Nitrogen-phosphorus co-doped ordered mesoporous carbon material and preparation method thereof and application thereof

A mesoporous carbon and co-doping technology, applied in non-aqueous electrolyte battery electrodes, electrical components, battery electrodes, etc., can solve the problems of complex process, potential safety hazards, low yield, etc., to increase surface defects and improve electrical conductivity. , the effect of facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

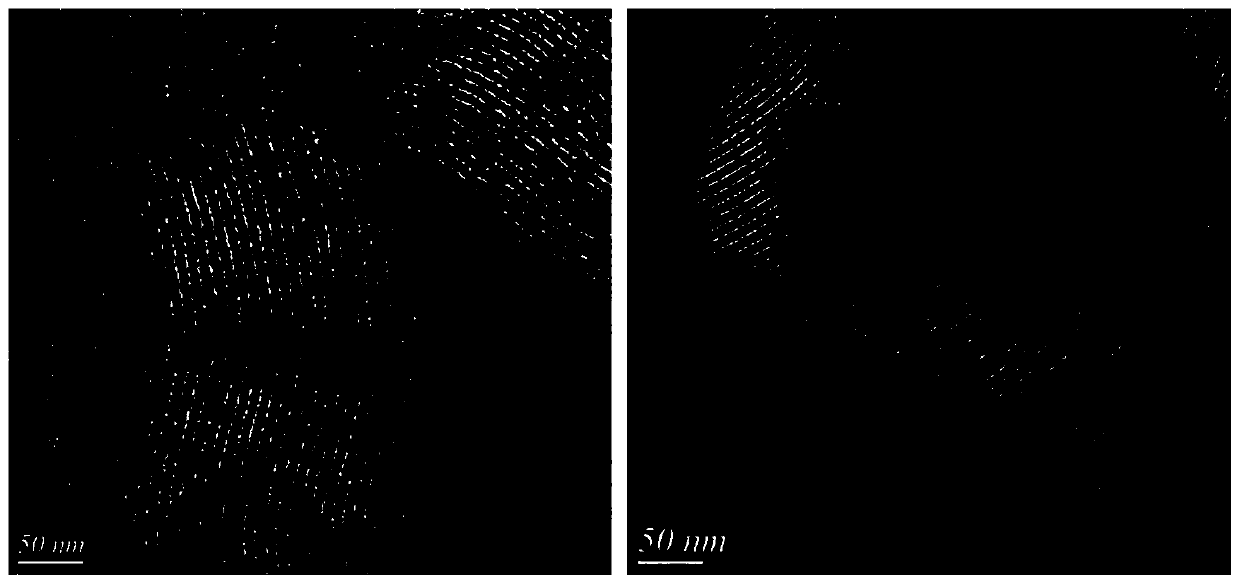

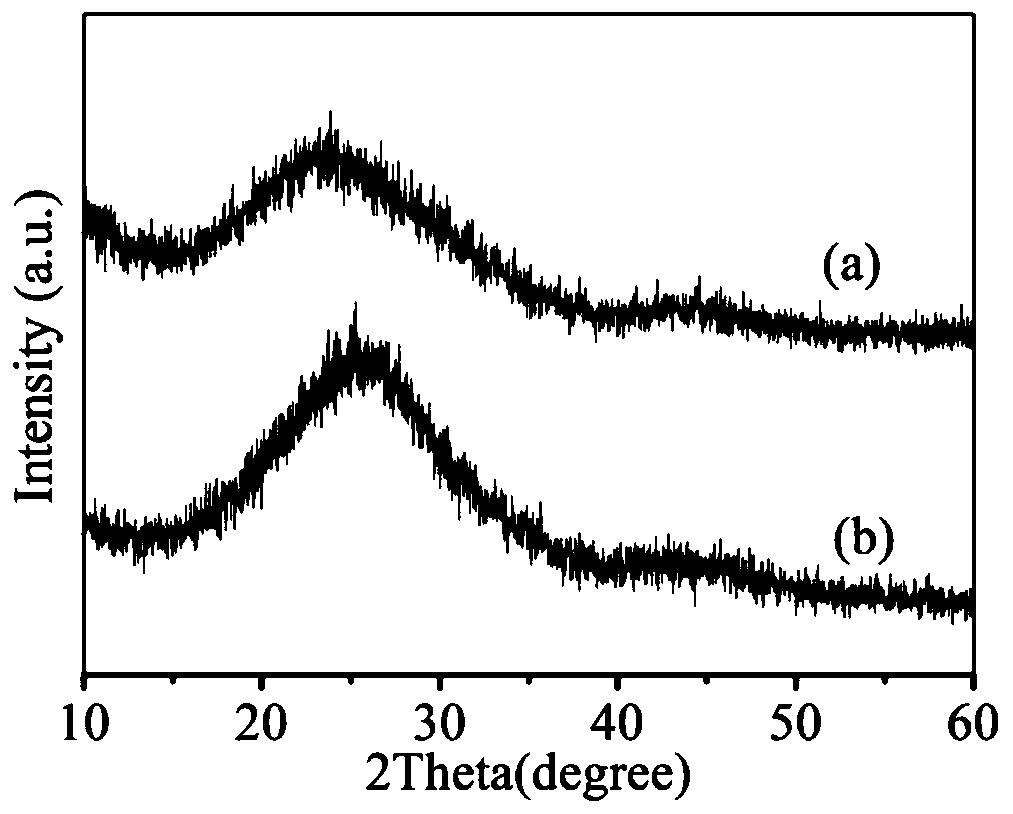

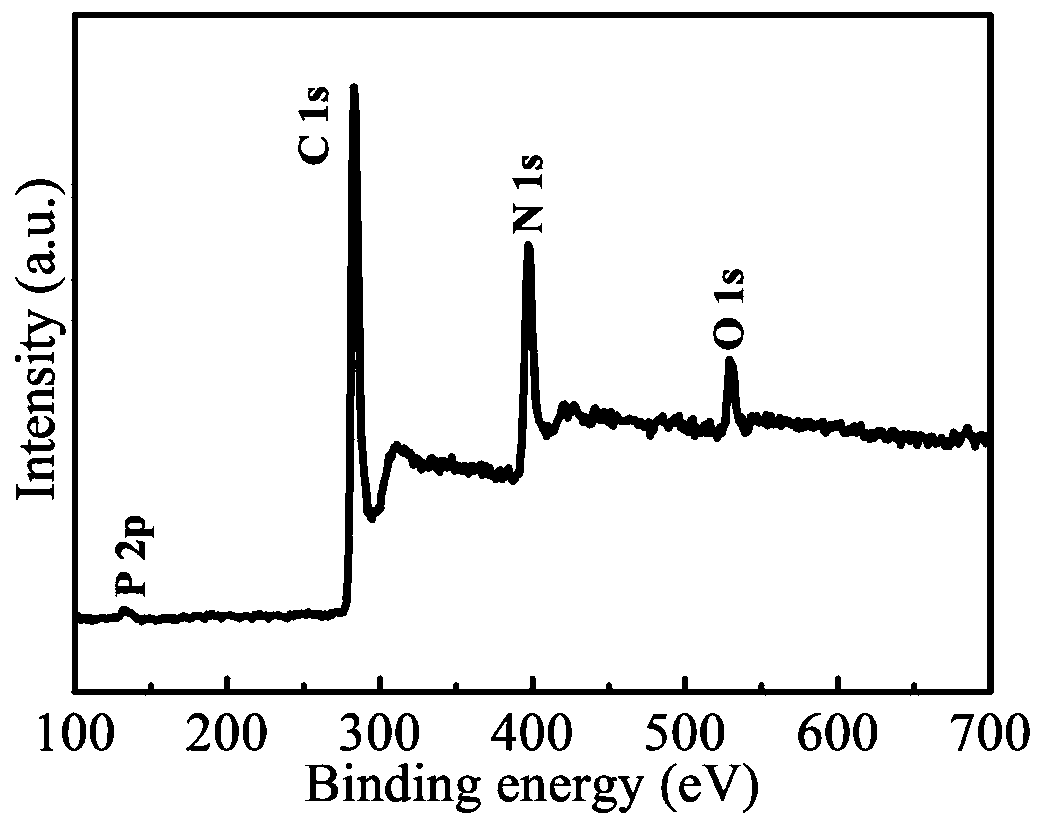

[0025] Weigh 1.25 g of sucrose and place it in a beaker, then use a graduated cylinder to measure 5 mL of deionized water and add it to the above beaker, stir until completely dissolved, then add 0.14 g of concentrated sulfuric acid dropwise as a dehydrating agent and stir evenly. Weighed 1 g of SBA-15 and slowly added it into the above solution and continued to stir until it became a white viscous paste, followed by ultrasonic treatment for 10 min to improve its dispersibility. It was dried in an oven at 100°C for 6 hours, then heated to 160°C and dried for 6 hours to obtain a composite of ordered mesoporous carbon and SBA-15.

[0026]Weigh 1 g of the above composite solid and grind it into a powder, mix it with 5 g of ammonium dihydrogen phosphate and dissolve it in deionized water, then place it in a water bath at 60 °C to evaporate the solvent water, and after drying, grind the obtained powder into a powder in Calcined at 800 °C for 5 hours in a tube furnace under an argon...

Embodiment 2

