Method for preparing super-clean and high-purity acetic acid and apparatus thereof

A preparation device and technology of acetic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems that the quality cannot meet the requirements of integrated circuit processing, low impurity content, etc., and achieve small footprint and low impurity ion content , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

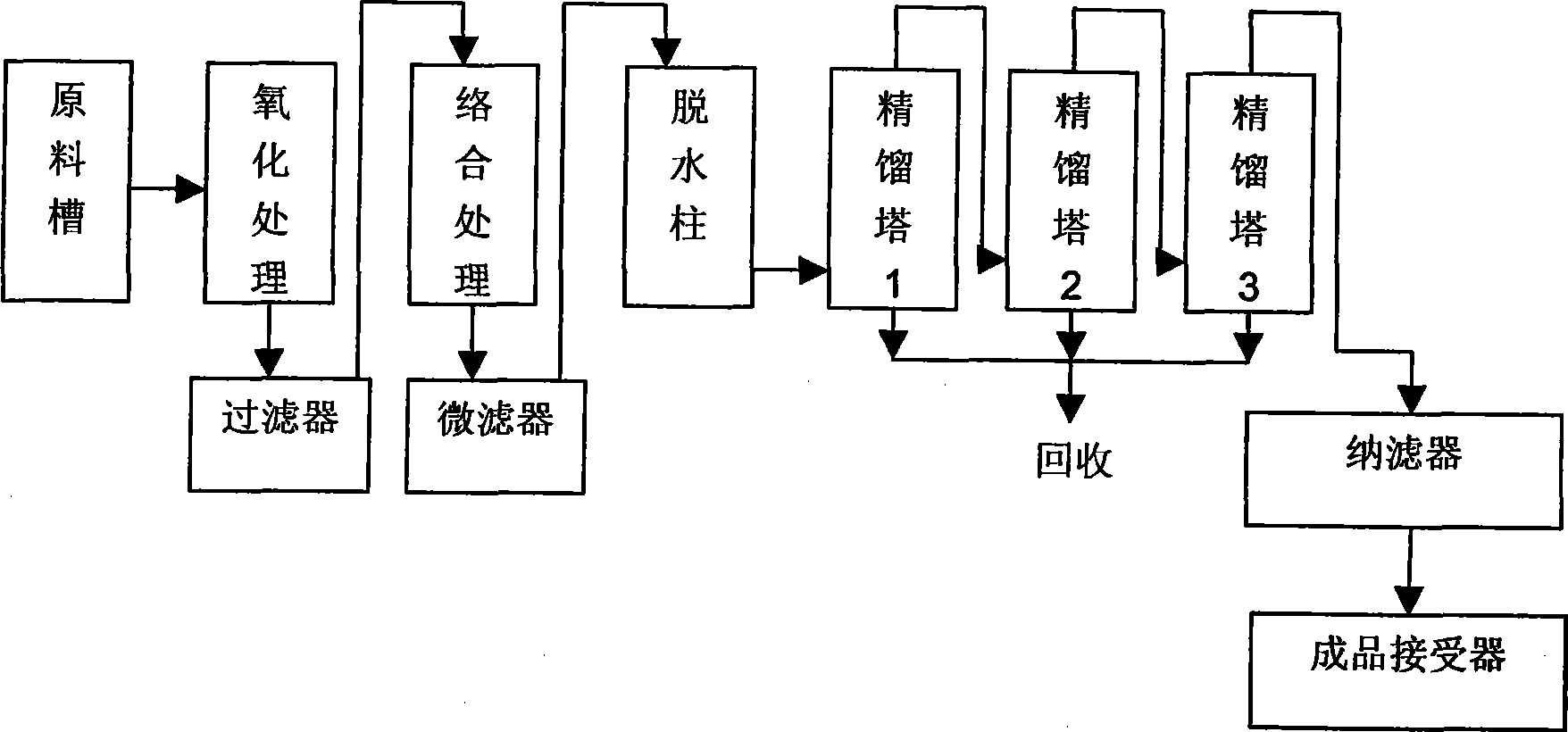

[0012] Embodiment 1: the preparation method of ultra-clean high-purity acetic acid

[0013] First mix industrial-grade acetic acid (99.0%) raw materials with potassium permanganate accounting for 0.1% to 5% of the weight of industrial-grade acetic acid raw materials in an oxidation processor, filter after 30 to 60 minutes at normal temperature and pressure, and filter the filtrate with diene The organosilicon polymer complexing agent of propyl 18-crown-6 ether is mixed in the complexing processor for 30-120 minutes, and then filtered through the micro-filtration membrane of the micro-filter under the operating pressure of 0.1-0.2 MPa, and the filtrate is The speed of 0.05-0.20mm / s enters the rectification tower through the 2000mm dehydration column, and the semi-finished product out of the tower is filtered by the nanofiltration membrane of the nanofilter under the operating pressure of 0.5-0.8MPa and then enters the finished product receiver. In this embodiment, the dehydrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com