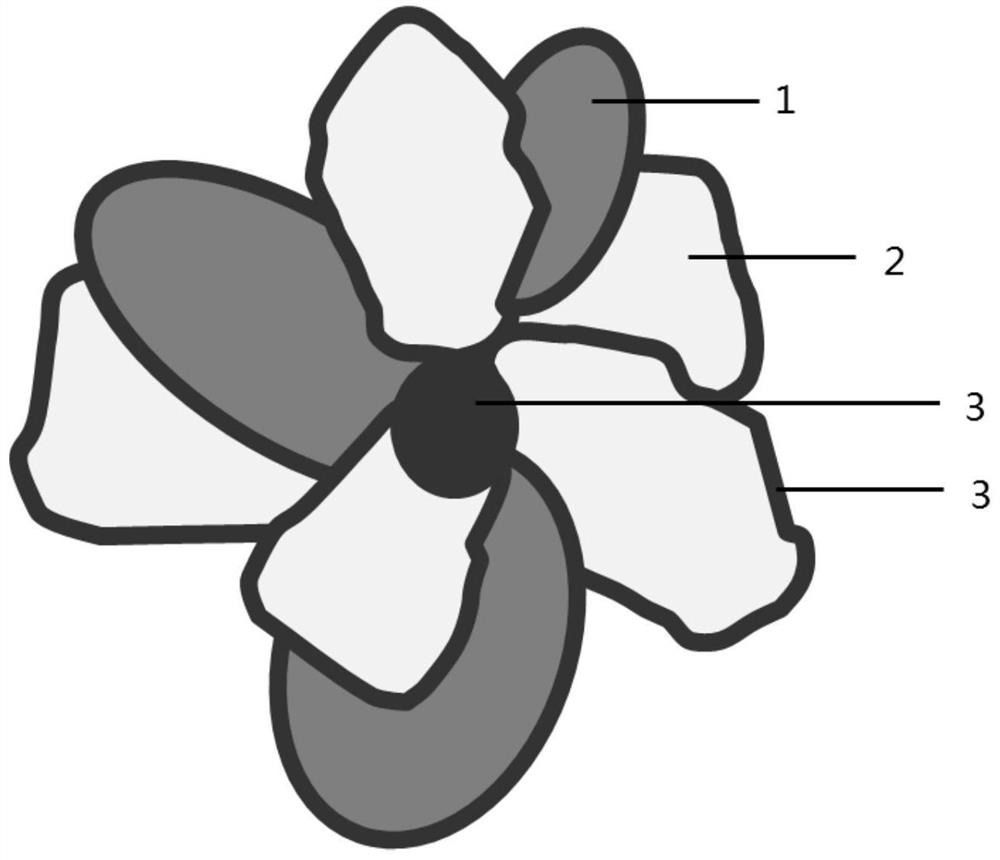

High-capacity, high-compaction and quick-charge composite graphite negative electrode material and preparation method thereof

A technology of composite graphite and negative electrode materials, applied in graphite, negative electrodes, battery electrodes, etc., can solve the problem that graphite negative electrode materials cannot take into account high capacity, high compaction and fast charging performance, and achieve excellent fast charging performance and accelerated migration rate , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

