Preparation method of silicon-aluminum film opening agent and film opening agent

A technology of opening agent and thin film, which is applied in the field of polymer material processing, can solve the problems of low affinity, affecting opening performance, and difficult dispersion, so as to improve affinity, reduce friction coefficient and adhesion resistance, and improve antistatic Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

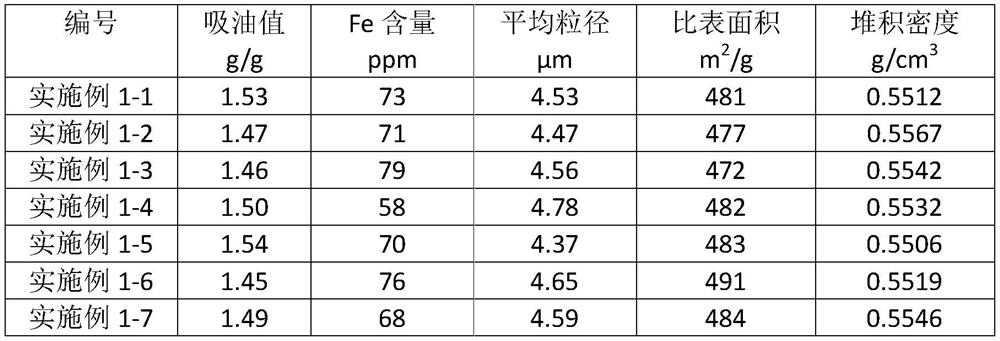

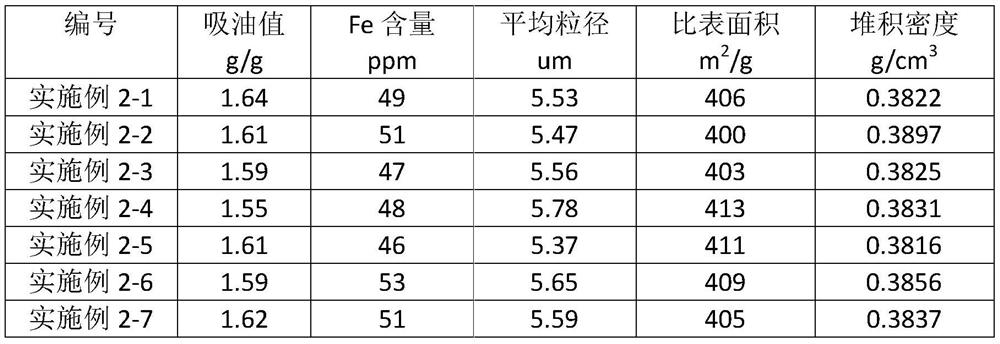

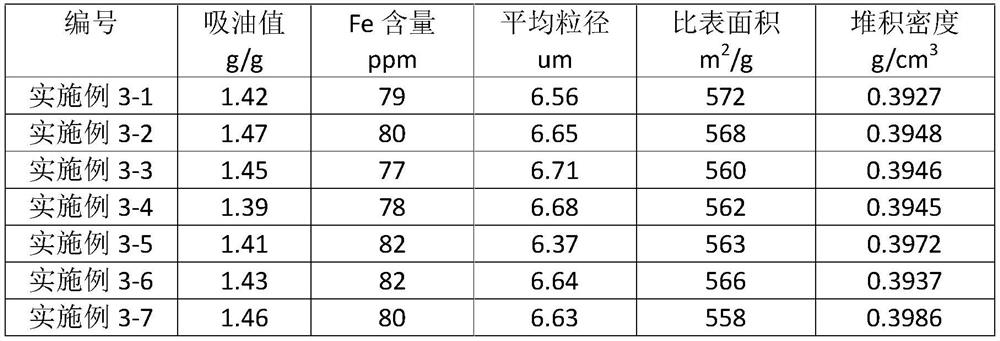

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of silicon-aluminum film opening agent, it comprises the steps:

[0041] S1: Prepare a water glass solution with a silicon dioxide concentration of 10-20wt% and a modulus of 3.35 for use;

[0042] S2: Add water and aluminum salt into the reaction kettle at a temperature of 30°C-60°C, and after the aluminum salt is completely dissolved, add sulfuric acid with a concentration of 10-30wt%, and adjust the pH value to 1-3;

[0043] S3: Add the prepared water glass solution and sulfuric acid to the aluminum salt solution at the same time, and the co-flow time is 30min-60min, keeping the pH value of the system at 1-3;

[0044] S4: After the parallel flow is completed, add sodium hydroxide to adjust the pH value to 8-10, and at the same time raise the temperature to 80°C-100°C, and keep aging at this temperature for 2 hours;

[0045] S5: After the aging is completed, add dilute sulfuric acid, adjust the pH value to 2-4, age f...

Embodiment 1

[0052] At a temperature of 30°C, inject 50L of bottom water and 45 moles of aluminum sulfate into the stirred reaction vessel. After the aluminum sulfate is completely dissolved, add sulfuric acid with a concentration of 30wt% to adjust the pH of the system to 2, and add a concentration of 20wt. % water glass 75L and the sulfuric acid of 30wt%, the maintenance system pH value is 2 and the parallel flow time is 30 minutes.

[0053] After the parallel flow is completed, the temperature is adjusted to 90°C, the pH value is adjusted to 9 by adding sodium hydroxide, and aged for 2 hours. After aging, sulfuric acid was added to adjust the pH value to 3, aged for 0.5 hour, then cooled to 60° C., and filtered to obtain a filter cake. Wash the filter cake with 1wt% sulfuric acid, then mix and wash with tap water and pure water, and press filter to form a filter cake. Re-disperse the filter cake in a small amount of water, and add 3% solid content organic silane dispersant KH550. Afte...

Embodiment 2

[0058] At a temperature of 60°C, inject 50L of bottom water and 15 moles of aluminum nitrate into the stirred reaction vessel. After the aluminum nitrate is completely dissolved, add sulfuric acid with a concentration of 10wt% to adjust the pH value of the system to 2, and add a concentration of 20wt. % water glass 75L and 10wt% sulfuric acid, keep the pH value of the system at 2 and the co-current time is 90 minutes.

[0059] After the co-current flow is completed, the temperature is adjusted to 100°C, the pH value is adjusted to 10 by adding sodium hydroxide, and aged for 2 hours. After aging, sulfuric acid was added to adjust the pH value to 2, aged for 1.5 hours, then cooled to 60° C., and filtered to obtain a filter cake. Wash the filter cake with 3wt% sulfuric acid, then mix and wash with tap water and pure water, and press filter to form a filter cake. Re-disperse the filter cake in a small amount of water, and add 1% solid content organic silane dispersant KH550. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com