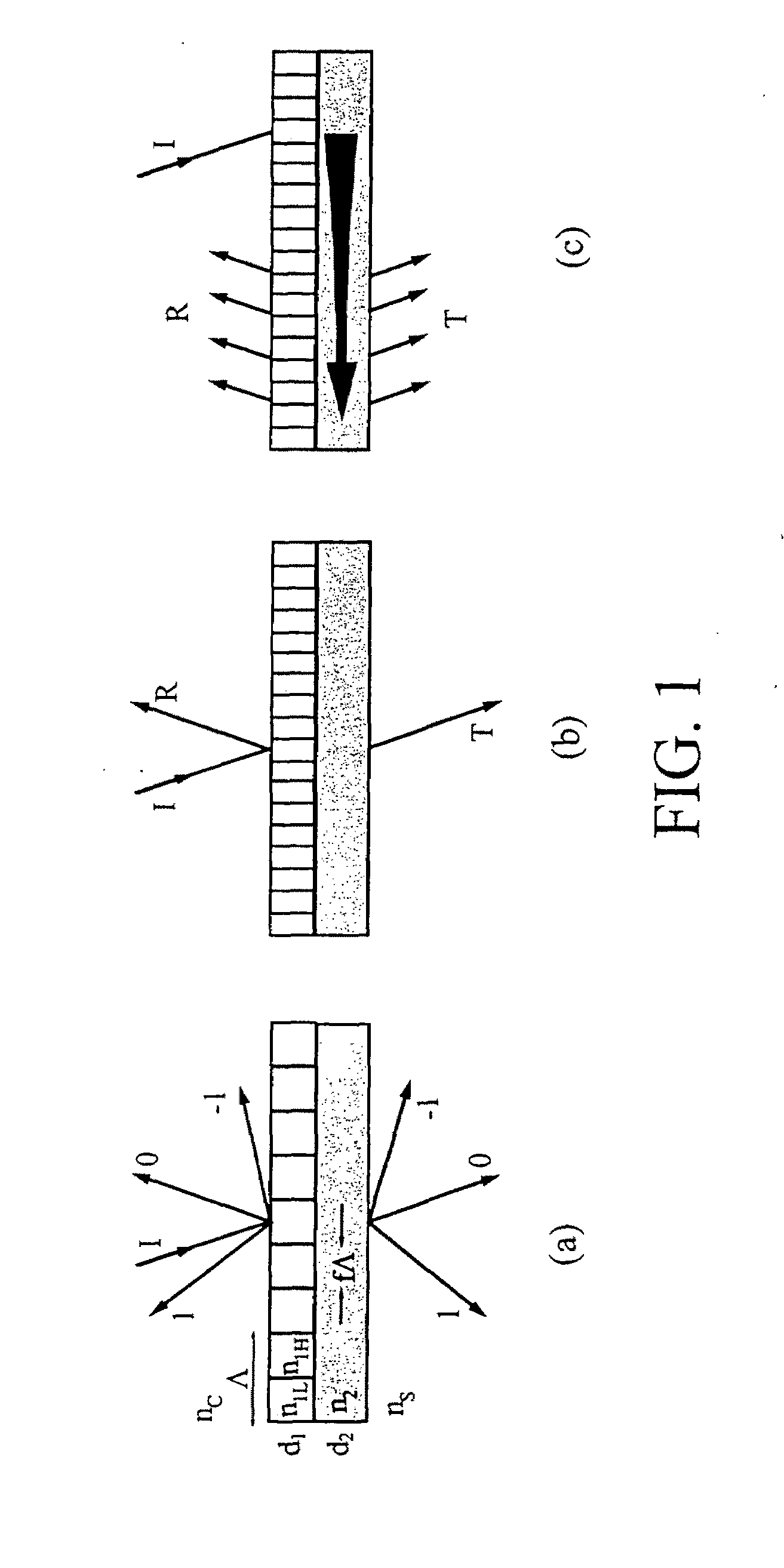

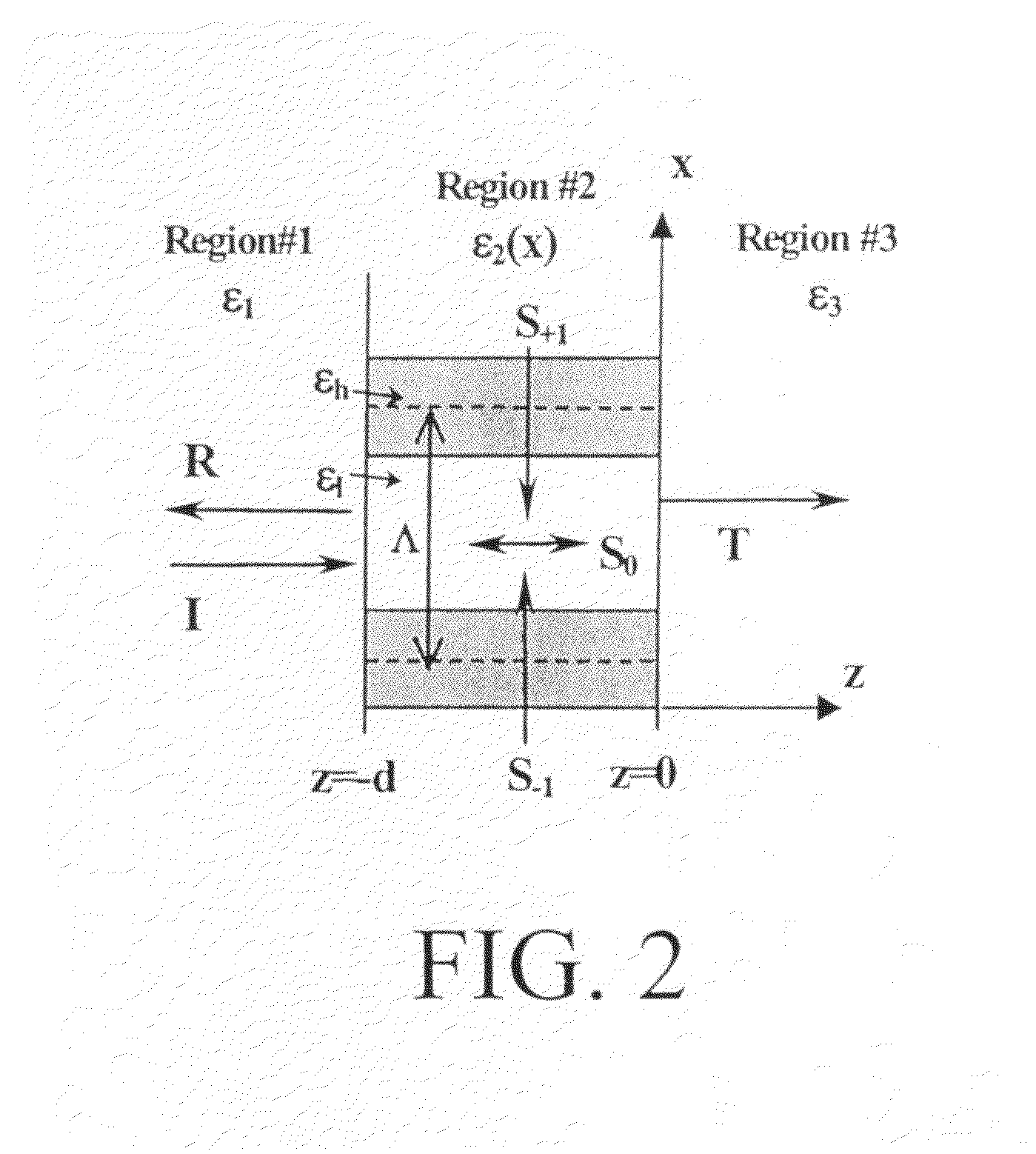

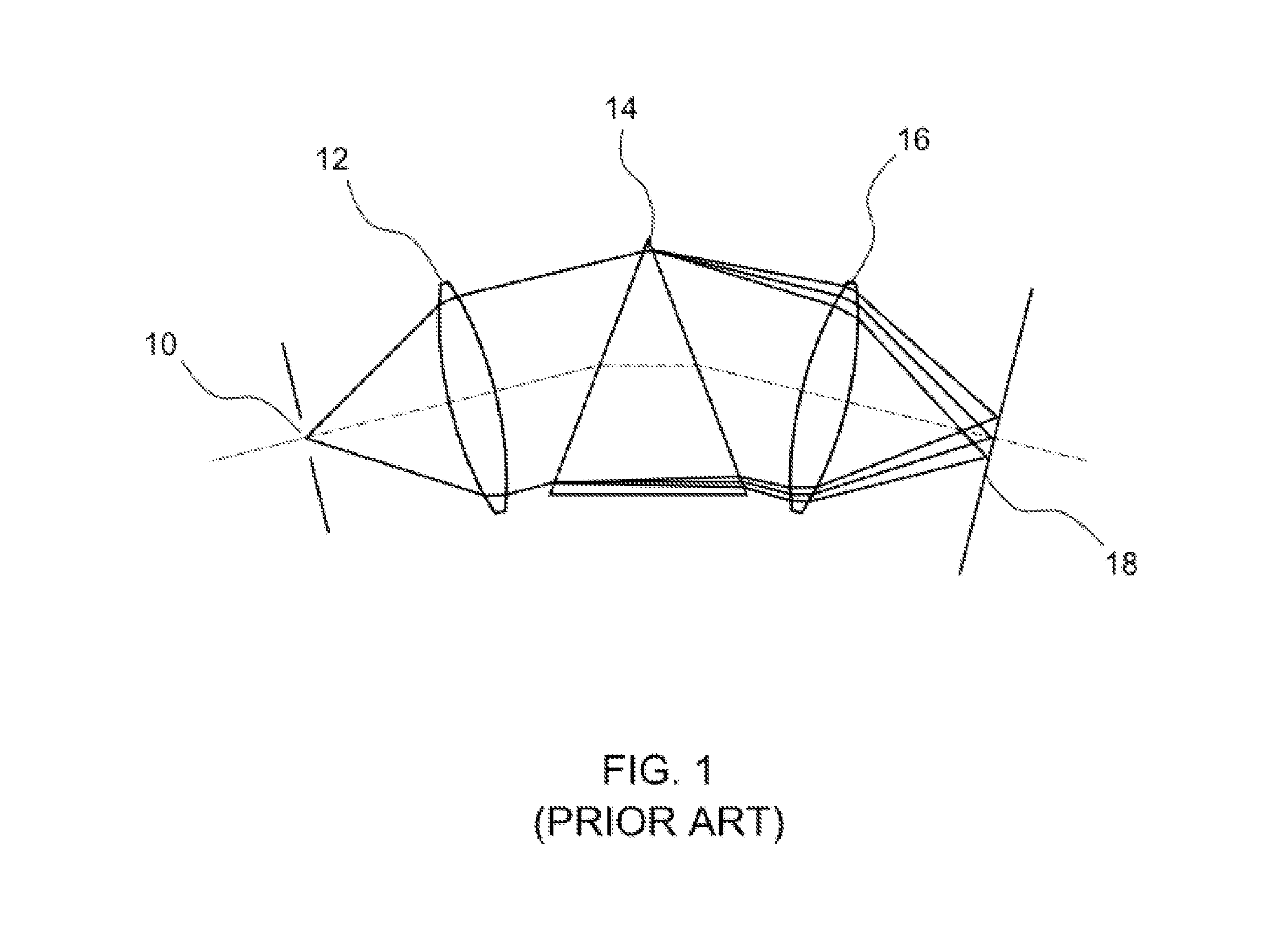

Resonant Leaky-Mode Photonic Elements and Methods for Spectral and Polarization Control

ActiveUS20100092124A1Increase varietyImprove performanceCoupling light guidesSpecial surfacesDiffraction orderFtir spectra

Optical devices with versatile spectral attributes are provided that are implemented with one or more modulated and homogeneous layers to realize leaky-mode resonance operation and corresponding versatile spectral-band design. The first and / or higher multiple evanescent diffraction orders are applied to excite one or more leaky modes. The one- or two-dimensional periodic structure, fashioned by proper distribution of materials within each period, can have a resulting symmetric or asymmetric profile to permit a broadened variety of resonant leaky-mode devices to be realized. Thus, the attributes of the optical device permit, among other things, adjacent, distinct resonance frequencies or wavelengths to be produced, convenient shaping of the reflection and transmission spectra for such optical device to be accomplished, and the wavelength resonance locations to be precisely controlled so as to affect the extent to which the leaky modes interact with each other. Further, the profile asymmetry allows for the precise spectral spacing of interactive leaky modes so as to provide greater flexibility in optical device design.

Owner:UNIV OF CONNECTICUT

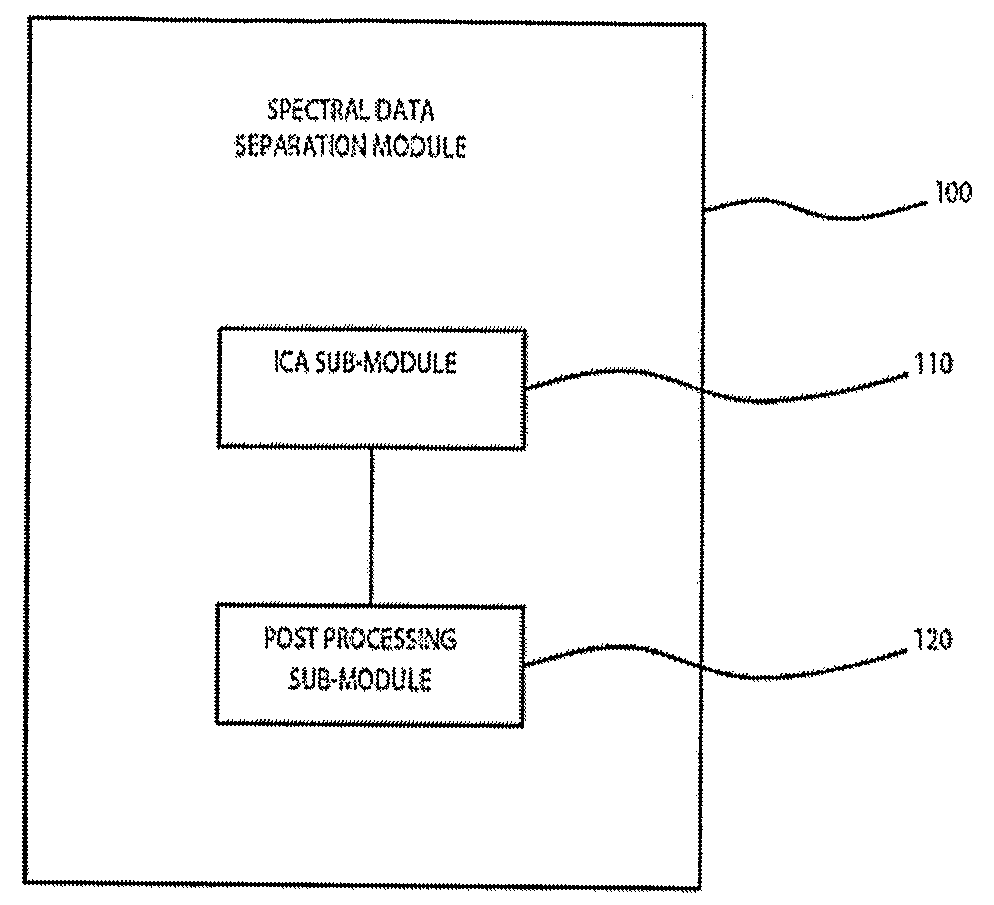

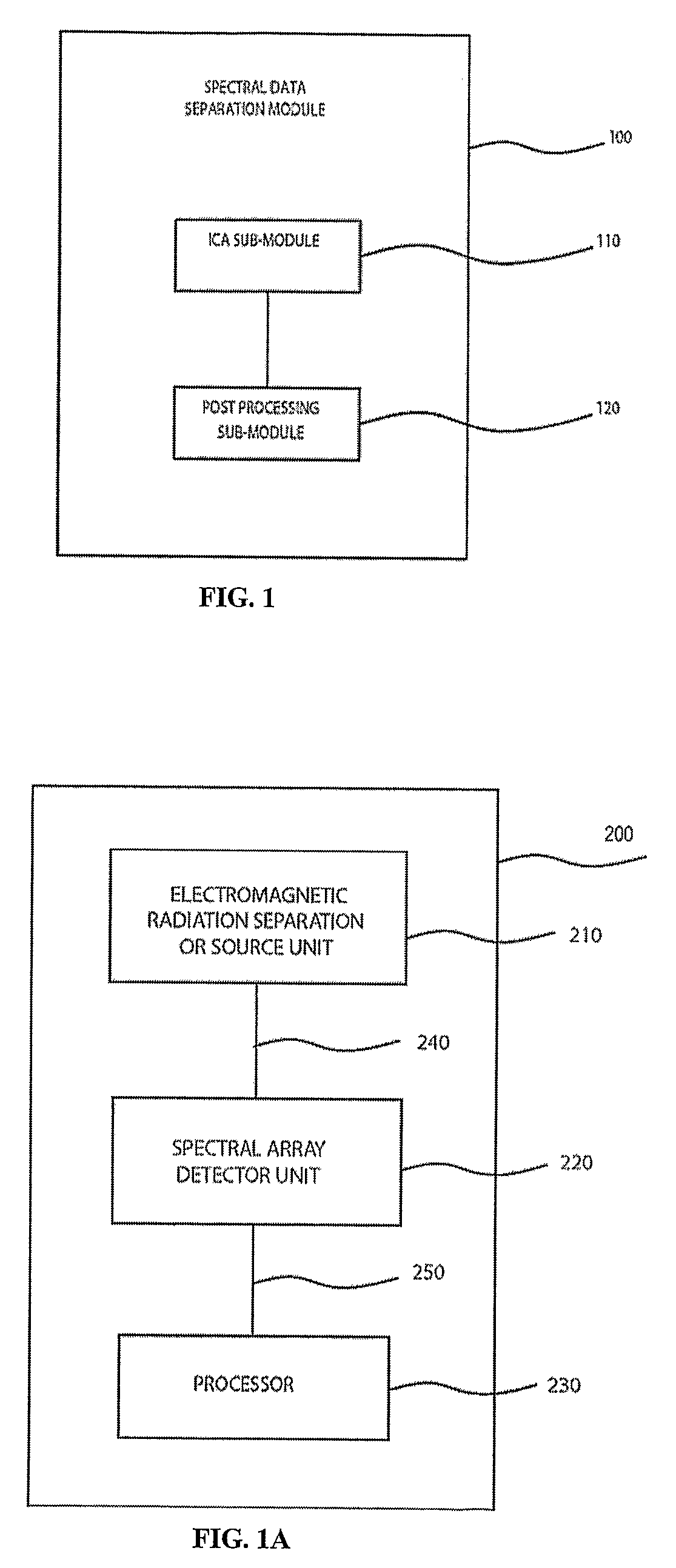

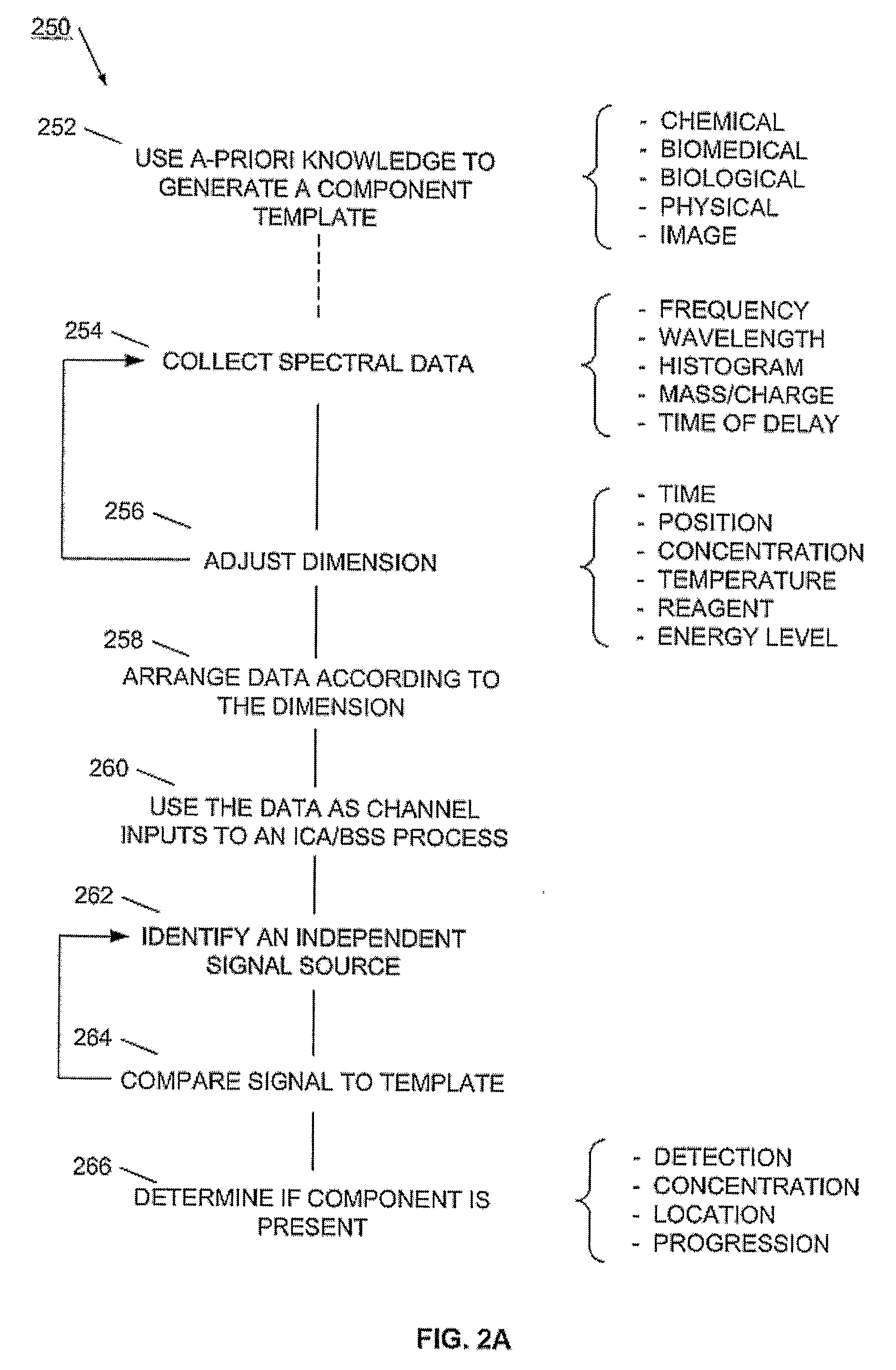

System and Method for Spectral Analysis

InactiveUS20090001262A1High detection sensitivityIncreased chemical shift dispersionIsotope separationCharacter and pattern recognitionFtir spectraIndependent component analysis

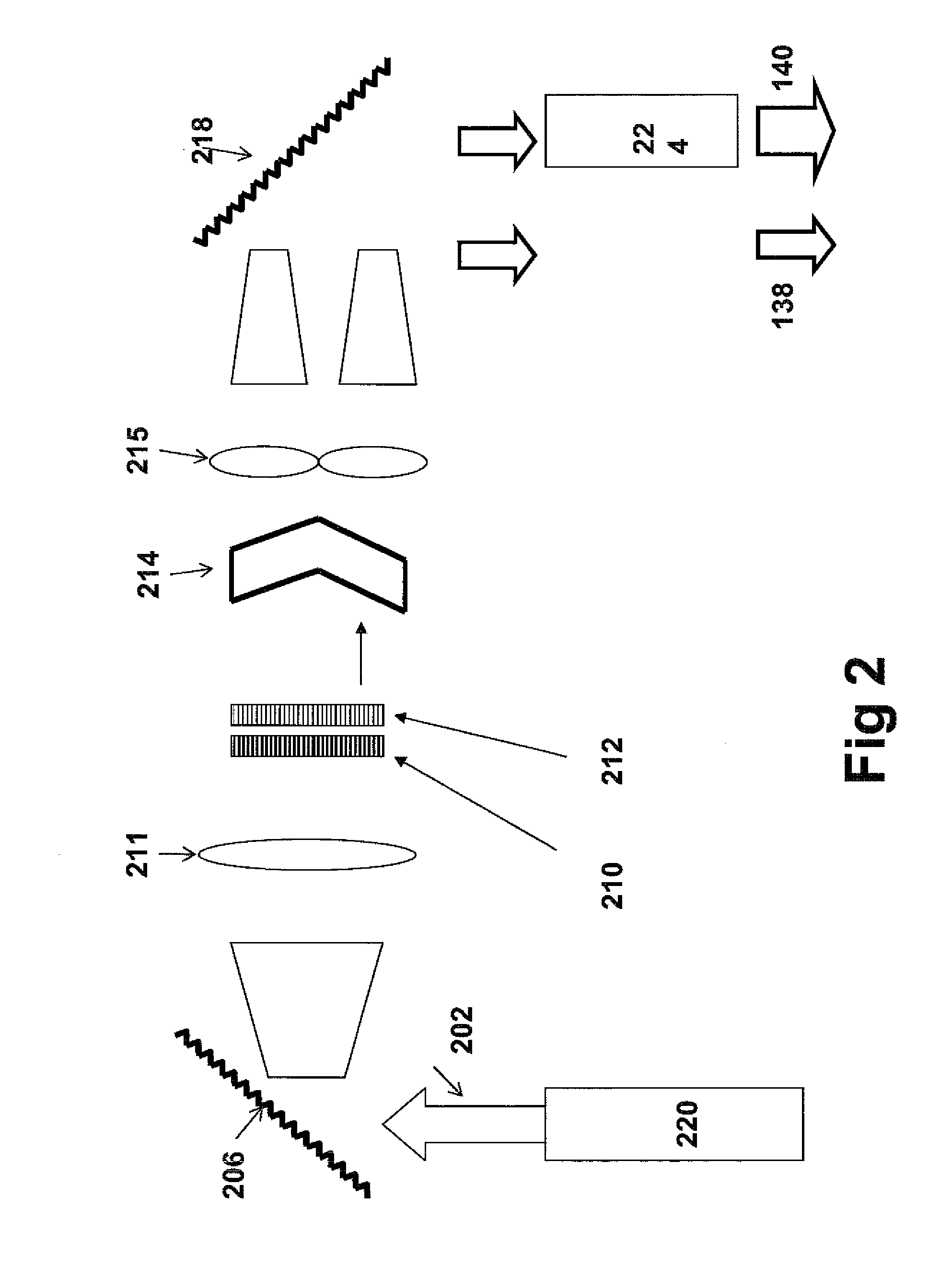

The system and method for spectral analysis uses a set of spectral data. The spectral data is arranged according to a second dimension, such as time, temperature, position, or other condition. The arranged spectral data is used in a signal separation process, such as an independent component analysis (ICA), which generates independent signals. The independent signals are then used for identifying or quantifying a target component.

Owner:SIGMED

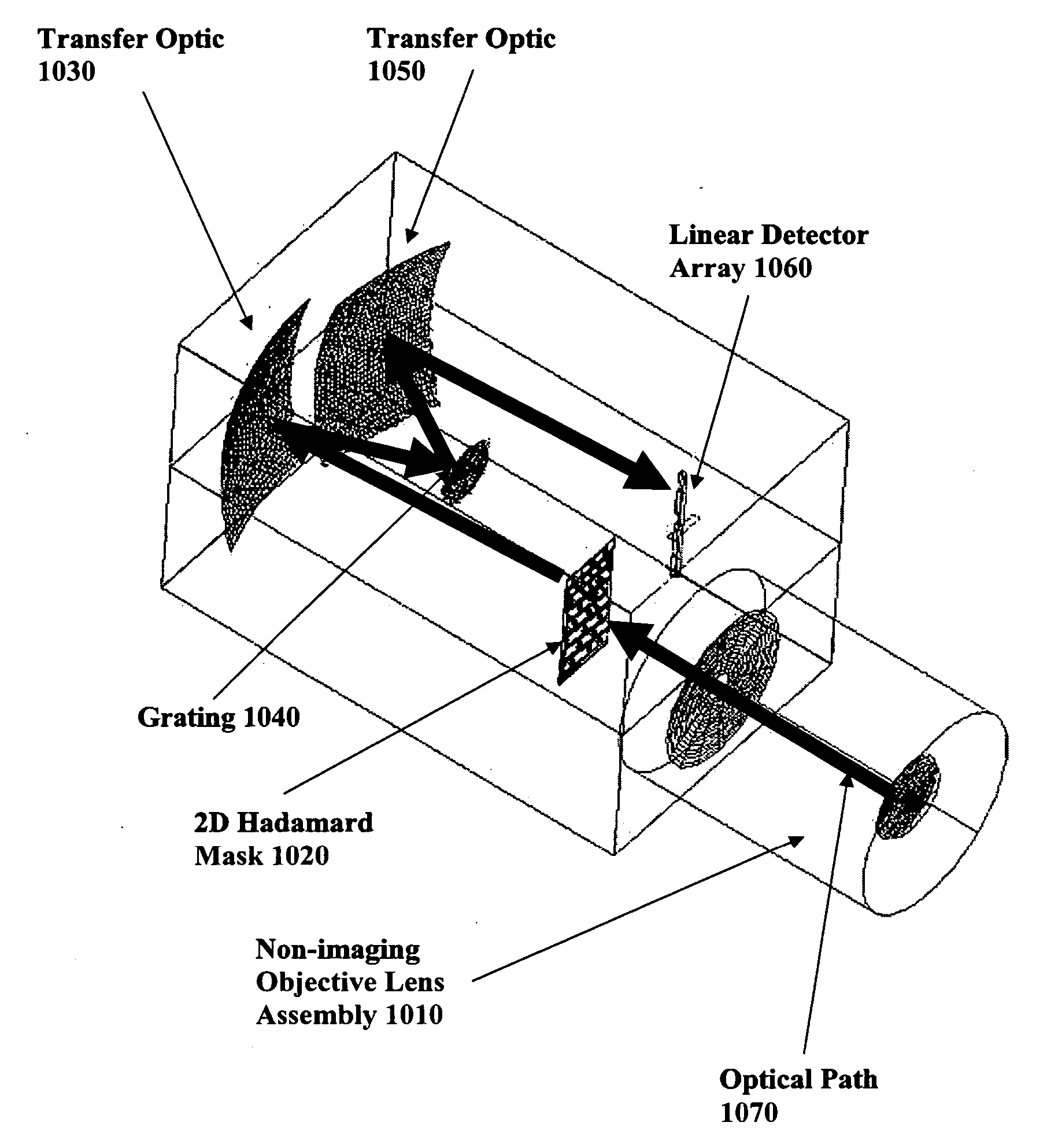

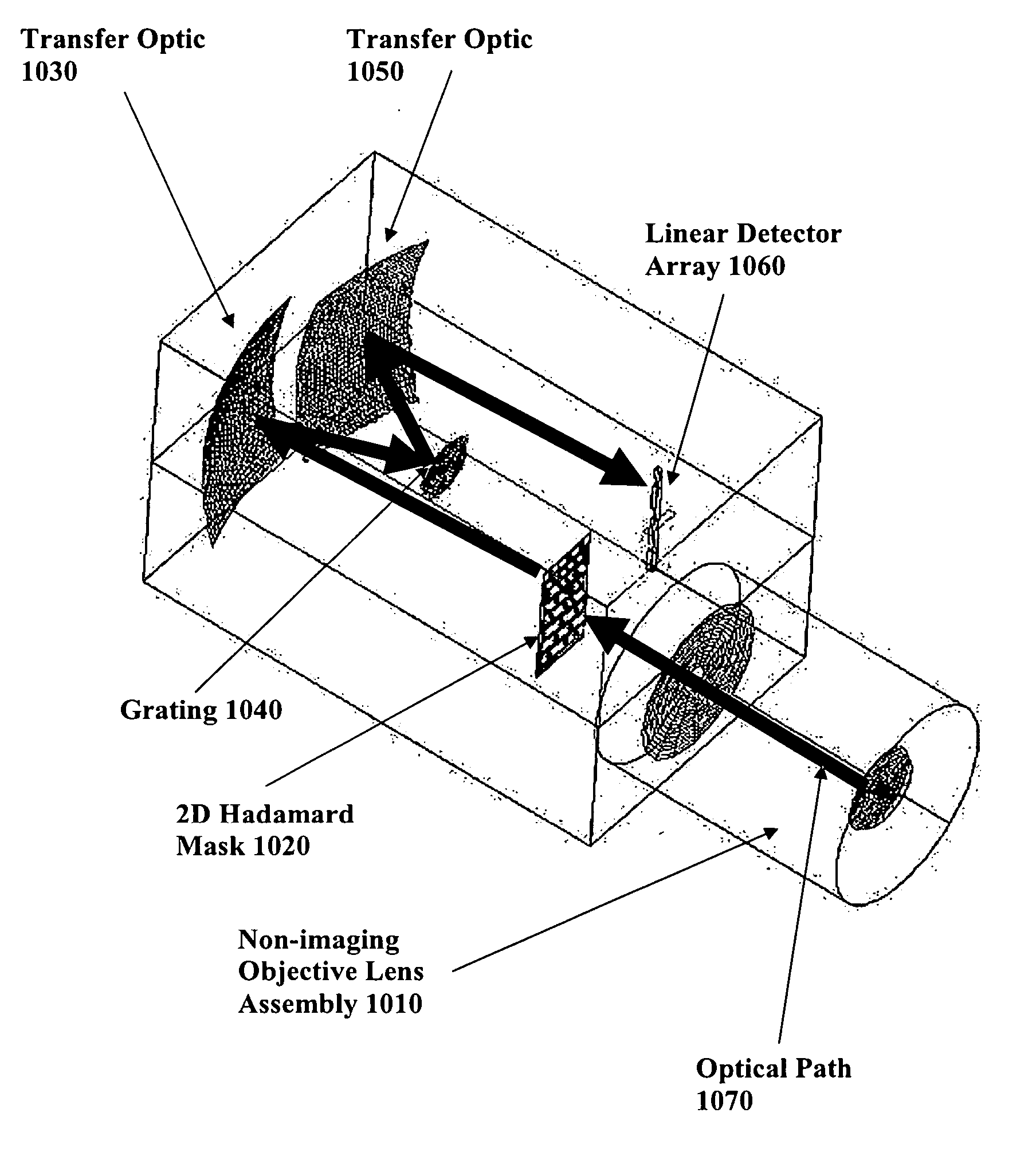

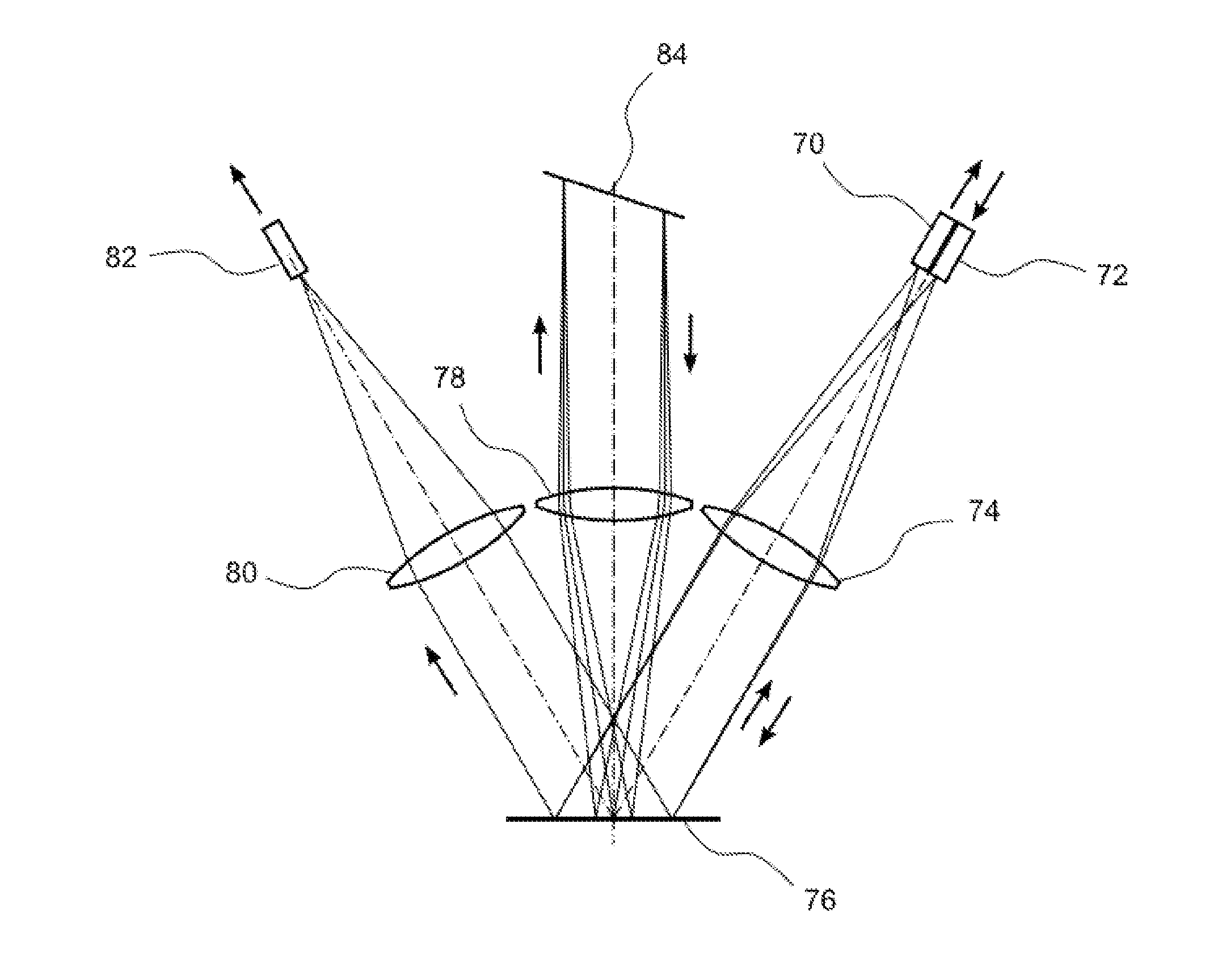

Devices and method for spectral measurements

InactiveUS20050243312A1Quick collectionImprove throughputRadiation pyrometrySpectrum generation using diffraction elementsMeasurement deviceFtir spectra

A spectral measurement device comprising an entrance aperture for receiving an electromagnetic energy and a mask located at the entrance aperture in the form of a two-dimensional encodement pattern. An optical element conditions the electromagnetic energy received from the mask for presentation to the spectral dispersion element and the and a spectral dispersion element disperses the electromagnetic energy in one or more dimensions. Additionally, the optical element conditions the dispersed electromagnetic energy onto an array of detector elements.

