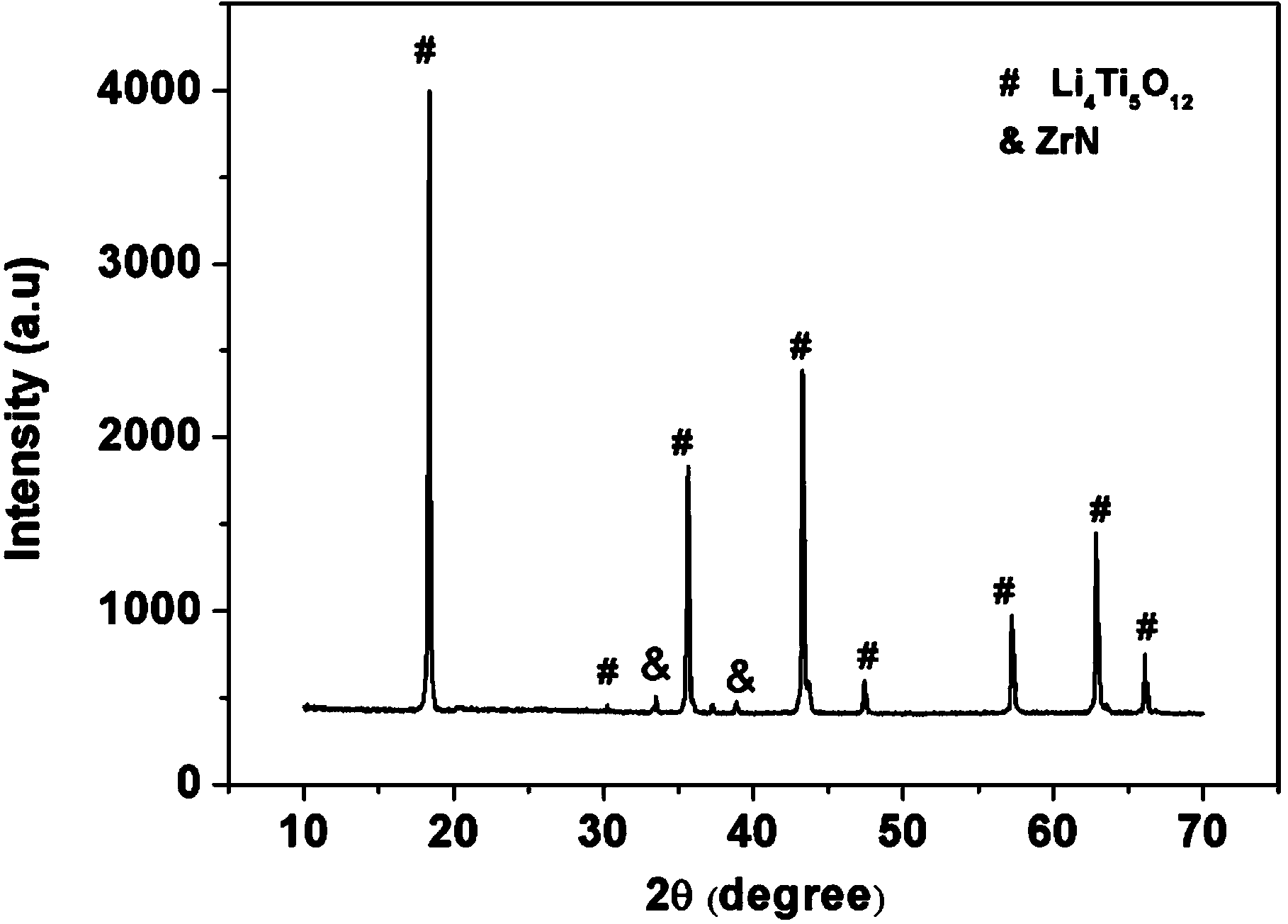

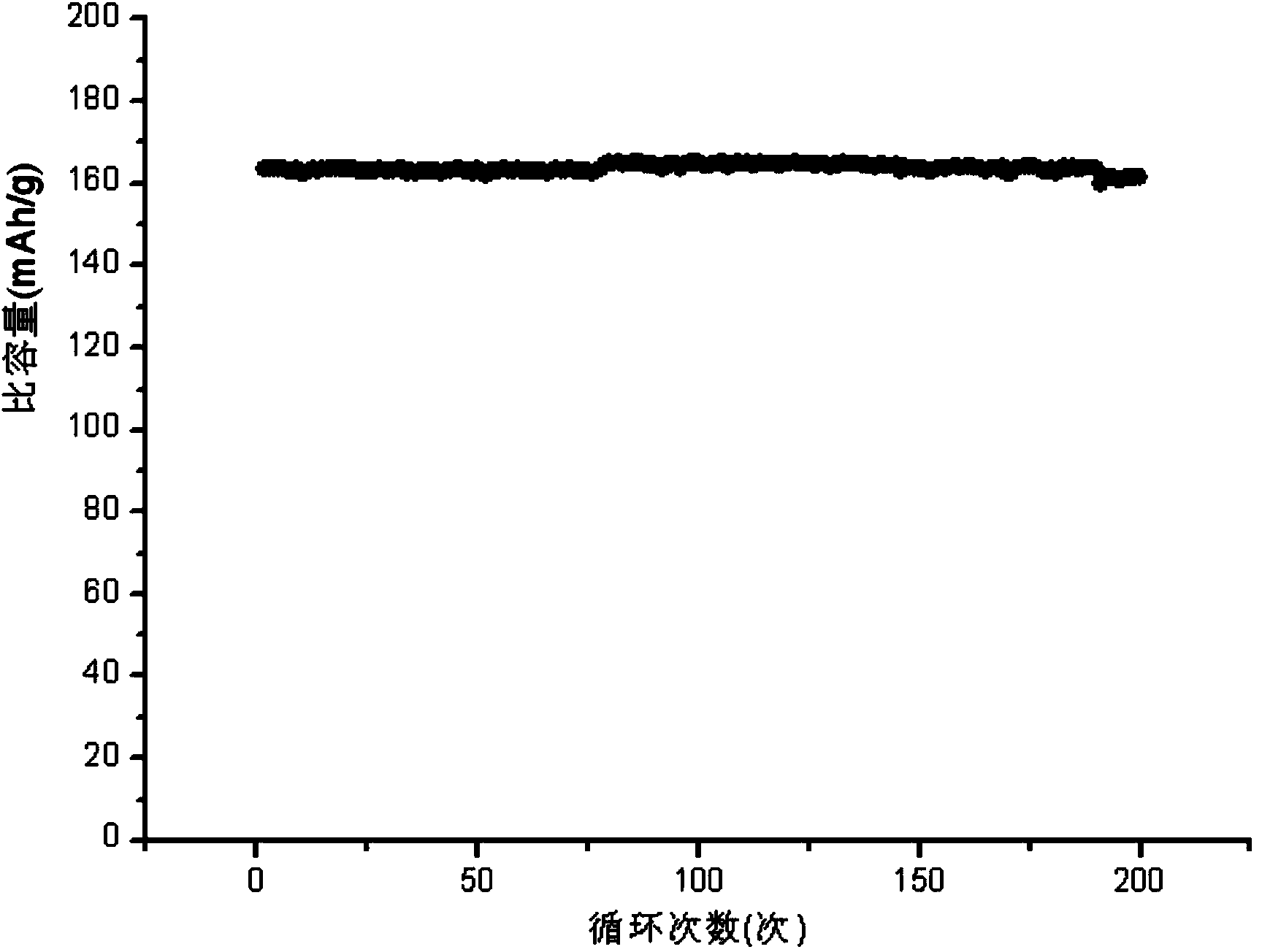

Preparation method for zirconium nitride-coated lithium titanate composite material

A technology of zirconium nitride coating lithium titanate and composite materials, which is applied to electrochemical generators, electrical components, battery electrodes, etc., and can solve problems affecting battery life, electrolyte failure decomposition, and high resistivity of lithium titanate , to achieve good chemical stability, good coating effect, simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh lithium carbonate and titanium dioxide according to the molar ratio of lithium and titanium elements being 0.82, perform ball milling dispersion treatment with alcohol for 6 hours, and then dry the obtained slurry in a vacuum oven at 100°C for 10 hours to obtain titanic acid Lithium precursor powder.

[0033] (2) Weigh aluminum powder and lithium titanate precursor powder in a high-energy ball mill tank according to the molar ratio of zirconium and titanium elements of 0.03, and then add ammonium chloride additive accounting for 5% of the total material mass percentage, the ball-to-material ratio is 20:1, the filling ratio is 1 / 4, the ball milling tank is sealed after filling with argon, and the high-energy ball milling is performed for 4 hours.

[0034] (3) Transfer the above ball-milled uniform material to the material boat under the blowing of flowing argon gas 5L / min and send it into the tube-type nitriding atmosphere furnace that has been emptied of air, ...

Embodiment 2

[0039] (1) Weigh lithium carbonate and titanium dioxide according to the molar ratio of lithium and titanium elements being 0.82, perform ball milling dispersion treatment with deionized water for 6 hours, and then dry the obtained slurry in a vacuum oven at 100°C for 10 hours to obtain Lithium titanate precursor powder.

