Preparation method of acid and alkali resistant anti-puncture anti-seepage material

An anti-seepage material and puncture-resistant technology, which can be used in protective devices, adhesive additives, construction, etc., can solve problems such as low strength, easy corrosion, and poor puncture resistance, and achieve broad application prospects and high fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

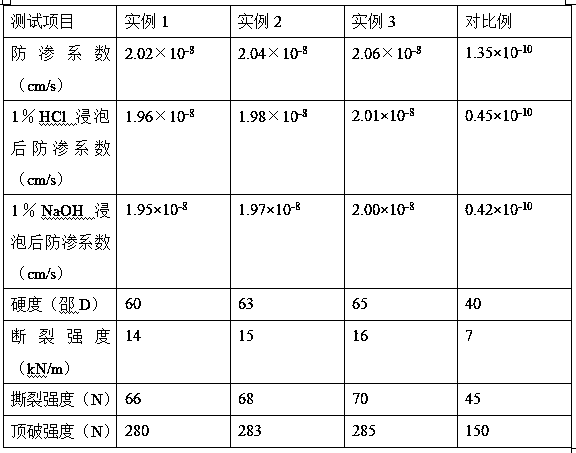

Examples

Embodiment Construction

[0023]In parts by weight, mix 60-70 parts of polystyrene and 30-40 parts of vinyl acetate resin to obtain a mixed resin, pour the mixed resin into a three-necked flask containing 60-70 parts of styrene, and heat the three-necked flask Raise the temperature to 80-90°C, start the agitator, stir and disperse at a speed of 300-350r / min, keep warm and stir for 4-5 hours, discharge the material, naturally cool down to room temperature to obtain polyester glue, and set aside; Aluminum hydroxide powder Put it in a high-pressure airflow machine, and pulverize it by airflow for 10-15 minutes to obtain superfine aluminum hydroxide powder with a particle size of 50-80 μm. Pour 200-220 g of superfine aluminum hydroxide powder into In a beaker of sodium silicate solution, the mixed solution is obtained, and the mixed solution is placed in a high-speed disperser at a speed of 3000-3300r / min to disperse at a high speed to obtain a dispersion glue; in parts by weight, 20-25 parts of E-51 Epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com