Patents

Literature

133results about How to "Fast chemical reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiple function, self-repairing composites with special adhesives

InactiveUS20070087198A1Fast chemical reactionExtended shelf lifeLayered productsConstructions elementsFiber matrixChemical substance

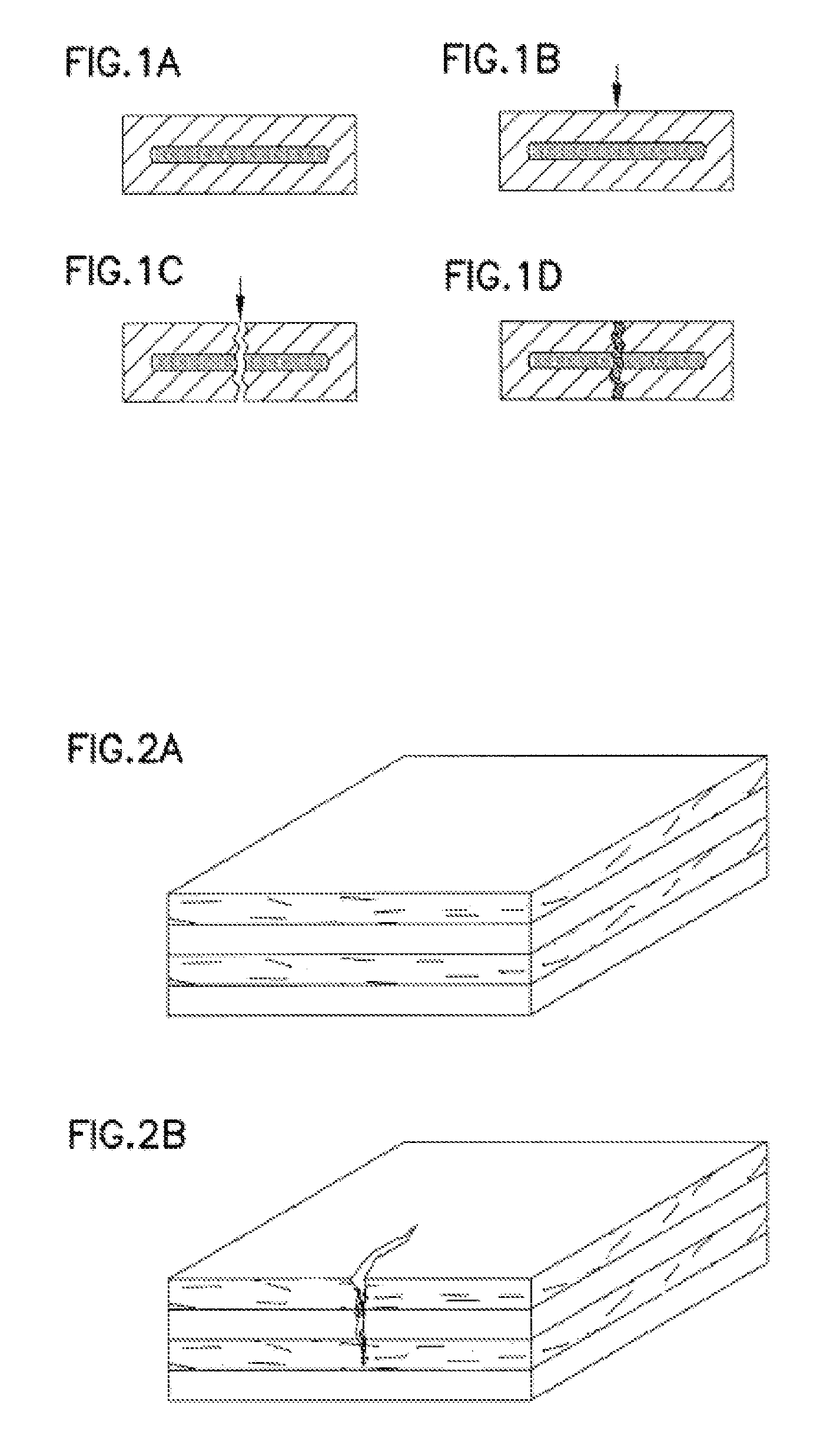

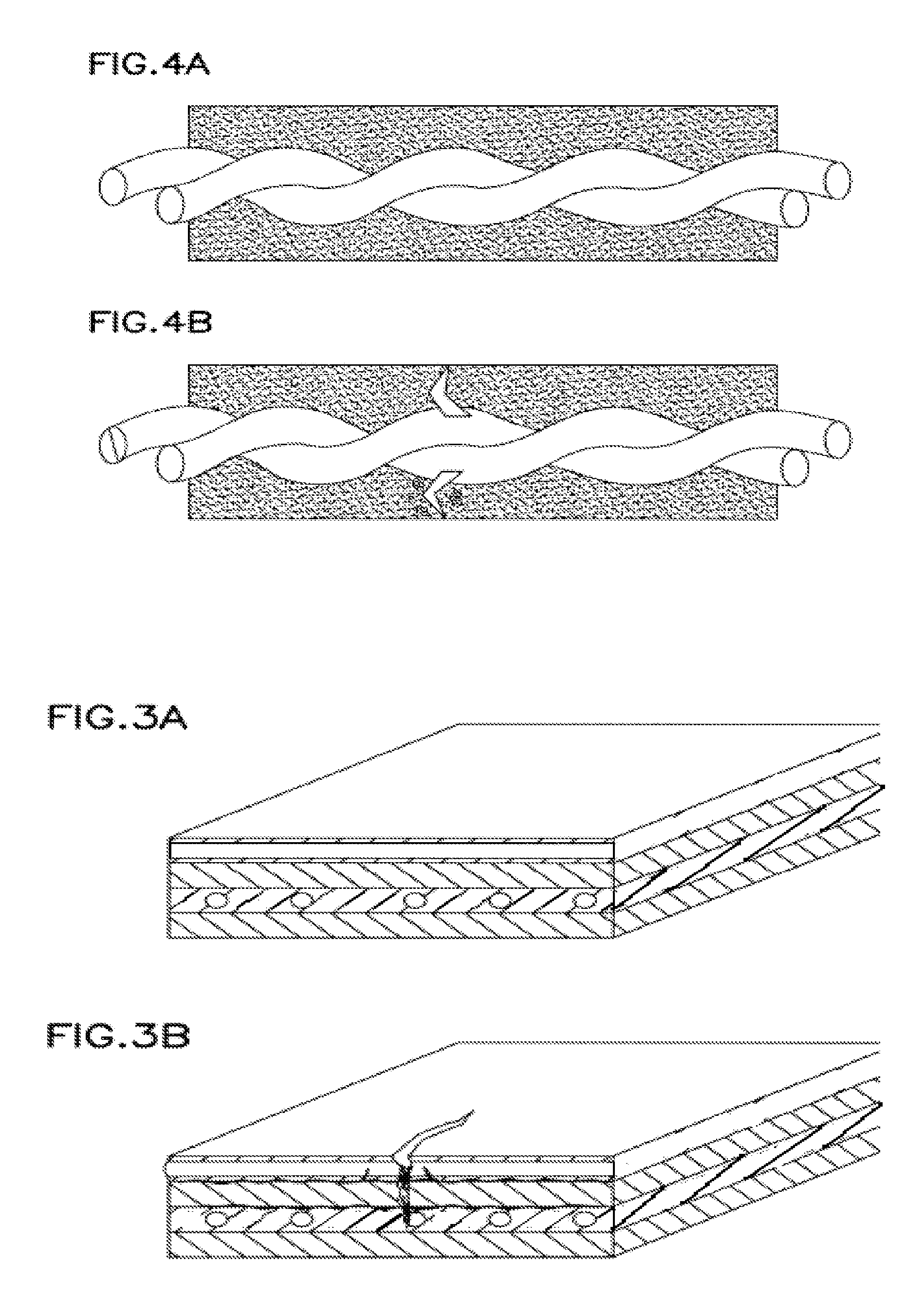

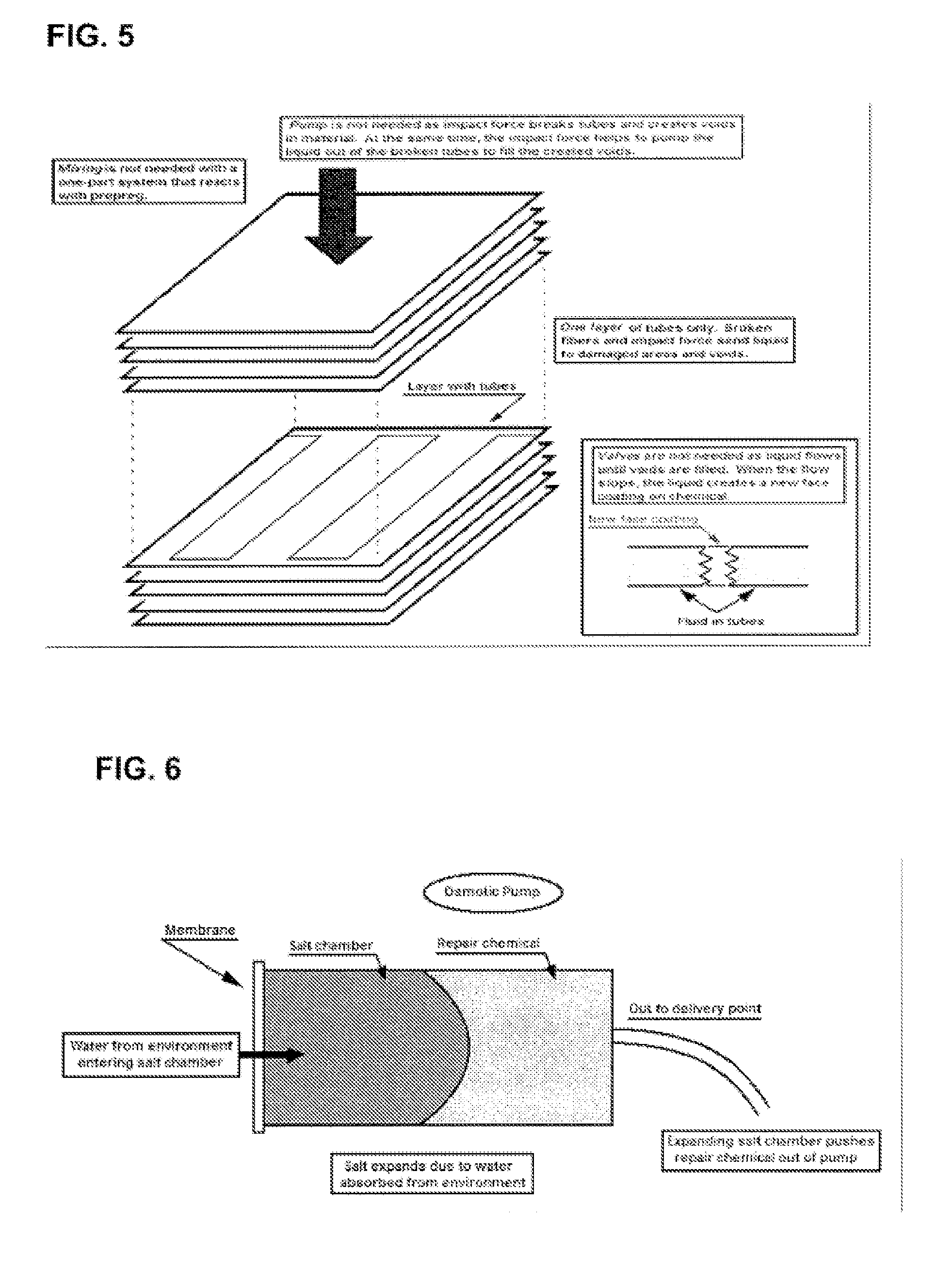

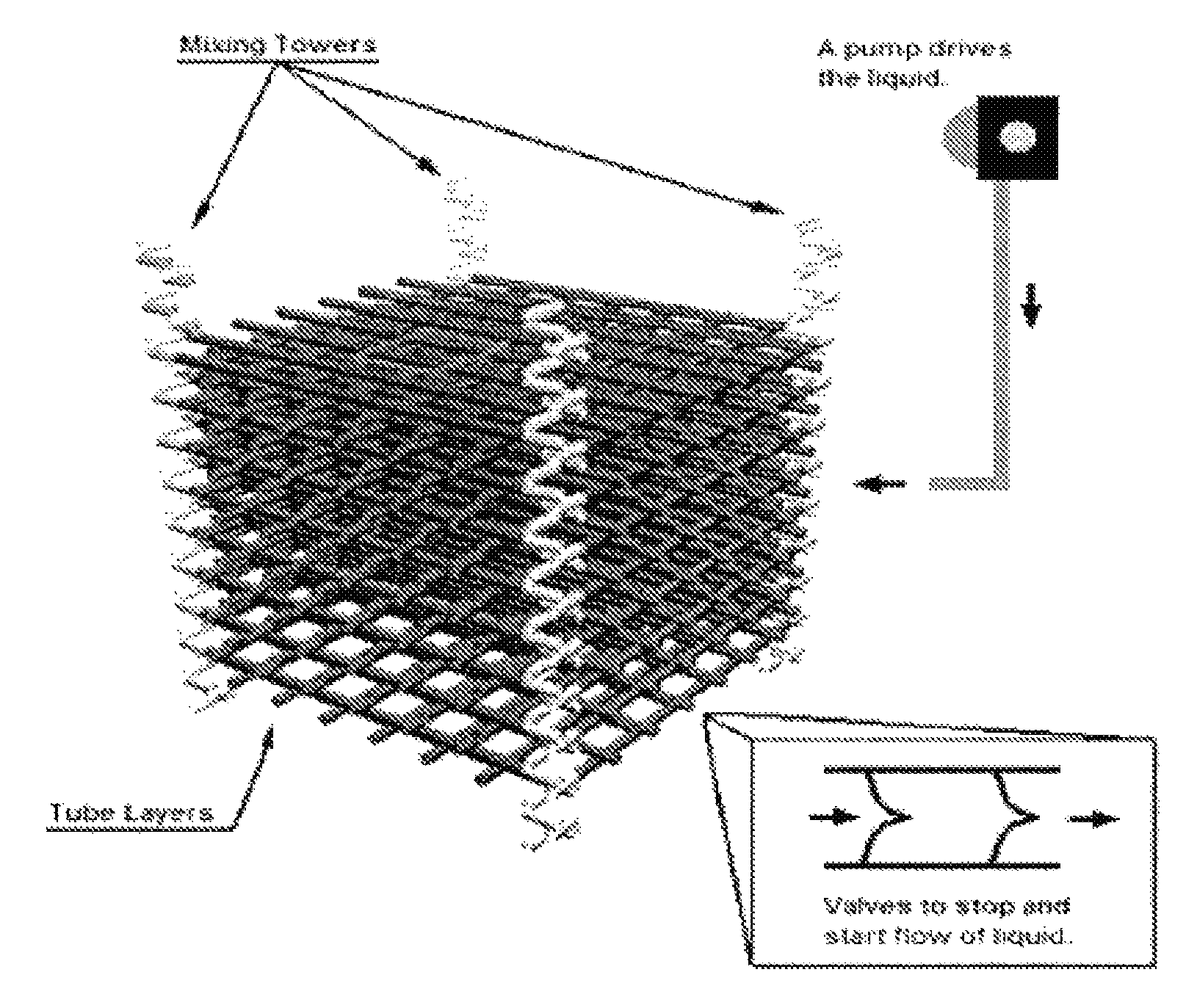

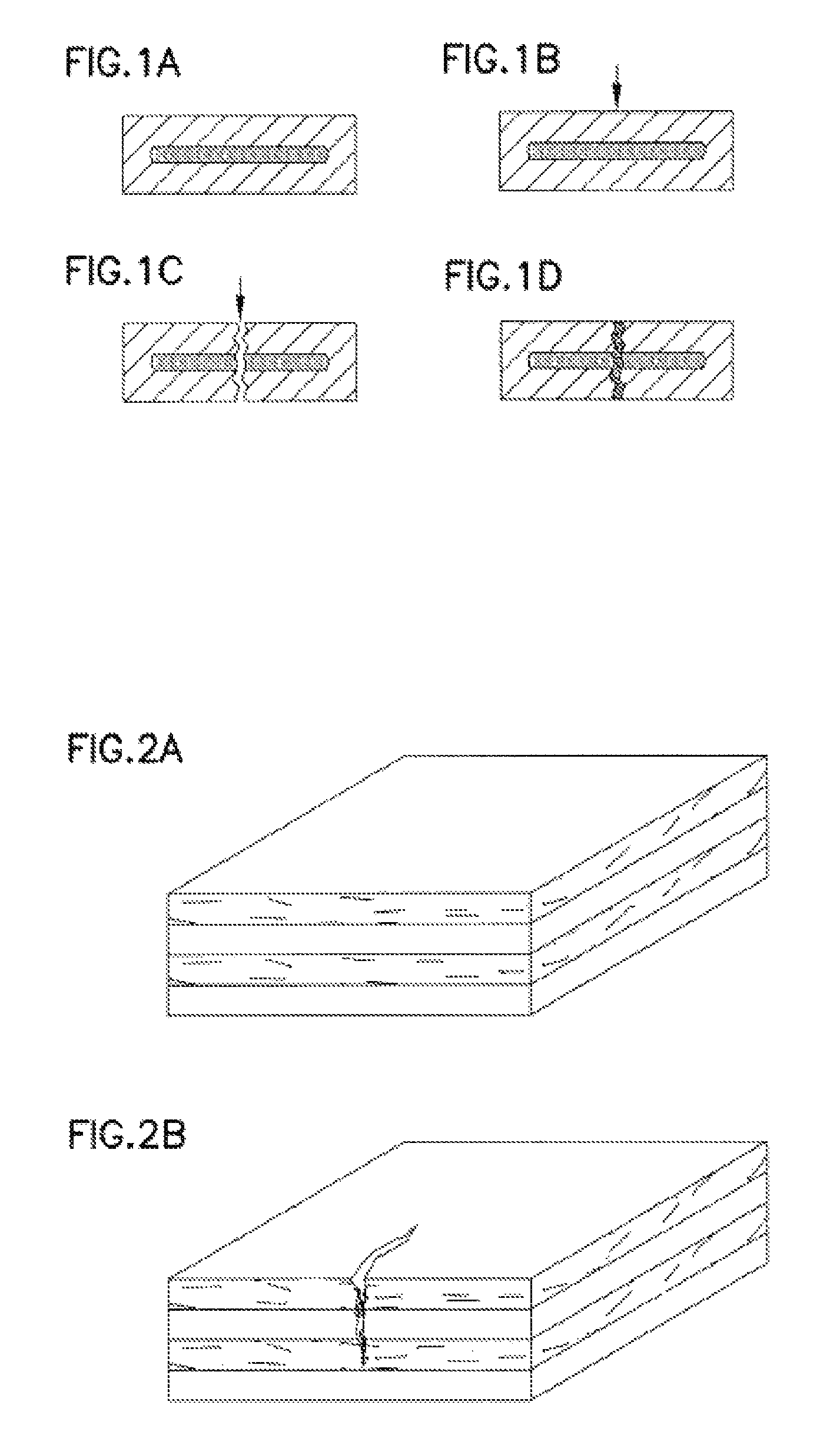

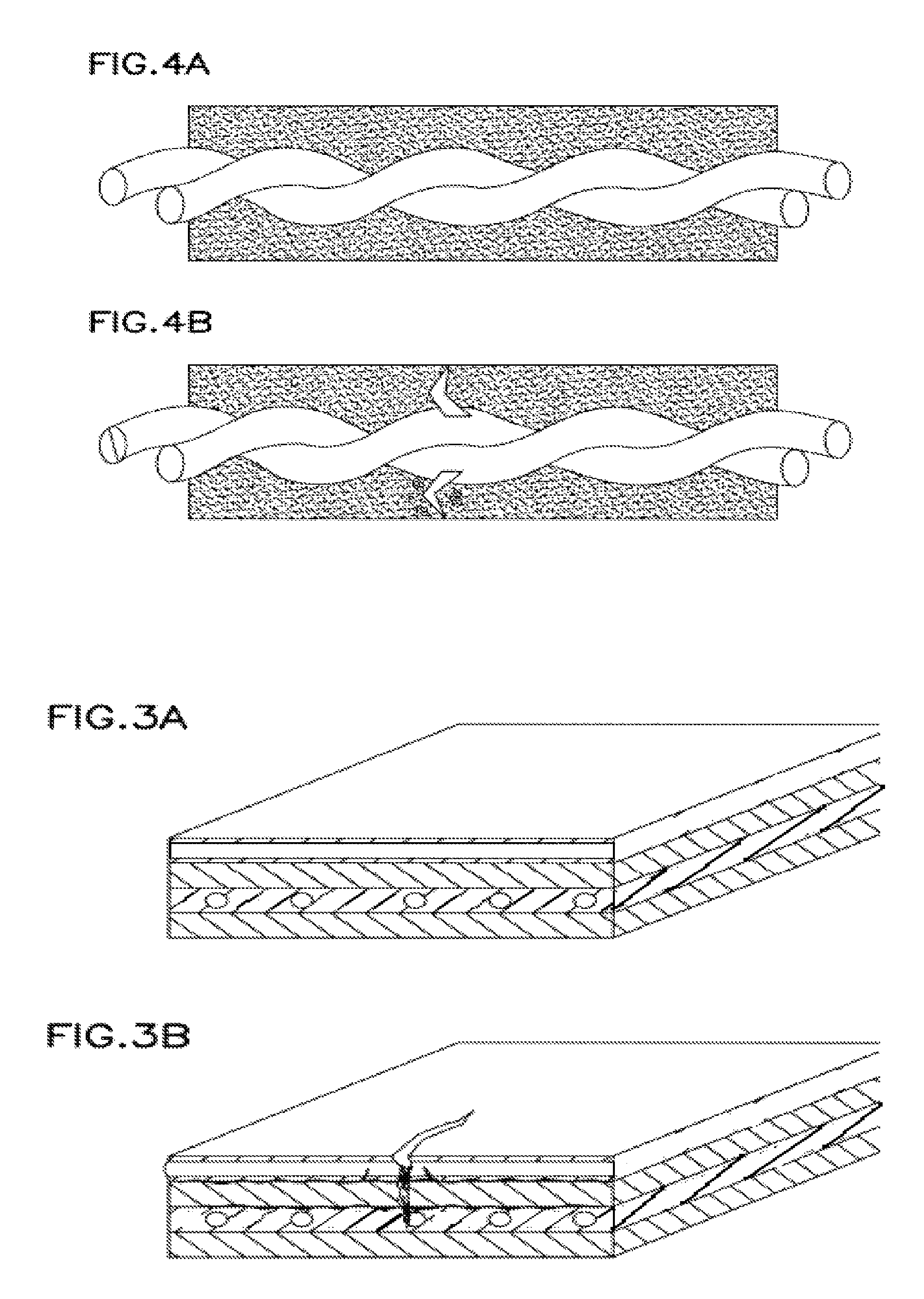

A system for self-repairing matrices such as concrete or cementitous matrices, polymeric matrices, and / or fibrous matrices, including laminates thereof. The system includes repair agents retained in and / or on vessels, such as hollow fibers, within the matrix. Upon impact, the vessel rupture, releasing the chemicals. For multi-layer laminates, the systems provides a total dynamic energetic circulation system that functions as an in situ fluidic system in at least one layer or area. The energy from the impact ruptures the vessels to release the chemical(s), and mixes the chemical(s) and pushes the chemical(s) and / or resulting compound through the matrix. The repair agents can withstand high temperatures, such as the heat of processing of many laminates, e.g., 250-350° F.

Owner:DRY CAROLYN

Multiple function, self-repairing composites with special adhesives

