CoS-SnS-NC composite material with heterojunction structure as well as preparation method and application thereof

A composite material and heterojunction technology, applied to structural parts, active material electrodes, electrical components, etc., can solve the problems of long ion transmission path, poor cycle stability, and low specific capacity of sodium storage, shortening the diffusion distance, reducing Agglomeration, the effect of reducing the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

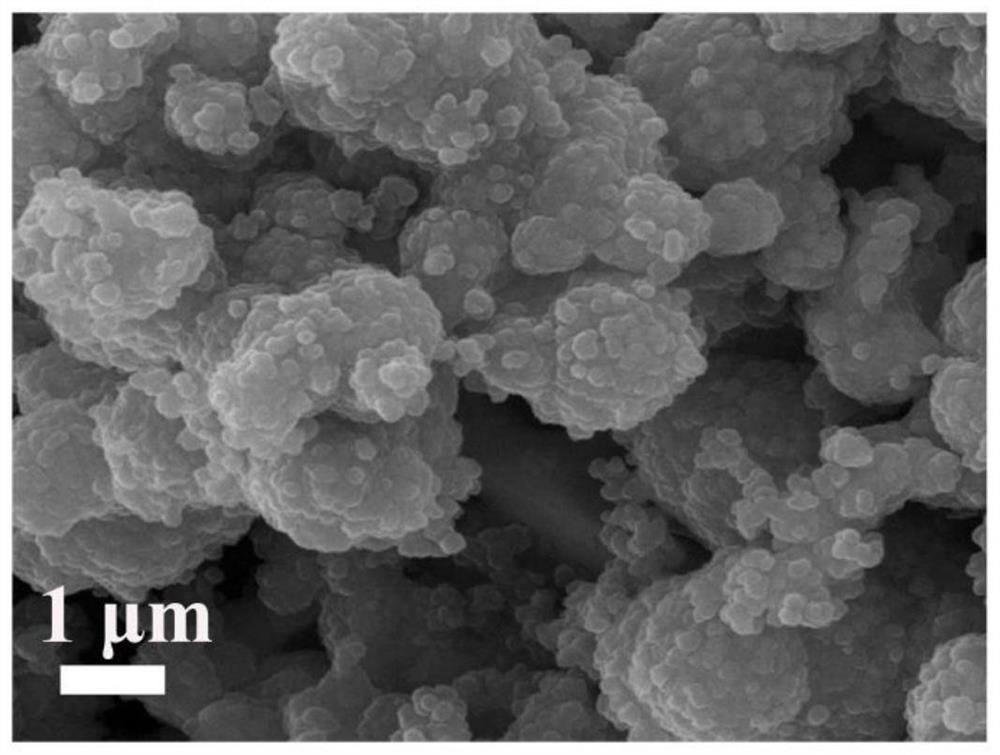

[0037] A method for preparing a CoS-SnS-NC composite material with a heterojunction structure, specifically comprising the steps of:

[0038] S1. Dissolve 2mmol cobalt nitrate, 6mmol urea and 3mmol ammonium fluoride in 60mL deionized water, heat to 120°C in an oven for 12h, centrifuge, wash and dry to obtain the Co precursor;