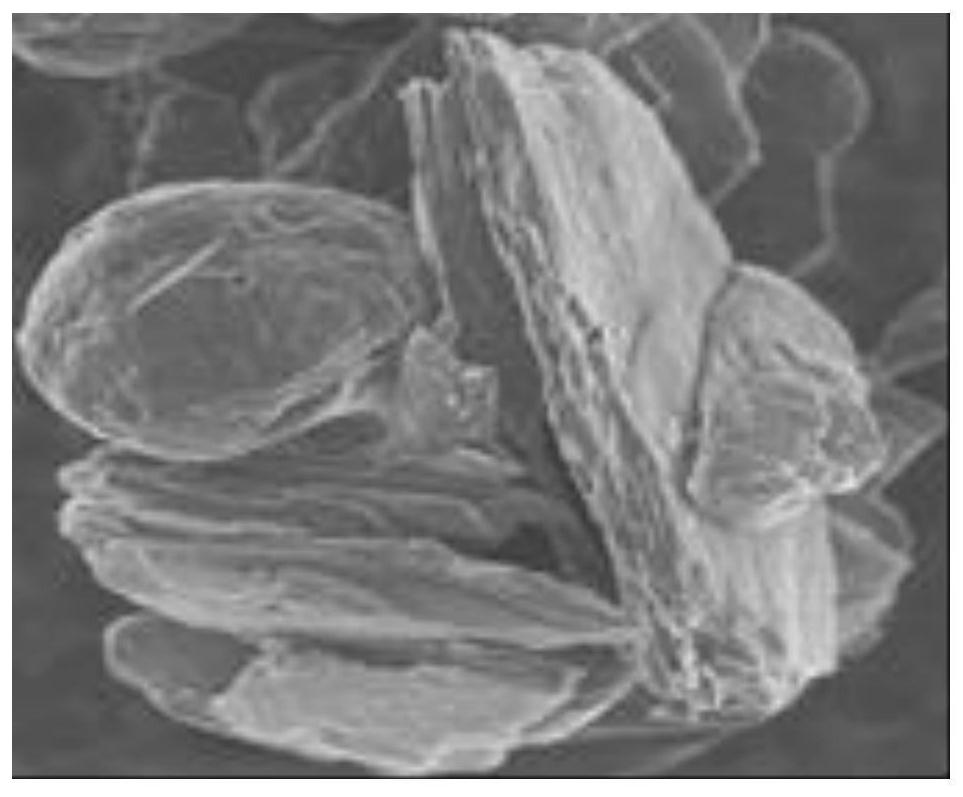

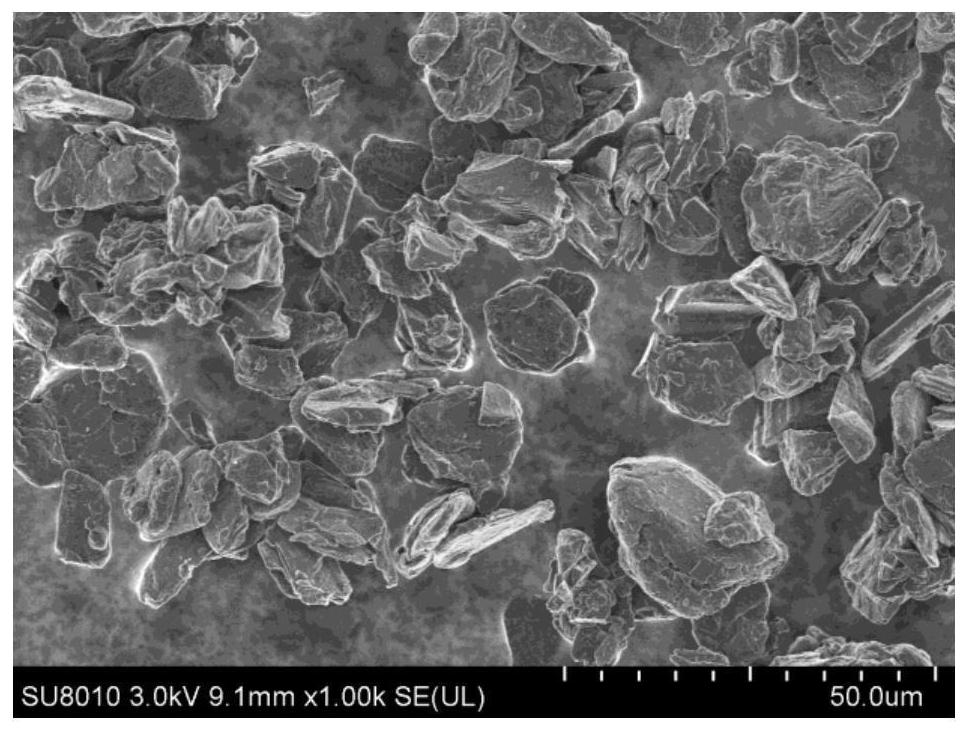

Embodiment 1

[0037] ① 22.8Kg of flake graphite, 37.2Kg of artificial graphite prepared from needle-shaped coke raw powder with a degree of graphitization ≥ 94%, and 10.8Kg of high-temperature petroleum pitch were mixed in a V-type mixer at 25r / min for 60min to obtain a mixture, of which natural stone The particle size D50 of ink is 6-12 μm, the particle size D50 of artificial graphite is 8-16 μm, and the particle size D50 of amorphous carbon is 3-5 μm;

[0038] ②Put the mixture into the vertical reactor, the stirring speed is 25r / min, at room temperature (25°C) the temperature is raised at a rate of 2°C / min, the heating time is 150min, and the temperature is kept constant for 120min to obtain secondary particles of composite graphite;

[0039] ③Carbonize the above-mentioned secondary particles under the protection of nitrogen at a temperature of 1150°C for 15 hours, and cool down to room temperature;

[0040] The above-mentioned carbonized product was mixed with a V-type mixer at 25r / min f...

Embodiment example 2

[0042] ① 25.2Kg of spherical graphite, 34.8Kg of artificial graphite prepared from petroleum coke raw powder with a degree of graphitization ≥ 94%, and 11.4Kg of epoxy resin were mixed in a V-type mixer at 35r / min for 60min to obtain a mixture, of which natural graphite The particle size D50 is 6-16 μm, the particle size D50 of artificial graphite is 10-15 μm, and the particle size D50 of amorphous carbon is 2-5 μm;

[0043] ②Put the mixture into the vertical reactor, the stirring speed is 40r / min, at room temperature (25°C) the temperature is raised at a rate of 1°C / min, the heating time is 300min, and the temperature is kept constant for 300min to obtain the secondary particles of composite graphite;

[0044] ③Carbonize the above-mentioned secondary particles under the protection of nitrogen at a temperature of 800°C for 15 hours, and cool down to room temperature;

[0045] ④ Mix the above carbonized product with a V-type mixer at 25r / min for 60min and pass through a 250-mes...

Embodiment example 3

[0047] ① 31.8Kg of microcrystalline graphite, 28.2Kg of artificial graphite prepared by natural pitch coke with a degree of graphitization ≥ 94%, and 9.6Kg of high-temperature petroleum pitch were mixed in a V-type mixer at 30r / min for 60min to obtain a mixture, of which natural graphite The particle size D50 is 10-16 μm, the particle size D50 of artificial graphite is 10-16 μm, and the particle size D50 of amorphous carbon is 5-8 μm;

[0048] ②Put the mixture into a vertical reactor with a stirring speed of 35r / min, and heat up at room temperature (25°C) at a rate of 5°C / min for 30min, then keep the temperature for 200min to obtain secondary particles of composite graphite;

[0049] ③Carbonize the above-mentioned secondary particles under the protection of nitrogen at a temperature of 1500°C for 15 hours, and cool down to room temperature;

[0050] ④ Mix the above carbonized product with a V-type mixer at 25r / min for 60min and pass through a 250-mesh sieve to obtain the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com