Owner:PLAIN SIGHT SYST

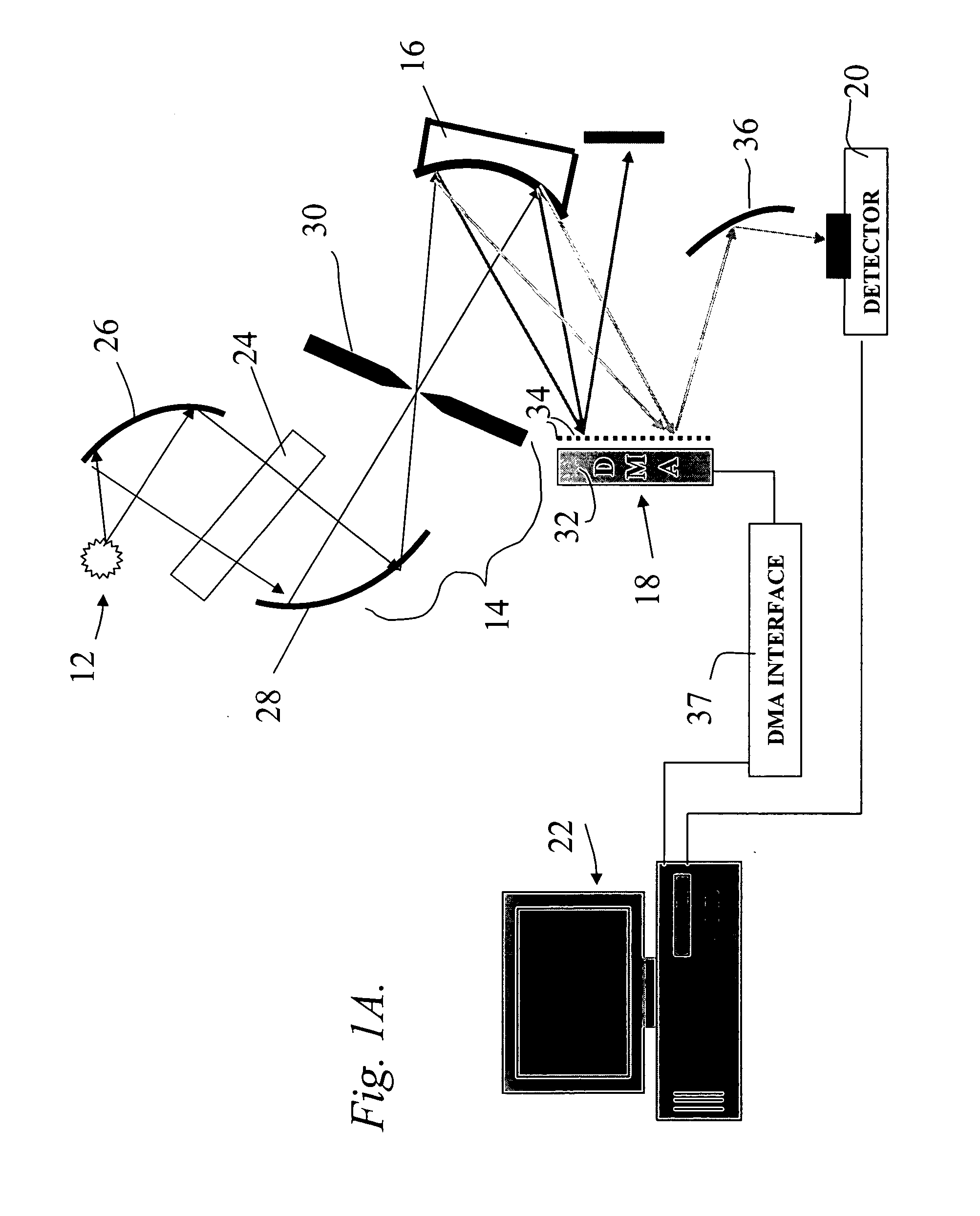

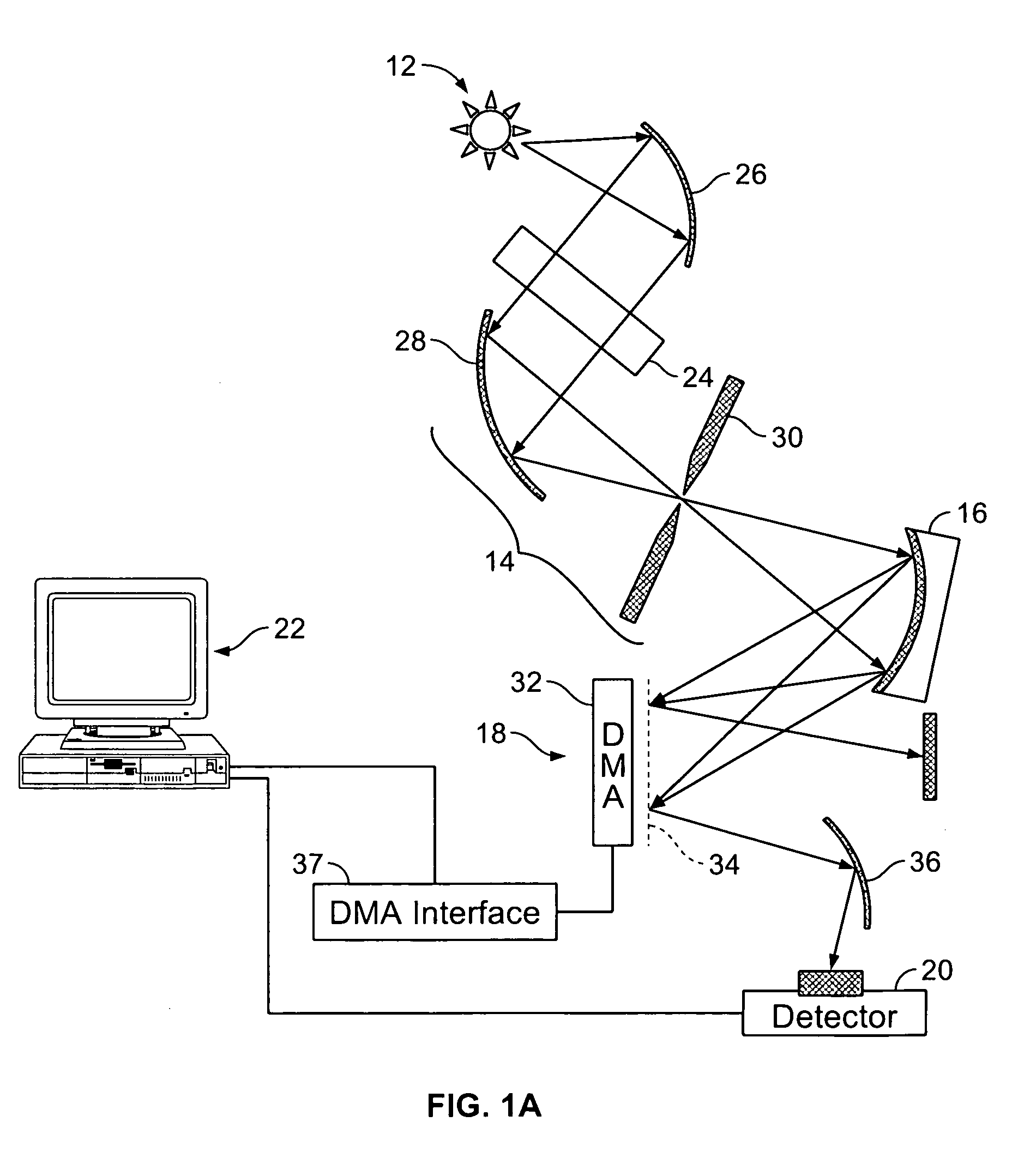

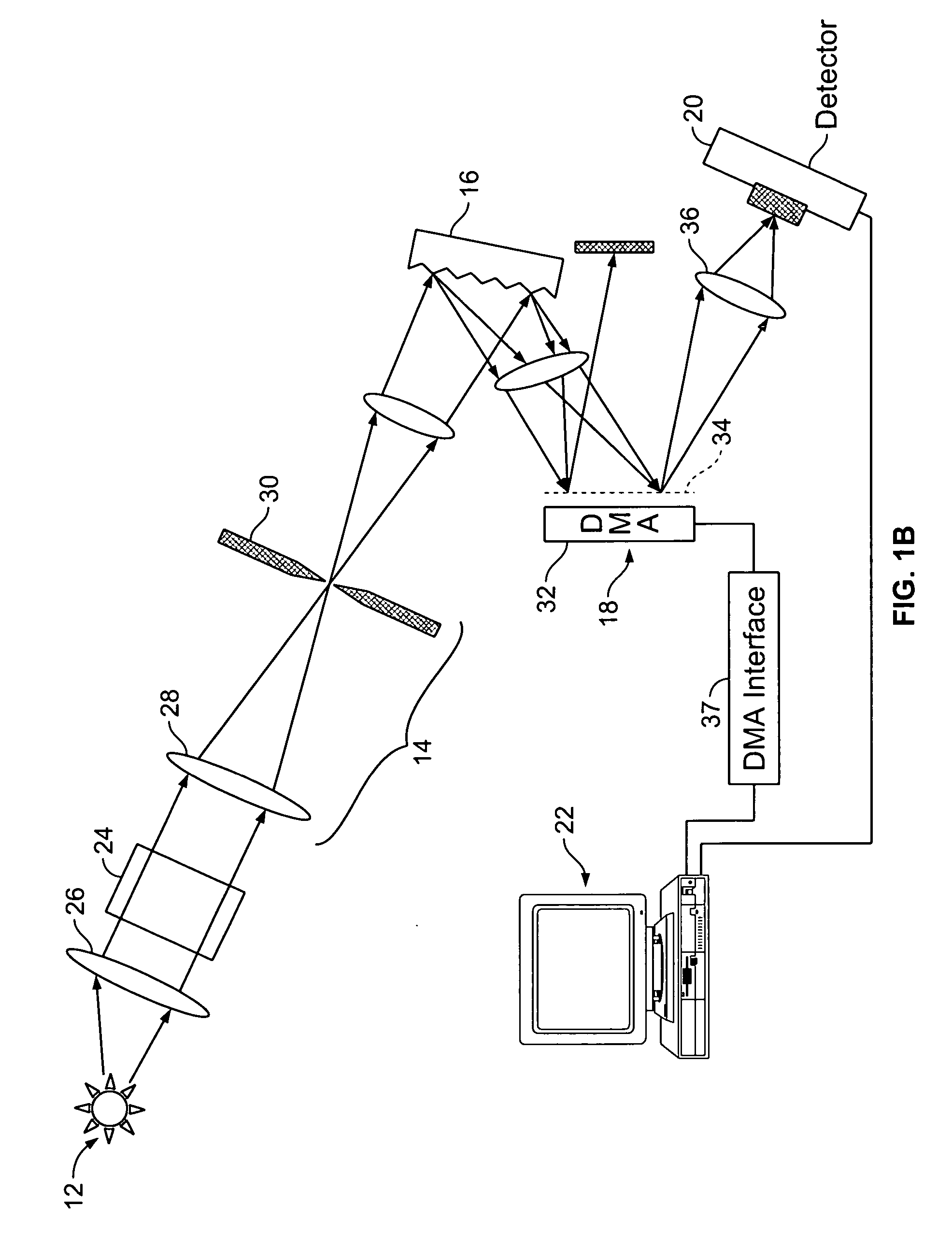

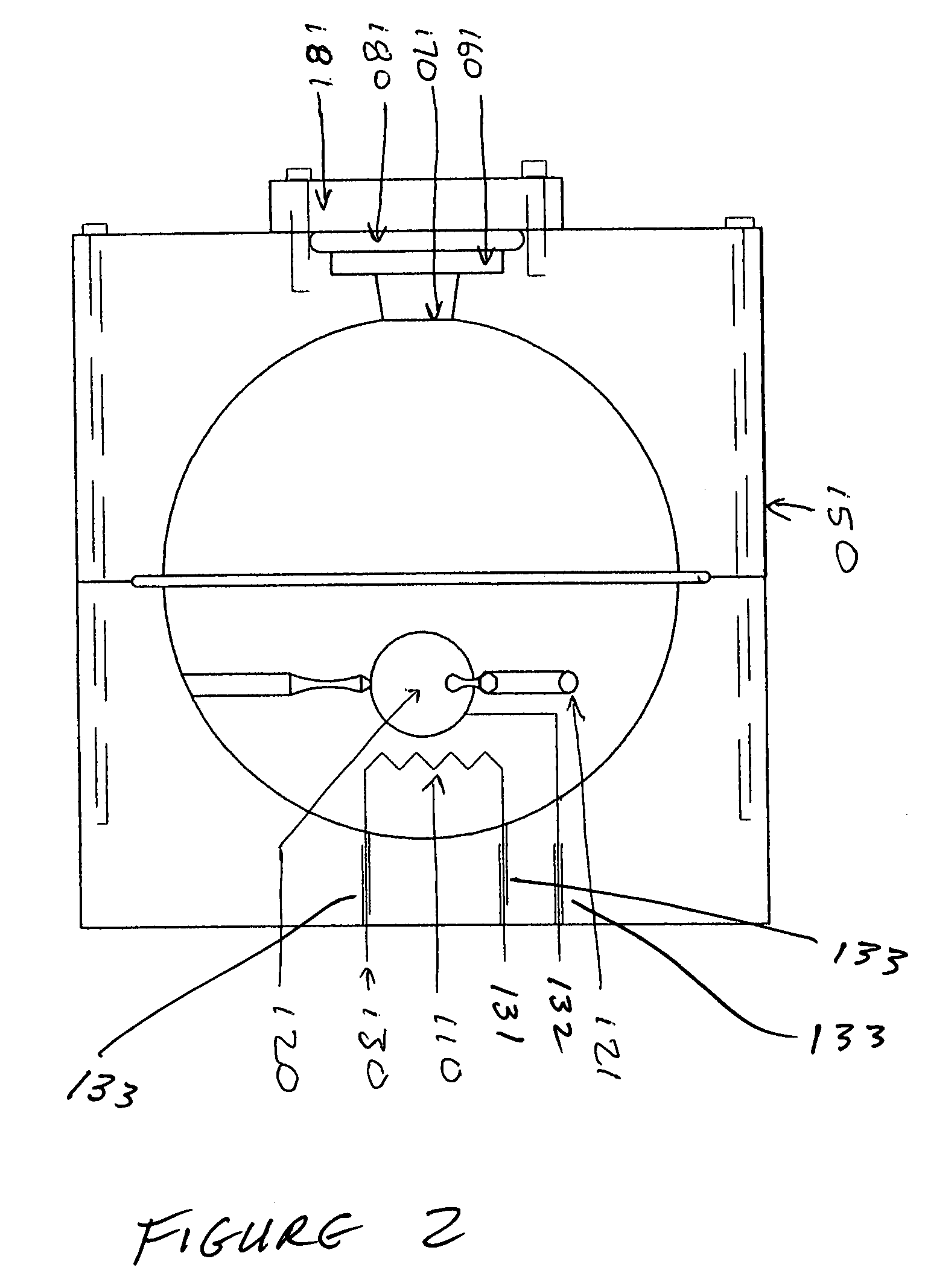

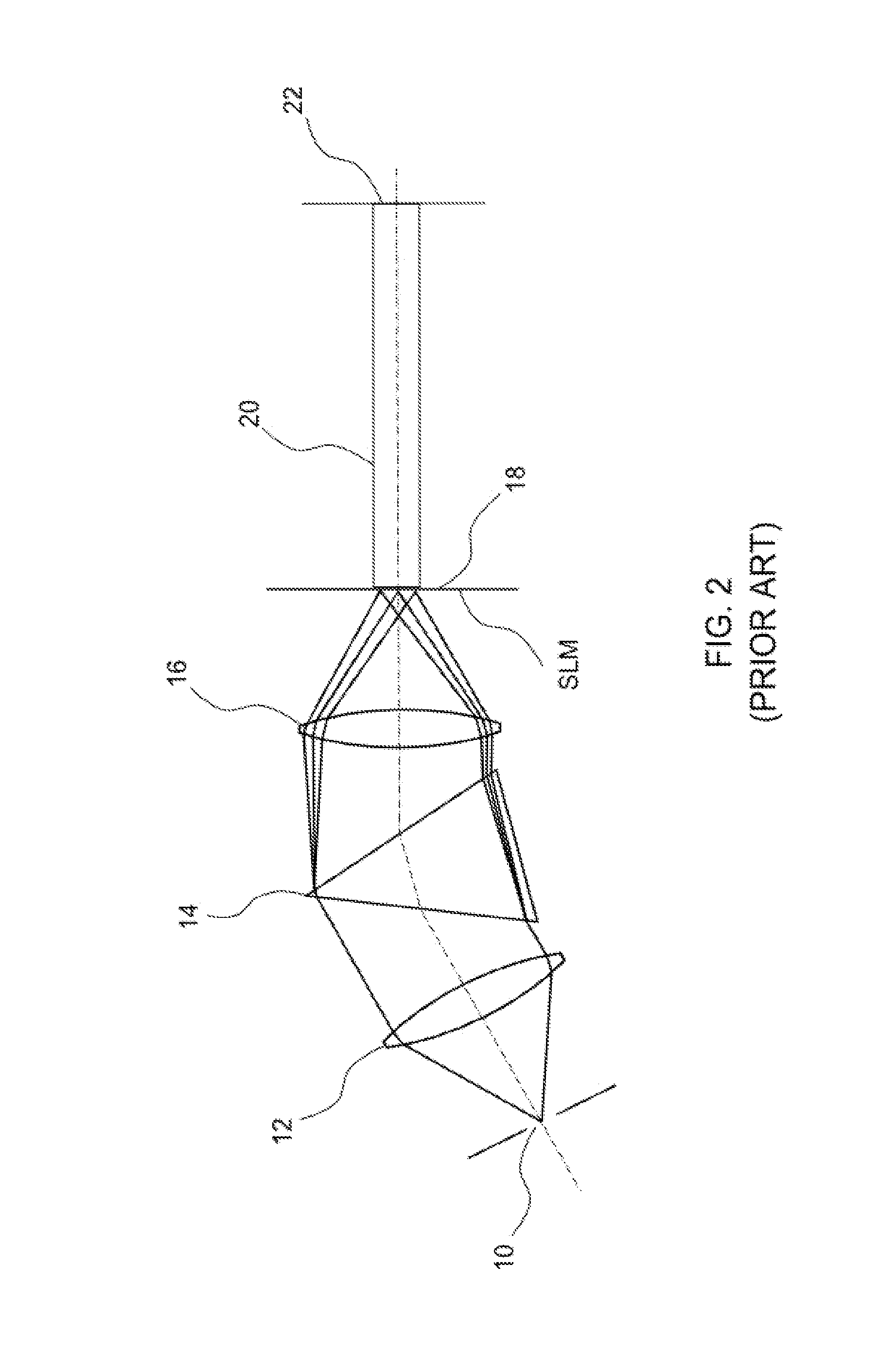

Illumination device and method for spectroscopic analysis

InactiveUS6862091B2Eliminate needMinimal effectRadiation pyrometryPolarisation spectroscopyBandpass filteringSignal-to-noise ratio (imaging)

An illumination subsystem for use in optical analysis which provides spatially and angularly homogenized radiation to the sample being analyzed. The system eliminates the illumination system as an interferent in the overall optical analysis. Thus, modest translations or rotations of the illumination source or changing the illumination source does not require recalibration of the instrument or prior modeling of illumination variability due to such changes. Illumination stability is achieved by incorporating a light pipe which both angularly and spatially homogenizes the light. Further, a series of filters and / or lenses are incorporated to provide bandpass filtering which eliminates unwanted wavelengths or bands of wavelengths from contacting the tissue and allows for a higher signal-to-noise ratio when the sample is tissue, while preventing thermal damage.

Owner:RIO GRANDE MEDICAL TECH

Devices and method for spectral measurements

InactiveUS20060092414A1Quick collectionImprove throughputRadiation pyrometrySpectrum generation using diffraction elementsMeasurement deviceFtir spectra

A spectral measurement device comprising an entrance aperture for receiving an electromagnetic energy and a mask located at the entrance aperture in the form of a two-dimensional encodement pattern. An optical element conditions the electromagnetic energy received from the mask for presentation to the spectral dispersion element and the and a spectral dispersion element disperses the electromagnetic energy in one or more dimensions. Additionally, the optical element conditions the dispersed electromagnetic energy onto an array of detector elements.

Owner:PLAIN SIGHT SYST

Handheld FT-IR spectrometer

InactiveUS20080204757A1Improves state-of-the-artRadiation pyrometryInterferometric spectrometryMetrologyFtir spectra

Novel spectrometer arrangements are described. They may employ a resin-based preconcentration system to sample chemical vapors. A field-widened interferometer modulates radiant energy. The signal generated by the interaction of the radiant energy with the sample is detected and processed by a computer. A variety of enhancements to the basic design are described, providing a family of related spectrometer designs. These spectrometers have applications in spectrometry, spectral imaging and metrology.

Owner:MANNING CHRISTOPHER

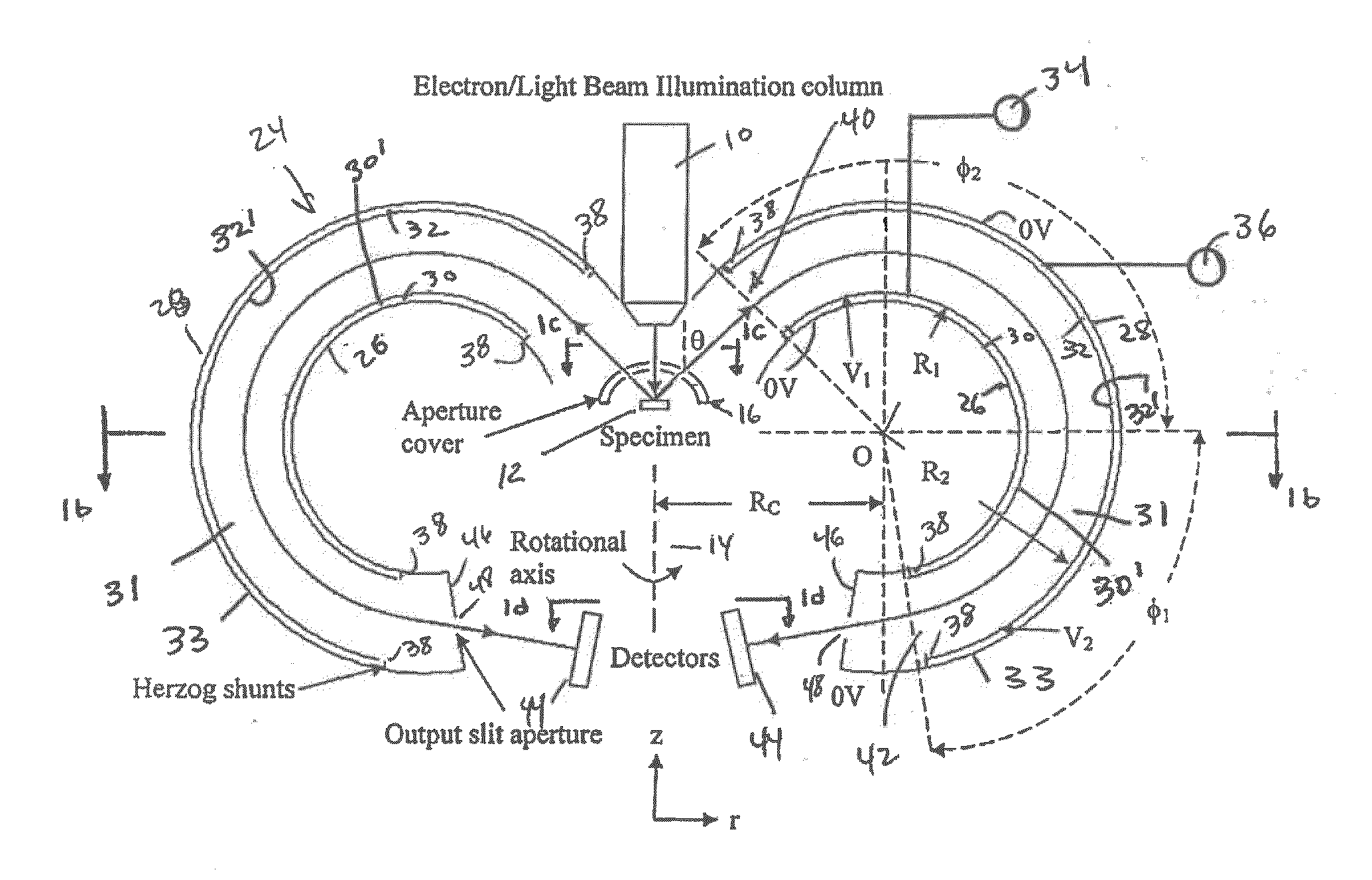

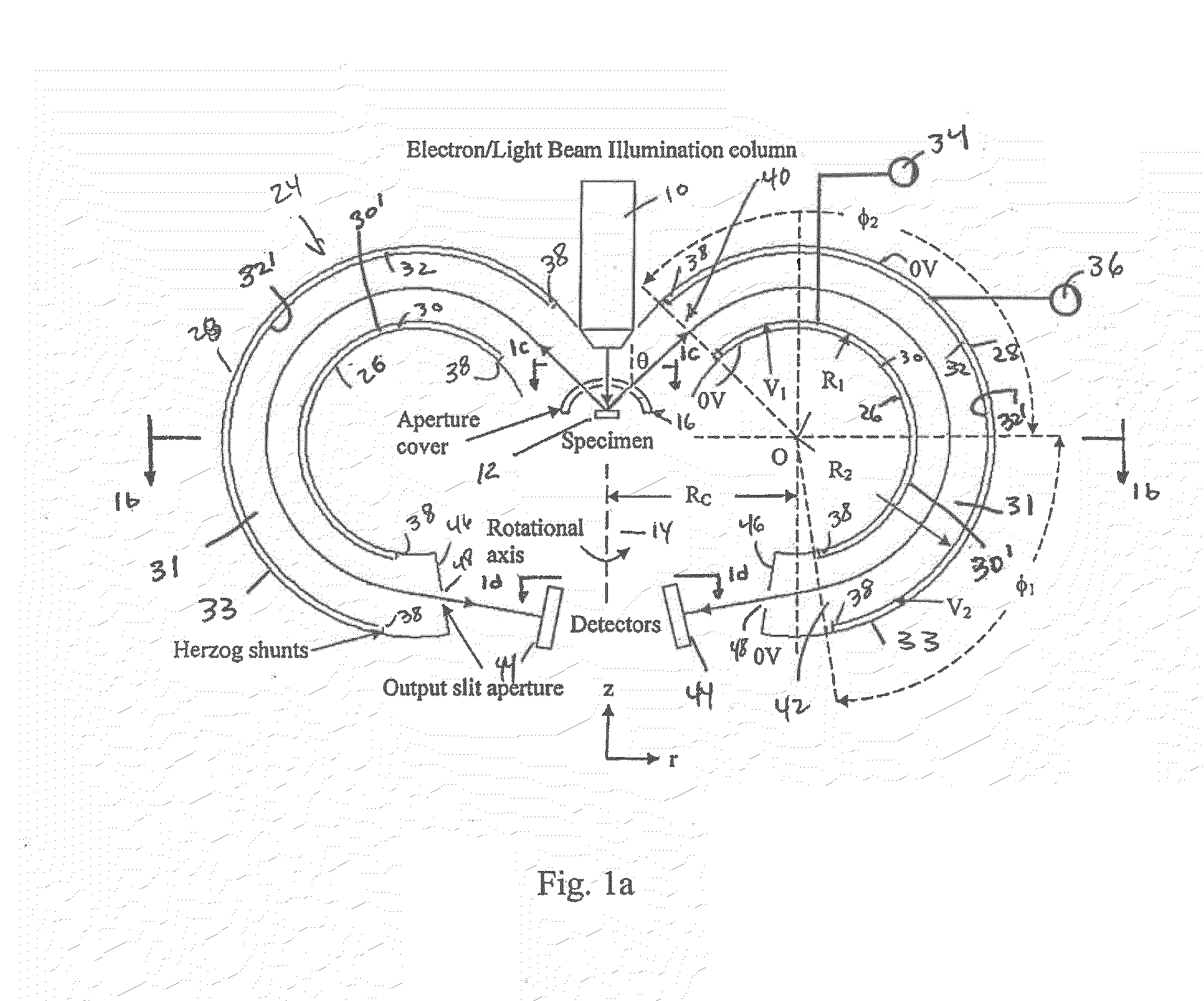

Electrostatic electron spectrometry apparatus

ActiveUS20100127168A1Improved energy resolutionShortening of trajectory run timeMaterial analysis using wave/particle radiationPhotoelectric discharge tubesFtir spectraSpectrometer

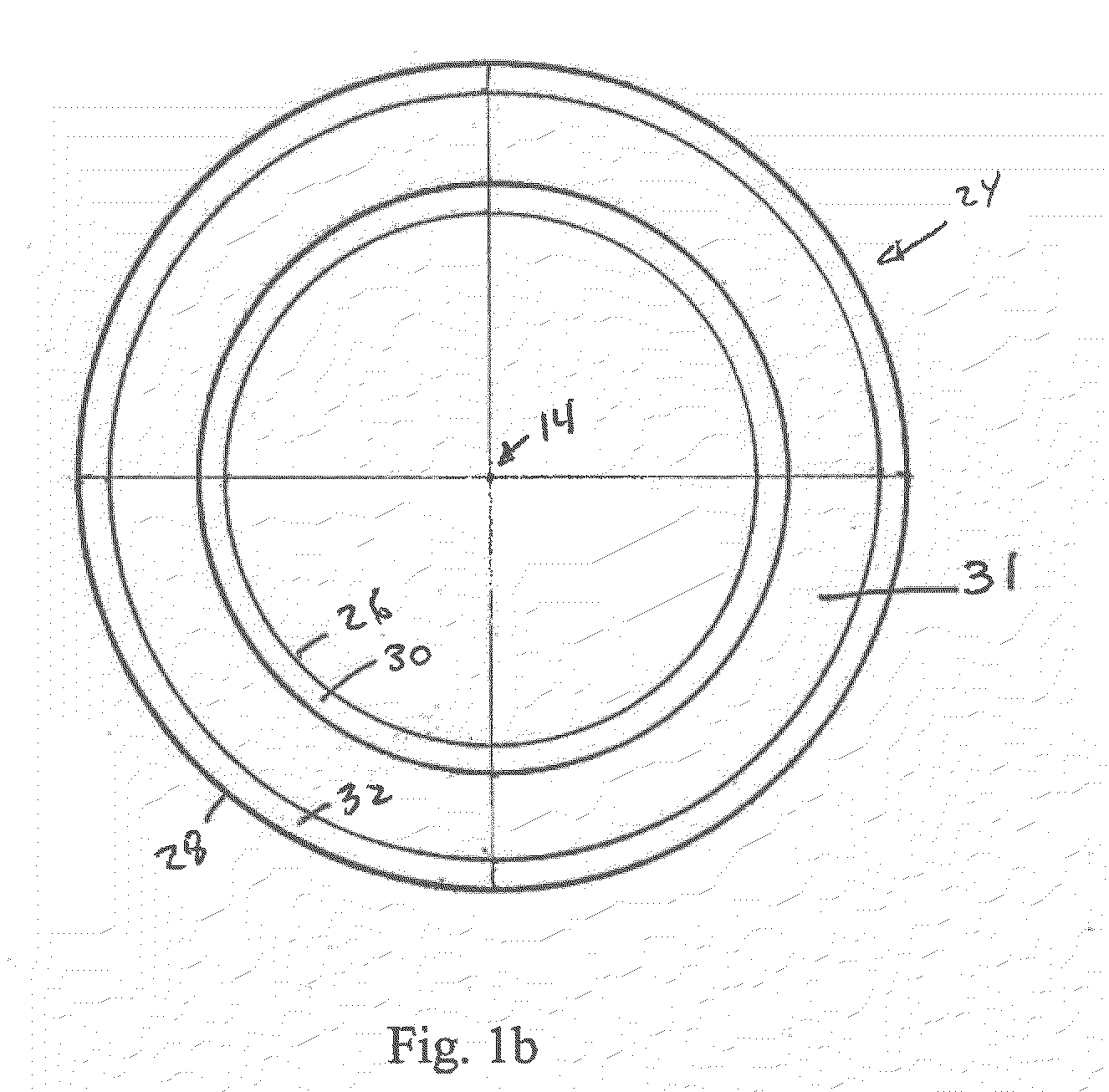

An apparatus for spectrometry that includes a spectrometer configured for second order focusing and capable of 2π azimuthal collection.