InactiveUS7811666B2Fast chemical reactionExtended shelf lifeLayered productsConstructions elementsFiberAdhesive

A system for self-repairing matrices such as concrete or cementitous matrices, polymeric matrices, and / or fibrous matrices, including laminates thereof. The system includes repair agents retained in and / or on vessels, such as hollow fibers, within the matrix. Upon impact, the vessel rupture, releasing the chemicals. For multi-layer laminates, the systems provides a total dynamic energetic circulation system that functions as an in situ fluidic system in at least one layer or area. The energy from the impact ruptures the vessels to release the chemical(s), and mixes the chemical(s) and pushes the chemical(s) and / or resulting compound through the matrix. The repair agents can withstand high temperatures, such as the heat of processing of many laminates, e.g., 250-350° F.

Owner:DRY CAROLYN

Antiwear antifriction composite additive for lubricating oil (grease)

InactiveCN104046407AIncrease surface areaIncrease the speed of diffusionAdditivesMetallurgyReaction rate

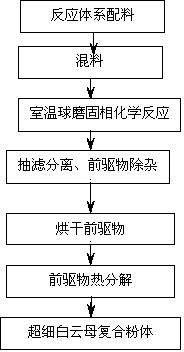

The invention discloses an antiwear antifriction composite powder for lubricating oil (grease) and a preparation method thereof and relates to a nano-rare earth oxide-cladding ultrafine muscovite composite powder for the fields of lubricating oil, lubricating grease and the like. the invention is characterized in that a muscovite powder, rare-earth salt and its ligand are used as raw materials; a solid-phase reaction system is crushed by shear force and impact force generated during the ball-milling process, specific surface area of reactants is increased, and reaction rate is raised so as to raise ratio of nucleation rate to growth rate; a fine and uniform precursor is prepared, and then washing, drying and control of thermal decomposition temperature and time are carried out so as to obtain the nano-rare earth oxide-cladding ultrafine muscovite composite powder with different particle sizes and cladding systems; and after undergoing surface modification, the nano-rare earth oxide-cladding ultrafine muscovite composite powder is added into base oil or lubricating grease at different proportions of (0.5%-3%). In four-ball friction, friction coefficient can be reduced, and friction-pair wear scar diameter is minimized.

Owner:SICHUAN UNIV

Fuel additive composition and its preparation

InactiveUS20060059768A1High porosityLow densityLiquid carbonaceous fuelsFuel additivesCombustionEngineering

A fuel additive composition for the reduction / removal of vanadium-containing ash deposits in gas turbines and other by combustion of vanadium-containing fuel driven apparatuses, which composition as its active ingredient comprises a compound of a metal capable of forming a vanadate with vanadium of said ash deposits is disclosed.

