Patents

Literature

153results about How to "Improve surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

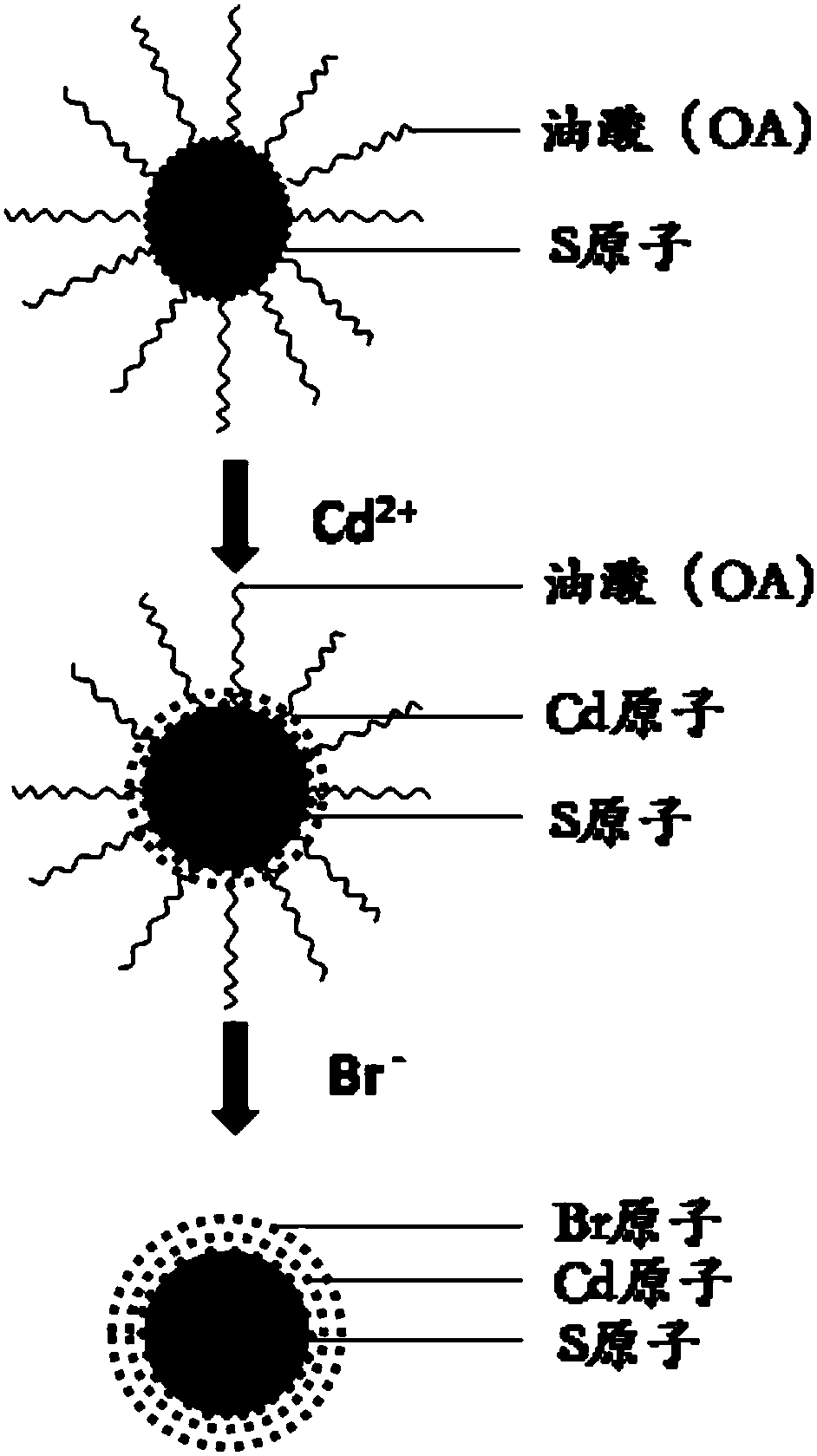

Passivation quantum dot film and preparation method thereof

InactiveCN106701060AImprove surface defectsImprove mobilityLuminescent compositionsSemiconductor devicesOrganic solventHalogen

The invention provides a preparation method of a passivation quantum dot film. The preparation method comprises the following steps: providing oil-soluble quantum dots, a metal ion precursor storing solution and a halogen substituted organic matter; dissolving the oil-soluble quantum dots to obtain an oil-soluble quantum dot solution; mixing the oil-soluble quantum dot solution with a reaction medium, carrying out heating and degassing treatment, then adding the metal ion precursor storing solution, and carrying out heating and stirring reaction to obtain passivation quantum dots; providing a substrate, dissolving the passivation quantum dots into a passivation quantum dot solution, and depositing the passivation quantum dot solution on the substrate by a solution method to obtain the passivation quantum dot film; dissolving the halogen substituted organic matter to prepare a halogen substituted organic matter storing solution; cleaning the passivation quantum dot film by adopting the halogen substituted organic matter storing solution, and carrying out surface ligand exchange; cleaning by adopting an organic solvent to remove a fallen organic ligand in an exchange process; repeating the steps of cleaning by the halogen substituted organic matter storing solution and cleaning by the organic solvent.

Owner:TCL CORPORATION

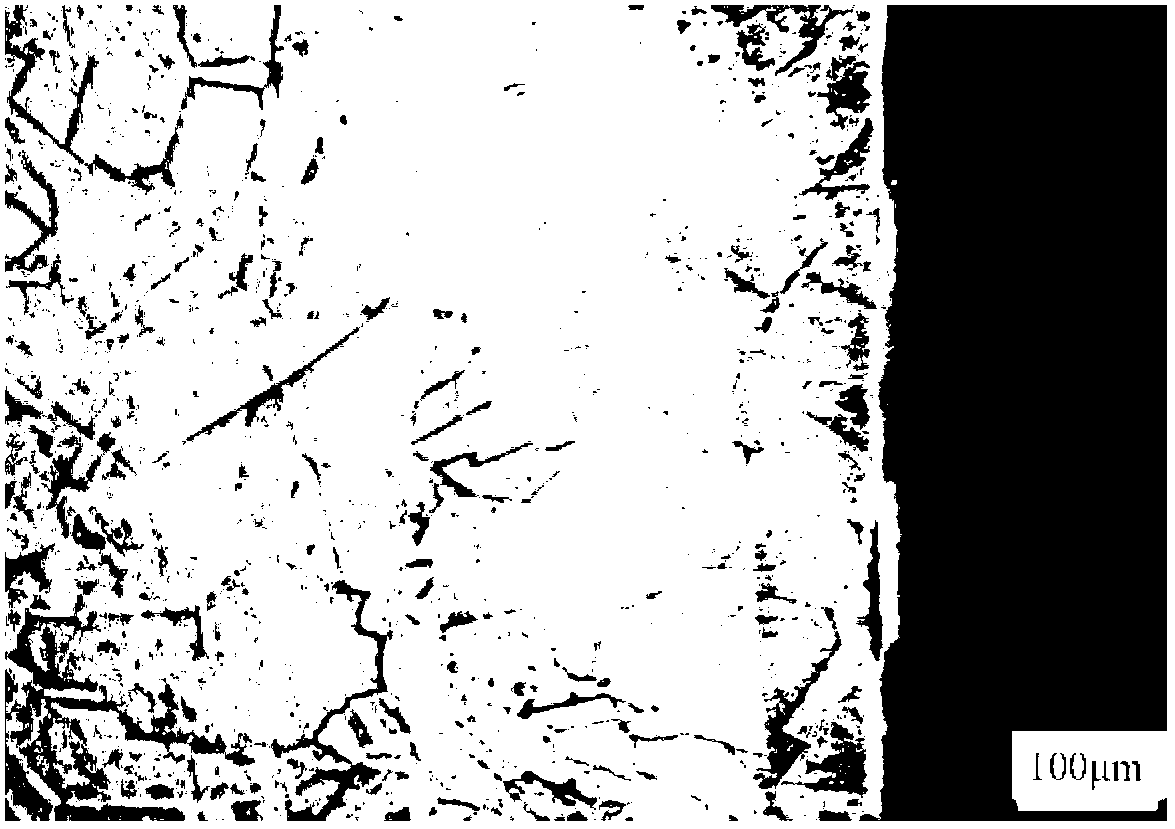

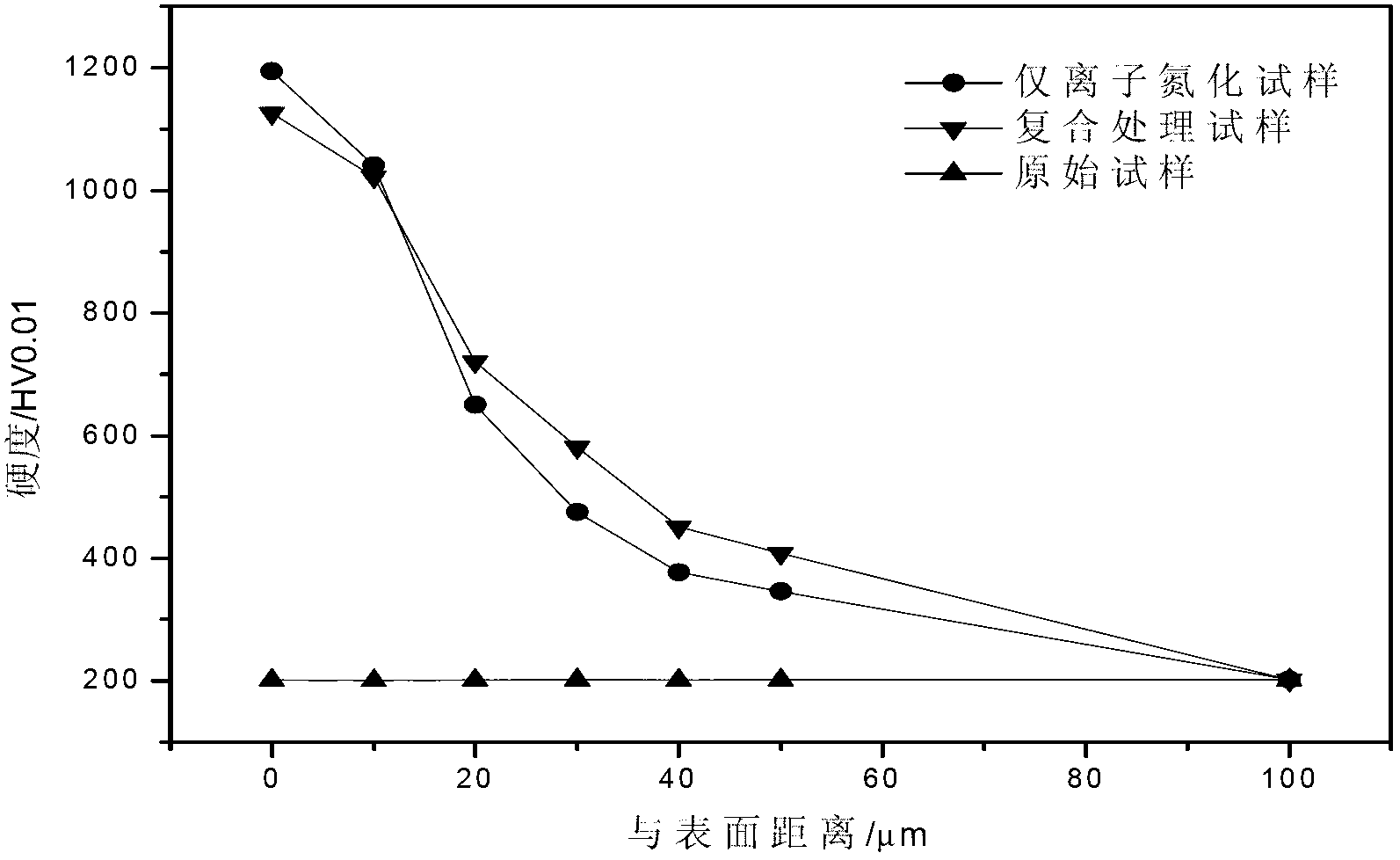

Austenitic stainless steel ion nitriding permeation catalyzing process

InactiveCN103014601AQuality improvementImprove bindingSolid state diffusion coatingHydrogenMetallurgy

The invention relates to a stainless steel ion nitriding process, and in particular relates to an austenitic stainless steel ion nitriding permeation catalyzing process. The process mainly comprises the following steps: 1) washing the surface of a stainless steel surface, and removing the oil stain and impurities on the surface of the workpiece; 2) carrying out pre-oxidation treatment on the stainless steel workpiece; 3) putting the stainless steel workpiece into an ion nitriding furnace after being cooled down, introducing dried hydrogen, building up of luminance and heating up, after reaching a certain temperature, introducing nitrogen, adjusting the ratio of the nitrogen to the hydrogen and the pressure in the furnace, subsequently starting to time, after nitriding for a certain time, closing the ion nitriding furnace and cooling down the workpiece along with the furnace. The austenitic stainless steel treated by using the process can obtain a compound layer which is thicker than that of an ordinary ion nitriding process.

Owner:CHANGZHOU UNIV

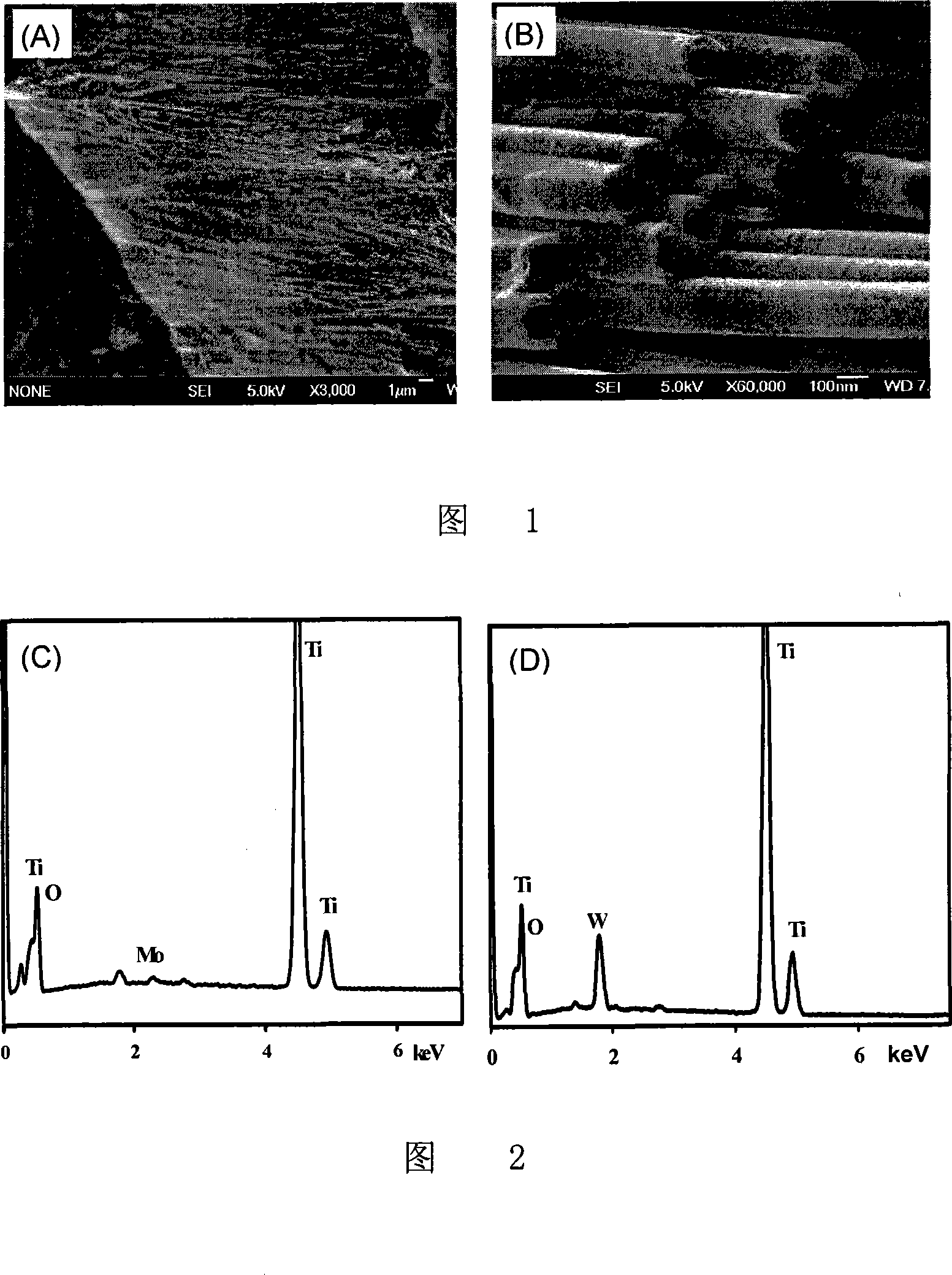

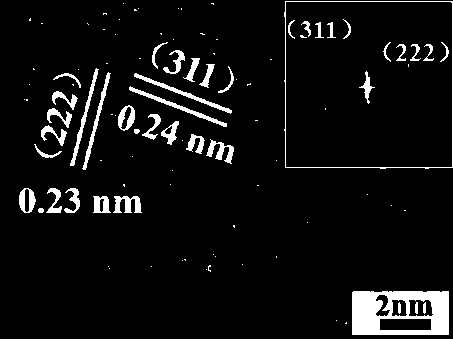

Method for producing titanium dioxide nano tube array with molybdenum tungsten doped anodizing method

InactiveCN101109096ALarge specific surface areaImprove surface defectsFinal product manufactureSurface reaction electrolytic coatingElectrolysisTitanium alloy

The invention discloses a method for preparing titanium dioxide nanometer tube array by molybdenum-tungsten mixture anode oxidation. Wherein, an electrolyte is an organic electrolyte system of hydrofluoric acid with HF content by mass of 0.5 swung dash 3% and dimethyl sulfoxide; under a DC voltage of 25 swung dash 100 V, some pure titanium or titanium alloy is taken as an anode, a platinum sheet as a cathode, and the nanometer tube is prepared by electrolyzing in the electrolyte; then the prepared TiO2 nanometer tube array is immersed in clearing solution of WO3 or MoO3 taking O22- as chelant for 10 swung dash 90 min., then TiO2 nanometer tube array mixed with tungsten and molybdenum is prepared. The invention increases the length of TiO2 nanometer tube, enlarges the specific surface area of the light-pole material, and widens the absorption spectrum of the TiO2 nanometer tube array in visible light area.