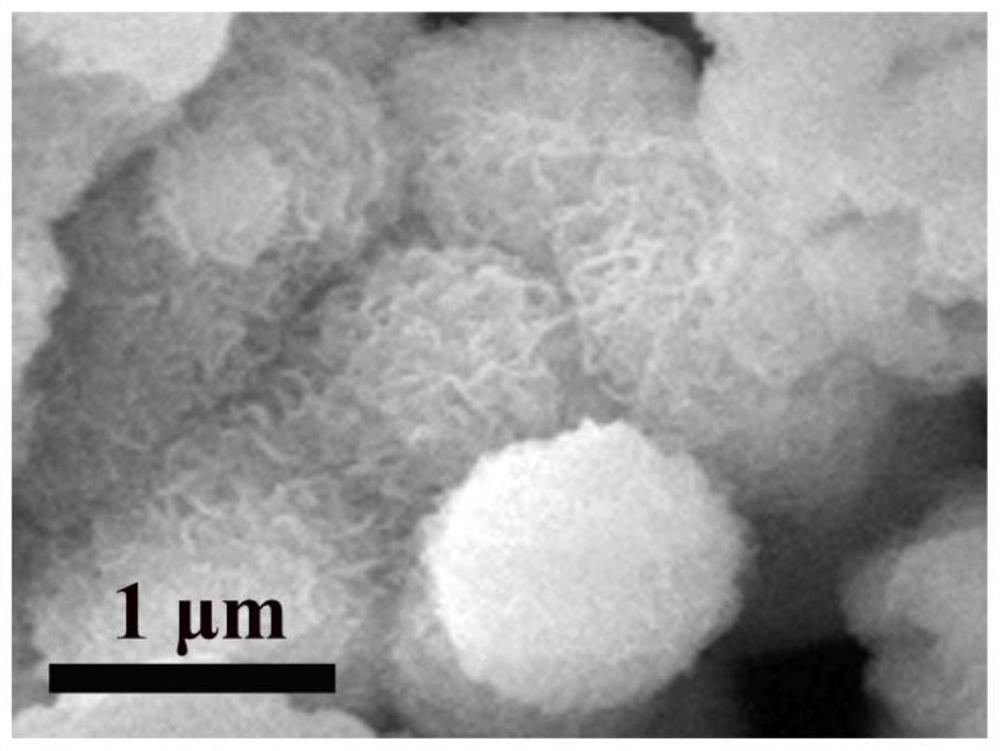

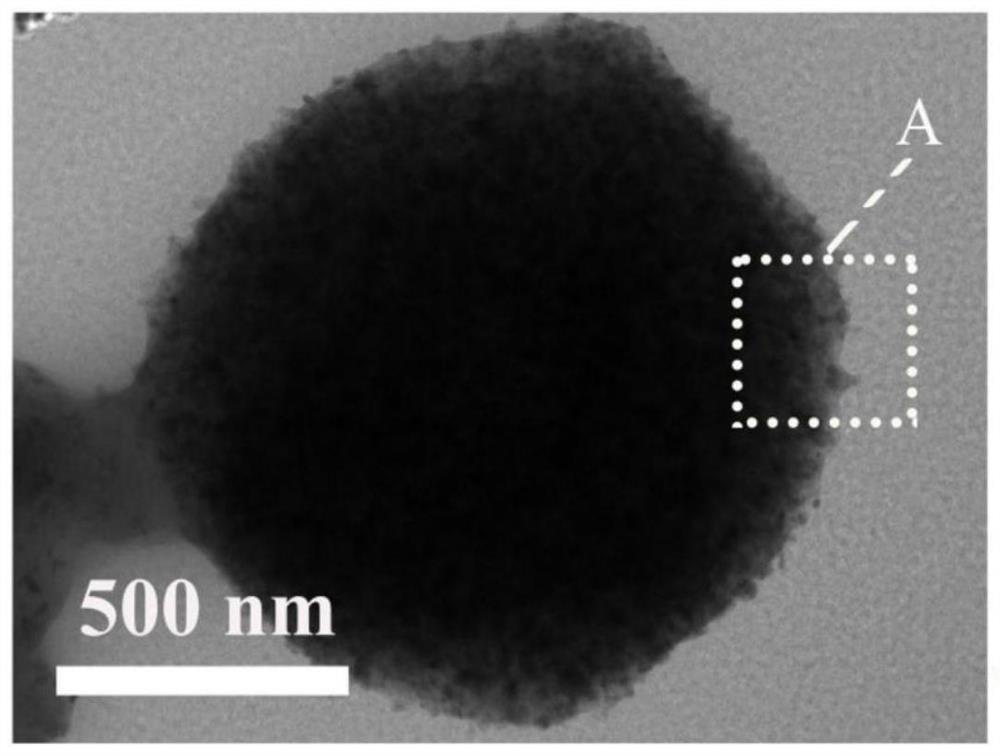

[0039] S2. Take 50 mg of the Co precursor obtained in step S1 and disperse it in 50 ml of absolute ethanol, then add 200 mg of thioacetamide (TAA) and 175 mg of tin tetrachloride, heat to 140 ° C for solvothermal reaction for 12 h, cool to room temperature, and Centrifuge, wash, and dry at 60°C for 12 hours to obtain Co 3 S 4 @SnS 2 Composite particles;

[0040] S3. Take 100mg Co 3 S 4 @SnS 2 After mixing evenly, ultrasonically disperse in 10mmol tris (Tris) buffer, adjust the pH value to 8.5 by hydrochloric acid, then add 100mg dopamine hydrochloride to stir the reaction, after washing and drying, Co 3 S 4 @SnS 2 - PDA;

[0041] S4. the Co ob...

Embodiment 2

[0044] A method for preparing a CoS-SnS-NC composite material with a heterojunction structure, specifically comprising the steps of:

[0045] S1. Dissolve 2mmol cobalt nitrate, 4mmol urea and 4mmol ammonium fluoride in 60mL deionized water, heat to 120°C in an oven for 12h, centrifuge, wash and dry to obtain the Co precursor;

[0046] S2. Take 25 mg of the Co precursor obtained in step S1 and disperse it in 50 ml of absolute ethanol, then add 300 mg of thioacetamide (TAA) and 175 mg of tin tetrachloride, heat to 160 ° C for solvothermal reaction for 8 h, cool to room temperature, and Centrifuge, wash, and dry at 60°C for 12 hours to obtain Co 3 S 4 @SnS 2 Composite particles;

[0047] S3. Take 100mg Co 3 S 4 @SnS 2 After mixing evenly, ultrasonically disperse in 10mmol tris (Tris) buffer, adjust the pH value to 8.5 by hydrochloric acid, then add 100mg dopamine hydrochloride to stir the reaction, after washing and drying, Co 3 S 4 @SnS 2 - PDA;

[0048] S4. the Co obt...

Embodiment 3

[0051] A method for preparing a CoS-SnS-NC composite material with a heterojunction structure, specifically comprising the steps of:

[0052] S1. Dissolve 2mmol of cobalt nitrate, 8mmol of urea and 8mmol of ammonium fluoride in 60mL of deionized water, heat to 120°C in an oven for 12h, centrifuge, wash and dry to obtain the Co precursor;

[0053] S2. Take 100 mg of the Co precursor obtained in step S1 and disperse it in 50 ml of absolute ethanol, then add 200 mg of thioacetamide (TAA) and 175 mg of tin tetrachloride, heat to 120 ° C for solvothermal reaction for 16 h, cool to room temperature, and Centrifuge, wash, and dry at 60°C for 12 hours to obtain Co 3 S 4 @SnS 2 Composite particles;

[0054] S3. Take 100mg Co 3 S 4 @SnS 2 After mixing evenly, ultrasonically disperse in 10mmol tris (Tris) buffer, adjust the pH value to 8.5 by hydrochloric acid, then add 100mg dopamine hydrochloride to stir the reaction, after washing and drying, Co 3 S 4 @SnS 2 - PDA;

[0055] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com