Owner:SYSTEMSEPARATION SWEDEN AB

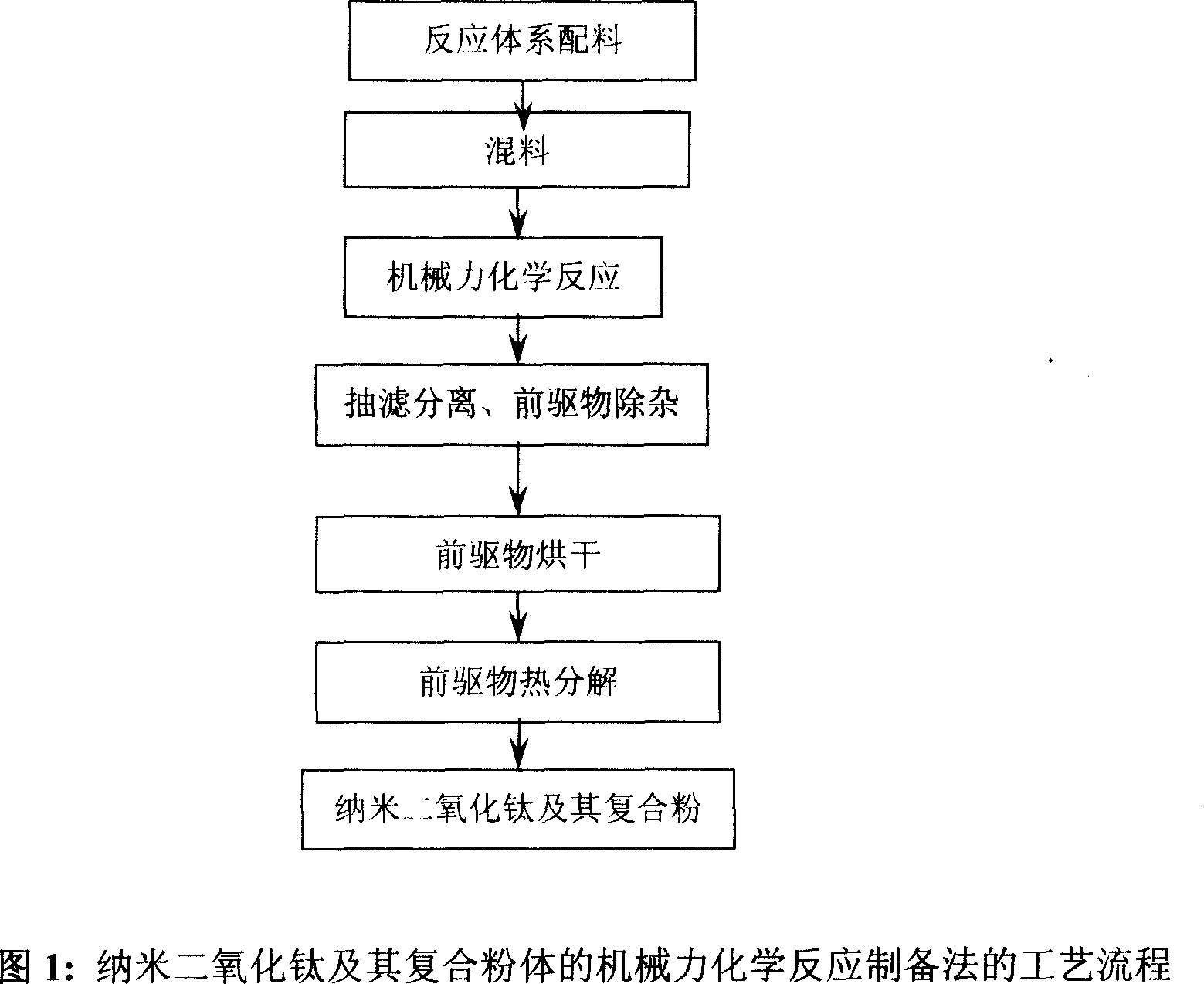

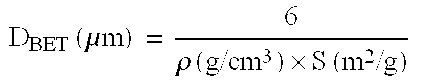

Nano titanium oxide and mechanical force chemical reaction preparation method for its composite powder

InactiveCN101062780ALarge specific surface areaIncrease the speed of diffusionTitanium dioxideSolid phasesDecomposition

The invention discloses a preparing technology of nanometer titanium oxide and composite powder body, which comprises the following steps: using shearing force and impact force generated in balling course to bruise solid phase reacting system; increasing specific surface area of the reactant; improving reaction rate to advance the ratio of nucleation rate and growth rate; preparing fine and even forerunner material; washing; drying; controlling the temperature and time of heat decomposition; getting nanometer titanium oxide and composite powder body with diverse crystal system and grain size; realizing surface coating of nanometer titanium oxide. This method possesses simple craft and can control crystal system, outlook and grain diameter of nanometer titanium oxide, which powder grain diameter distribution is 30-80nm.

