Novel method for carrying out low-temperature surface catalysis and nitriding on alloy cast iron

A technology of alloy cast iron and surface catalysis, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of large deformation of parts, pore pitting, etc., achieve fast nitriding rate, promote diffusion, Effect of low nitriding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

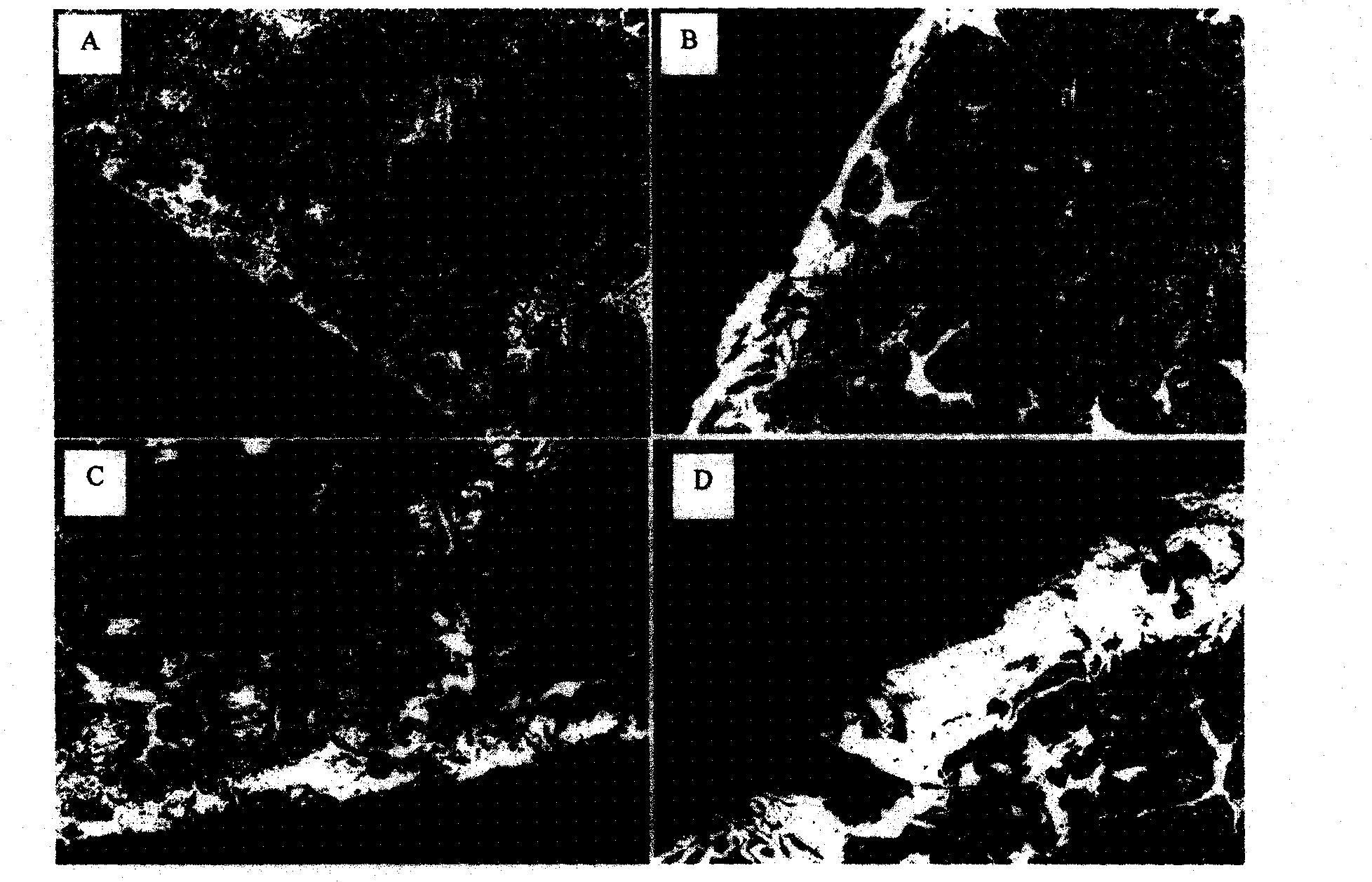

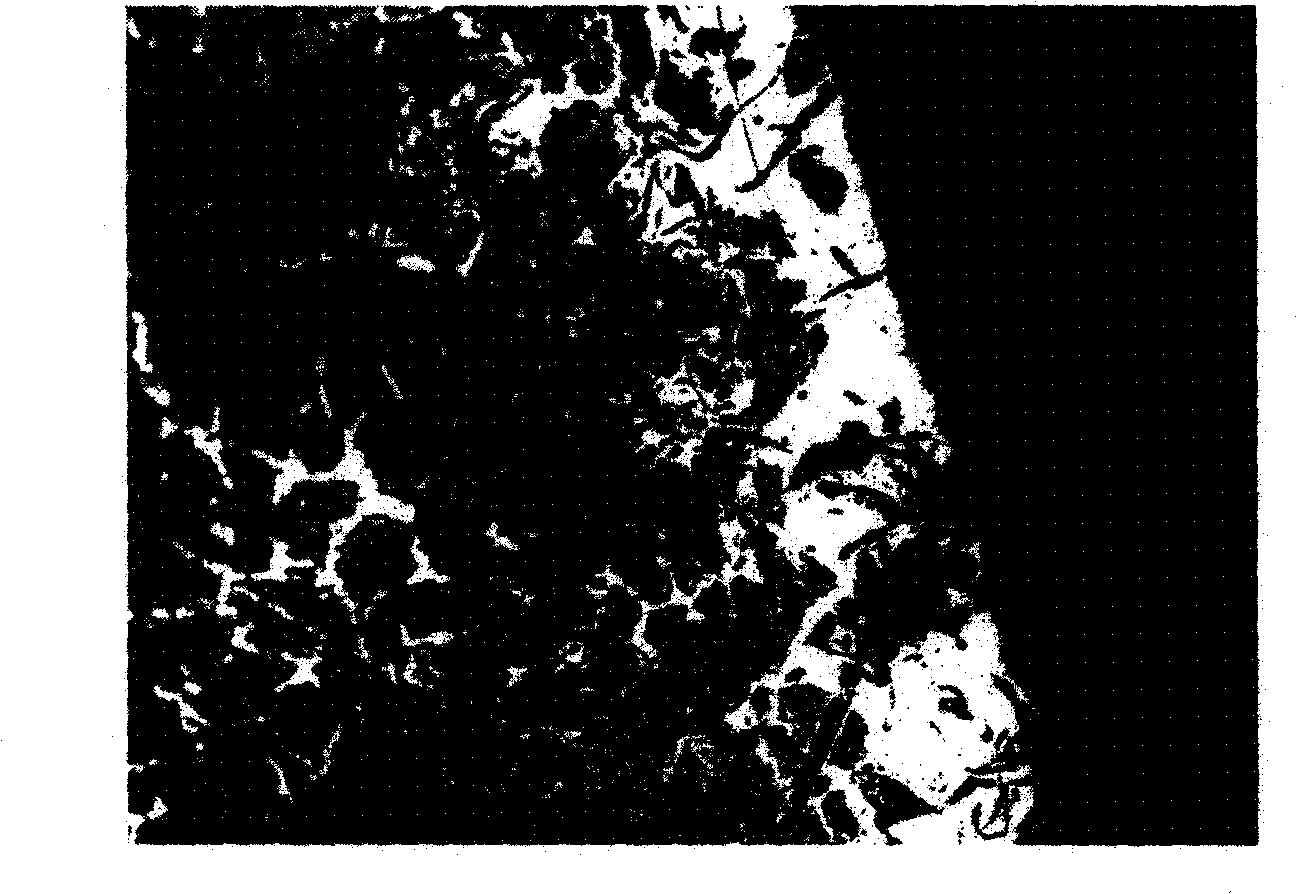

Image

Examples

Embodiment 1

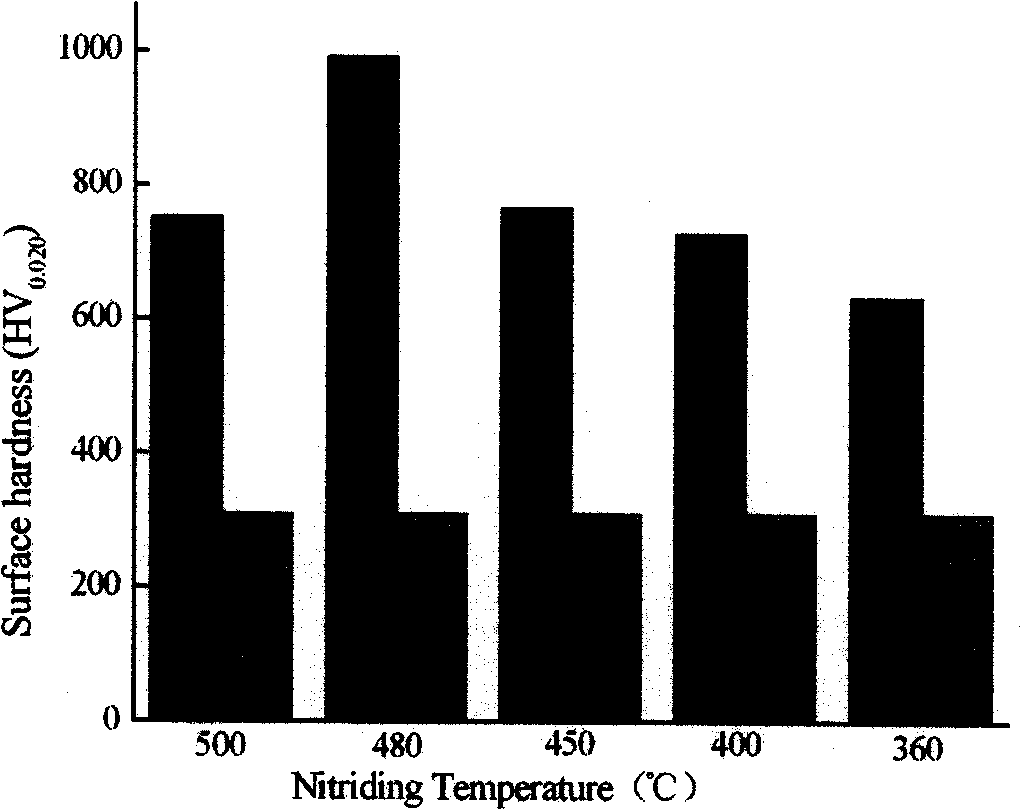

[0026] Example 1 400℃×10h low temperature nitriding

[0027] Alloy cylinder liner composition (see Table 1), surface hardness: 220-280HB, tensile strength: 245MPA.

[0028] Table 1. Alloy cylinder liner composition

[0029]

[0030] Technical requirements: surface nitriding treatment, white bright layer greater than 6 microns, microhardness HV600-800.