Owner:HUNAN UNIV

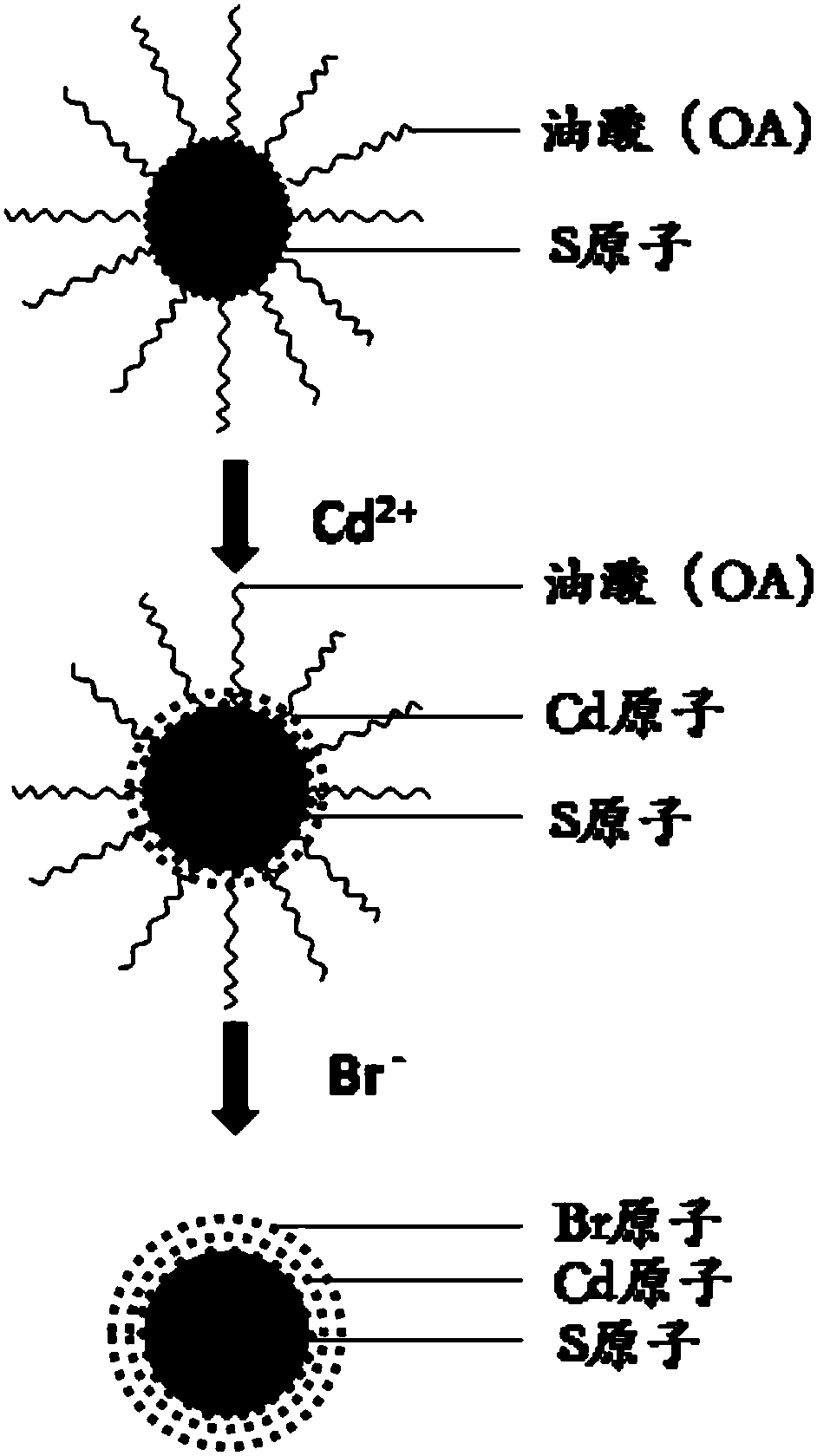

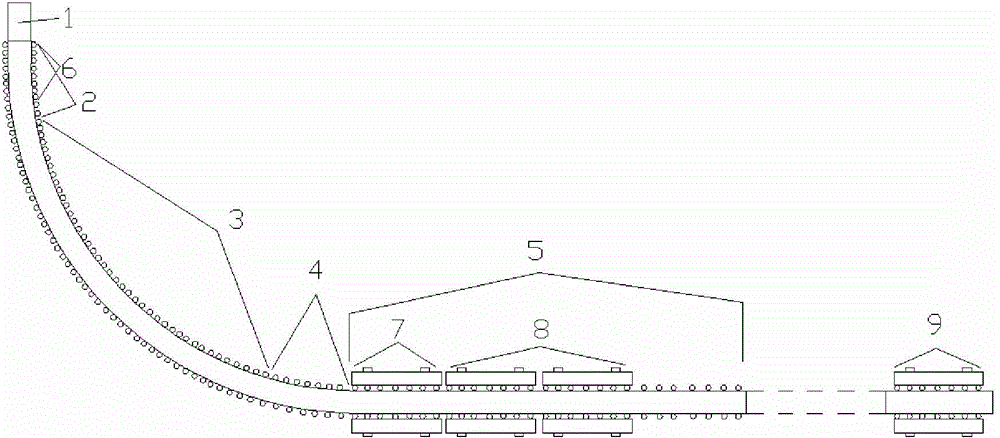

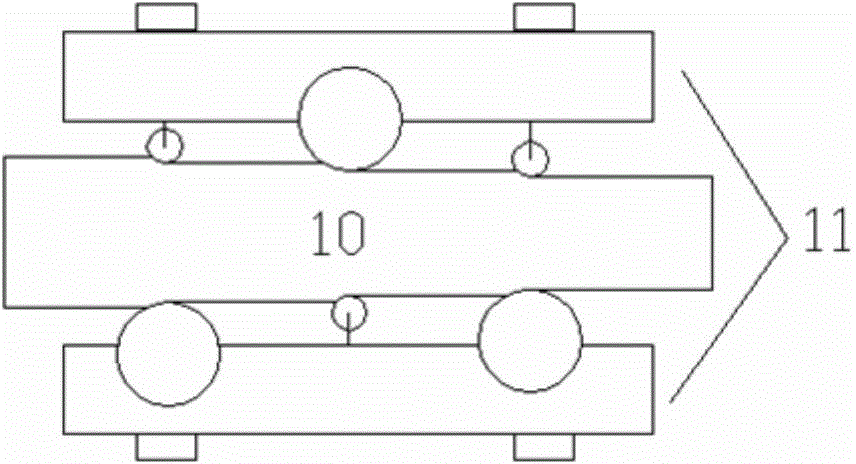

Method for producing ultra-thick plate continuous casting blank

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

Stainless steel having excellent antibacterial property and method for producing the same

InactiveUS6391253B1Improve corrosion resistanceImprove workabilitySilver particlesContinuous casting

The present invention provides a stainless steel being excellent in workability, corrosion resistance and antibacterial property. To be more specific, a stainless steel containing 10 wt % or more of Cr is rendered to contain 0.0001-1 wt % of Ag, or further one or more members selected from Sn: 0.0002-0.02 wt %, Zn: 0.0002-0.02 wt %, Pt: 0.0002-0.01 wt %, and, in addition, is rendered to dispersedly contain a total of 0.001 % or more in an area percentage of one or more members of a silver particle, a silver oxide and a silver sulphide each having a mean grain diameter of 500 mum or less. To disperse the silver particle, silver oxide and silver sulphide uniformly, the casting rate of continuous casting is preferably controlled to range from 0.8 to 1.6 m / min.

Owner:KAWASAKI STEEL CORP

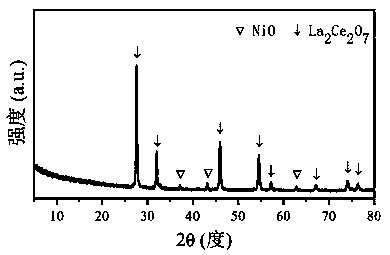

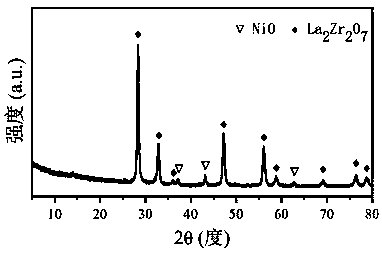

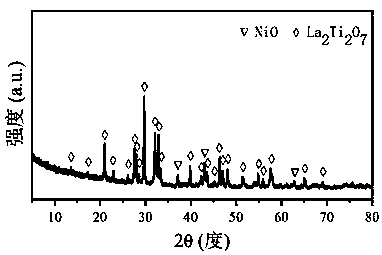

Ni/La2X2O7 catalyst for hydrogen production by autothermal reforming of acetic acid

ActiveCN111111674AGood choiceHigh catalytic activityHydrogenHeterogenous catalyst chemical elementsAcetic acidPtru catalyst

The invention relates to a Ni / La2X2O7 catalyst for hydrogen production by autothermal reforming of acetic acid. , Aiming at the problem of inactivation of an existing catalyst in the acetic acid autothermal reforming process, the invention provides the novel catalyst which is stable in structure and high in activity. A catalyst precursor is prepared by adopting a sol-gel method, and roasted by adopting an impregnation method to obtain the Ni / La2X2O7 (X is Ce, Zr or Ti) catalyst. According to the catalyst, the stability of active components is improved, the yield of hydrogen is increased, and generation of byproducts such as methane and acetone is effectively inhibited.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

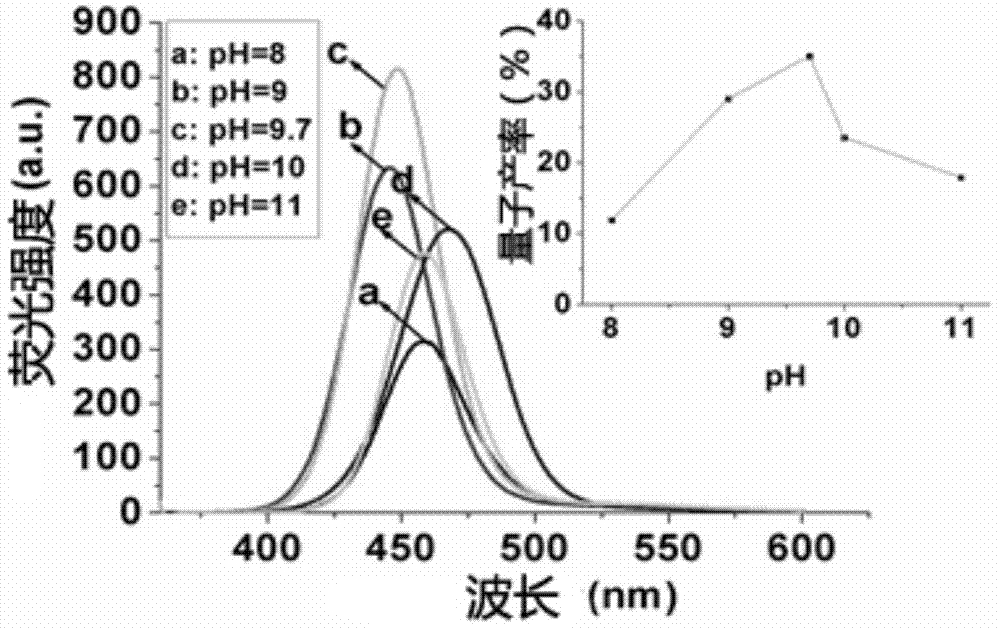

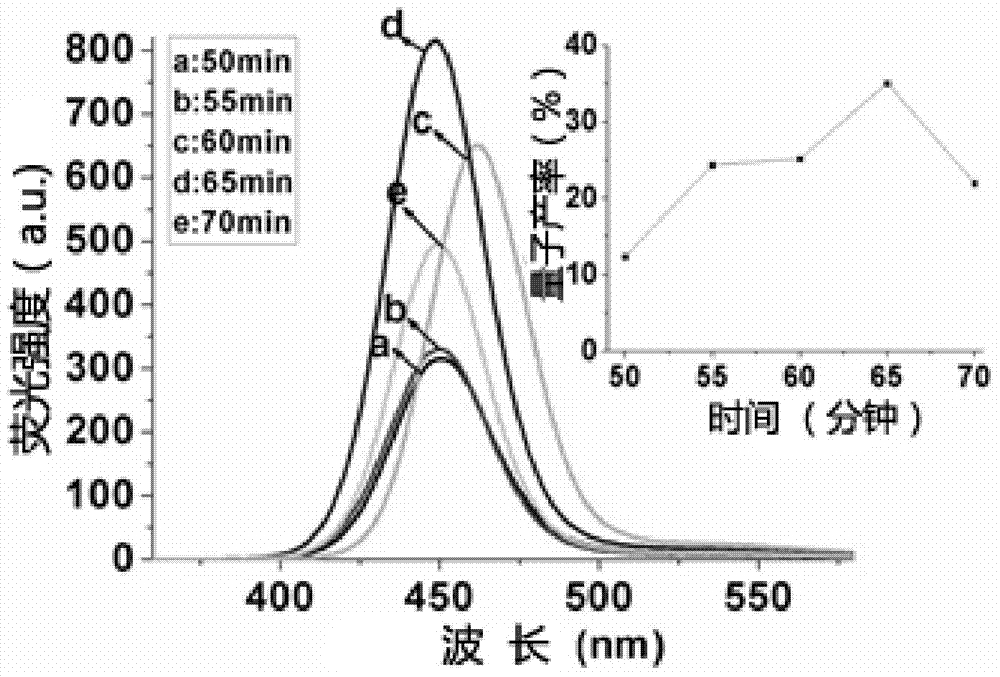

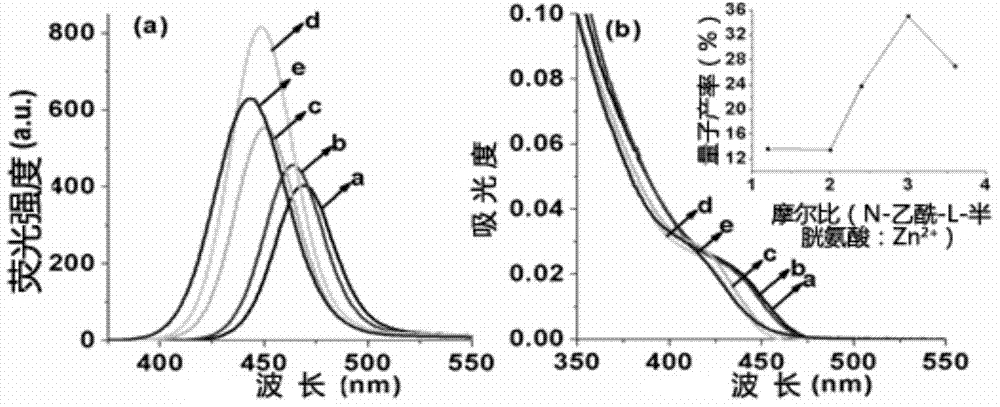

Aqueous phase preparation method for water-soluble chiral ZnCdSe quantum dot

InactiveCN104710989AGood optical performanceOperational securityNanoopticsLuminescent compositionsWater solubleAqueous solution

The invention discloses an aqueous phase preparation method for a water-soluble chiral ZnCdSe quantum dot. The preparation method comprises the following steps: (a) preparing a NaHSe or KHSe solution as a selenium source solution, dissolving a zinc salt and a water-soluble chiral mercapto compound in water so as to obtain a precursor solution of zinc and preparing an aqueous solution of a cadmium salt; (b) blowing inert gas into the precursor solution of zinc, injecting the selenium source solution and the aqueous solution of the cadmium salt and carrying out stirring so as to prepare a ZnCdSe precursor solution; and (c) subjecting the ZnCdSe precursor solution to a reflux reaction under stirring at a temperature of 80 to 100 DEG C for 1 to 5 h under the protection of inert gas, or transferring the ZnCdSe precursor solution to a reaction vessel and heating the ZnCdSe precursor solution to 160 to 210 DEG C for a reaction for 45 to 90 min so as to prepare an aqueous solution of the water-soluble chiral ZnCdSe quantum dot. The preparation method substantially reduces the usage amount of cadmium and is safe, simple and convenient to operate; and the obtained quantum dot has excellent photochemical properties and chirality and has wide application prospects in aspects like detection, location and targeted tracing of chiral substances.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

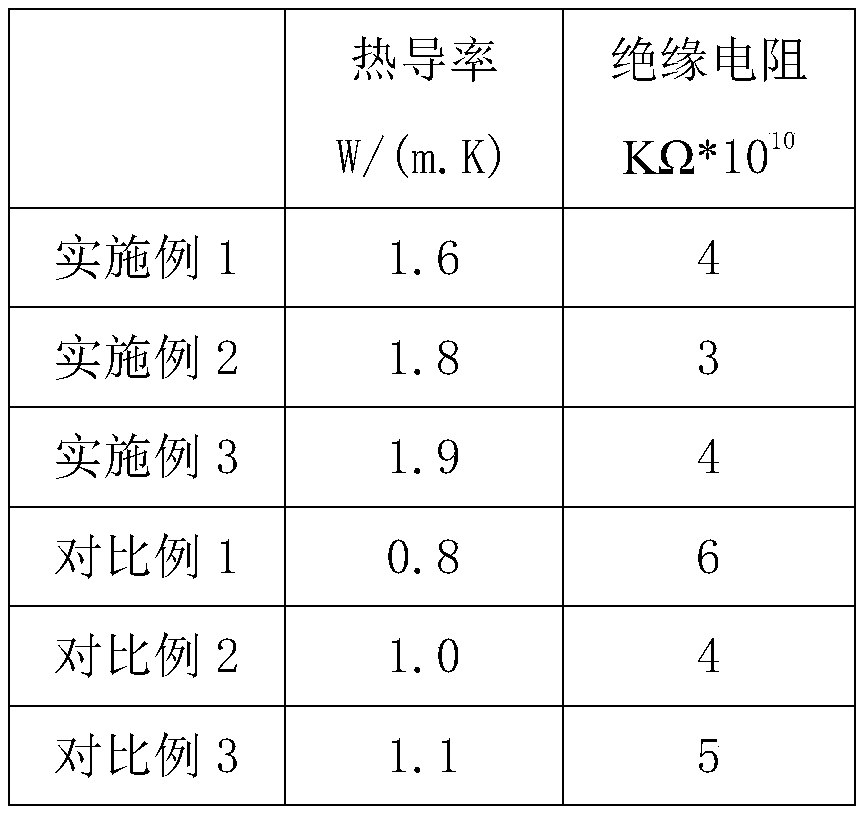

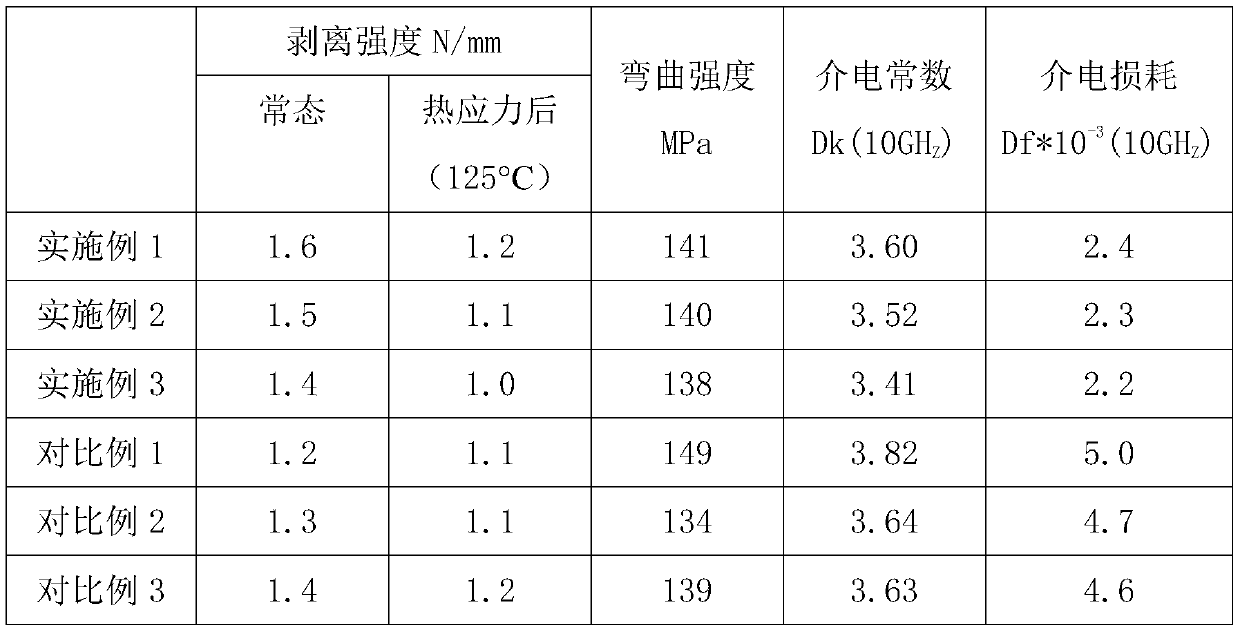

High-thermal-conductivity modified polytetrafluoroethylene copper-clad plate and preparation method thereof

PendingCN111251676AHigh thermal conductivityGood electrical performanceLamination ancillary operationsLaminationGlass fiberCopper foil

The invention discloses a high-thermal-conductivity modified polytetrafluoroethylene copper-clad plate and a preparation method thereof, which belong to the technical field of copper-clad plates. Themethod comprises the following steps: firstly, pretreating glass fiber cloth by adopting a silane coupling agent; then, preparing a PTFE / PFEP / L-tryptophan modified graphene oxide dispersion glue solution; impregnating the glass fiber cloth pretreated by the silane coupling agent in the glue solution, drying to obtain an impregnated film, laminating the impregnated film into a raw substrate with aspecified thickness, and covering copper foils on the two sides of the raw substrate for hot pressed sintering to obtain the modified PTFE copper-clad plate. The method is simple to operate, and the copper-clad plate prepared by the method has high thermal conductivity and excellent electrical performance.

