Passivation quantum dot film and preparation method thereof

A quantum dot film and quantum dot technology, which are applied in the field of passivation quantum dot film and its preparation, can solve problems such as poor device stability, and achieve the effects of avoiding instability, improving mobility, and improving surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

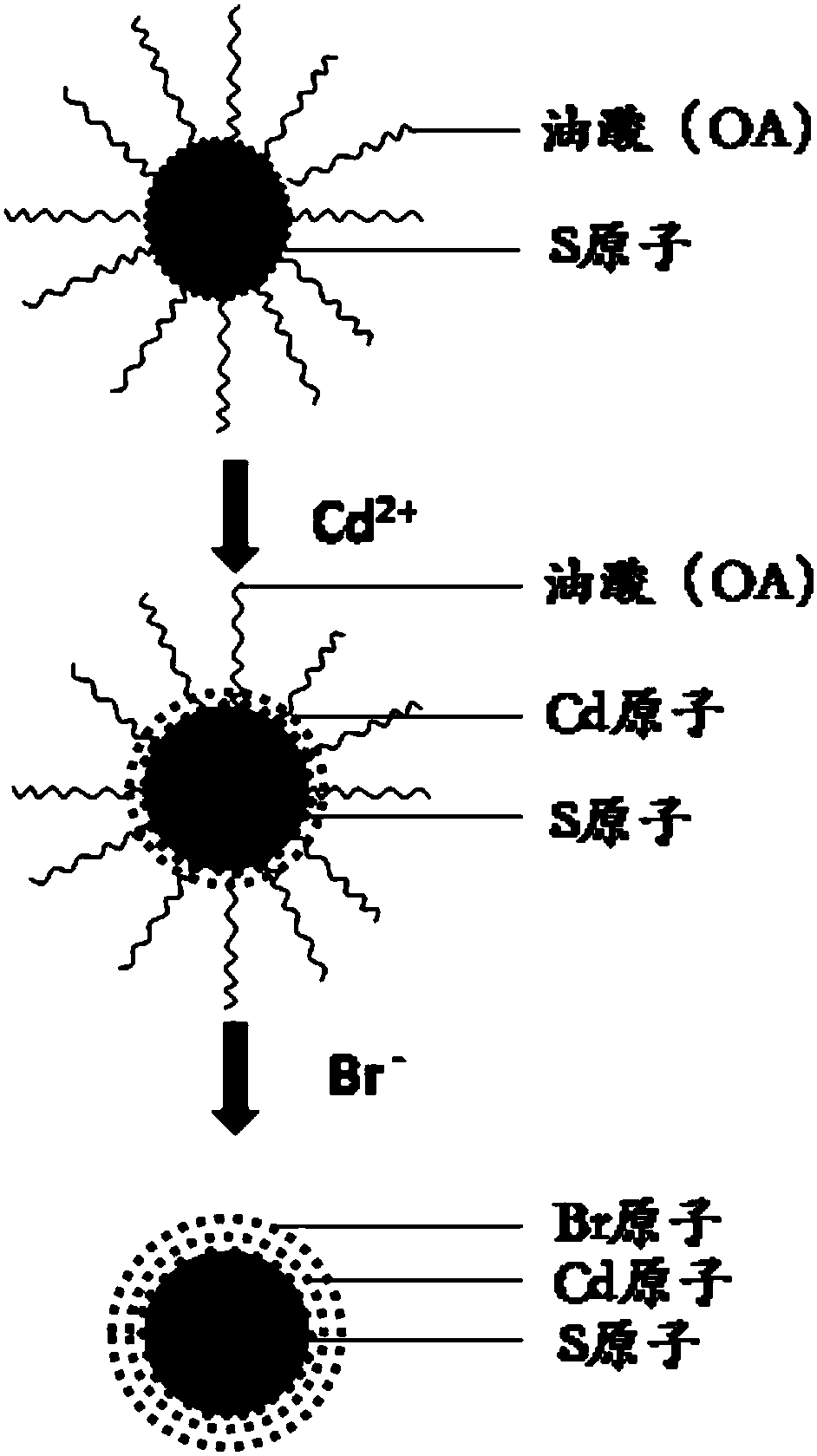

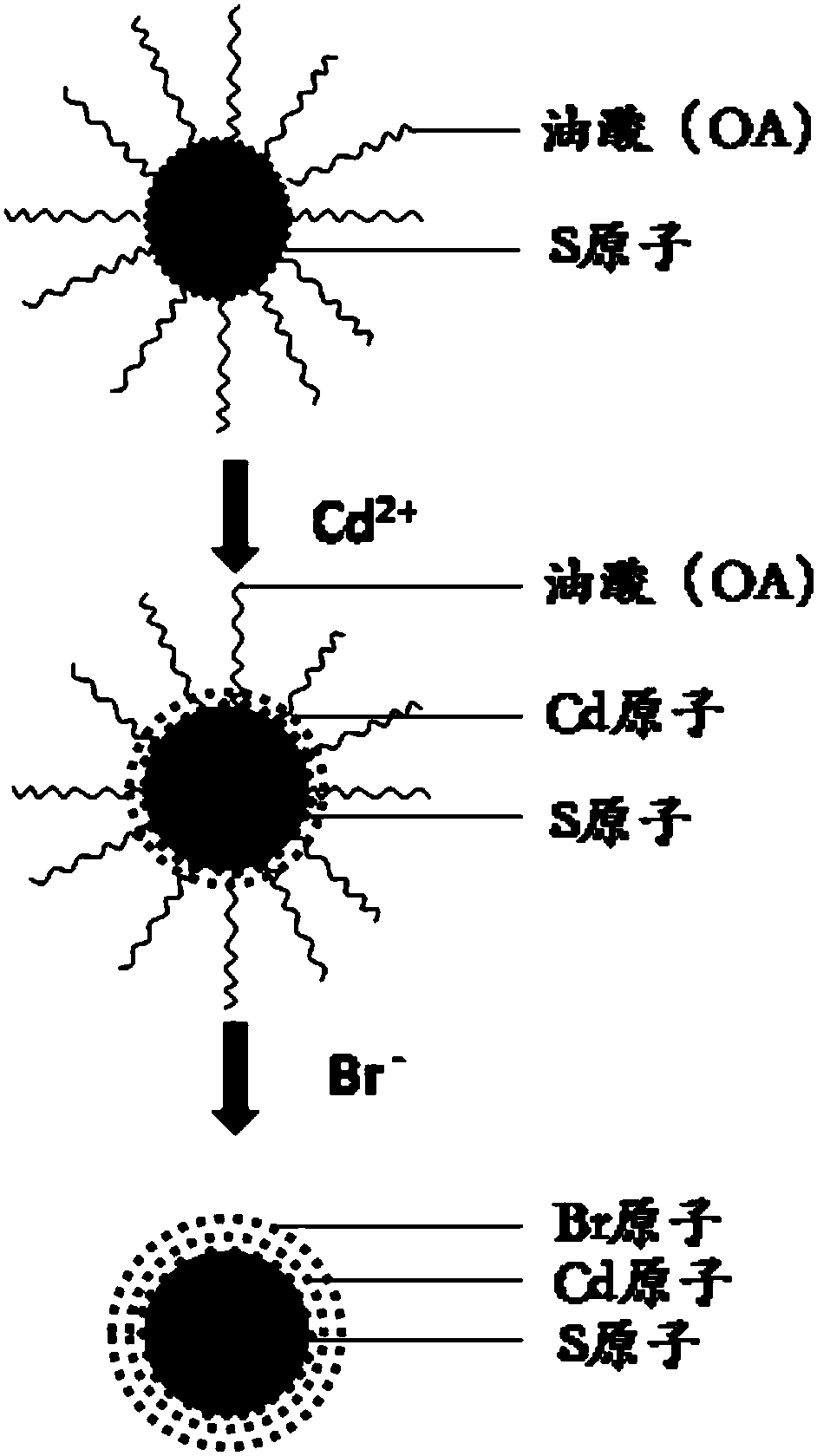

[0019] And, the embodiment of the present invention also provides a method for preparing a passivated quantum dot film, comprising the following steps:

[0020] S01. Provide oil-soluble quantum dots, metal ion precursor stock solutions, and halogen-substituted organic substances;

[0021] S02. Dissolving the oil-soluble quantum dots to obtain an oil-soluble quantum dot solution, mixing the oil-soluble quantum dot solution with the reaction medium, heating and degassing, then adding the metal ion precursor stock solution, heating and stirring the reaction , performing metal ion surface passivation on the oil-soluble quantum dots to obtain passivated quantum dots;