[0040] (2) According to the molar ratio of zirconium and titanium elements of 0.03, weigh zirconium powder and lithium titanate precursor powder in a high-energy ball mill tank, and then add ammonium chloride additive accounting for 3% of the total material mass percentage, the ball-to-material ratio is 20:1, the filling ratio is 1 / 4, the ball milling tank is sealed after filling with argon, and the high-energy ball milling is performed for 4 hours.

[0041] (3) Transfer the above ball-milled uniform material to the material boat under the blowing of flowing argon gas 5L / min and send it into the tube-type nitriding atmosphere furnace that has been emptied of...

Embodiment 3

[0044] (1) Weigh lithium nitrate and titanium dioxide according to the molar ratio of lithium and titanium elements being 0.84, perform ball milling dispersion treatment with alcohol for 6 hours, and then dry the obtained slurry in a vacuum oven at 100°C for 10 hours to obtain titanic acid Lithium precursor powder.

[0045] (2) Weigh zirconium powder and lithium titanate precursor powder in a high-energy ball mill tank according to the molar ratio of zirconium and titanium elements of 0.05, and then add ammonium chloride additive accounting for 5% of the total material mass percentage, the ball-to-material ratio is 20:1, the filling ratio is 1 / 4, the ball milling tank is sealed after filling with argon, and the high-energy ball milling is performed for 4 hours.

[0046] (3) Transfer the above ball-milled uniform material to the material boat under the blowing of flowing argon gas 5L / min and send it into the tube-type nitriding atmosphere furnace that has been emptied of air, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com