Owner:无锡睿龙新材料科技有限公司

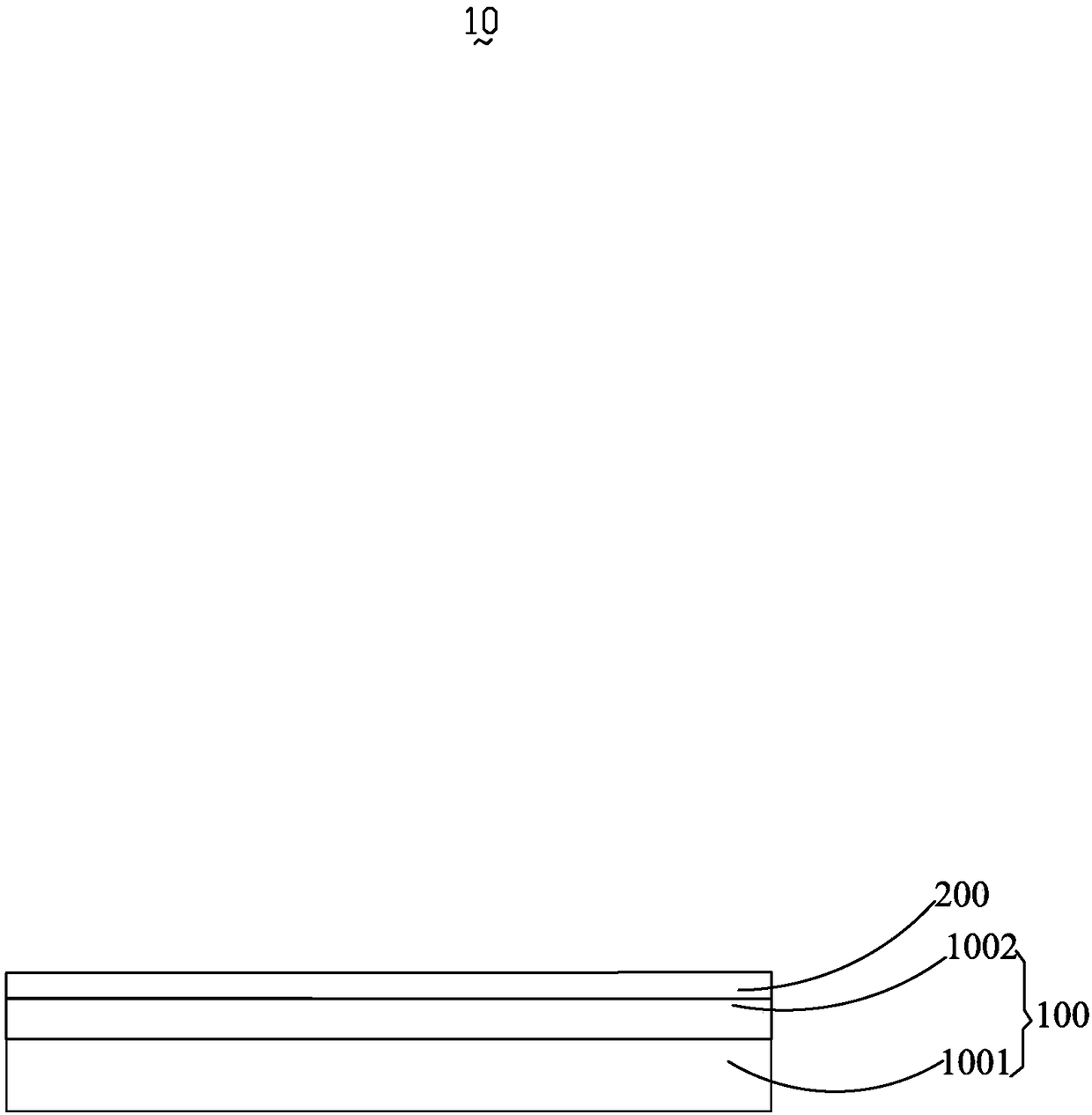

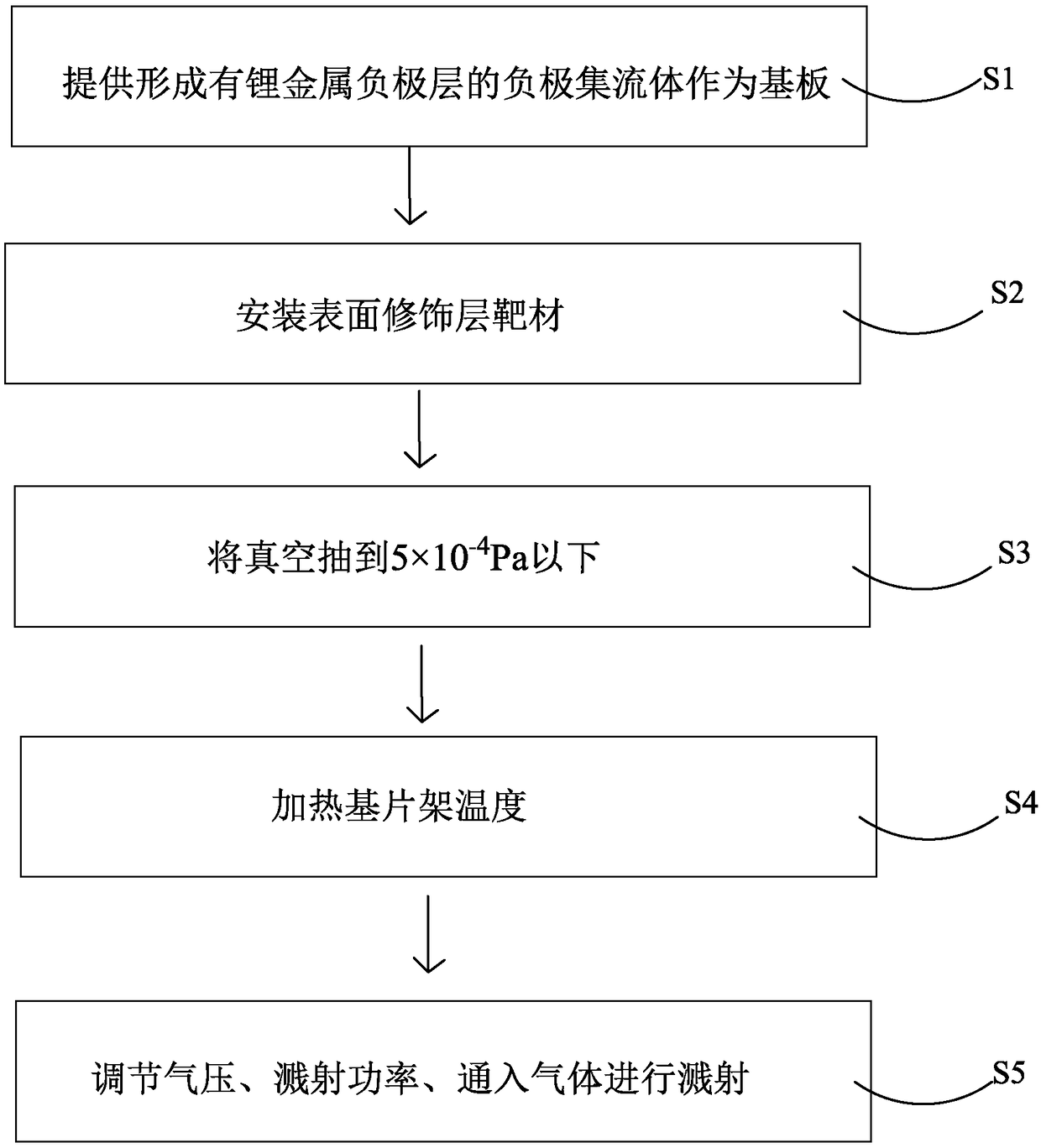

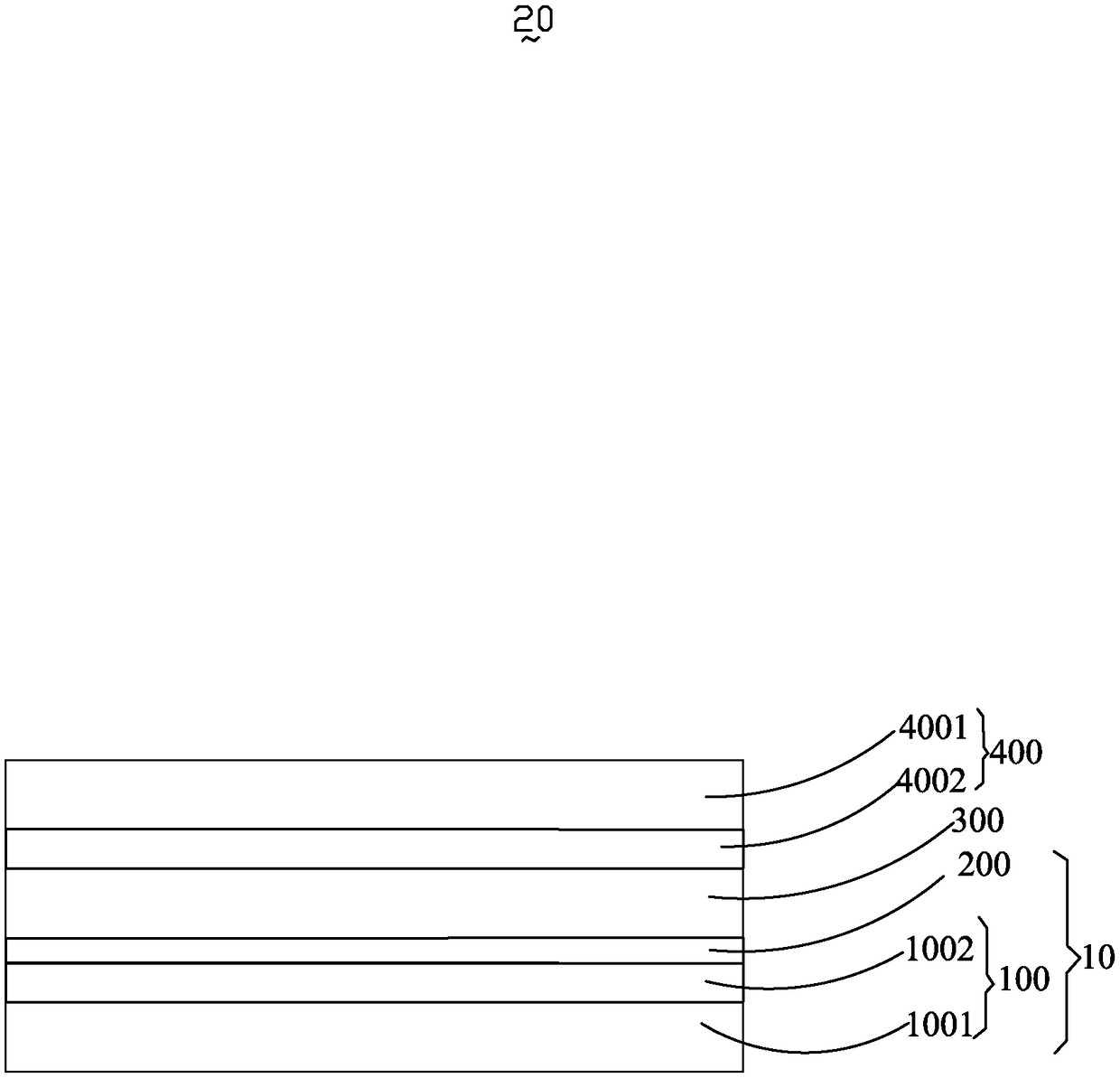

Lithium metal negative electrode structure combination, preparation method thereof and lithium battery cell

InactiveCN108365169AEnsure normal conductionGood ion conductivityFinal product manufactureSecondary cells servicing/maintenanceCharge dischargeLithium compound

The invention relates to the technical field of a lithium battery, in particular to a lithium metal negative electrode structure combination and a preparation method thereof. The metal lithium negative electrode structure combination comprises a negative electrode structure and a surface modification layer, wherein the surface modification layer is formed on the negative electrode structure, the negative electrode structure comprises a negative current collector and a lithium metal negative electrode layer, the lithium metal negative electrode layer is formed on the negative current collector,the negative current collector, the lithium metal negative electrode layer and the surface modification layer are arranged in a lamination way, the lithium metal negative electrode layer comprises alithium metal active material, and the surface modification layer comprises a lithium compound having ion conduction characteristic. The surface modification layer has a modification effect on a surface of the lithium metal negative electrode layer, the surface defect of the lithium metal negative electrode layer is improved, the situations that charges are not uniformly distributed on the lithiummetal negative electrode layer during the charge-discharge process to form lithium dendrites and an electrolyte separator layer is punctured to cause short circuit of the battery are prevented, meanwhile, the lithium dendrites are limited from being formed on the lithium metal negative electrode layer, so that the charges are uniformly distributed on the lithium metal negative electrode layer, and the specific capacity density of the lithium metal negative electrode layer is improved.

Owner:成都亦道科技合伙企业(有限合伙)

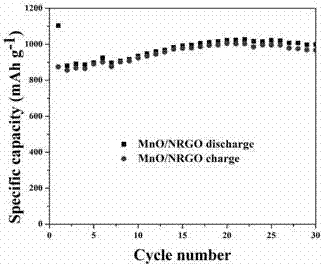

Preparation method of manganese monoxide/nitrogen-doped reduced graphene oxide composite electrode material

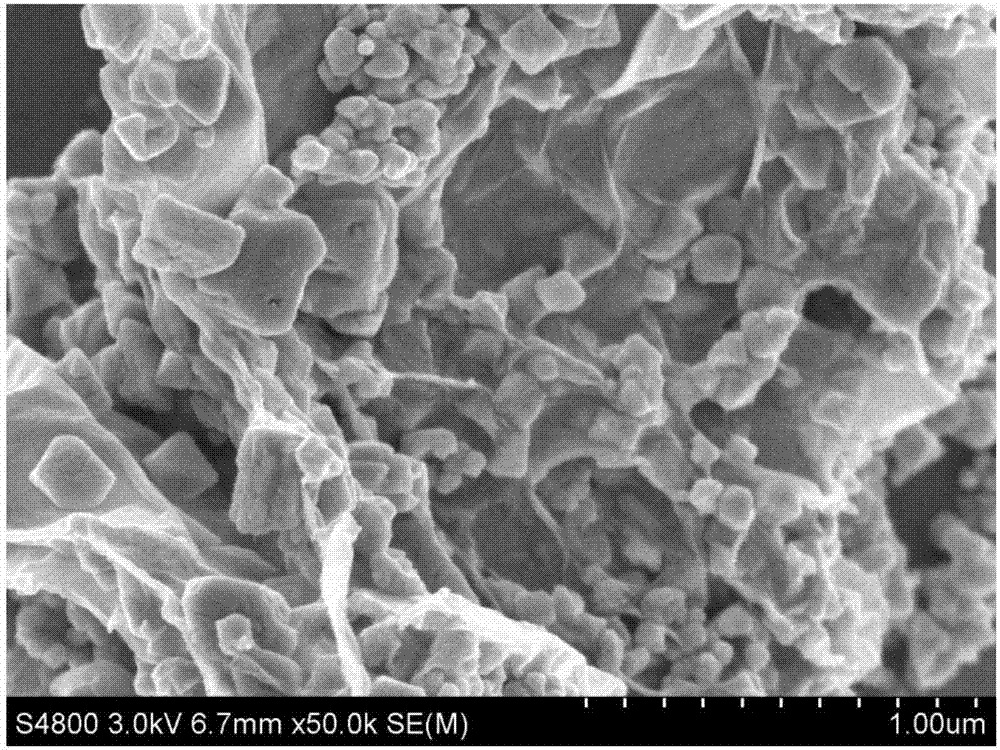

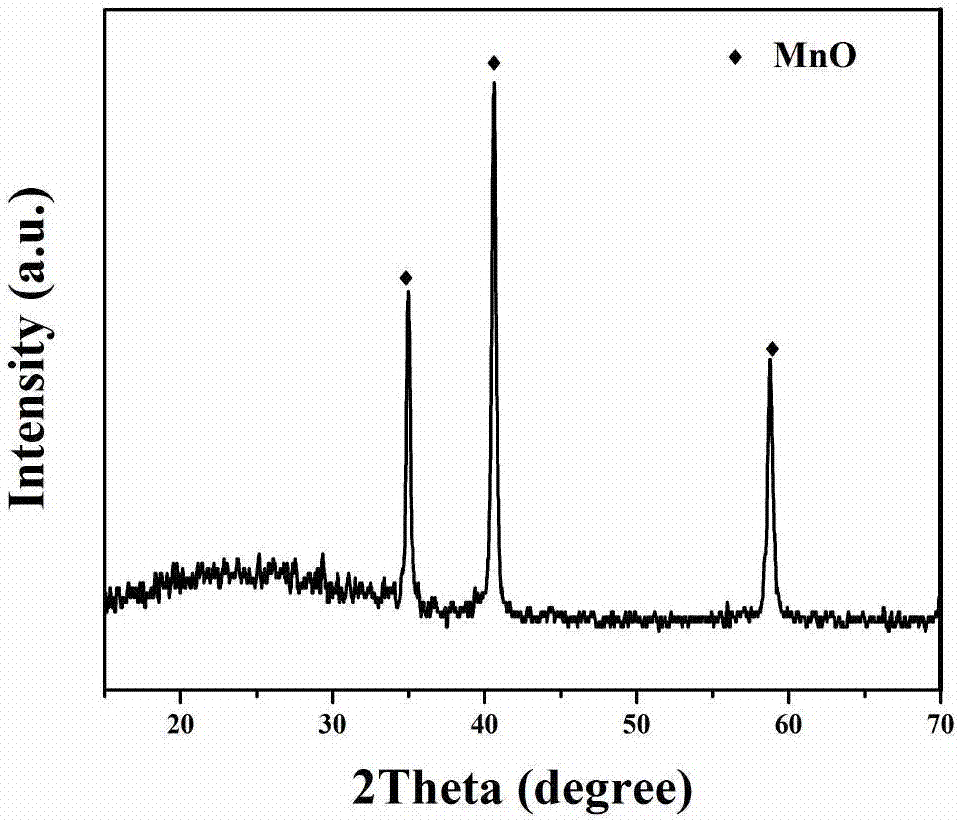

InactiveCN107195878AIncreased active sitesFavorable for adsorption growthCell electrodesSecondary cellsCvd grapheneUrea

