Patents

Literature

50results about How to "Lower nitriding temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

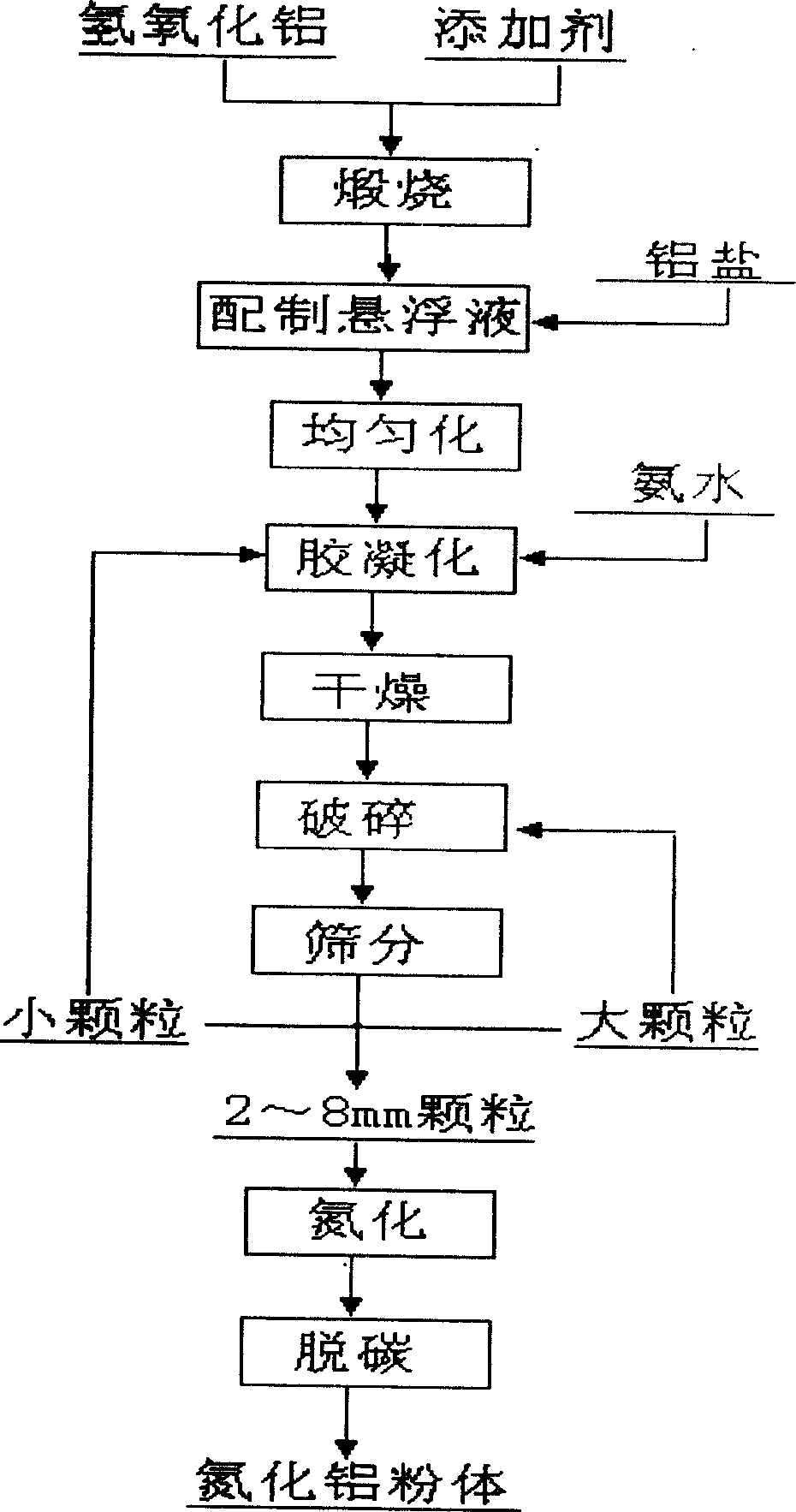

Method for preparing aluminium nitride powder by carbothermic reduction method

ActiveCN1631772AImprove qualityLow reaction temperatureAluminium compoundsNitrogen compoundsBorideAluminium hydroxide

The invention is an aluminum nitride powder preparation by a kind of carbon thermal recovery and relates to techniques of aluminum nitride powder preparation by carbon thermal recovery. If features that burning the mixture of aluminum hydroxide and fluoride or boride at the temperature between 500 to 900 deg C for 2 or 4 hours in the preparation to obtain a multiaperture active aluminum oxide, crush up the obtained aluminum oxide to powder and prepare in the water into suspending liquid, add aluminate, carbon powder to gelate, then dry and crush up into powder, finally inlet nitrogen to obtain the nitride powder. This so prepared aluminum nitride is of tiny particles, no hard conglobation meanwhile the reaction temperature is compared low.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

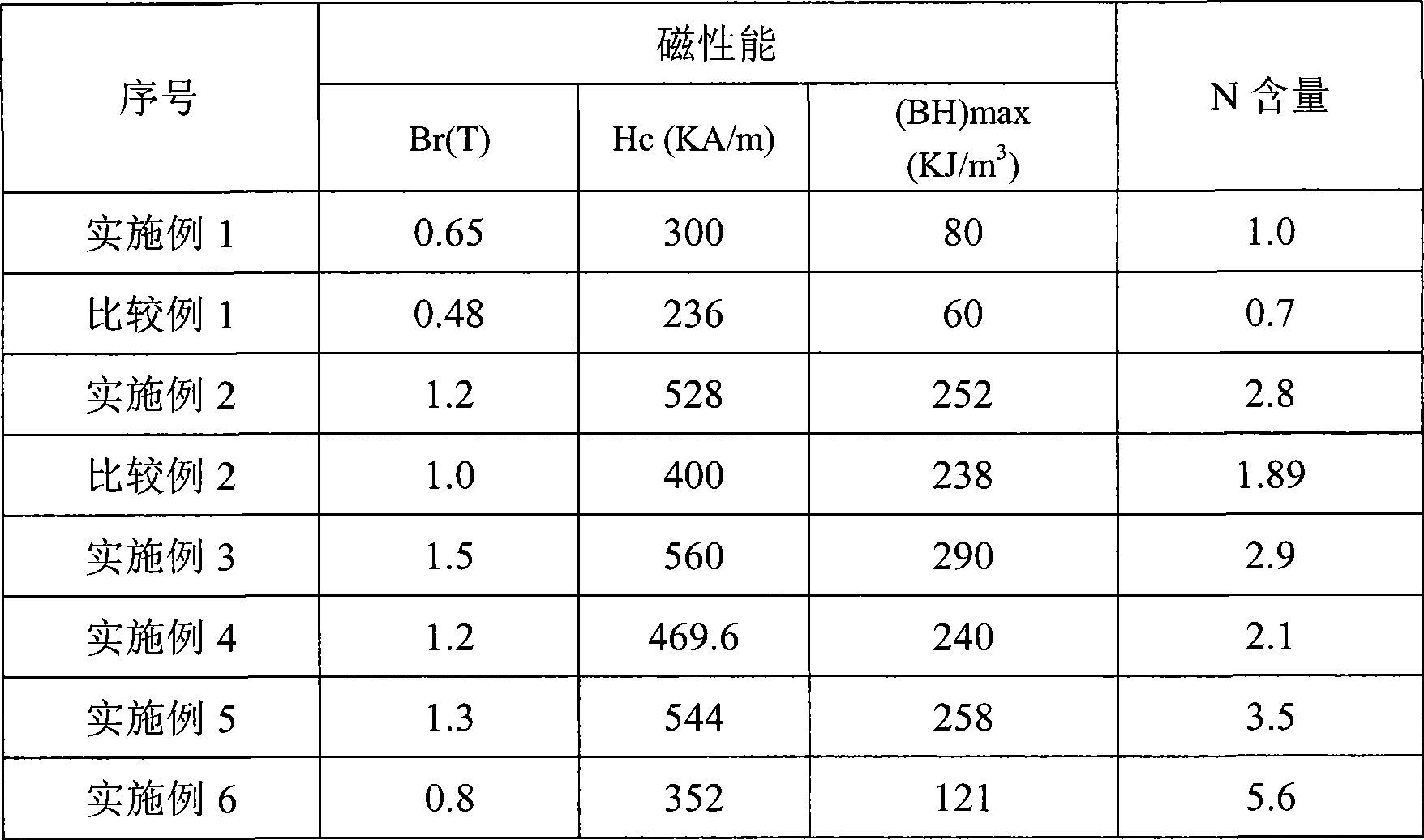

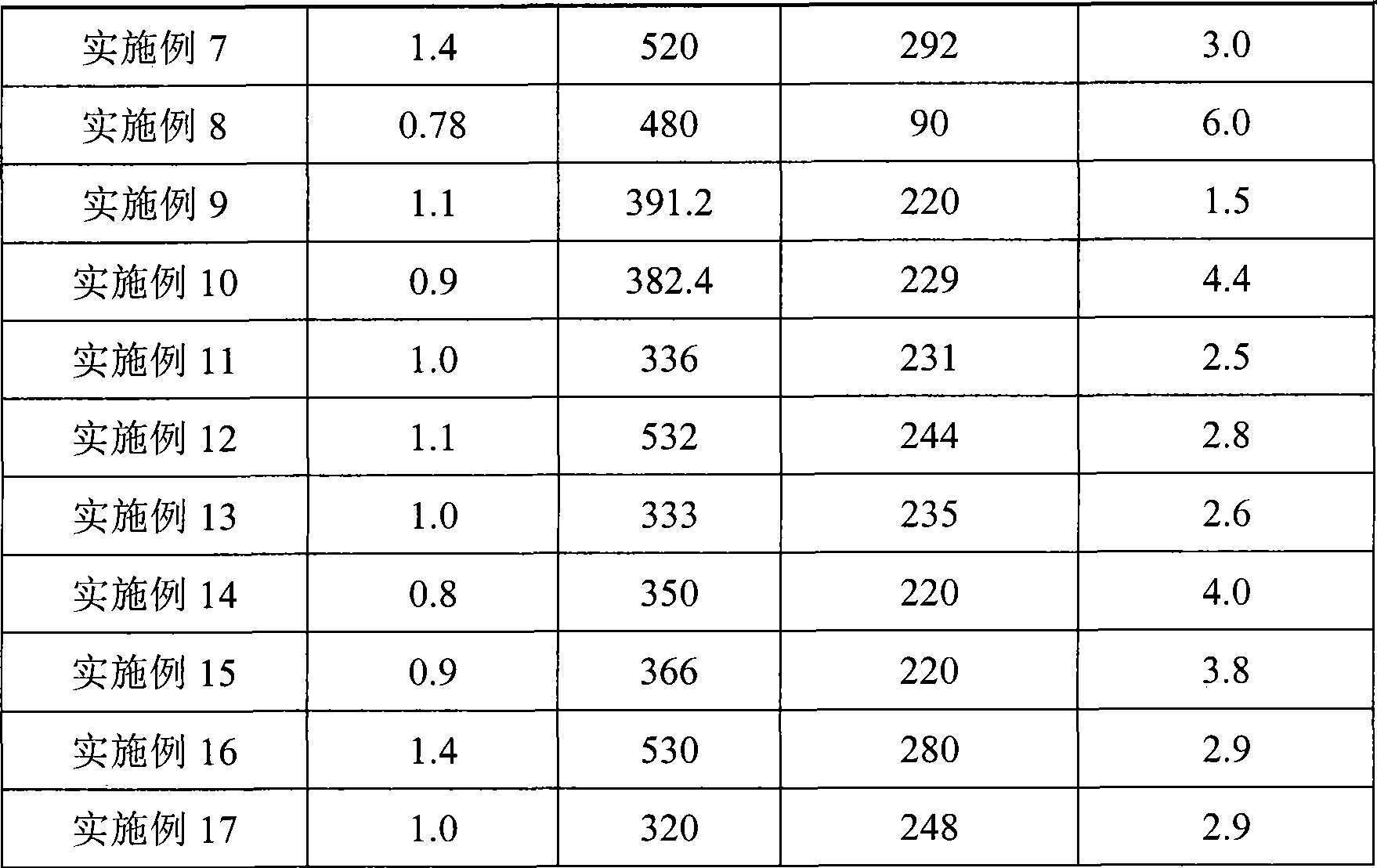

Nitrogen-containing rare-earth magnetic powder and preparation method thereof

ActiveCN101546642AIncrease the speed of diffusionPromote decompositionInorganic material magnetismRare-earth elementLanthanide

The invention discloses a nitrogen-containing rare-earth magnetic powder prepared by taking ferrocene, cyclopentadienyl lanthanide, metallic iron and rare earth as the main raw materials. The nitrogen-containing rare-earth magnetic powder comprises the following component of R2Fe17-xMxNy, wherein the R is one or more kinds of 17 kinds of rare earth elements including Sc and Y, the M includes transitional elements except for Fe and is one or more kinds of Al, Ga, In, Si, Ge, Sn, Pb, Mg and Ca, the x is equal to 0 to 5, and the y is equal to 1 to 6; and the preparation method comprises the following steps: working procedure of preparation of the R2Fe17-xMx compound powder; working procedure of nitridation; and working procedure of magnetic powder refining and nitriding.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

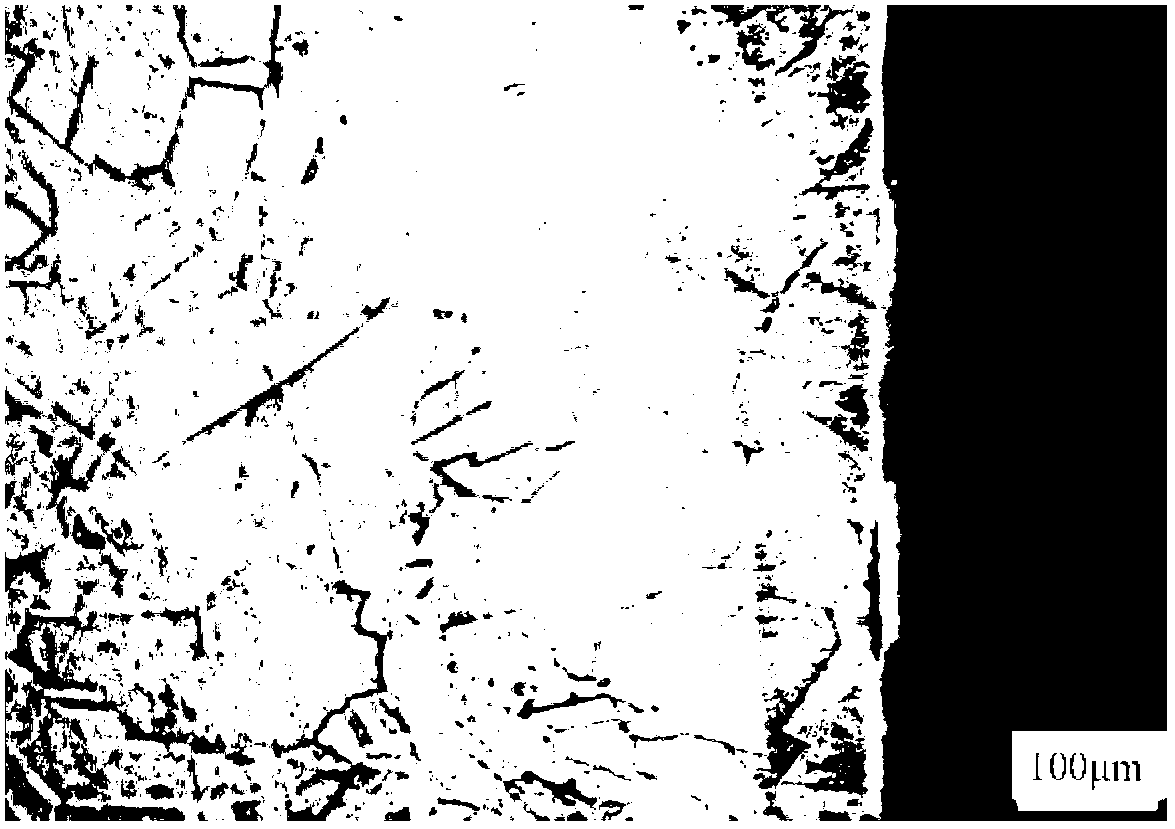

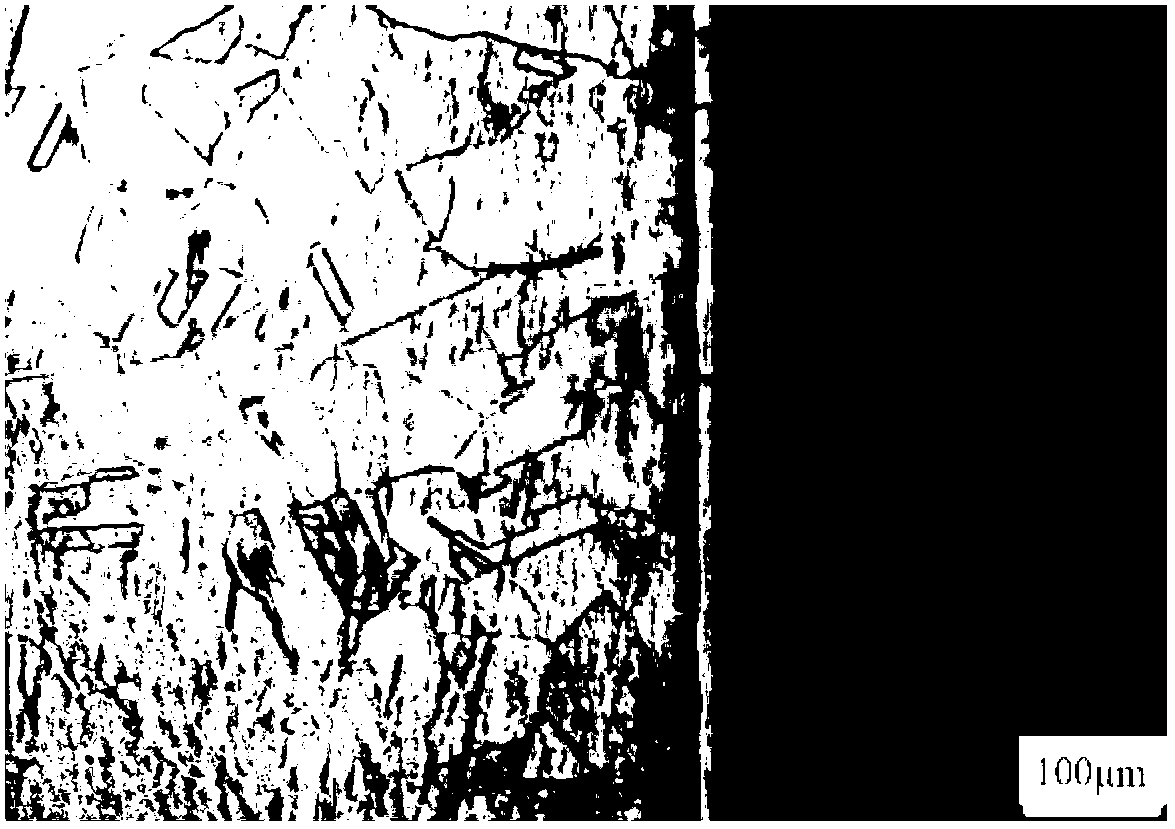

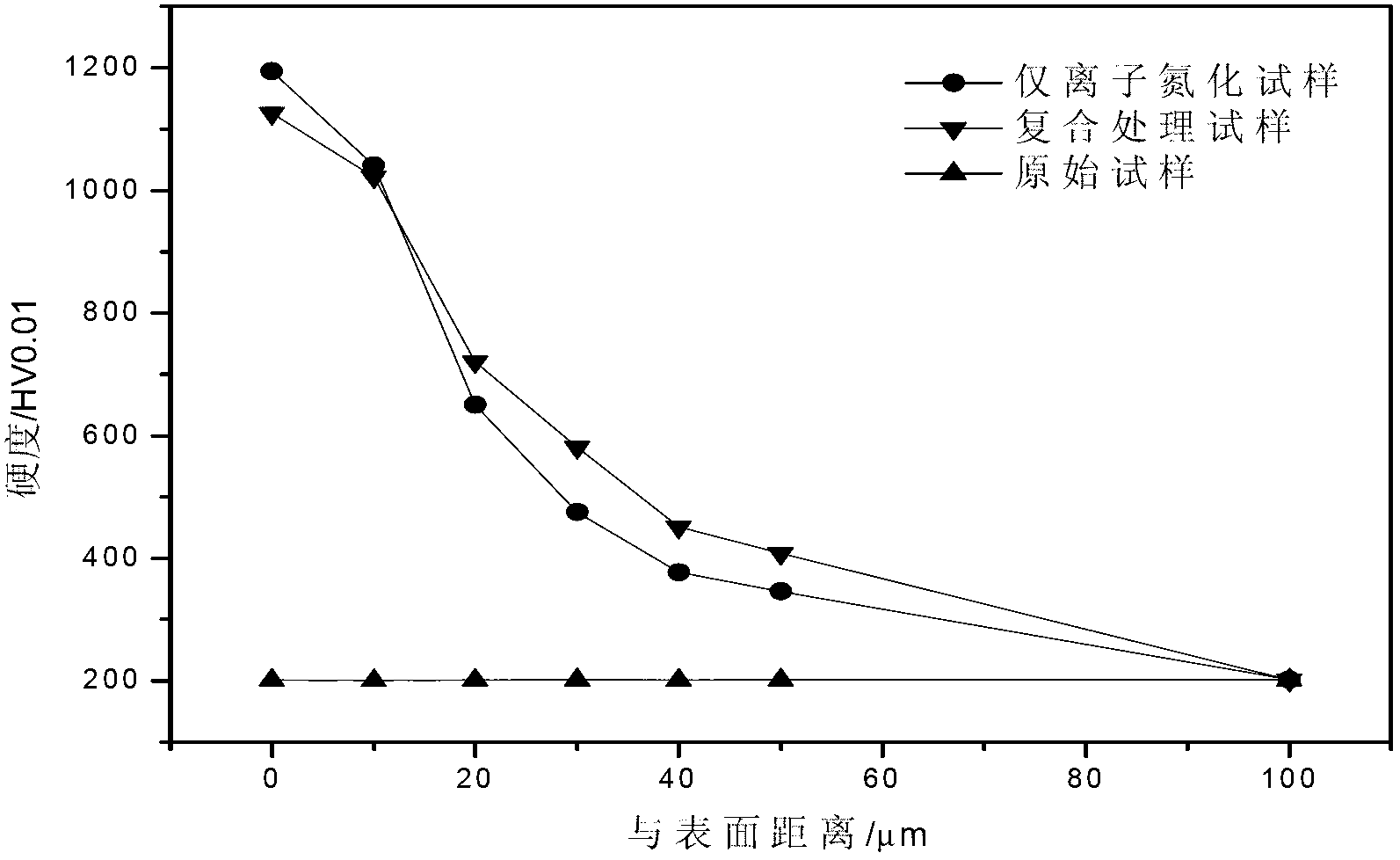

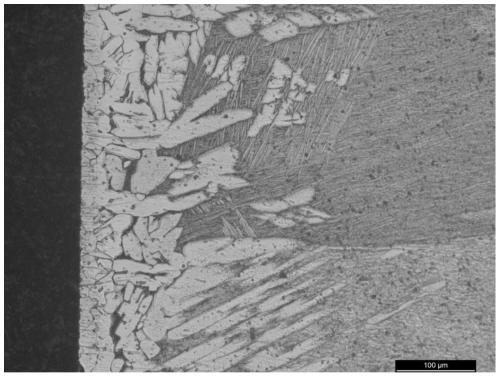

Austenitic stainless steel ion nitriding permeation catalyzing process

InactiveCN103014601AQuality improvementImprove bindingSolid state diffusion coatingHydrogenMetallurgy

The invention relates to a stainless steel ion nitriding process, and in particular relates to an austenitic stainless steel ion nitriding permeation catalyzing process. The process mainly comprises the following steps: 1) washing the surface of a stainless steel surface, and removing the oil stain and impurities on the surface of the workpiece; 2) carrying out pre-oxidation treatment on the stainless steel workpiece; 3) putting the stainless steel workpiece into an ion nitriding furnace after being cooled down, introducing dried hydrogen, building up of luminance and heating up, after reaching a certain temperature, introducing nitrogen, adjusting the ratio of the nitrogen to the hydrogen and the pressure in the furnace, subsequently starting to time, after nitriding for a certain time, closing the ion nitriding furnace and cooling down the workpiece along with the furnace. The austenitic stainless steel treated by using the process can obtain a compound layer which is thicker than that of an ordinary ion nitriding process.

