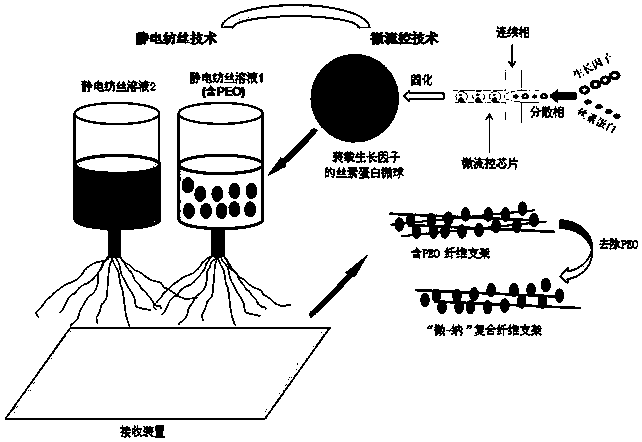

Three-dimensional nanofiber stent based on microfluidic technology and electrospinning technology and preparation method thereof

A three-dimensional nano-fiber scaffold technology, used in electrospinning, fiber processing, pharmaceutical formulations, etc., can solve problems such as low long-term patency rate and lumen narrowing, and achieve improved long-term patency rate and good biocompatibility. , the effect of promoting growth and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Remove sericin on the surface of silk fiber:

[0034] Bombyx mori silk was exposed to 0.1% Na 2 CO 3 In the solution, treat at 98-100 DEG C for 30 minutes, repeat three times to remove sericin on the surface of silk fiber, and dry in air at room temperature.

[0035] (2) Preparation of silk fibroin solution:

[0036] Dissolve the degummed silk in 9.3mol / L lithium bromide aqueous solution at the ratio of 27g:100mL, put it in an oven at 60°C for 4 hours, and obtain the silk fibroin solution after dialysis, which is ready for use. And take a part of the silk fibroin solution to freeze-dry to obtain the silk fibroin sponge, which is set aside.

[0037] (3) Preparation of microfluidic chip:

[0038] The SU-8 template of the vertical microchannel was made by soft lithography technology, A glue and B glue were stirred and mixed, poured on the SU-8 template and the blank template, placed on the horizontal test bench for 30 minutes to remove air bubbles, and then placed ...

Embodiment 2

[0046] (1) Using microfluidic technology to prepare silk fibroin microdroplets loaded with growth factors:

[0047] A microfluidic chip device capable of preparing monodisperse silk fibroin microdroplets is adopted, including micropumps, microfluidic chips, droplet receiving and storage containers. The silk fibroin solution prepared in Example 1 was added with growth factors required for embedding and sustained release as a dispersed phase; a mixture of Span 80 and medium-chain fat triglycerides was used as a continuous phase, and the mixing ratio was 2%. Using different flow rates or pressure ratios, the microfluidic parameters are preferably as follows: the dispersed phase is 20mba-120mba, the continuous phase is 150mba-600mba, and sheared into monodisperse droplets encapsulating growth factors. The droplets then pass through the collection tube into a collection sump filled with Span 80 oil phase. (2) Preparation of silk fibroin microspheres:

[0048] Cool the collected d...

Embodiment 3

[0052] (1) Using microfluidic technology to prepare silk fibroin microdroplets loaded with growth factors:

[0053] A microfluidic chip device capable of preparing monodisperse silk fibroin microdroplets is adopted, including micropumps, microfluidic chips, droplet receiving and storage containers. The silk fibroin solution prepared in Example 1 was added with growth factors required for embedding and sustained release as a dispersed phase; a mixture of polyoxyethylene hydrogenated castor oil and sunflower oil was used as a continuous phase, and the mixing ratio was 2%. Using different flow rates or pressure ratios, the microfluidic parameters are preferably: the dispersed phase is 20mba-120mba, the continuous phase is 150mba-600mba, and sheared into monodisperse droplets encapsulating growth factors. The droplets then pass through a collection tube into a collection tank filled with polyoxyethylene hydrogenated castor oil oil phase.

[0054] (2) Preparation of silk fibroin m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com