The invention discloses a preparation method of a manganese monoxide / nitrogen-doped reduced graphene oxide composite electrode material. Manganese acetate, graphene and urea are regarded as main raw materials; and the preparation method comprises the steps of firstly preparing a compound of manganese carbonate and graphene by adopting a hydrothermal method; then carrying out heat treatment for the compound in a tubular atmosphere furnace to prepare granular MnO loaded on a thin graphene sheet; meanwhile, carrying out nitrogen doping for the graphene to enable the graphene to serve as an anode material for a lithium-ion battery. Due to addition of the urea in the synthetic method, for one thing, N atoms are introduced to dope the graphene, defects on the surface of the graphene are increased, the active sites are increased and the adsorptive growth of the Mn2+ is better facilitated; and for another, the urea which has a certain dispersion effect in the whole system enables the MnO particles to be uniformly diffused on the graphene sheet. As the MnO particles are loaded on the reduced graphene oxide sheet, the poor conductivity of the MnO is not only improved, but also gathering and powdering of the MnO particles in a continuous charging and discharging process is prevented; and accordingly, the electrochemical performance of the MnO particles is effectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

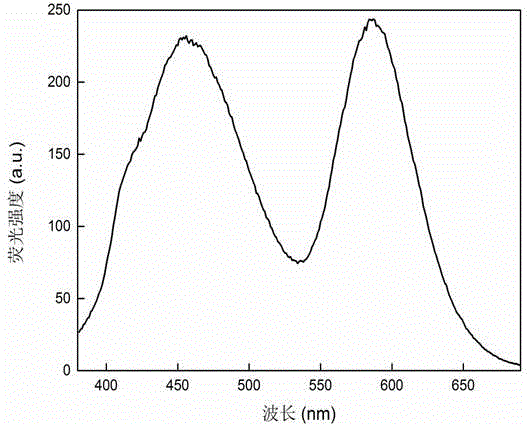

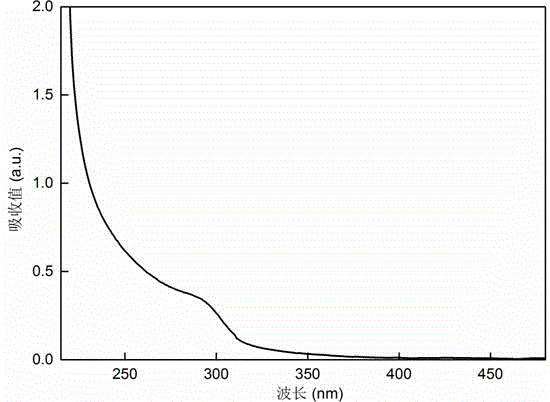

Water-soluble copper-and-manganese-codoped ZnS(Se) white-light quantum dot and preparation method thereof

InactiveCN104610970AGood water solubilityImprove stabilityEnergy efficient lightingLuminescent compositionsQuantum yieldPhysical chemistry

The invention belongs to the technical field of quantum dot light-emitting materials, and particularly discloses a water-soluble copper-and-manganese-codoped ZnS(Se) white-light quantum dot and a preparation method thereof. The method comprises steps as follows: firstly, a reaction precursor solution is prepared and adjusted to a proper pH value, and then the copper-and-manganese-codoped ZnS(Se) quantum dot is obtained through microwave-assisted heating. The method is simple to operate and environment-friendly, conditions are mild, and the cost is low. The prepared copper-and-manganese-codoped ZnS(Se) quantum dot is good in water-solubility and stability, higher in quantum yield and capable of being excited to directly emit white light under the certain wavelength or the certain voltage.

Owner:FUDAN UNIV

High-capacity, high-compaction and quick-charge composite graphite negative electrode material and preparation method thereof

InactiveCN111646466AReduce bloatExpansion constraintsGraphiteSecondary cellsElectrode materialLithium battery

The invention relates to the field of lithium batteries, and especially relates to a high-capacity, high-compaction and quick-charge composite graphite negative electrode material. Artificial graphiteand natural graphite single particles are tightly anchored together through amorphous carbon to form a composite graphite secondary particle structure, and a layer of amorphous carbon is applied between the artificial graphite and the natural graphite particles and on the surface of each component particle in a coating manner. The defect that a graphite negative electrode material developed in the prior art cannot give consideration to high capacity, high compaction or quick charging performance is overcome, the advantages of the natural graphite are utilized to ensure the high capacity and high compaction performance of the material, meanwhile, the natural graphite is compounded with the artificial graphite with partial isotropy to buffer the expansion of the natural graphite, and the layer of amorphous carbon is formed between the artificial graphite and the natural graphite particles and on the surface of each single particle, so that the migration rate of lithium ions between thesurface of the graphite and different graphite is increased while the surface defects of the natural graphite are improved.

Owner:WANXIANG 123 CO LTD

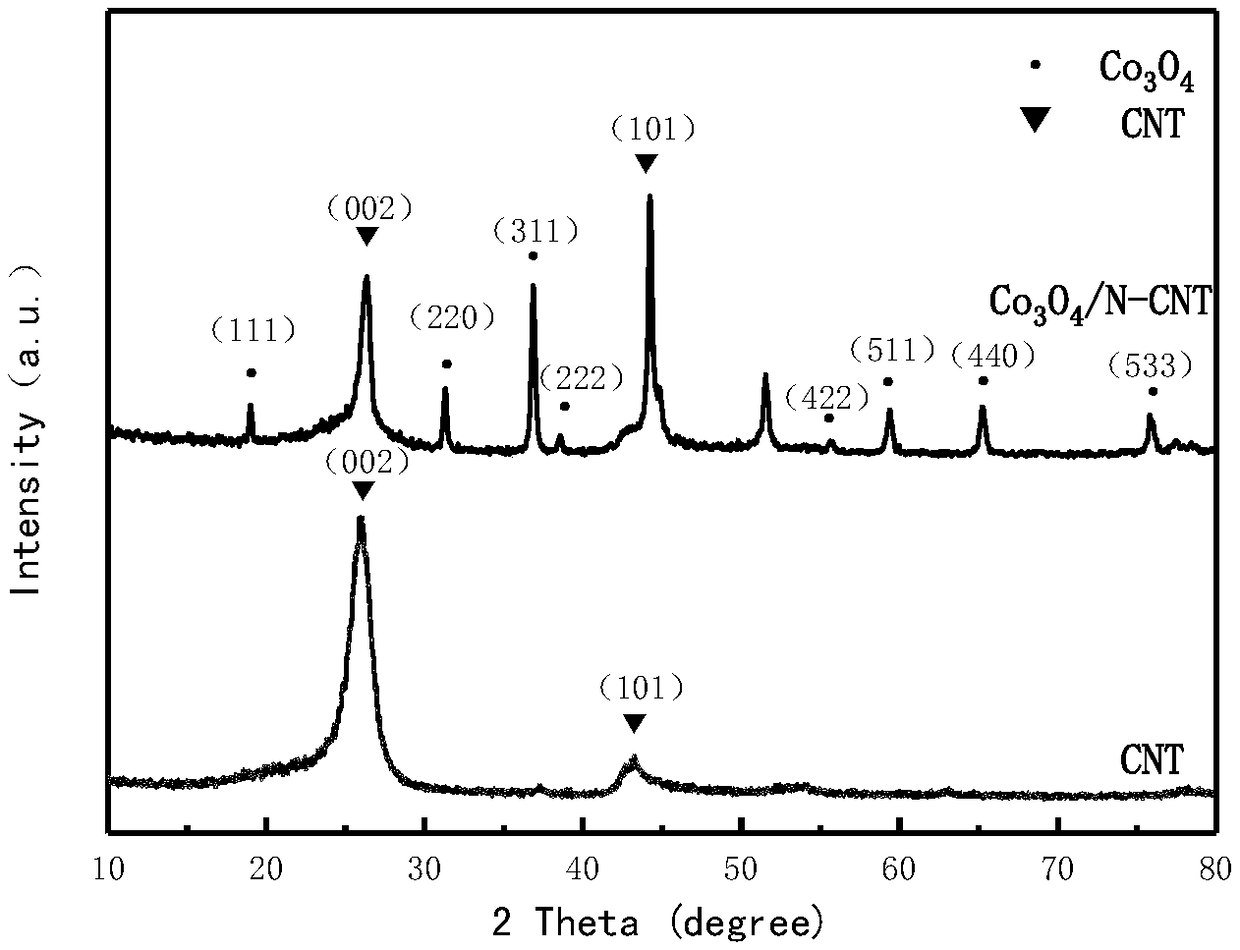

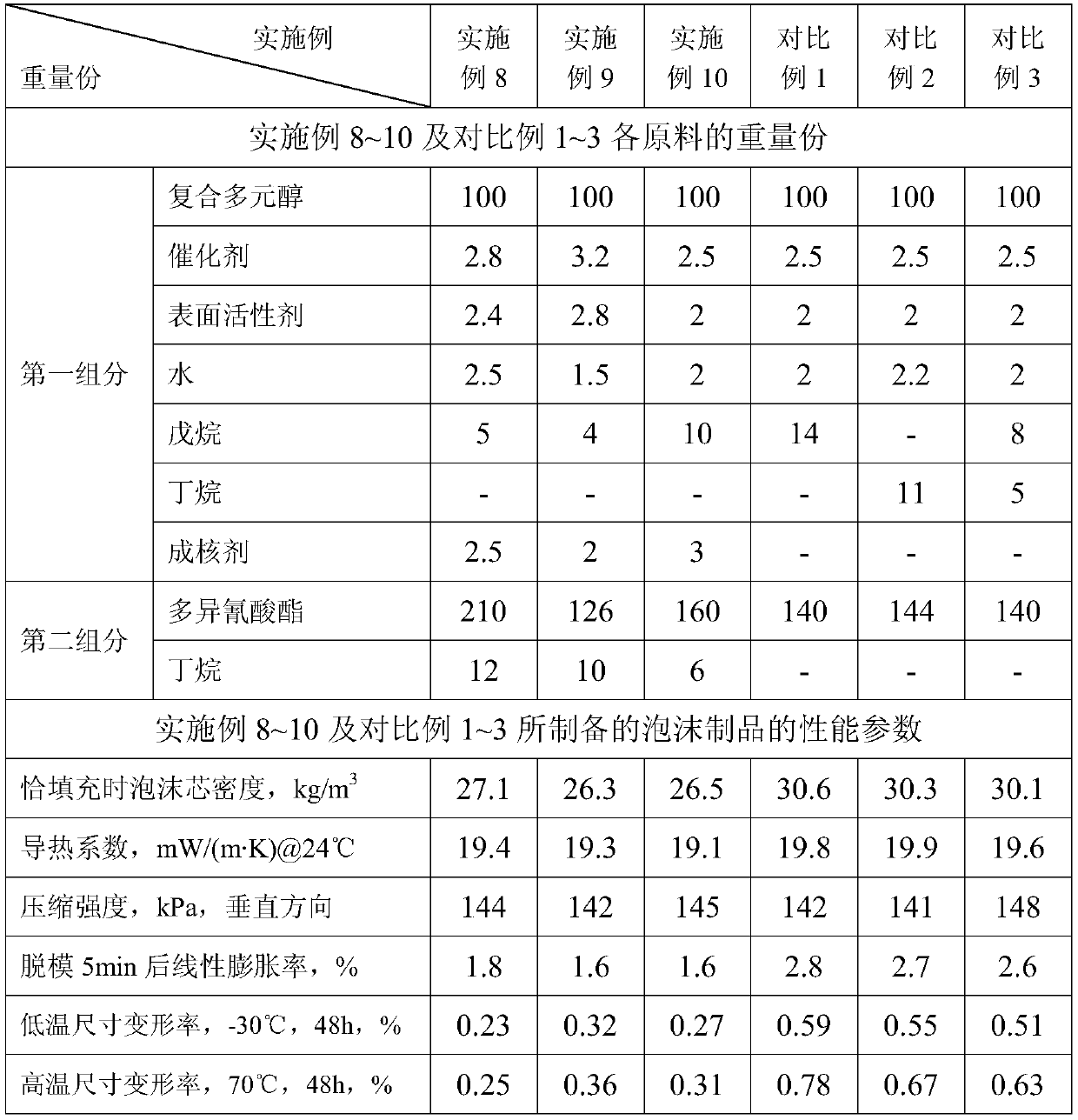

Cobalt oxide/nitrogen co-doped carbon nanotube composite material and preparation and application thereof

ActiveCN108816261AThe preparation process is simple, clean and controllableRaw materials are easy to obtainPhysical/chemical process catalystsWater contaminantsPhenolNitrogen doped

The invention discloses a cobalt oxide / nitrogen co-doped carbon nanotube composite material and a preparation and an application thereof. The specific steps of preparation are as follows: a certain proportion of carbon source and nitrogen source dicyandiamide and cobalt salt are taken as raw materials, urea is taken as an alkali source to adjust the solution to alkaline, polyvinylpyrrolidone is used as a surfactant in a ultrasonic reaction instrument for a full mixing reaction and is heat to dryness, and an obtained mixture is carbonized, pickled, and washed with water to obtain a material encapsulated in nitrogen-doped carbon nanotubes with cobalt oxide. The material has novel structure, simple and easy acquisition of raw materials, simple process, clean reaction process and no secondarypollution. The material is applied to the degradation and removal of phenol in water, the method is simple and the removal effect is good, and for treating phenol with a concentration of 0.1 mmol / L, the removal rate of phenol can reach 99% within 20 minutes.

Owner:CENT SOUTH UNIV

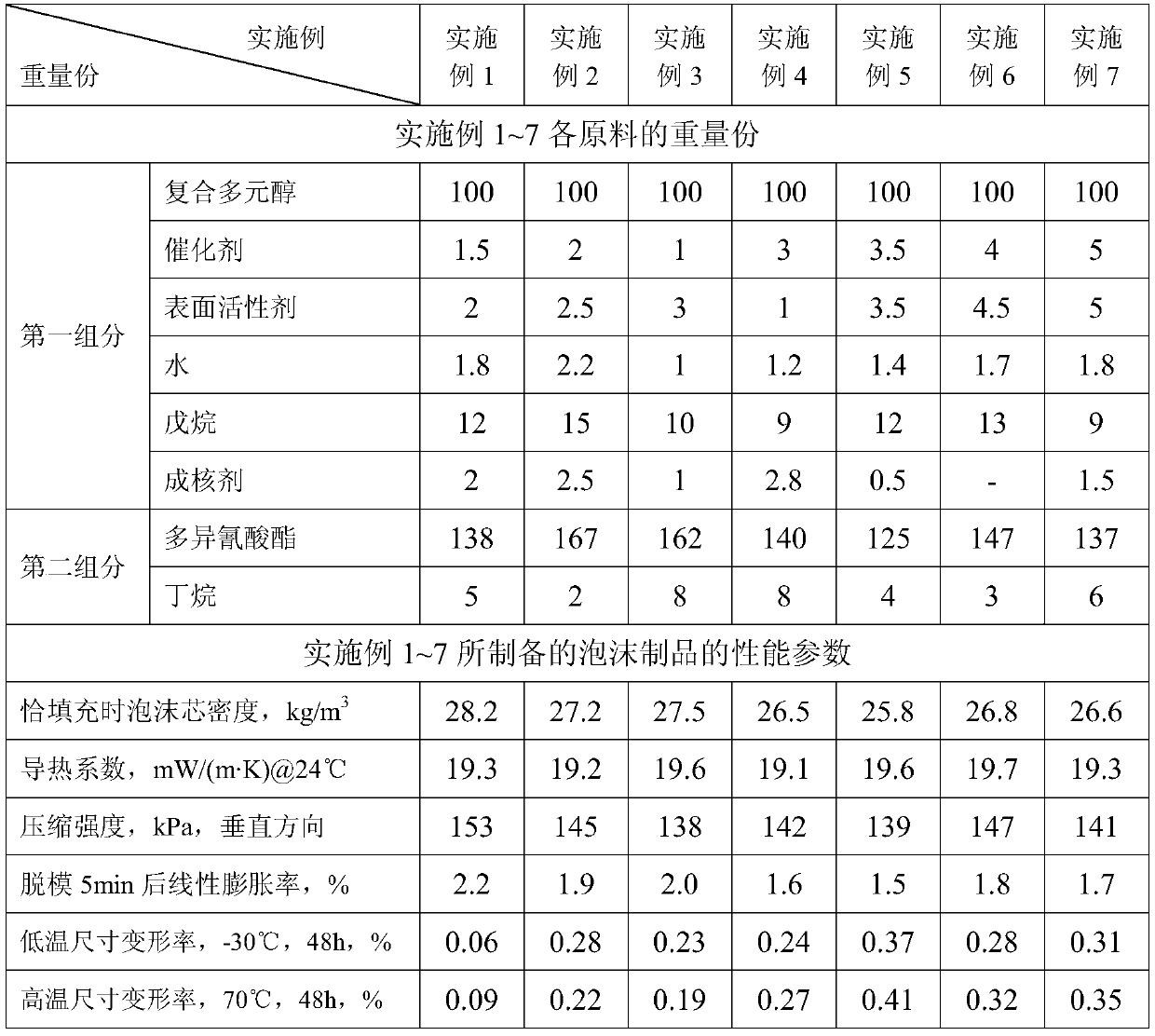

Ultra-low-density rigid polyurethane foam and preparation method thereof

The invention relates to ultra-low-density rigid polyurethane foam with pentane and butane as foaming agents. The ultra-low-density rigid polyurethane foam is prepared by well premixing a component Aand a component B, and then well mechanically mixing and foaming the component A and the component B, wherein the component A is prepared from the components in parts by weight: 100 parts of pluronicpolyols, 4-15 parts of the pentane, 1-5 parts of a catalyst, 1-5 parts of an organosilicon surfactant, 1-2.5 parts of water and 0-3 parts of a nucleating agent, the component B is prepared from the components in parts by weight: 2-12 parts of the butane and 120-210 parts of polyisocyanates, and raw materials are based on 100 parts of pluronic polyols. According to the prepared foam, foam holes arefine and uniform, the heat conductivity coefficient is small, the compression strength is high, and the overall performance is excellent. The invention further discloses a preparation method of the rigid polyurethane foam.