Owner:CHANGZHOU UNIV

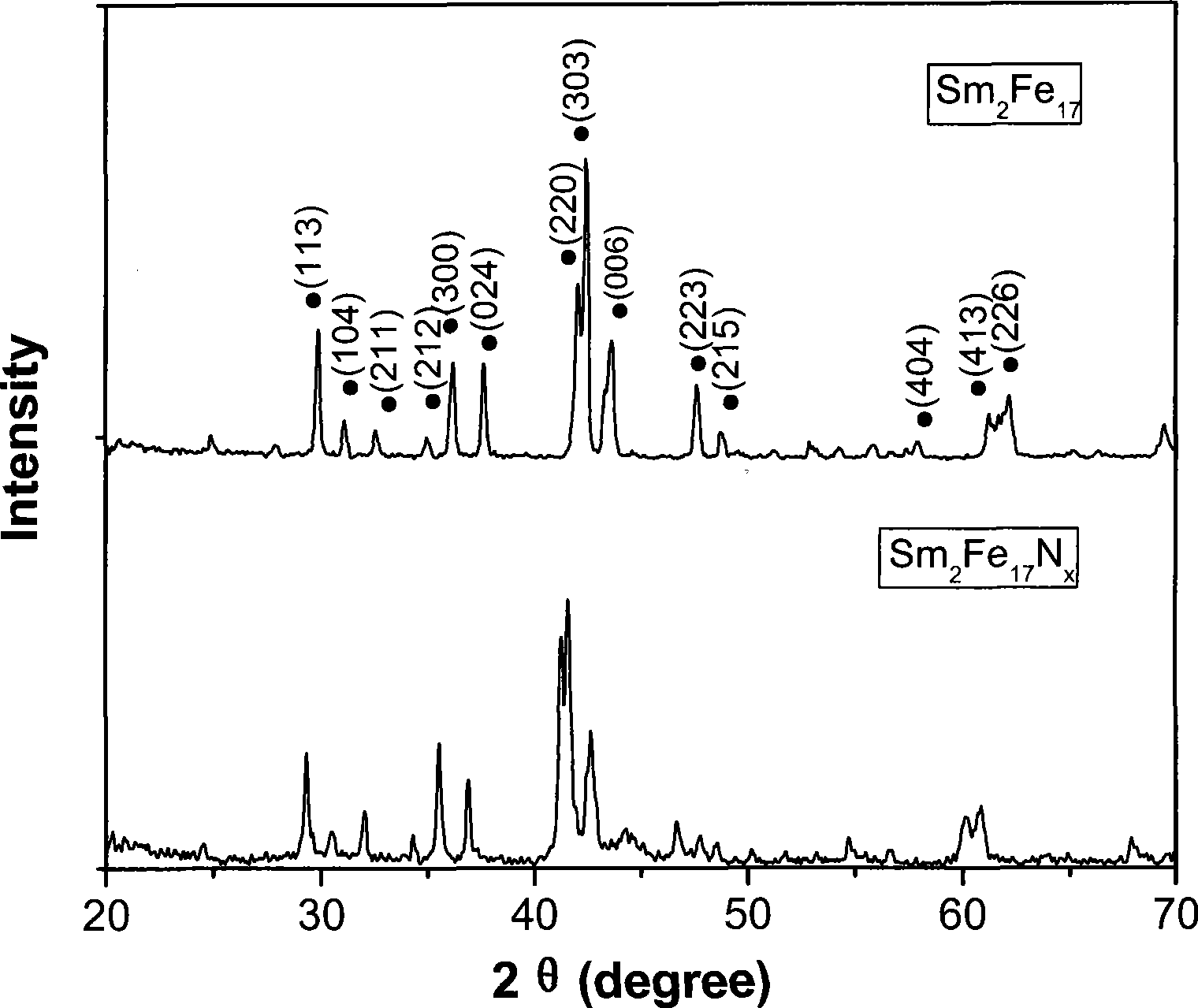

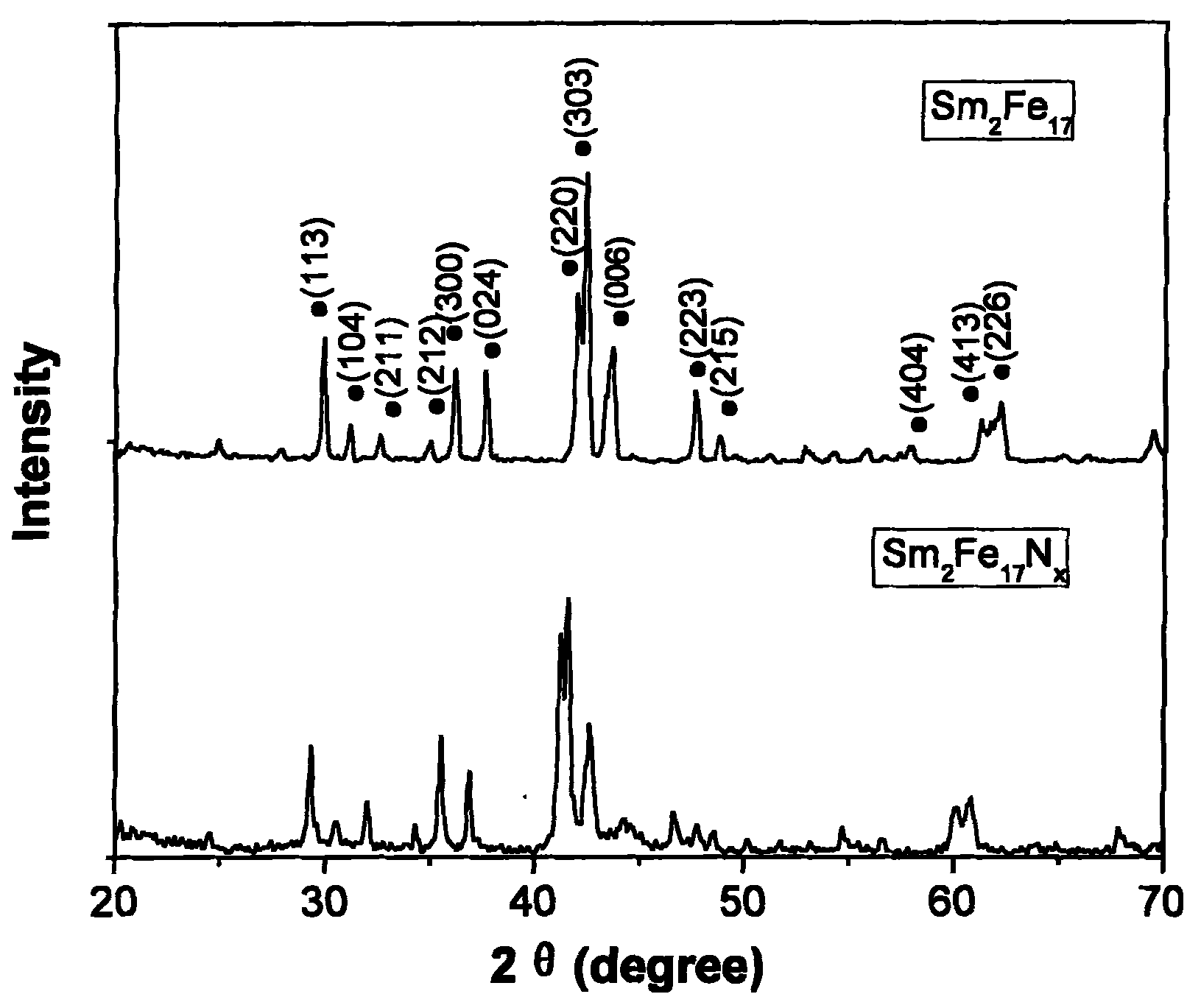

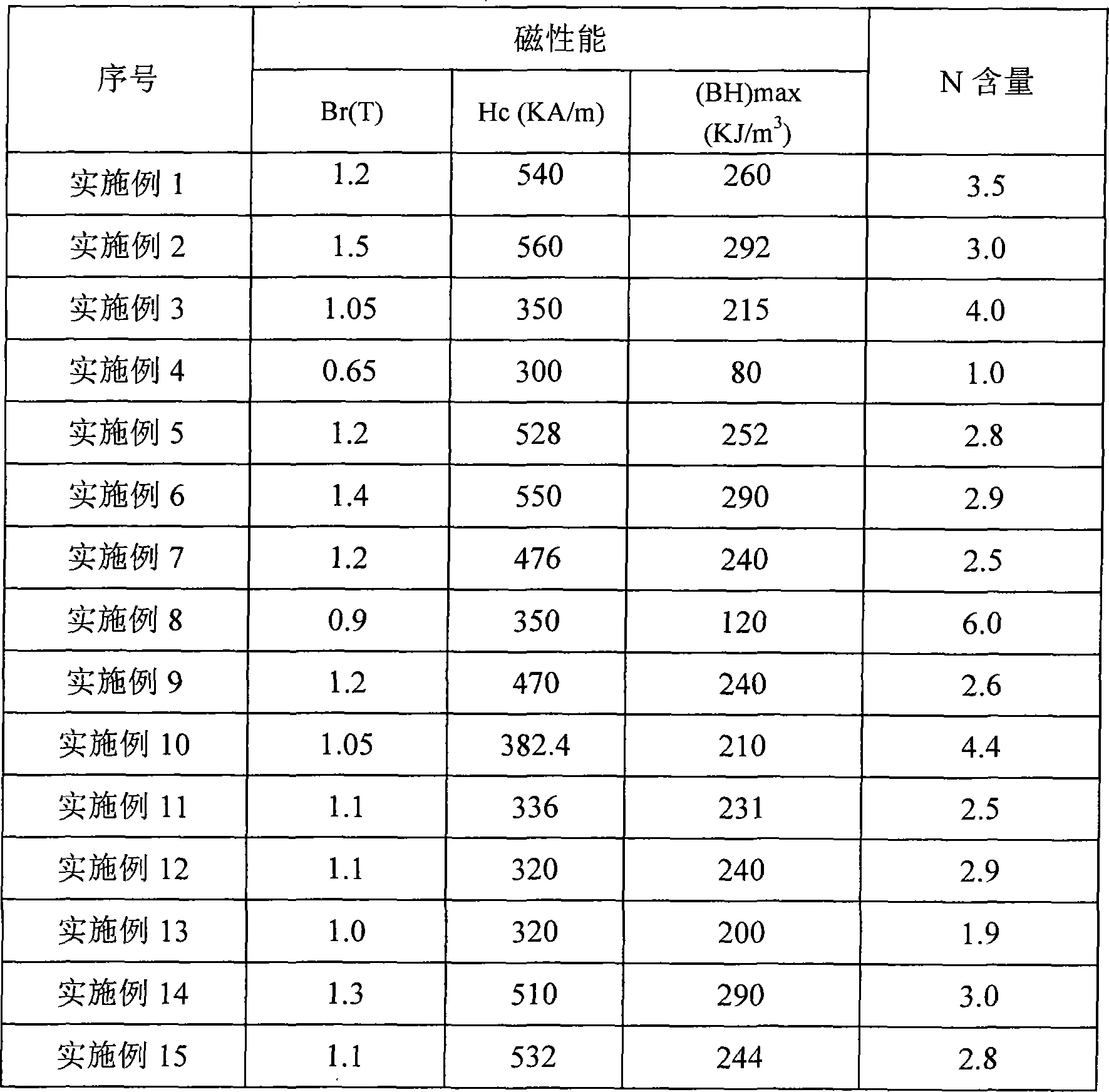

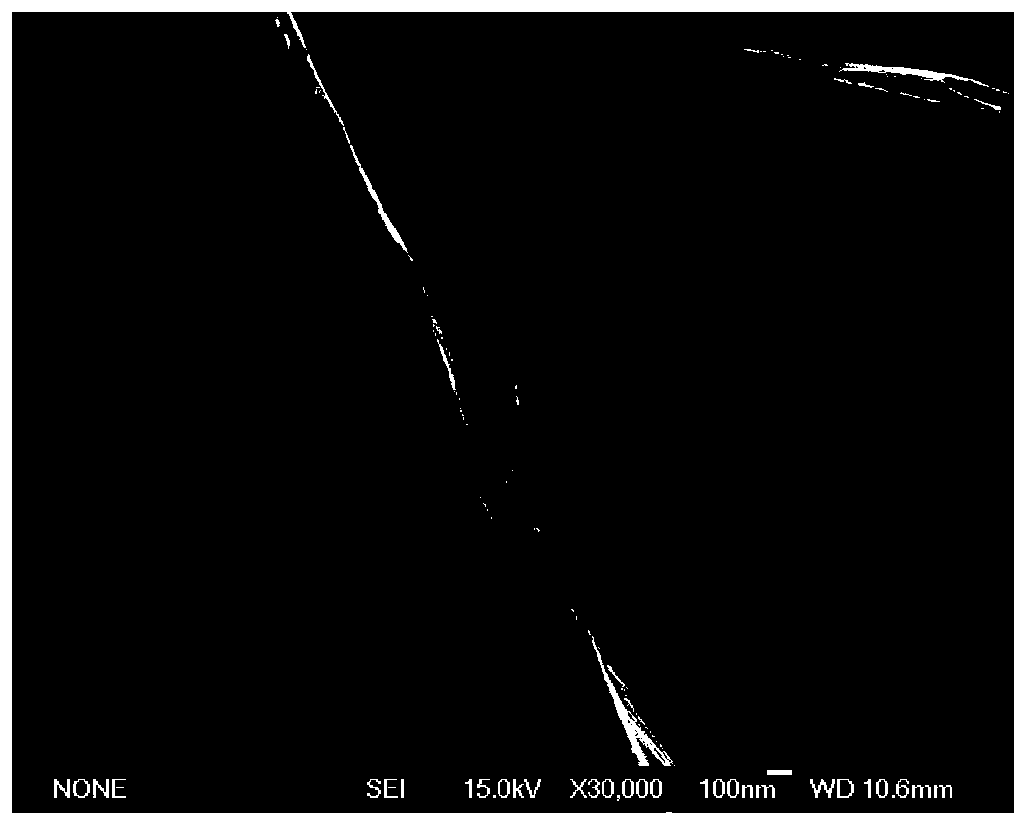

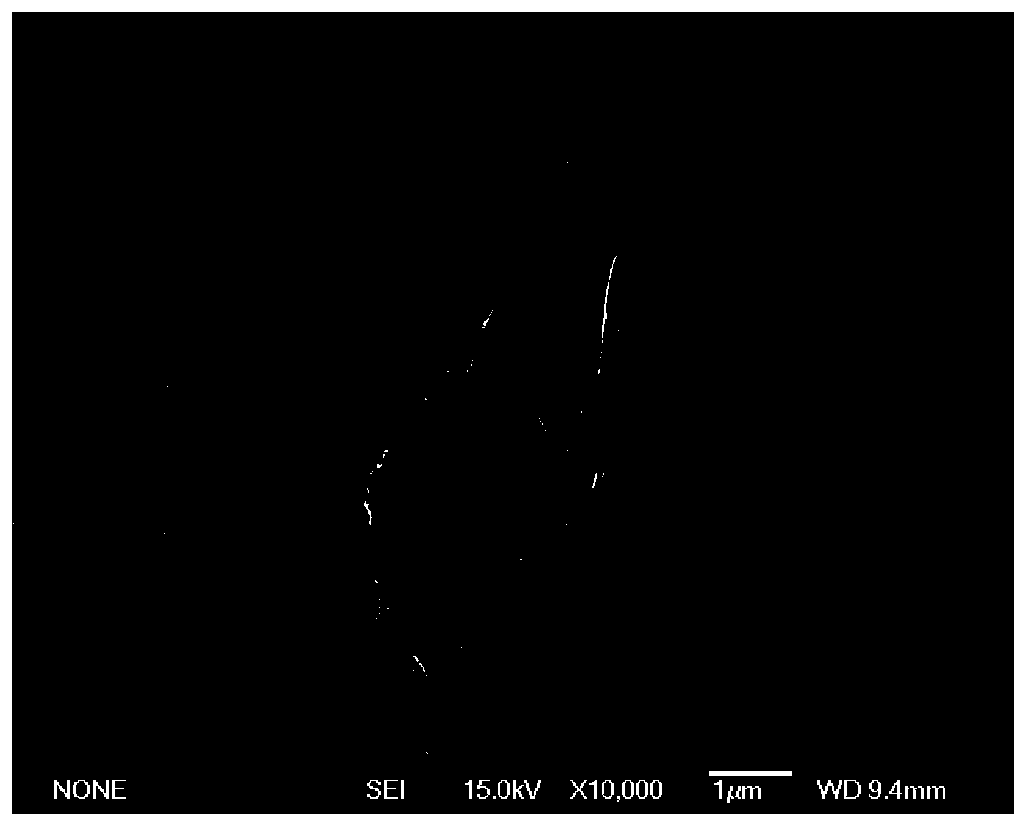

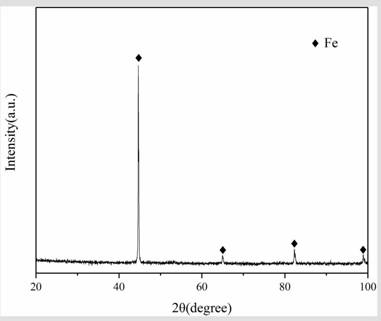

Low-temperature nitridation preparation method of iron-based rare earth permanent magnet powder

InactiveCN102816991AEffective driving forceLower nitriding temperatureSolid state diffusion coatingMagnetic materialsHigh energyRare earth

The invention discloses a low-temperature nitridation preparation method of iron-based rare earth permanent magnet powder. The method is characterized in comprising the steps that: (1) under Ar gas protection, Sm2Fe17 alloy is smelted by using pure samarium and pure iron in a vacuum induction furnace, such that an ingot is obtained; the ingot is subjected to a homogenization treatment, and is crushed into powdery particles with an average particle size smaller than 40mun; (2) a surfactant, grinding balls and the powdery particles are added into a ball milling tank; a ball milling medium is filled into the tank; and with the cooperation of the surfactant and high-energy ball milling, flaky powder with a nano-crystalline structure is obtained, wherein the surfactant is coated on the surface of the powder; (3) the powder is filtered, such that the ball milling medium is removed; and the powder is subjected to vacuum drying; and (4) the powder is subjected to a nitridation treatment under a low temperature of 300-400 DEG C. The microstructure of the obtained permanent magnet powder is nano-crystals with grain sizes of 8-20nm. The nano-sheet thickness is approximately 5-200nm, Hc is 5-14kOe, and (BH) max is 10-28MGOe. On the basis that an original structure and advantages are maintained, the nitridation temperature is greatly reduced. The nano-sheet powder can be prepared into a high-performance bonding magnet which can be used in fields such as motors and engines.