[0030] Weigh 2.25 g of glucose and place it in a beaker, then use a graduated cylinder to measure 5 mL of deionized water and add it to the above beaker, stir until completely dissolved, then add 0.24 g of concentrated sulfuric acid dropwise as a dehydrating agent and stir evenly. Weighed 1 g of SBA-15 and slowly added it into the above solution and continued to stir until it became a white viscous paste, followed by ultrasonic treatment for 10 min to improve its dispersibility. It was dried in an oven at 100 °C for 6 hours, then heated to 160 °C and dried for 6 hours to obtain a composite of ordered mesoporous carbon and SBA-15.

[0031] Weigh 1 g of the above composite solid and grind it into a powder, mix it with 5 g of ammonium phosphate and dissolve it in deionized water, then place it in a water bath at 80 °C to evaporate the solvent water, and after drying, grind the obtained powder into a powder in a tube Calcined at 800°C for 5 hours under an argon atmosphere in the f...

Embodiment 3

[0035] Weigh 1.25 g of fructose and put it in a beaker, then use a graduated cylinder to measure 5 mL of deionized water and add it to the above beaker, stir until completely dissolved, then add 0.14 g of concentrated sulfuric acid dropwise as a dehydrating agent and stir evenly. Weighed 1 g of SBA-15 and slowly added it into the above solution and continued to stir until it became a white viscous paste, followed by ultrasonic treatment for 10 min to improve its dispersibility. It was dried in an oven at 100°C for 6 hours, then heated to 160°C and dried for 6 hours to obtain a composite of ordered mesoporous carbon and SBA-15.

[0036] Weigh 1 g of the above composite solid and grind it into powder, mix it with 7 g of hexachlorotripolyphosphazene and dissolve it in deionized water, then place it in a water bath at 60 °C to evaporate the solvent water, and after drying, grind the obtained product into The powder was calcined at 600 °C for 5 hours under an argon atmosphere in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com