Online abrasion monitoring method based on electrostatic induction, online abrasion monitoring device based on electrostatic induction and experimental system

A technology of electrostatic induction and monitoring device, which is applied in the direction of measuring device, suspension and porous material analysis, particle suspension analysis, etc. Reflect problems such as wear and tear to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

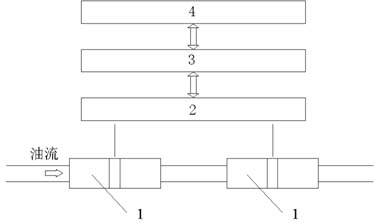

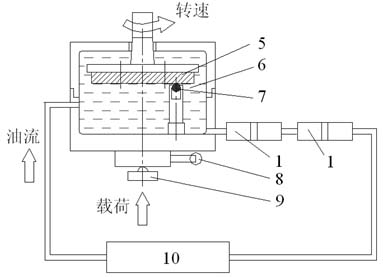

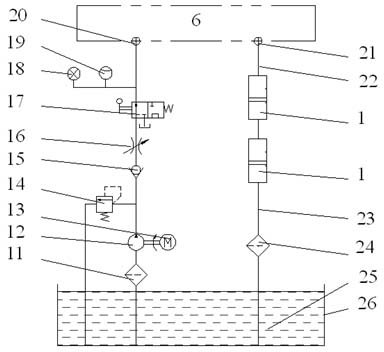

[0026] The on-line wear monitoring device based on electrostatic induction of the present invention is used for on-line monitoring of wear conditions under circulating lubrication conditions, such as figure 1 As shown, the device includes a pair of identical electrostatic sensors 1 installed on the main oil circuit of circulating lubrication according to a preset distance, and a signal processing unit connected with the two electrostatic sensors. In this specific embodiment, the signal processing unit includes a signal conditioning circuit 2, a signal acquisition module 3, and a computer 4 connected in sequence, wherein the signal acquisition module adopts a NI company WLS 9234 digital acquisition card, and the computer adopts a general-purpose PC based on the Windows platform. Design the NI LabVIEW acquisition program to collect the electrostatic induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com