Owner:NAT UNIV OF SINGAPORE

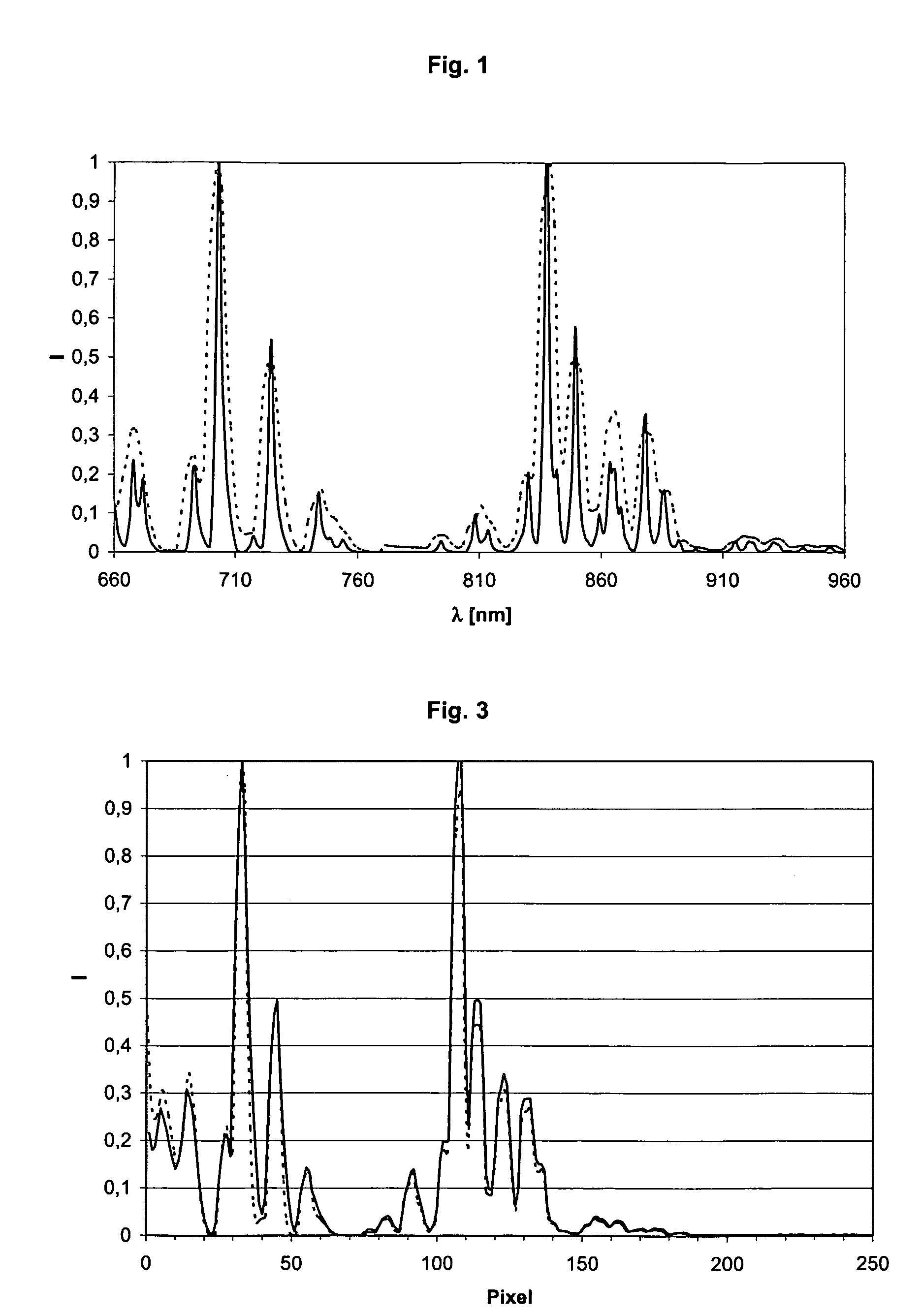

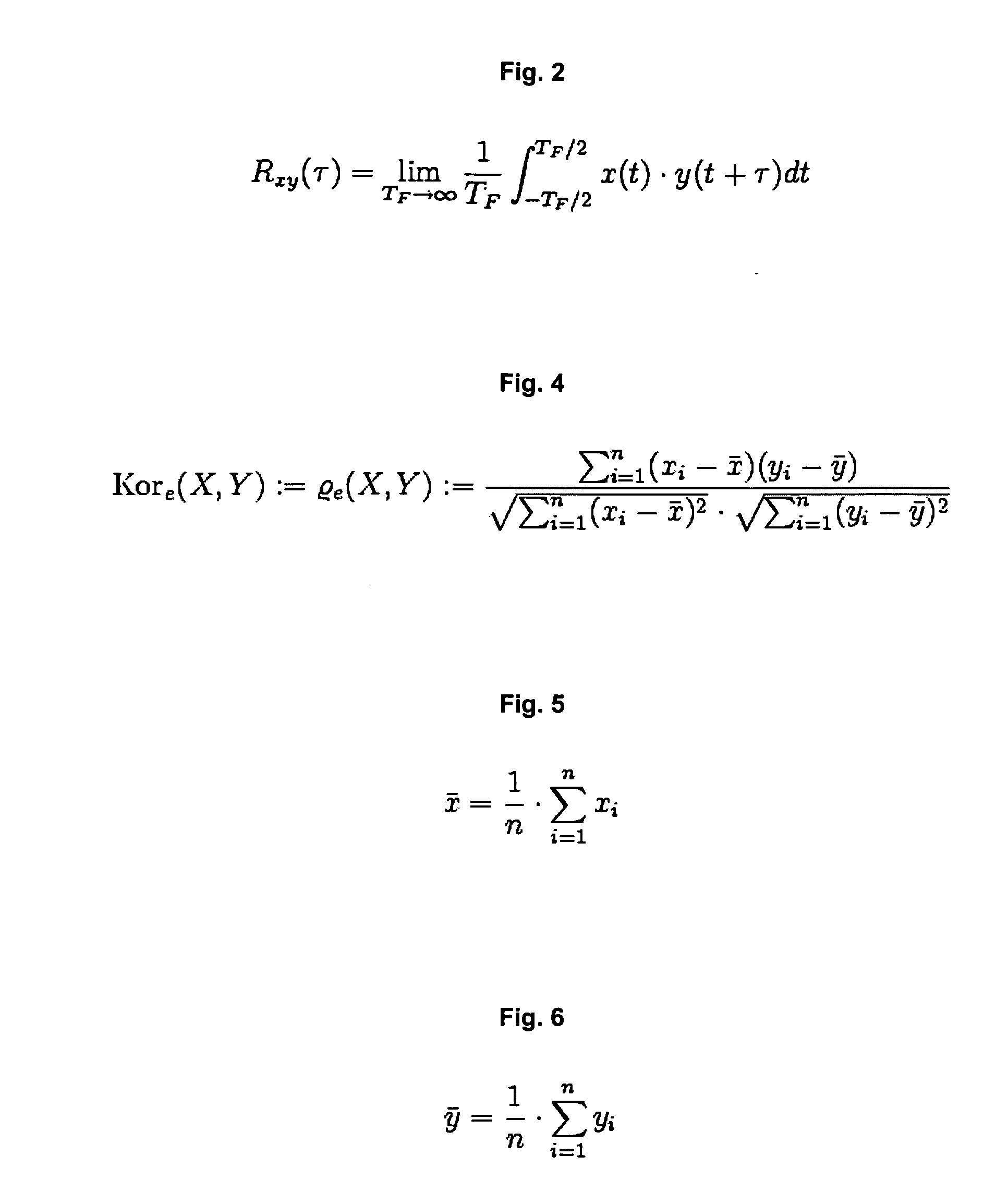

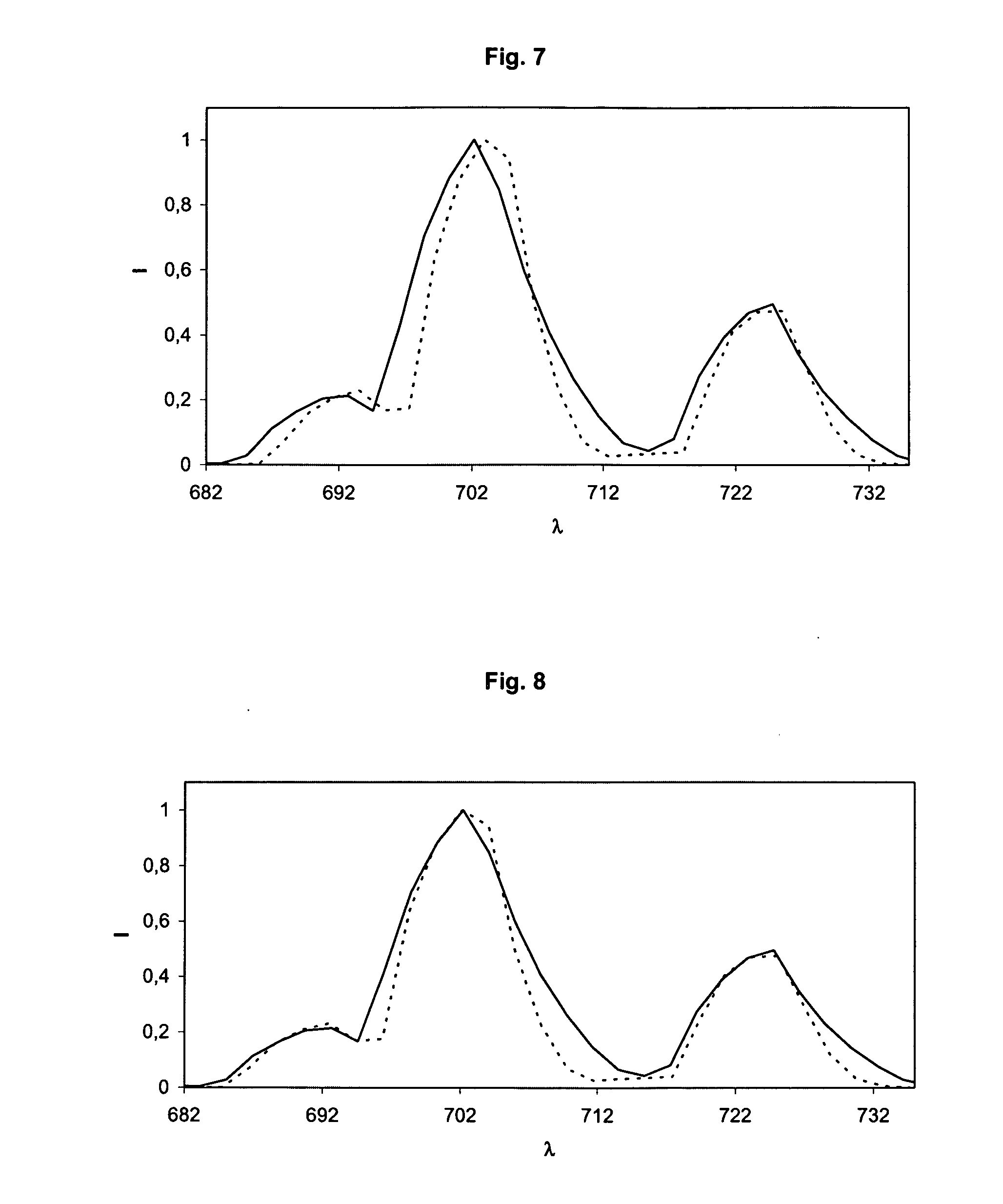

Method for the wavelength calibration of a spectrometer

InactiveUS20080297796A1Improve calibration accuracySimplerRadiation pyrometryTesting/calibration apparatusFtir spectraPeak value

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

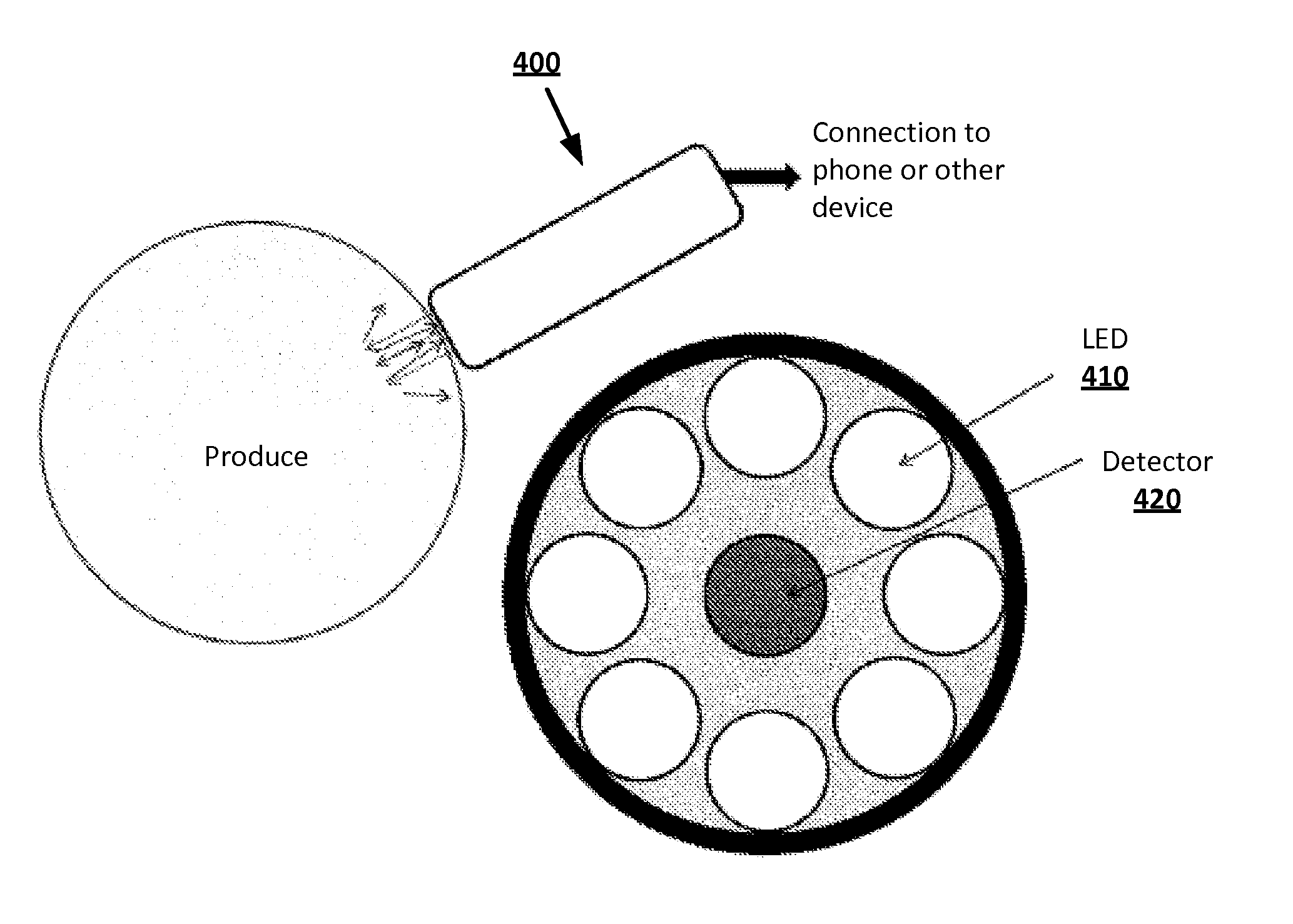

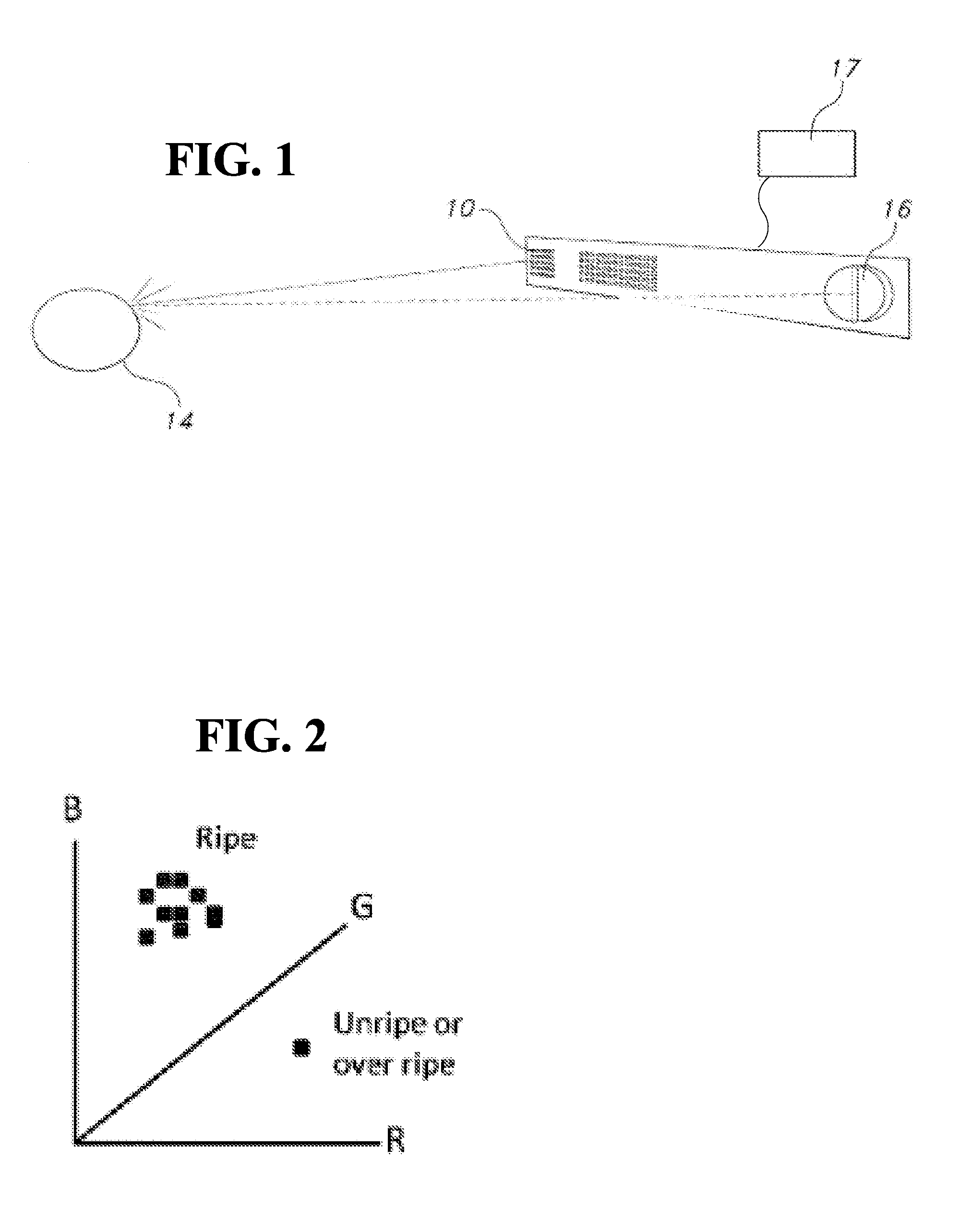

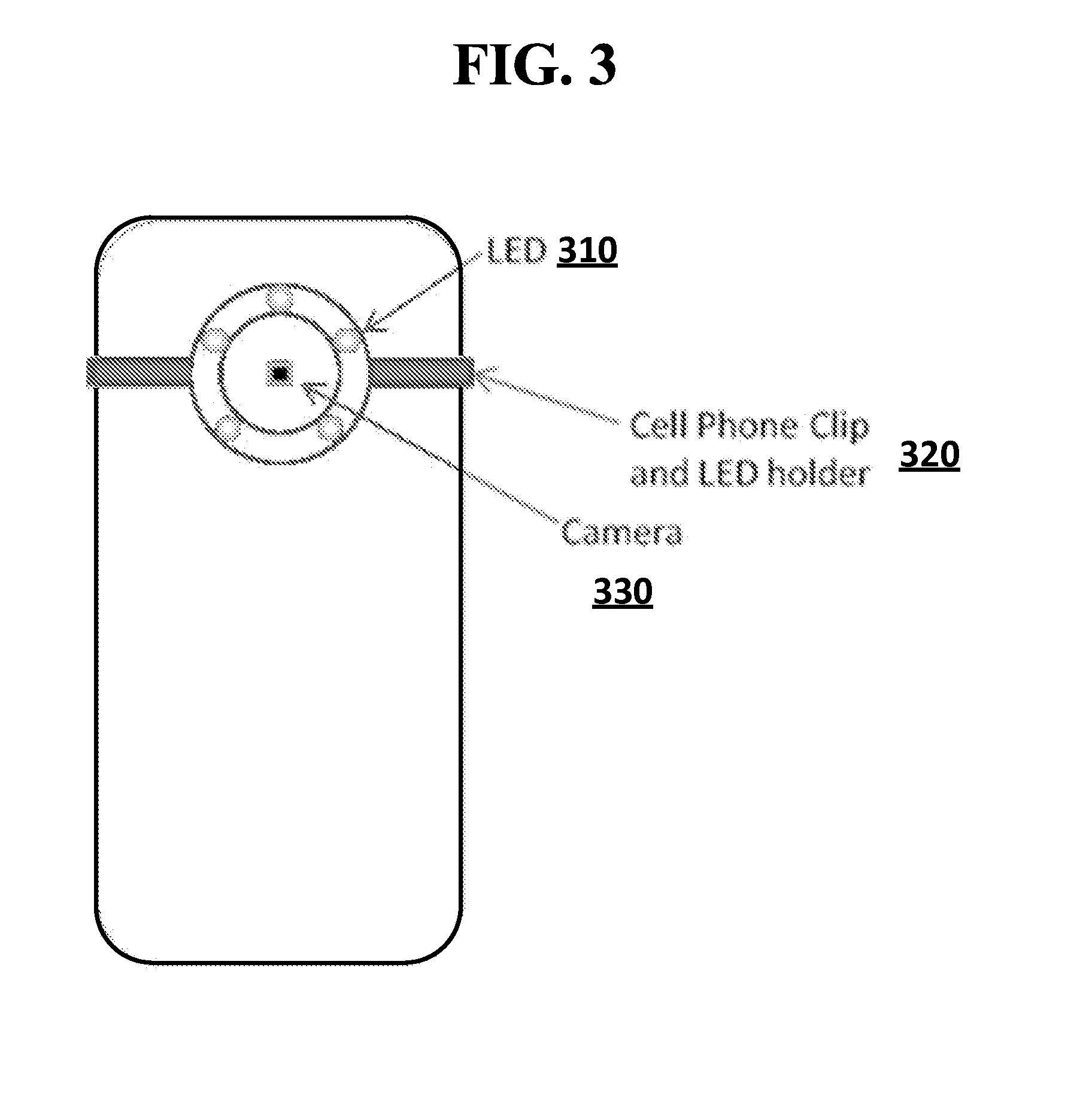

Portable device and method for spectroscopic analysis

InactiveUS20110261355A1Eliminate covarianceRadiation pyrometryAbsorption/flicker/reflection spectroscopyTarget surfaceAnalyte

Spectroscopic devices and techniques for determining the presence or absence of an analyte of interest or the presence or absence of desired characteristics of an object are provided. In an embodiment, a portable device or attachment for a smart phone or comparable device includes a light source and a detector. The detector detects light after reflection from a target surface and, based upon attributes in the detected light absent from the emitted light such as covariances among different wavelengths, determines the presence or absence of the analyte of interest.

Owner:ESCENT TECH

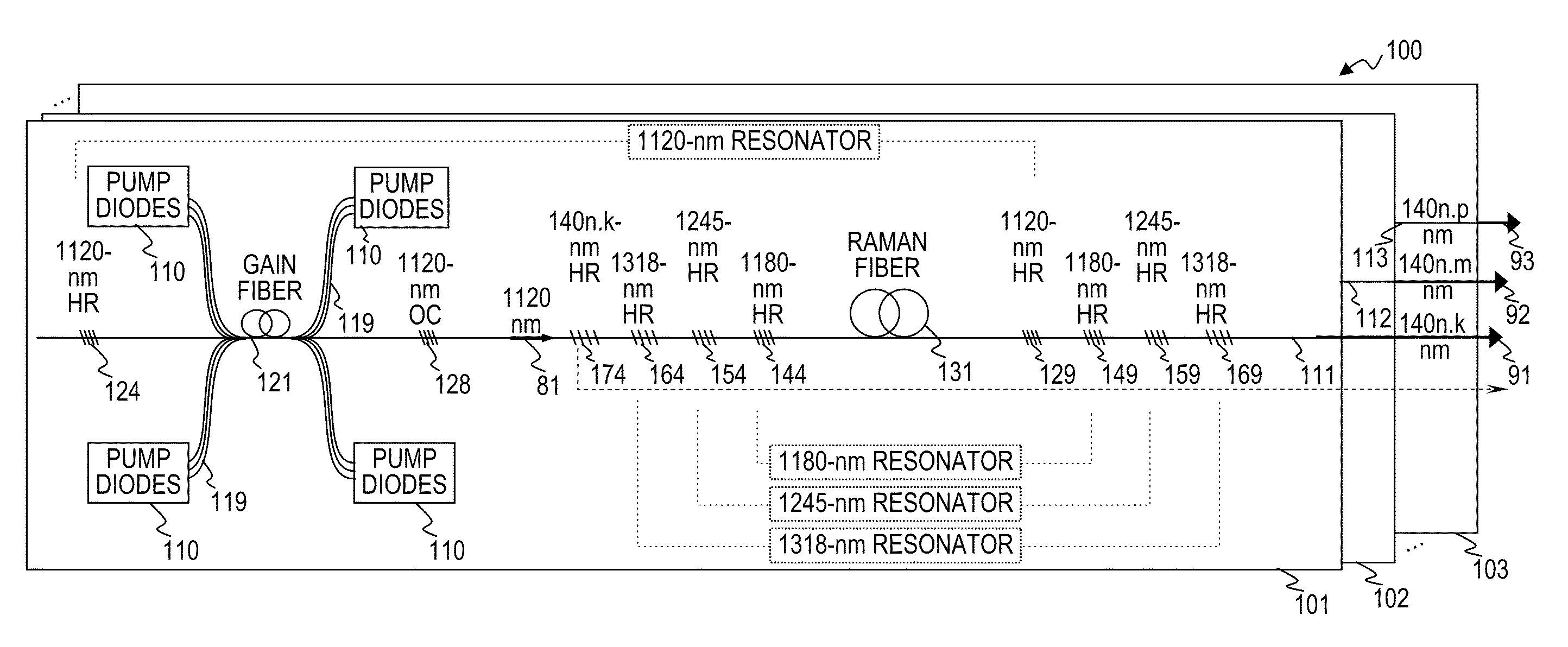

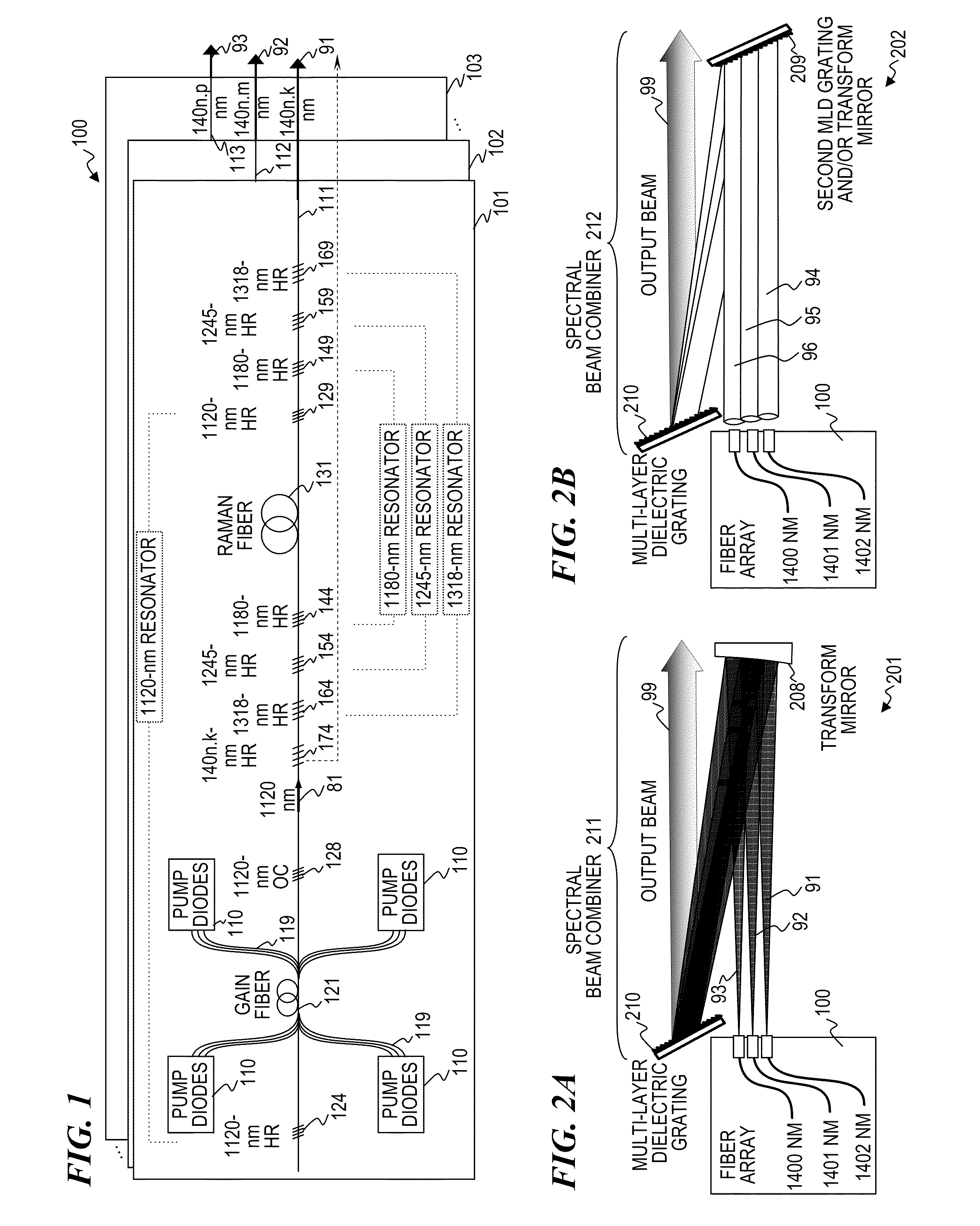

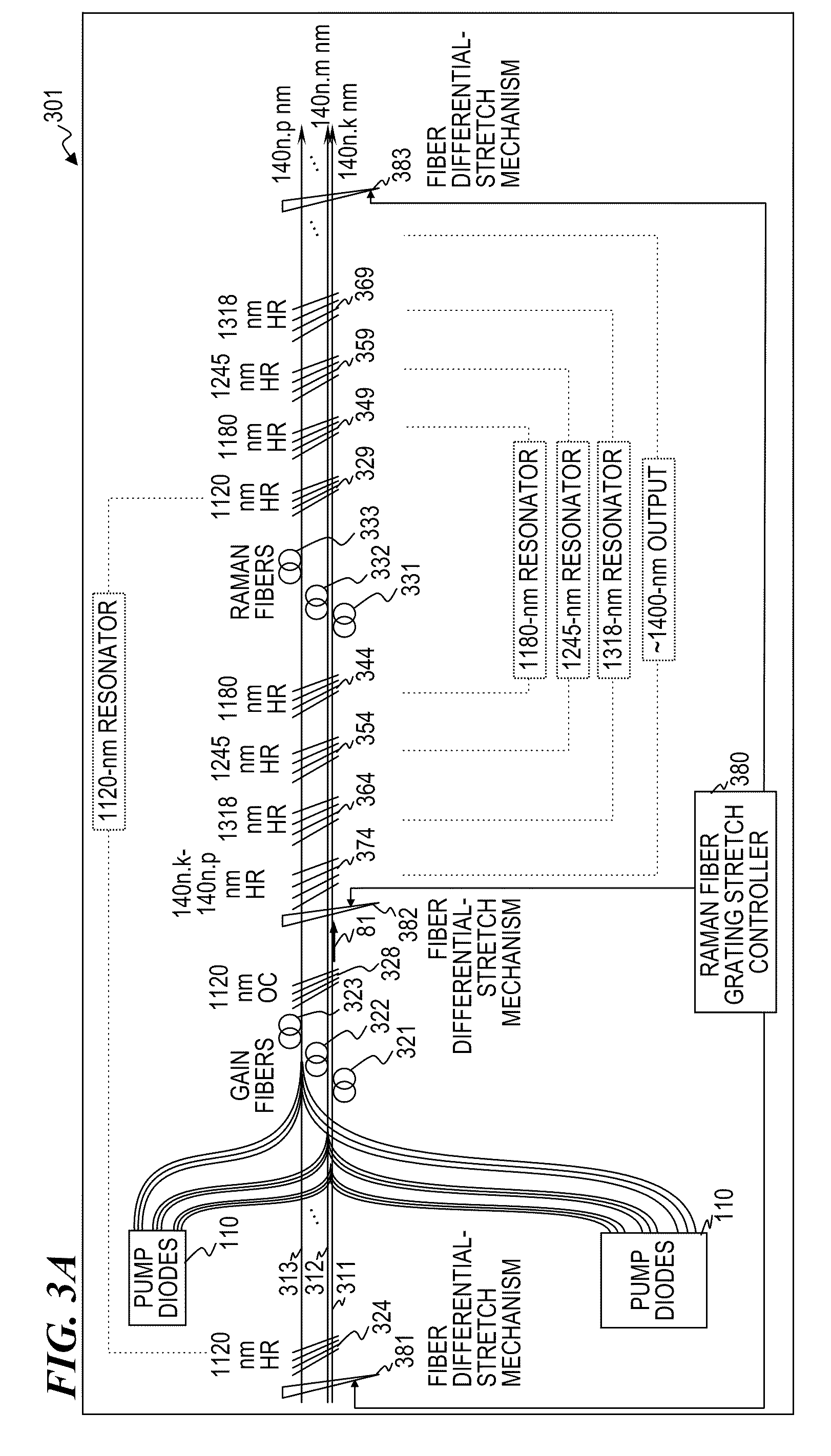

Spectrally beam combined laser system and method at eye-safer wavelengths

ActiveUS20110122482A1Avoid less flexibilityEasy to useLaser using scattering effectsLight demodulationGratingFiber Bragg grating

Fiber-laser light is Raman shifted to eye-safer wavelengths prior to spectral beam combination, enabling a high-power, eye-safer wavelength directed-energy (DE) system. The output of Ytterbium fiber lasers is not used directly for spectral beam combining. Rather, the power from the Yb fiber lasers is Raman-shifted to longer wavelengths, and these wavelengths are then spectrally beam combined. Raman shifting is most readily accomplished with a “cascaded Raman converter,” in which a series of nested fiber cavities is formed using fiber Bragg gratings.