Owner:SICHUAN UNIV

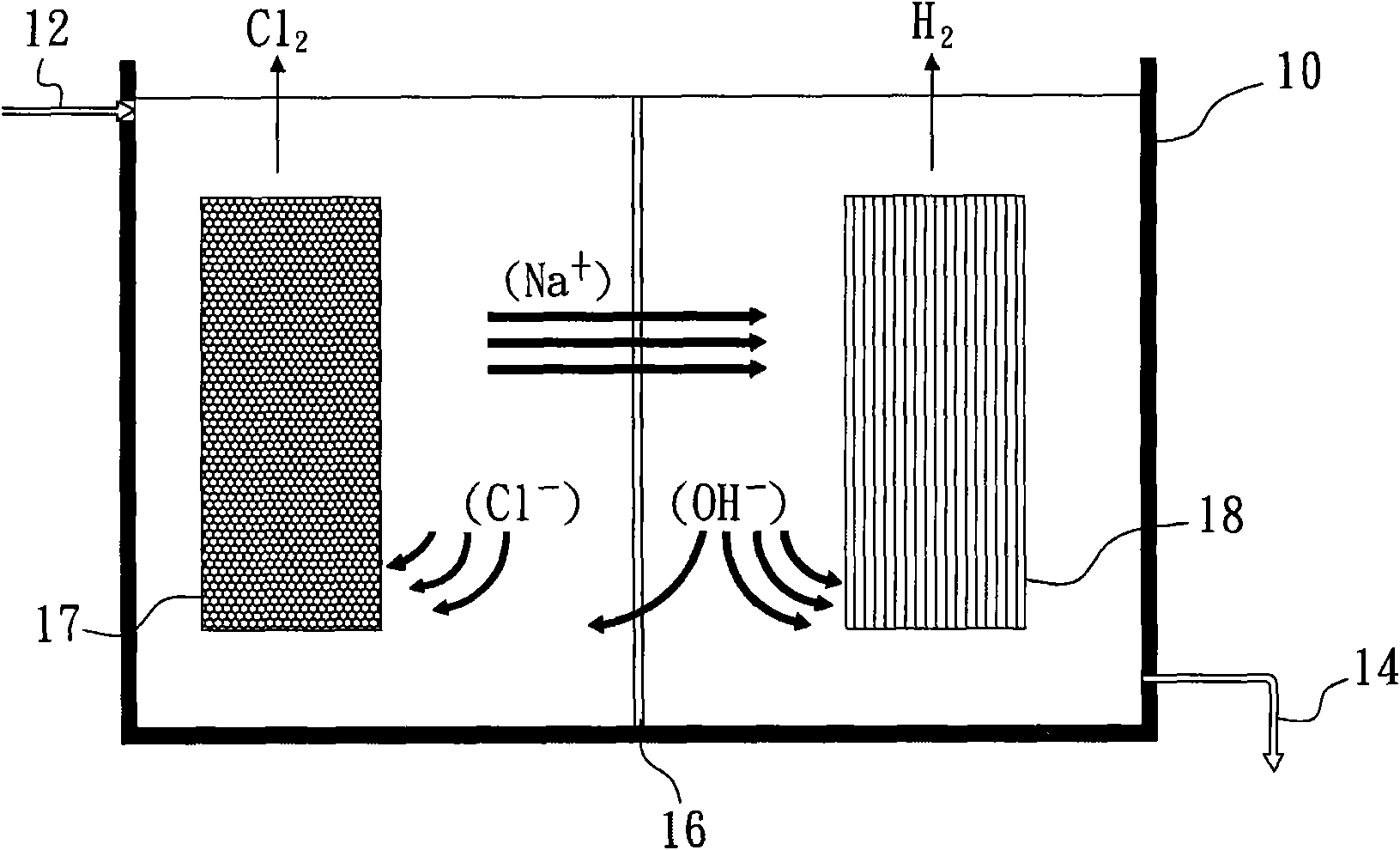

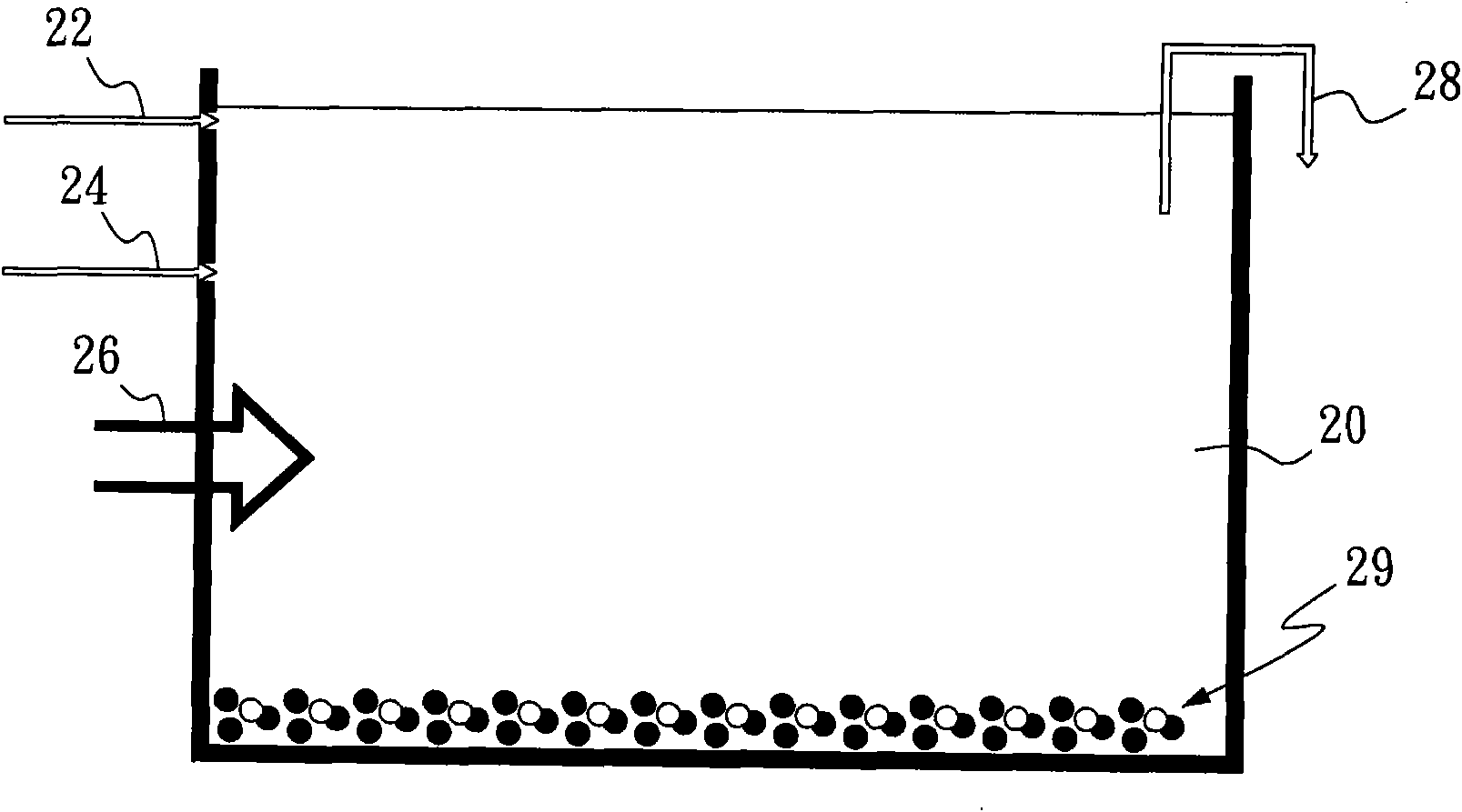

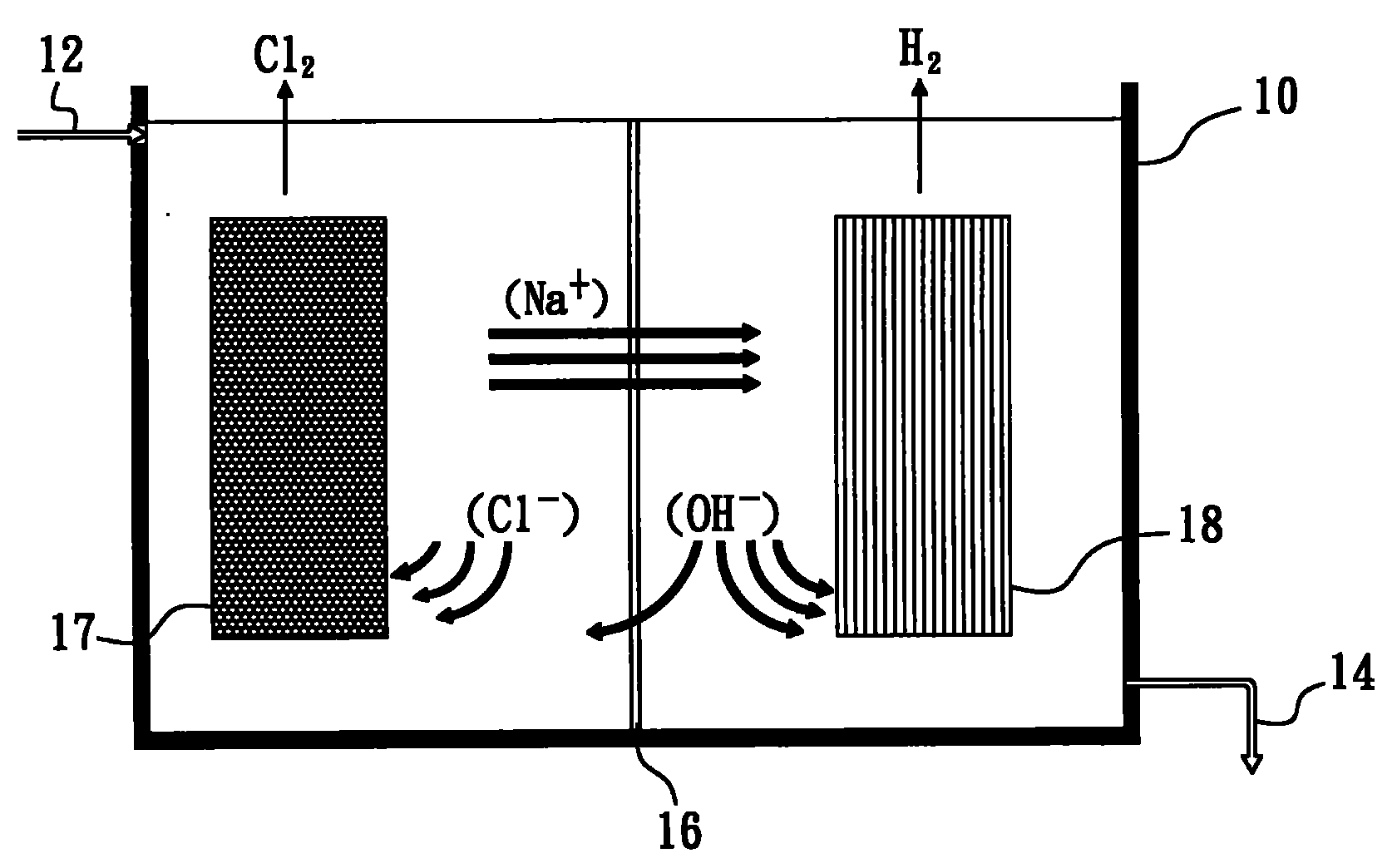

Method for trapping carbon dioxide

InactiveCN101773766AFast chemical reactionSafeguard storageProductsReagentsCalcium chloride transformationElectrolysis

The invention relates to a method for trapping carbon dioxide. The method comprises the following steps of: (1) electrolyzing a saturated saline solution to obtain sodium hydroxide; (2) adding the sodium hydroxide into seawater to convert magnesium chloride and calcium chloride in the seawater into magnesium hydroxide and calcium hydroxide; and (3) leading carbon dioxide into the water containing the magnesium hydroxide and the calcium hydroxide to convert into magnesium carbonate and calcium carbonate. The invention can effectively, quickly and safely trap the carbon dioxide, decrease the content of carbon dioxide in the air and achieve the effect of emission reduction of carbon dioxide.

Owner:林健峰

NdFeB (neodymium iron boron) magnetic material with ultrafine powder and preparation method thereof

InactiveCN103151132AInhibit growthGuaranteed uniformityInorganic material magnetismChemical reactionGrain boundary

The invention discloses a NdFeB (neodymium iron boron) magnetic material with ultrafine powder and a preparation method thereof. The ultrafine powder generated through air-current mill is added into normal magnetic powder which comprises certain amount of Pr-Nd-Dy, mixed rare earth (La-Ce), B, Al, Cu and the balance of Fe to prepare the NdFeB product. Proper addition can enrich rare earth phase; the product is prevented from being oxidized because of over low total amount of rear earth; a crystal boundary is strengthened, and the coercivity is improved; and NdFeB crystalline grains are prevented from being grown in a sintering process, the uniformity of the grains in the product is guaranteed, and the squareness of the product is improved. The granularity of the ultrafine powder is less than 2 mu m, the grains are large in specific surface area and few in defects, so that the surface activity is high, chemical reaction speed is high, the solubility is high, particularly the coercivity is very high, the sintering temperature of a magnetic body is reduced, and the coercivity is increased.