[0022] S03. Provide a substrate, dissolve the passivated quantum dots into a passivated quantum dot solution, and deposit the passivated quantum dot solution on the substrate by a solution method to obtain a passivated quantum dot film;

[0023] S04. Dissolving the halogen-substituted organic matter to prepare a hal...

Embodiment 1

[0040] A preparation method of passivated quantum dot film, comprising the following steps:

[0041] S11. Provide oil-soluble quantum dots, metal ion precursor stock solutions, and halogen-substituted organic substances.

[0042] Wherein, the oil-soluble quantum dots are near-infrared oil-soluble PbS quantum dots, and the metal ion precursor stock solution is a cadmium precursor stock solution (CdCl 2 -TDPA-OLA), the halogen-substituted organic compound is cetyltrimethylammonium bromide (CTAB).

[0043] Specifically, the preparation of S111. near-infrared oil-soluble PbS quantum dots is as follows:

[0044] S1111. Weigh 0.15g of lead oxide (PbO), 0.64ml of oleic acid (OA), and 10ml of octadecene (ODE) into a 50ml three-neck flask, exhaust at room temperature for 10min, and then heat to 120°C Exhaust for 60min, then maintain at 120°C to prepare lead oleate {Pb(OA) 2}Pre-body spare.

[0045] S1112. Take 100 microliters of hexamethyldisilathane (TMS) and add it to 12ml of oct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com