Owner:HEBEI UNIV OF ENG

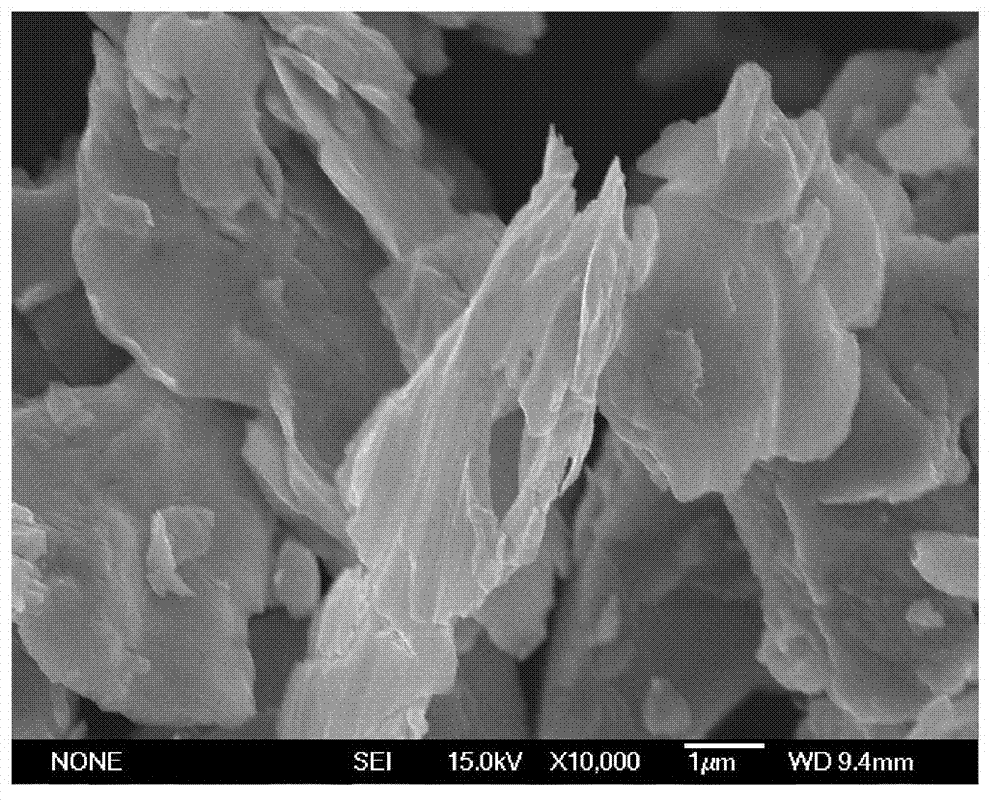

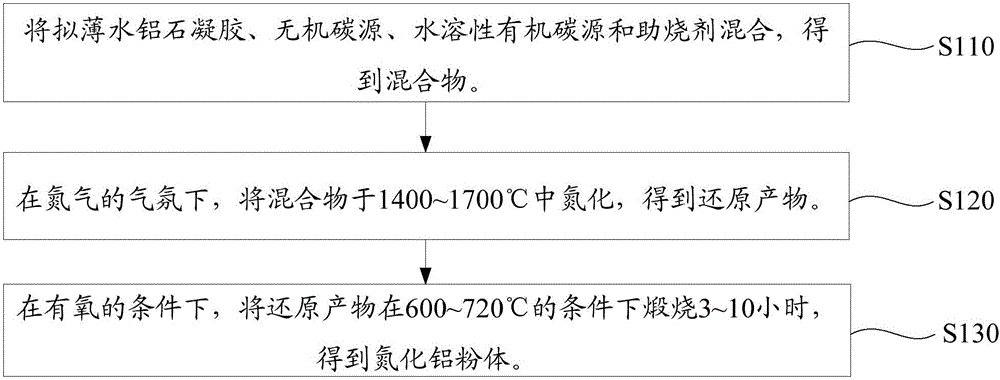

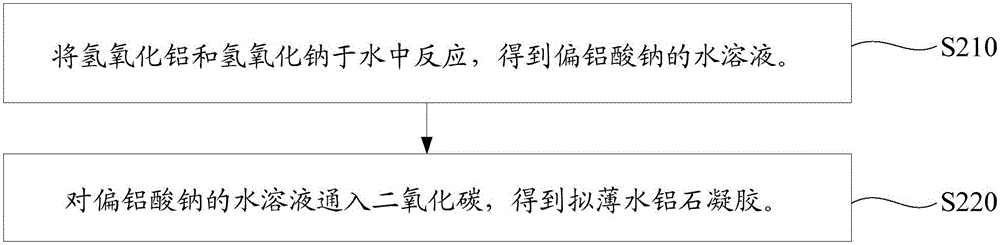

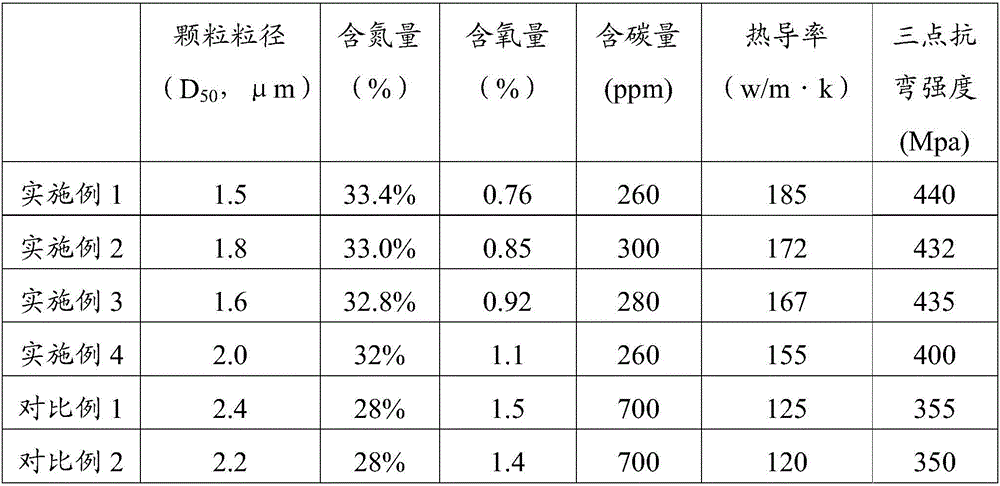

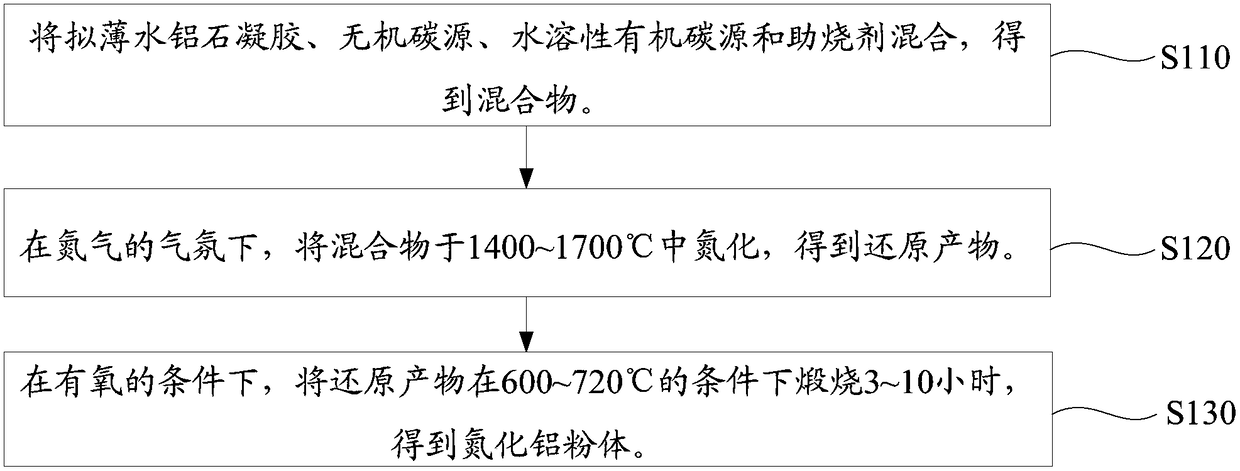

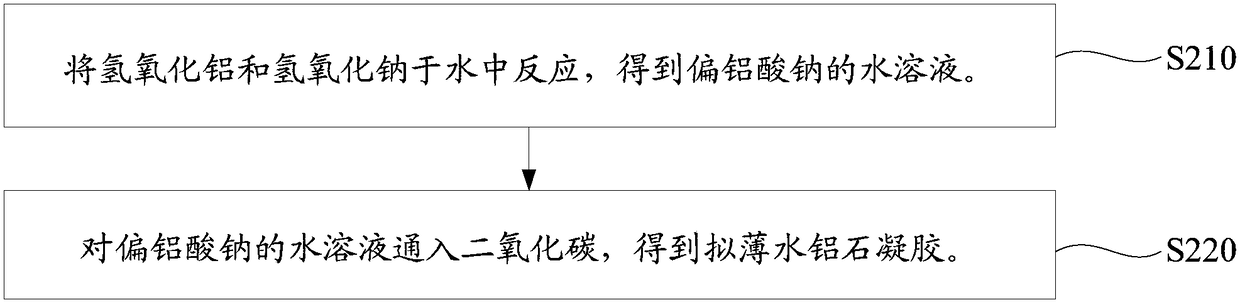

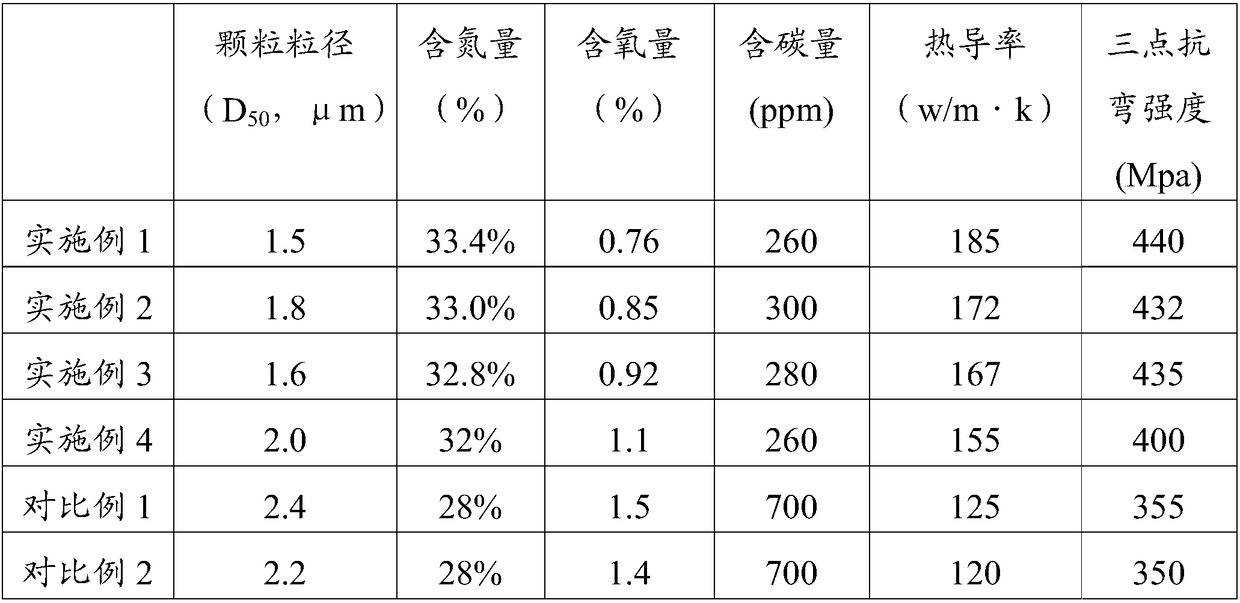

Method for preparing aluminum nitride powder

The invention relates to a method for preparing aluminum nitride powder. The method for preparing the aluminum nitride powder comprises the following steps that pseudo-boehmite gel, an inorganic carbon source, a water-soluble organic carbon source and a sintering agent are mixed, and a mixture is obtained; in a nitrogen atmosphere, the mixture is nitrogenized at the temperature of 1,250 DEG C to 1,700 DEG C, and a reduction product is obtained; under the aerobic condition, the reduction product is calcined for 3-10 hours at the temperature of 600 DEG C to 720 DEG C, and the aluminum nitride powder is obtained. The aluminum nitride powder prepared through the method is high in purity.

Owner:CHAOZHOU THREE CIRCLE GRP

Novel method for carrying out low-temperature surface catalysis and nitriding on alloy cast iron

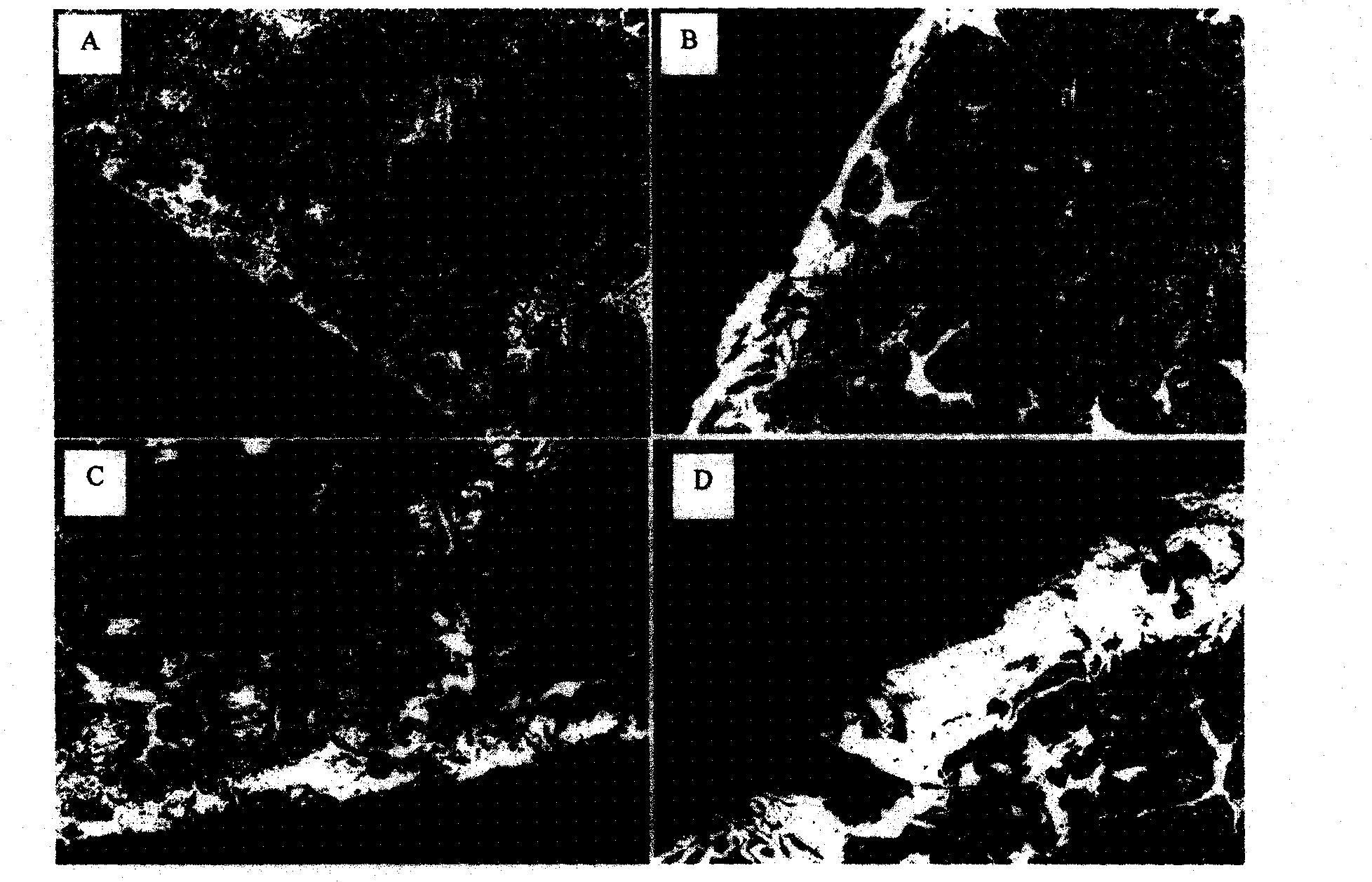

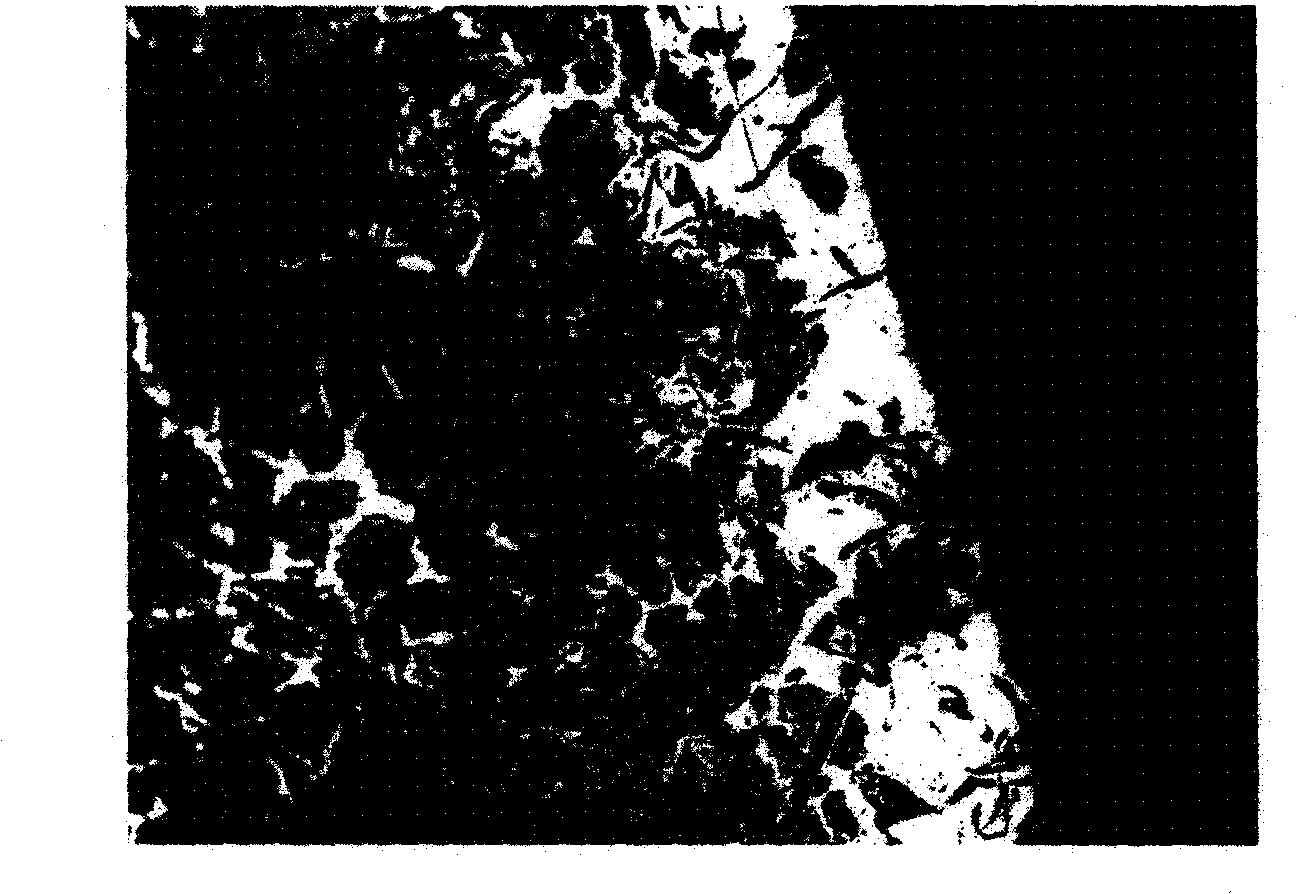

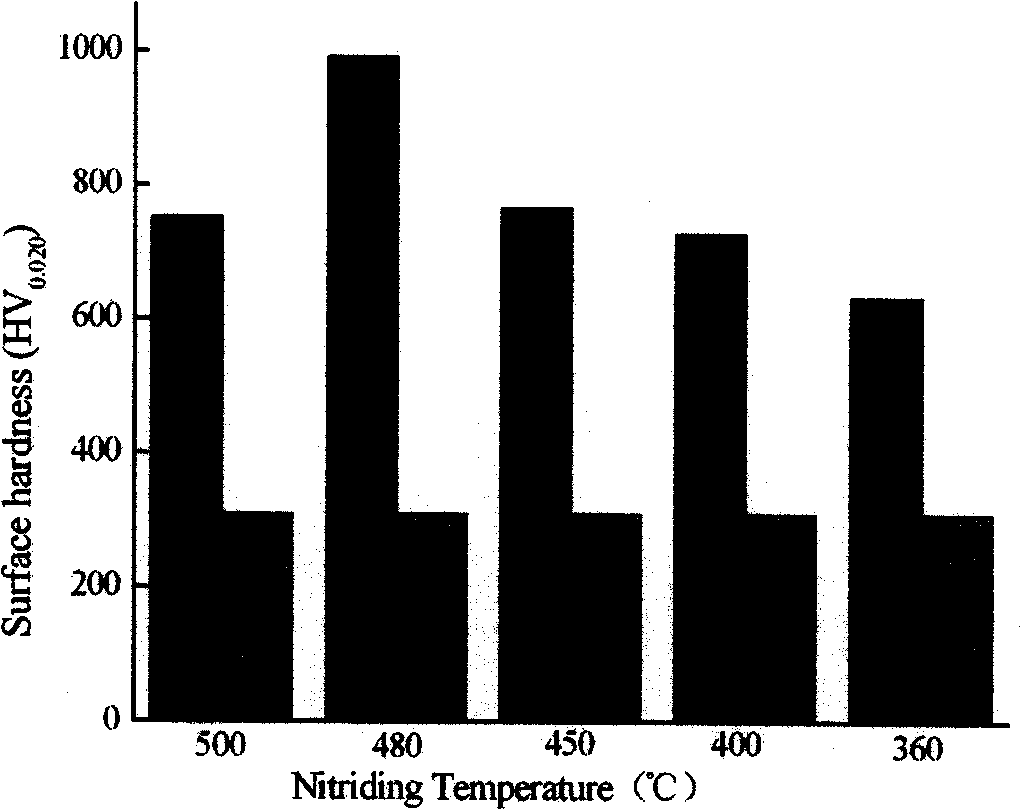

ActiveCN101880851AHigh catalytic activityPromote spreading rateSolid state diffusion coatingCatalytic decompositionAlloy

The invention relates to a novel method for carrying out low-temperature surface catalysis and nitriding on alloy cast iron, belongs to the technical field of the surface chemical heat treatment application of metal materials and is suitable for low-temperature and rapid surface nitrogen treatment (in the strengthening nitriding process, the temperature is less than 480 DEG C and the time is less than 10 hours; and in the corrosion-resisting nitriding process, the temperature is between 500 and 520 DEG C and the time is less than 4 hours) of an alloy cast iron cylinder sleeve and an alloy cast iron piston ring. Based on the surface catalysis theory, the invention designs an active catalyst component, utilizes an adjustable bidirectional pulse power supply to form a catalytic film, i.e. a surface catalyst, on the surface of the alloy cast iron, improves the activity that the metal surface carries out catalytic decomposition on ammonia at the low temperature and also effectively adsorbs the decomposed free nitrogen to form a nitrogen adsorption layer. Moreover, the catalyst can permeate into a substrate to form solid solution so as to promote the diffusion rate of nitrogen. Compared with the conventional gas nitriding method, the process increases a working procedure of adjustable bidirectional pulse surface deposition treatment. The working procedure has the advantages of stable conditioning fluid and short processing time. The novel process is suitable for the existing gas nitriding equipment.