Owner:辽宁恒德磁业有限公司

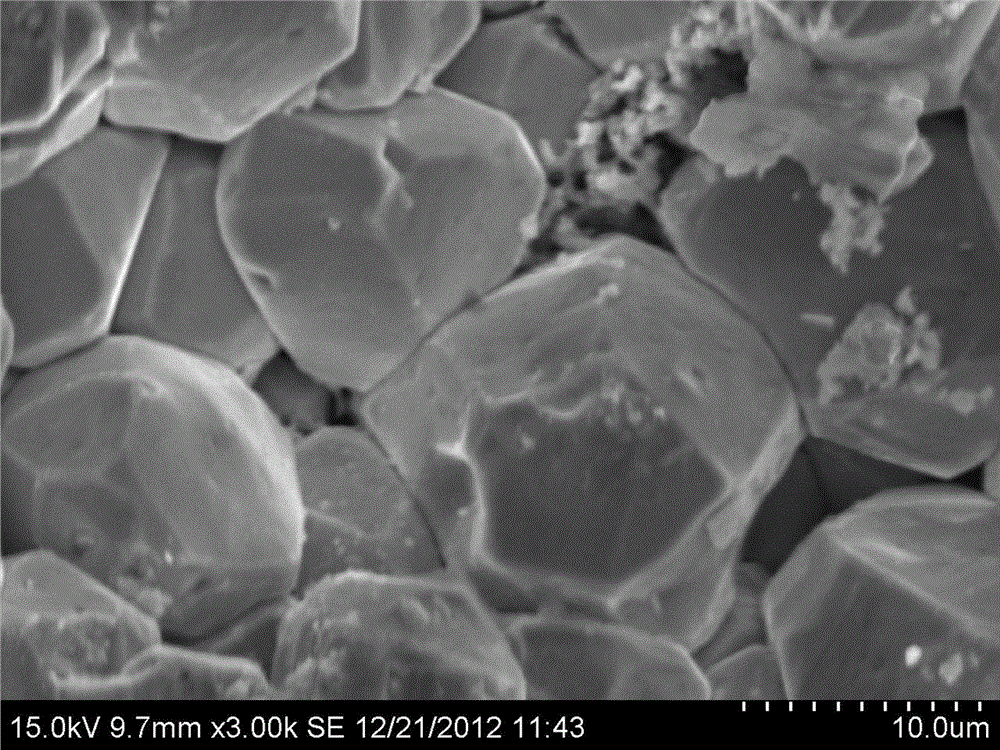

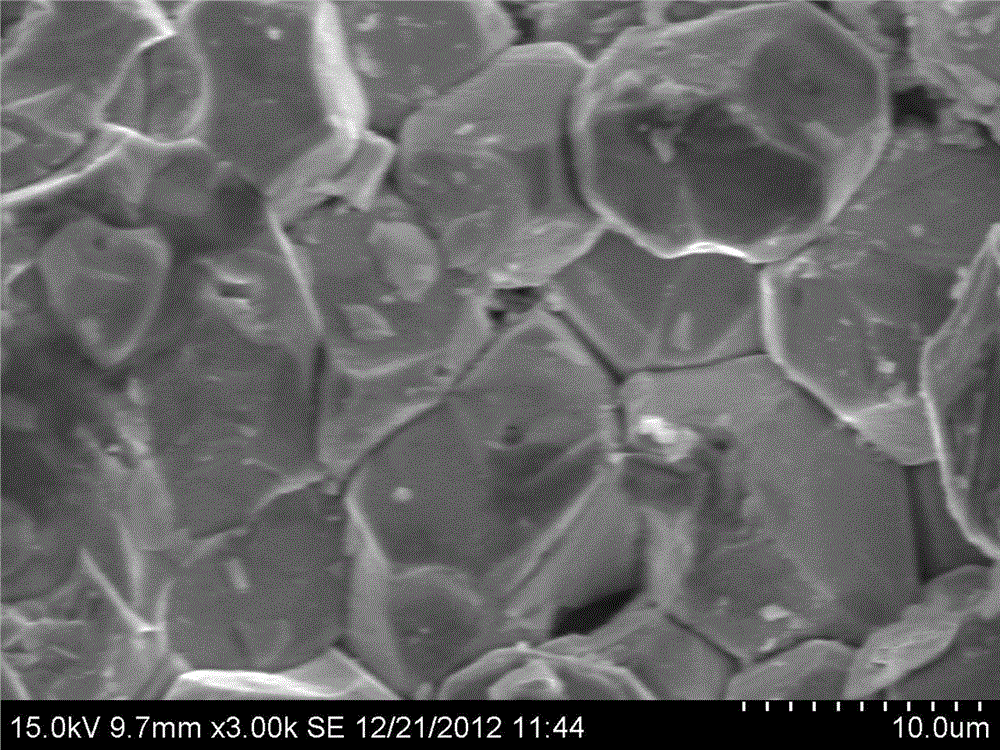

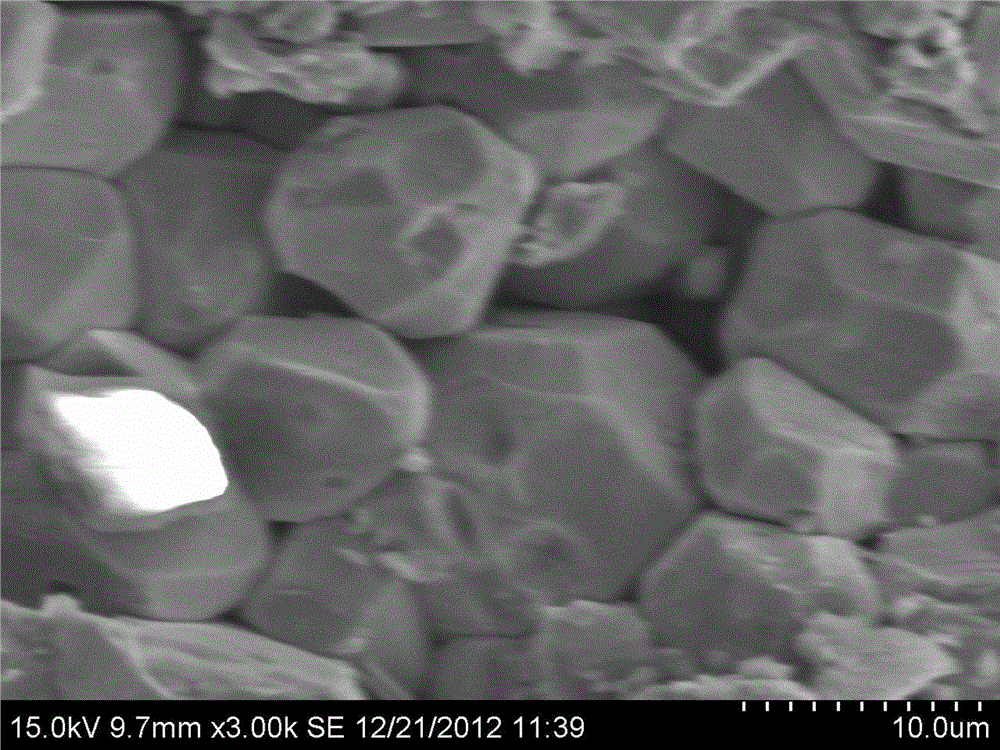

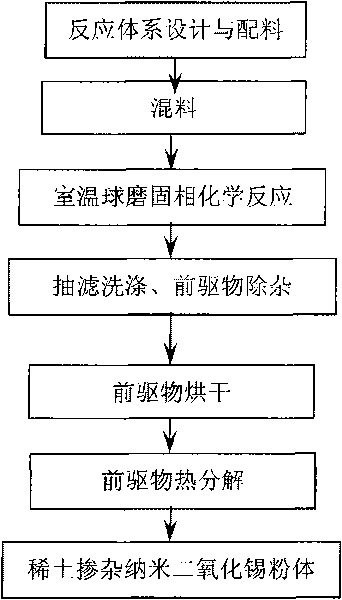

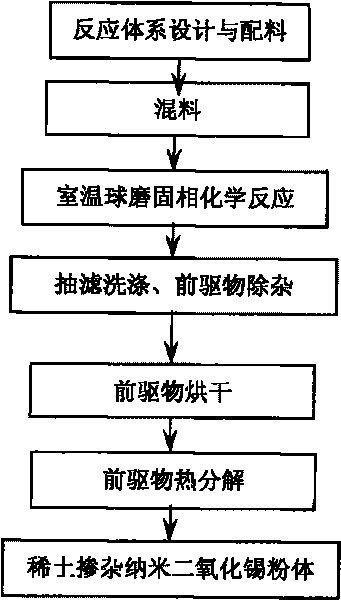

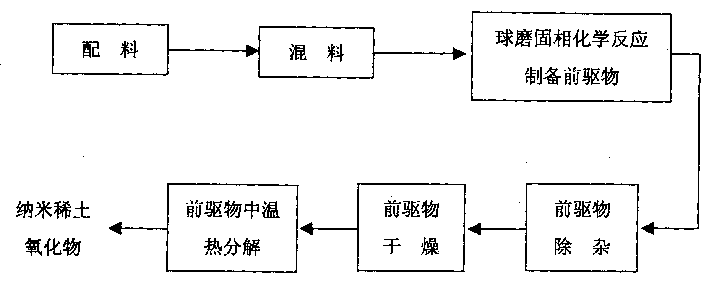

Preparation method of room-temperature ball-milling solid phase chemical reaction of rare earth mixing with nano stannic oxide

InactiveCN101746812ALarge specific surface areaIncrease the speed of diffusionTin oxidesChemical reactionReaction rate

The invention discloses a preparation method of room-temperature ball-milling solid phase chemical reaction of rare earth mixing with nano stannic oxide, relates to a preparation technology of the rare earth mixing with the nano stannic oxide, which can be applied for antistatic coating, plastics, fibre and other fields. Inorganic salts containing stannum and rare earth are taken as reactants, oxalic acid, ammonium carbonate, ammonium bicarbonate, sodium oxalate or sodium carbonate is taken as a ligand, the processing steps are sequentially dosing, mixing and preparing precursors of the room-temperature ball-milling solid phase chemical reaction, and the targeted product can be obtained after impurity removing, drying and thermal decomposition. The preparation method is characterized in that the reaction process does not use water, the stannum ion can be prevented from hydrolysis, uniform mixing can be realized, a solid phase reaction system is broken by utilizing the shearing force and the impact force generated during the ball milling process, the specific surface area of the reactant is increased, the reaction rate is increased, micro-fine and uniform precursors can be prepared, then the processes of cleaning, drying and controlling the thermolysis temperature and time are carried out, and thereby the rare earth mixing with nano stannic oxide powder, the particle size distribution of which is 30 to 80nm and has controllable morphology, can be obtained.