Owner:NANJING HONGBAOLI POLYURETHANE

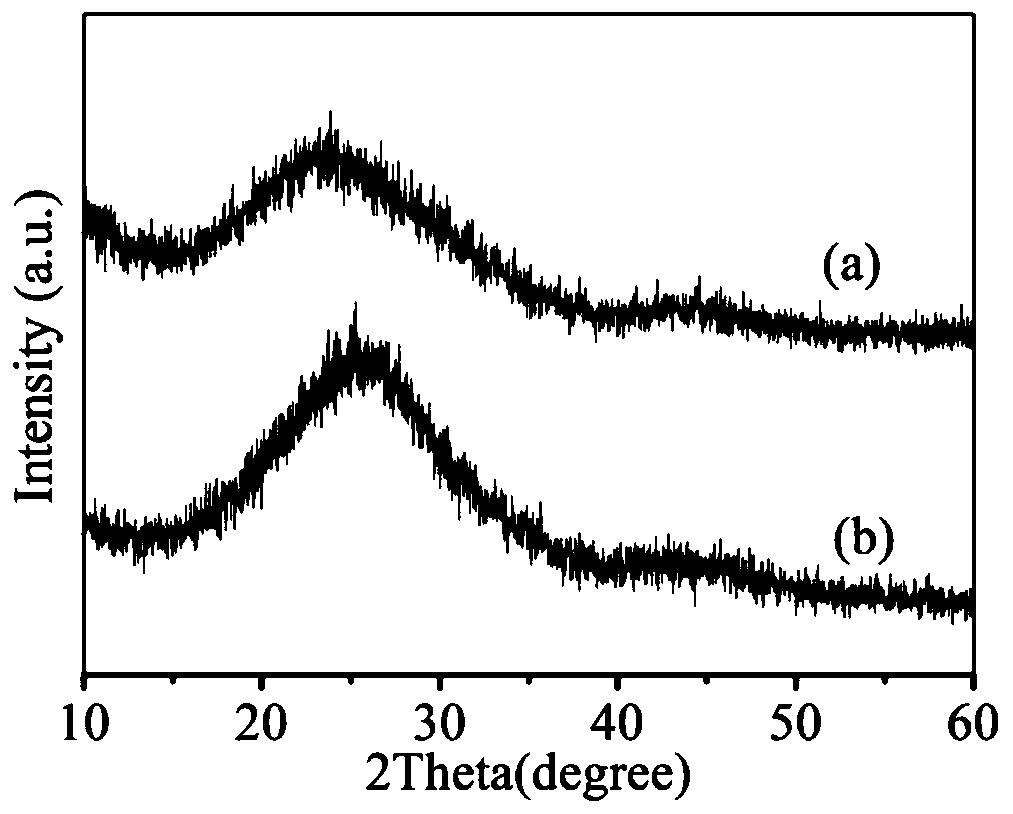

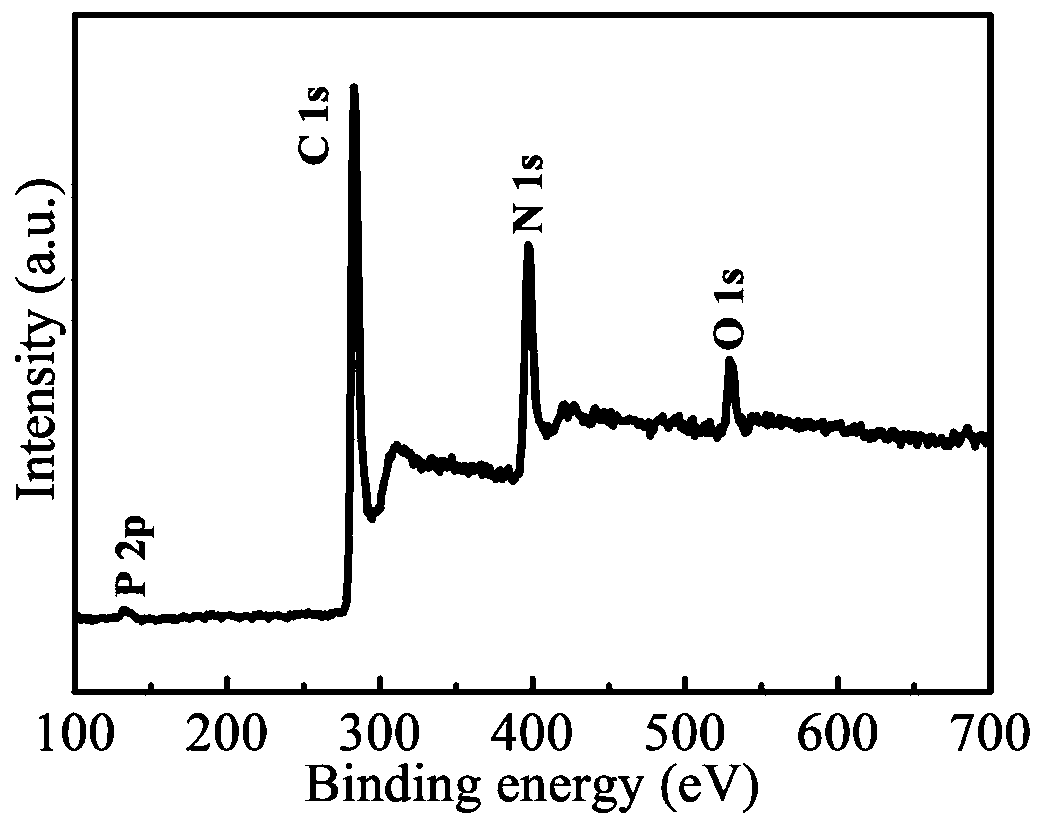

Nitrogen-phosphorus co-doped ordered mesoporous carbon material and preparation method thereof and application thereof

ActiveCN109728246AIncrease surface defectsGood for storageNon-aqueous electrolyte accumulator electrodesIonDecomposition

The invention discloses a preparation method of a nitrogen-phosphorus co-doped ordered mesoporous carbon material and application of a nitrogen-phosphorus co-doped ordered mesoporous carbon material.The nitrogen-phosphorus co-doped ordered mesoporous carbon material takes organic sugar as a carbon source, a mesoporous template agent is employed to synthesize ordered mesoporous carbon, the orderedmesoporous carbon is mixed with the nitrogen and phosphorus source with different proportions to form a solution and perform water bath drying by distillation, the obtained mixture is subjected to high-temperature calcination and pyrogenic decomposition to achieve nitrogen-phosphorus co-doping, and the mesoporous template agent is removed to obtain a high-performance sodium-ion battery anode material. The nitrogen-phosphorus co-doped ordered mesoporous carbon material is simple and convenient in preparation process and high in doping amount, is taken as a sodium-ion battery anode material tohave excellent cycle performance and a large rate charge and discharge performance and have a broad application prospect in the energy storage field.

Owner:TAIYUAN UNIV OF TECH

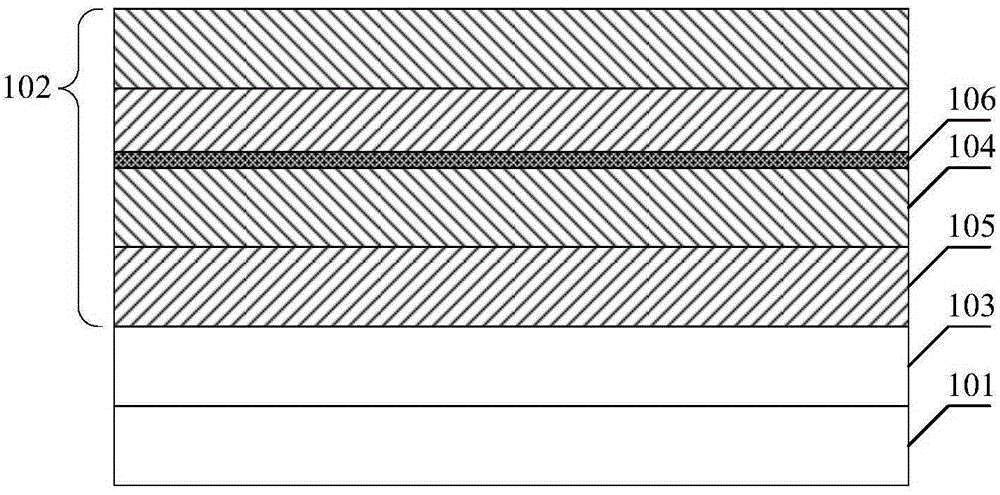

Display panel and manufacturing method thereof

ActiveCN105304685AImprove surface defectsLoose surfaceSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOxygen

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises an array substrate and an encapsulation structure which is arranged on the array substrate. An organic light emitting structure is arranged between the array substrate and the encapsulation structure. The encapsulation structure comprises a stacked structure formed by at least one organic layer and at least one inorganic structure, wherein at least one side surface, close to the organic layer, of the at least one inorganic structure is sputtered with metallic elements, forming an interface mixing structure including the metallic elements and inorganic layer materials. The encapsulation effect and the capability of isolating water and oxygen are improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

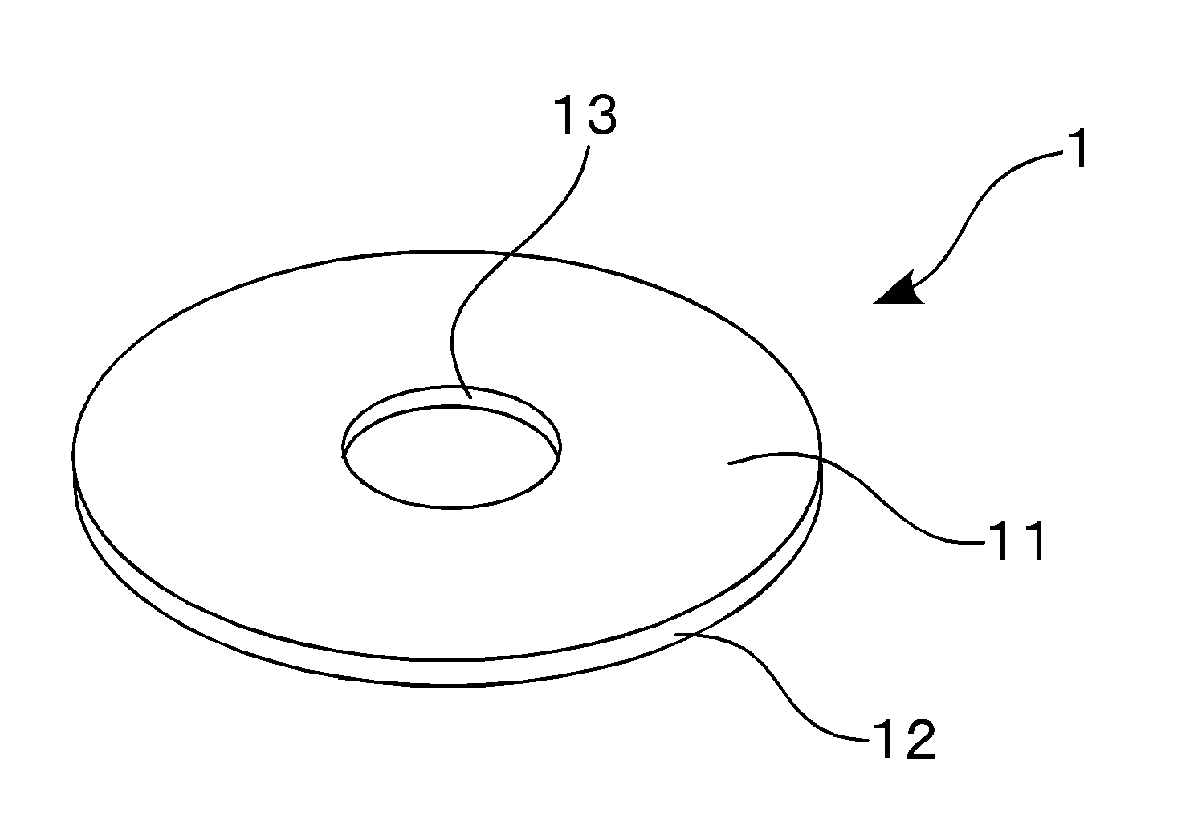

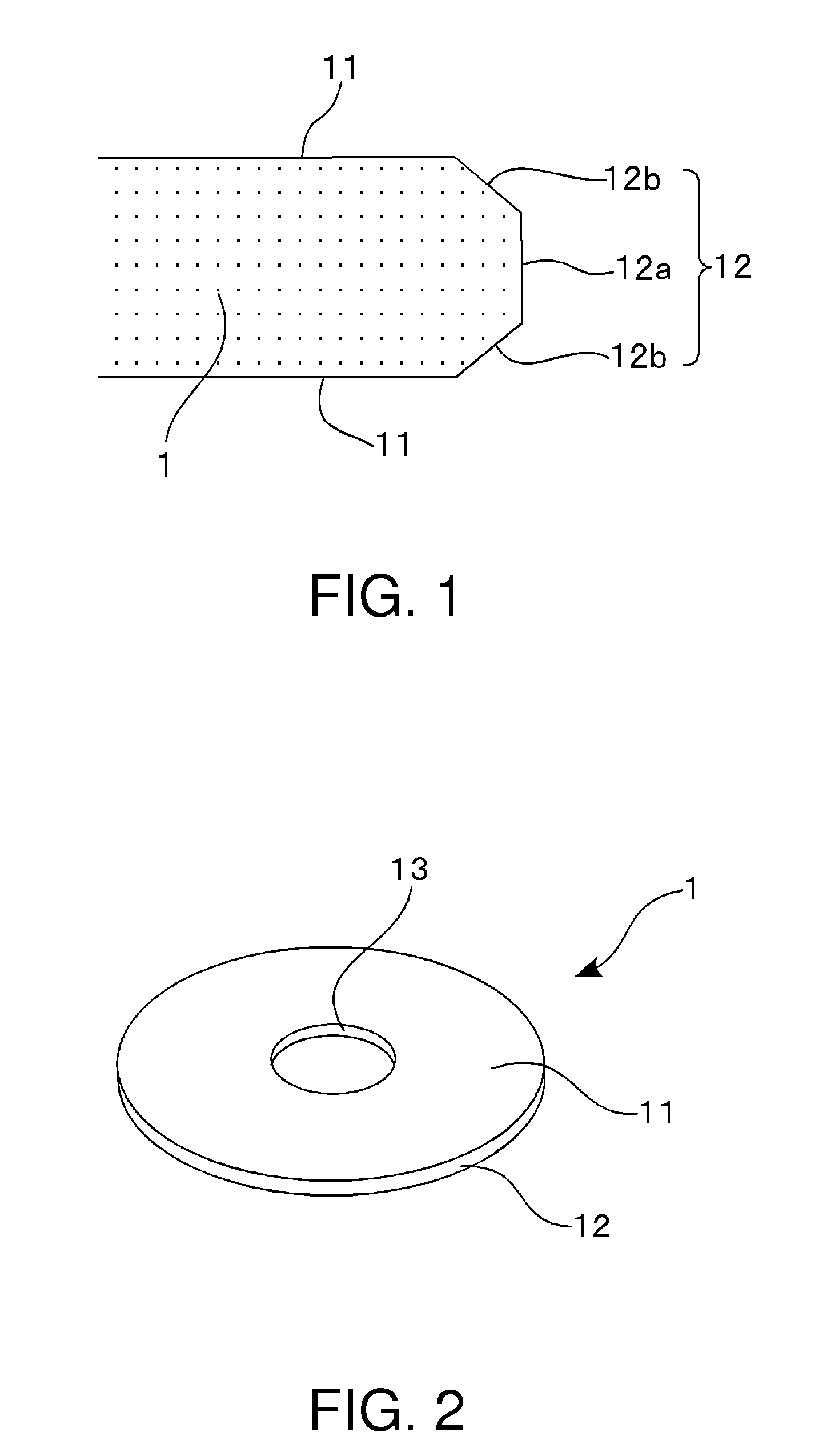

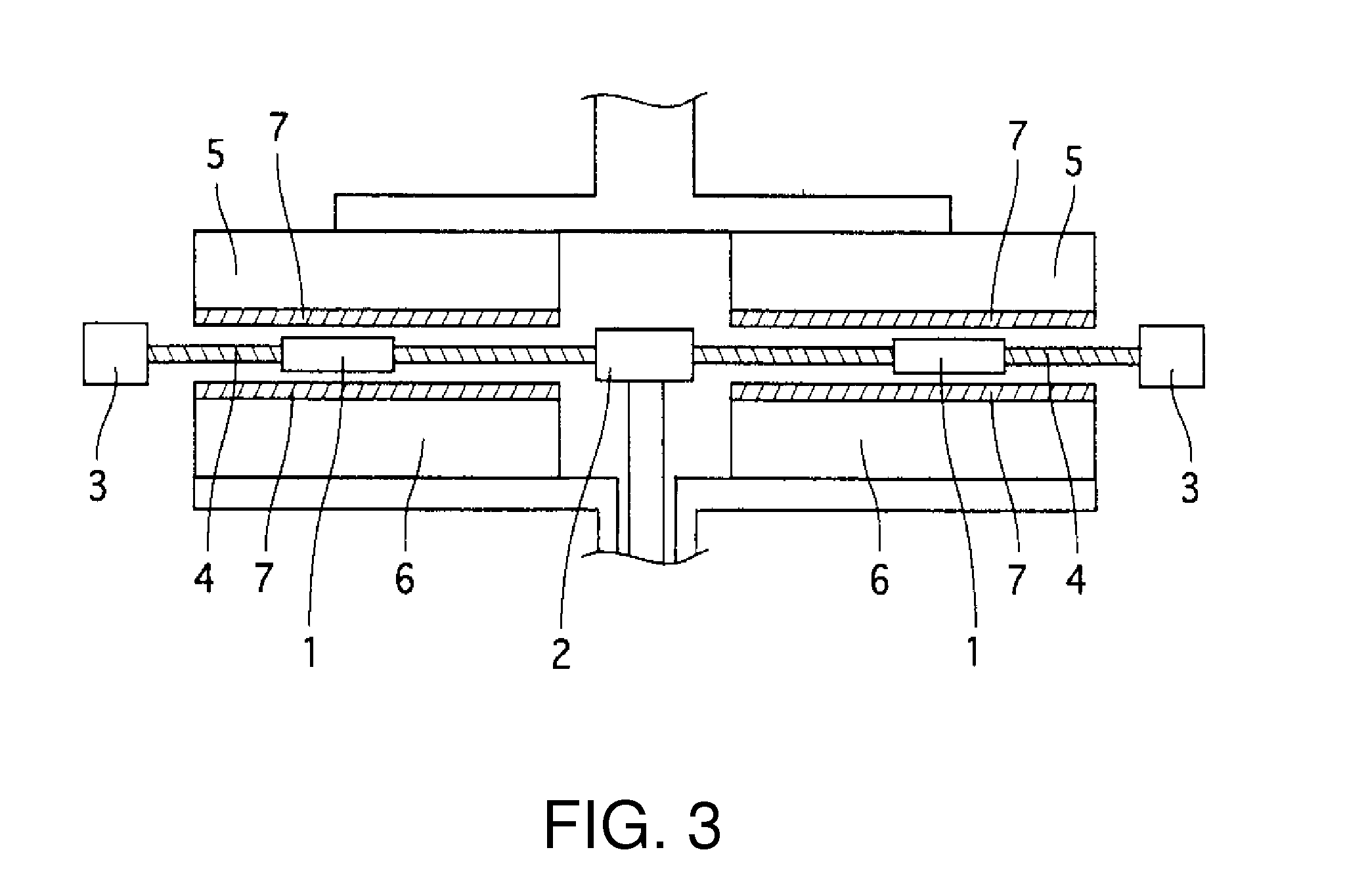

Method of manufacturing a glass substrate for a magnetic disk and method of manufacturing a magnetic disk

ActiveUS20120196033A1High polishing rateLow costBase layer manufactureSpecial surfacesOptoelectronicsMagnetic disks

A method of manufacturing a glass substrate for a magnetic disk includes a polishing step of polishing a main surface of a glass substrate by sandwiching the glass substrate between a pair of surface plates each having a polishing pad on its surface and by supplying a polishing liquid containing polishing abrasive particles between the glass substrate and the polishing pads. In the polishing step, the polishing liquid and each polishing pad are adjusted so that the friction coefficient falls in a range of 0.02 to 0.05.

