Nano titanium oxide and mechanical force chemical reaction preparation method for its composite powder

A technology of nano-titanium dioxide and composite powder, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of harsh synthesis conditions, high production costs, and increased processing technology, so as to speed up the chemical reaction and shorten the chemical reaction time , the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

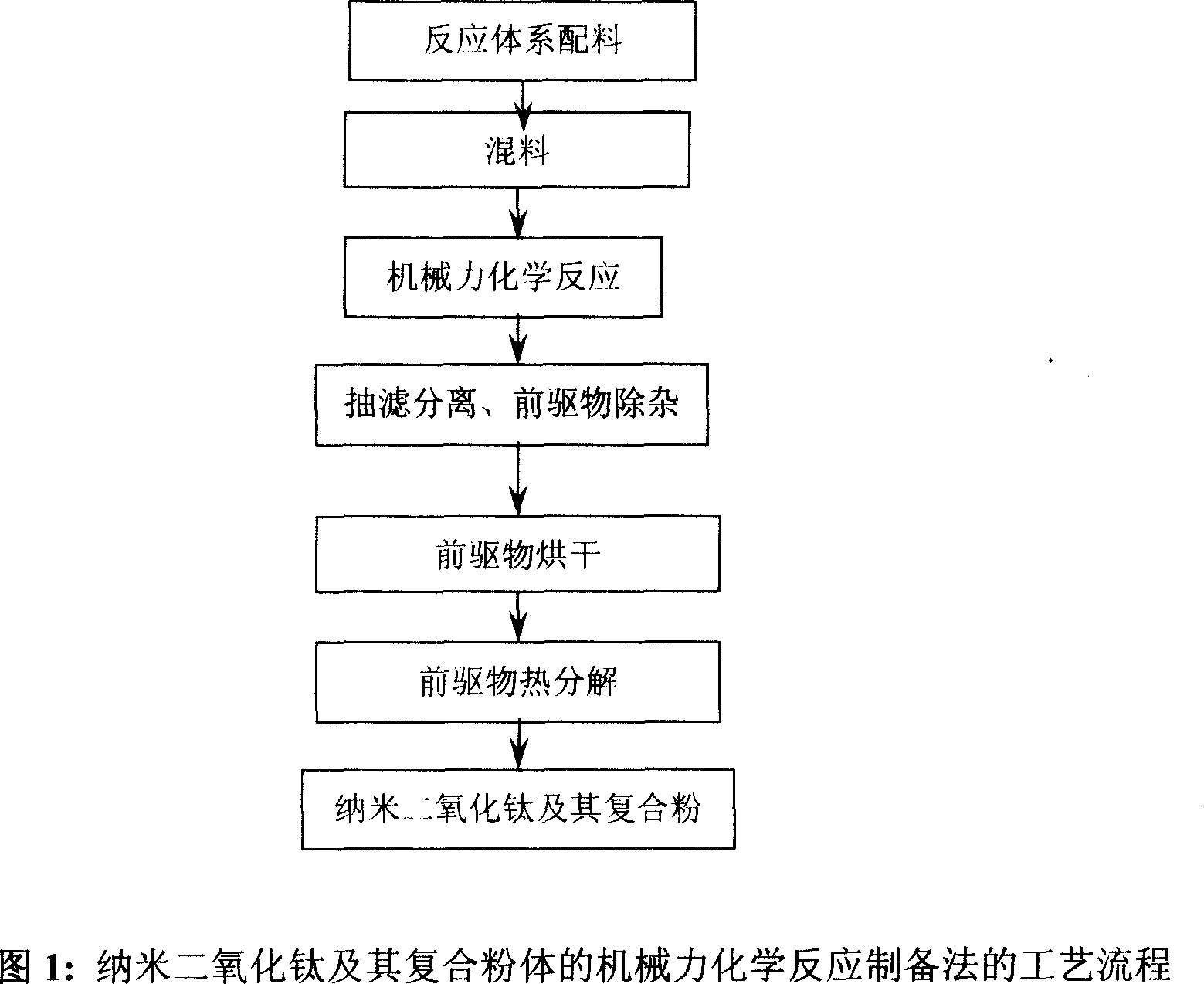

[0026] In this embodiment, the reactant is butyl titanate, and the ligand is oxalic acid. The process flow is shown in Figure 1, with the following steps in sequence

[0027] 1. Ingredients

[0028] The molar ratio of butyl titanate to oxalic acid is 1:3

[0029] 2. Mixing

[0030] Mix the proportion of butyl titanate and oxalic acid until uniform;

[0031] 3. Preparation of precursors by mechanochemical reaction method

[0032] The uniformly mixed butyl titanate and oxalic acid are ball milled at room temperature and normal pressure, so that they react to form precursors under the action of mechanical shear force and impact force generated during the ball milling process, and the speed of the ball mill is controlled at 300 rpm , 50 minutes of ball milling can make butyl titanate and oxalic acid completely react to form precursors;

[0033] 4. Precursor removal

[0034] The impurity removal of the precursor adopts the washing and filtering method, the detergent is ethanol...

Embodiment 2

[0041] In the present embodiment, the reactant is titanium sulfate, and the ligand is sodium carbonate. The process flow is shown in Figure 1, and the following steps are arranged successively

[0042] 1. Ingredients

[0043] The molar ratio of titanium sulfate to sodium carbonate is 1:4

[0044] 2. Mixing

[0045] Mix titanium sulfate and sodium carbonate in proportion until uniform;

[0046] 3. Preparation of precursors by mechanochemical reaction method

[0047] The uniformly mixed titanium sulfate and sodium carbonate are ball milled at room temperature and normal pressure, so that they react to form precursors under the action of mechanical shear force and impact force generated during the ball milling process. The speed of the ball mill is 320 rpm. It takes 40 minutes to completely react titanium sulfate and sodium carbonate to form precursors;

[0048] 4. Precursor removal

[0049] The impurity removal of the precursor adopts the washing and filtering method, the d...

Embodiment 3

[0056] In this embodiment, the reactant is a complex of titanium sulfate and zinc sulfate, and the ligand is oxalic acid. The process flow is shown in Figure 1, and there are the following steps in turn

[0057] 1. Ingredients

[0058] The molar ratio of the complex of titanium sulfate and zinc sulfate to oxalic acid is 1:3, and the molar ratio of titanium sulfate and zinc sulfate in the complex is 10:1;

[0059] 2. Mixing

[0060] Mix the composite of titanium sulfate and zinc sulfate in proportion with oxalic acid until uniform;

[0061] 3. Preparation of precursors by mechanochemical reaction method

[0062] The uniformly mixed reaction system is ball milled at room temperature and normal pressure, so that it reacts to form a precursor under the action of mechanical shear force and impact force generated during the ball milling process. It can completely react titanium sulfate, zinc sulfate and oxalic acid to form precursors;

[0063] 4. Precursor removal

[0064] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com