Owner:SHANDONG UNIV OF SCI & TECH

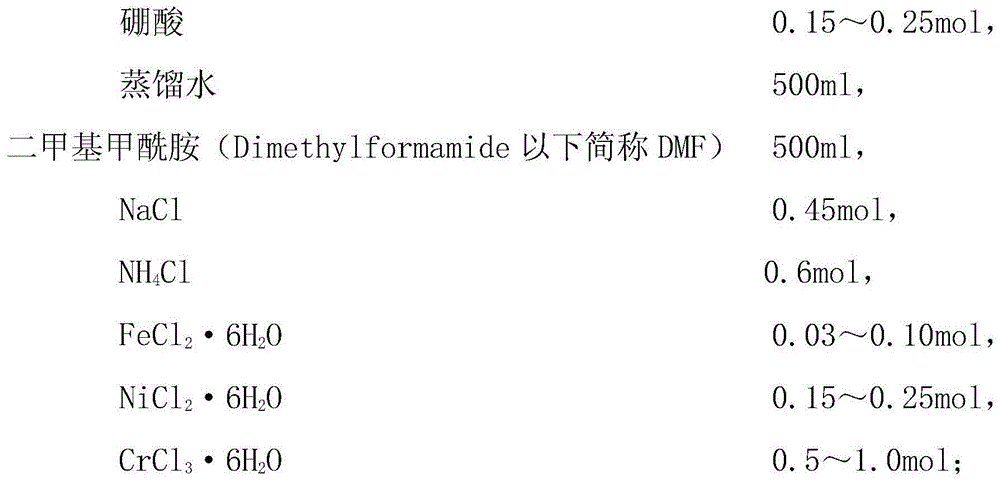

Low-temperature anti-corrosion gas nitriding method for metal workpiece and metal workpiece

ActiveCN104911533AImprove corrosion resistanceWill not deformSolid state diffusion coatingMicro nanoAlternating current

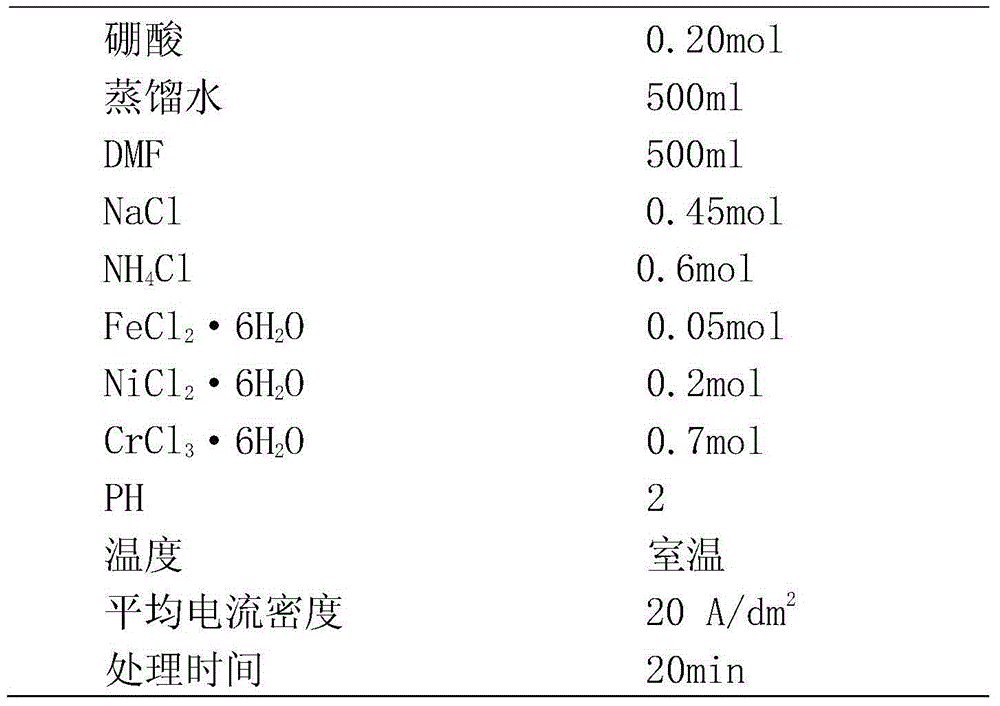

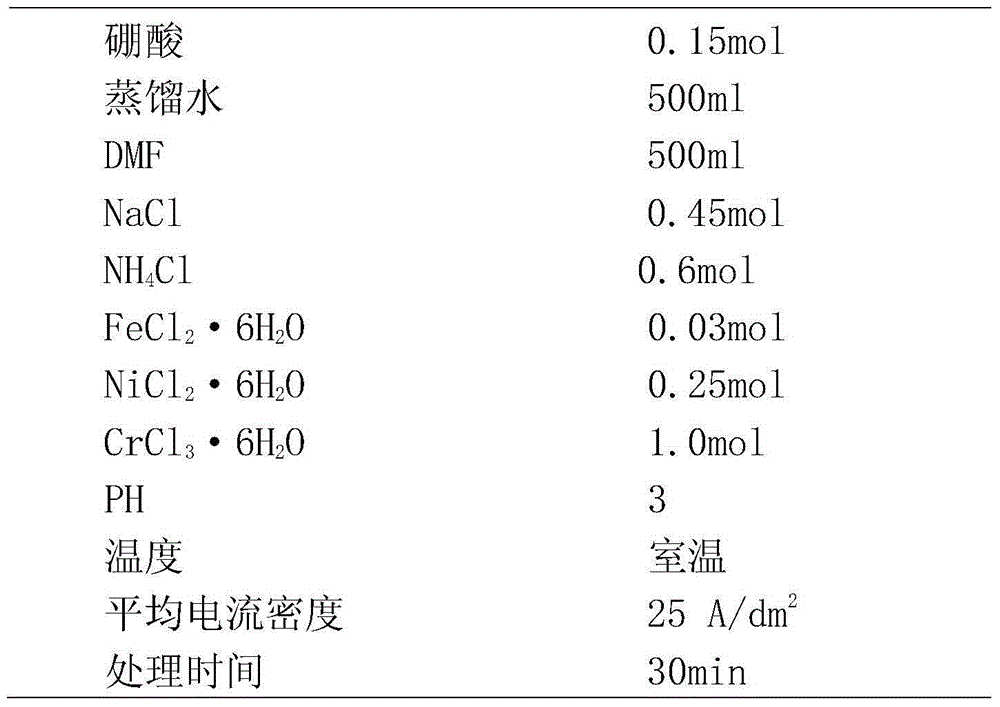

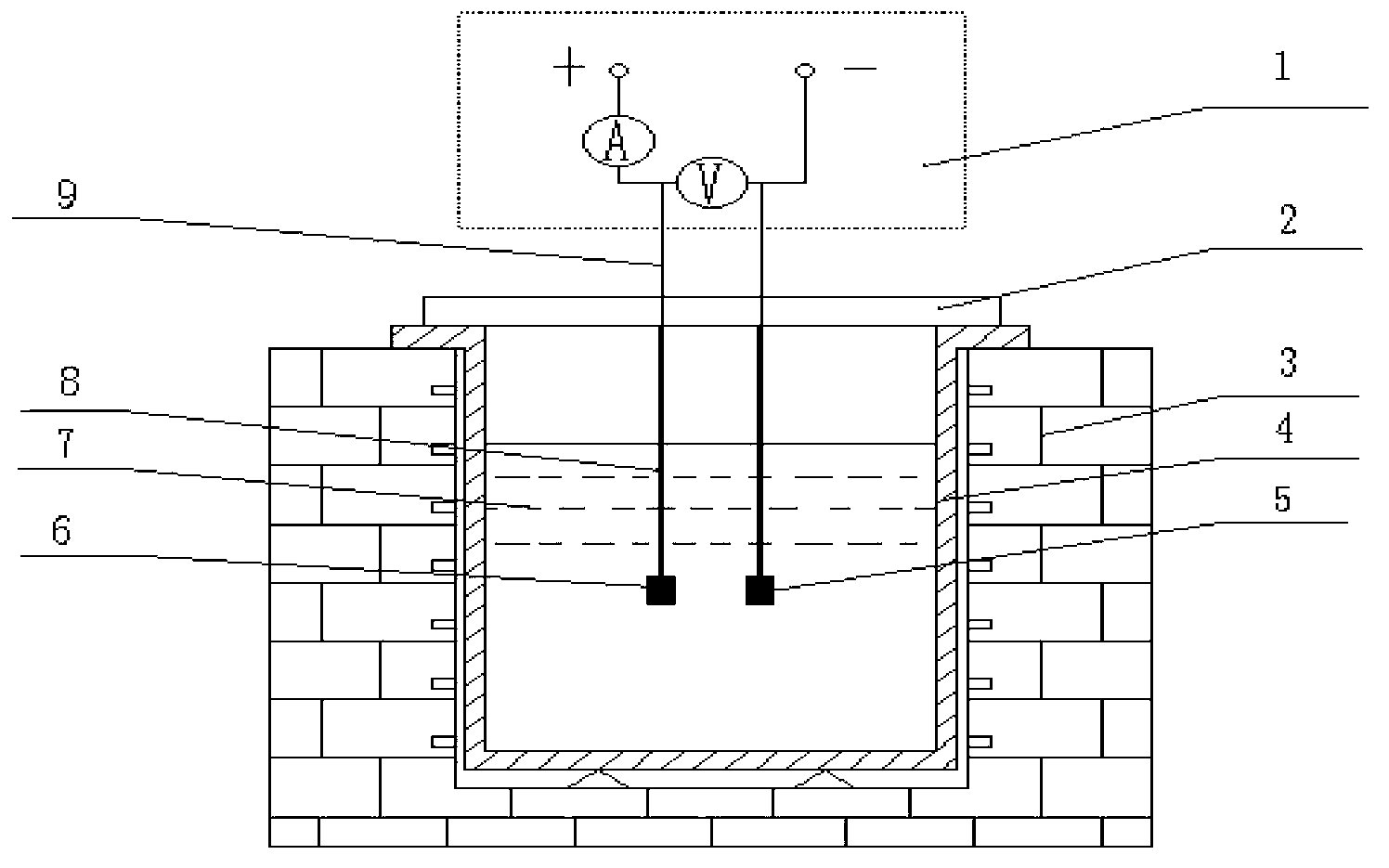

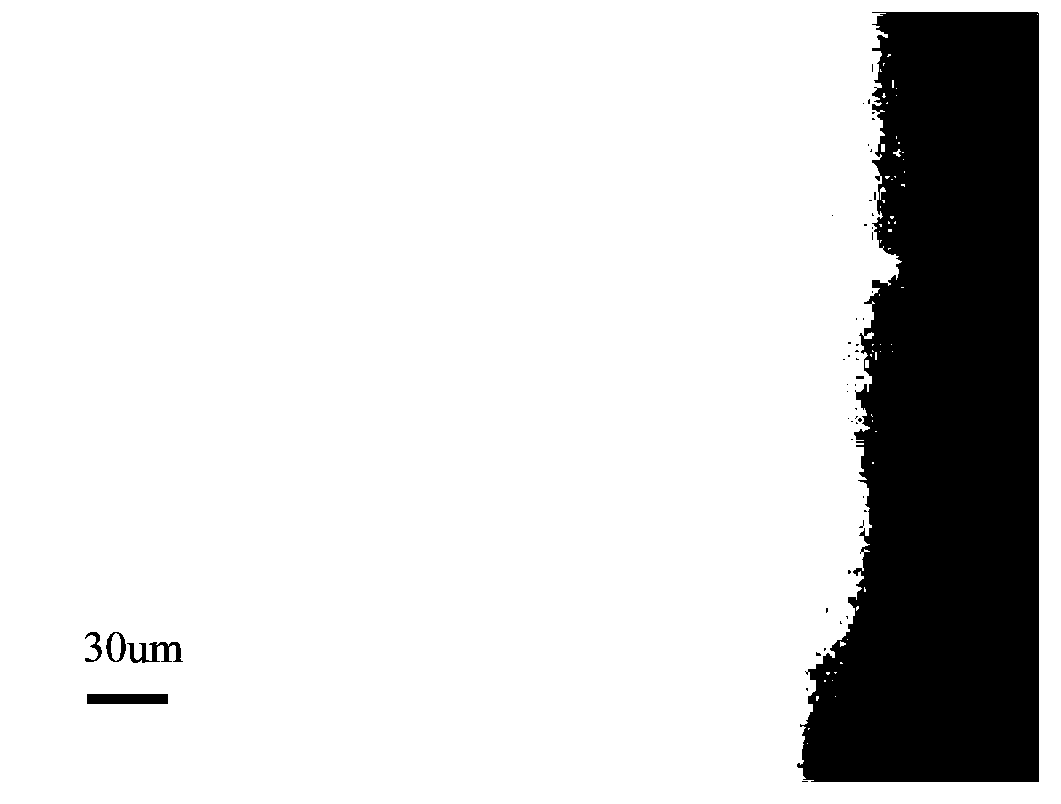

The invention relates to a low-temperature anti-corrosion gas nitriding method for a metal workpiece and the metal workpiece. According to the method, the metal workpiece is put in configured electrolyte, a common electro-deposition is utilized for carrying out pulse or alternating current treatment on the surface of the metal workpiece to form a micro-nano structural layer containing Ni<2+> and Cr<3+> on the surface of the metal workpiece under the effect of an electric field, grains on the surface of the workpiece are refined, and the activation energy is enhanced; by virtue of introduced Ni<2+> and Cr<3+>, nitriding can be promoted, the low-temperature nitriding is realized, and the corrosion resistance of the workpiece is improved; without recourse to a dense nitride layer (white bright layer), the danger caused by brittleness is solved, and the corrosion resistance of the workpiece is improved. In conclusion, by virtue of electro-deposition pretreatment provided by virtue of the method, the metal workpiece is not deformed, meanwhile, the nitriding temperature can be effectively decreased, the nitriding period can be shortened, the electro-deposition pretreatment is applicable to parts with complex shapes and precise parts, and the energy is saved.

Owner:SHANDONG UNIV OF SCI & TECH

Rapid QPQ (Quench-Polish-Quench) treatment method of application electric field and equipment thereof

InactiveCN103194721AIncrease concentrationHigh activitySolid state diffusion coatingQuenchingElectric field

The invention relates to a metal surface chemical thermal treatment process and equipment, and in particular relates to a rapid QPQ (Quench-Polish-Quench) treatment method and equipment thereof for improving the surface property of a metal by adding a direct current electric field. The method comprises the following steps of: taking a profiling plate electrode which is arranged parallel to a surface (of a part) to be nitrided in a salt bath nitriding agent as the anode of the electric field, taking a metal piece to be nitrided as the cathode, putting the anode and the cathode into a pit furnace with the salt bath, heating the anode and the cathode, and at the same time applying the direct current electrode field to the metal piece to be nitrided and the anode so as to realize rapid nitridation. Compared with an ordinary QPQ technique, the method can increase the nitridation speed, reduce the nitridation temperature and improve the utilization rate of the nitriding agent at different temperatures within the range of 510 DEG C to 580 DEG C. Therefore, the method can take the place of multiple processes of high-frequency quenching cemented quenching, tempering, blackening (chroming) and the like, and the strength of automobiles and industrial dies can be remarkably improved when the method is applied to the industries, so that the service lives of the automobiles and industrial dies are greatly prolonged, and the production cost is lowered.

Owner:CHANGZHOU UNIV

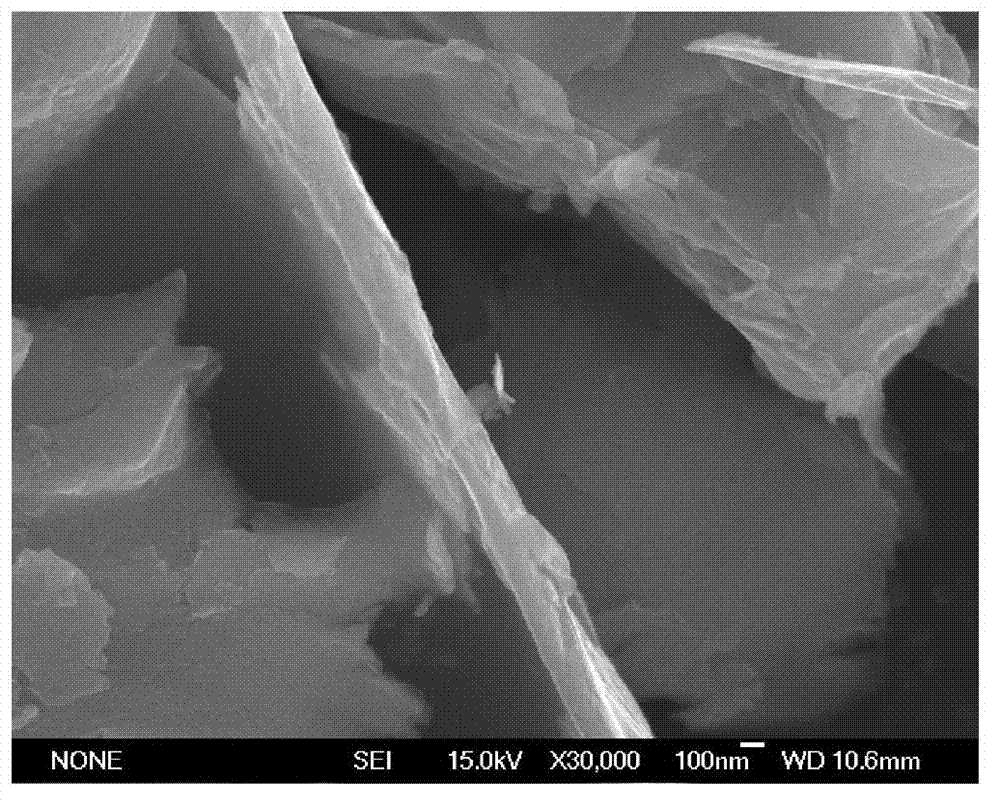

Nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy and preparation method thereof