Owner:HOYA CORP

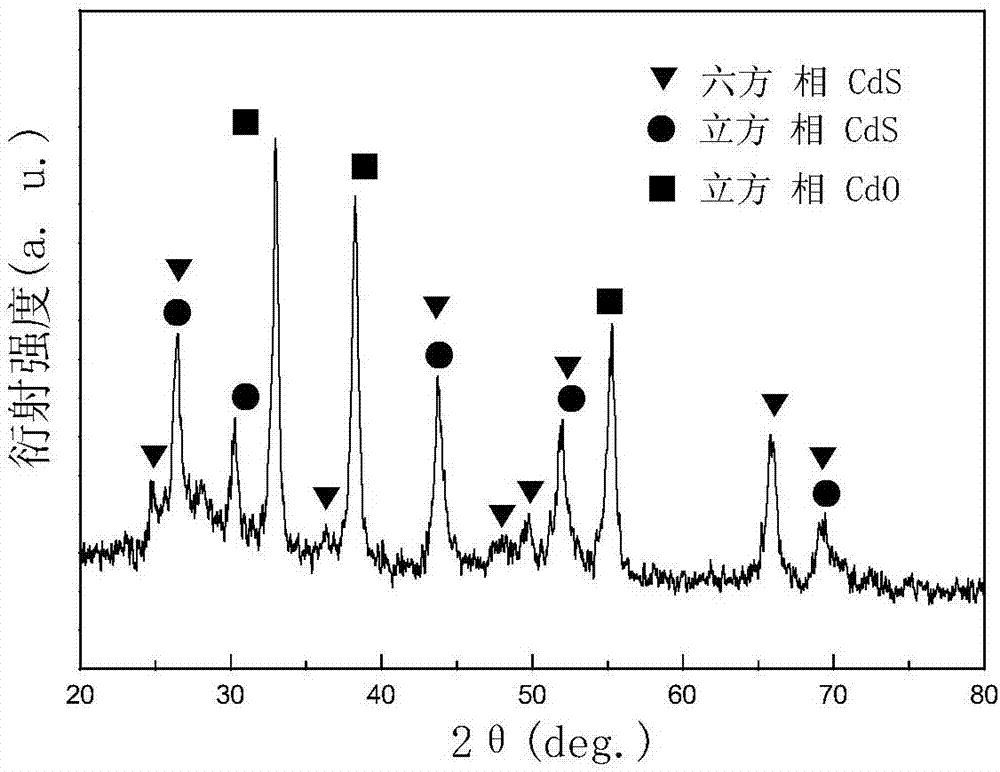

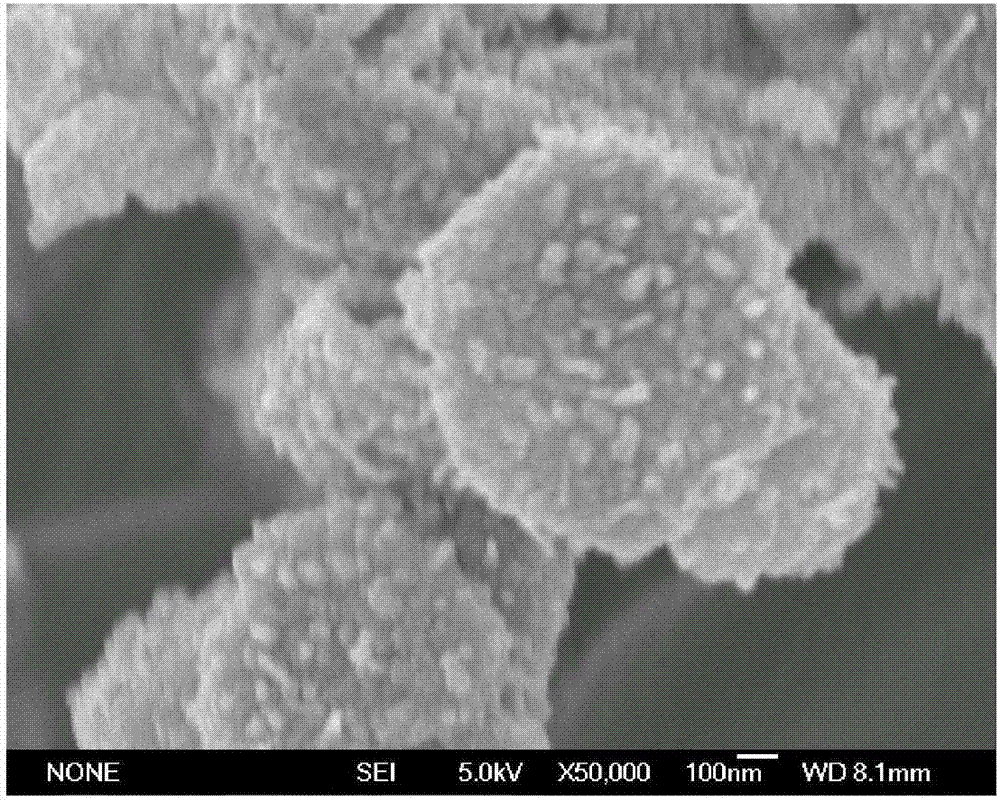

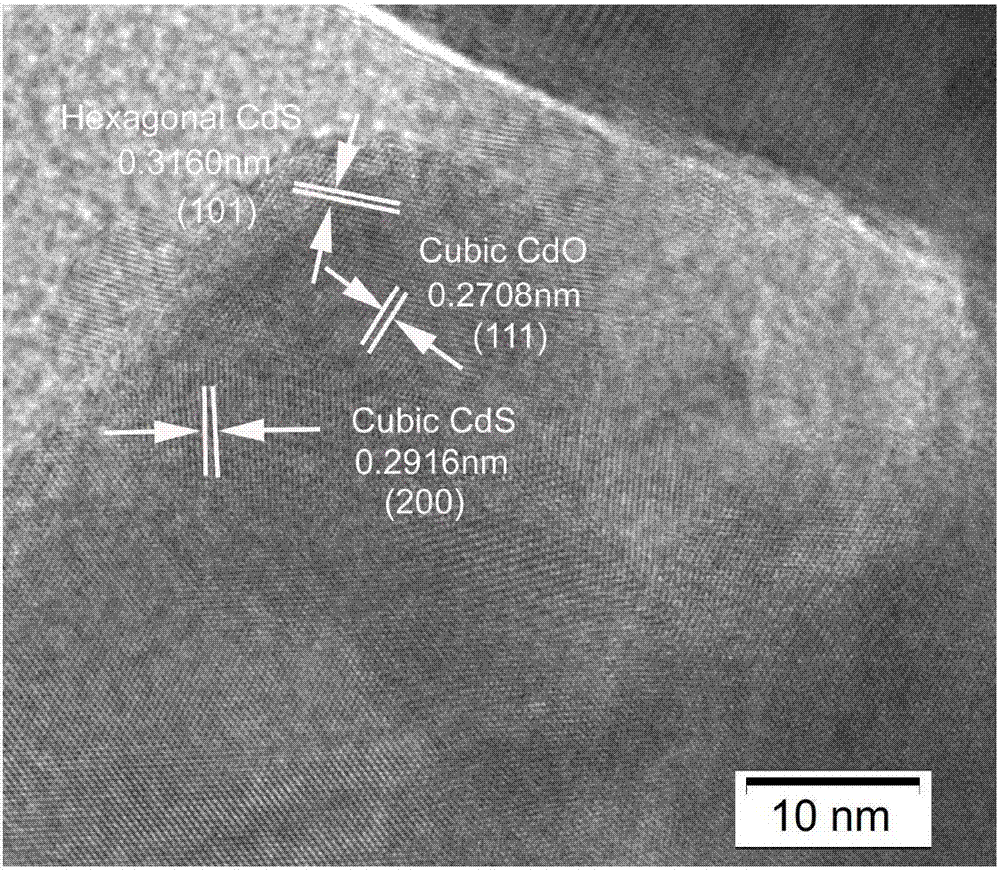

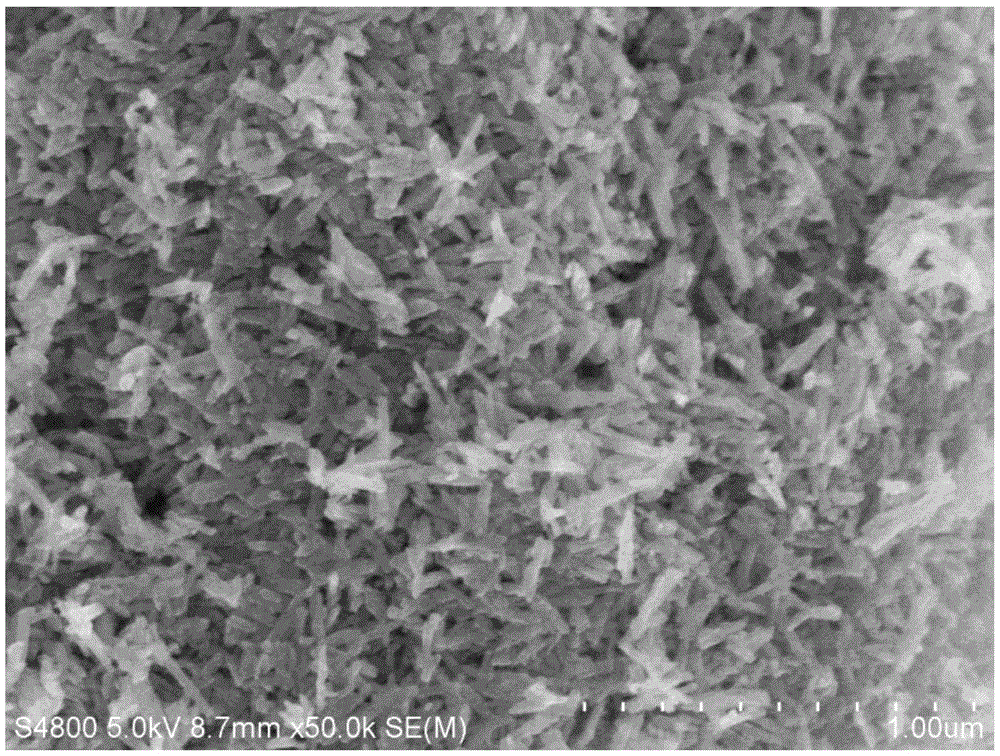

Method for simply preparing hexagonal CdO/CdS heterojunction nano composite material

InactiveCN107051548AInhibitory complexImprove photocatalytic efficiencyMaterial nanotechnologyPhysical/chemical process catalystsHeterojunctionOrganic dye

The invention relates to a method for simply preparing a hexagonal CdO / CdS heterojunction nano composite material. The method mainly comprises the following steps: preparing cadmium hydroxide, used as a precursor, from cadmium nitrate and lithium hydroxide through a solvothermal method, and performing roasting, thus obtaining nano cadmium oxide; then adding the prepared nano cadmium oxide into sodium sulfide for sulfidizing through a hydrothermal method, and performing roasting treatment, thus obtaining the CdO / CdS heterojunction nano composite material. The product has a morphology feature of hexagon consisting of nano particles. The obtained CdO / CdS heterojunction nano composite material is used for photocatalytically degrading methylene blue used as an organic dye and is relatively high in photocatalysis performance.

Owner:QUFU NORMAL UNIV

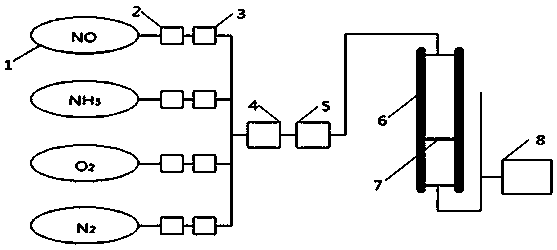

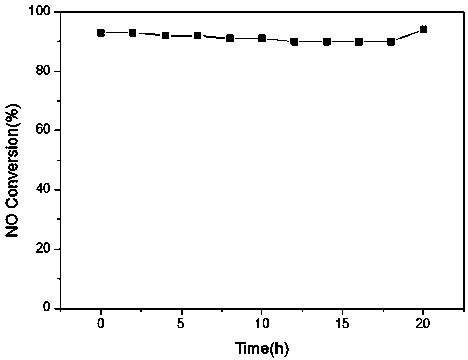

Nanorod-like low-temperature denitration catalyst and preparation method thereof

ActiveCN105618031AHigh activityLarge specific surface areaMaterial nanotechnologyHeterogenous catalyst chemical elementsMANGANESE ACETATEWater baths

The invention discloses a nanorod-like low-temperature denitration catalyst. TiO2 of anatase is taken as a carrier and manganite is taken as an active component; the length-diameter ratio of nanorod is (10 to 20):1. The nanorod-like low-temperature denitration catalyst is prepared by adopting an improved sol-gel method and is particularly prepared by the following steps of firstly, uniformly mixing and stirring tetra-n-butyl titanate, ethanol, acetic acid and ethyl acetoacetate, adding a template agent for fully stirring, dropping a manganese acetate solution into a mixed solution, and dropping while stirring; after the dropping is finished, continuously stirring, and then heating an obtained solution in a water bath to obtain a gel substance; drying the gel substance, performing roasting treatment on the dried gel substance, and finally performing ultraviolet radiation on a product to obtain a final product. Compared with a traditional MnOx / TiO2 low-temperature denitration catalyst, the nanorod-like low-temperature denitration catalyst prepared by a preparation method disclosed by the invention has the characteristics of better nanorod-like structure, greater specific surface area, more Lewis acid sites, higher lattice oxygen content, high removal rate of nitrogen oxide and the like.

Owner:WUHAN UNIV OF TECH

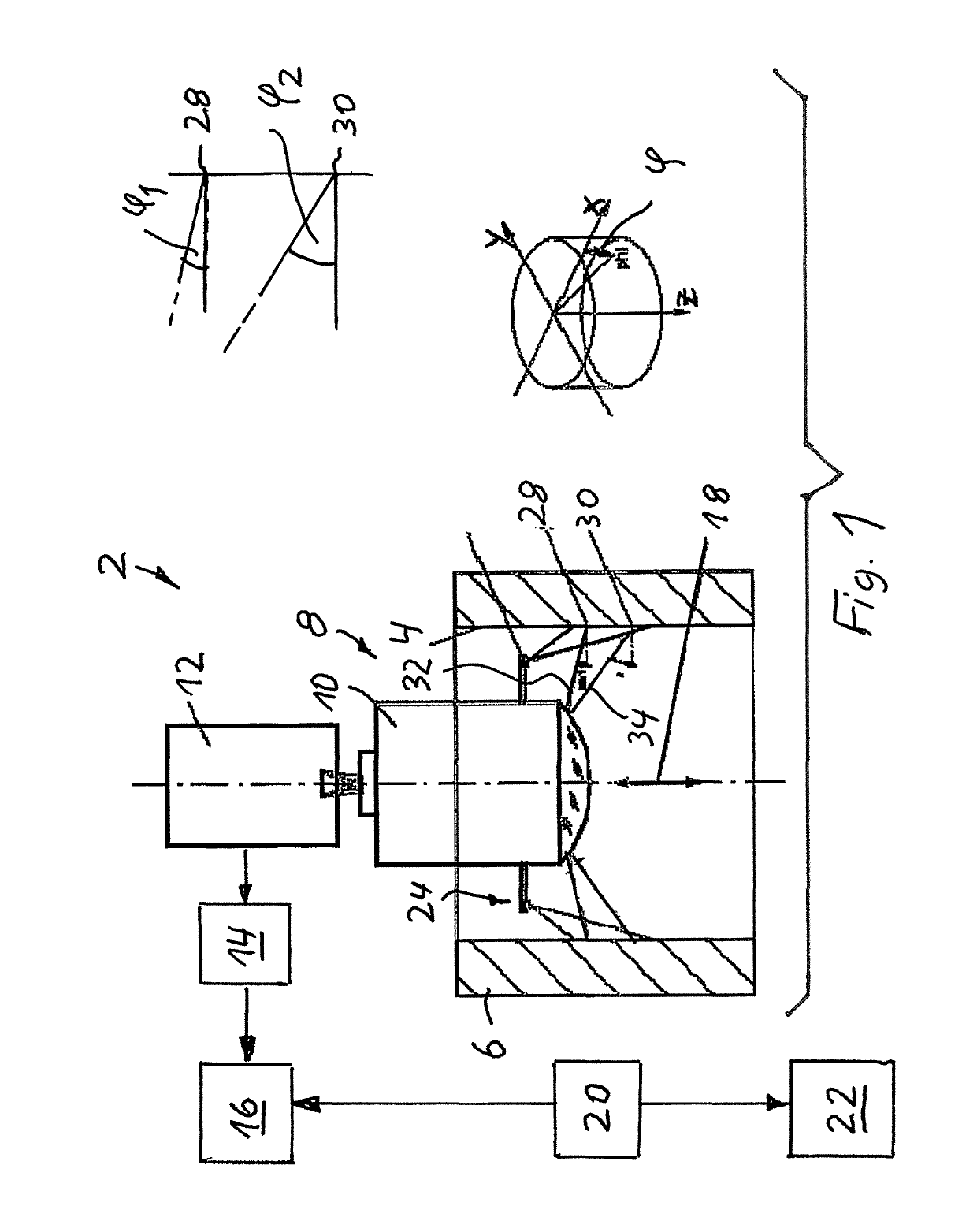

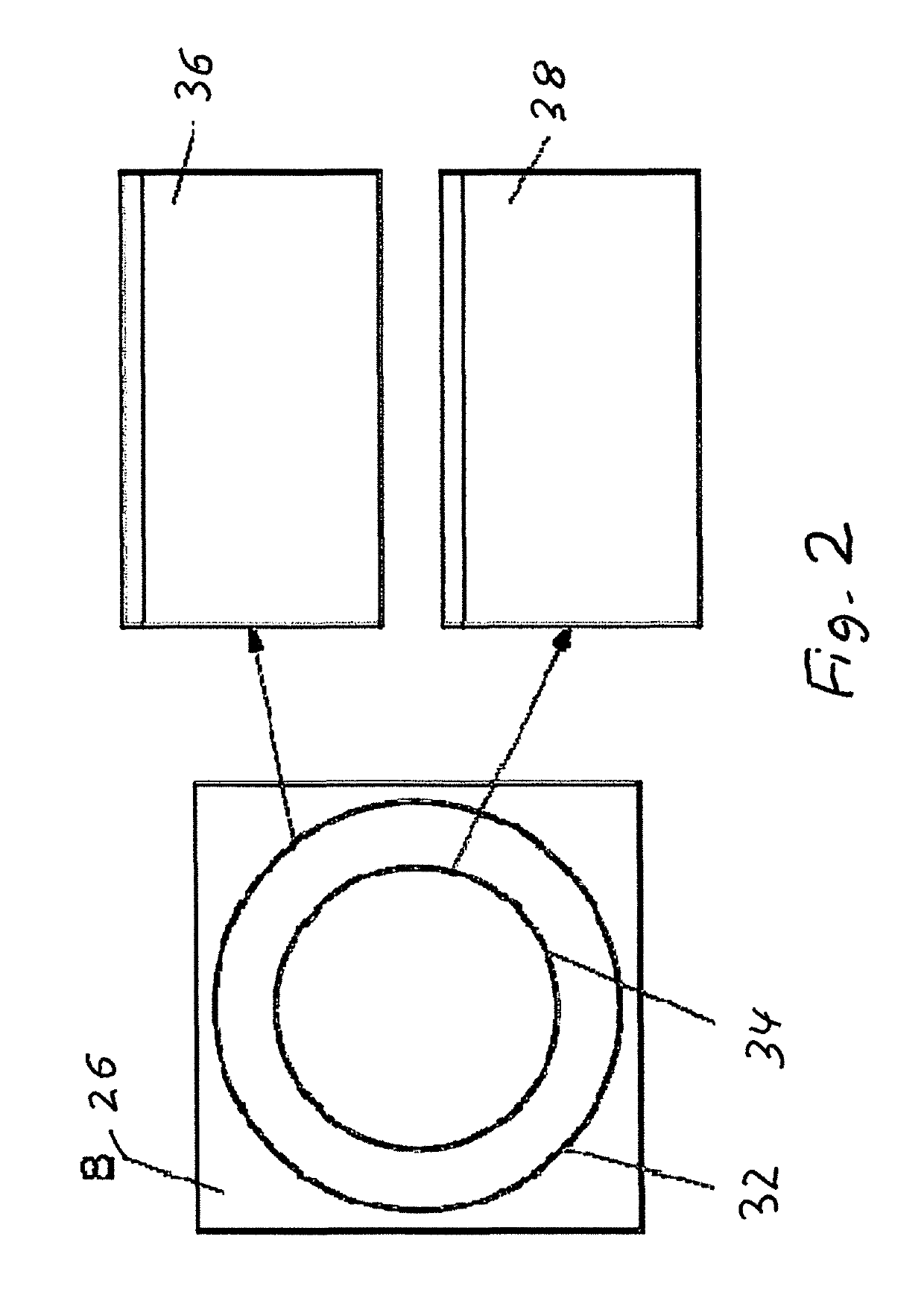

Borehole inspection device

ActiveUS10330915B2Improve surface defectsImprove scalabilityMachine part testingTelevision system detailsImage transferDigital image

Borehole inspection device for inspecting a borehole in a workpiece has a measuring head which includes an endoscope and is insertable into the borehole to be inspected and movable relative to the borehole in different axial positions. Borehole inspection device has an imaging optics with a panoramic view for imaging the inner surface of the borehole, and the imaging optics is in image transmission connection with a digital image recorder. Device has a memory for storing the images recorded in different axial positions of the measuring head, and an evaluation apparatus for evaluating the images stored in the memory. In order to obtain surface depth information about the inner surface of the borehole, the evaluation apparatus is configured for evaluating images recorded at different viewing angles of the imaging optics with regard to the particular surface location, using a 3D reconstruction method.