Owner:SICHUAN UNIV

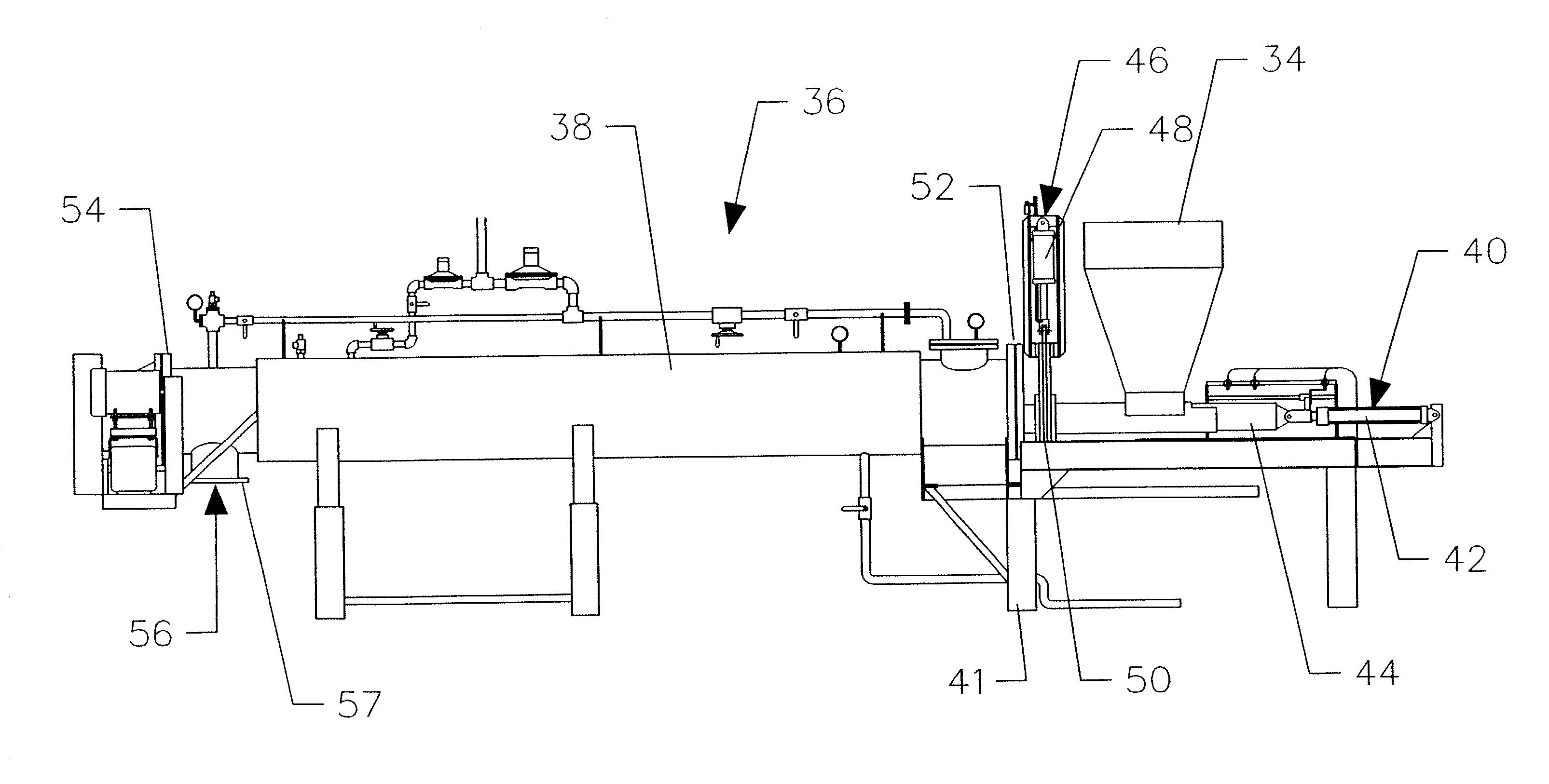

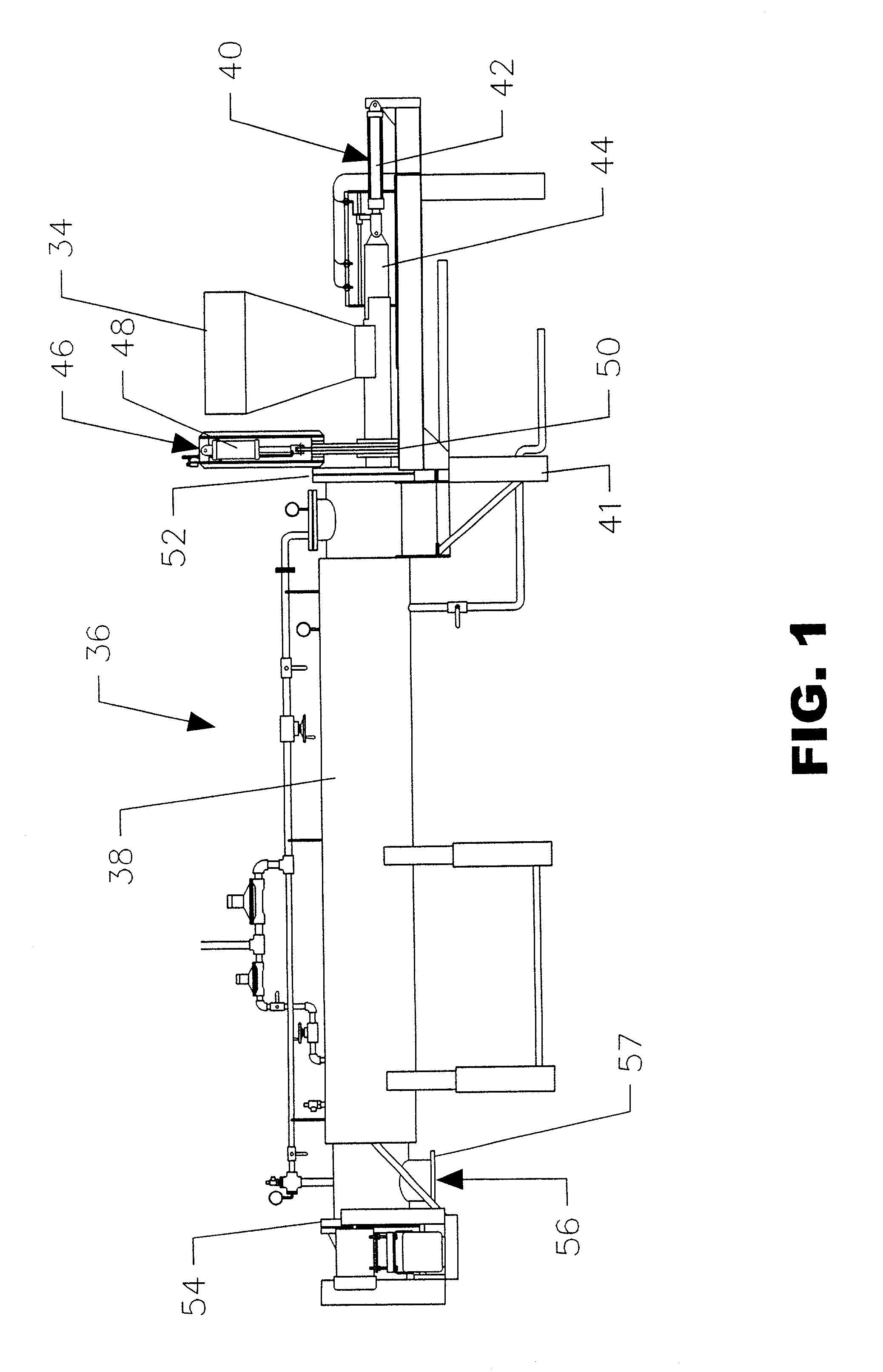

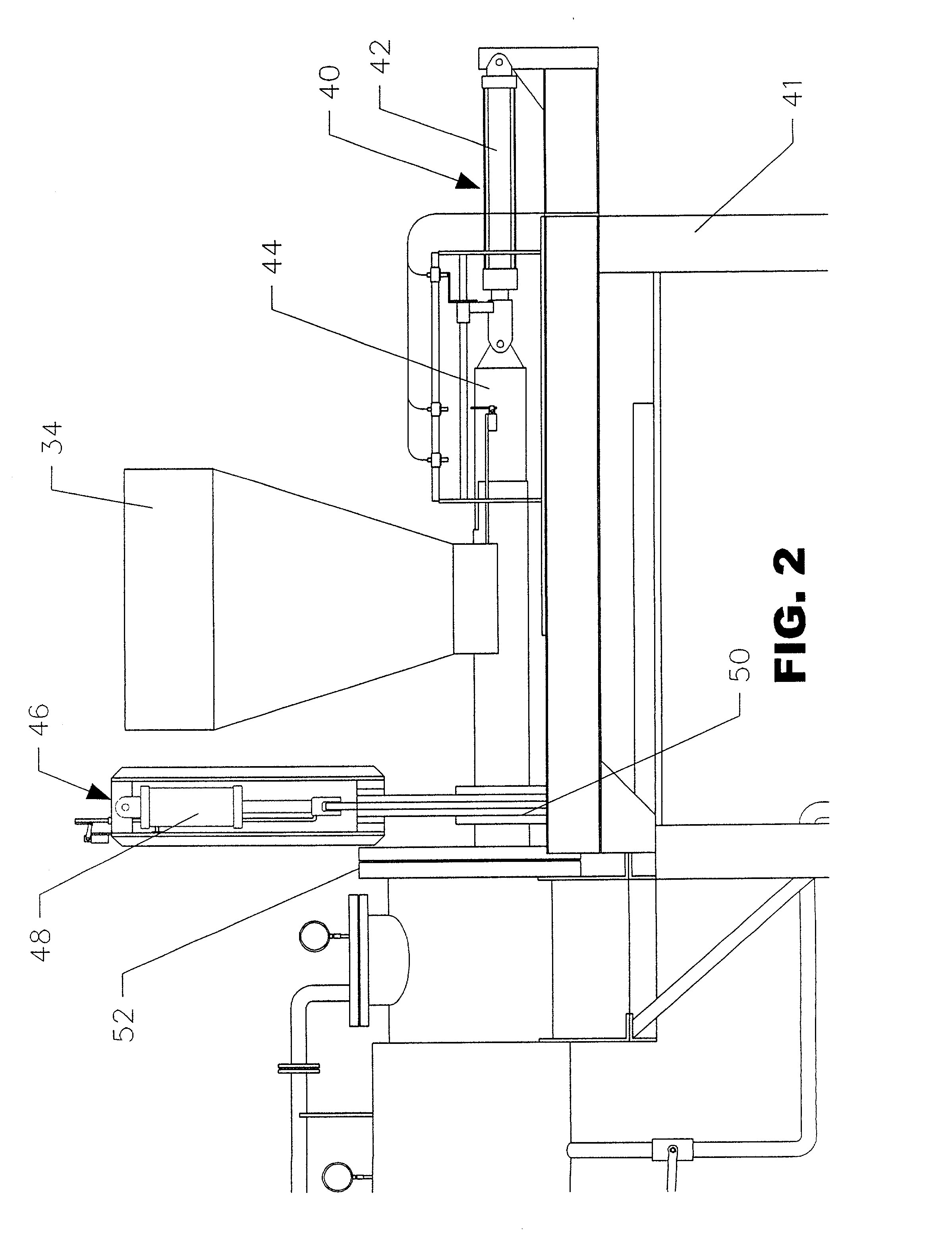

Containment system for continuous flow hydrolyzers

InactiveUS7101164B2Increase pressureIncrease temperatureTransportation and packagingSolid waste disposalReciprocating motionContinuous flow

A material handling system for a hydrolyzer comprises a material injection assembly having a ram; a sleeve in which the ram reciprocates during use; a gate plate operable from between an open position, wherein a plug of municipal solid waste may exit the sleeve, and a closed position; and a material exit assembly. The material exit assembly comprises a processed material handling apparatus including a processed material compaction chamber; and a plunger assembly attached to the compaction chamber and further including a working cylinder having a cylinder shaft and a ram operably connected to the shaft enabling the ram to compact the processed material within the compaction chamber upon actuation of the cylinder and the extension of the shaft therefrom.

Owner:BOULDIN CORP

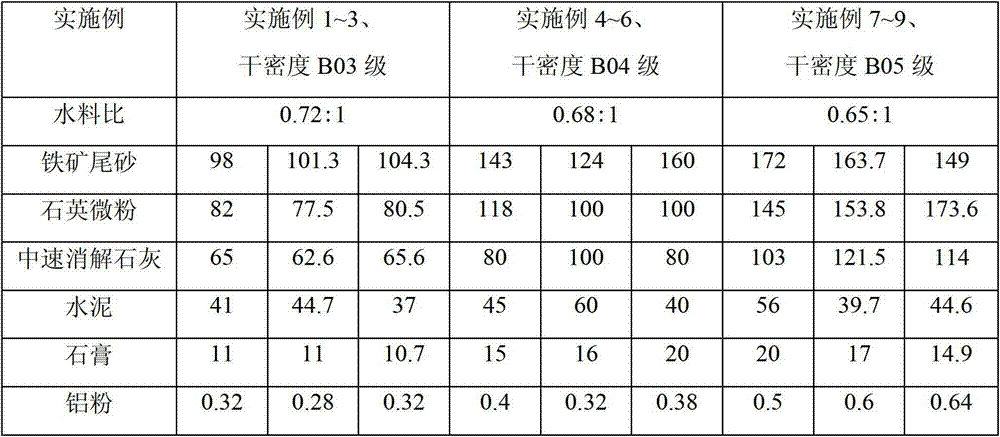

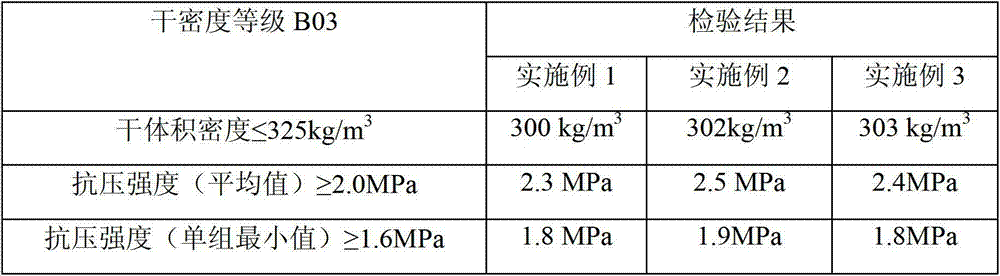

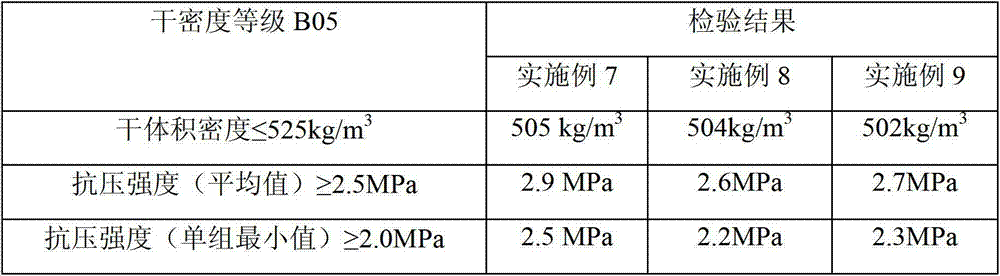

Low-density aerated concrete product and preparation method thereof

The invention discloses a low-density aerated concrete product and a preparation method thereof, and belongs to the technical field of building materials. The preparation method adopting quartz micro powder and iron core tailing, which are respectively 25%-35% and 30%-40% of a dry material, as the primary materials comprises the following steps of: adding cement and lime for cementing; initiating by aluminum powder; and adjusting the component proportion and the steam-curing environment to prepare a light high-strength aerated concrete product with desiccated bulk density of 300kg / m<3>-525kg / m<3> and absolute-dry compressive strength of 2.0 MPa-3.0 MPa. According to the preparation method disclosed by the invention, low-carbon, environment-friendly and energy-saving production concept is adopted, and the quartz micro powder and iron ore tailing, which are discarded after quartz sand ore-dressing, are adopted as the primary materials for producing the low-density autoclaved aerated concrete product as the wall self-insulation material.

Owner:山东高阳建材有限公司