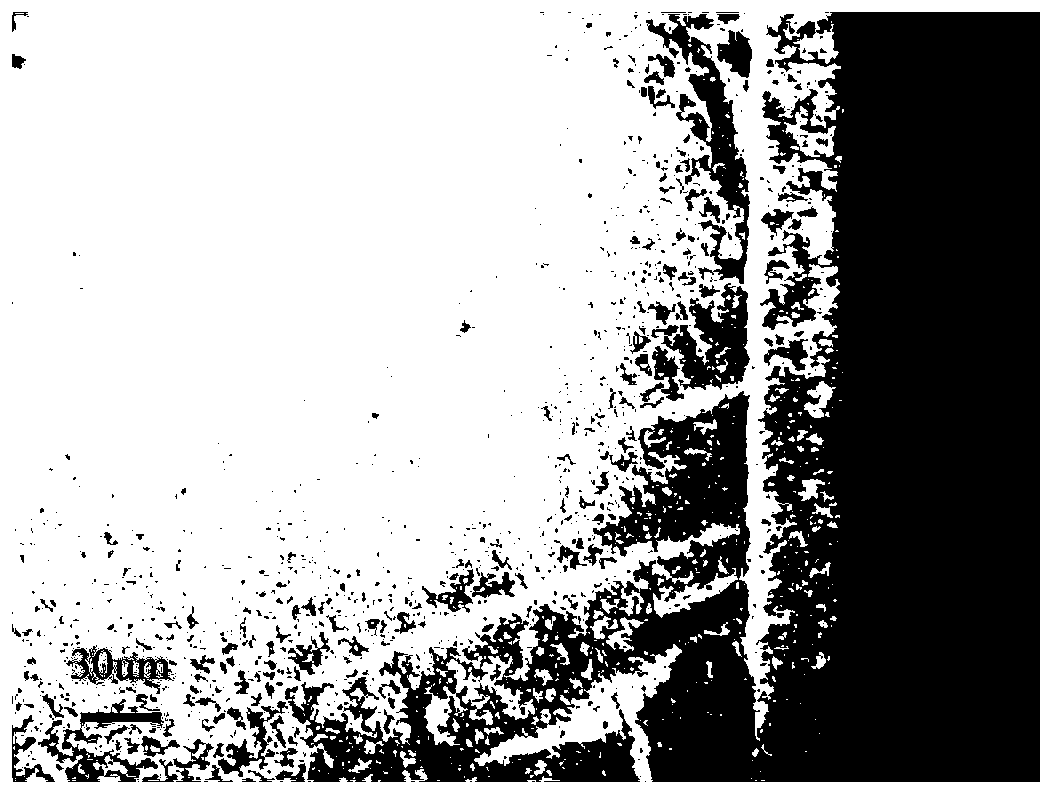

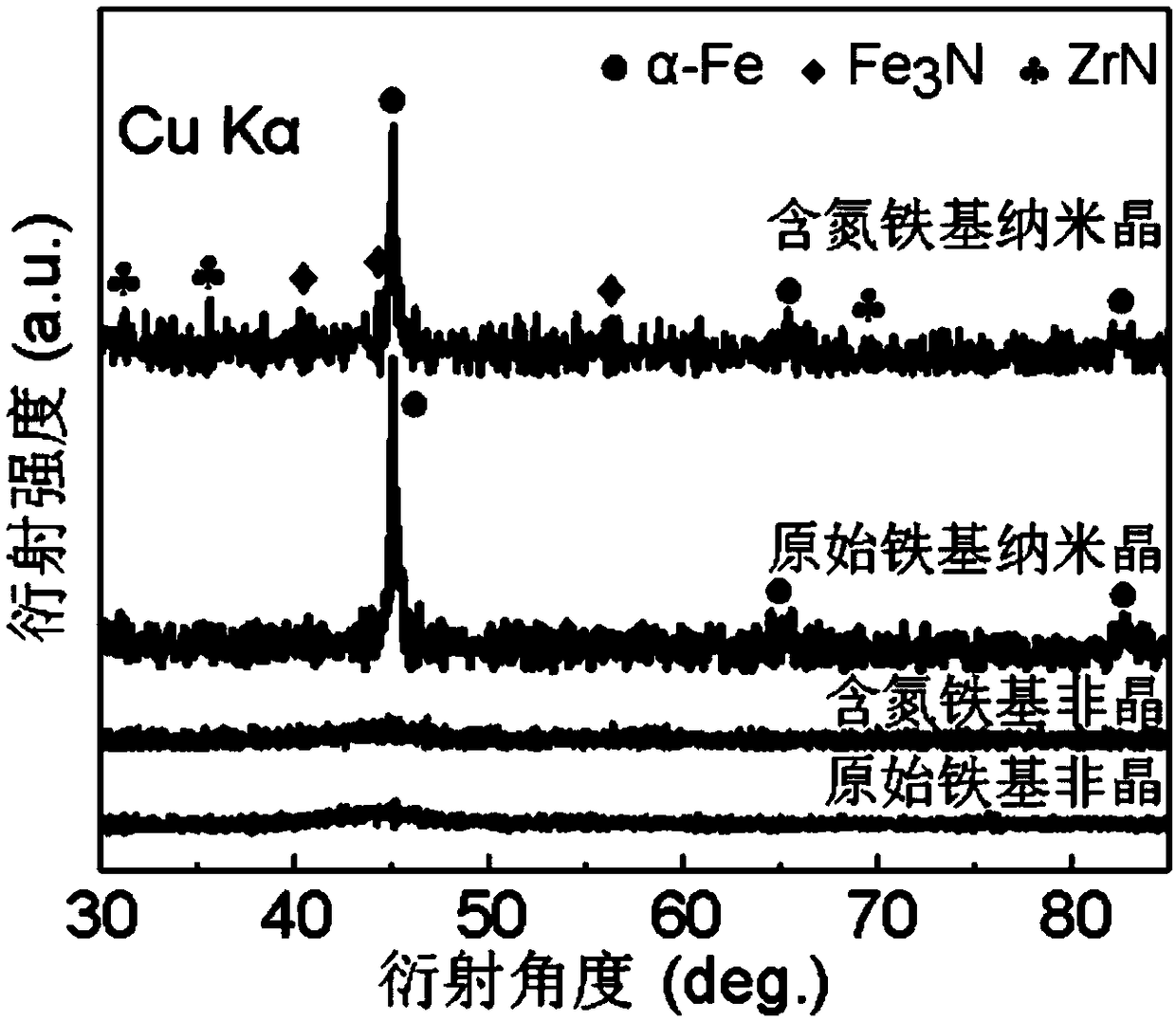

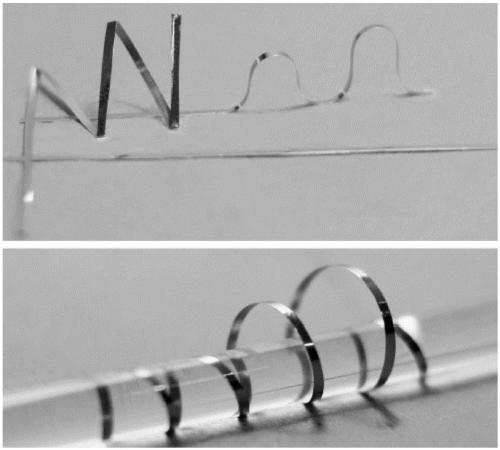

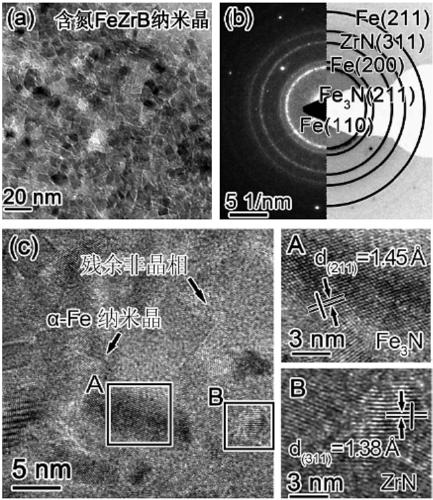

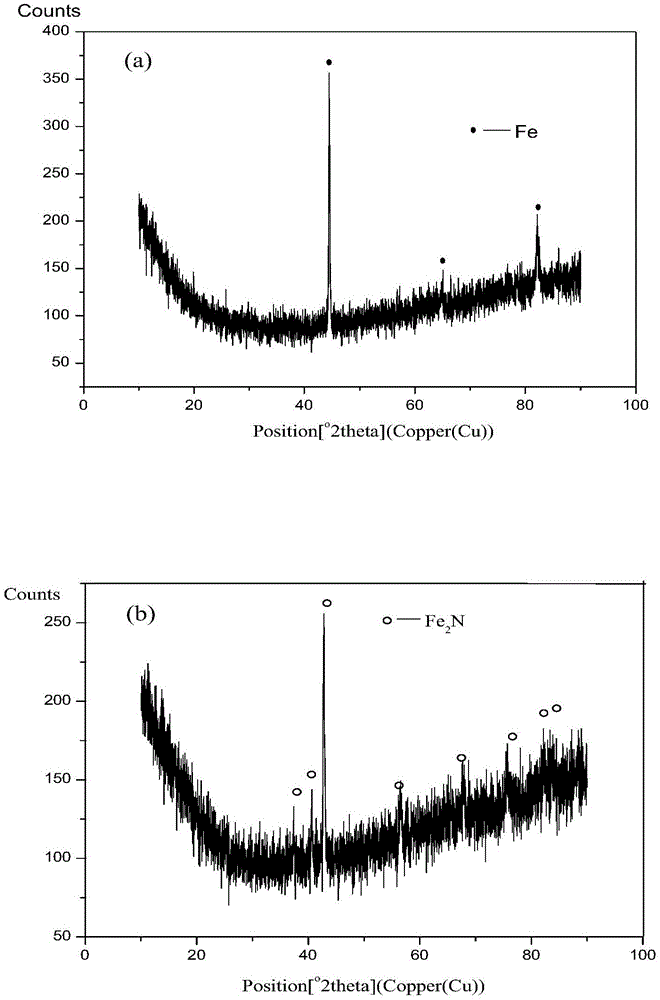

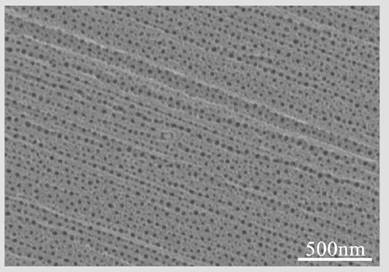

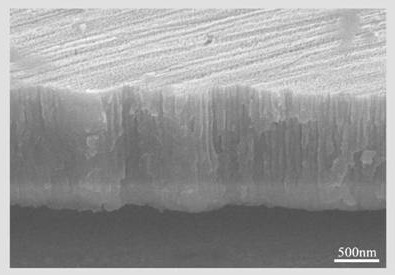

ActiveCN109440058AFast processOvercoming the problem of crystallizationSolid state diffusion coatingMagnetic materialsNitrogenToughness

The invention discloses a preparation method of a nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy. The preparation method comprises the following steps that an iron-basedamorphous soft magnetic alloy is subjected to plasma nitriding to obtain a nitrogen-containing iron-based amorphous soft magnetic alloy with a completely amorphous structure, and annealing treatment is carried out to obtain the nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy, wherein the temperature for plasma nitriding is 100-400 DEG C, and the nitriding time is 10-60min. The preparation method has the characteristics of being low in nitriding temperature and short in nitriding time, the problem of iron-based amorphous crystallization in the nitriding process issolved, and the problems that the iron-based amorphous soft magnetic alloy is poor in toughness and uneasy to machine after nitriding are solved. The invention further discloses the nitrogen-containing iron-based amorphous soft magnetic alloy and the nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy which are prepared by using the preparation method. The crystal grain size of nanocrystalline is 10-15 nm, and the saturation magnetic induction intensity is 1.48-1.74 T.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

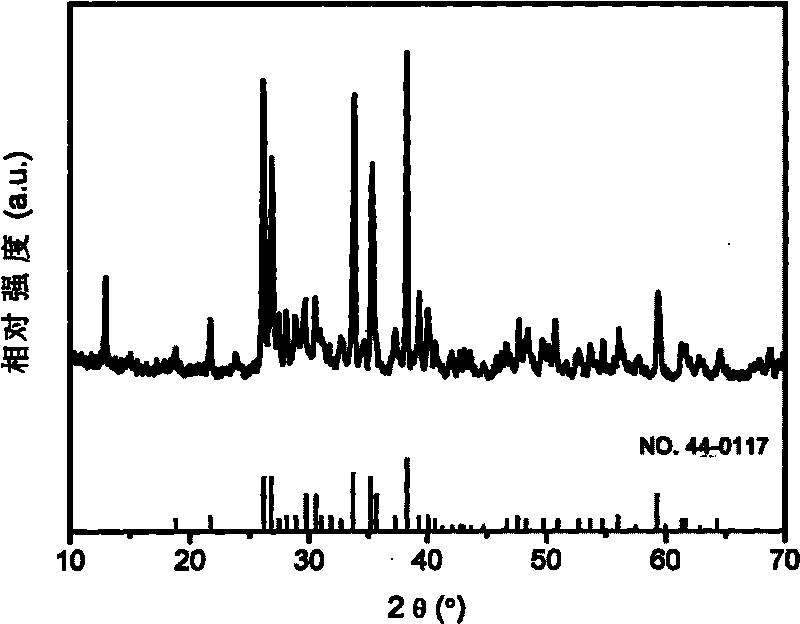

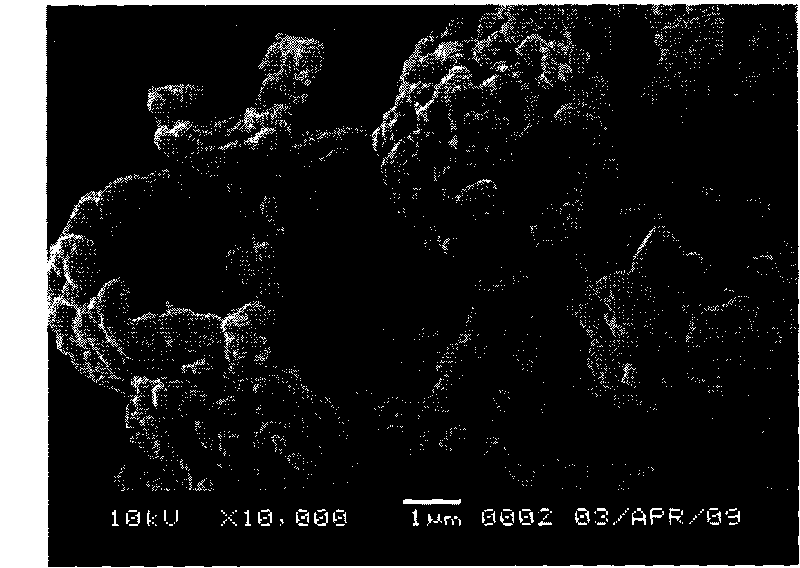

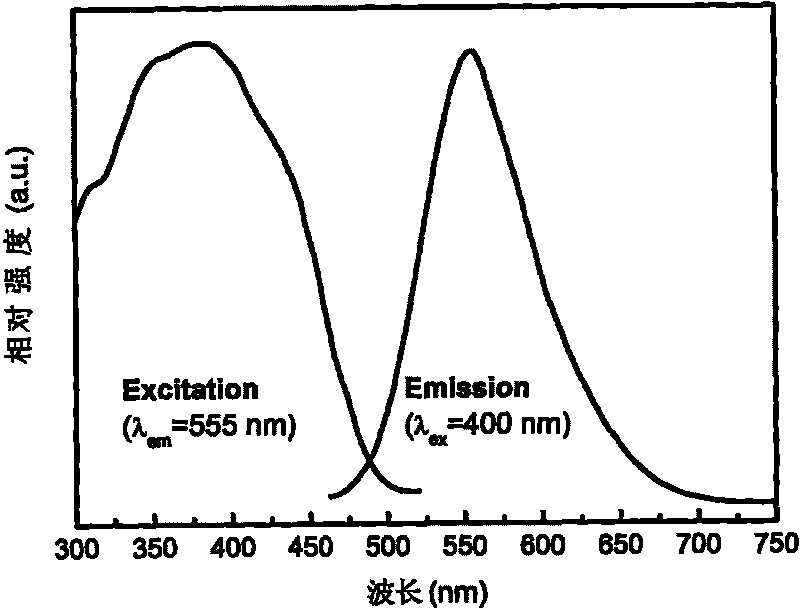

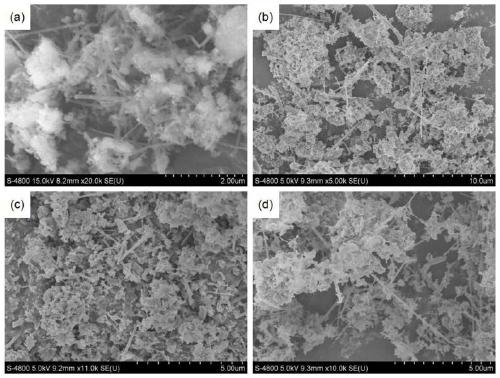

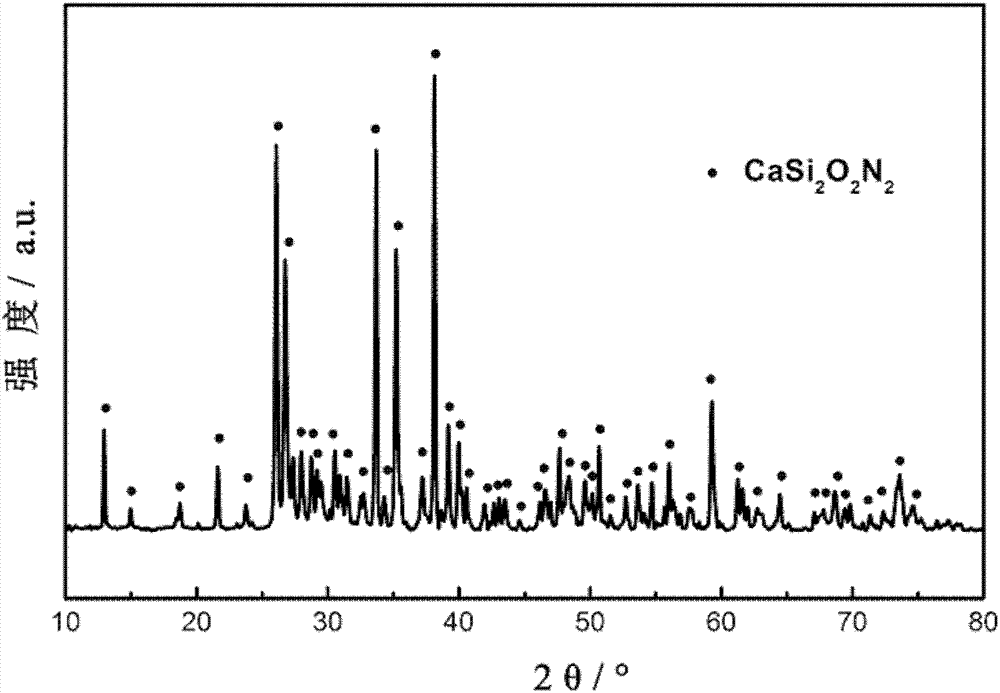

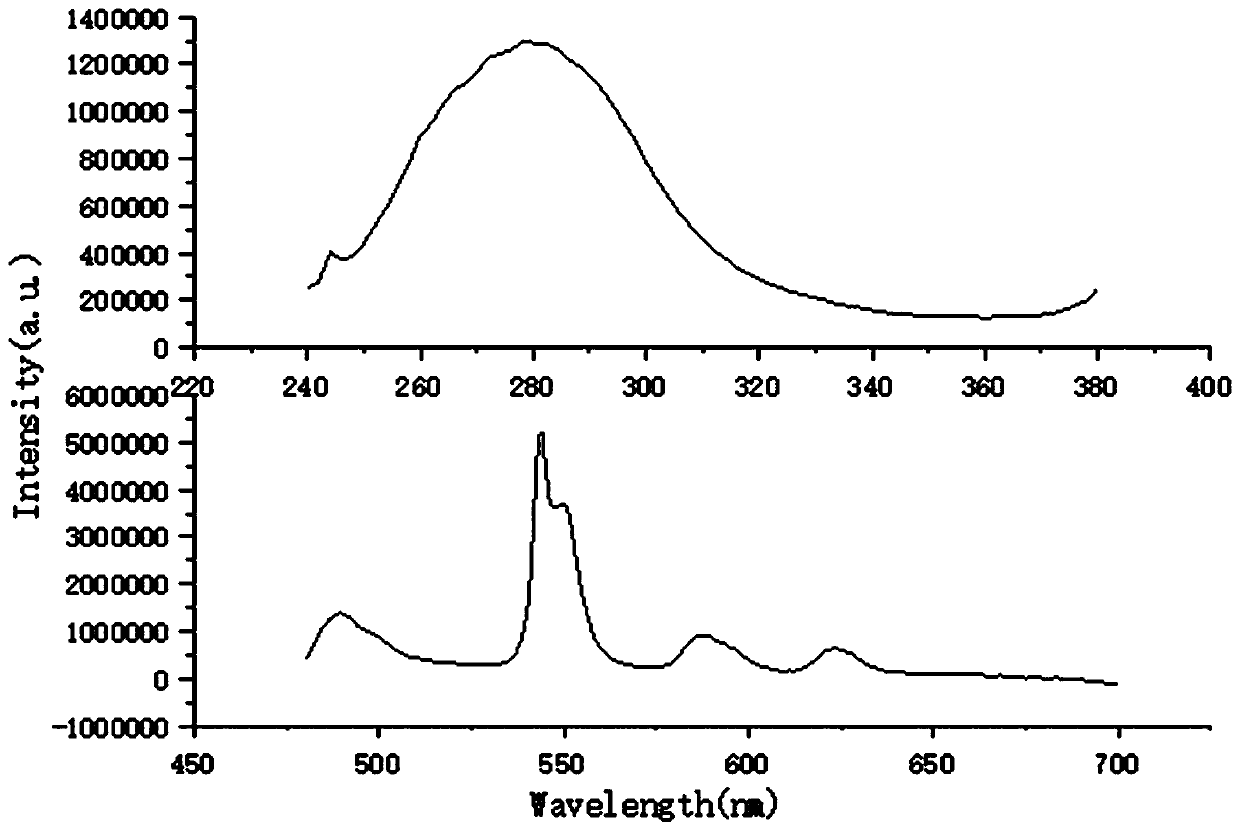

Method for preparing porous spherical CaSi2O2N2:Eu2 plus fluorescent powder

InactiveCN101698799AReduce consumptionEasy to prepareLuminescent compositionsDispersityPolyethylene glycol

The invention relates to a method for preparing porous spherical CaSi2O2N2:Eu2 plus fluorescent powder, which comprises the following steps: (1) dissolving calcium chloride, europium chloride and polyethylene glycol into water to prepare solution A, dissolving sodium carbonate, polyethylene glycol 6,000 and sodium dodecyl sulfate into the water to prepare solution B, pouring the solution A into the solution B for stirring, standing, water-rinsing and drying, taking and dispersing (Eu, Ca)CO3 into the water, adding Na2SiO3 solution, adjusting a pH value of the solution to 7 to 8, and then stirring, water-rinsing and drying the mixed solution; and (2) under the air current of NH3, heating a product obtained by the treatment in the step (1) to 1,250 to 1,400 DEG C, preserving the temperature and then cooling the product to a room temperature to obtain the porous spherical CaSi2O2N2:Eu2 plus fluorescent powder. The method of the invention is characterized by simpleness, low cost, simple required production equipment, low nitriding temperature, short nitriding time, energy consumption reduction and easy realization of industrial production; and the obtained porous spherical CaSi2O2N2:Eu2 plus fluorescent powder is good in dispersity, is not easy to agglomerate and keeps porous spherical appearance.