Owner:JENOPTIK IND METROLOGY GERMANY

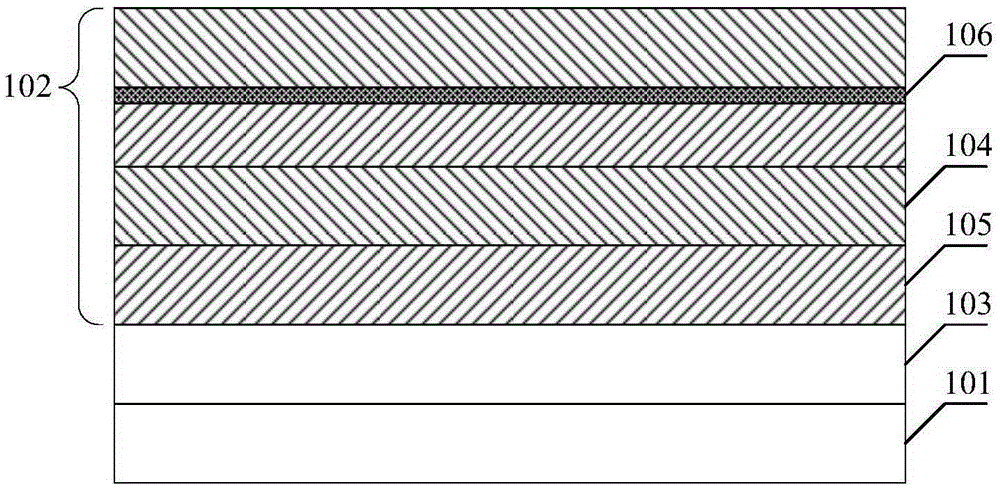

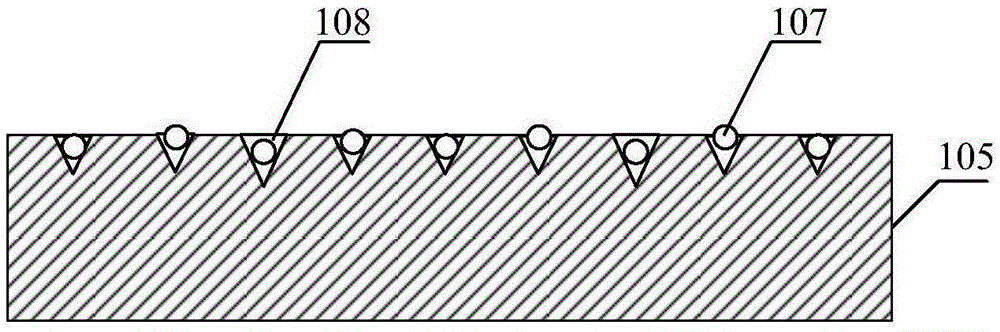

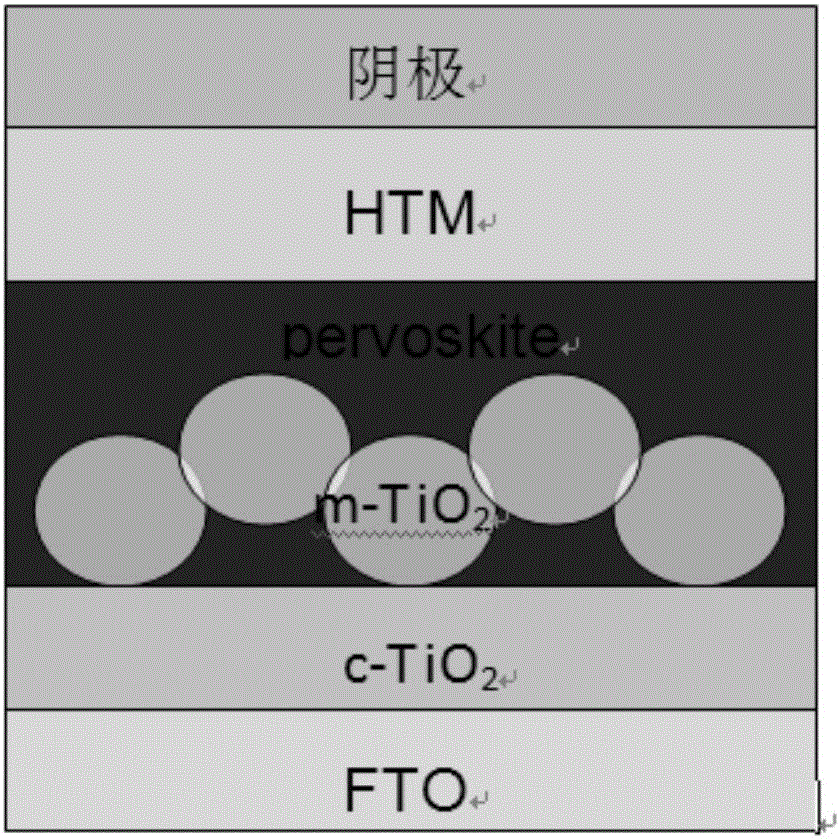

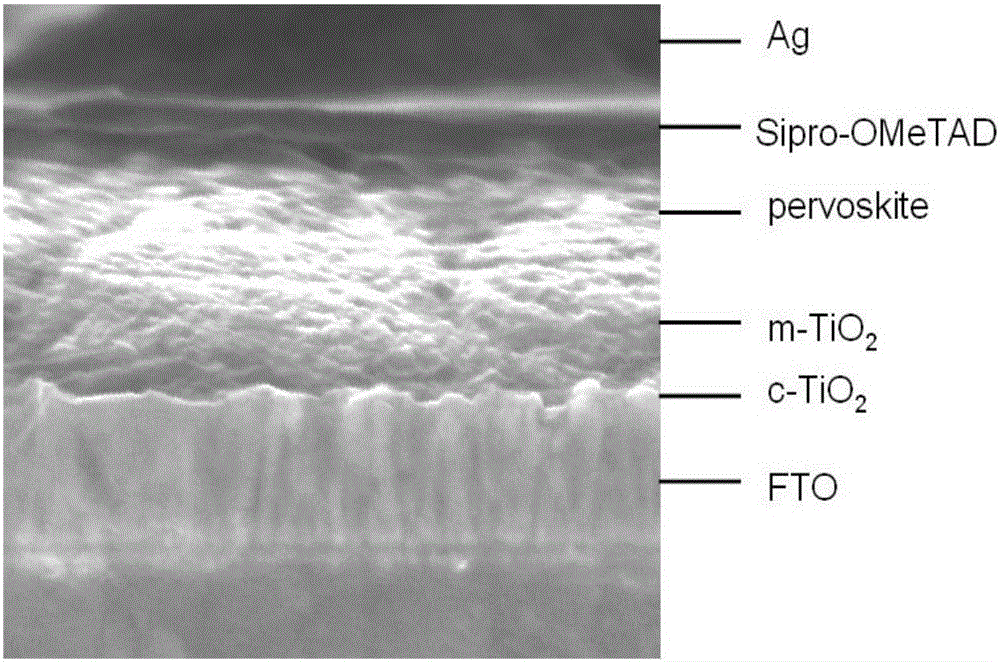

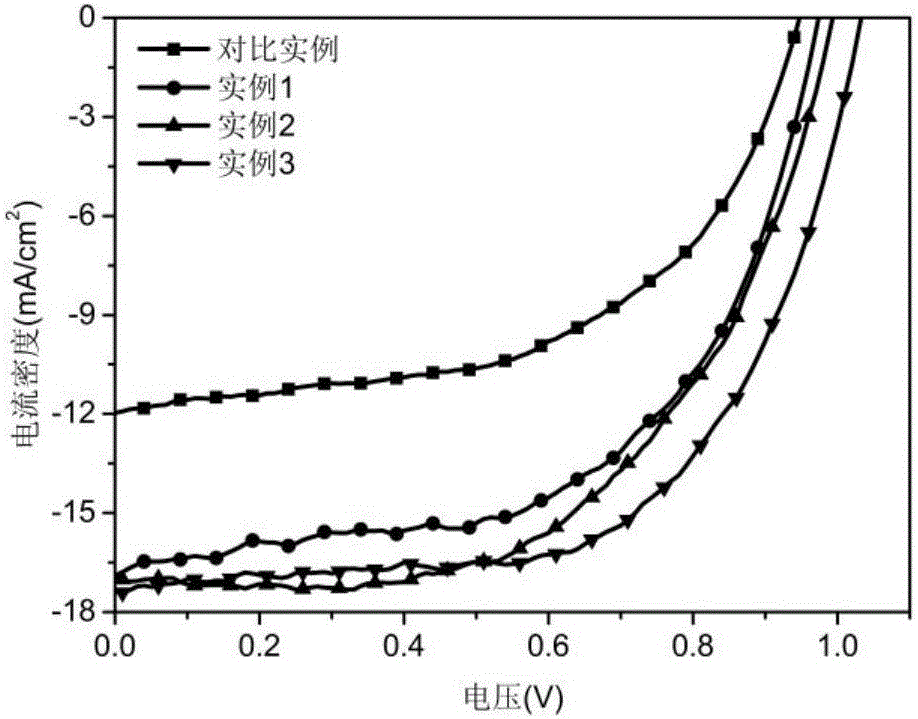

Preparation method of inorganic trans-perovskite solar cell based on quantum dot modification

InactiveCN110176508AIncrease profitEnhanced charge extraction capabilityPhotovoltaic energy generationSemiconductor devicesAbsorption capacityComposite film

The invention discloses a preparation method of an inorganic trans-perovskite solar cell based on quantum dot modification. The preparation method comprises the following steps: (1) washing transparent FTO conducting glass; (2) preparing a CuOx inorganic hole transport layer; (3) preparing an inorganic perovskite / quantum dot composite film on the inorganic hole transport layer as a light absorption layer and an electron transport layer of the device together; and (4) enabling the inorganic perovskite / quantum dot composite film to be covered with a counter electrode so as to obtain the inorganic trans-perovskite solar cell based on quantum dot modification. The light absorption layer is prepared from quantum dots with light absorption capacity and an inorganic perovskite light absorption material together, so that the utilization rate of sunlight is improved, the quantum dots are used as the electron transport layer while the charge extraction capacity of the device is improved, and thepreparation technology is simplified; and moreover, the inorganic perovskite crystal structure and film-forming property are improved through partial doping of the quantum dots, so that the stabilityof the device is improved, and the transportation and separation of carriers are further accelerated while the charge recombination is reduced effectively.

Owner:CENT SOUTH UNIV

Method for preparing SO42-/TiO2 through supercriticalo exsiccation

InactiveCN1562478AHigh crystallinityImprove photocatalytic activityCatalyst activation/preparationSupercritical dryingAlcohol

A process for preparing the catalyst SO4 / TiO2 by supercritical drying method includes slowly dropping the sulfuric acid-alcohol-water solution in butyl titanate-alcohol solution to obtain TiO2 sol, ageing to obtain wet gel, mixing it with alcohol, staying in inertial atmosphere and supercritical condition for 0.5-8 hr, cooling and calcining. Its adantages are high specific surface area and photocatalytic activity, and long service life.

Owner:SHANGHAI NORMAL UNIVERSITY

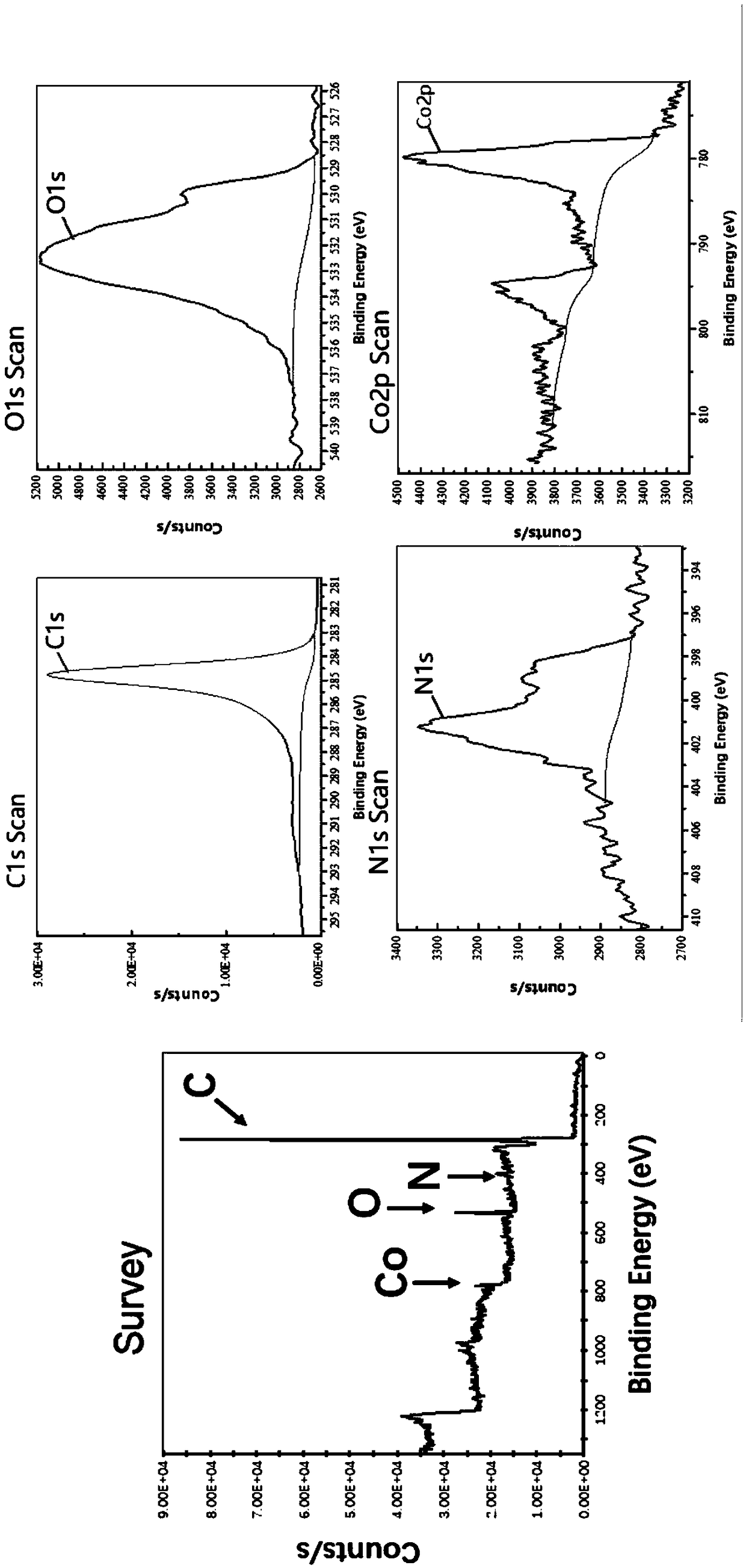

Cobaltosic oxide catalyst, preparation method and application thereof

PendingCN110787822ARaw materials are easy to obtainLow costCatalyst activation/preparationIncinerator apparatusNitrogen plasmaPtru catalyst

The invention discloses a cobaltosic oxide catalyst, a preparation method and application thereof. The preparation method includes: (a) preparing a cobaltosic oxide nanorod Co3O4-110 with an exposed crystal surface (110); and (b) doping N atom to the surface of Co3O4-110 to obtain the cobaltosic oxide catalyst N-Co3O4-110. The preparation method of the cobaltosic oxide catalyst provided by the invention has easily controllable reaction conditions, can be operated at room temperature, and by changing the nitrogen plasma treatment time, different nitrogen doping amounts and oxygen vacancy content can be obtained. The cobaltosic oxide catalyst obtained by the preparation method disclosed by the invention has the advantages of simple and easily available raw materials, and lower cost than platinum, palladium and the like, and simple operation method, and is suitable for industrial application. The cobaltosic oxide catalyst has more surface defects, higher surface oxygen content and highercharge transfer efficiency, and can be used for catalyzing various oxidation reactions.

