Nitrogen-containing rare-earth magnetic powder and preparation method thereof

A rare earth magnetic powder and rare earth technology, which is applied in the field of nitrogen-containing rare earth magnetic powder and its preparation, can solve the problems of prolonging the nitriding time, reducing the magnetic properties of R-Fe-N magnetic powder, and continuously uneven distribution of nitrogen content, and achieving increased diffusion speed, nitriding temperature is low, and the effect of increasing nitrogen diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

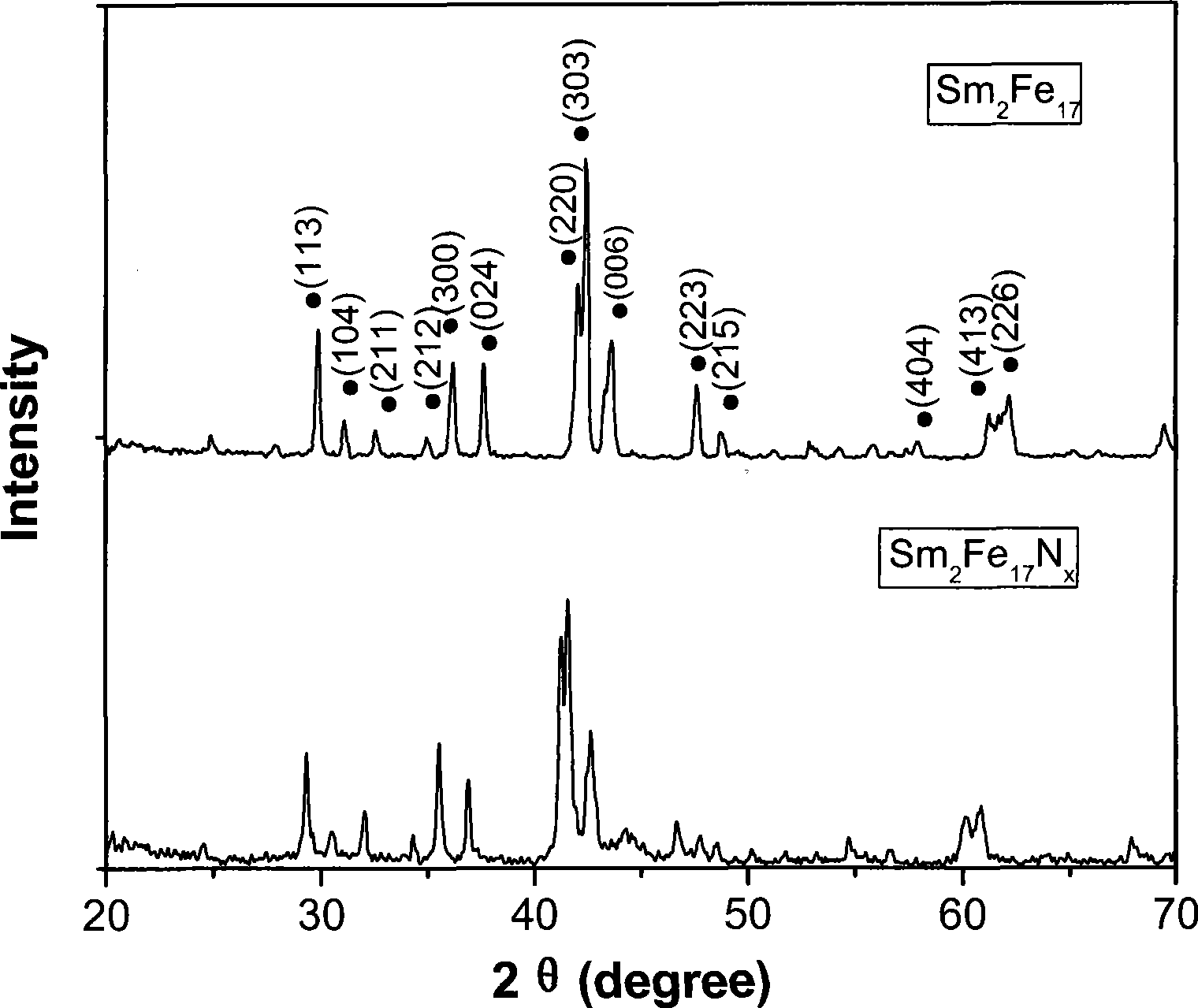

Image

Examples

Embodiment 1

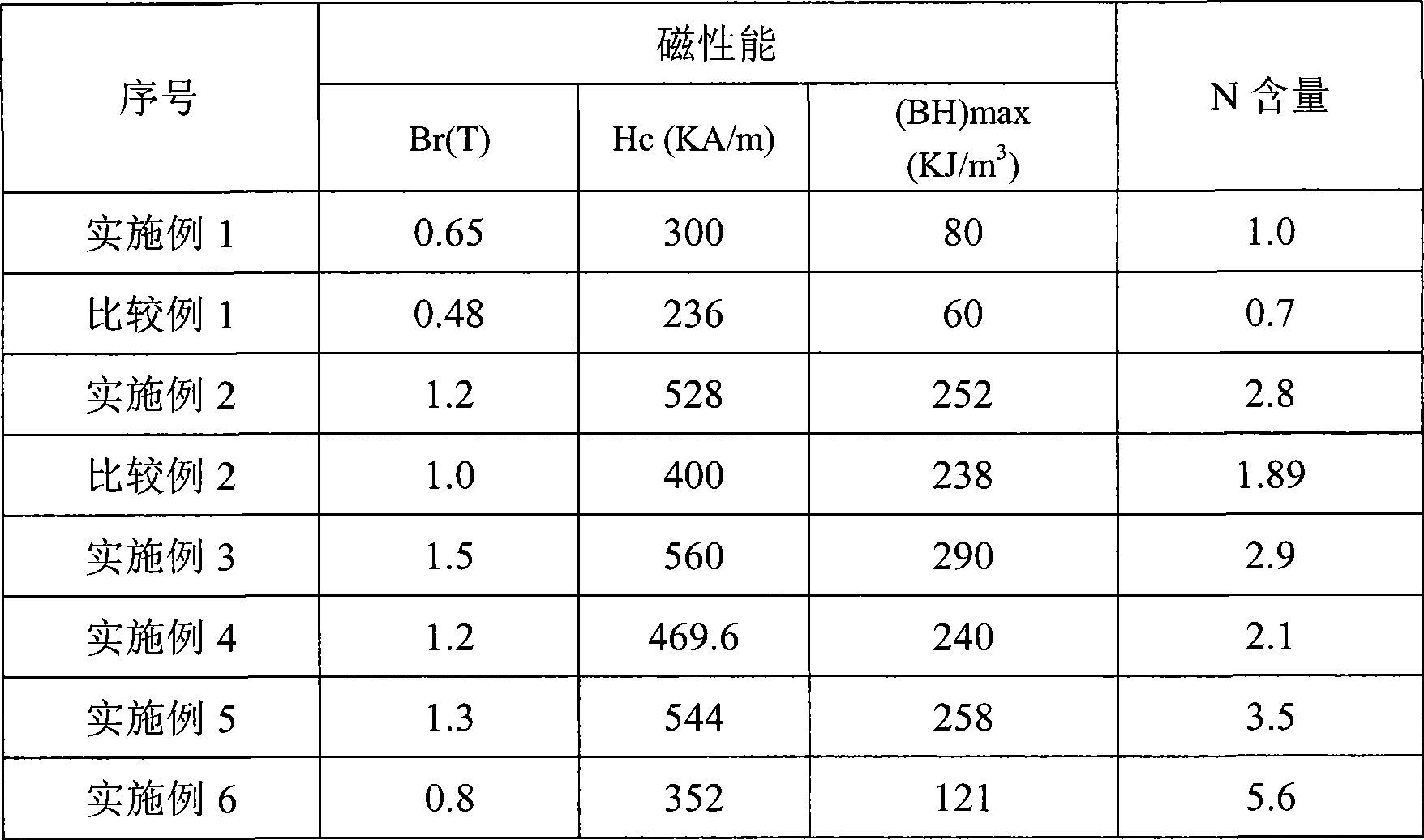

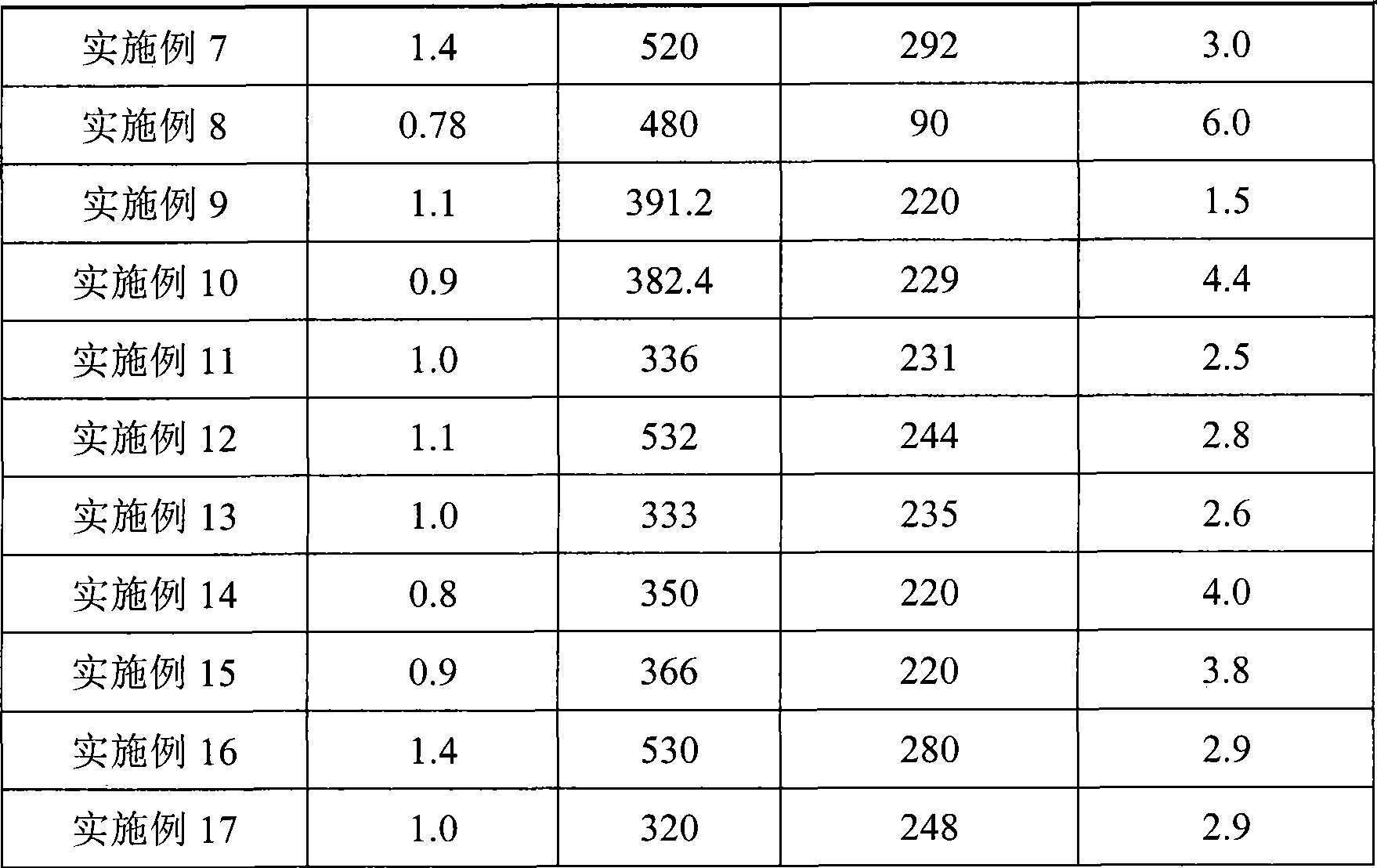

[0025] The smelted Sm-FeCo alloy is melted under the protection of an inert gas, and sprayed under pressure through the pores at the bottom of the container onto the outer edge of a water-cooled copper roller rotating at high speed, cooling rapidly and forming amorphous or microcrystalline thin strips. The obtained Sm-FeCo amorphous or microcrystalline strips are homogenized and crushed