Owner:DONGHUA UNIV

Preparation method of samarium-iron-nitrogen series permanent magnet material

ActiveCN107557551AIncrease the amount of nitridingImprove uniformitySolid state diffusion coatingMagnetic materialsDecompositionShear band

The invention discloses a preparation method of a samarium-iron-nitrogen series permanent magnet material. The method comprises the steps that metastable state samarium-iron alloy is subjected to severe plastic deformation and then is subjected to nitrogen treatment and annealing crystallization treatment, and therefore the samarium-iron-nitrogen series permanent magnet material can be obtained. In the method, when the deformed samarium-iron-nitrogen series permanent magnet material is subjected to nitrogen treatment, since the free volume 'defect' content in the metastable state alloy can beincreased through multiple shear bands produced in the severe plastic deformation process, entering and diffusion of nitrogen atoms are facilitated, and the nitriding amount and nitriding uniformity of the alloy can be remarkably improved; since the multiple shear bands are produced through the severe plastic deformation, the follow-up crystallization annealing temperature can also be reduced, andnitride is reduced or prevented from being produced; and generation of the metastable phase is restrained, grains are refined, and coercive force is improved. By means of the method, the nitriding speed can be improved, the nitriding temperature can be reduced, decomposition of a samarium-iron-nitrogen compound is restrained, the microstructure is refined, and the nitriding efficiency of samarium-iron alloy for preparing the samarium-iron-nitrogen magnetic material is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

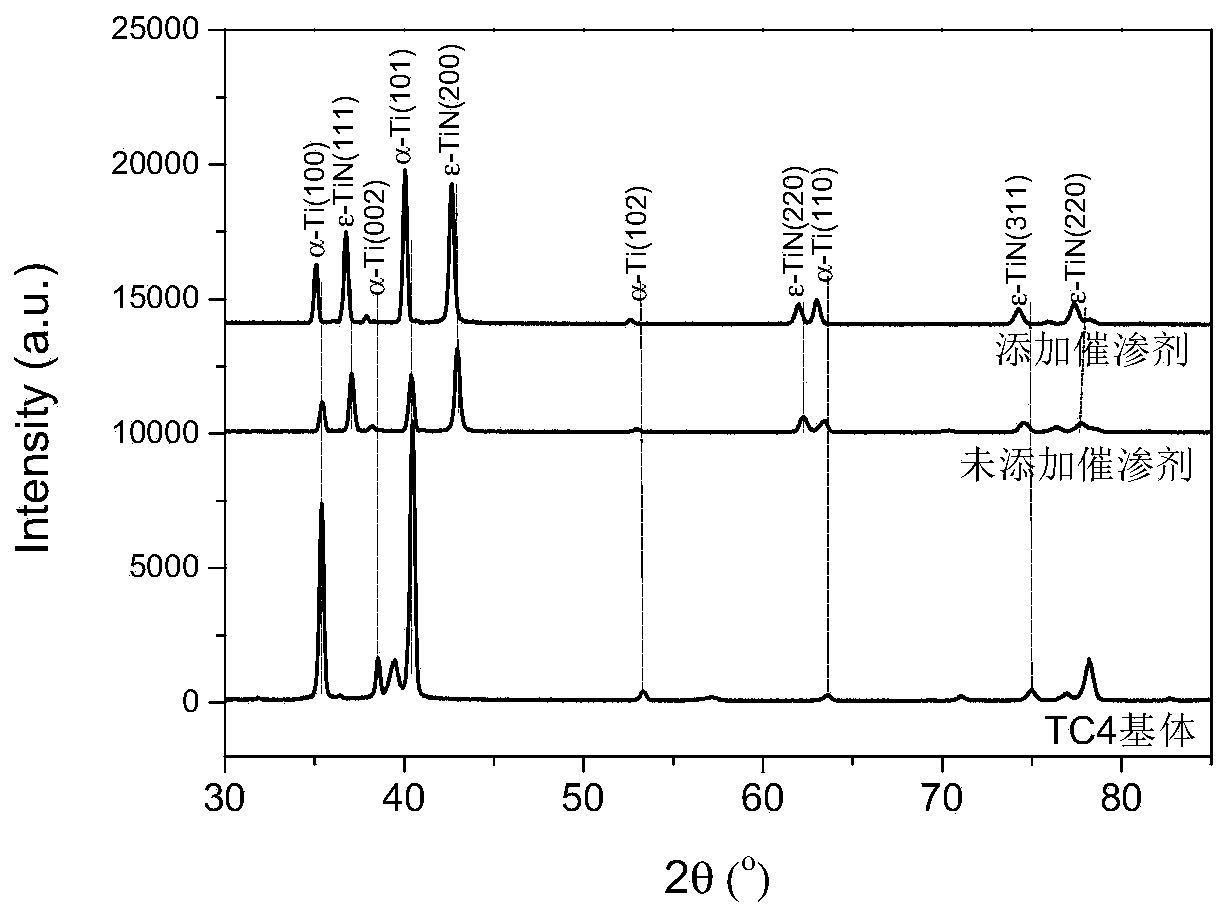

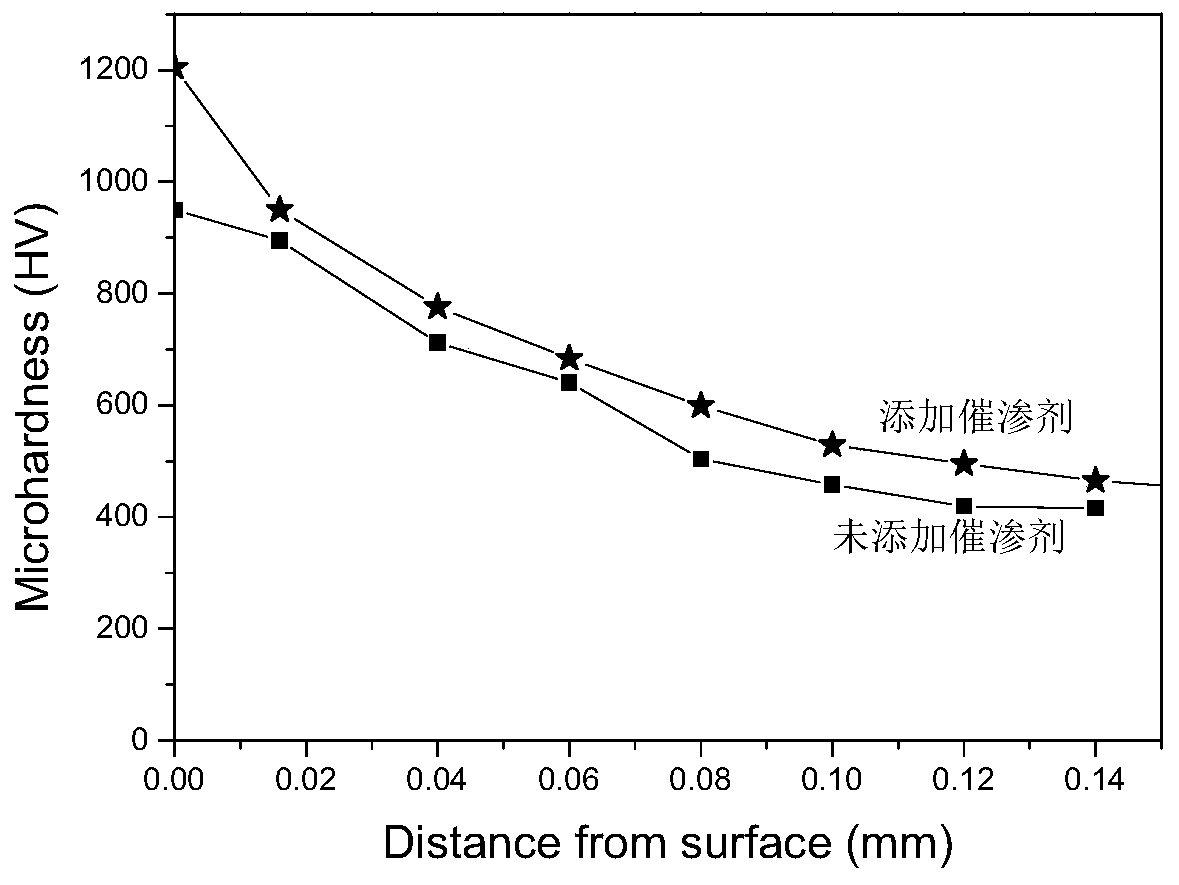

Ion nitriding method for titanium alloy

InactiveCN111270198ALower nitriding temperatureFast penetrationSolid state diffusion coatingTitanium alloyArgon gas

The invention discloses an ion nitriding method for titanium alloy, and relates to the technical field of surface treatment. The method comprises the steps that a workpiece is placed in a plasma nitriding furnace, nitriding gas is introduced, the nitriding voltage is controlled to range from 500 V to 700 V, the temperature in the plasma nitriding furnace is controlled to slowly rise to 750 DEG C to 950 DEG C, the air pressure ranges from 500 Pa to 1500 Pa, and heat preservation is carried out to obtain a required nitriding layer thickness; and the nitriding gas comprises nitrogen-containing gas, hydrogen, argon and a permeation accelerant, and the permeation accelerant comprises at least one of rare earth oxide, oxygen-containing gas and carbon-containing gas. The nitriding method has thecharacteristics of high nitriding speed, capability of reducing the nitriding temperature, thick nitriding layer, high hardness, good wear resistance and small workpiece deformation.

Owner:GUANGDONG INST OF NEW MATERIALS

Method for preparing silicon nitride powder with low energy consumption and cost

The invention relates to a method for preparing silicon nitride powder with low energy consumption and cost. In the method, a nitridation synthetic reaction is performed on the basis of the principle of a silicon powder direct nitridation method, a nitridation reaction is performed in a nitriding furnace, and the temperature of the nitriding furnace is regulated by a heating element in the furnace wall and a temperature-control system. The method comprises the main steps of: 1, performing a nitridation synthetic reaction directly, namely calcining 99.99 percent of monocrystalline silicon powder serving as raw materials in the nitriding furnace at the temperature of 1,250 DEG C, and keeping the temperature for 30 to 38 hours under the nitriding condition of introducing N2 at a flow rate of 4L / minute; and 2, performing aftertreatment such as ball-milling, scouring and the like on silicon nitride powder obtained by calcining to obtain Si3N4 powder of which the purity is up to 99.99 percent. The method has the advantages that (1) a reaction is quick, namely the synthetic reaction is finished within 38 to 40 hours; (2) the energy consumption is low, and the temperature of direct nitriding is lower than that of the conventional method; (3) equipment is simple, investment is small, and the generality is high; and (4) the nitriding activity is high, and the preparation time is short.

Owner:宁波华标特瓷采油设备有限公司

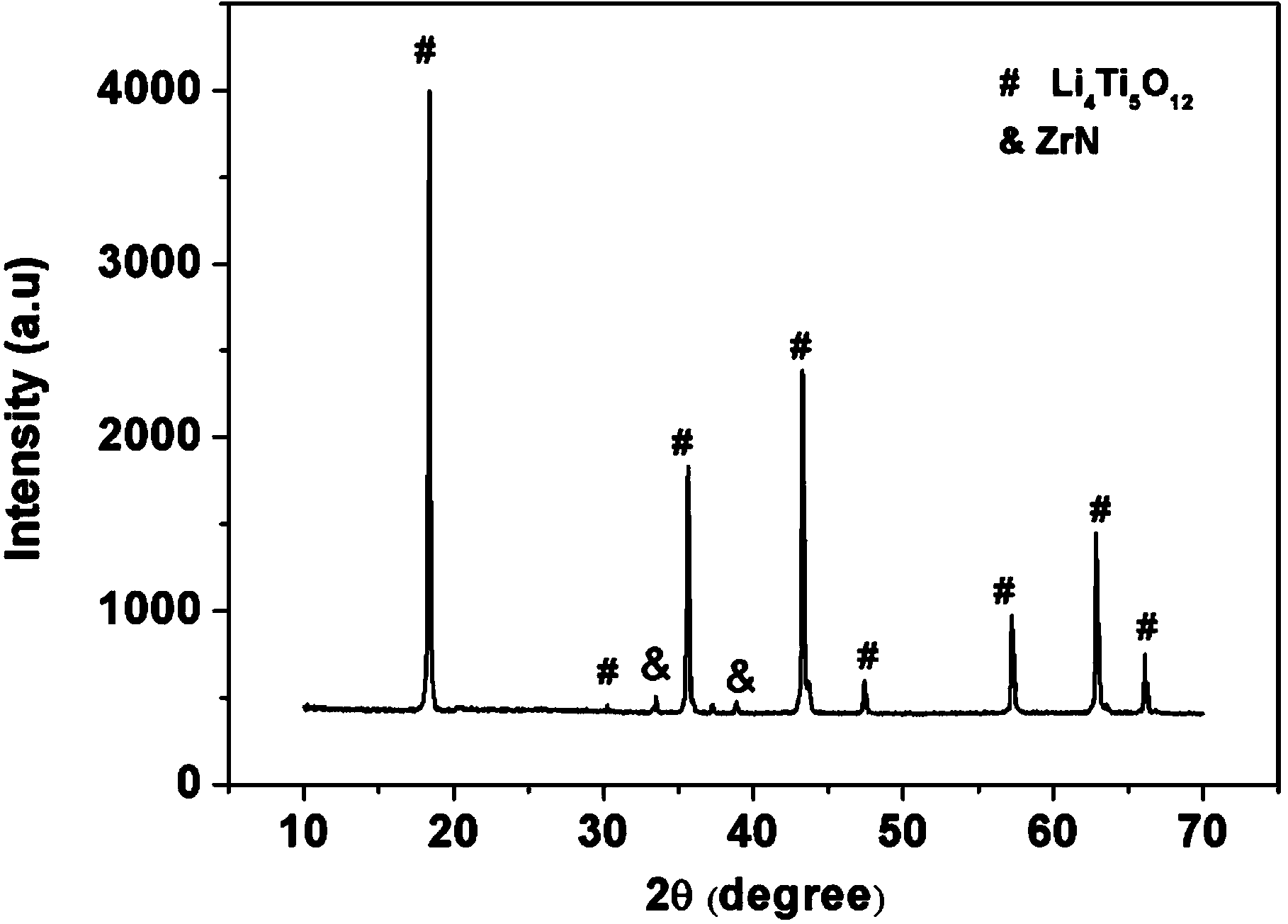

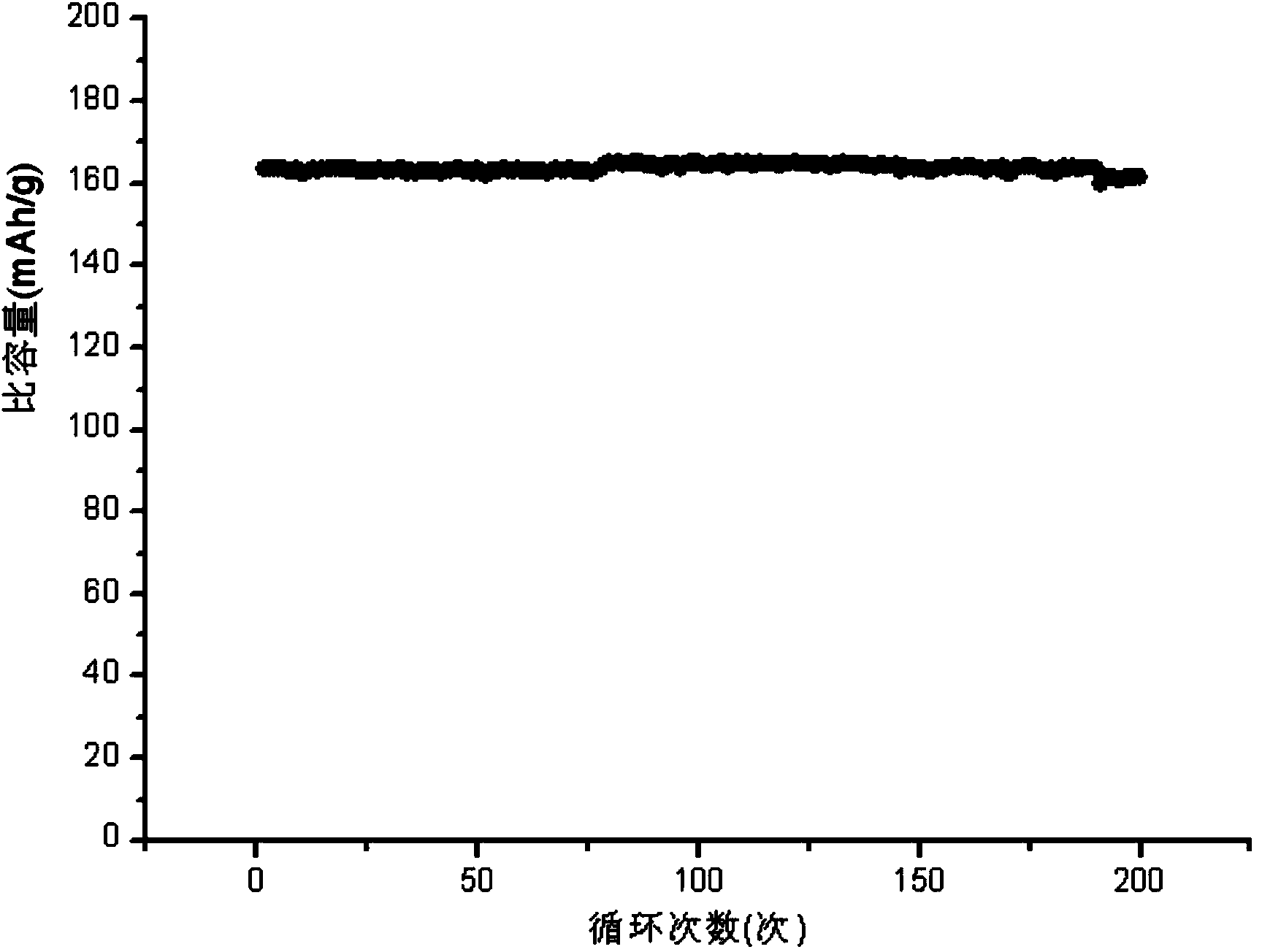

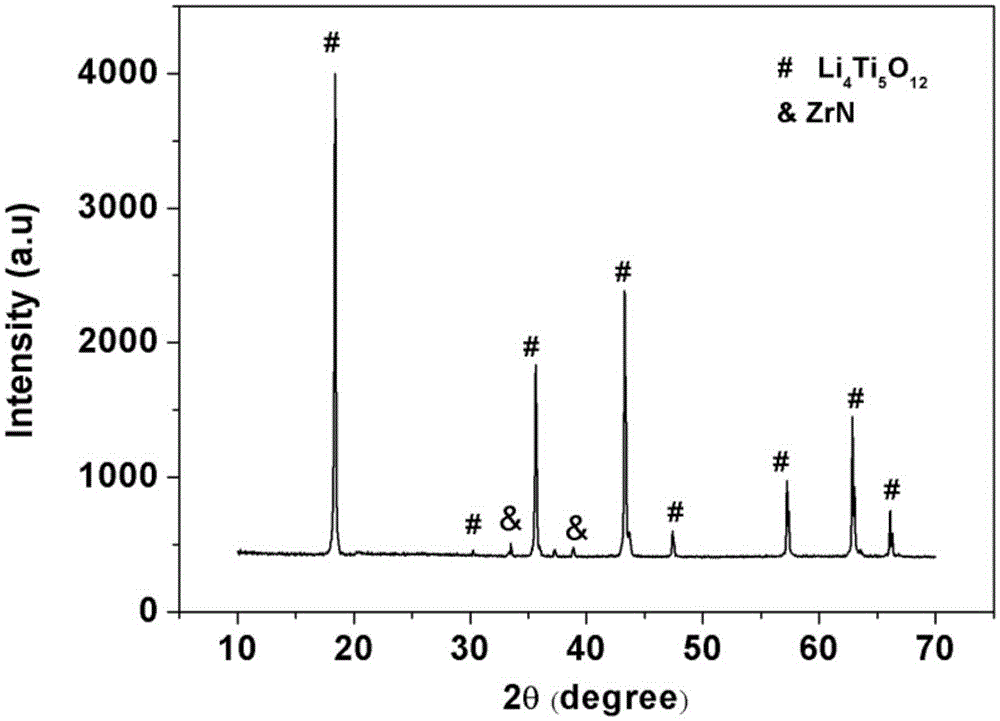

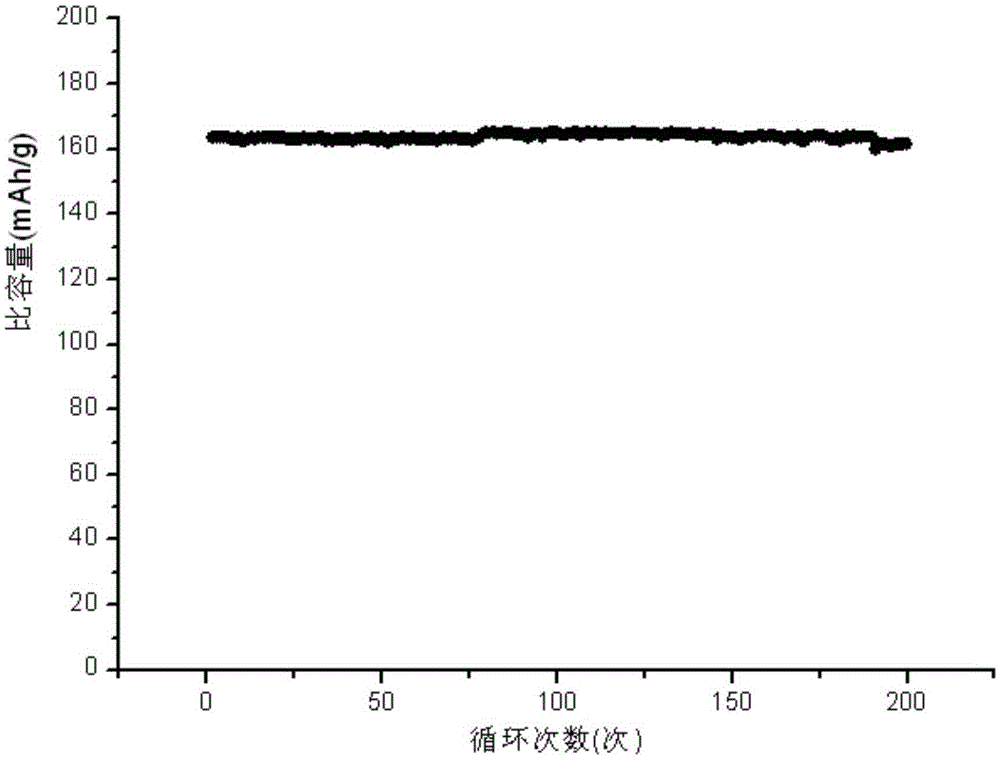

Preparation method for zirconium nitride-coated lithium titanate composite material

ActiveCN103985852AImprove uniformityGood coating effectCell electrodesSecondary cellsHigh energyCyclic stability

The invention discloses a preparation method for a zirconium nitride-coated lithium titanate composite material, relating to the field of a negative electrode material of a lithium ion battery. The preparation method comprises the steps of preparing lithium titanate precursor powder, performing high-energy ball grinding on zirconium powder, a lithium titanate precursor and an additive under inert atmosphere, and finally performing high-temperature sintering under nitrogen mixing atmosphere to realize synthesis of lithium titanate and nitridation reaction of surface zirconium. According to the zirconium nitride-coated lithium titanate composite material prepared by the preparation method disclosed by the invention, the zirconium nitride coating layer is high in uniformity, good in coating effect and high in conductivity; the problem of low conductivity of lithium titanate is solved; meanwhile, the problem of swelling of a battery of the lithium titanate system is effectively solved; the circulation stability of a lithium titanate negative electrode material is improved, and the cycle life of the battery is greatly prolonged; furthermore, the preparation process of the preparation method is simple and controllable; the coating degree of the zirconium nitride can be controlled by controlling technical parameters for preparing the zirconium nitride-coated lithium titanate composite material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Nitrogen-contained rare earth magnetic powder and preparation method thereof

ActiveCN101599329BIncrease the speed of diffusionPromote decompositionMagnetic materialsRare-earth elementMischmetal

The invention discloses a preparation method of nitrogen-contained rear earth magnetic powder which takes dicyclopentadienyl iron, alum rare earth, metallic iron and rare earth as main raw materials and has the main component of R2Fe(17-x)MxNy, wherein R stands for one or several of 17 rear earth elements containing Sc and Y; M is one or a plurality of transition elements of Al, Ga, In, Si, Ge, Sn, Pb, Mg and Ca except Fe; x=0-5 and y=1-6. The preparation method comprises the following steps: preparation process of R2Fe(17-x)Mx alloy casting; nitridation process; and milling process.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Low-temperature nitridation preparation method of iron-based rare earth permanent magnet powder

InactiveCN102816991BLower nitriding temperatureSolid state diffusion coatingMagnetic materialsHigh energyRare earth

Owner:HEBEI UNIV OF ENG

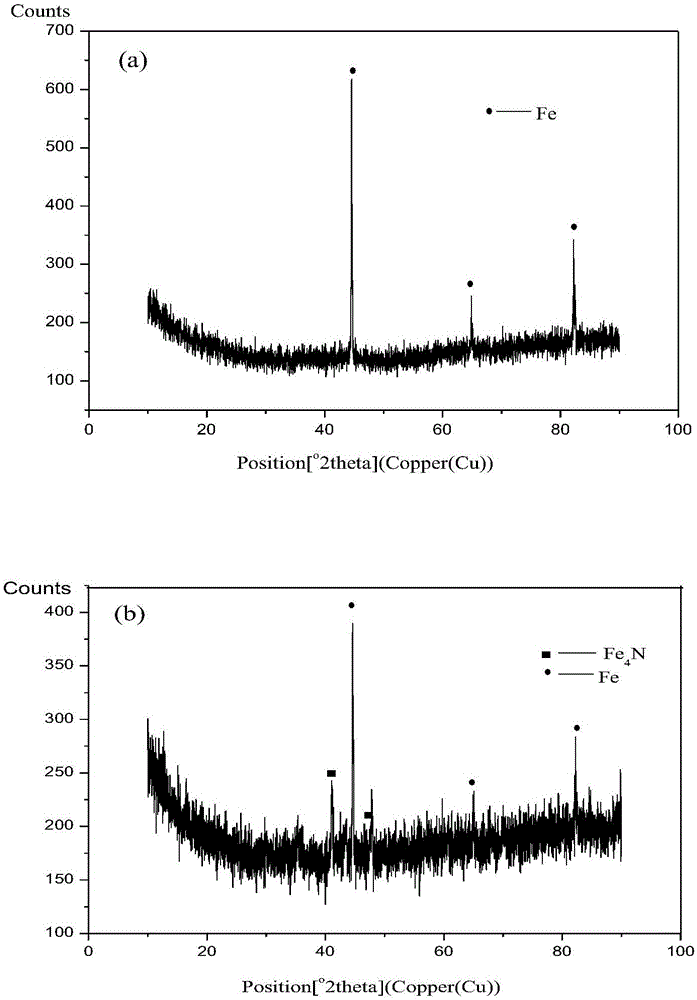

Magnetic abrasive material and preparation method thereof

ActiveCN105131904AEasy to prepareLower nitriding temperatureOther chemical processesIron powderIron nitride

The present invention discloses a magnetic abrasive material and a preparation method thereof, wherein iron powder or iron-based alloy powder is subjected to a high temperature nitriding reaction from outside to inside so as to form the component iron nitride having the grinding capacity in an in-situ manner, and the iron nitride has characteristics of high hardness, magnetization capability and corrosion resistance. According to the present invention, with the abrasive material, the problem of easy shedding of the abrasive particles is solved, and the abrasive material has characteristics of long service life and grinding capacity increasing; after the grinding material of the present invention is used to carry out magnetic grinding on the 45 steel plane work-piece with a starting surface roughness Ra of 1.43 [mu]m, the surface roughness of the work-piece is 0.124-0.147 [mu]m, and the service life of the abrasive material is 60 min; and the preparation process is simple, the nitriding temperature is low, the energy consumption is low, and the product does not require crushing and screening.

