Water-soluble copper-and-manganese-codoped ZnS(Se) white-light quantum dot and preparation method thereof

A co-doping and water-soluble technology, applied in chemical instruments and methods, luminescent materials, climate sustainability, etc., can solve the problems of low efficiency of multi-layer structure, complex preparation process, change of white light, etc., and achieve good water solubility. , the reaction conditions are simple, the effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, the preparation of zinc chloride and cysteine aqueous solution: add 80ml deionized water and 0.8mol / L zinc chloride solution to cysteine in a three-necked flask, wherein zinc chloride and cysteine The molar ratio is 1:2;

[0022] Second, add the manganese chloride solution of 0.05mol / L and the cupric chloride solution of 0.05mol / L in the first step solution, wherein the mol ratio of manganese chloride and zinc chloride is 1:100, cupric chloride and The mol ratio of zinc chloride is 0.5:100, and the solution is stirred for 20min under nitrogen protection;

[0023] Third, adjust the pH value of the second step solution to 9 with NaOH aqueous solution, and quickly inject 0.8mol / L sodium sulfide solution, wherein the molar ratio of sodium sulfide to zinc chloride is 1:1, and stir rapidly for 20min;

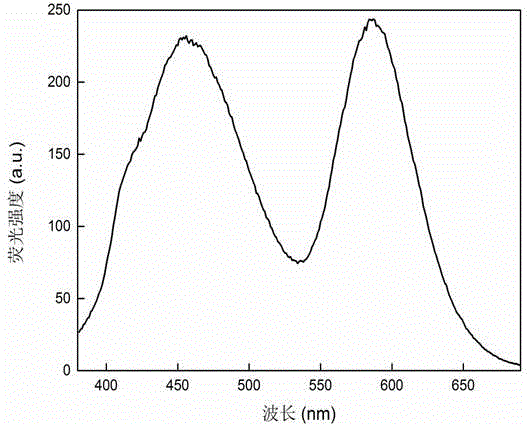

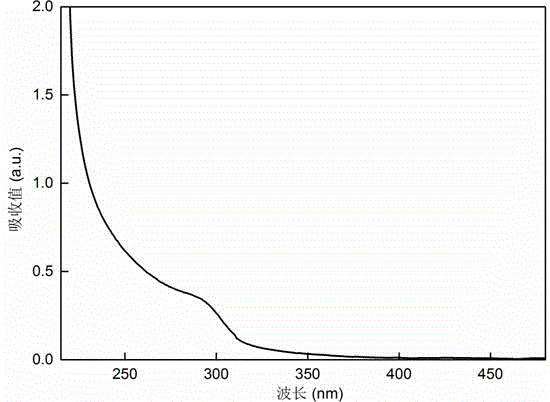

[0024] Fourth, transfer the solution in the third step to a microwave reactor, raise the temperature to 60 degrees Celsius, and react for 30 minutes to obtain coppe...

Embodiment 2

[0027] First, the preparation of zinc chloride and thioglycolic acid aqueous solution: add 100ml deionized water and 1mol / L zinc chloride solution to thioglycolic acid in a three-necked flask, wherein the mol ratio of zinc chloride to thioglycolic acid is 1:5 ;

[0028] Second, add the manganese chloride solution of 0.1mol / L and the cupric chloride solution of 0.1mol / L in the first step solution, wherein the mol ratio of manganese chloride and zinc chloride is 5:100, cupric chloride and The mol ratio of zinc chloride is 3:100, and the solution is stirred for 30min under nitrogen protection;

[0029] Third, adjust the pH value of the second-step solution to 12 with NaOH aqueous solution, and quickly inject 1mol / L sodium sulfide solution, wherein the molar ratio of sodium sulfide to zinc chloride is 1:1, and stir rapidly for 30min;

[0030] Fourth, transfer the solution in the third step to a microwave reactor, raise the temperature to 40 degrees Celsius, and react for 3 hours ...

Embodiment 3

[0033] First, the preparation of zinc chloride and mercaptopropionic acid aqueous solution: add 100ml deionized water and 1mol / L zinc salt aqueous solution to mercaptopropionic acid in a three-necked flask, wherein the mol ratio of zinc chloride to mercaptopropionic acid is 1 :1;

[0034] Second, add the manganese chloride solution of 0.1mol / L and the cupric chloride solution of 0.05mol / L in the first step solution, wherein the mol ratio of manganese chloride and zinc chloride is 1:100, cupric chloride and The mol ratio of zinc chloride is 0.5:100, and the solution is stirred for 30min under nitrogen protection;

[0035] The 3rd, the pH value of the second step solution is adjusted to 10 with NaOH aqueous solution, and inject the sodium selenium hydride solution of freshly prepared 1mol / L rapidly, wherein the mol ratio of sodium selenium hydride and zinc chloride is 1:1, quickly Stir for 20min;

[0036] Fourth, transfer the solution in the third step to a microwave reactor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com