Nitrogen-doped graphene for in-situ growth of self-assembled denitration sulfur-resistant catalyst, and preparation method thereof

A technology of nitrogen-doped graphene and in-situ growth, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effects of reducing agglomeration, reaction synthesis methods, simple operation, and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

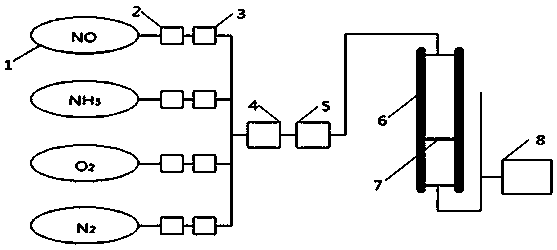

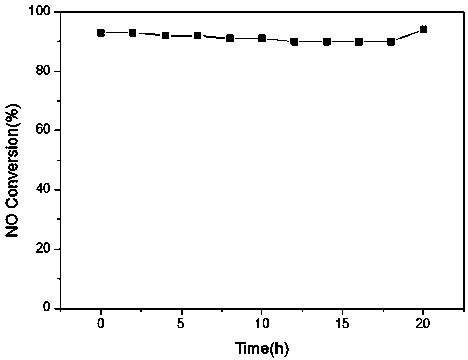

Method used

Image

Examples

Embodiment 1

[0037] Accurately weigh 0.1g of GO@TAP-CA, dissolve it in 50mL of DMF, add PVP after ultrasonication for 10min, and then add 0.2g of Ce(Ac) after ultrasonication for 10min 3 , put into a stirrer, stir at room temperature for 1 hour, until Ce(Ac) 3 Dissolve completely; then add 0.221g of SnCl 4 , continue to stir at room temperature for 1 hour, until the SnCl 4 Dissolve completely; then accurately weigh 0.099g KMnO 4 Dissolve it in 20mL of DMF, add it to the above solution, and continue to react at room temperature for 4h. After the reaction, transfer the reaction solution to a watch glass and dry it in an oven at 102°C. Add the dried product to 1M concentrated sulfuric acid dissolved in the solution, then transferred to a polytetrafluoroethylene liner, subjected to hydrothermal reaction at 160°C for 10 hours, and the obtained product was repeatedly centrifuged and washed until neutral, and then dried in an oven at 102°C; Calcined at 800°C for 2 hours in a high-temperature t...

Embodiment 2

[0040] Accurately weigh 0.1g of GO@TAP-CA, dissolve it in 50mL of DMF, add PVP after ultrasonication for 10min, and then add 0.3g of Ce(Ac) after ultrasonication for 10min 3 , put into a stirrer, stir at room temperature for 1 hour, until Ce(Ac) 3 Dissolve completely; then add 0.331g of SnCl 4 , continue to stir at room temperature for 1 hour, until the SnCl 4 Dissolve completely; then accurately weigh 0.149g KMnO 4 Dissolve it in 20mL of DMF, add it to the above solution, and continue to react at room temperature for 4h. After the reaction, transfer the reaction solution to a watch glass and dry it in an oven at 102°C. Add the dried product to 1M concentrated sulfuric acid dissolved in the solution, then transferred to a polytetrafluoroethylene liner, subjected to hydrothermal reaction at 160°C for 10 hours, and the obtained product was repeatedly centrifuged and washed until neutral, and then dried in an oven at 102°C; Calcined at 800°C for 2 hours in a high-temperature t...

Embodiment 3

[0043] Accurately weigh 0.1g of GO@TAP-CA, dissolve it in 50mL of DMF, add PVP after ultrasonication for 10min, and then add 0.4g of Ce(Ac) after ultrasonication for 10min 3 , put into a stirrer, stir at room temperature for 1 hour, until Ce(Ac) 3 Dissolve completely; then add 0.442g of SnCl 4 , continue to stir at room temperature for 1 hour, until the SnCl 4 Dissolve completely; then accurately weigh 0.198g KMnO 4 Dissolve it in 20mL of DMF, add it to the above solution, and continue to react at room temperature for 4h. After the reaction, transfer the reaction solution to a watch glass and dry it in an oven at 102°C. Add the dried product to 1M concentrated sulfuric acid dissolved in the solution, then transferred to a polytetrafluoroethylene liner, subjected to hydrothermal reaction at 160°C for 10 hours, and the obtained product was repeatedly centrifuged and washed until neutral, and then dried in an oven at 102°C; Calcined at 800°C for 2 hours in a high-temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com