Owner:UNIV OF SCI & TECH LIAONING

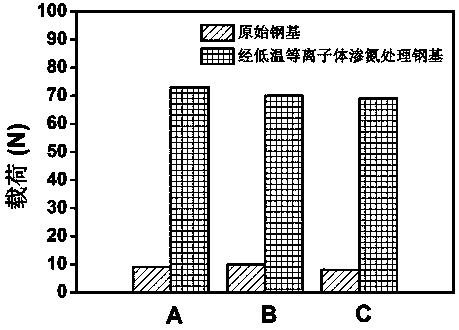

A method for increasing binding force between a fullerene-like carbon film and a steel substrate

InactiveCN108165950AReduce internal stressImprove bindingSolid state diffusion coatingChemical vapor deposition coatingCarbon filmAlloy

A method for increasing binding force between a fullerene-like carbon film and a steel substrate is disclosed. Low-temperature plasma nitriding is performed on a substrate under combined actions of aradio-frequency power supply and a pulse minus bias by adopting a plasma enhanced chemical vapor deposition technique and a low-temperature plasma nitriding technique, adopting a stainless steel sheetas the substrate, and adopting argon and nitrogen as gas sources. The method is characterized in that the method is simple in process, economical, efficient, low in nitriding temperature and good inrepeatability, and the binding force between the fullerene-like carbon film and the steel substrate is obviously increased. By adoption of the method, a situation that the fullerene-like carbon film falls under high-strength working conditions so that the fullerene-like carbon film on the steel substrate cannot achieve a lubricating effect is avoided. The method is suitable for stainless steel surfaces, is also suitable for the fields of cast iron, alloys, ceramics, polymer materials, and other materials, and has a wide application prospect, and therefore the method has a great application potential.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

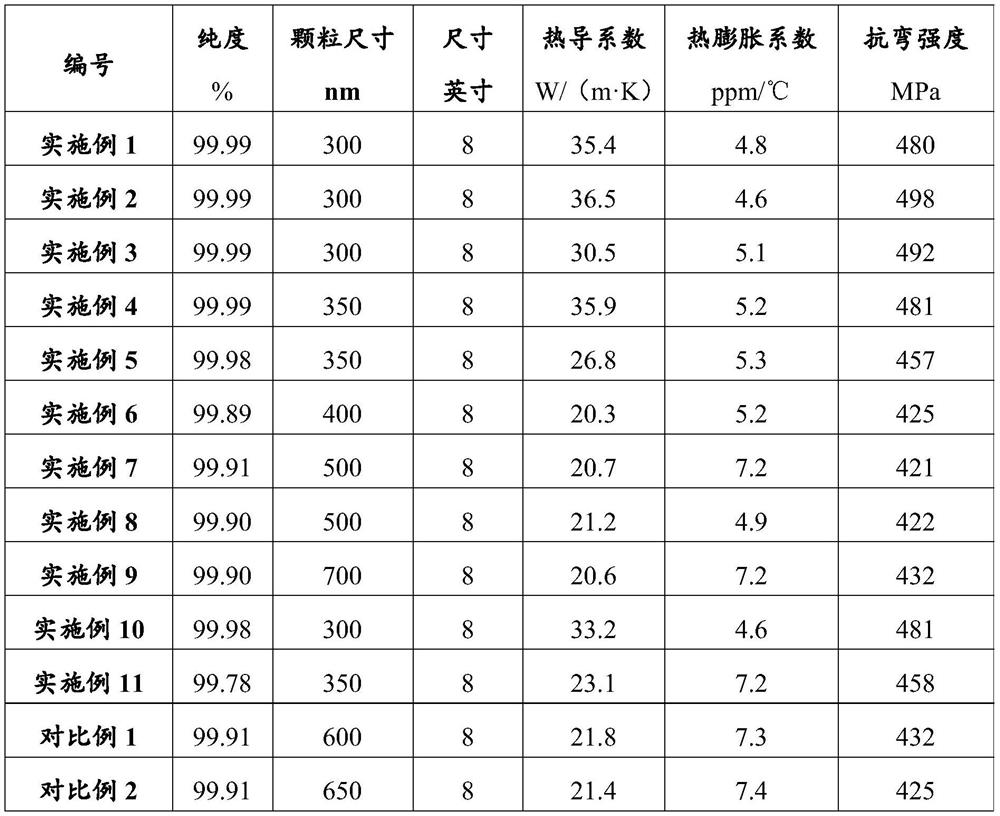

Aluminum nitride powder as well as preparation method and application thereof

The invention discloses aluminum nitride powder as well as a preparation method and application thereof. The preparation method of the aluminum nitride powder is characterized in that the method comprises the following steps: enabling an aluminum source, activated carbon and a pore-foaming agent to be subjected to a hydrothermal reaction and obtaining a solid precursor is obtained, wherein the aluminum source is aluminum salt, and the pore-foaming agent is water-soluble hydroxide; and calcining the solid precursor and a nitrogen source to obtain the aluminum nitride powder. The activated carbon is used as a carbon source reducing agent, the pore-foaming agent is utilized to form a nano structure, the nano activated carbon structure not only can be used as a template for growth of nano aluminum nitride, but also can enable the aluminum element and the activated carbon to be mixed more uniformly, and the obtained aluminum nitride powder is higher in purity.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

A kind of preparation method of samarium-iron-nitrogen permanent magnet material

ActiveCN107557551BIncrease the amount of nitridingImprove uniformitySolid state diffusion coatingMagnetic materialsDecompositionStrontium

The invention discloses a preparation method of a samarium-iron-nitrogen series permanent magnet material. The method comprises the steps that metastable state samarium-iron alloy is subjected to severe plastic deformation and then is subjected to nitrogen treatment and annealing crystallization treatment, and therefore the samarium-iron-nitrogen series permanent magnet material can be obtained. In the method, when the deformed samarium-iron-nitrogen series permanent magnet material is subjected to nitrogen treatment, since the free volume 'defect' content in the metastable state alloy can beincreased through multiple shear bands produced in the severe plastic deformation process, entering and diffusion of nitrogen atoms are facilitated, and the nitriding amount and nitriding uniformity of the alloy can be remarkably improved; since the multiple shear bands are produced through the severe plastic deformation, the follow-up crystallization annealing temperature can also be reduced, andnitride is reduced or prevented from being produced; and generation of the metastable phase is restrained, grains are refined, and coercive force is improved. By means of the method, the nitriding speed can be improved, the nitriding temperature can be reduced, decomposition of a samarium-iron-nitrogen compound is restrained, the microstructure is refined, and the nitriding efficiency of samarium-iron alloy for preparing the samarium-iron-nitrogen magnetic material is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of realizing low-temperature nitriding of steel part in complex shape

ActiveCN113652626AImprove adsorption capacityIncrease contact areaAnodisationSolid state diffusion coatingWire cuttingNanostructure

The invention discloses a method of realizing low-temperature nitriding of a steel part in a complex shape. The method specifically comprises the following steps of: cutting a pure iron plate into a square plate by linear cutting, grinding and polishing the surface of the square plate by abrasive paper, and then conducting ultrasonic cleaning and blow-drying; preparing an oxide layer with a certain thickness and of a nano structure on the surface of a sample through an anodic oxidation method; reducing the sample subjected to anodic oxidation at a certain temperature to obtain elemental iron of a nano structure, and then realizing surface nanocrystallization; and conducting gas nitriding treatment on the reduced sample at a certain temperature. As being a chemical method, the method can achieve surface nanocrystallization of the steel part in the complex shape, can use the nanocrystallization structure to lower the nitriding treatment temperature and the process period of the steel part in the complex shape, promotes the rapid diffusion effect of the nano structure to be really applied and achieves the purposes of reducing deformation and energy consumption.

Owner:HEFEI UNIV OF TECH

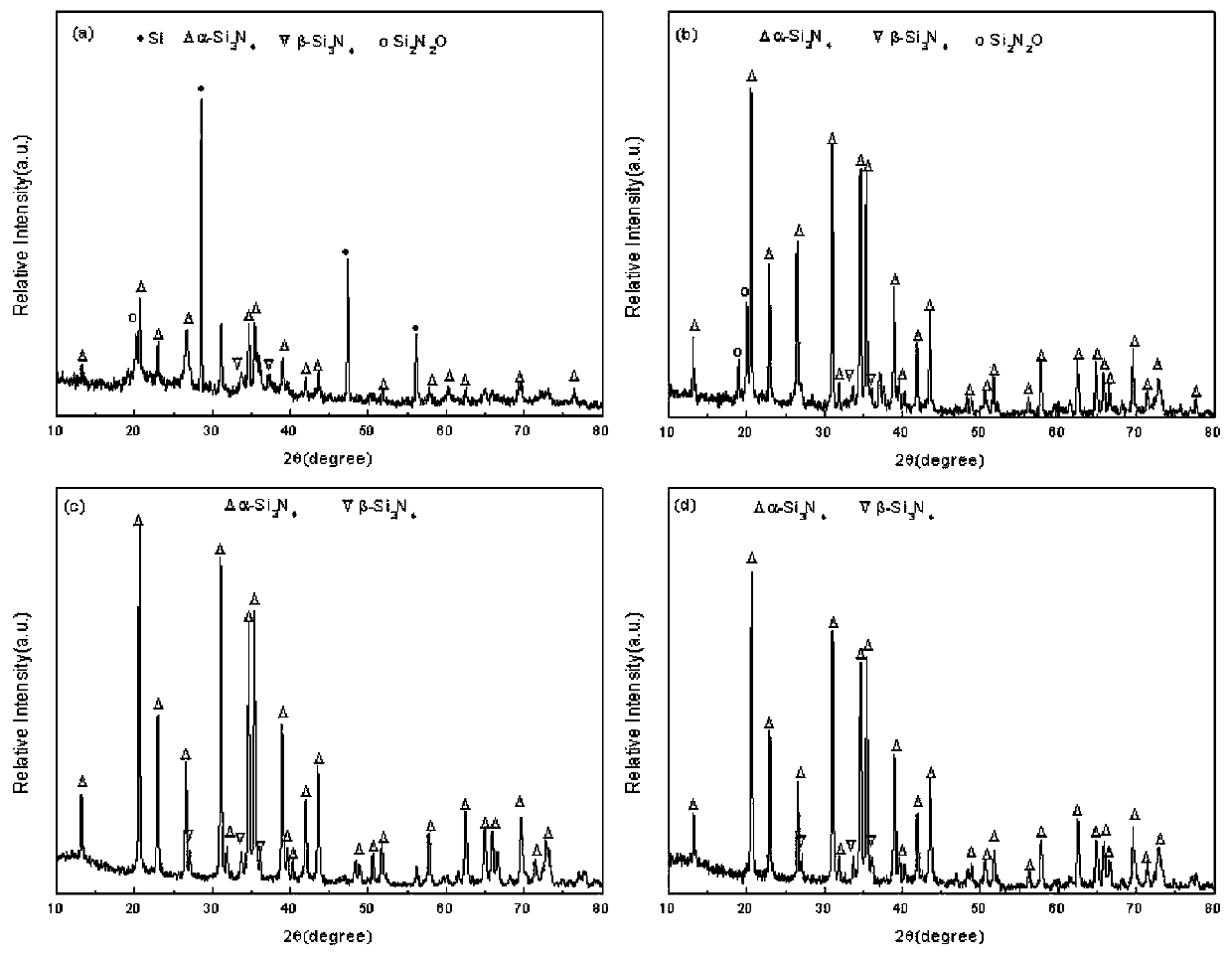

Preparation method of alpha-silicon nitride powder

InactiveCN109970035ALower nitriding temperatureShorten nitriding timeNitrogen compoundsHydrogenAlcohol

The invention discloses a preparation method of alpha-silicon nitride powder, which comprises the following steps: carrying out ball milling on silicon powder doped with Cr2O3 powder, adding a siliconnitride grinding ball and alcohol; putting the silicon powder into a ball mill for ball milling, carrying out suction filtration on the ball milled Cr2O3 silicon powder, and removing the alcohol in the silicon powder; drying the filtered powder in a vacuum drying oven, and removing residual alcohol; grinding and sieving a sample subjected to vacuum drying to obtain powder with uniform particles;putting the ground silicon powder doped with Cr2O3 into a high-temperature tubular furnace, vacuumizing, introducing a nitrogen-hydrogen mixed gas, raising the temperature to 800 DEG C at less than orequal to 5 DEG C / min, and raising the temperature to 1300-1400 DEG C / min, keeping the temperature for 2-4 hours to obtain the silicon nitride powder. The preparation method has the advantages of lownitriding temperature, low cost and short nitriding period, wherein the prepared alpha-Si3N4 phase is as high as 96 wt% in the prepared power, and the particle size is small, and part of the Si3N4 phase is fibrous.

Owner:TIANJIN UNIV

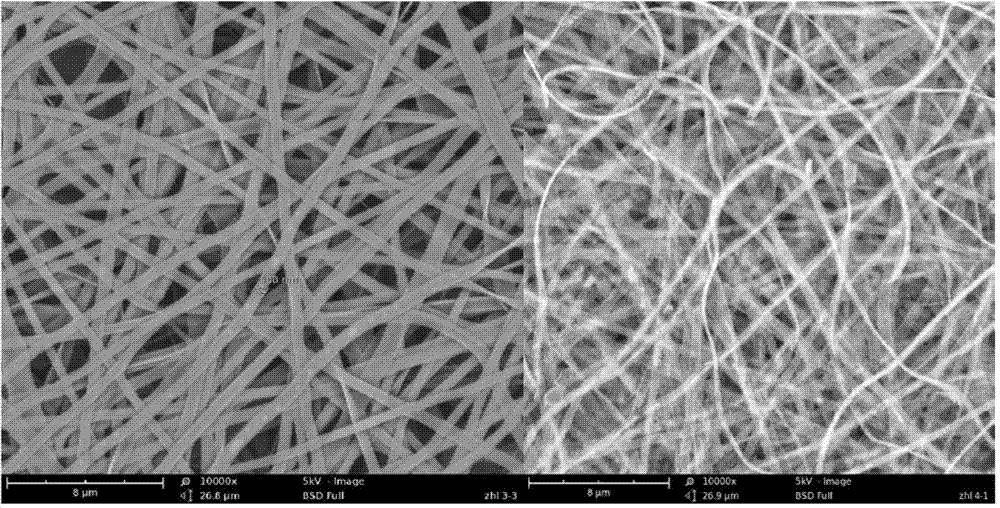

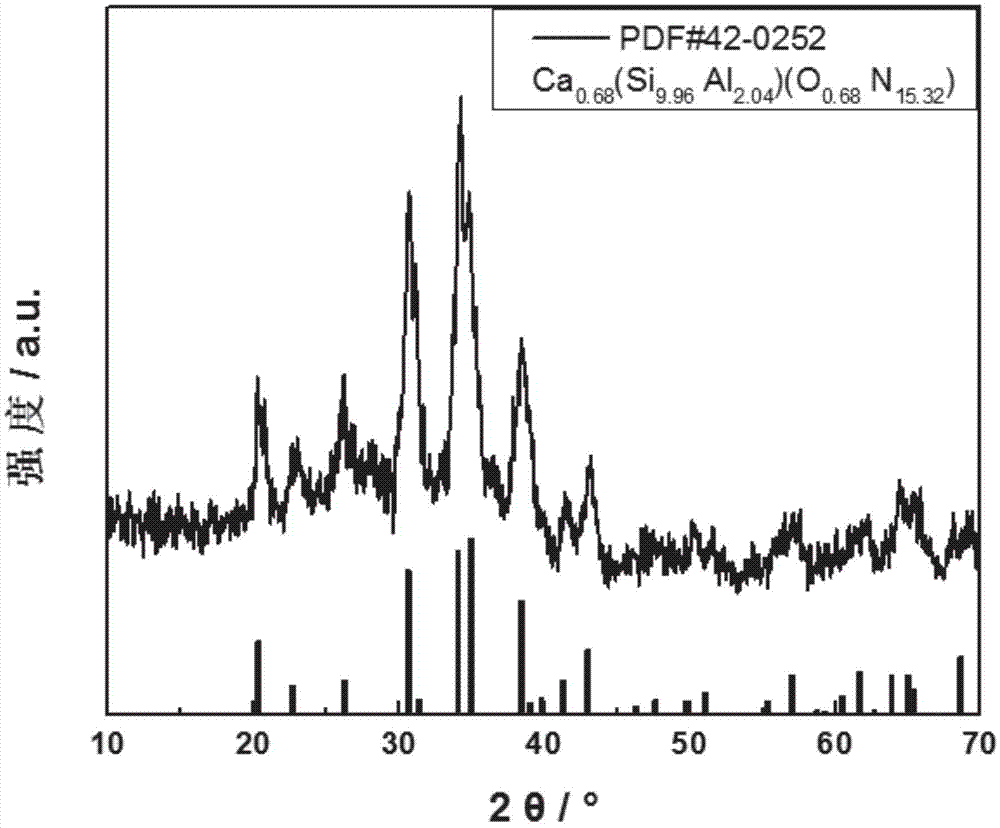

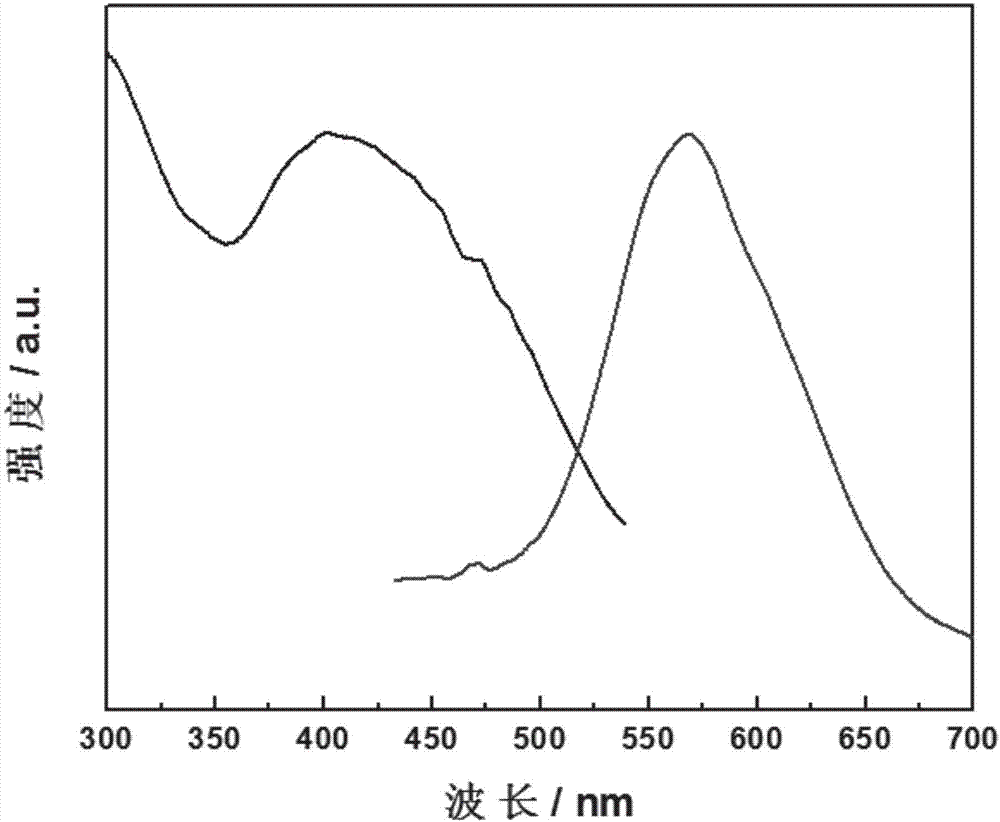

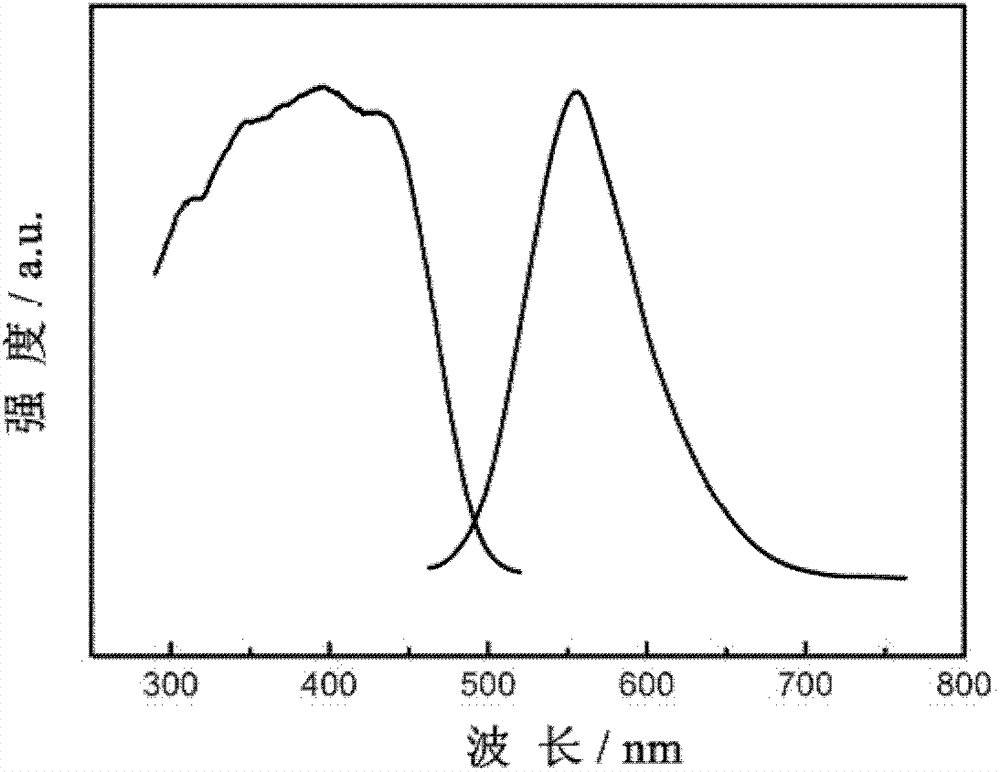

Preparation method of Ca-alpha-SiAlON:Eu<2+> fluorescent nanoribbon fiber

ActiveCN104278363ASimple methodLower nitriding temperatureInorganic material artificial filamentsLuminescent compositionsTetraethyl orthosilicateSolvent