into powders with a particle size of 20-40 μm. Add 20wt% of organic compounds, wherein the organic compound composition is 20wt% of the acene compound (ferrocene:rare earth=1:49) and the balance is isobutanol, propanol and isopropanol (isobutanol:propanol: Isopropanol=1:1:1), vacuumize to less than 3×10 -3 Pass into N after Pa 2 To 1atm, keep it at 450°C for 1 hour to obtain the composition Sm 2 Fe 15.2 co 1.8 N 1.0 The nitrogen-containing rare earth magnetic powder is ball-milled into a magnetic powder with a particle size of 0.3-10 μm. The magnetic properties and nitrogen content of the...

Embodiment 2

[0029] The raw materials are smelted in the crucible, and then the alloy liquid is cast on the rotating water-cooled roller in a planar flow through the casting trough to form the Sm-FeAlCrGa alloy cast sheet. The obtained Sm-FeAlCrGa alloy cast flakes were crushed into powders with a particle size of 30-40 μm. Add 1wt% of organic compound, wherein the organic compound composition is 80wt% of the cene compound (ferrocene: rare earth = 1:4) and the balance is methanol, vacuumize to less than 3 × 10 -3 Pass into NH after Pa 3 -H 2 Mix the gas to 1atm, keep it at 450°C for 1 hour to obtain the composition Sm 2 Fe 16 (Al 0.03 Cr 0.03 Ga 0.04 )N 2.8 The nitrogen-containing rare earth magnetic powder is ball milled into a magnetic powder with a particle size of 10-20 μm. The magnetic properties and nitrogen content of the magnetic powder are shown in Table 1.

Embodiment 3

[0033] The industrial pure metals Sm, Fe, Zr, Nb are used as raw materials, smelted in a vacuum induction furnace under the protection of argon and cast into Sm-FeZrNb alloy ingots. Add 5wt% organic compound, wherein the organic compound composition is 70wt% of the cene compound (ferrocene: cene Sm=1:9) and the balance is methanol, vacuumize to less than 3 * 10 -3 NH after Pa 3 -H 2 Mix the gas to 1.5atm, keep it at 450°C for 1 hour to obtain the composition Sm 2 Fe 15.5 (Zr 1.0 Nb 0.5 )N 2.9 The nitrogen-containing rare earth magnetic powder is ball-milled into a magnetic powder with a particle size of 10-20 μm. The magnetic properties and nitrogen content of the magnetic powder are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com