Owner:LOCKHEED MARTIN CORP

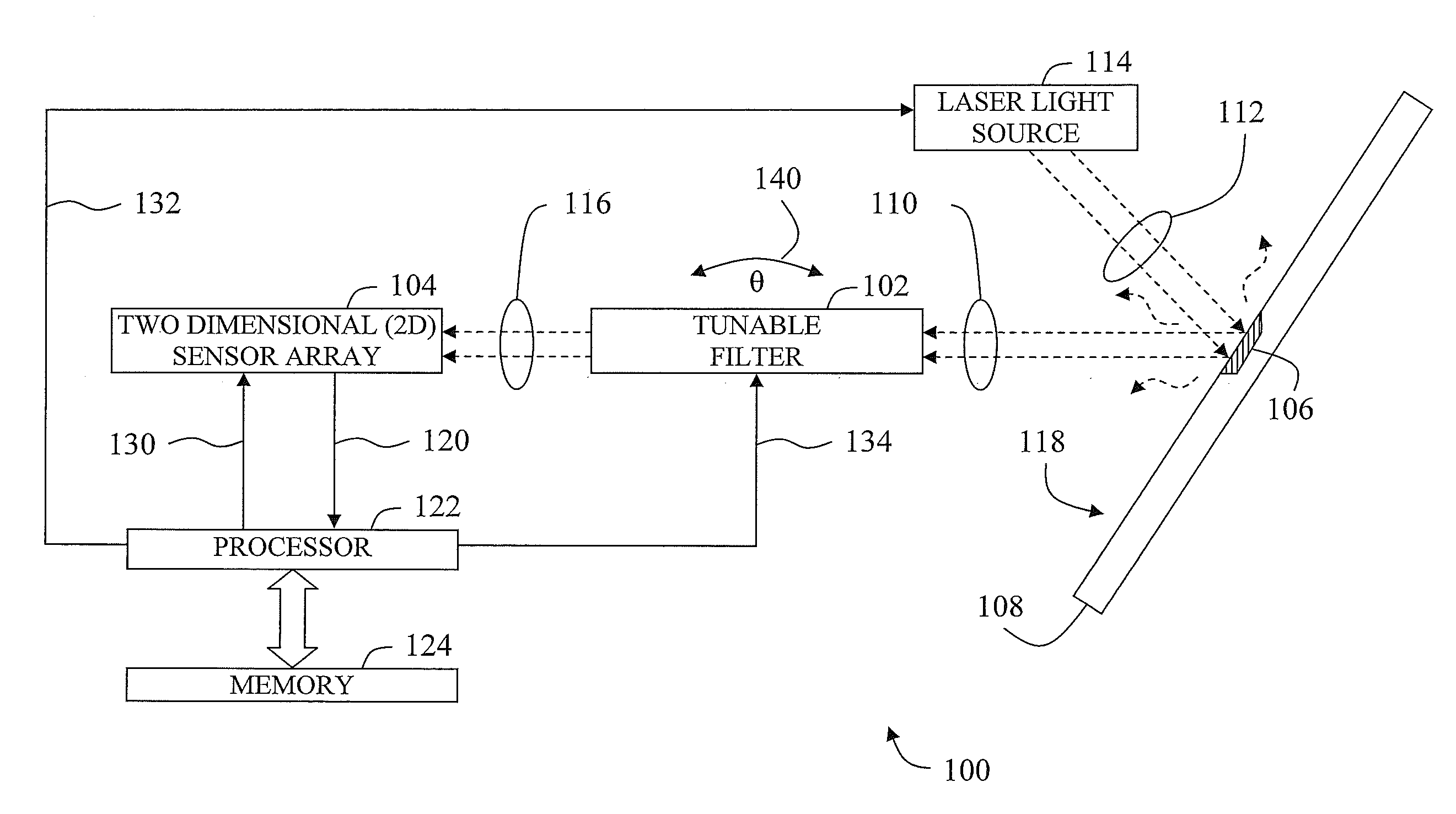

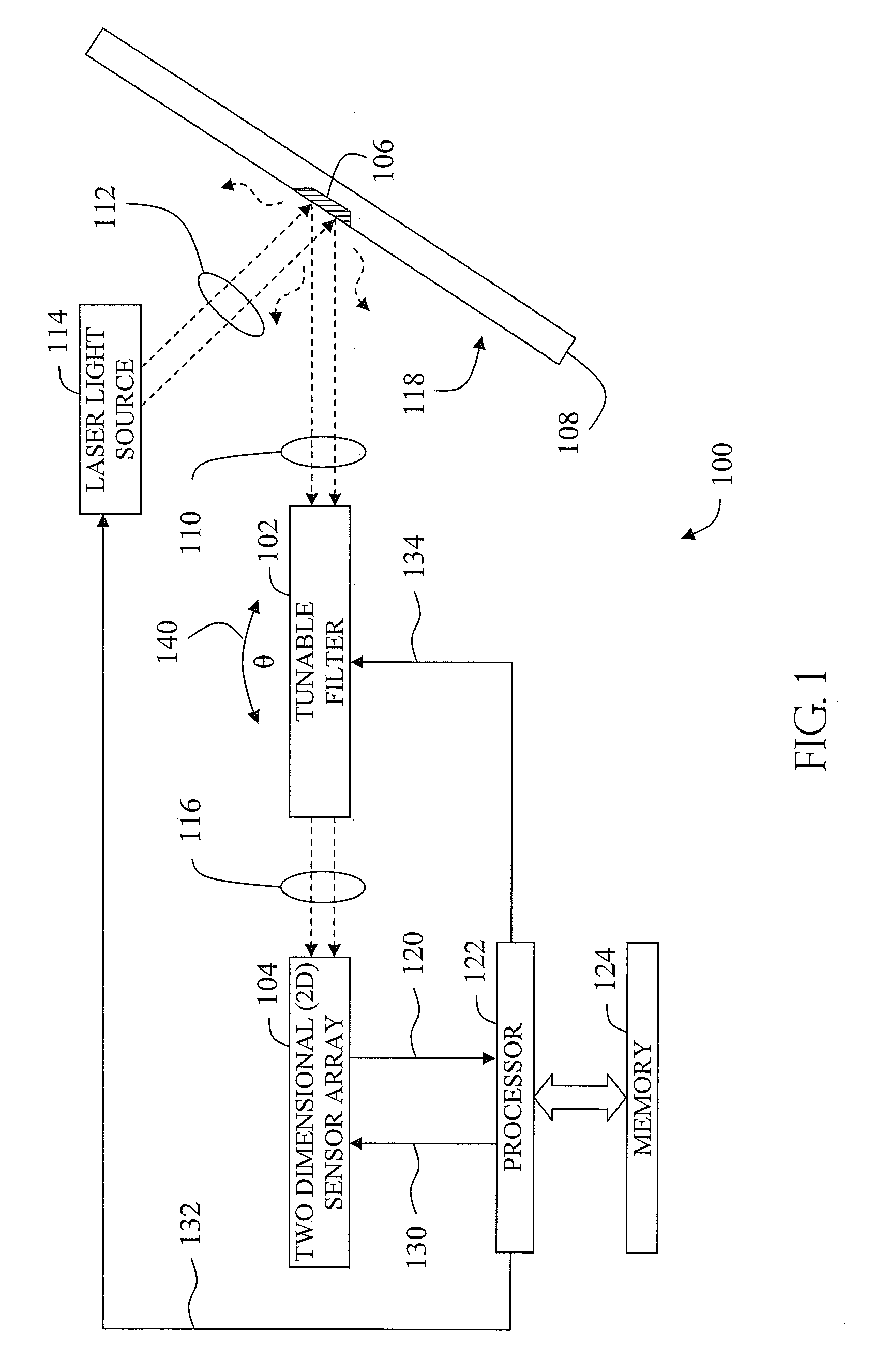

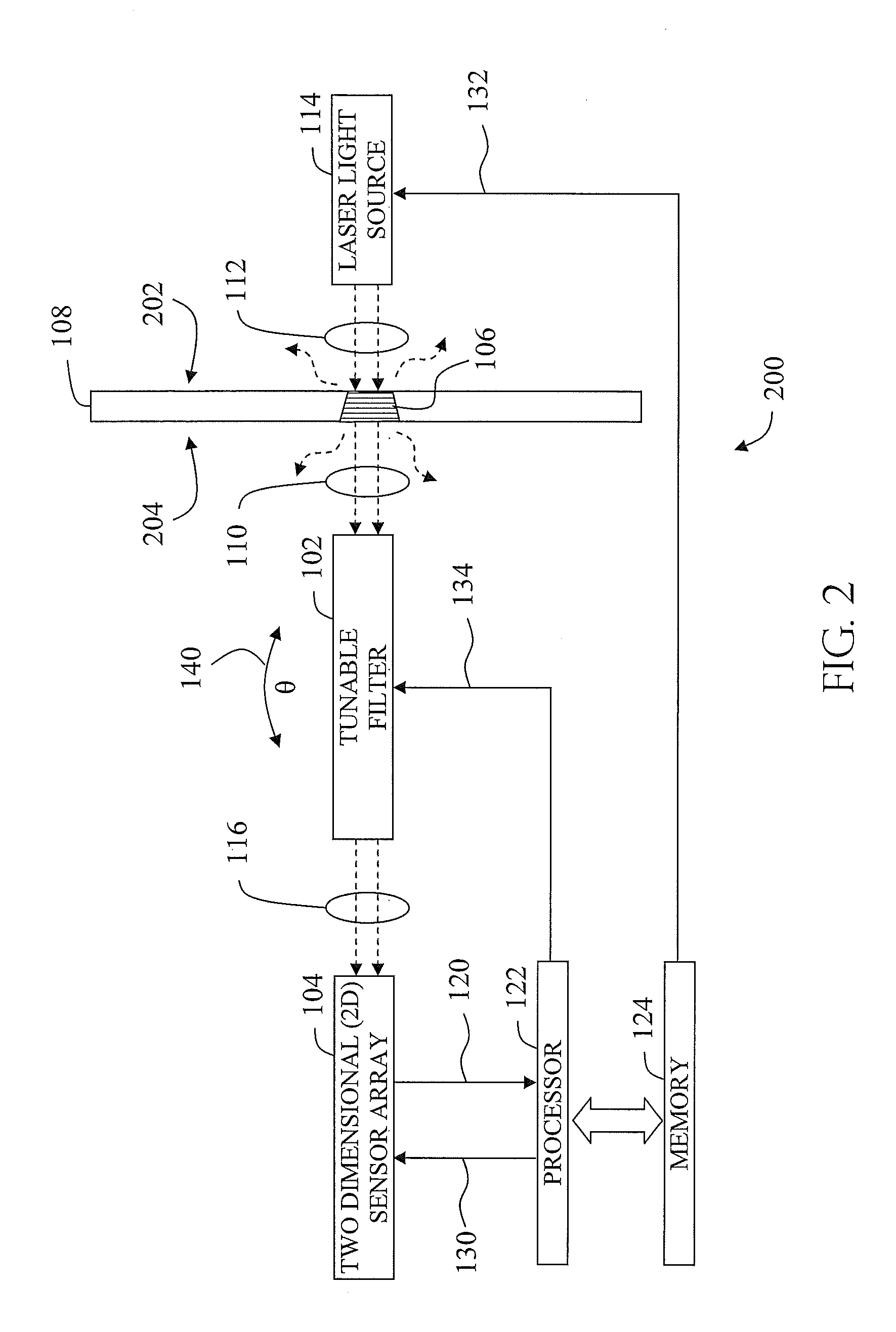

Spectral imaging device

Systems and methods for spectral imaging are disclosed. Such spectral imaging can be used to determine properties of a subject material at different locations upon the surface and / or within the material. For example, strain and / or stress within an imaged area of the material can be determined. A system for spectral imaging can include a light source, a two-dimensional sensor array configured to image light from a two-dimensional area of a subject material, a filter configured to filter light from the subject material before the light is imaged and a processor in communication with the two-dimensional sensor array. The processor can be configured to determine a property of the subject material at a plurality of locations within the two-dimensional area of the subject material. Such spectral imaging systems can facilitate the performance of piezospectroscopic measurements of two-dimensional surfaces in a rapid manner while preserving accuracy.

Owner:METROLASER

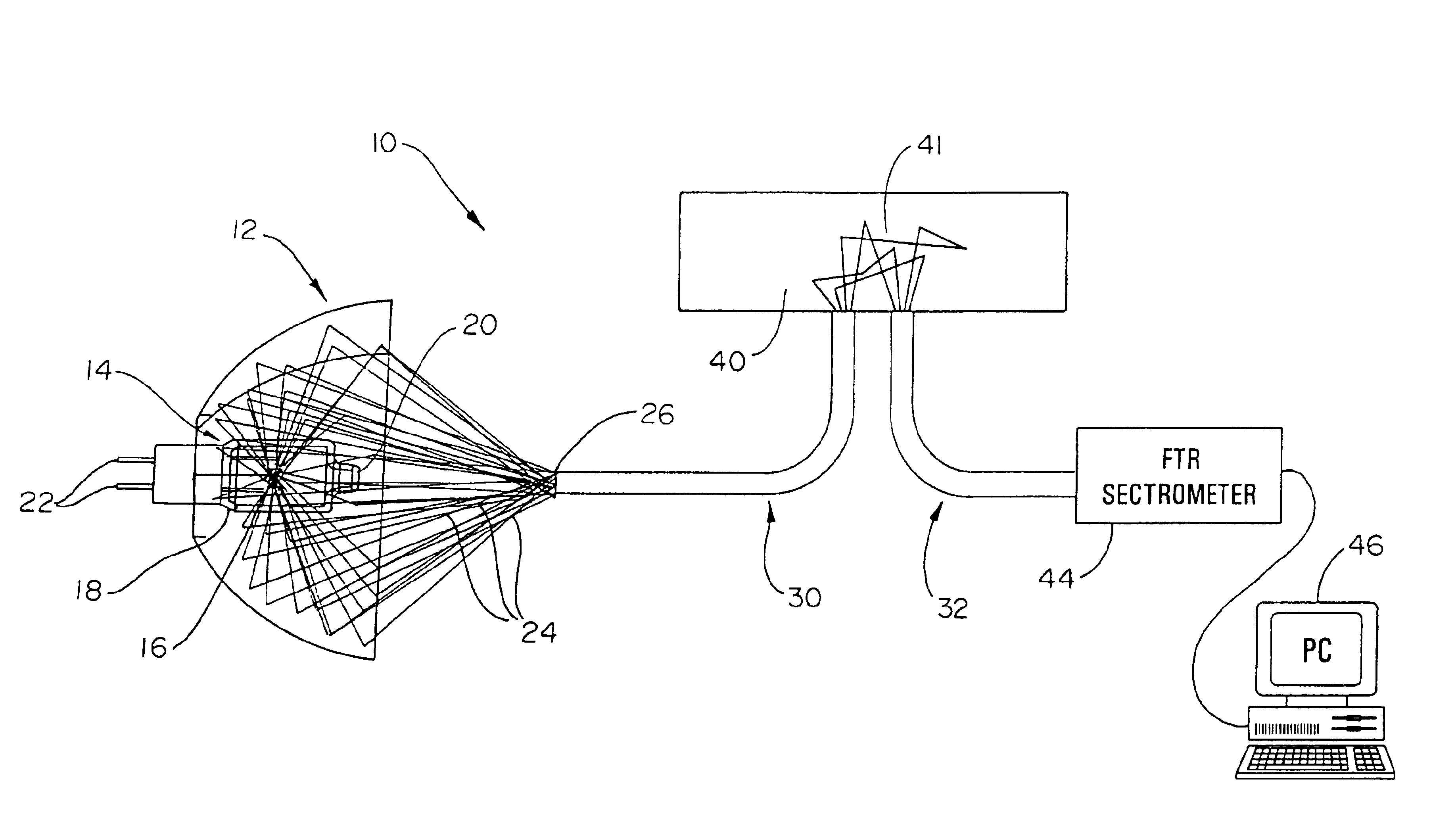

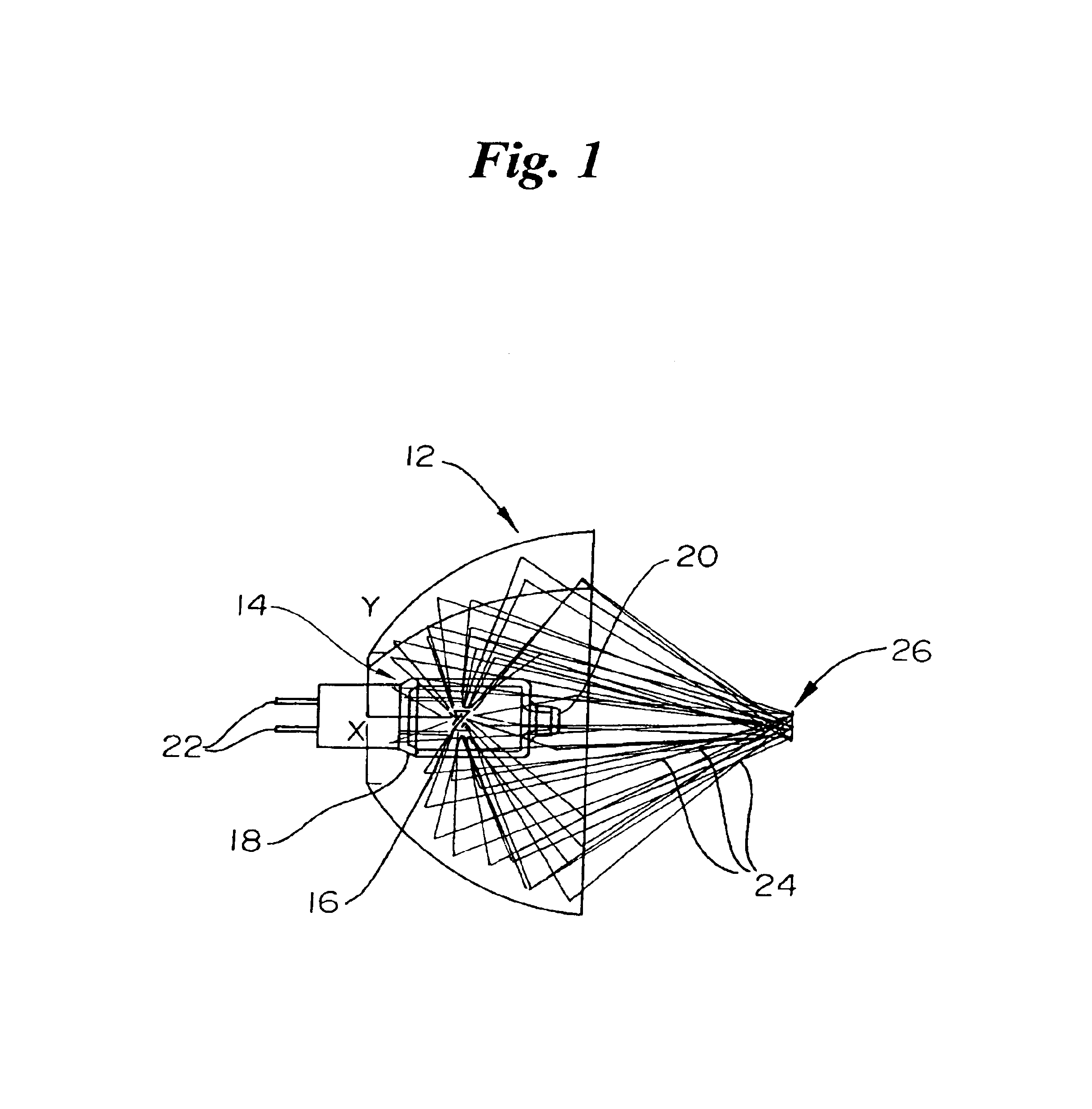

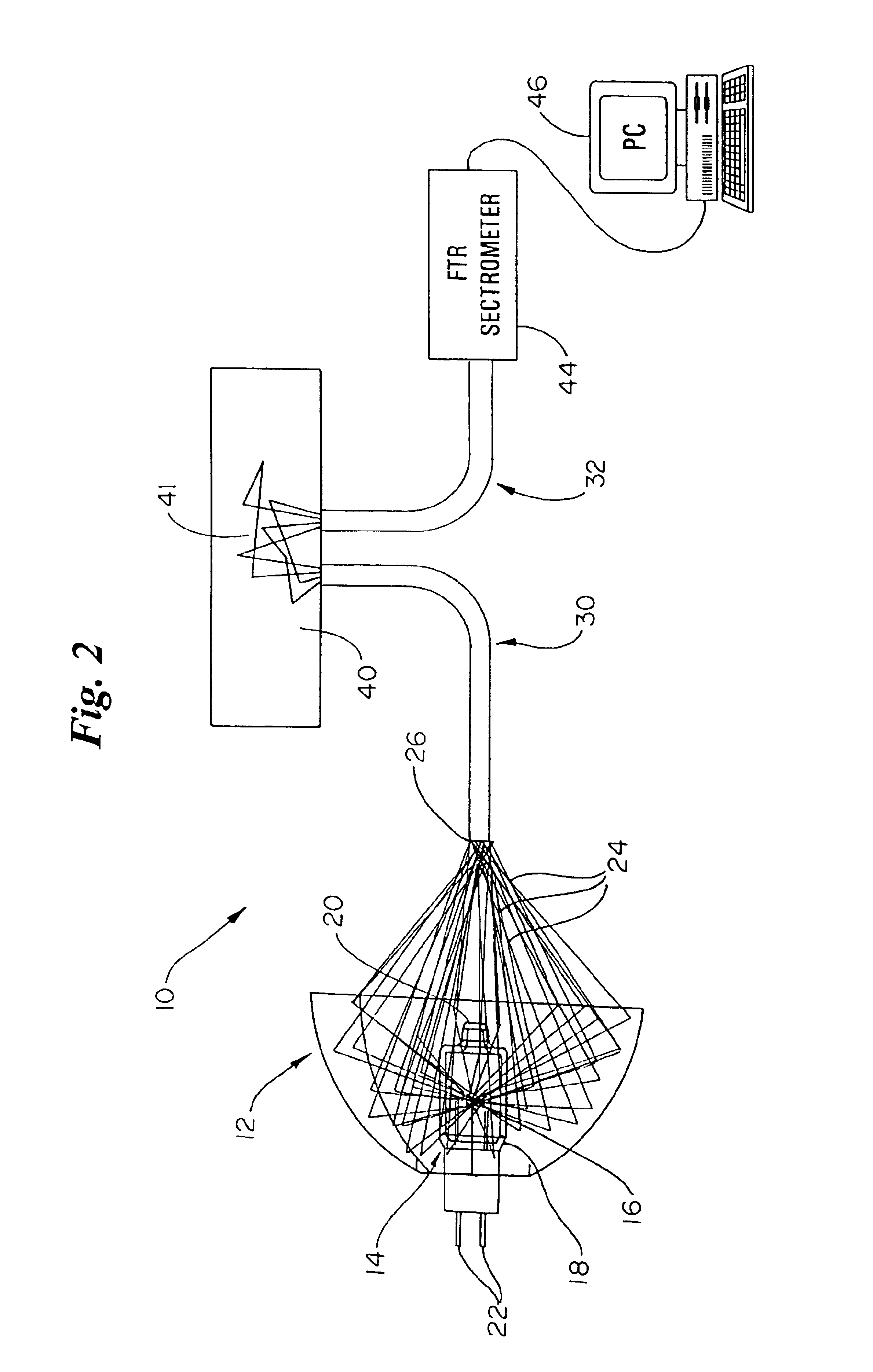

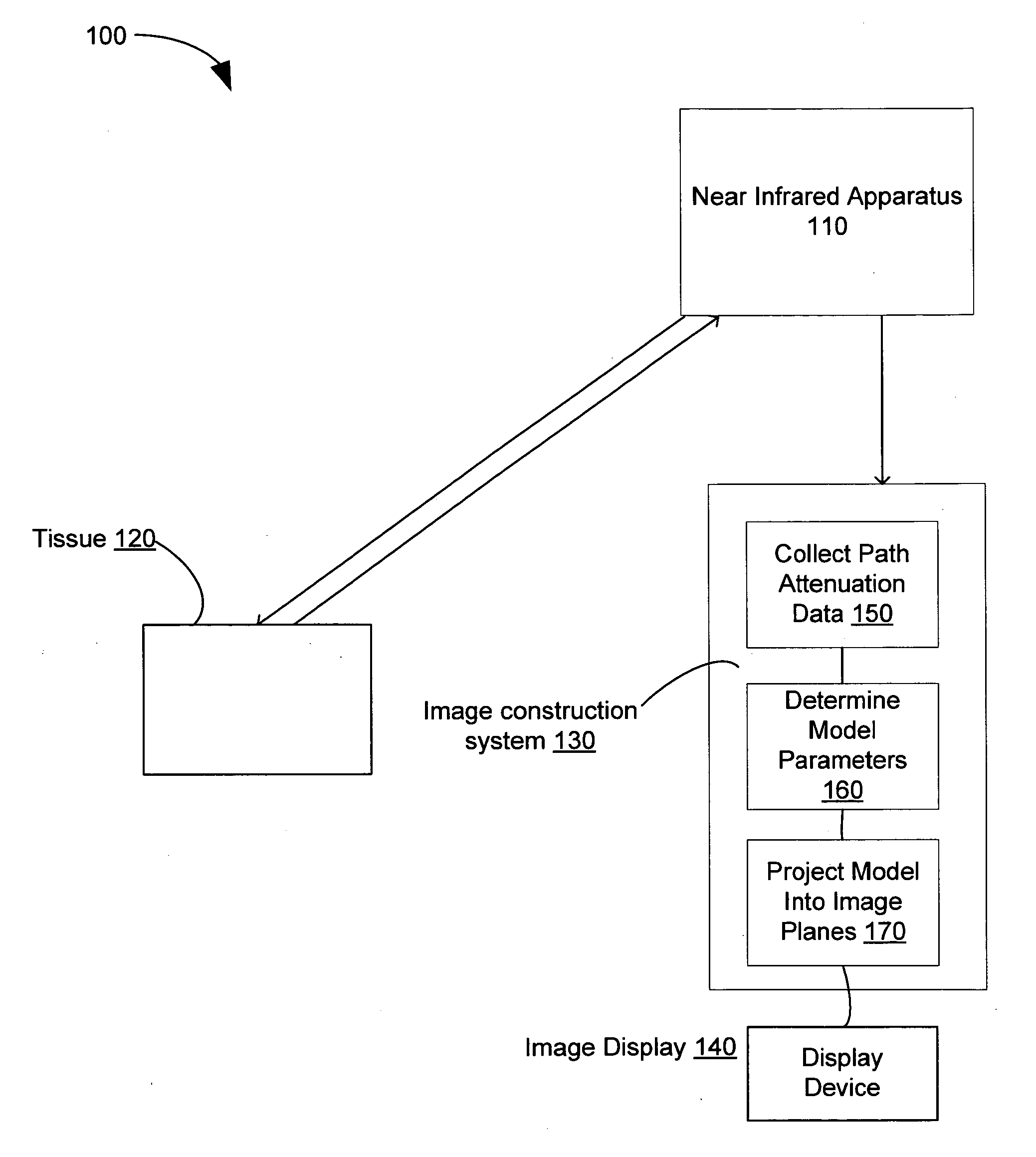

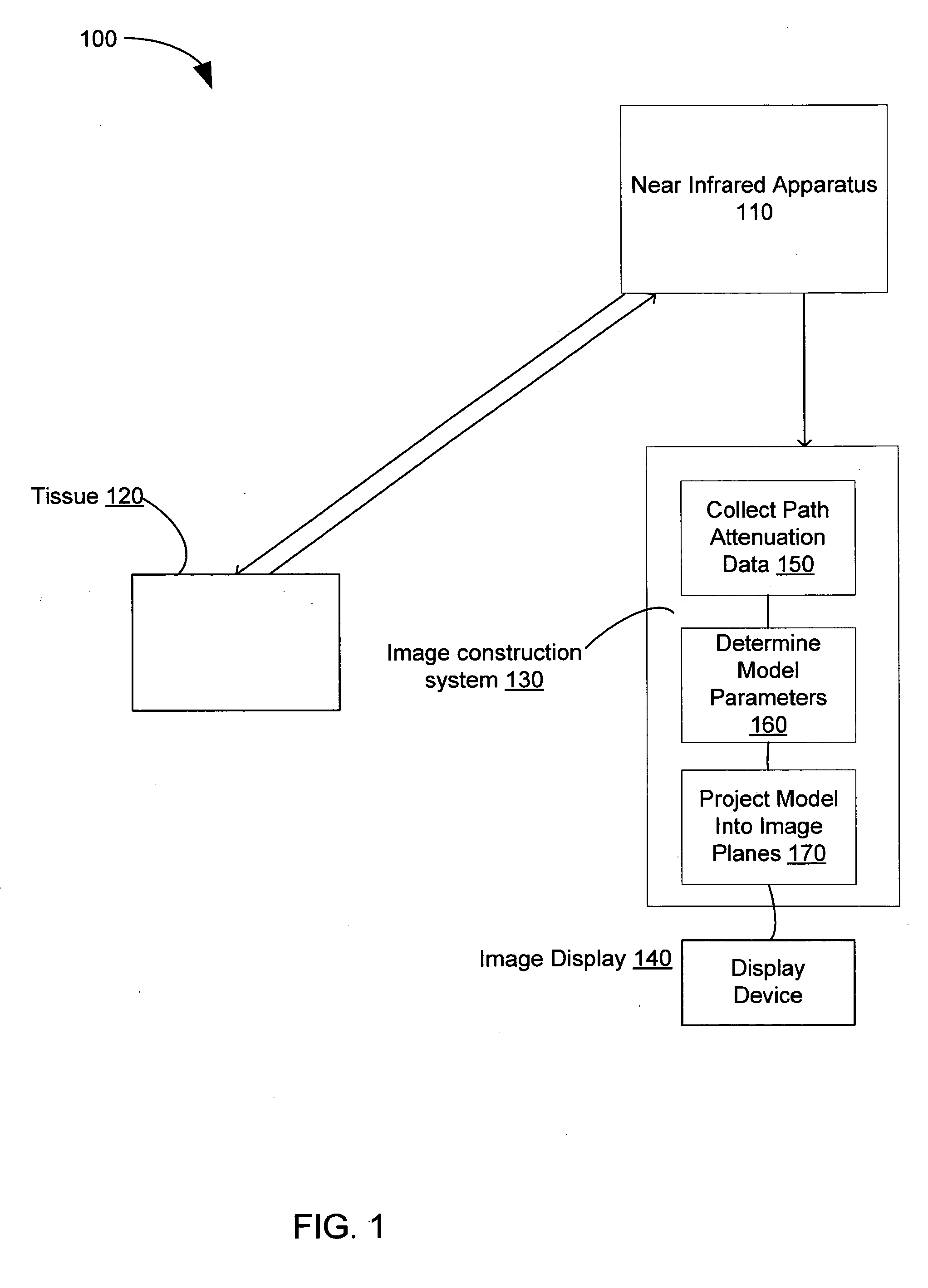

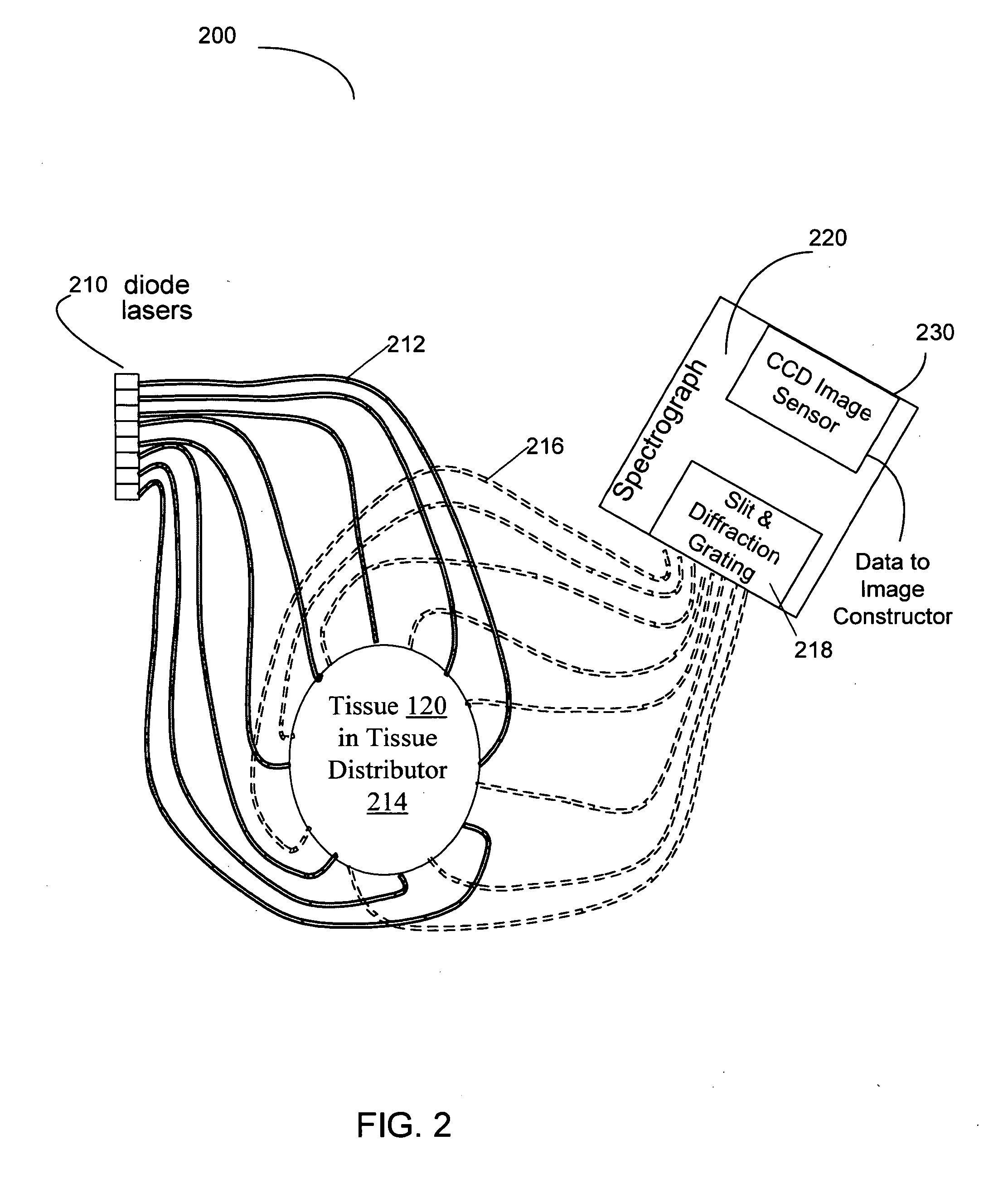

System and method for spectral-encoded high-rate hemodynamic tomography

An optical tomography system has a group of lasers for generating light of multiple distinct wavelengths within a first wavelength band. Light from these lasers is directed into mammalian tissue at laser-specific locations on the tissue, and light from the mammalian tissue is collected at a plurality of reception points. Collected light from each reception point is separated according to its wavelength, and received by a photodetector to produce path attenuation signals representing attenuation along paths between the laser-specific locations on the tissue and the reception points. Image construction apparatus generates a tomographic image of heme concentrations in the mammalian tissue from the path attenuation signals. In an alternative embodiment, there is a second group of lasers operating in a second wavelength band, and the image construction apparatus can generate an image of heme oxygenation In the mammalian tissue.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

Automated polarized light microscope combined with a spectroscopy/spectral imaging apparatus

InactiveUS20060082762A1Radiation pyrometryMaterial analysis by optical meansFtir spectraMid infrared

There is disclosed a device or apparatus that is particularly suitable for use in the analytical fields of polarized light microscopy and spectroscopy / spectral imaging. The apparatus comprises an automated polarized light microscope combined with means for achieving spectroscopic analysis. The apparatus may optionally include means for spectral imaging associated with the means for achieving spectroscopic analysis. Any means for achieving spectroscopic analysis may be utilized for example Raman, mid-infrared, near-infrared, ultraviolet, visible, luminescence, and the like.