The invention relates to a preparation method of a Ca-alpha-SiAlON:Eu<2+> fluorescent nanoribbon fiber. The preparation method comprises the following steps: (1) dissolving calcium nitrate, calcium nitrate and aluminum nitrate in an alcohol-water mixed solvent, adding tetraethyl orthosilicate while stirring, adding polyvinyl butyral after stirring, and stirring continuously to obtain a spinning solution; (2) sucking the spinning solution into a needle cylinder, carrying out electrostatic spinning and collecting fibers on an accepted aluminum foil; and (3) putting white fibers in a high-temperature tubular atmosphere furnace for heat treatment, reducing the temperature along with the temperature reduction of the furnace to obtain the Ca-alpha-SiAlON:Eu<2+> fluorescent nanoribbon fiber. The method is simple, low in nitridation temperature and short in time, and obtained Ca-alpha-SiAlON:Eu<2+> fluorescent powder keeps the good fiber morphology, is beneficial to improving the luminescence property and the later encapsulation in LEDs, and the Ca-alpha-SiAlON:Eu<2+> fluorescent nanoribbon fiber has the good application prospect.

Owner:DONGHUA UNIV

Preparation method of zirconium nitride coated lithium titanate composite material

ActiveCN103985852BControl the degree of coatingImprove uniformityCell electrodesSecondary cellsHigh energyNitrogen

The invention discloses a preparation method for a zirconium nitride-coated lithium titanate composite material, relating to the field of a negative electrode material of a lithium ion battery. The preparation method comprises the steps of preparing lithium titanate precursor powder, performing high-energy ball grinding on zirconium powder, a lithium titanate precursor and an additive under inert atmosphere, and finally performing high-temperature sintering under nitrogen mixing atmosphere to realize synthesis of lithium titanate and nitridation reaction of surface zirconium. According to the zirconium nitride-coated lithium titanate composite material prepared by the preparation method disclosed by the invention, the zirconium nitride coating layer is high in uniformity, good in coating effect and high in conductivity; the problem of low conductivity of lithium titanate is solved; meanwhile, the problem of swelling of a battery of the lithium titanate system is effectively solved; the circulation stability of a lithium titanate negative electrode material is improved, and the cycle life of the battery is greatly prolonged; furthermore, the preparation process of the preparation method is simple and controllable; the coating degree of the zirconium nitride can be controlled by controlling technical parameters for preparing the zirconium nitride-coated lithium titanate composite material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Plasma nitriding method for cylinder sleeve

InactiveCN103045991AReduce consumptionReduce distortionSolid state diffusion coatingMetallurgyGasoline

The invention relates to a plasma nitriding method for a cylinder sleeve. The method comprises the following steps of: by adopting a plasma nitriding furnace, after being inspected, drying the cylinder sleeve cleaned by using a cleaning agent or gasoline, and charging into the furnace; and vacuumizing in the furnace, charging ammonia, heating to 400 DEG C at the speed which is not rapider than 50 DEG C / h, preserving heat for 1h, slowly heating up to 480 DEG C, preserving heat for 5hours, cooling to 150 DEG C at the speed which is not rapider than 50 DEG C / h, and discharging out of the furnace. The color of the nitrided cylinder sleeve is silver gray, and the plasma nitriding temperature is lower than the gas nitriding temperature, so that a product is very less in deformation, the use requirement can be met without the follow-up machining, and the product is good in surface quality.

Owner:严方

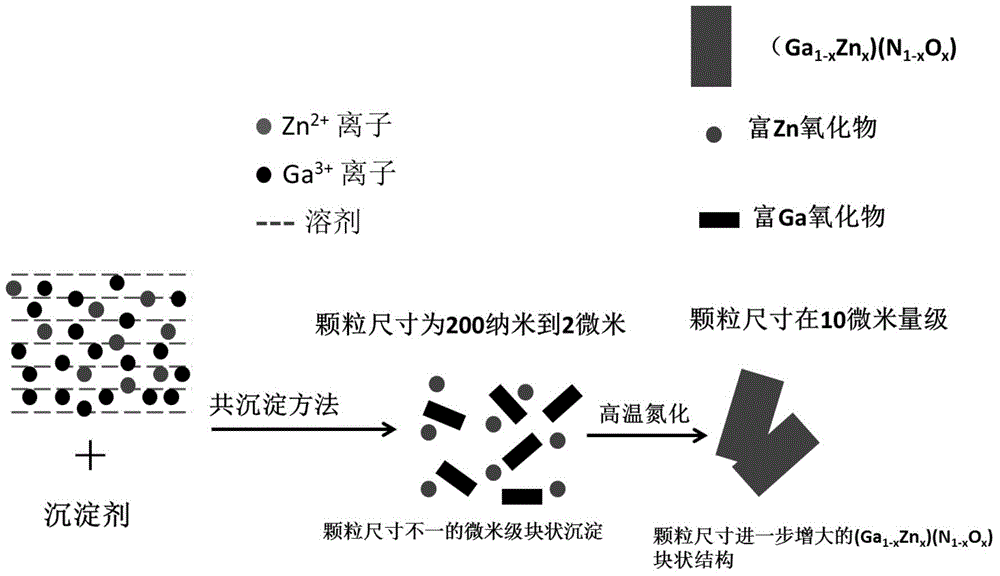

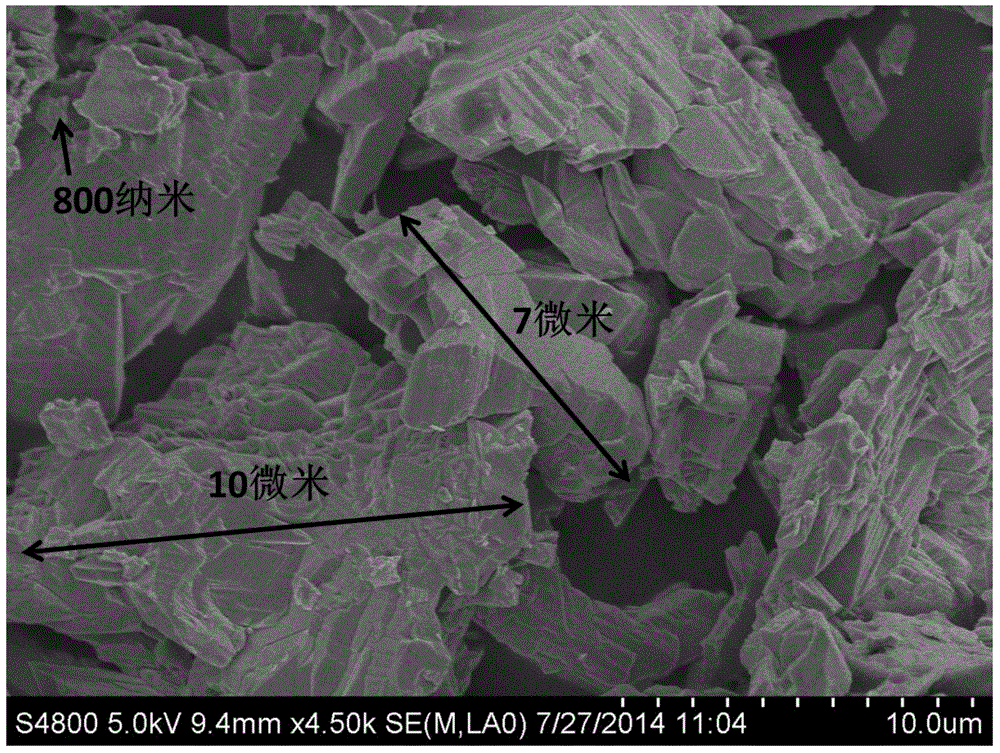

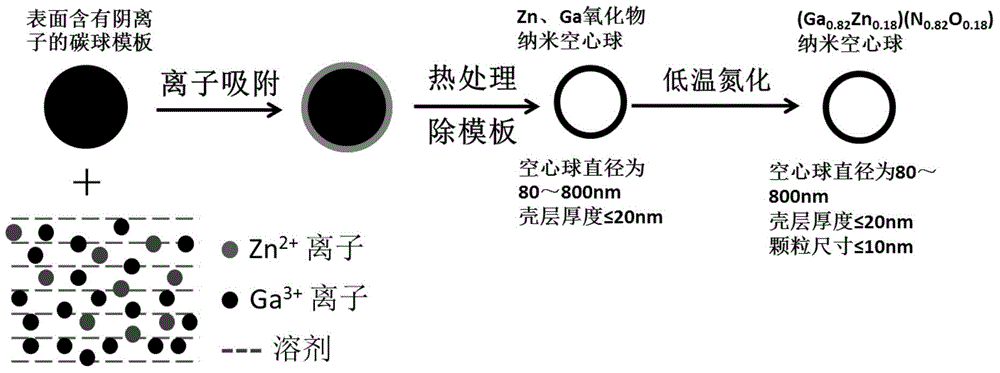

Nanometer hollow structure of multi-metal nitrogen oxide as well as preparation method and application of nanometer hollow structure

ActiveCN104925763ASolve the key technical problems of nanotechnologyHigh specific surface areaNitrogen and non-metal compoundsNitrogen oxideLayer thickness

The invention discloses a nanometer hollow structure of multi-metal nitrogen oxide as well as a preparation method and application of the nanometer hollow structure. The nanometer hollow structure material of the multi-metal nitrogen oxide is prepared and obtained by using a template adsorption method, a multi-metal ion solution and subsequent nitrogen treatment. The nanometer hollow structure of an oxide with multiple metal components is nitrogenized and prepared into the nanometer hollow structure of various nitrogen oxide, such as a solid solution nitrogen oxide (Ga1-xZnx)(N1-xOx), a chemometry nitrogen oxide LaTiO2N, and a mixed nitrogen oxide (Ga1-xZnx)(N1-xOx)-InN. The specific surface area of the nanometer hollow structure is larger than or equal to 50m<2>. g<-1>, which is far larger than the specific surface area (smaller than or equal to 5m<2>. g<-1>) of conventional multi-metal nitrogen oxide; the shell layer thickness of the nanometer hollow structure is smaller than or equal to 20 nanometers; the granule size of the nanometer hollow structure is smaller than or equal to 10 nanometers, which is far smaller than the granule size (micron dimension) of conventional multi-metal nitrogen oxide; therefore, the defects that the multi-metal nitrogen oxide is difficult to realize nanocrystallization and the specific surface area is extremely low are overcome; the use efficiency of a catalyst can be greatly improved, the usage amount of the catalyst is reduced, and the catalyst has good application prospects; in addition, the nanometer hollow structure can also be used for the respects of gas catalysis, gas sensitivity, lithium ion batteries and the like.

Owner:ZHEJIANG UNIV

Preparation method of aluminum nitride powder

The invention relates to a method for preparing aluminum nitride powder. The method for preparing the aluminum nitride powder comprises the following steps that pseudo-boehmite gel, an inorganic carbon source, a water-soluble organic carbon source and a sintering agent are mixed, and a mixture is obtained; in a nitrogen atmosphere, the mixture is nitrogenized at the temperature of 1,250 DEG C to 1,700 DEG C, and a reduction product is obtained; under the aerobic condition, the reduction product is calcined for 3-10 hours at the temperature of 600 DEG C to 720 DEG C, and the aluminum nitride powder is obtained. The aluminum nitride powder prepared through the method is high in purity.

Owner:CHAOZHOU THREE CIRCLE GRP

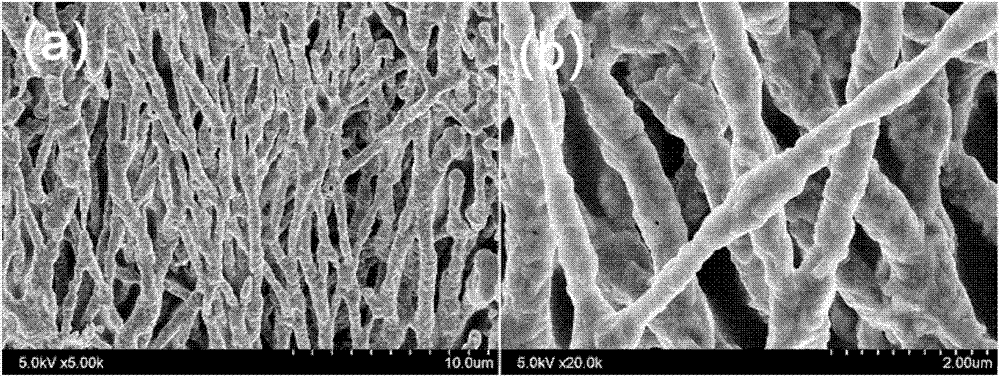

Preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber

InactiveCN102358963BGood fiber shapeSimple methodFilament/thread formingArtificial filament heat treatmentFluorescenceSolvent

The present invention relates to a preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method comprises the following steps: (1) dissolving calcium nitrate and europium nitrate in a mixed solvent comprising alcohol and water; adding tetraethyl orthosilicate while stirring; adding polyvinylpyrrolidone after stirring; continuously stirring to obtain a spinning liquid; (2) pouring the spinning liquid into a syringe, carrying out electrostatic spinning to collect a layer of uniform white fiber on receiving aluminum foil; (3) placing the white fiber into a high-temperature tubularatmosphere furnace to carry out a heat treatment; finally carrying out cooling along with the furnace to obtain the CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method of the present invention has characteristics of simpleness, low nitridation temperature and short time. The prepared CaSi2O2N2:Eu<2+> phosphor has good fiber morphology so as to contribute to improvement of the luminescent property and the later package in the LED, and has a good application prospect.

Owner:DONGHUA UNIV

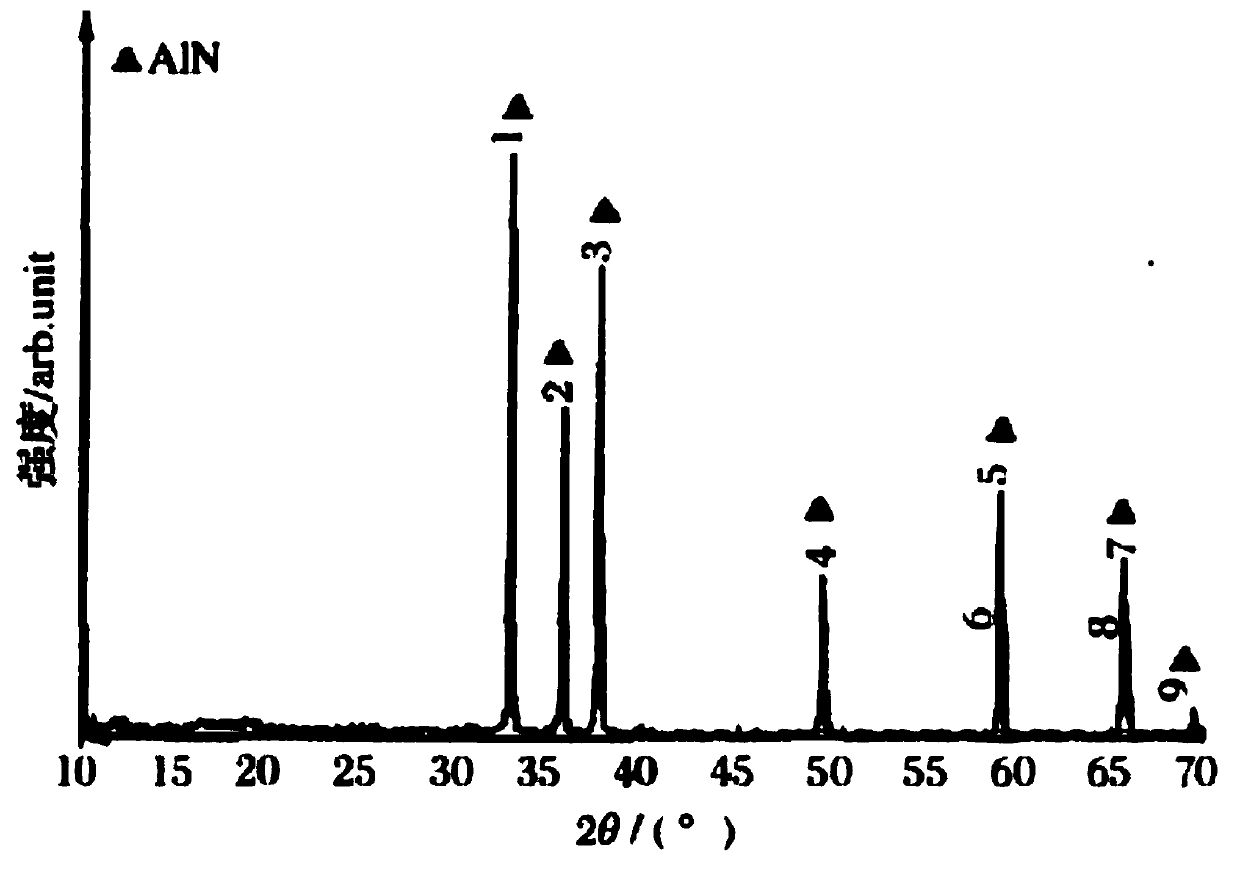

Preparation method of green AIN:Tb fluorescent powder material

InactiveCN110079307AImprove nitriding rateSimple preparation processLuminescent compositionsFluorescenceThermal insulation

The invention relates to a preparation method of a green AIN:Tb fluorescent powder material. The preparation method comprises following steps: S1), aluminum powder, magnesium powder, ammonium chlorideand terbium powder are sufficiently mixed by grinding, the mixture is transferred into an alumina ceramic ark, and reaction precursor powder is obtained; S2), the alumina ceramic ark is transferred into a tube type resistance furnace, nitrogen gas is introduced for nitrogen treatment, and the green AIN:Tb fluorescent powder material is obtained by thermal insulation and cooling. The preparation method has the advantages that the preparation process is simple, the preparation cost is low, the nitriding temperature is low and the material has good performance, high purity, small particles anduniform particle size, the nitridation rate of a product is increased by adding magnesium powder and ammonium chloride as catalysts, nitridation can be realized at a lower temperature, and the preparation process is high in controllability and convenient to implement; the green AIN:Tb fluorescent powder material has the characteristic of green fluorescence property, a sample is subjected to crystal phase analysis through X-ray diffraction, and a diffraction peak is free of impurity phase and is relatively sharp.

Owner:WUYI UNIV

Plasma nitriding process

InactiveCN103451594AReduce consumptionReduce distortionSolid state diffusion coatingVacuum pumpingMetallurgy

A plasma nitriding furnace is adopted, and after a cylinder sleeve meeting the dimensional requirements is approved, the cylinder sleeve is cleaned through a cleaning agent or gasoline and aired and then enters the furnace. Vacuum pumping is performed in the furnace, ammonia gas is led into the furnace, the furnace is warmed to 400 DEG C at a speed of no higher than 50 DEG C per hour, heat is preserved for 1 hour, the furnace is slowly warmed to 480 DEG C, heat is preserved for 5 hours, and cooling is performed at a speed of no higher than 50 DEG C per hour, and the cylinder sleeve is discharged when the furnace is cooled to 150 DEG C. The cylinder sleeve having undergone nitriding processing is silver grey, product deformation is extremely small because the plasma nitriding temperature is lower than the gas nitriding temperature, the use requirements can be met without needing follow-up process, and surface quality is good.

Owner:TIANJIN BODI SHIPPING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com