[0031] The traditional nitriding temperature is 500-510°C, keep the temperature for 7 hours, and then cool down. After the cylinder liner is nitrided, it is polished once, and the product has polished pits, that is, pores. Now perform the following process: the cylinder liner is degreased, derusted, cleaned, dried, and put into the treatment liquid for treatment. The nitriding temperature is 400°C, the ammonia gas flow rate is 300-1000ml / min, the furnace pressure is 5-15mm water column, and the preset nitriding temperature is maintained for 10 hours. At the same time, turn on the hydrogen analyzer to detect the ammonia d...

Embodiment 2

[0032] Example 2 500℃×4h low temperature nitriding

[0033] The performance of the alloy cylinder liner is the same as above, and now the following process is carried out: the cylinder liner is degreased, derusted, cleaned, dried, and put into the treatment liquid for treatment. The nitriding temperature is 500°C, the ammonia flow rate is 800-1600ml / min, the furnace pressure is 6-10mm water column, and the preset nitriding temperature is maintained for 4 hours. At the same time, turn on the hydrogen analyzer to detect the ammonia decomposition rate. Record the ammonia decomposition rate every hour, and adjust the flow of ammonia gas to ensure that the ammonia decomposition rate is between 20% and 45%. After nitriding at 500℃×4h, the thickness of the compound layer is 20μm, the nitrided layer is 90um, and the surface microhardness is HV752.

[0034] From the above implementation results, the new nitriding process of this patent invention, the catalytic film prepared by surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com