Owner:CARGILL INC

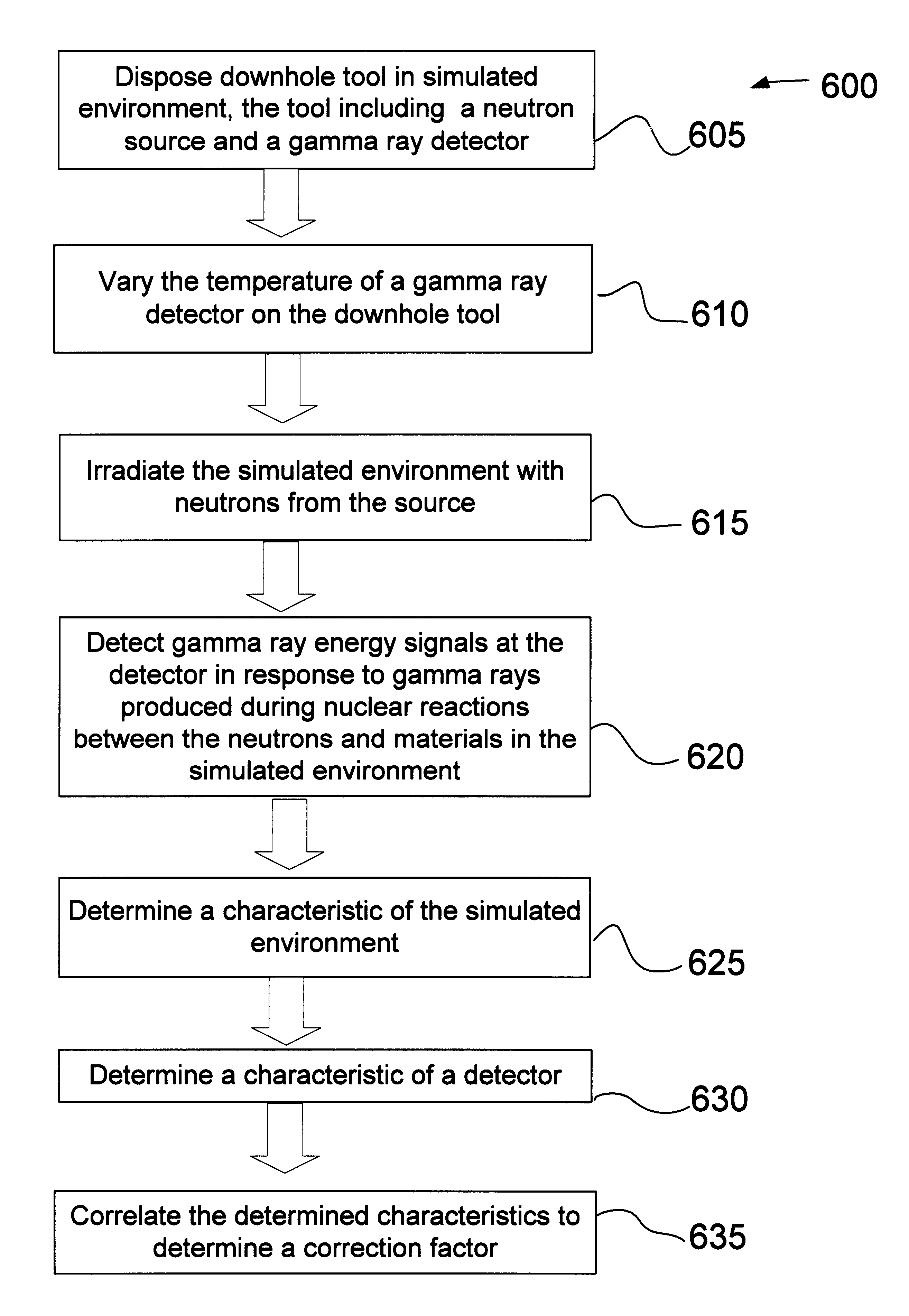

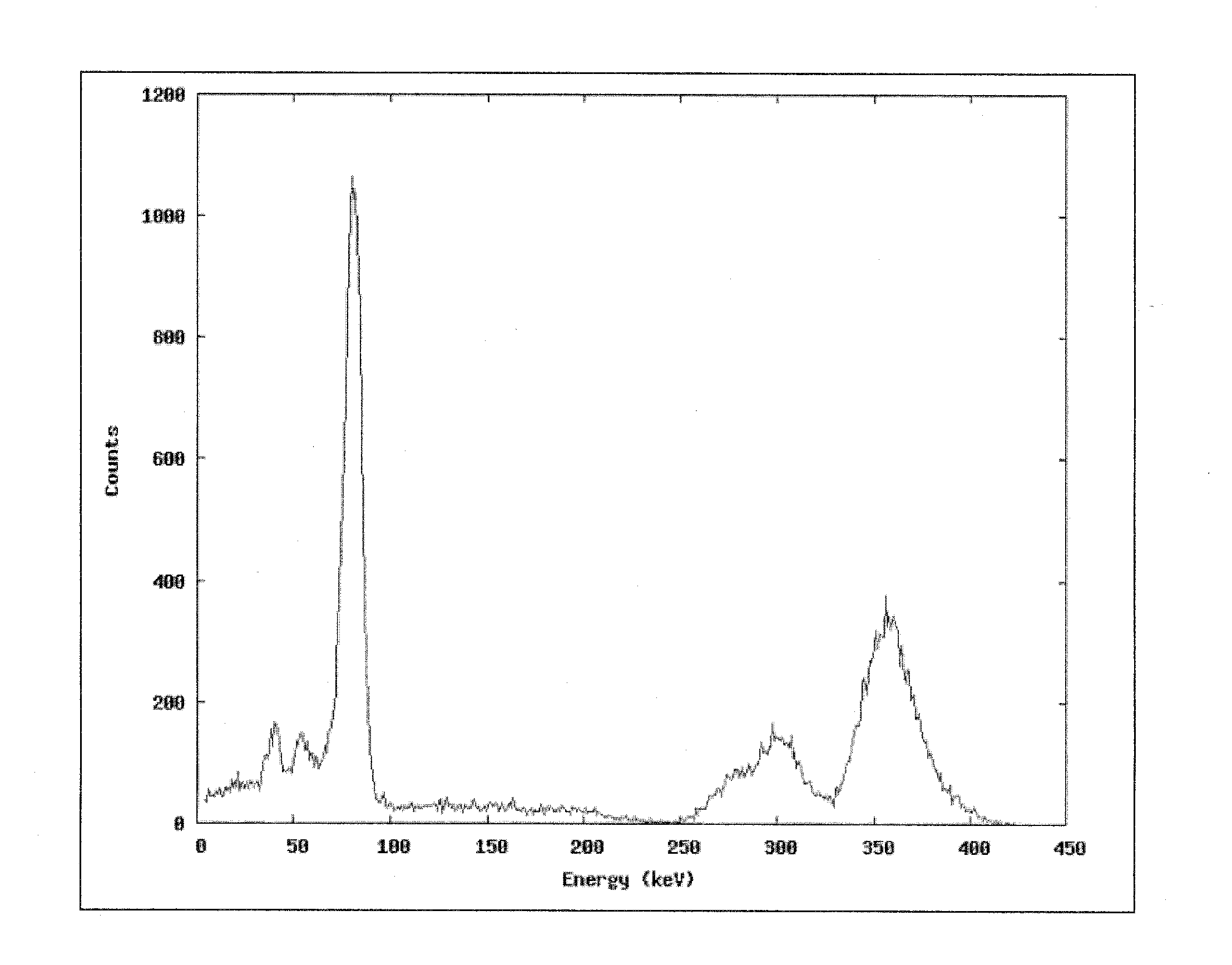

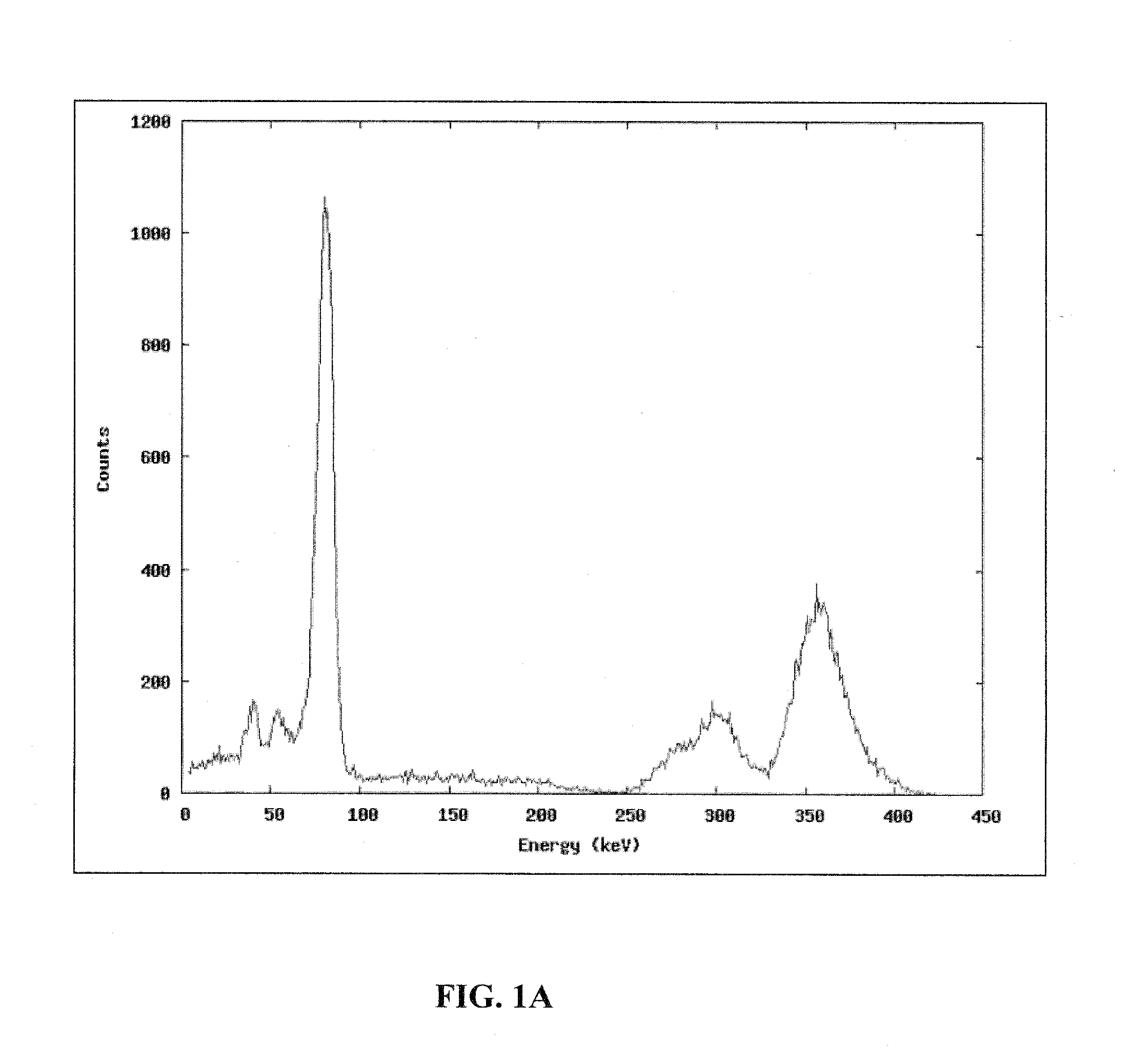

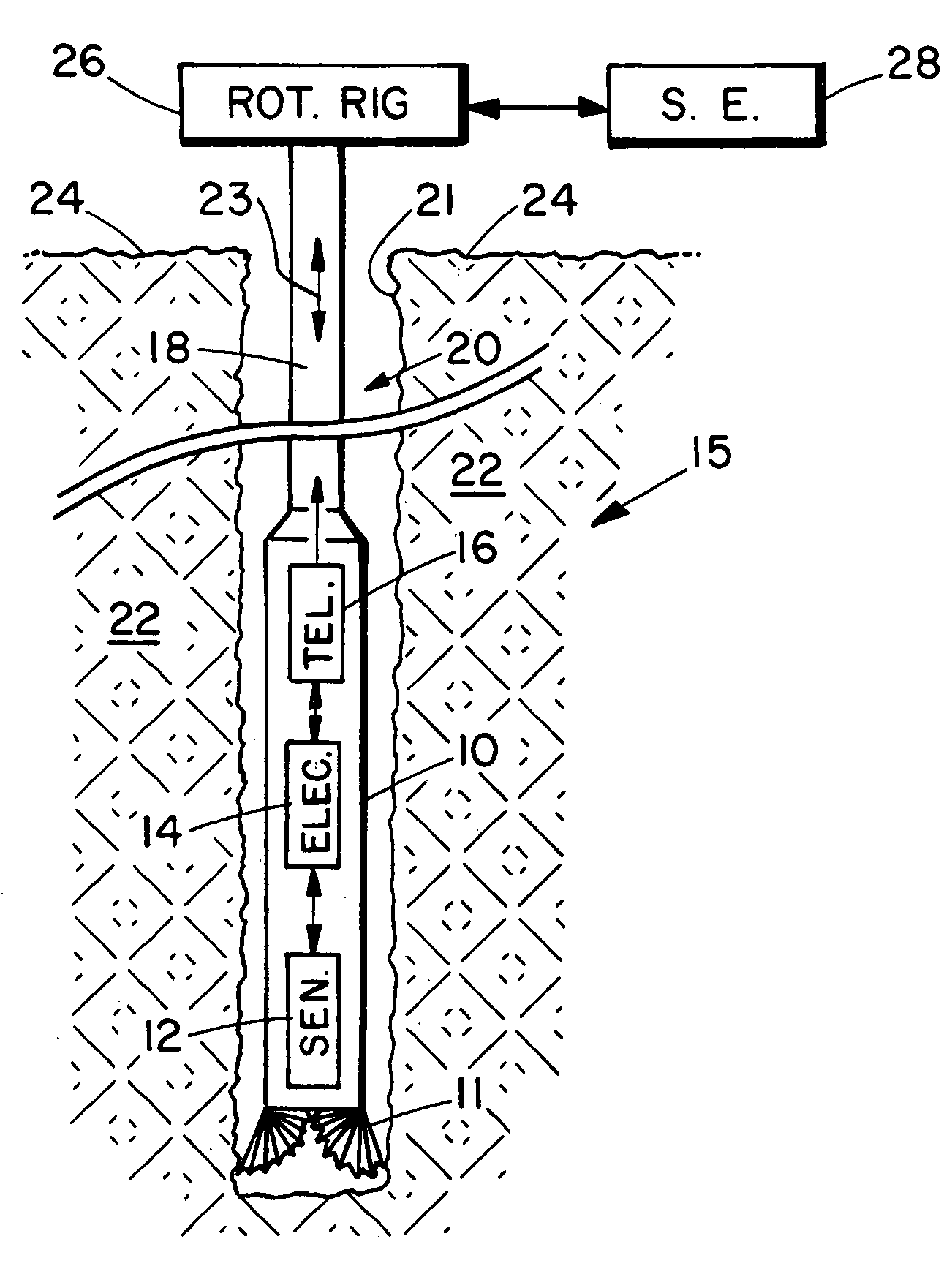

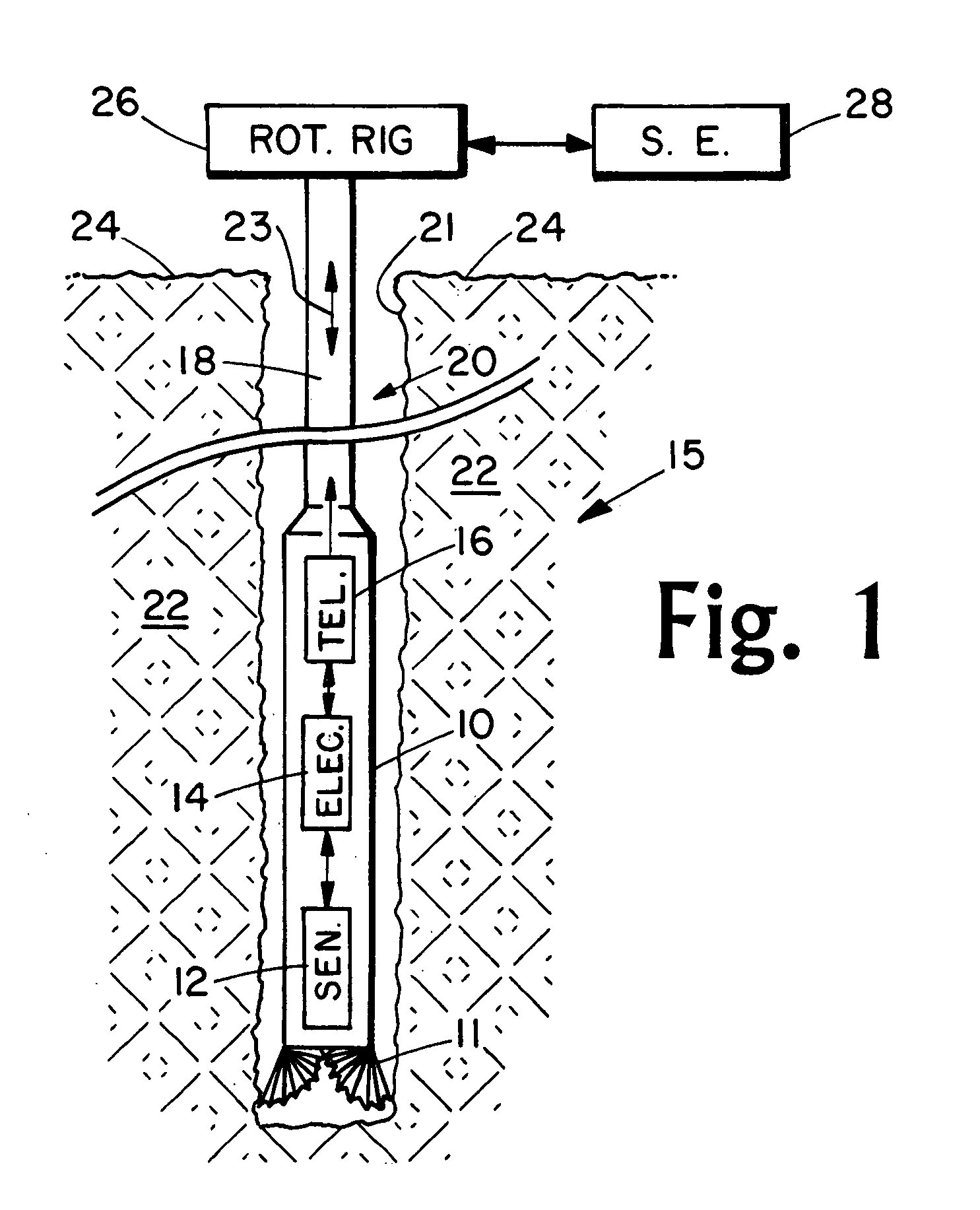

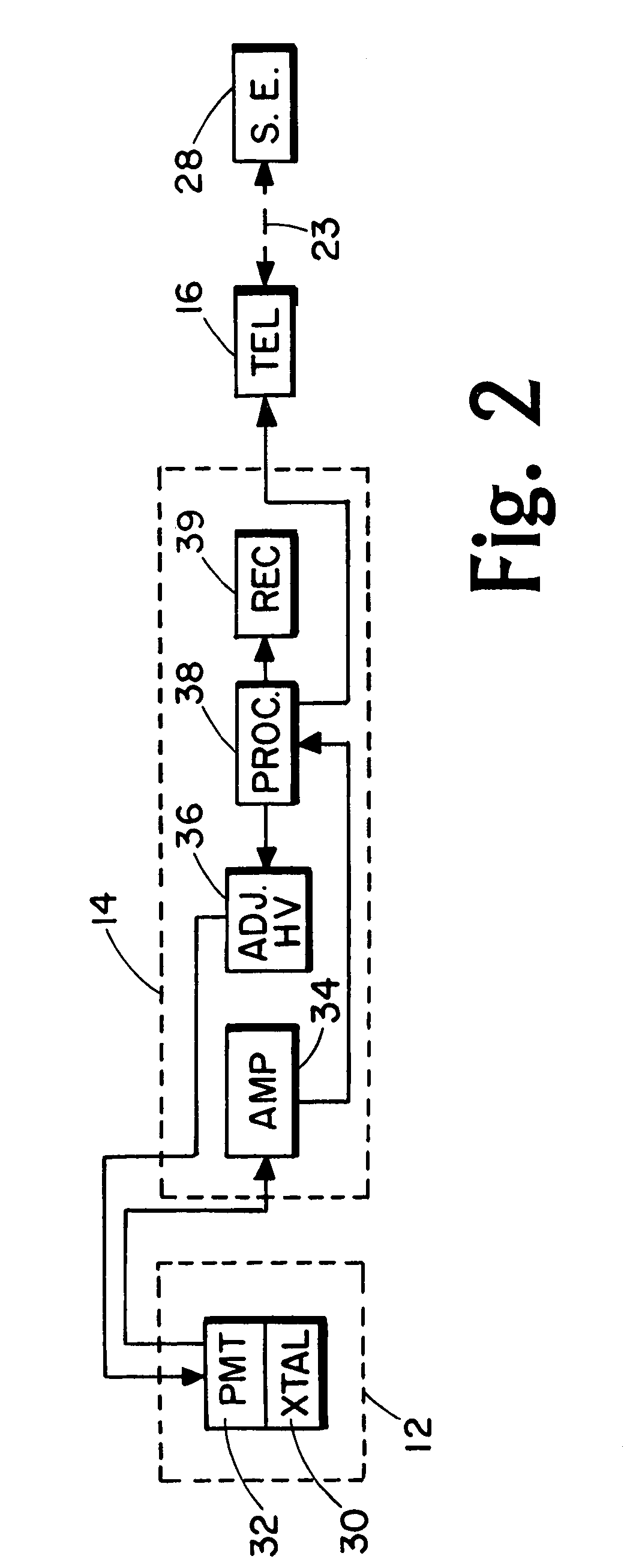

Downhole tool data correction method and apparatus

InactiveUS6289283B1Electric/magnetic detection for well-loggingSeismology for water-loggingFrequency spectrumFtir spectra

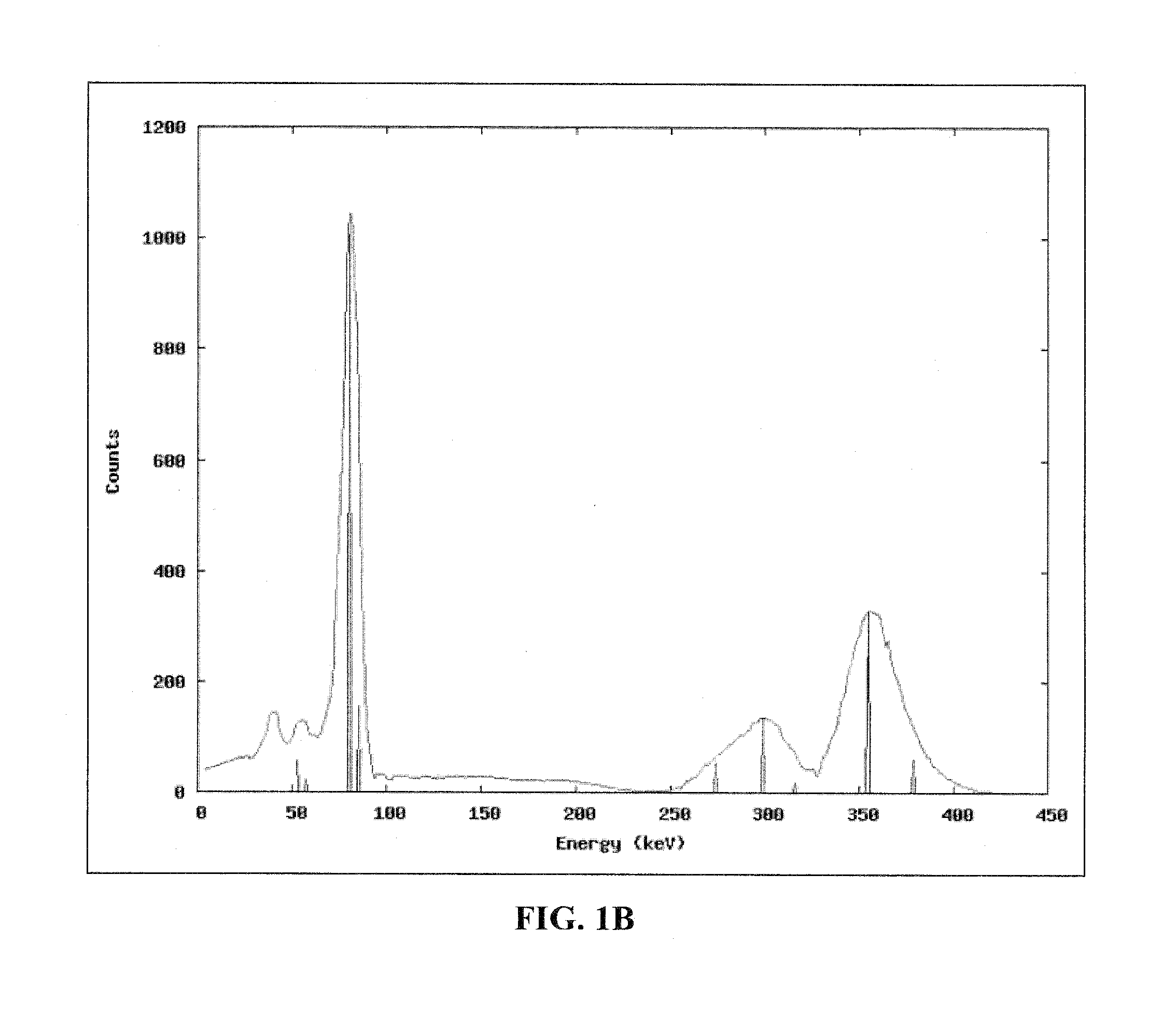

A method and apparatus are provided for correcting gamma ray data representative of gamma ray energies for spectral degradation. The method and apparatus include degrading reference gamma ray spectra. At least one correction factor is calculated between the degraded gamma ray spectra and the reference gamma ray spectra. The gamma ray data are then corrected using a calculated correction factor. Another method is provided for determining a correction factor for correcting data representative of gamma ray energies for spectral degradation. The method includes disposing a downhole tool in a simulated environment representative of actual downhole conditions, the tool including a neutron source and at least one gamma ray detector. The temperature of at least one of the gamma ray detectors of the tool is then varied while the simulated environment is irradiated with neutrons emitted from the neutron source. Gamma ray energy signals are then detected at the at least one detector in response to gamma rays produced during nuclear reactions between the neutrons and materials in and of the simulated environment. A characteristic of the simulated environment is then determined along with a characteristic of the at least one detector. The determined characteristics of the simulated environment and of the at least one detector are then correlated to determine at least one correction factor.

Owner:SCHLUMBERGER TECH CORP

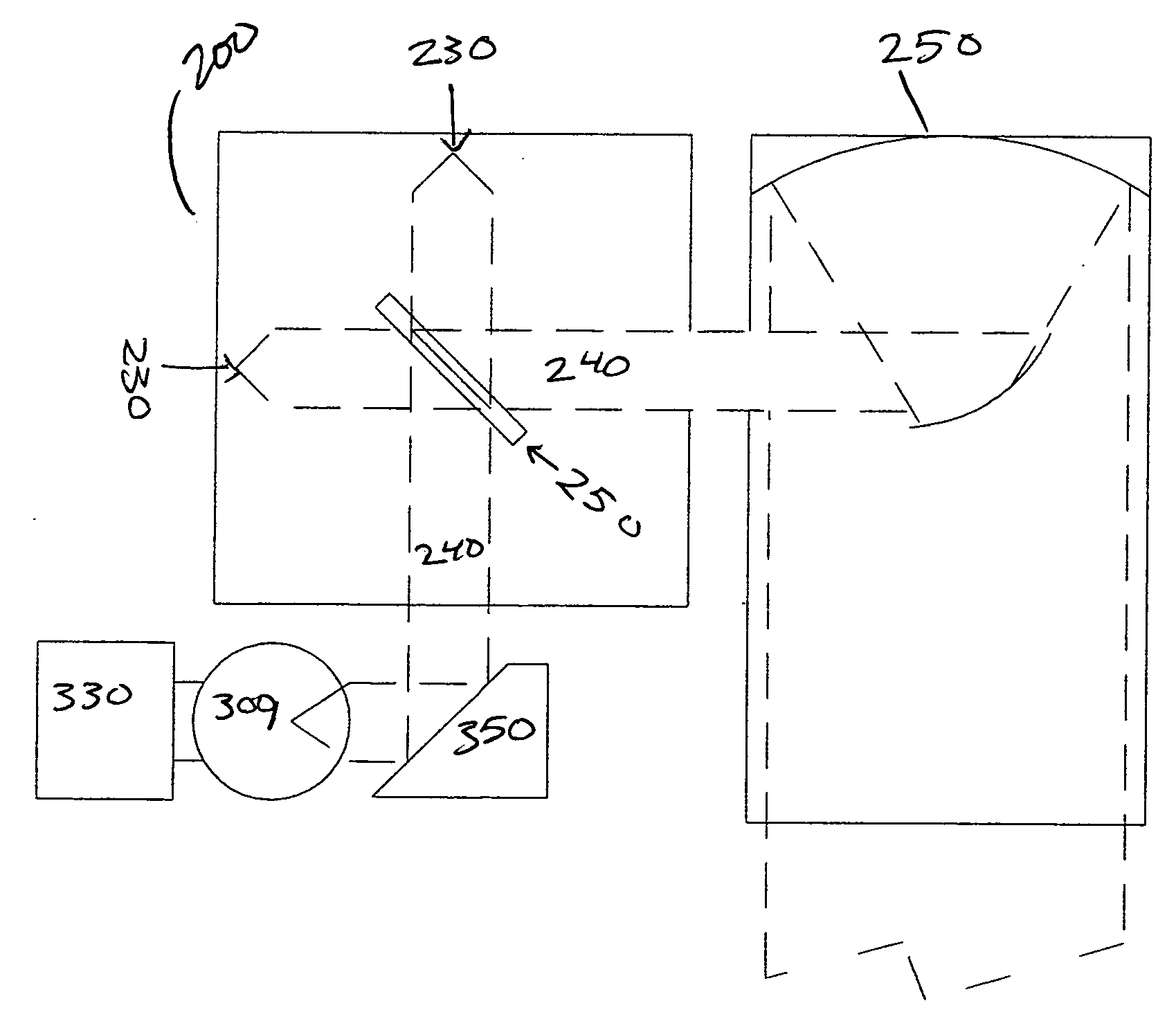

Imaging spectral device

InactiveUS20010052977A1Radiation pyrometrySpectrum investigationImaging analysisSpectral transmittance

An imaging spectral device for use in the spectrum image analysis for performing the spectroscopic analysis of the respective points in two dimensional field is disclosed. The device comprises an imaging spectral device composing a white-light source to illuminate an object to be measured, a tunable filter located in the optical path between the object and the white-light source, a driving mechanism for wavelength scanning of the tunable filter, and a control unit in which scanning rate of transmitting wavelength of the tunable filter is controlled by the above-mentioned driving mechanism in such a manner that the spectral transmittance of the tunable filter integrated within the exposure time becomes desired spectral distribution of the object to be measured.

Owner:SAITAMA UNIVERSITY

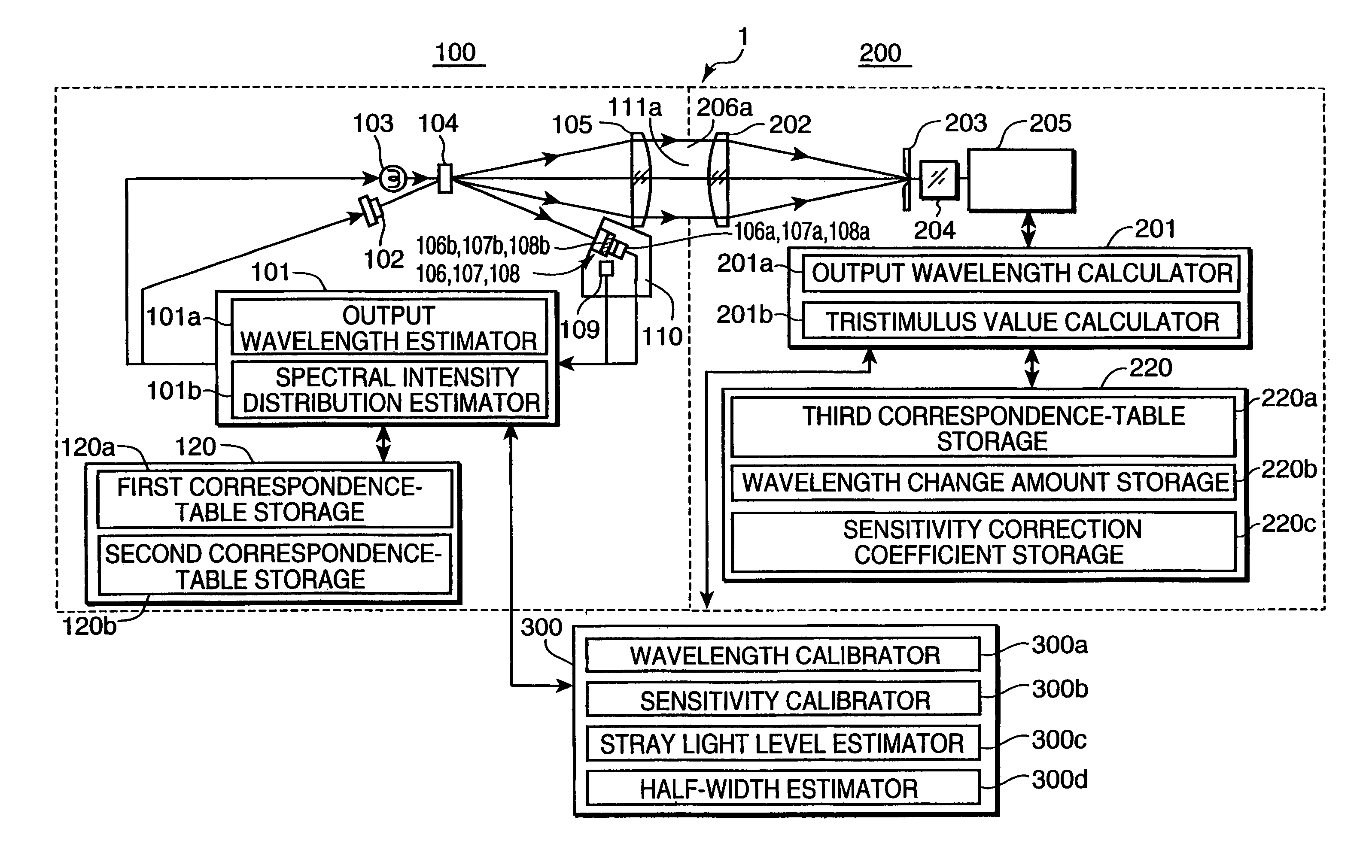

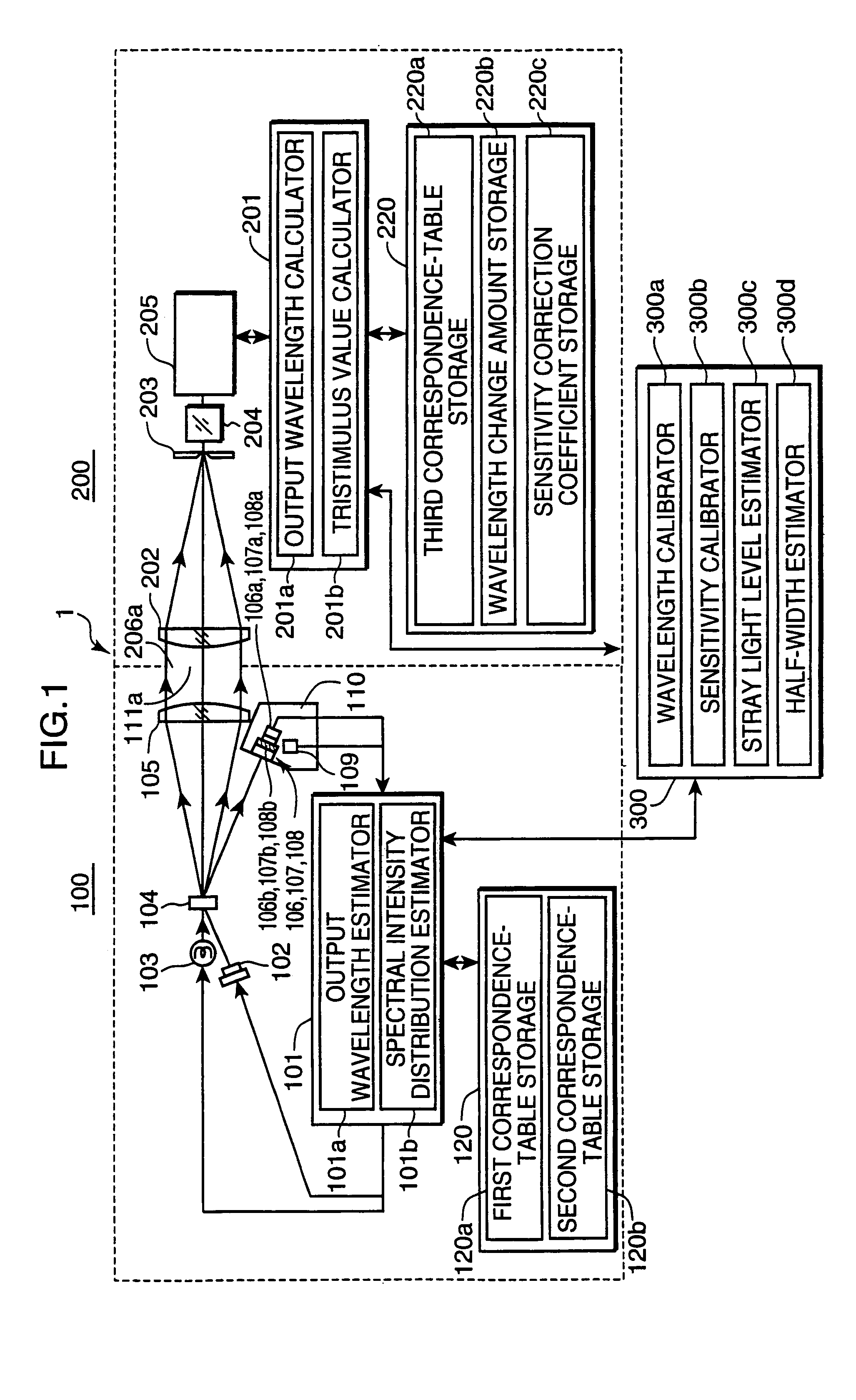

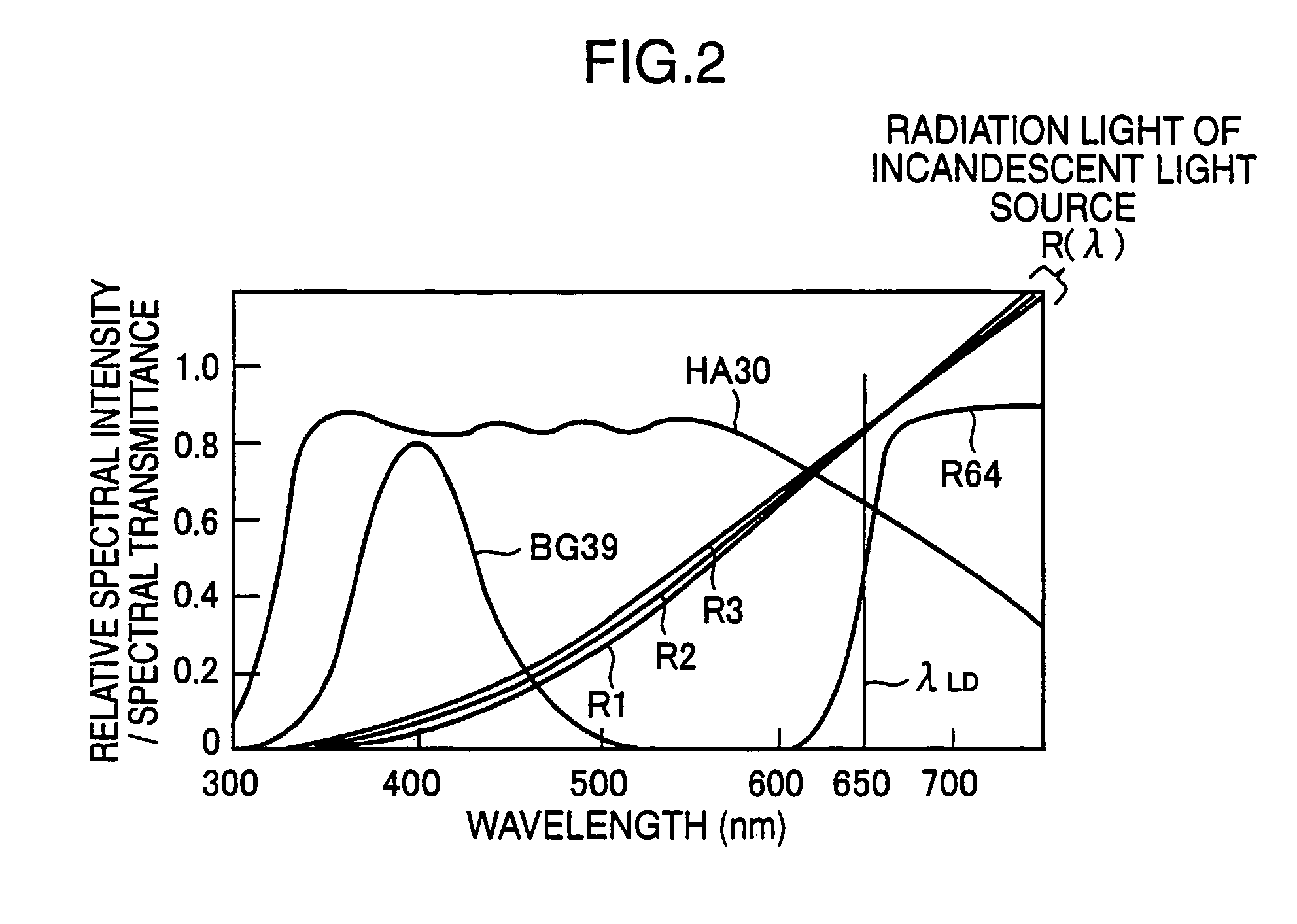

Calibration system for a spectral luminometer and a method for calibrating a spectral luminometer

ActiveUS7151600B2Calibrate the wavelength and sensitivity of the spectral luminometerRadiation pyrometrySpectrum investigationFtir spectraLength wave

A calibration light source outputs emission lines having a known emission-line wavelength, a spectral luminometer to be calibrated measures an emission-line output of the calibration light source, and a system control unit calibrates the wavelength of the spectral luminometer by estimating the wavelength of the emission-line output from ratios of outputs of a light receiving unit at a plurality of measurement wavelengths neighboring an emission-line wavelength and estimating a wavelength change amount from a difference between the estimated wavelength of the emission-line output and the known emission-line wavelength. The wavelength and the sensitivity of a spectral luminometer can be calibrated at a user side.

