Ultra-fast laser micro-nano processing device with online monitoring function

A technology of micro-nano processing and ultra-fast laser, which is applied in the direction of metal processing equipment, laser welding equipment, welding equipment, etc. The size is difficult to observe in real time, etc., to achieve the effect of improving the spectral detection speed, increasing the wavelength selectivity, and improving the sensitivity and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

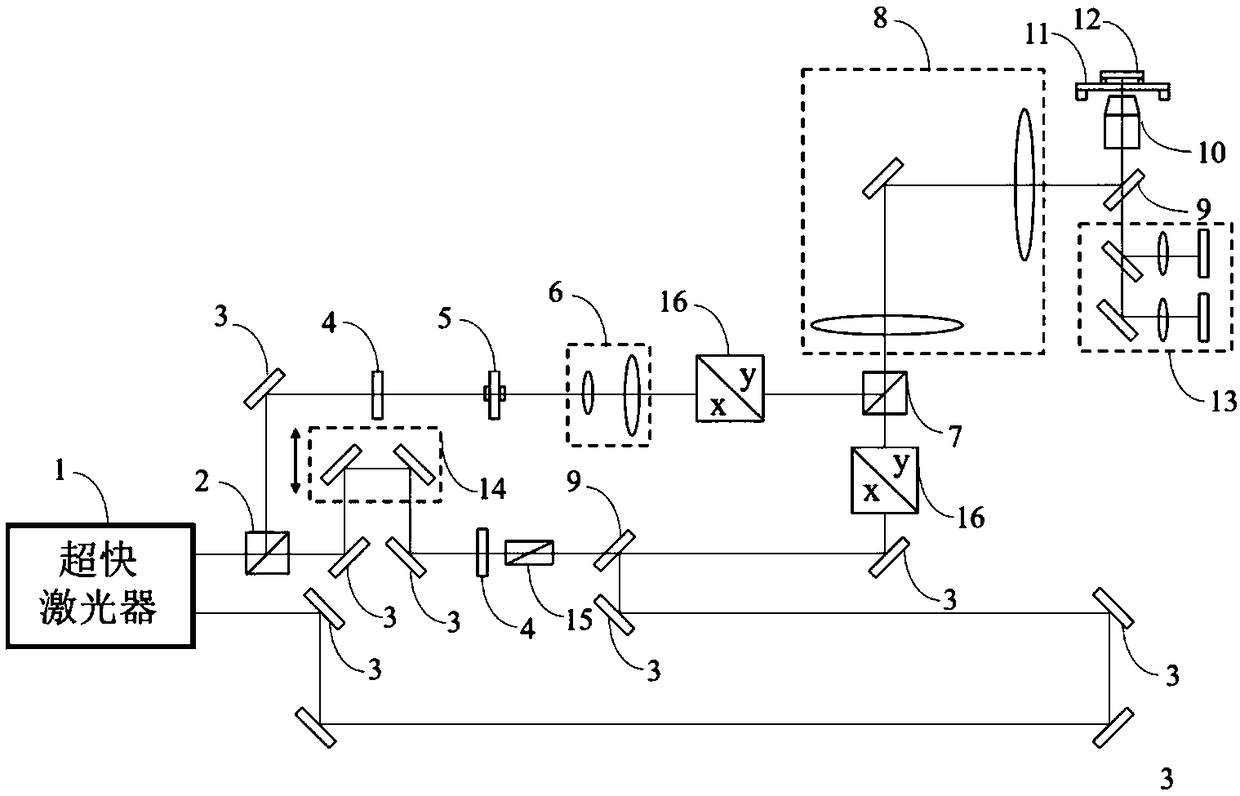

[0045] Taking the online monitoring of in-situ graphene generated by nonlinear spectroscopy as an example, when the device provided by the invention is used for processing, the specific operation steps are as follows:

[0046] (1) The carbon target and the nickel target are deposited on SiO by joint measurement and control sputtering in the measurement and control sputtering 2 Or on a glass substrate, the subsequent femtosecond laser direct writing method can be used on SiO 2 Or in-situ graphene generation on glass substrates;

[0047] (2) Turn on the femtosecond laser, tune the first output wavelength to 780nm, and divide this laser into the first beam for laser direct writing and the second beam for high-order nonlinear spectral imaging detection;

[0048] (3) The two-way light beams are combined in space, and pass through the achromatic beam expander 6 composed of doublet lenses;

[0049] (4) Combined beams pass through the 4F system 8;

[0050] (5) The combined beam is ...

example 2

[0055] Taking online monitoring of laser thinning molybdenum disulfide by nonlinear spectroscopy as an example, the method is described.

[0056] Si / SiO with multilayer molybdenum disulfide will be grown 2 The glass slide is placed on the loading platform, and the on-off and power of the laser are controlled by the acousto-optic modulator. When the laser is thinning molybdenum disulfide, the laser power of about 900mW is used, and the two-dimensional micro-nano platform and the three-dimensional precision press Electric platform, and take a certain gradient processing speed of about 10-1000μm / s to carry out laser thinning treatment on multi-layer molybdenum disulfide. During the processing, the pulse of the second beam and the second output Scanning is carried out on the molybdenum disulfide sample, the nonlinear four-wave mixing signal is collected by the spectrometer, and the image and spectral information changes in the process of thinning molybdenum disulfide are tracked a...

example 3

[0058] The online monitoring of processed proteins by nonlinear spectroscopy is taken as an example, and the method is illustrated.

[0059] (1) Preparation of materials: A mixed hydrogel with a solution concentration of 400 mg / mL of bovine serum albumin and 0.6 mg / mL of methylene blue was prepared. Bovine serum albumin was used as a precursor material for laser direct writing to generate cross-linking polymerization, while methylene blue was used as a photosensitizer material to initiate photo-induced cross-linking polymerization of proteins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com