Owner:QINGDAO UNIV

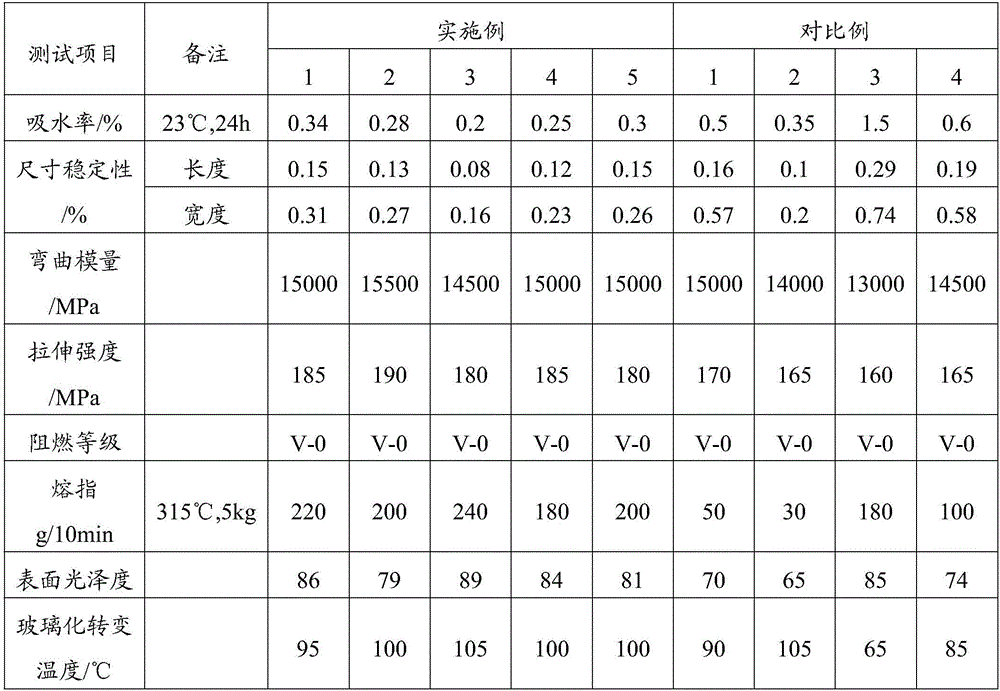

Polyamide resin composite material, and preparation method and application thereof

The invention provides a polyamide resin composite material, and a preparation method and application thereof. The flowability of the polyamide resin composite material is enhanced through the semi-aromatic polyamide with lower melting point, thereby improving the defect of poor surface in the semi-aromatic polyamide. The p-phenyldiformyldihexyldiamine-m-phenyldiformyldihexyldiamine copolyamide (PA12T-12I) with longer molecular chain lowers the water absorptivity of the material; and the hexamethylene adipamipe-p-phenyldiformylhexamethylenediamine copolyamide (PA66 / 6T) and m-phenyldiformylhexamethylenediamine-p-phenyldiformylhexamethylenediamine copolyamide (PA6I / 6T) with favorable strength and rigidity enhance the rigidity of the material. Glass fibers are used as a reinforcing material to enhance the strength of the resin material. The halogen-free flame retardant and flame-retardant aid are matched to enhance the flame retardancy.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Method for preparing perovskite active layer of perovskite solar battery in the air

InactiveCN107437587AQuality improvementHigh densityFinal product manufactureSolid-state devicesHigh humidityPerovskite solar cell

The invention discloses a method for preparing a perovskite active layer of a perovskite solar battery in the air. According to the method, a proper amount of pyridine type small organic molecules are added to a lead iodide solution to be used as an additive in the preparation of the perovskite active layer by a two-step method; by adoption of the method, influence from humidity in the preparation of the perovskite active layer can be reduced; the perovskite active layer with relatively high quality still can be prepared in a high-humidity natural air condition, to obtain the high-efficiency perovskite solar battery; and therefore, preparation of the high-efficiency perovskite solar battery in the air is realized, the preparation cost can be lowered, and industrialization of the perovskite solar battery can be facilitated.

Owner:CENT SOUTH UNIV

Nitrogen-doped graphene for in-situ growth of self-assembled denitration sulfur-resistant catalyst, and preparation method thereof

ActiveCN110961138AMany defectsGood denitrification and anti-sulfur performancePhysical/chemical process catalystsDispersed particle separationDoped graphenePtru catalyst

The invention discloses nitrogen-doped graphene for in-situ growth of a self-assembled denitration sulfur-resistant catalyst, and a preparation method thereof. The preparation method comprises the following steps: taking graphene oxide as a precursor, preparing modified nitrogen-doped graphene from 2,4,6-triaminopyrimidine and cyanuric acid, and growing a ternary Mn-Ce-SnOx catalyst on the surfaceof the modified nitrogen-doped graphene as a catalyst carrier in situ. The self-assembled ternary Mn-Ce-SnOx catalyst is uniformly and firmly loaded on the surface of the modified nitrogen-doped graphene in a surface in-situ growth manner, so that the obtained composite material has good sulfur resistance while having efficient denitration capability.

Owner:FUZHOU UNIV

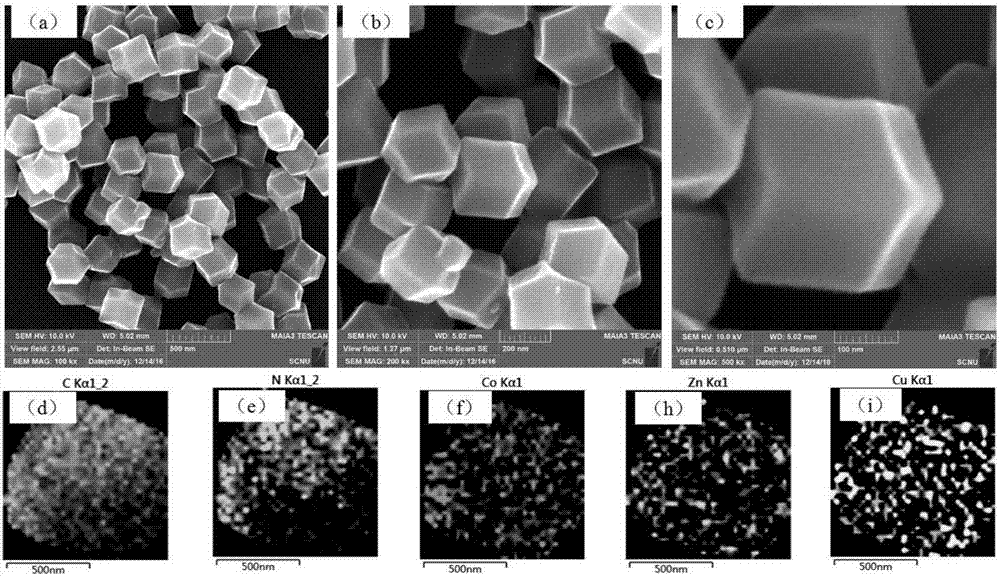

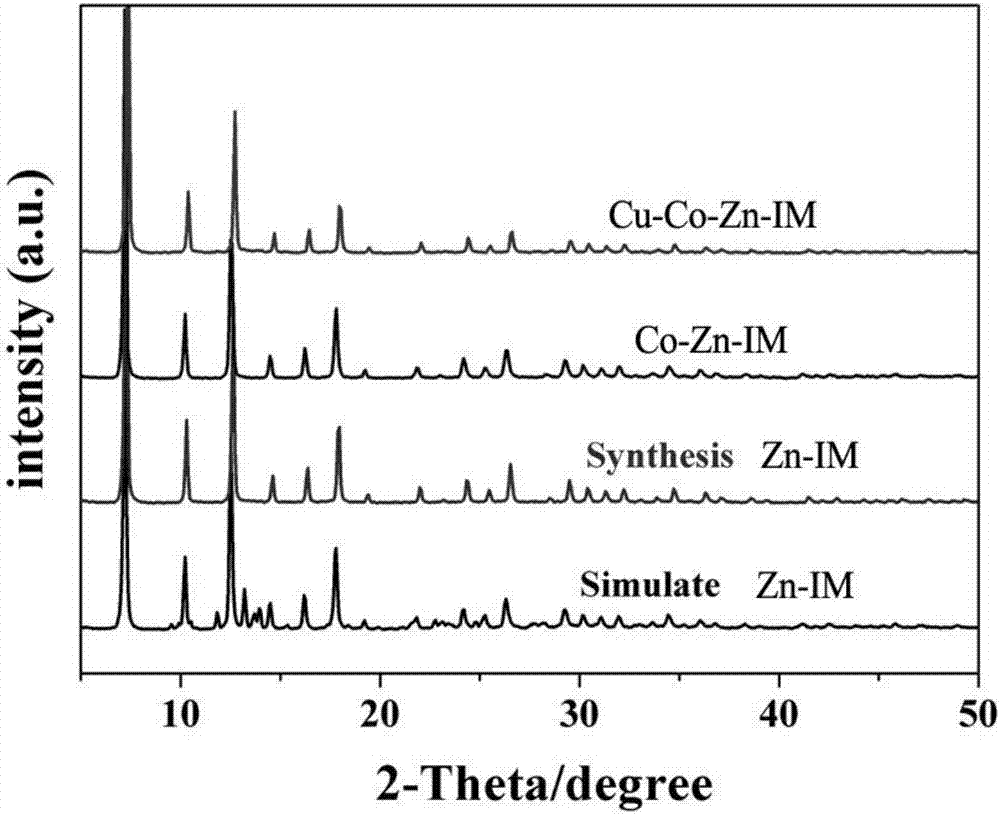

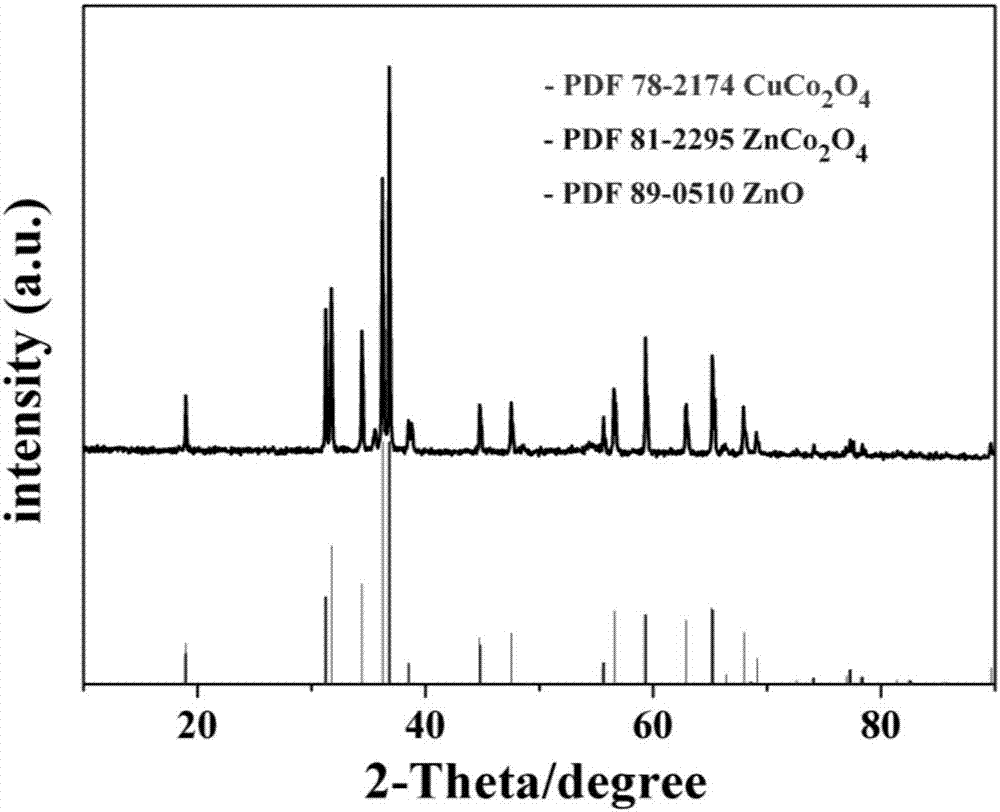

Preparation method and application of carbon-nitrogen doped ternary metal oxides

The invention relates to a preparation method and application of carbon-nitrogen doped ternary metal oxides. The preparation method includes the steps of S1, synthesizing a Zn-IM framework material coordinated by zinc and 2-methylimidazole; S2, weighing the Zn-IM framework material and cobalt nitrate hexahydrate, and dispersing the Zn-IM framework material and the cobalt nitrate hexahydrate into a solvent for microwave reaction to obtain a coordinated Co-Zn-IM framework material; S3, weighing the coordinated Co-Zn-IM framework material, sodium dodecyl sulfate, hexadecyl trimethyl ammonium bromide and copper chloride dihydrate, and dispersing the above materials into a solvent for microwave reaction to obtain a coordinated trimetallic heterozygous Cu-Co-Zn-IM framework material; S4, roasting the coordinated trimetallic heterozygous Cu-Co-Zn-IM framework material prepared in the step S3 so as to obtain the carbon-nitrogen doped ternary metal oxides. The preparation method has the advantages that with the 2-methylimidazole serving as a ligand, highly nitrogen-doped metal oxides can be obtained, and accordingly the prepared carbon-nitrogen doped ternary metal oxides are high in electrochemical stability and specific capacity and can act as an anode material of lithium ion batteries to improve the specific capacity of the lithium ion batteries.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Modified carbon nanotube-modified nickel cobalt manganese ternary composite electrode material and preparation method therefor

ActiveCN107706397AThe synthesis process is simpleHigh synthesis efficiencyCell electrodesBoronNanotube

The invention relates to a modified nanotube-modified nickel cobalt manganese ternary composite electrode material. The ternary composite electrode material is prepared from modified carbon nanotubesand a precursor; the modified carbon nanotubes comprise one or two kinds of nitrogen modified carbon nanotubes or boron modified carbon nanotubes; the modified carbon nanotubes account for 1-10% of the composite electrode material; the precursor comprises lithium carbonate and nickel cobalt manganese; and the molar ratio of the lithium element in nickel cobalt manganese to nickel cobalt manganeseis 1.0-1.05 to 1. The invention also provides a preparation method of the composite electrode material. By virtue of the preparation method, the problems of low electronic conductivity, poor rate stability, poor high-voltage cycling stability and the like can be solved.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

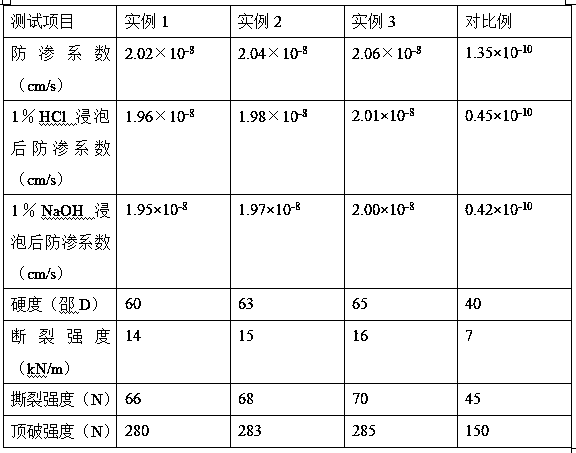

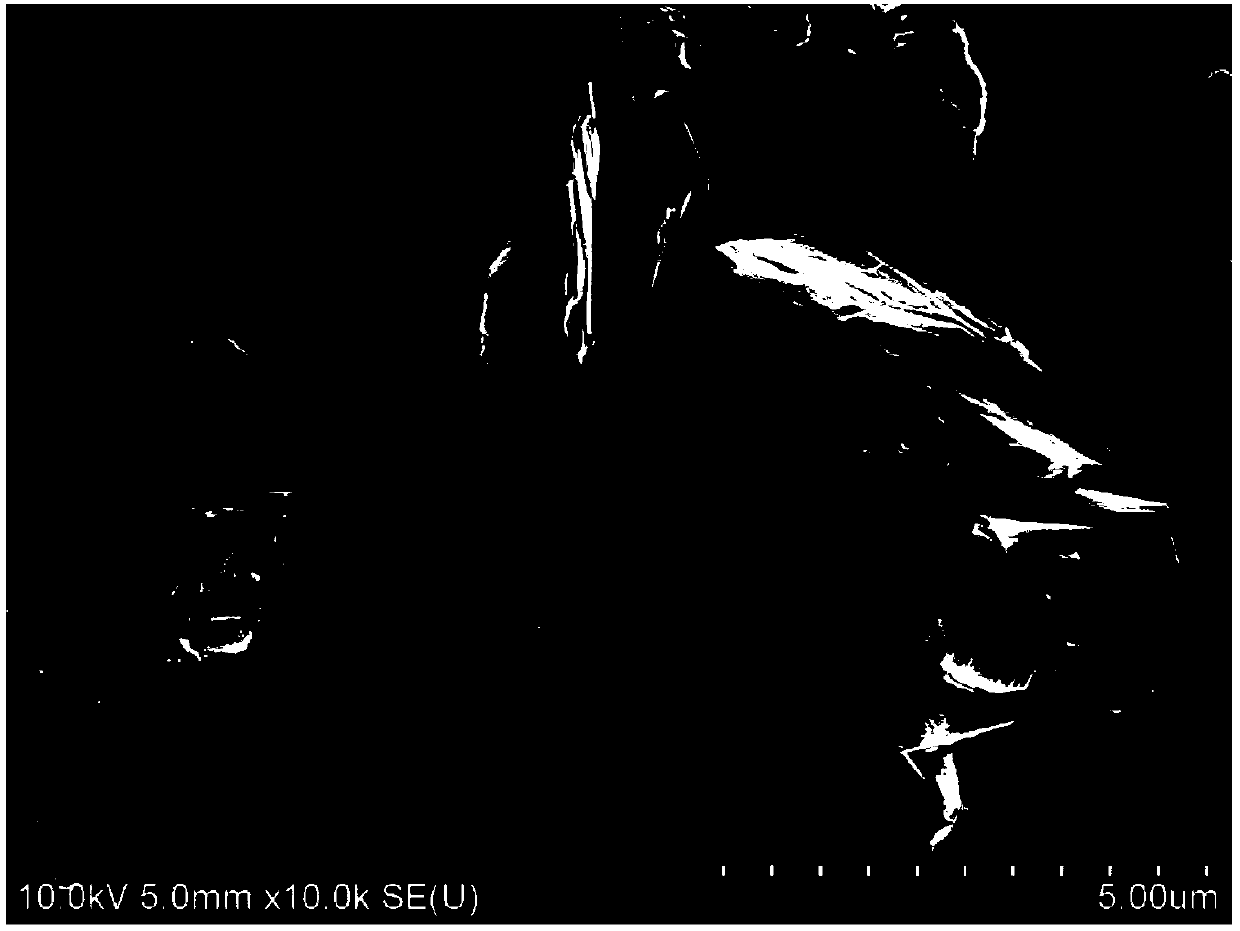

Preparation method of acid and alkali resistant anti-puncture anti-seepage material

InactiveCN108751907AImprove liquidityBroad application prospectsNon-macromolecular adhesive additivesProtective foundationIonCalcium hydroxide

The invention discloses a preparation method of an acid and alkali resistant anti-puncture anti-seepage material, and belongs to the technical field of preparation of environmental protection materials. Since fumed silica particles have large surface defects, many unpaired atoms and high surface activity, a large interfacial effect is generated on the surface of double-layered glass wool, and thefumed silica is dispersed in the gap of a polyester molecular chain, so that the elasticity of polyester resin and a fumed silica system is improved and resistant to plant root tip puncture. Quick lime reacts with water to form calcium hydroxide that reacts with sulfate in the manganese residue to form unite particles in the anti-seepage material. The heavy metal ions in the clay slurry componentmanganese slag are mostly in the form of sulfate, and the heavy metal ions of a landfill can be in complexing with modified polyester, hydrated silicate is insoluble under alkaline conditions, a claylayer in the anti-seepage material can be used as a protective film to make the clay slurry have acid and alkali resistance, so that the material has broad application prospects.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Graphite modification method and graphite/silicon composite material

InactiveCN107732195AImprove surface defectsImprove electrochemical performanceGraphiteCell electrodesGraphitePorous electrode

Disclosed is a graphite modification method. The graphite modification method comprises the steps of performing ball milling on graphite powder, grinding balls and a ball grinding medium at the mass ratio of 1:(1-10):(7-50) at the rotary speed of 650-1,200r / min for 2-48h. The graphite / silicon dioxide porous electrode and the graphite / silicon composite material prepared from graphite obtained by the modification method provided by the invention obtain excellent electrochemical performance.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com