Owner:KONICA MINOLTA SENSING INC

Method and system for raman, fluorescence, lithographic, stimulated emission and photochemical imaging beyond the diffraction limit

InactiveUS20120069332A1Improve signal-to-noise ratioMinimizes parasitic two-photon absorption effectsSpectrum investigationPhotomechanical apparatusResistFluorescence

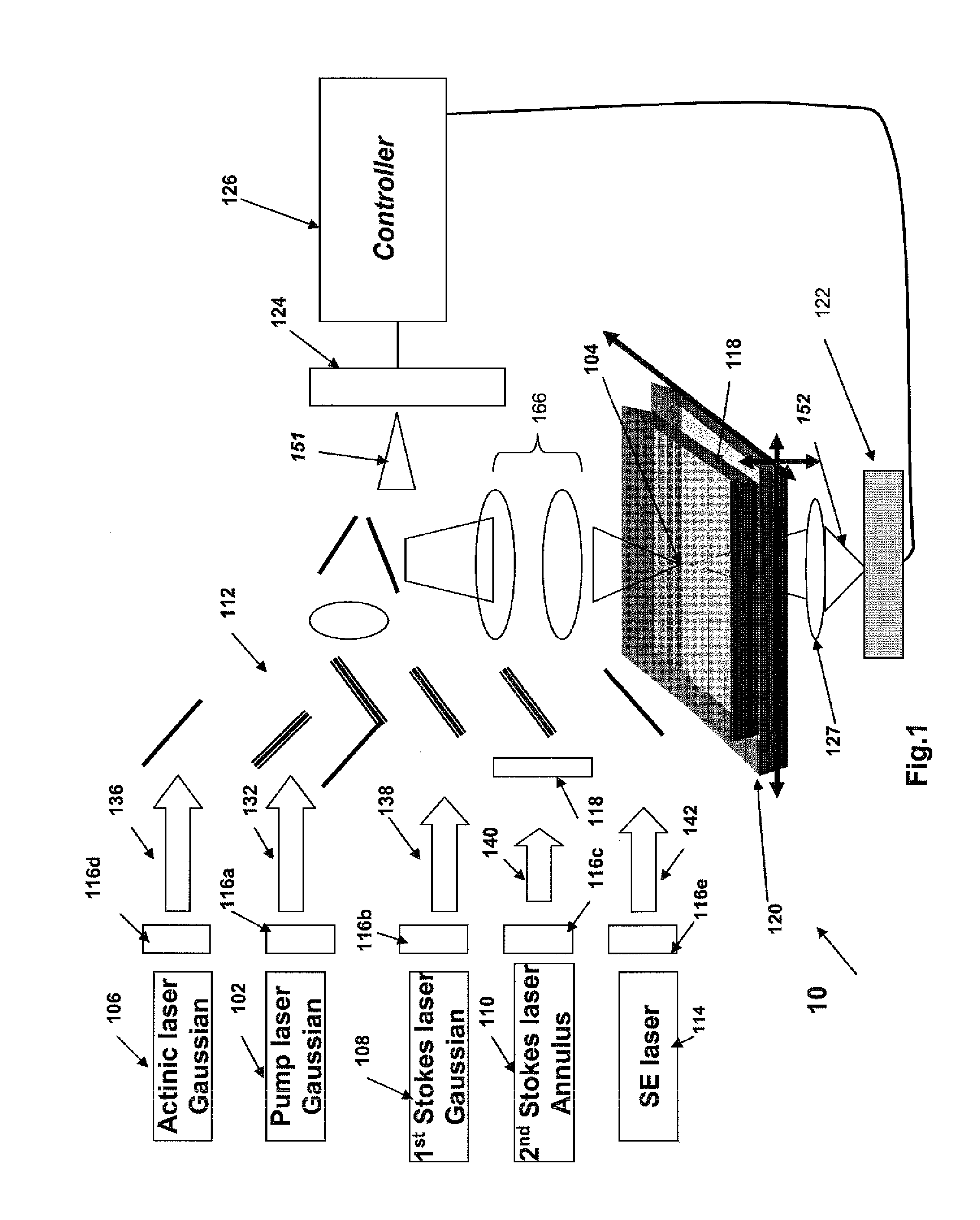

Systems and methods for hyper-resolution beyond the diffraction limit of optical microscopes for applications in spectroscopy, absorption and lithographic photochemical patterning are described. These systems are based on interference of a pump pulse and a Stokes laser pulse which interfere to localize the population of an excited vibrational state in an area that is smaller than the scanning resolution of the microscope. Another (interfering) Stokes pulse has an annular shape at focus and destructively interferes with the the Stokes laser pulse. This destructive interference causes narrowing of the population distribution of the vibrational excited state well below the diffraction limit, which in turn localizes the population of the central electronic excited state by a separate actinic laser pulse having a lower energy than the ground state excitation energy of the molecule.A stepped photolithography system uses two photomasks to produce photoresist images capable of printing features smaller than 10 nm.

Owner:FREL ROBERT D

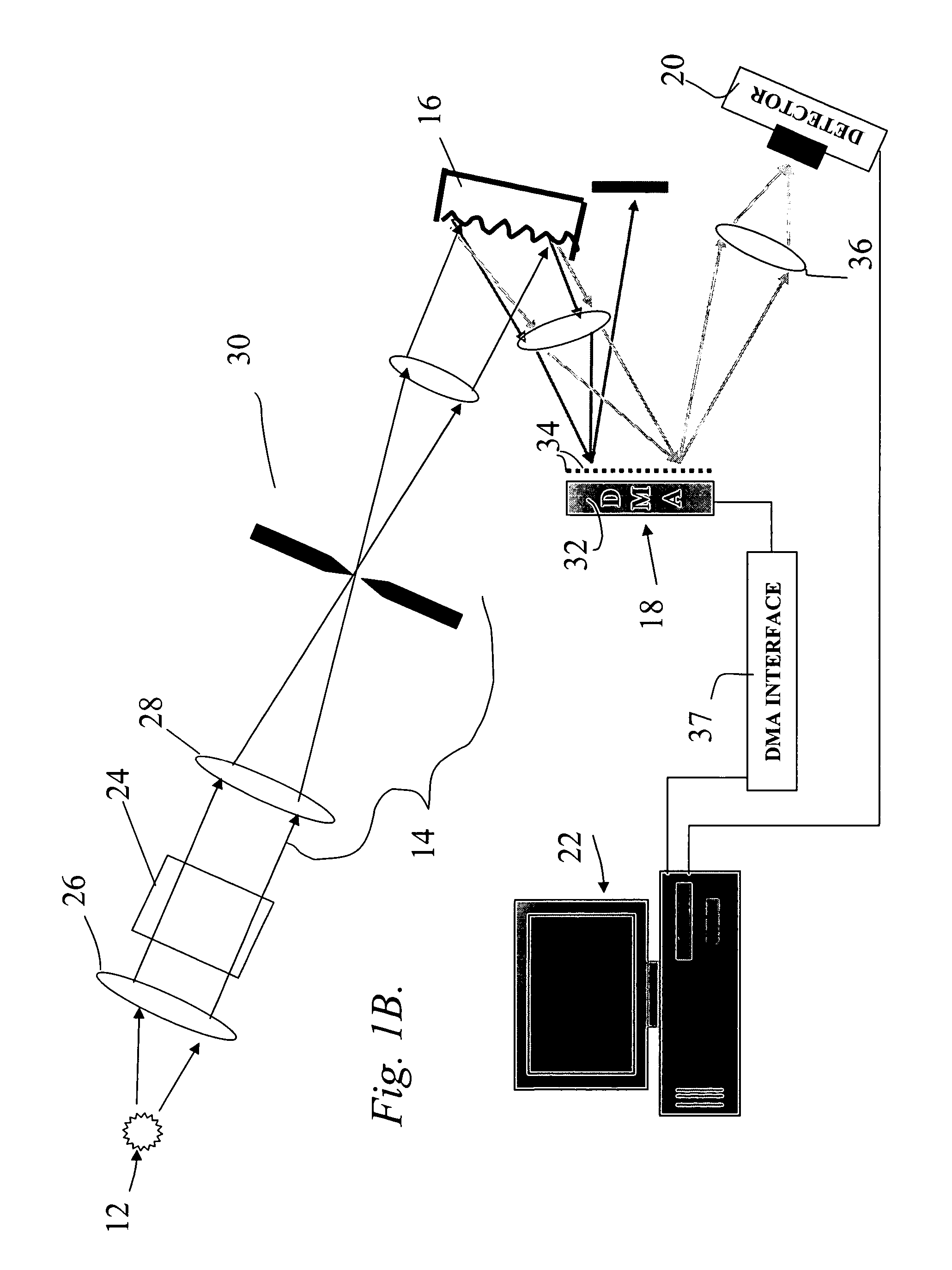

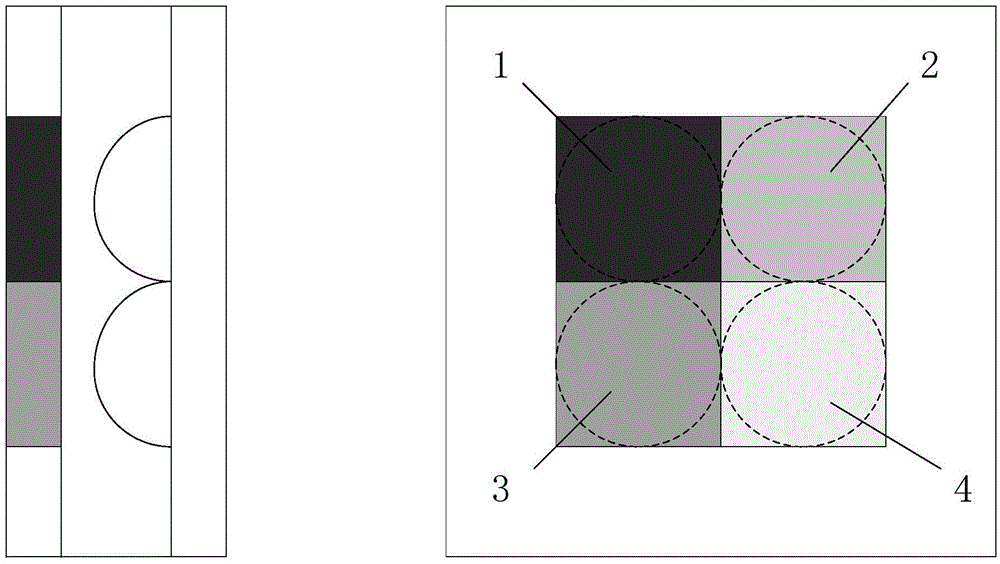

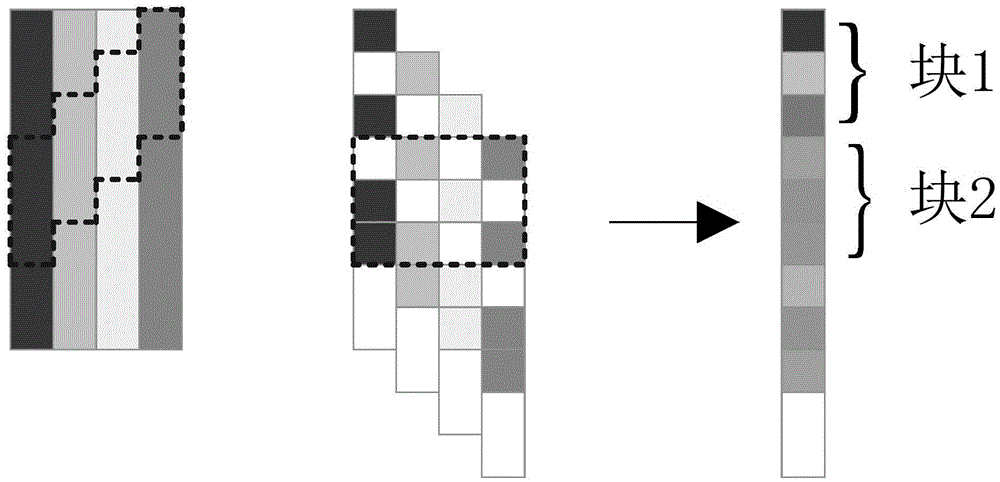

Coding and modulation for hyperspectral imaging

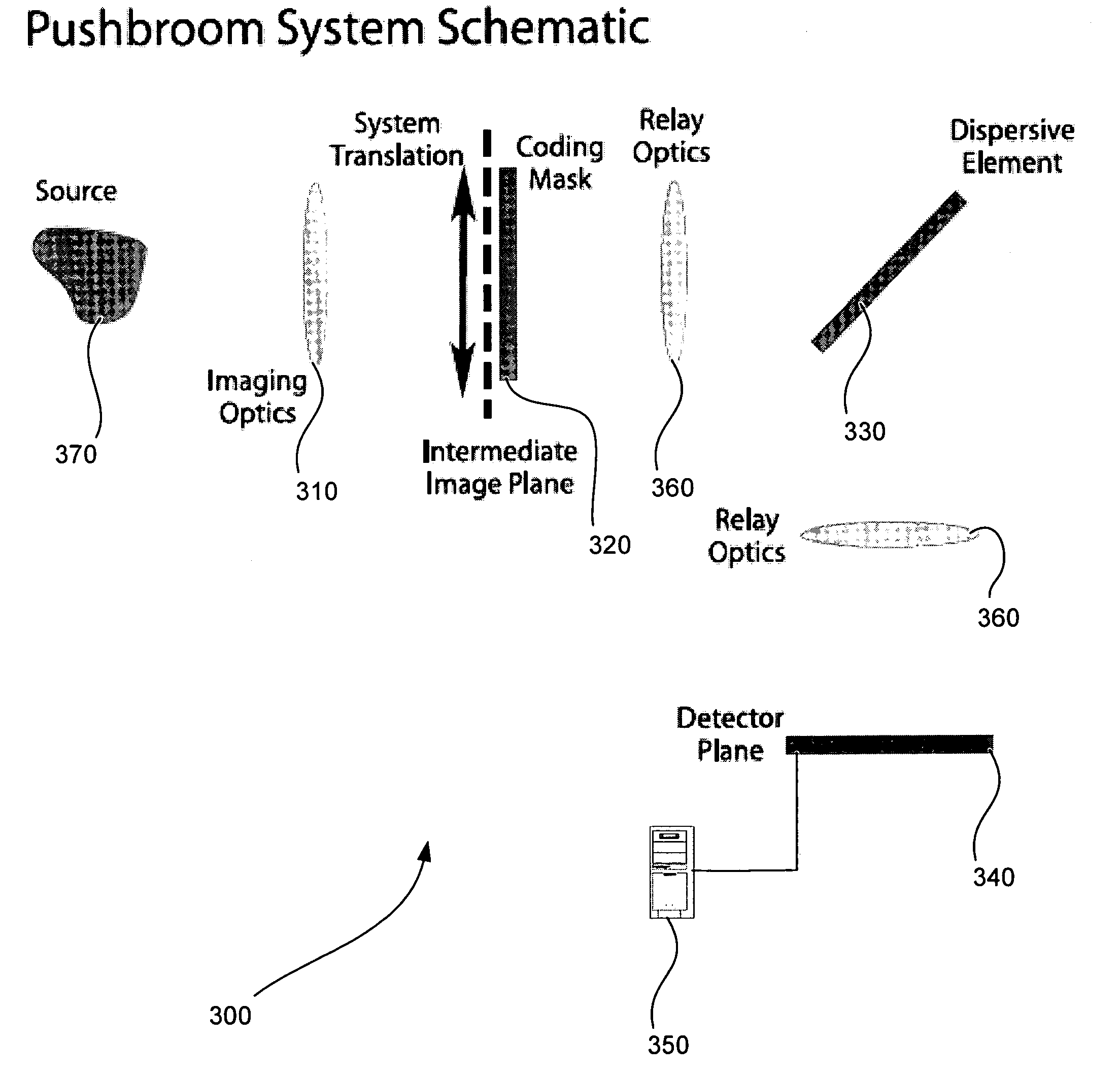

Embodiments of the present invention relate to systems and methods for spectral imaging. In one embodiment, an image of the scene is formed on a coded aperture of a spectrometer. A coded image from the coded aperture is detected on a two-dimensional detector array of the spectrometer through a spectrally dispersive element of the spectrometer. Data from the two-dimensional detector array is collected as the coded image is varied over time. The spectral image is estimated from the data collected and the variation of the coded image over time. The data collected is varied over time through translation, rotation, and defocus.

Owner:DUKE UNIV

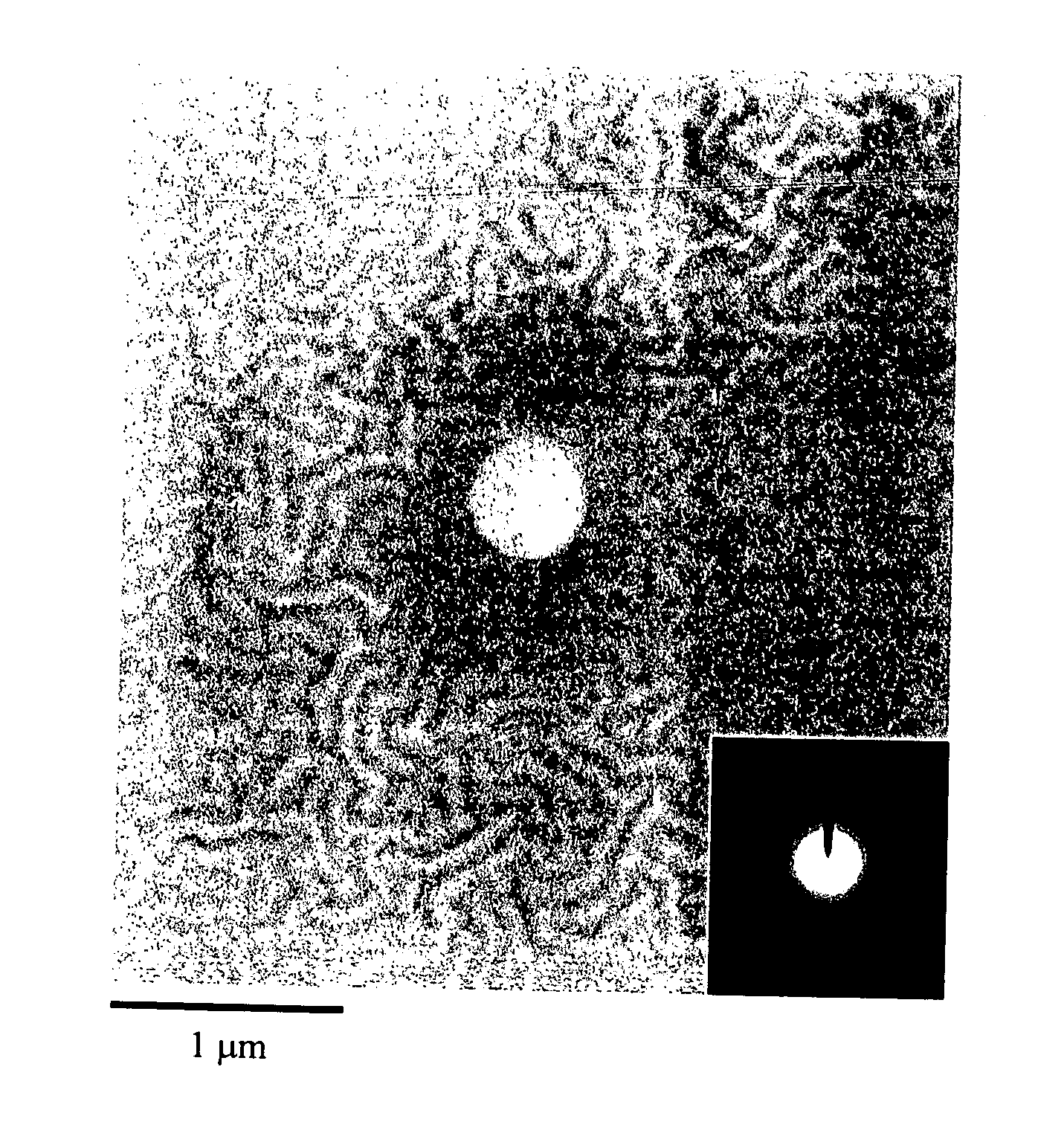

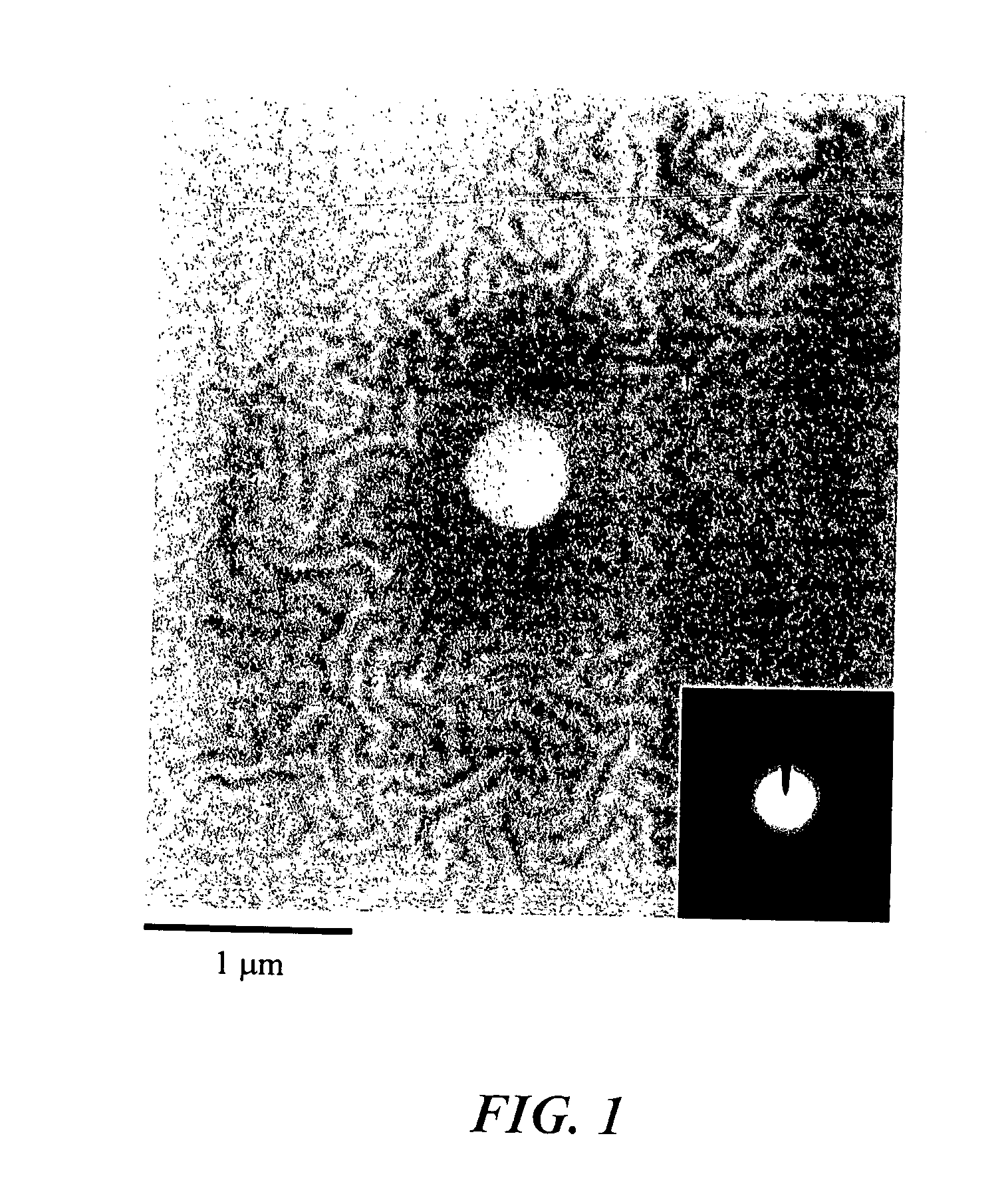

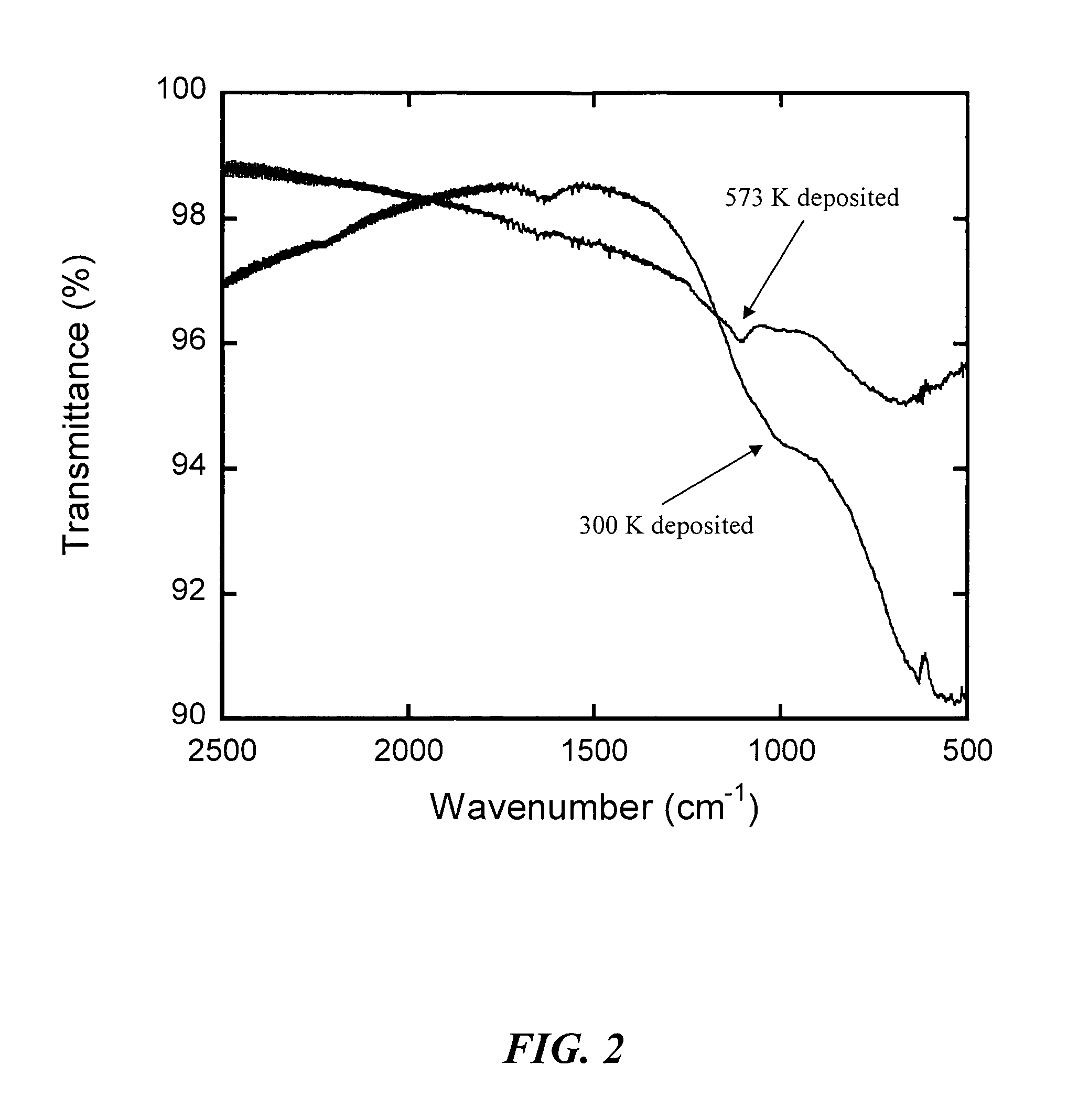

Ultra-hard low friction coating based on AlMgB14 for reduced wear of MEMS and other tribological components and system

InactiveUS20050100748A1Superior protective coatHigh hardnessVacuum evaporation coatingSolid-state devicesMicroelectromechanical systemsAlloy

Performance and reliability of microelectromechanical system (MEMS) components enhanced dramatically through the incorporation of protective thin film coatings. Current-generation MEMS devices prepared by the LIGA technique employ transition metals such as Ni, Cu, Fe, or alloys thereof, and hence lack stability in oxidizing, corrosive, and / or high temperature environments. Fabrication of a superhard, self-lubricating coating based on a ternary boride compound AlMgB14 is described in this letter as a potential breakthrough in protective coating technology for LIGA microdevices. Nanoindentation tests show that hardness of AlMgB14 films prepared by pulsed laser deposition ranges from 45 GPa to 51 GPa, when deposited at room temperature and 573 K, respectively. Extremely low friction coefficients of 0.04-0.05, which are thought to result from a self-lubricating effect, have also been confirmed by nanoscratch tests on the AlMgB14 films. Transmission electron microscopy studies show that the as-deposited films are amorphous, regardless of substrate temperature; however, analysis of FTIR spectra suggests that the higher substrate temperature facilitates formation of the B12 icosahedral framework, therefore leading to the higher hardness.

Owner:IOWA STATE UNIV RES FOUND

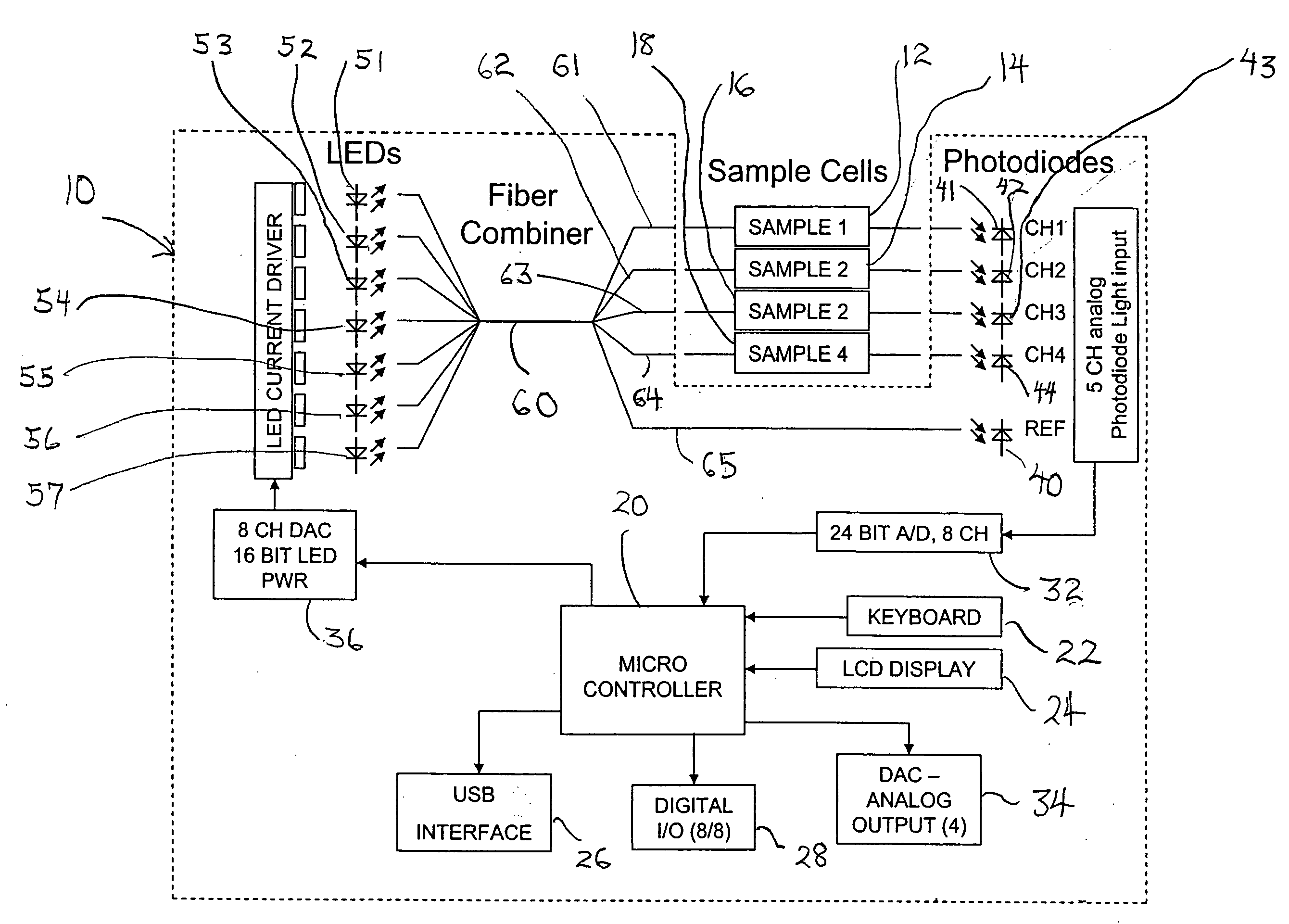

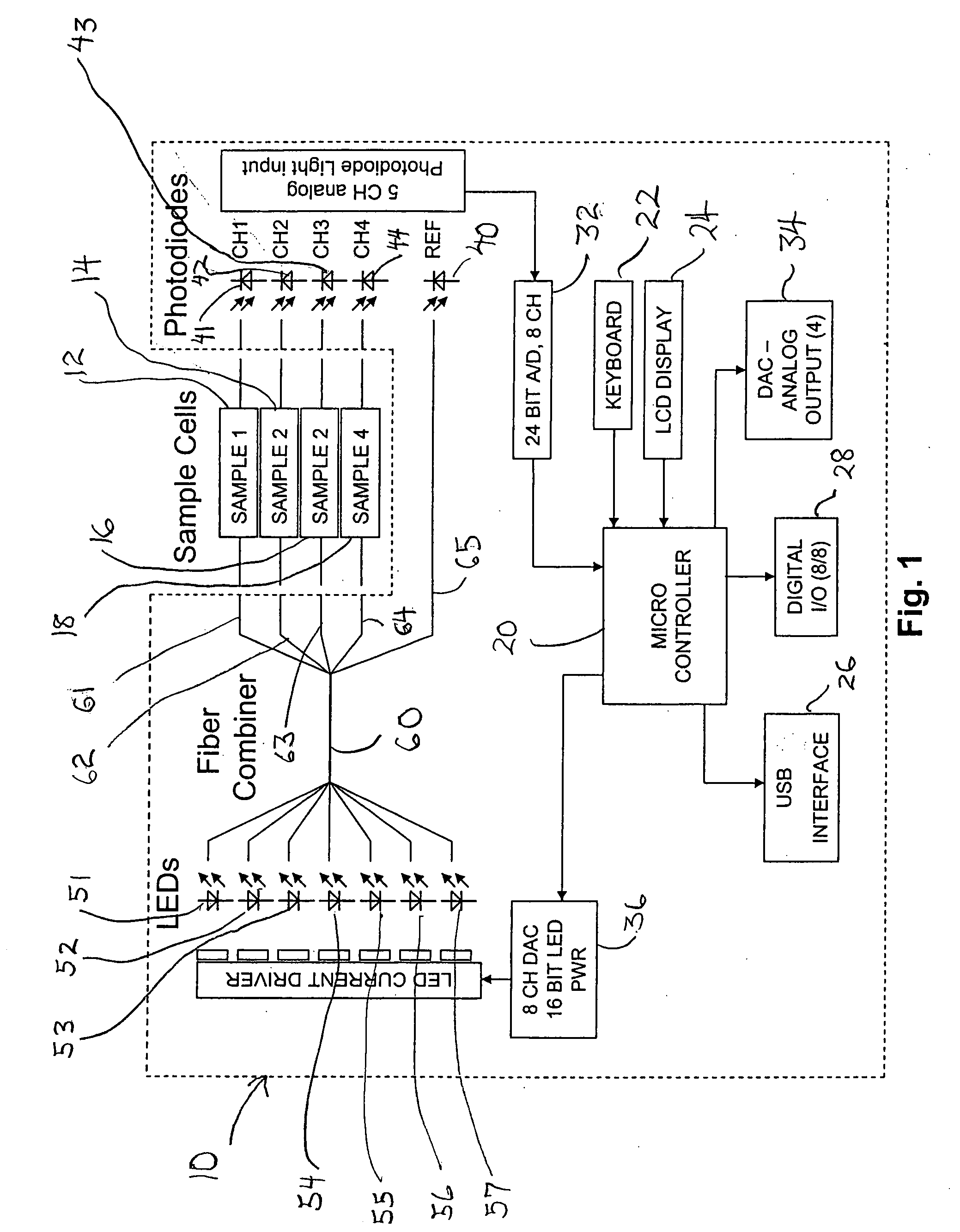

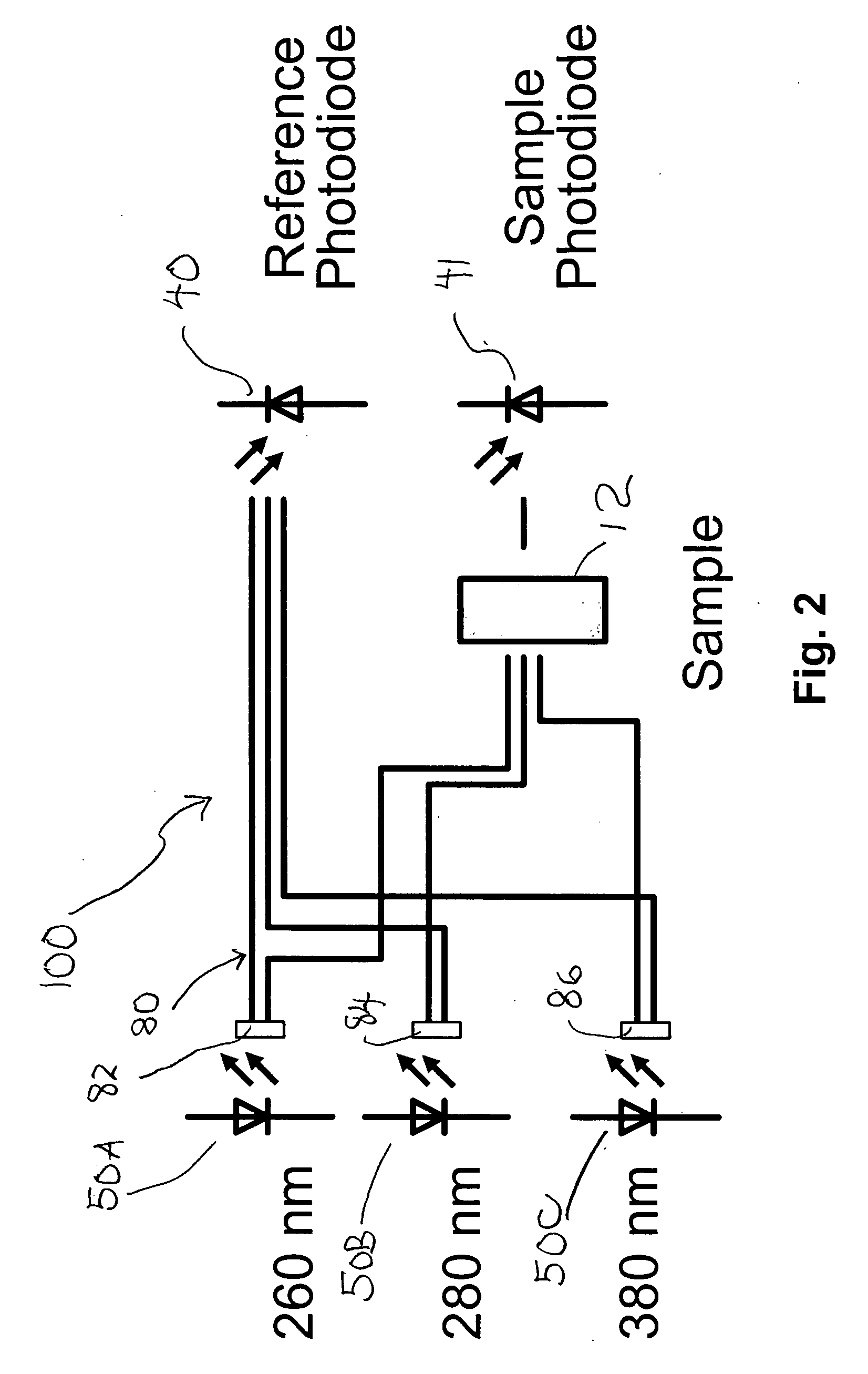

Self referencing LED detection system for spectroscopy applications

InactiveUS20080174768A1Attenuation bandwidthAccurate measurementOrganic chemistryMaterial analysis by optical meansSpectroscopyAbsorbance

