Method for preparing perovskite active layer of perovskite solar battery in the air

A solar cell and perovskite technology, applied in climate sustainability, circuits, photovoltaic power generation, etc., can solve problems such as hindering large-scale and industrialized production, and achieve the effects of improving photoelectric conversion efficiency, improving surface defects, and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

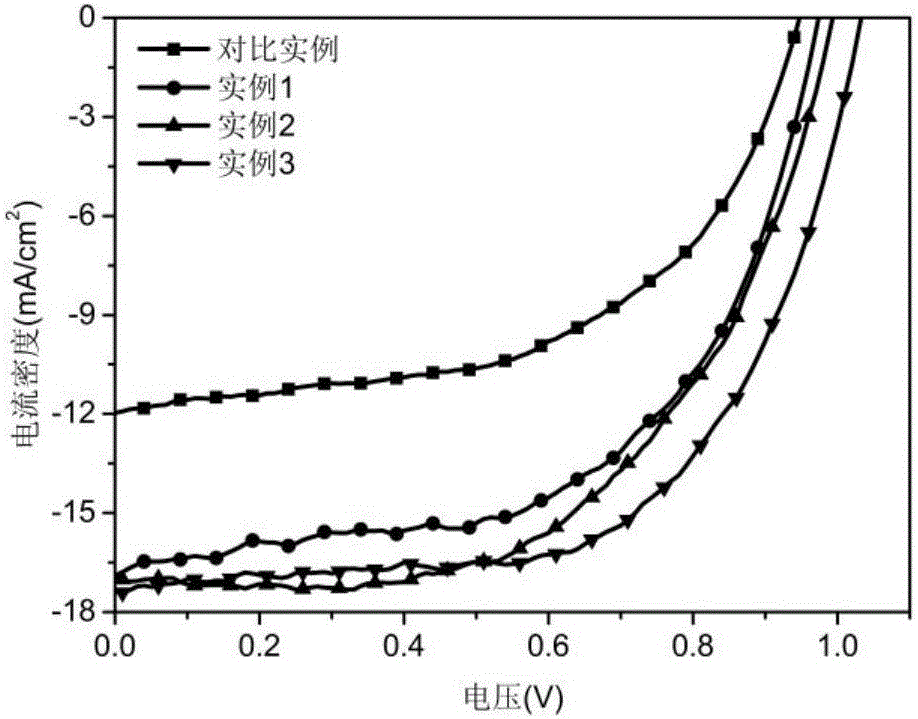

Embodiment 1

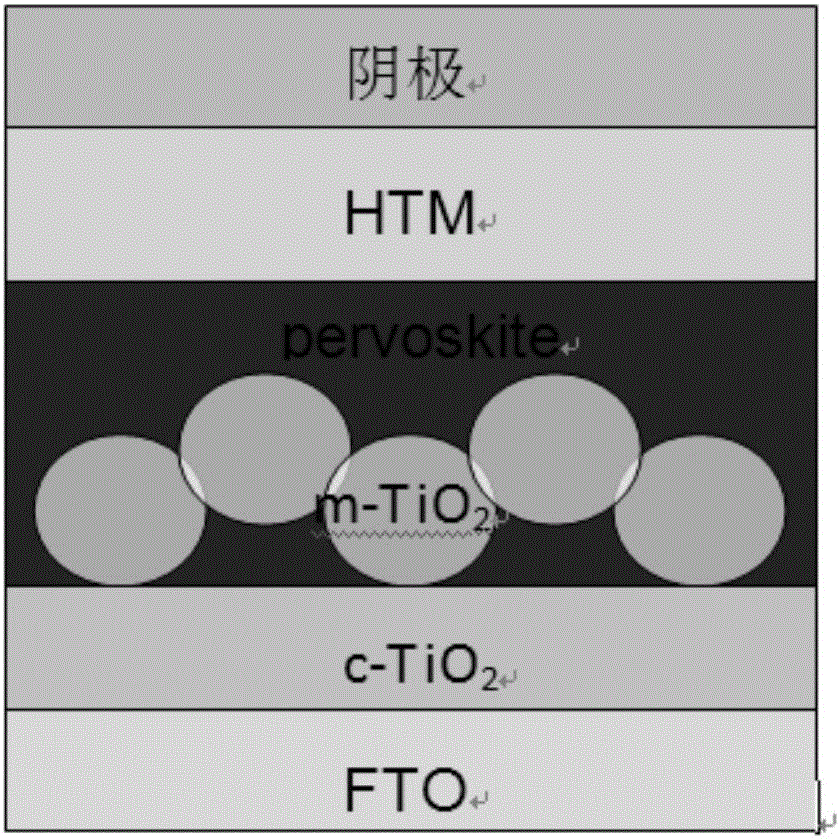

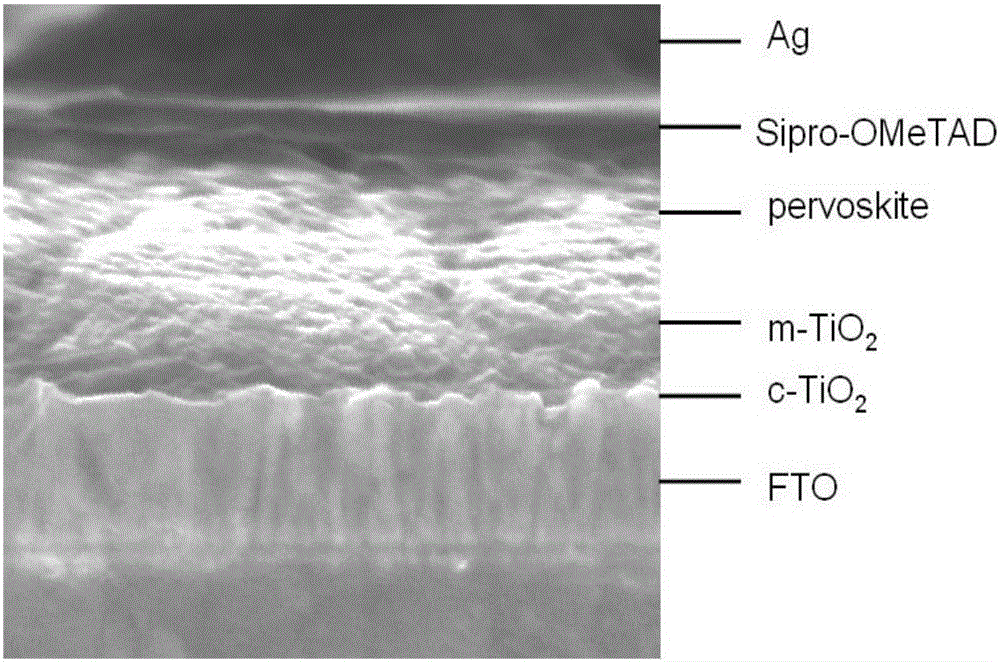

[0027] Such as figure 1 As shown, the perovskite solar cell device structure includes: FTO conductive glass glass substrate, titanium dioxide dense layer, titanium dioxide mesoporous layer, perovskite active layer, hole transport layer, and metal cathode.

[0028] In this example, the selected additive 3,5-lutidine is added in an amount of 100 μL per 1 mL of lead iodide solution.

[0029] In this example, the specific steps for preparing the perovskite active layer are: configure 1mol / L lead iodide solution, the solvent is N,N-dimethylformamide, add 100μL 3,5-dimethylformamide to 1mL lead iodide solution Pyridine, lead iodide and the glass substrate coated with TiO2 mesoporous layer were preheated at 70 °C, then the lead iodide solution was spin-coated on the TiO2 mesoporous layer, annealed at 70 °C, soaked in 10 mg / mL iodine In the methylamine solution, the perovskite active layer was obtained after annealing.

[0030] In this example, the hole transport layer is Spiro-OMeT...

Embodiment 2

[0034] In this example, the additive is 4-ethylpyridine, and 100 μL is added per 1 mL of lead iodide solution.

[0035] In this example, the hole transport layer is Spiro-OMeTAD and the metal electrode is silver.

[0036] In this example, the structure of the perovskite solar device, the preparation process and the thickness of each layer are consistent with Example 1.

[0037] In this example, the preparation process is carried out under two conditions of relative humidity control of 45% and 70%.

Embodiment 3

[0039] In this example, the additive is 4-tert-butylpyridine, and 100 μL is added per 1 mL of lead iodide solution.

[0040] In this example, the hole transport layer is Spiro-OMeTAD and the metal electrode is silver.

[0041] In this example, the structure of the perovskite solar device, the preparation process and the thickness of each layer are consistent with Example 1.

[0042] In this example, the preparation process is carried out under two conditions of relative humidity control of 45% and 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com