A light emitting diode (LED) based detection system is employed for spectroscopy based applications. LEDs are used as monochromatic light sources for applications at specific and pre-defined wavelengths. Spectrographic information is generated using LEDs of different wavelengths ranging from 260 nm to 1400 nm. Multiple wavelength information is generated by coupling light from each LED into an intensity and mode mixing fiber bundle. A dual beam approach of using a reference and a sample photodiode ensures automatic drift correction. Interference filters at the LED input fiber reduce the spectral bandwidth of the monochromatic light emission to a useful 10 nm bandwidth by cutting off the LEDs trailing emission distribution allowing for absorbance measurements similar to typical spectrometers.

Owner:WORLD PRECISION INSTR

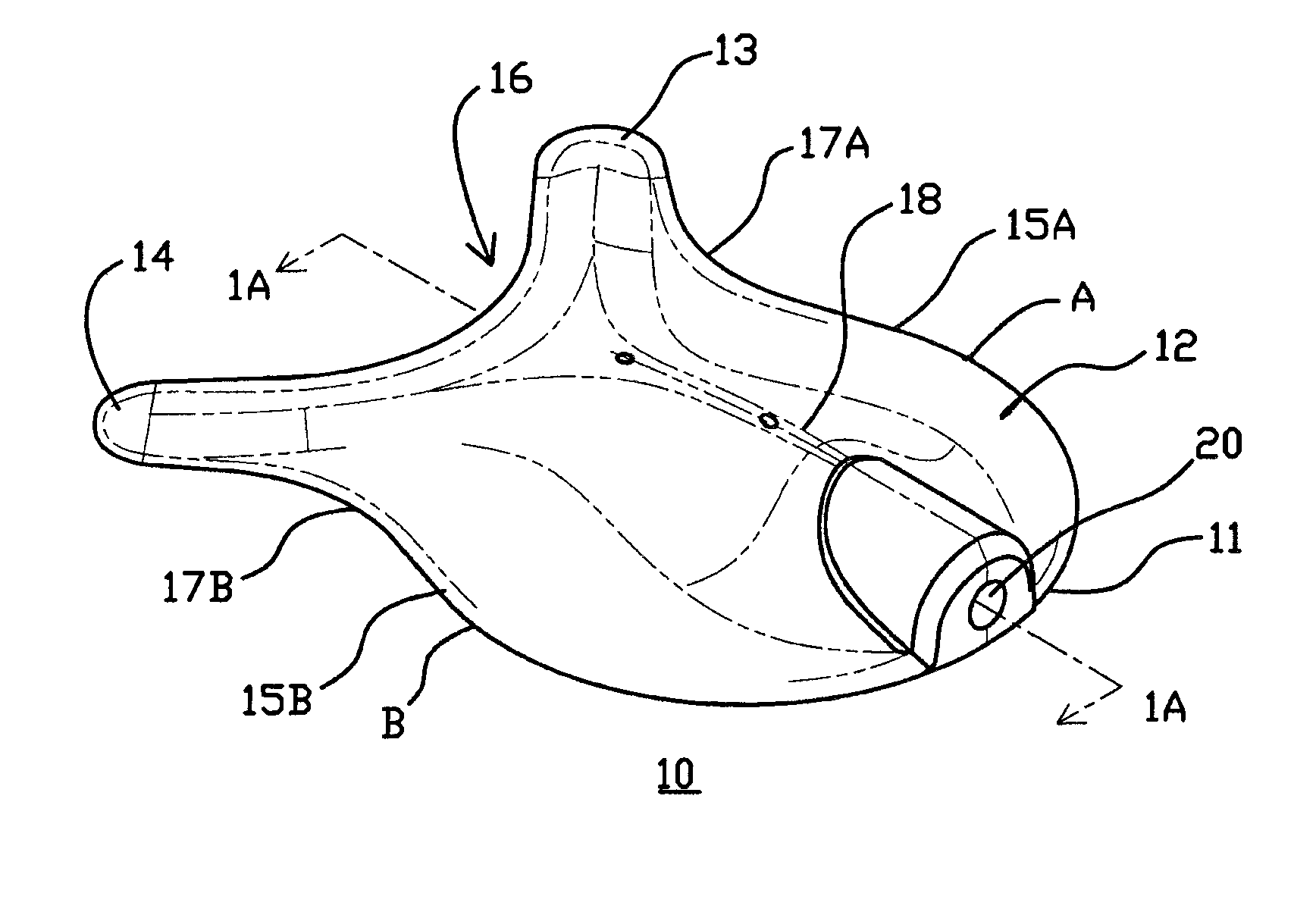

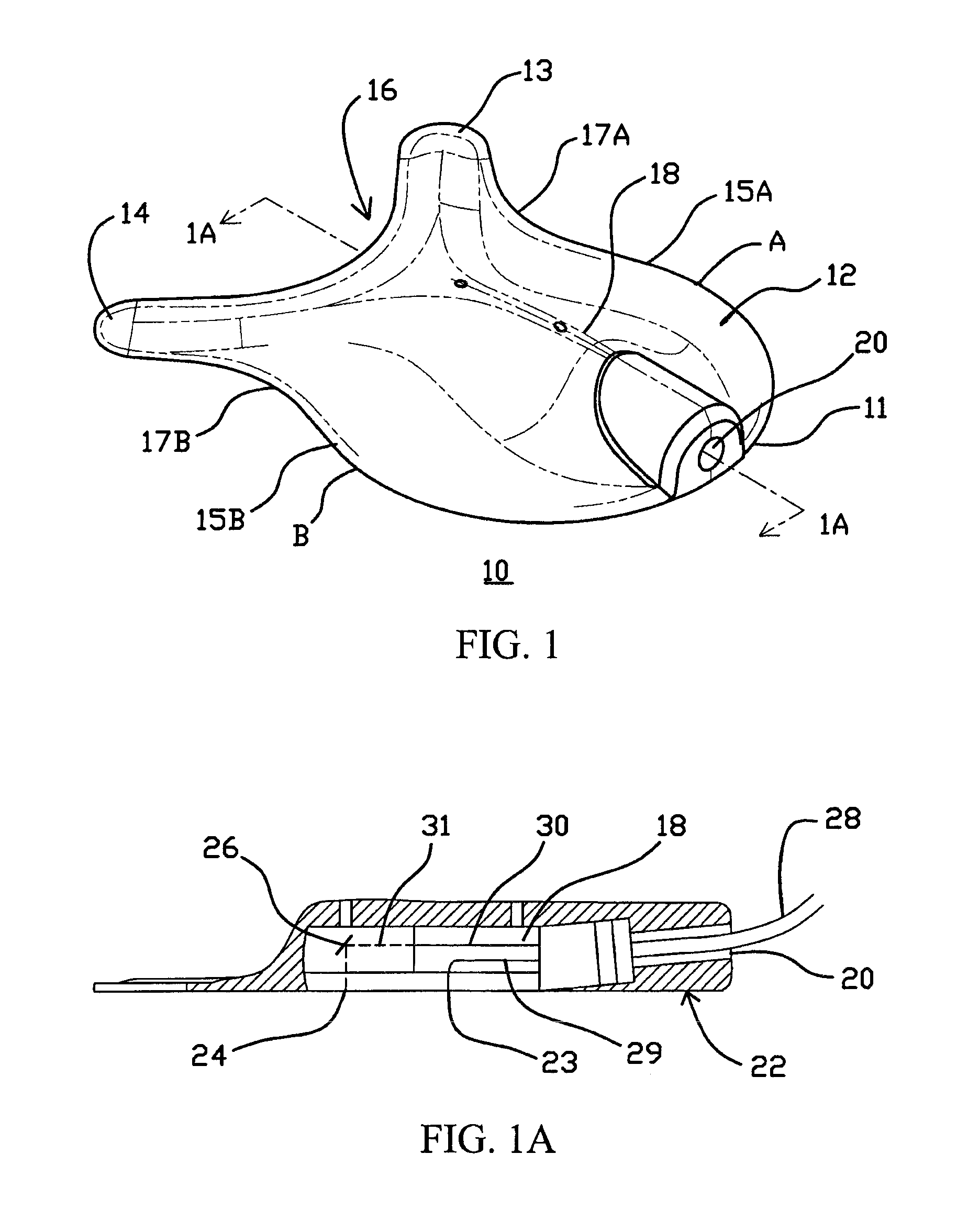

Patient interface for spectroscopy applications

A patient interface and a method of installing a patient interface for a spectroscopy kit on a patient. The patient interface includes a butterfly-shaped patient interface with a cap on top of the patient interface and in proximity to an optical head.

Owner:HUTCHINSON TECH

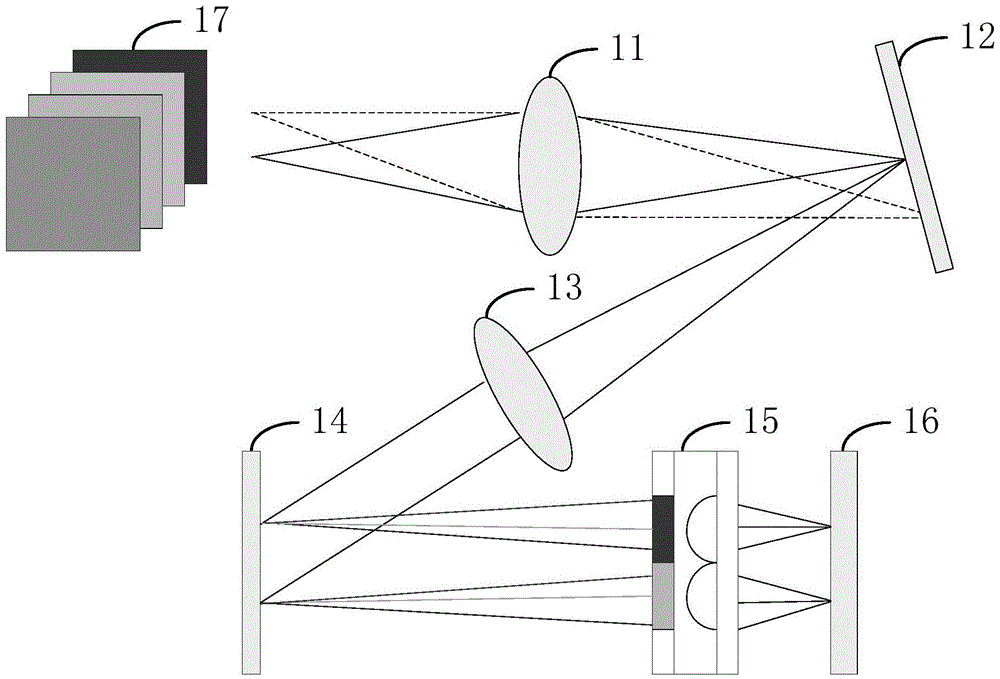

Coded aperture spectral imaging system

ActiveCN105675136AReduce time complexityImprove spatial resolutionSpectrum investigationImage codingGratingHybrid image

The invention is suitable for the spectral imaging technical field, and provides a coded aperture spectral imaging system which comprises a preposition imaging system, a digital micro-mirror, a collimation system, a reflection raster, a microlens array and a detector. The microlens array comprises a plurality of microlenses; the filtering bands of the filtering layer on each microlens are different; the preposition imaging system images an object to be measured on the digital micro-mirror; the image after coded modulation is incident on the reflection raster through the collimation system to perform light splitting; a space spectrum mixing image is obtained after light splitting; a plurality of images are obtained through the microlens array with a filtering function; the detector simultaneously receives the plurality of images, and performs fusion decoding on the plurality of images to obtain the spectral information of the object to be measured. The coded aperture spectral imaging system can maintain system single rapid measurement, and meanwhile substantially improve system spatial resolution.

Owner:SHENZHEN INST OF ADVANCED TECH

Method and Apparatus for Spectral Deconvolution of Detector Spectra

InactiveUS20100305873A1Generate accuratelyAccurate methodMaterial analysis using wave/particle radiationSolid-state devicesHigh energySodium iodide

Embodiments of the invention pertain to a method and apparatus for spectral deconvolution of detector spectra. In a specific embodiment, the method can be applied to sodium iodide scintillation detector spectra. An adaptive chi-processed (ACHIP) denoising technique can be used to remove the results of stochastic noise from low-count detector spectra. Embodiments of the ACHIP denoising algorithm can be used as a stand alone tool for rapid processing of one dimensional data with a Poisson noise component. In a specific embodiment, the denoising technique can be combined with the spectral deconvolution method. Embodiments of the denoising technique and embodiments of the deconvolution method can be applied to any detector material that provides a radiation spectrum. Specific embodiments can incorporate one or more of the following for spectral deconvolution: denoising, background subtraction, detector response function generation, and subtraction of detector response functions. Photopeaks can be rapidly identified, starting at the high-energy end of the spectrum. The detector response functions can be estimated for photopeaks with a combination of Monte Carlo simulations and simple transformations.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Gain stabilization apparatus and methods for spectral gamma ray measurement systems

ActiveUS7202456B2Minimize degradationMaximizing counting rateRadiation pyrometryX-ray spectral distribution measurementBiological activationLogging while drilling

Owner:WEATHERFORD TECH HLDG LLC

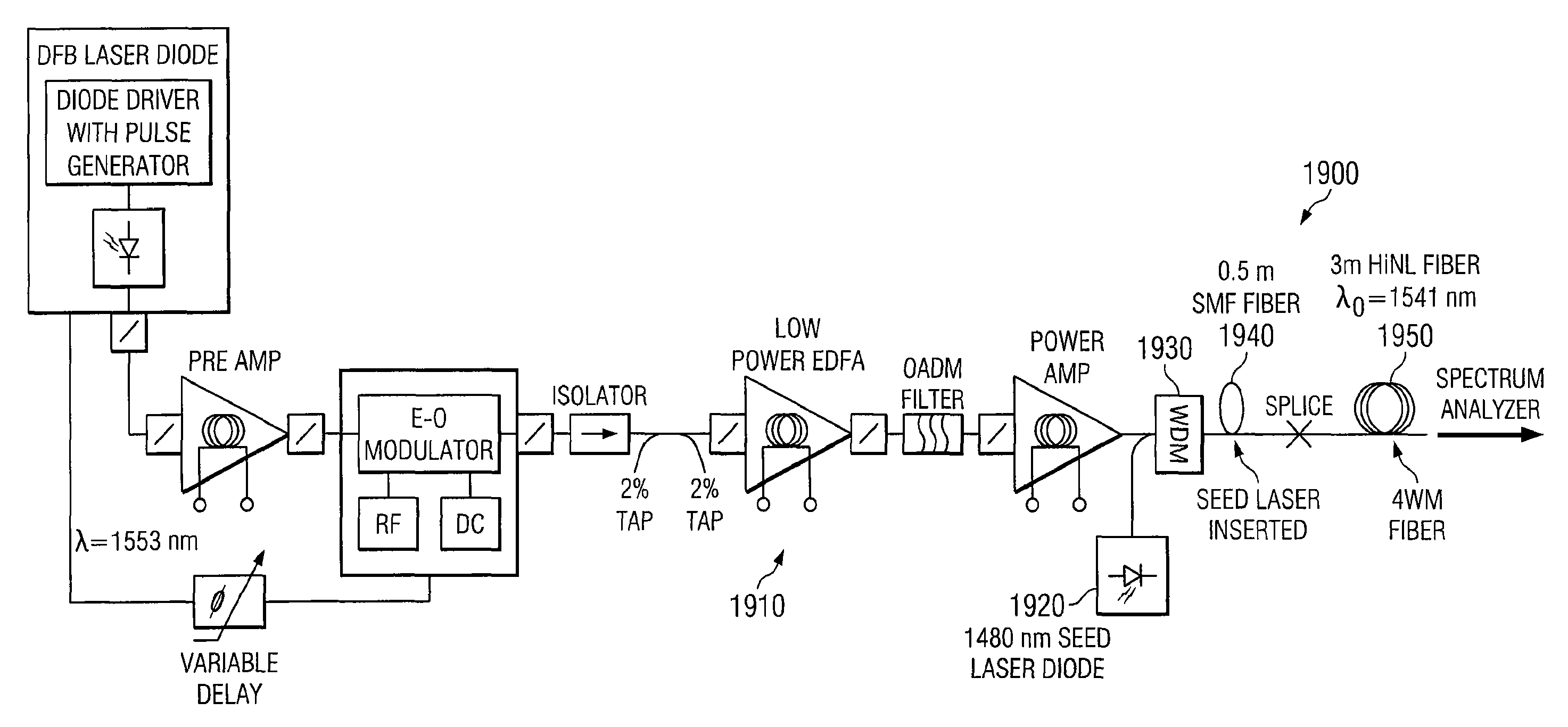

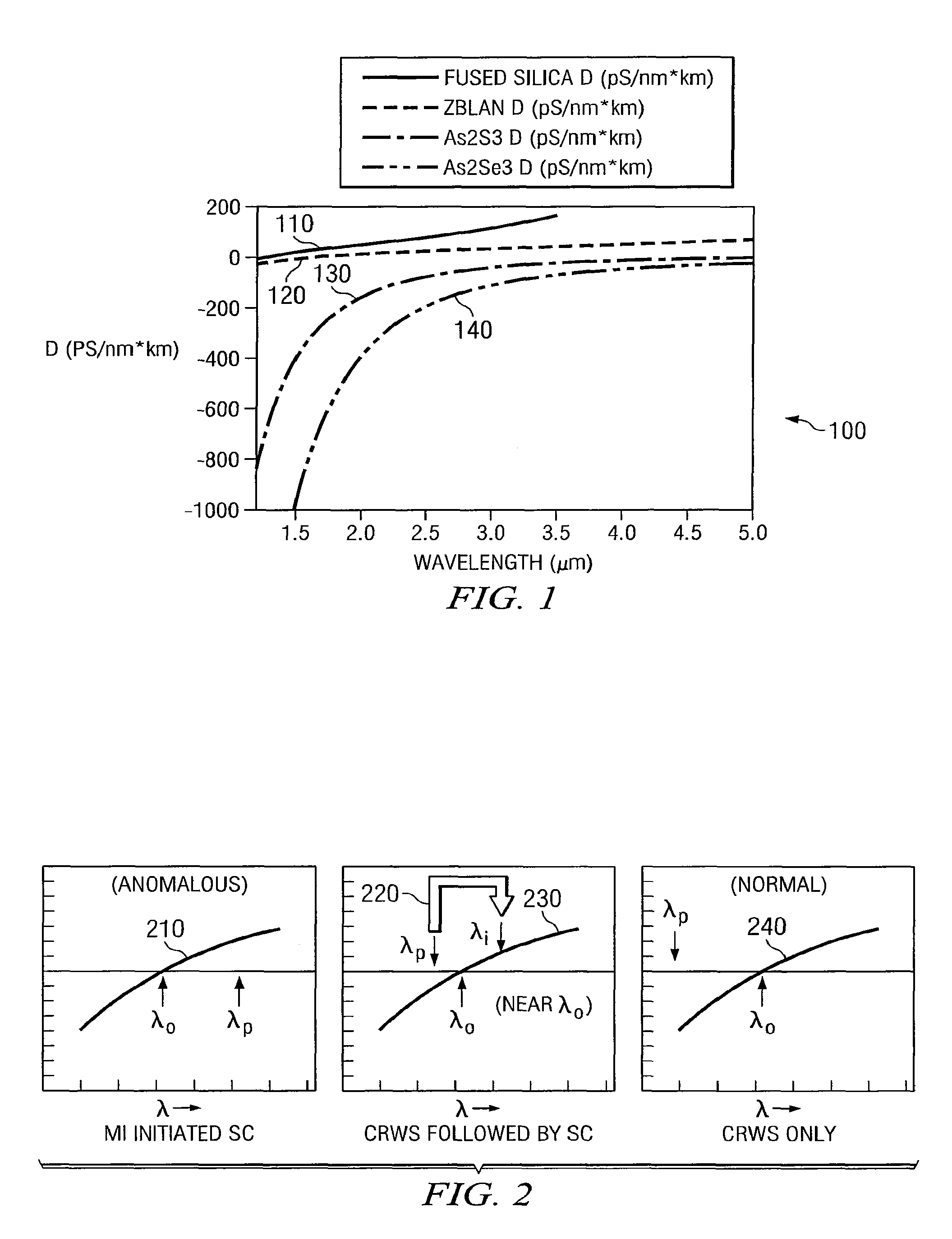

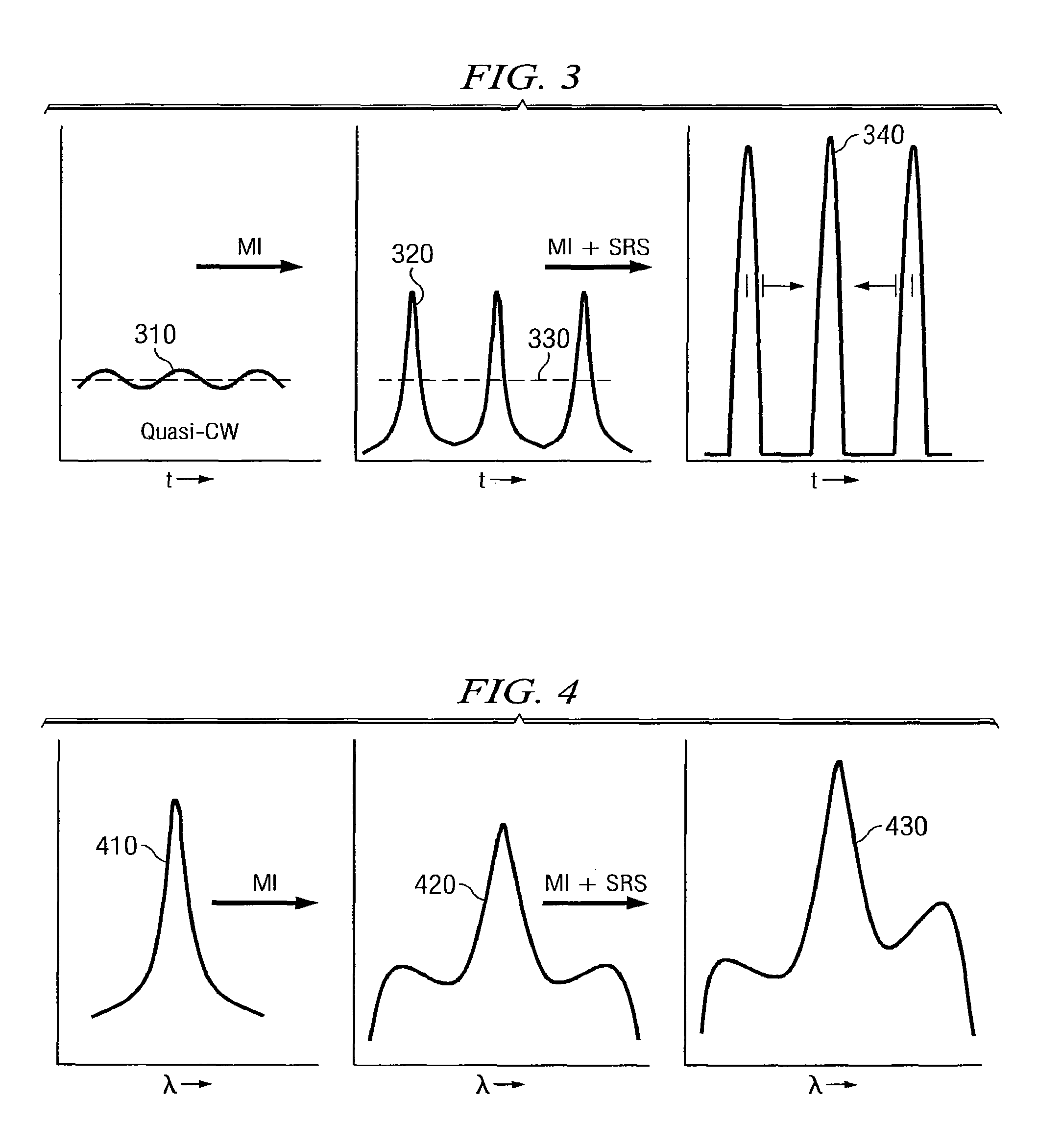

Broadband or mid-infrared fiber light sources

InactiveUS8670642B2Minimal requirementMore robustLaser detailsAbsorption/flicker/reflection spectroscopyFiberSpectroscopy

An optical system for use in a spectroscopy procedure includes one or more semiconductor diodes configured to generate an input signal beam with a wavelength shorter than 2.5 microns that is amplified and communicated through optical fiber(s) to a nonlinear element configured to broaden the spectral width to at least 50 nm through a nonlinear effect. A subsystem includes lenses or mirrors to deliver an output beam having a broadened spectrum selected to obtain a desired penetration depth and substantially minimize water absorption with a temporal duration greater than about 30 picoseconds to a sample to perform spectroscopy to characterize the sample. The output beam may have a repetition rate between continuous wave and one Megahertz or higher with a time averaged output power of 20 mW or more and a time averaged intensity of less than approximately 50 MW / cm2.

Owner:OMNI MEDSCI INC

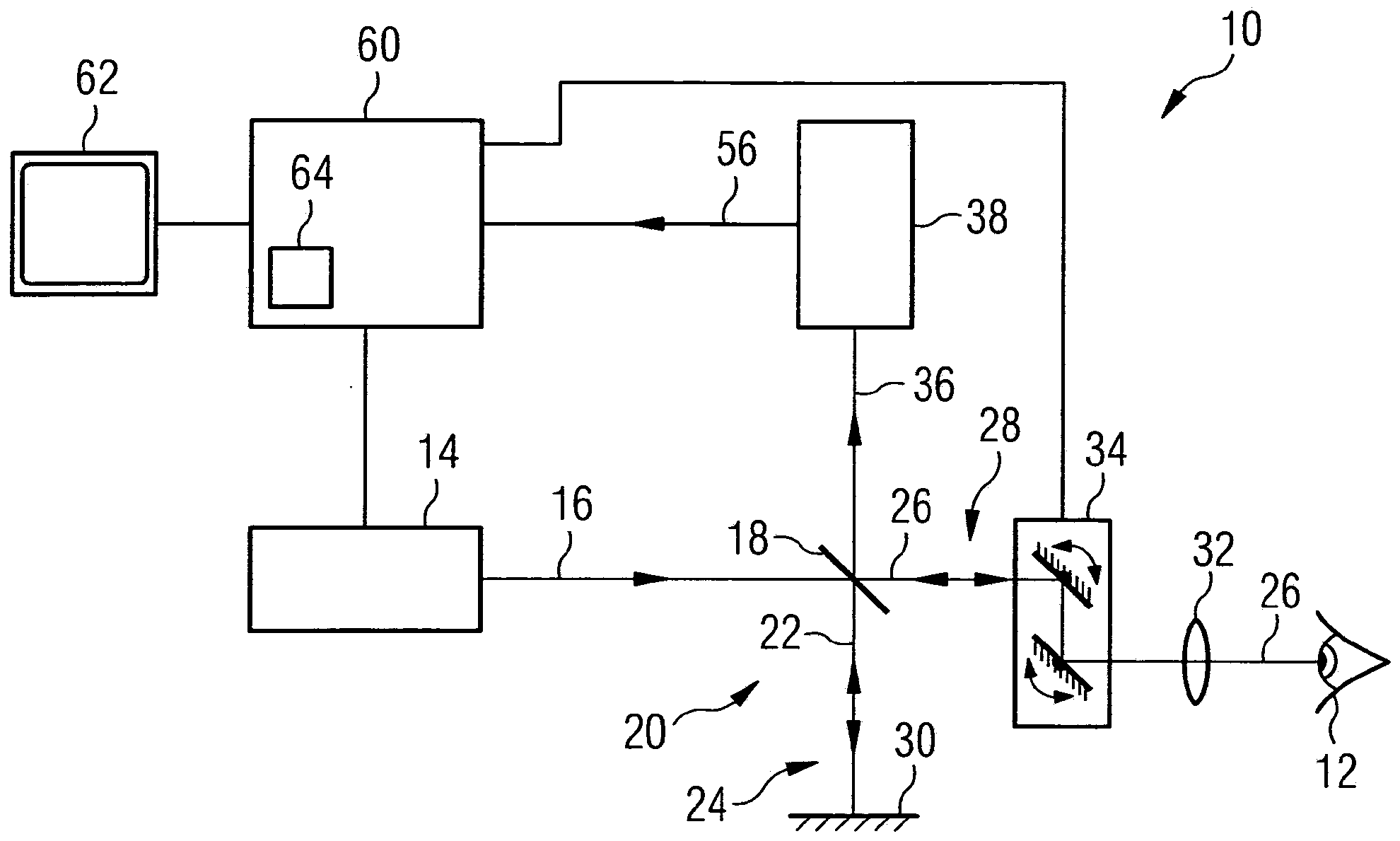

Light sources for spectrally controlled interferometry

A spectrally controlled light source includes a light source with a spectral distribution repeated with a predetermined spatial period along an input plane so as to produce multiple copies of the spectral distribution separated by the spatial period. All copies are propagated through dispersive optics to produce equally dispersed spectra on an image plane. A periodic modulating element with a given filter period is applied to each of the dispersed spectra to produce corresponding modulated outputs. According to the invention, the spatial period of the light source on the image plane and the filter period of the modulating element are selected so as to produce a resonance effect that greatly enhances the utility of the spectrally modulated source.

Owner:OLSZAK ARTUR

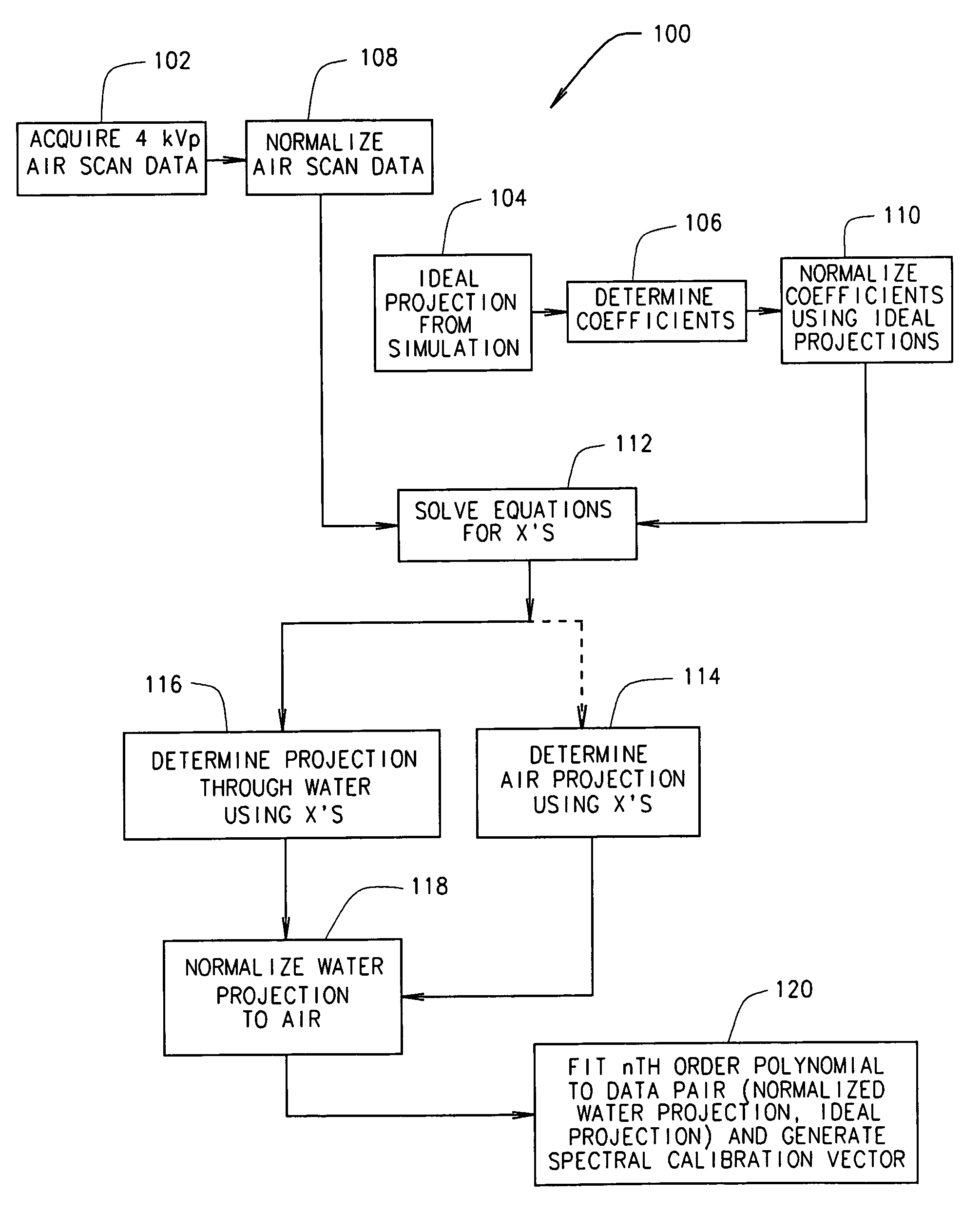

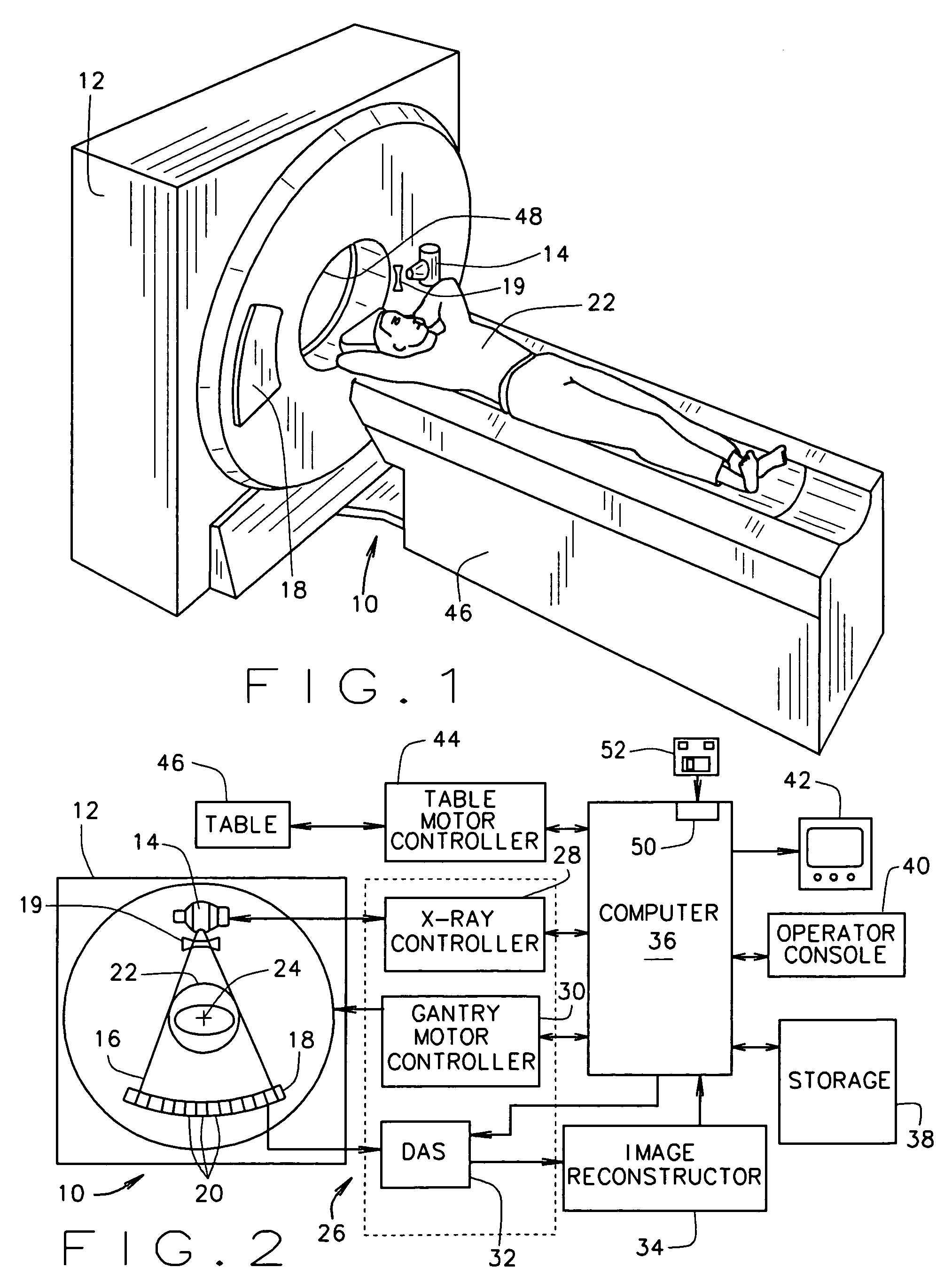

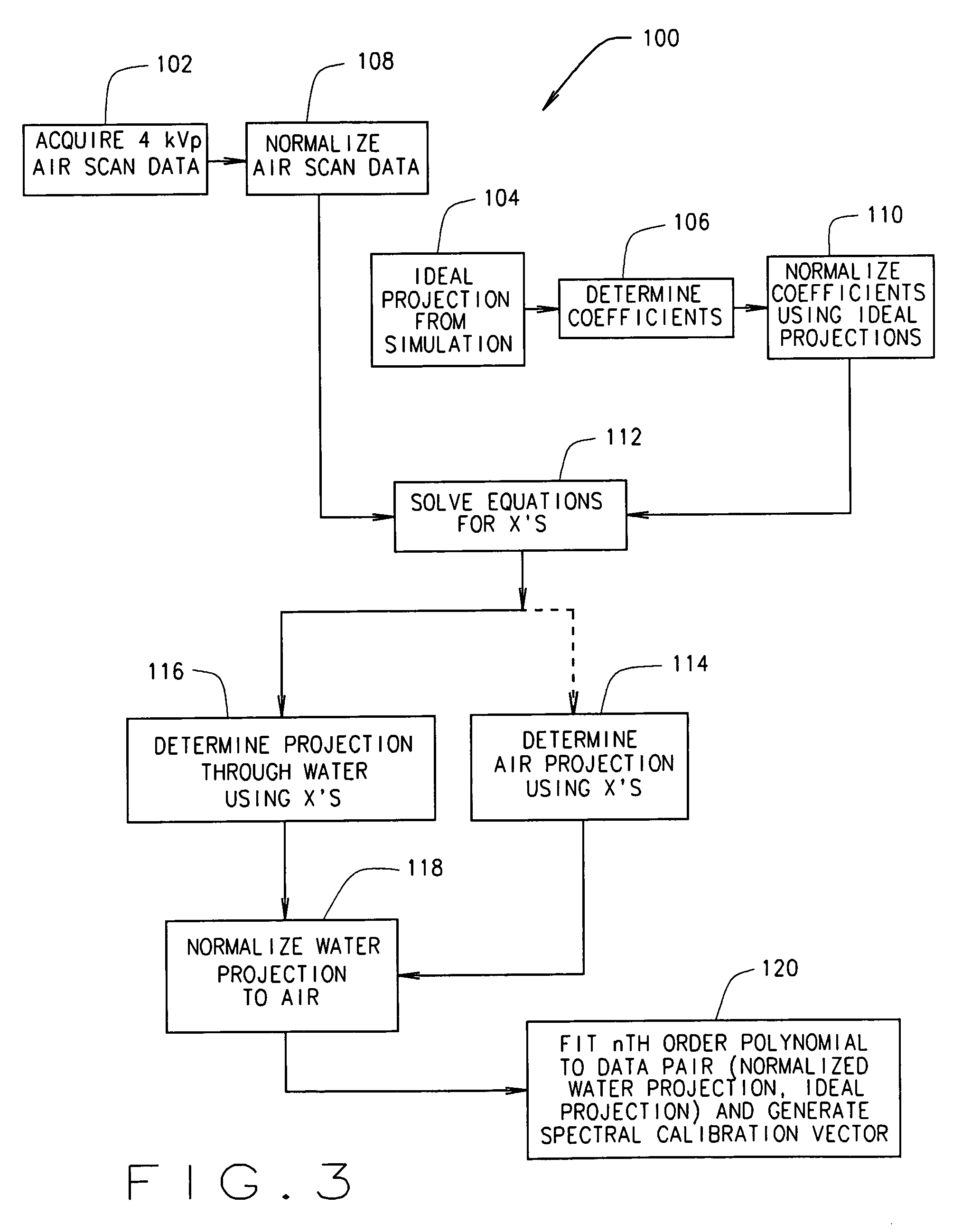

Methods for spectrally calibrating CT imaging apparatus detectors

InactiveUS7086780B2Reduce doseMaterial analysis using wave/particle radiationRadiation/particle handlingData setDetector array

A method for calibrating a computed tomographic imaging apparatus having a gantry, a radiation source operable at a plurality of kVp's, and a detector array having a plurality of detector elements includes using a system detection function to estimate signals of each detector element that would have been detected through air and through a given thickness of water to determine estimated datasets. The estimated datasets are used to determine data pair sets each comprising a normalized water projection value and an ideal projection value for each detector element. The method further includes determining and storing a representation of a mapping function of the normalized water projections values to the ideal projection values in a memory of the computed tomographic imaging apparatus as a spectral calibration of the computed tomographic imaging apparatus.

Owner:GENERAL ELECTRIC CO

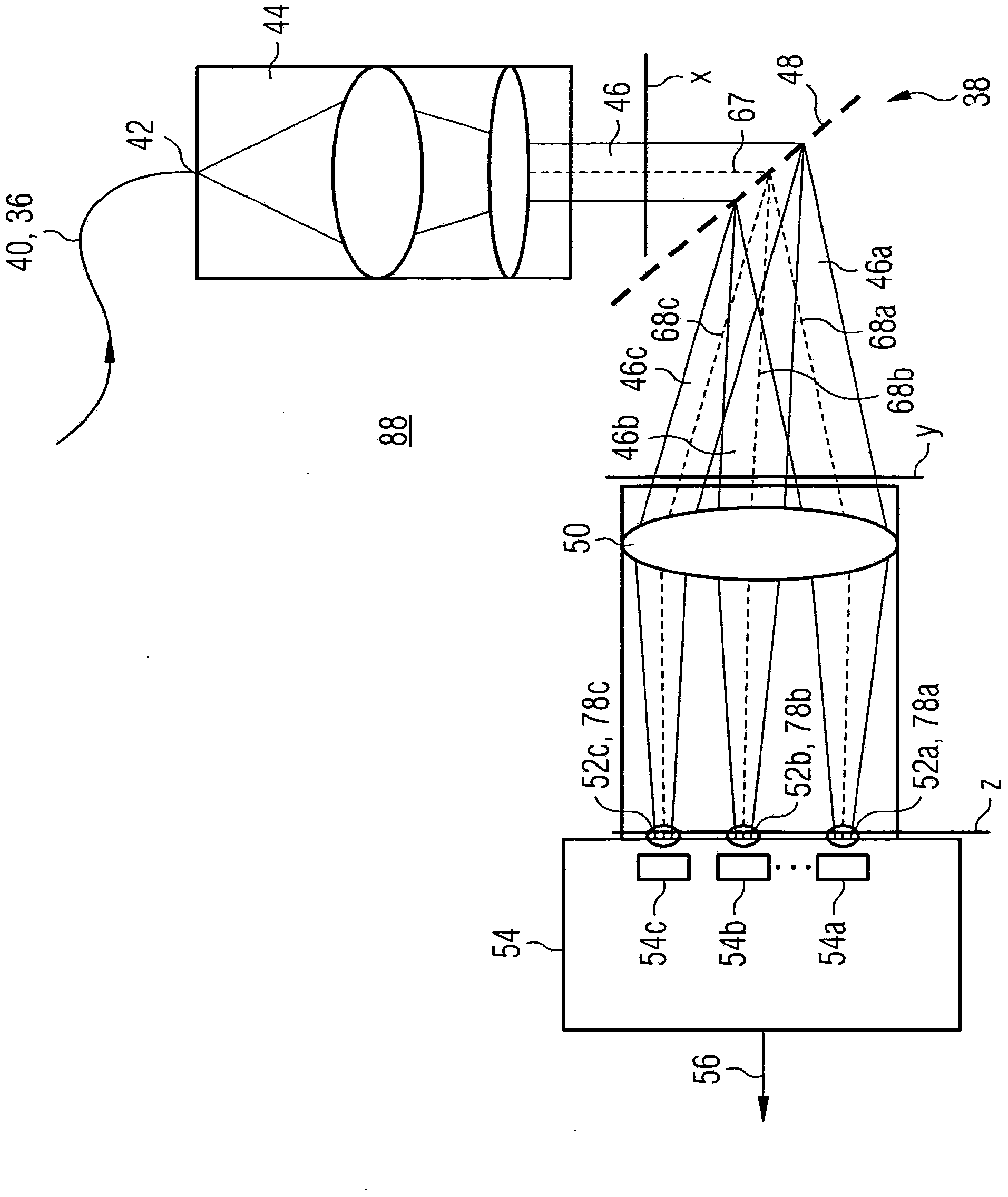

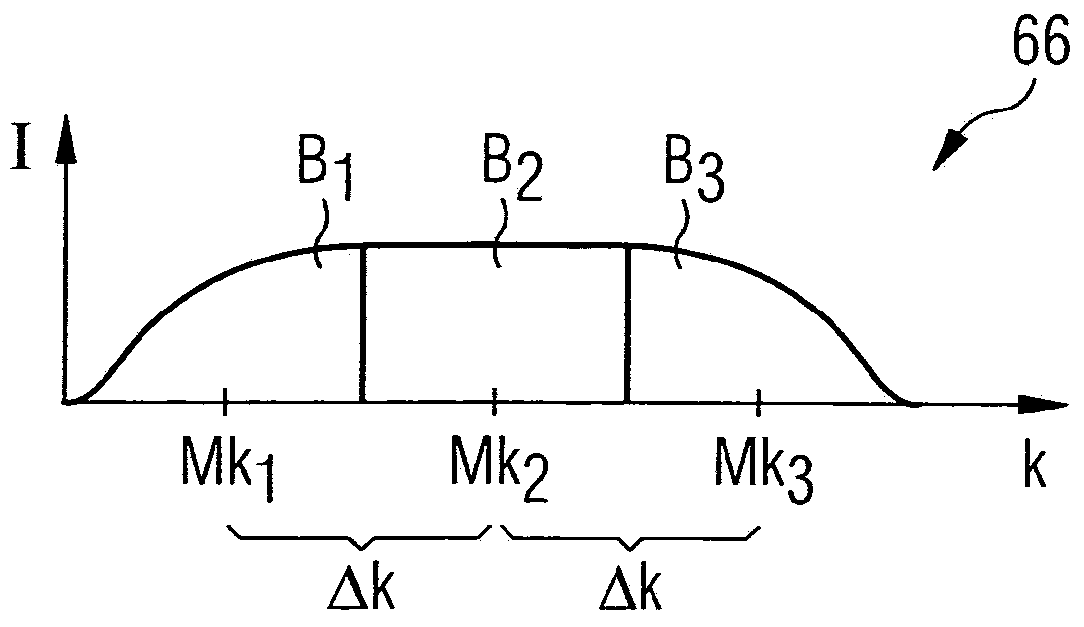

Spectroscopic instrument and process for spectral analysis

InactiveCN104040308AInterferometric spectrometrySpectrum generation using refracting elementsFtir spectraSpectral analysis

A spectroscopic instrument (38) includes a first optical component (48) for spatial spectral splitting of a polychromatic beam of light (46) impinging onto the first optical component (48), an objective (50), which routes various spectral regions (B1, B2, B3) of the split beam of light (46a, 46b, 46c) onto differing spatial regions (52a, 52b, 52c), and a sensor (54), situated downstream of the objective (50) in the beam path of the beam of light (46a, 46b, 46c), with a plurality of light-sensitive sensor elements (54a, 54b, 54c). The sensor elements (54a, 54b, 54c) are arranged in the beam path of the split beam of light 46a, 46b, 46c in such a manner that each sensor element (54a, 54b, 54c) registers the intensity of a spectral sector (A1, A2, A3) of the beam of light (46) and the medians (Mk1, Mk2, Mk3) of the spectral sectors (A1, A2, A3) are situated equidistant from one another in the k-space, where (k) denotes the wavenumber.

Owner:WAVELIGHT GMBH

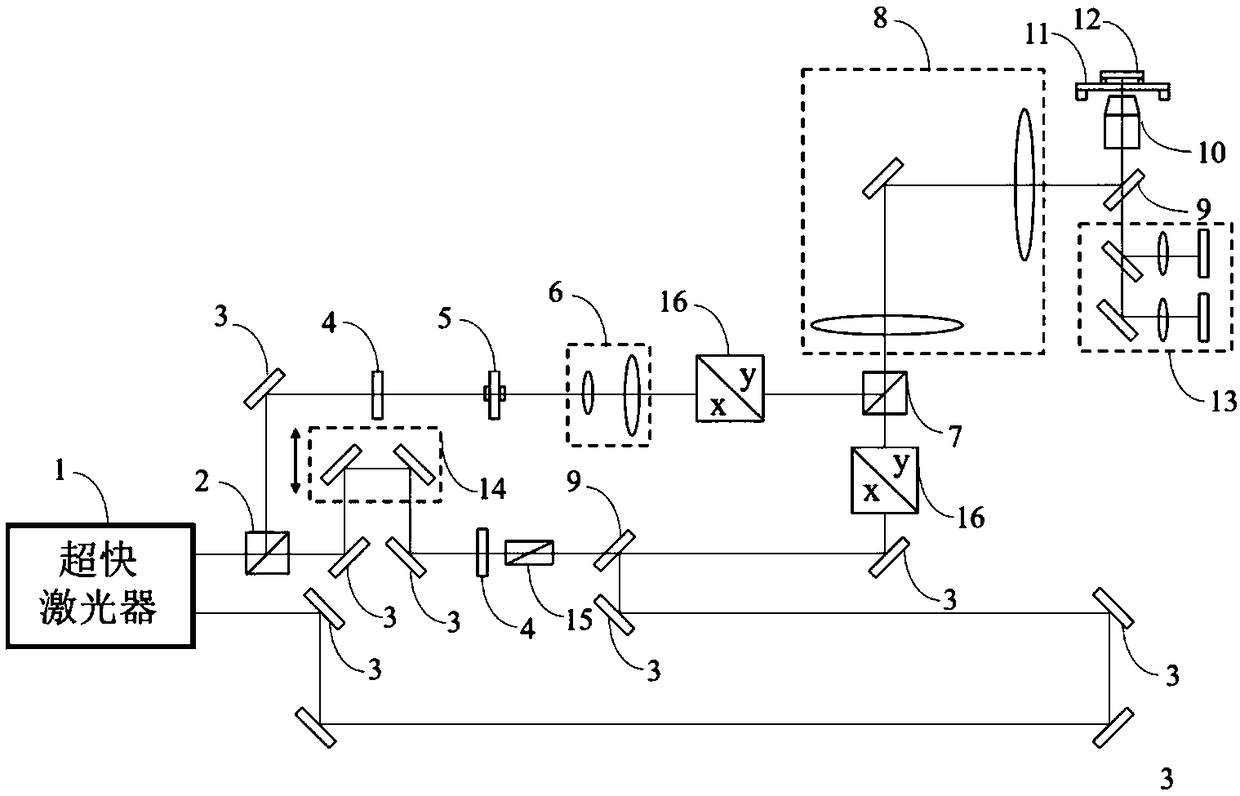

Ultra-fast laser micro-nano processing device with online monitoring function

ActiveCN108971747ARemove background noiseHigh sensitivityLaser beam welding apparatusMicro nanoFtir spectra

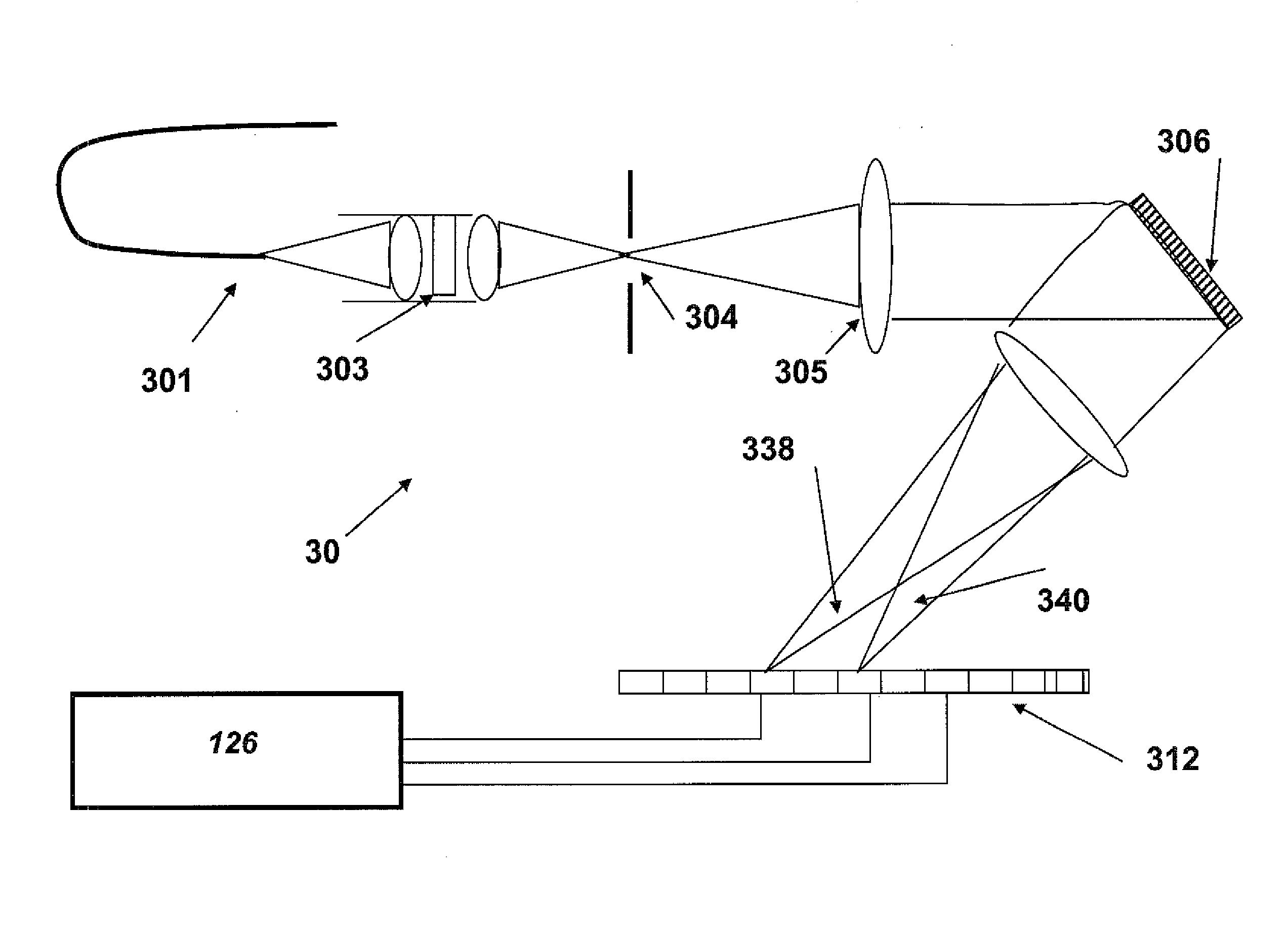

The invention belongs to the field of ultra-fast laser micro-nano processing and discloses an ultra-fast laser micro-nano processing device with an online monitoring function. The device comprises a laser unit, a dichroic mirror, a microscope, an object carrying platform and an imaging spectrometer. The laser unit is used for outputting two paths of pulsed laser with different wavelengths, and thefirst path of pulsed laser is divided into a first light beam and a second light beam, wherein the first light beam carries out laser micro-nano processing. The second light beam is combined with thesecond path of pulsed laser for spectral imaging and is combined with the first light beam at the same time. After passing through the dichroic mirror and the microscope, the combined light beams areconcentrated on an object to be processed so as to carry out cooperative laser micro-nano processing and real-time monitoring of spectra and imaging; and then non-linear optical signals such as backward coherent anti-stokes raman scattering generated by the object to be processed are collected backward and are to be received by an imaging spectrometer so as to realize real-time monitoring in theprocessing process. Through the ultra-fast laser micro-nano processing device, ultra-fast laser micro-nano processing with nonlinear imaging and spectrum online monitoring functions is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

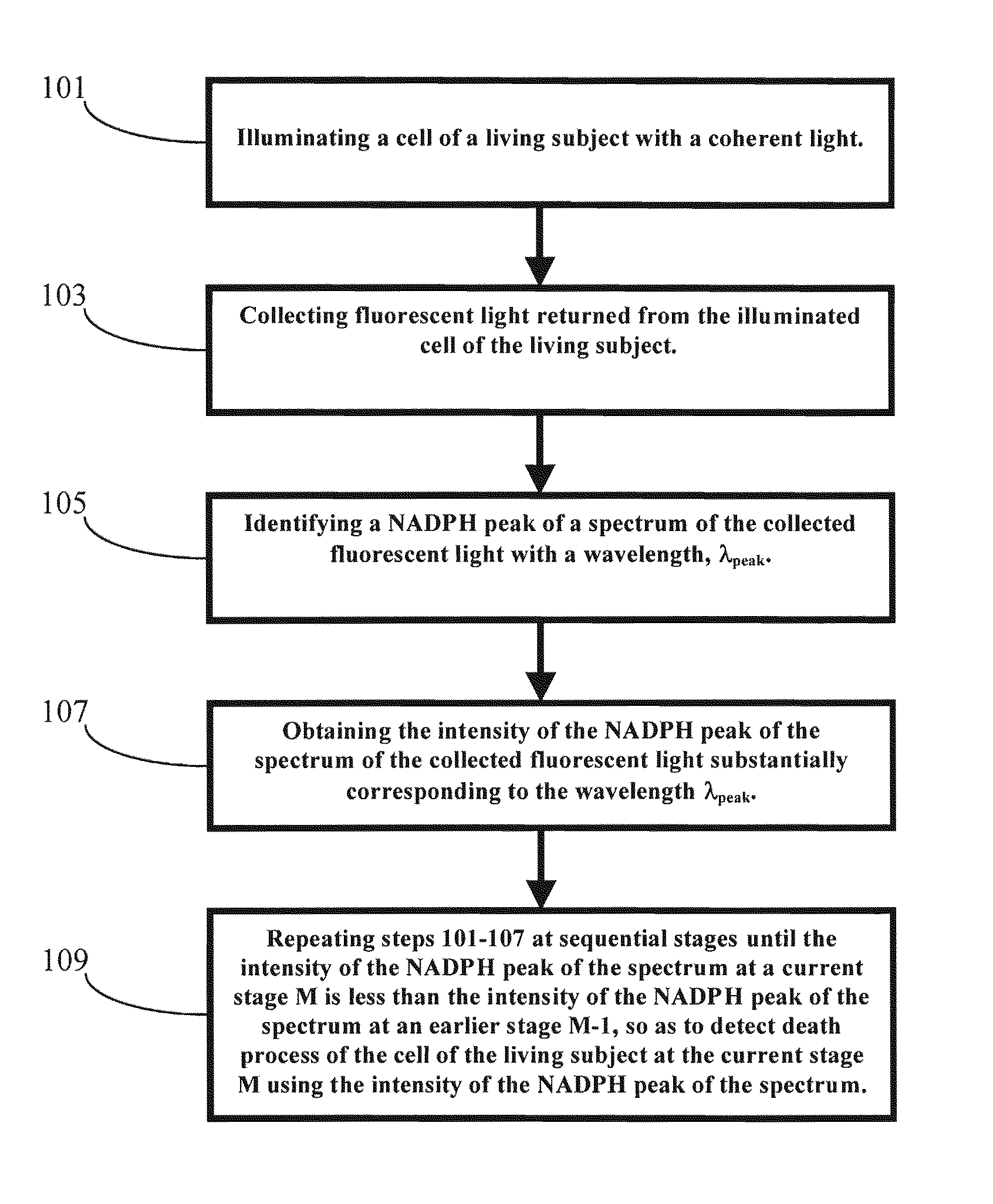

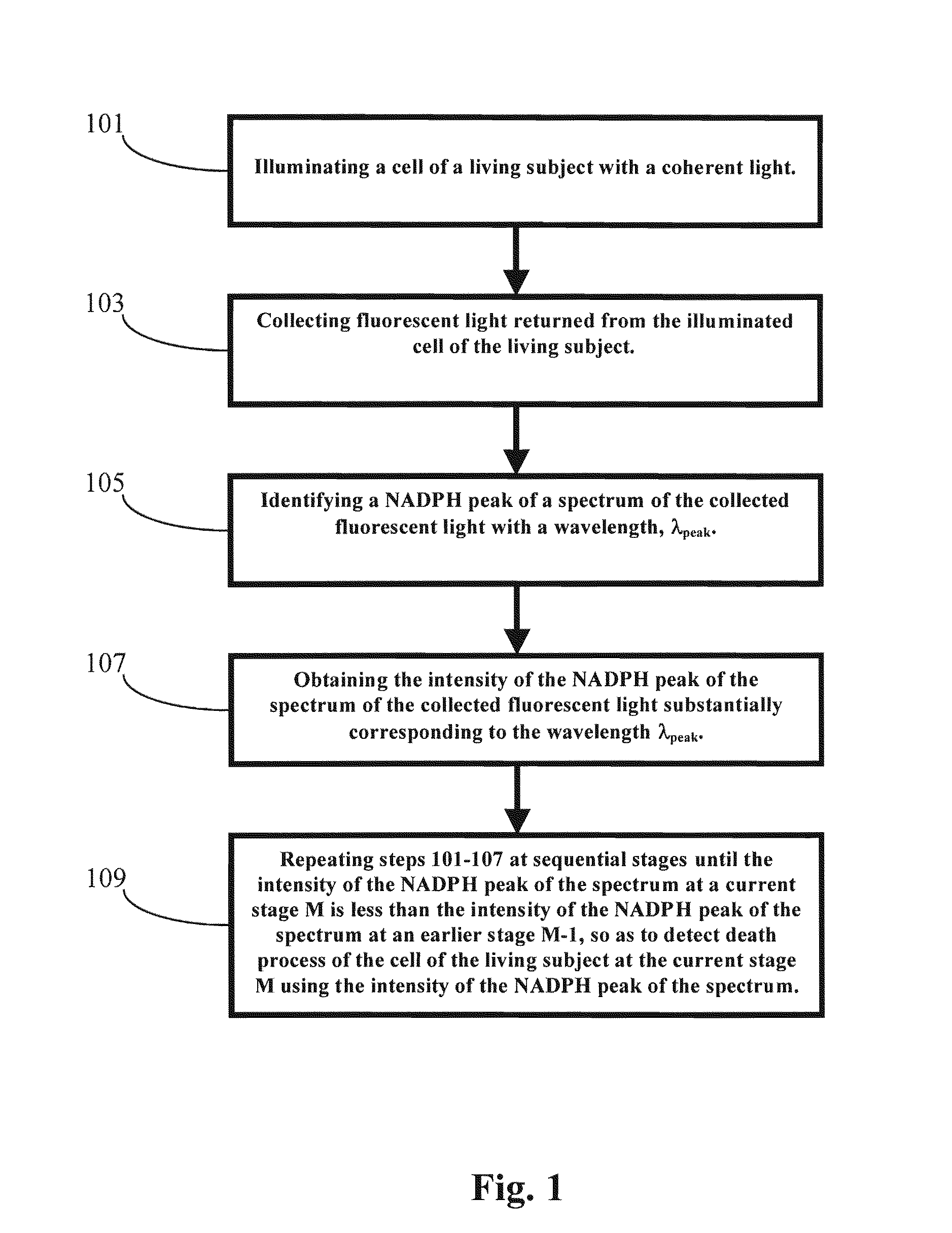

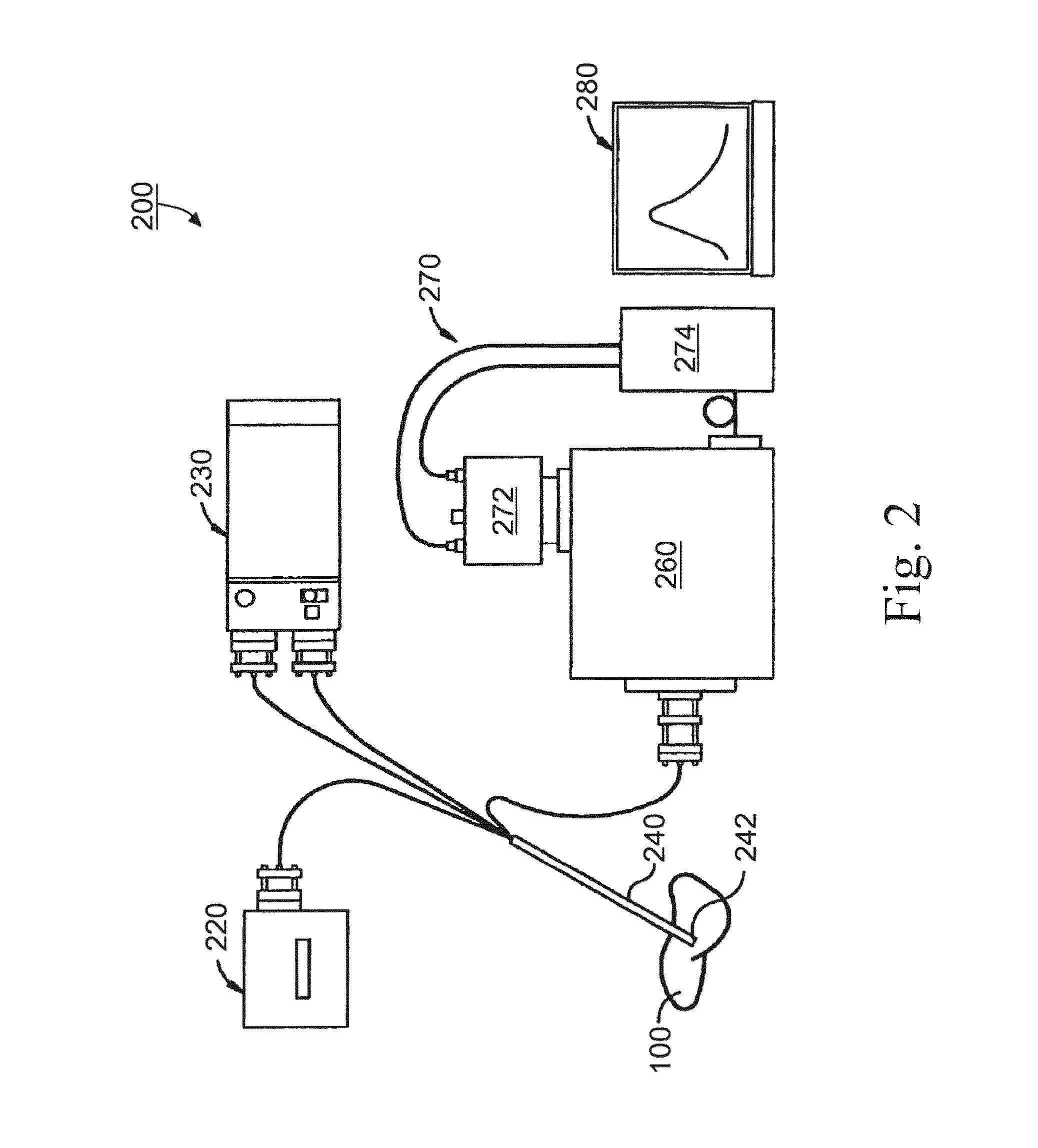

Methods and Apparatus for Optical Spectroscopic Detection of Cell and Tissue Death

A method for detecting death process of a cell or tissue of a living subject. In one embodiment, the method includes the steps of illuminating the cell or tissue of the living subject with a coherent light, collecting fluorescent light returned from the illuminated cell or tissue of the living subject, identifying a NAD(P)H peak of a spectrum of the collected fluorescent light with a wavelength, λpeak, and obtaining the intensity of the NAD(P)H peak of the spectrum of the collected fluorescent light substantially corresponding to the wavelength λpeak. These steps are repeated at sequential stages until the intensity of the NAD(P)H peak of the spectrum at a current stage is less than the intensity of the NAD(P)H peak of the spectrum at an earlier stage immediately prior to the current stage so as to detect death process of the cell of the living subject at the current stage using the intensity of the NAD(P)H peak of the spectrum.

Owner:VANDERBILT UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com