White polyurea waterproof paint and application

ActiveCN105585945AImprove waterproof performanceMeet production speed requirementsPolyurea/polyurethane coatingsPolyolSolid content

The invention relates to white polyurea waterproof paint and application. The waterproof paint is composed of a prepolymer component A and a curing agent component B, wherein the component A is prepared from, by mass, 40-65% of aliphatic polyisocyanate, 30-45% of polyether polyol, 0.1-0.3% of a catalyst and 0.001-0.3% of a polymerization inhibitor; the curing agent component B is prepared from, by mass, 30-60% of amine-terminated polyether resin, 20-50% of chain extender, 10-25% of white filler, 0.3-3% of an ultraviolet absorbent, 0.2-0.5% of a flatting agent and 0.2-0.5% of a dispersing agent. The waterproof paint has the 100% solid content, can be automatically cured completely within 10 min when sprayed onto an asphalt roll and has high luminous reflectance, and the requirement for online production speed of the asphalt roll is met completely.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

NCM ternary cathode material doped with Mo element in surface layer and bulk phase, and preparation method thereof

InactiveCN108878868AStable structureImprove electrochemical performanceSecondary cellsPositive electrodesMo elementManganese

The invention relates to an NCM ternary cathode material doped with a Mo element in a surface layer and a bulk phase, and a preparation method thereof, belonging to the field of chemical energy storage batteries. In total mass of 100% material, Mo element doped in the surface layer and the bulk phase accounts for 0.5-2%, and the other is NCM ternary cathode material. The method comprises the stepsof adding alcohol to a mixture of nickel-cobalt-manganese hydroxide precursor, ammonium molybdate and LiOH.H2O and grinding and mixing uniformly, so as to obtain dry grinded material; calcining the dry grinded material, precalcining the material for 300-400 minutes at 500-550DEG C, then calcining for 800-900 minutes at 700-750DEG C so as to obtain the material. The doped Mo element can stabilizethe material structure, lower charge transfer impedance, and improve electrochemical performance of the material. The method is easy to perform and the process technology are easy to realize.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

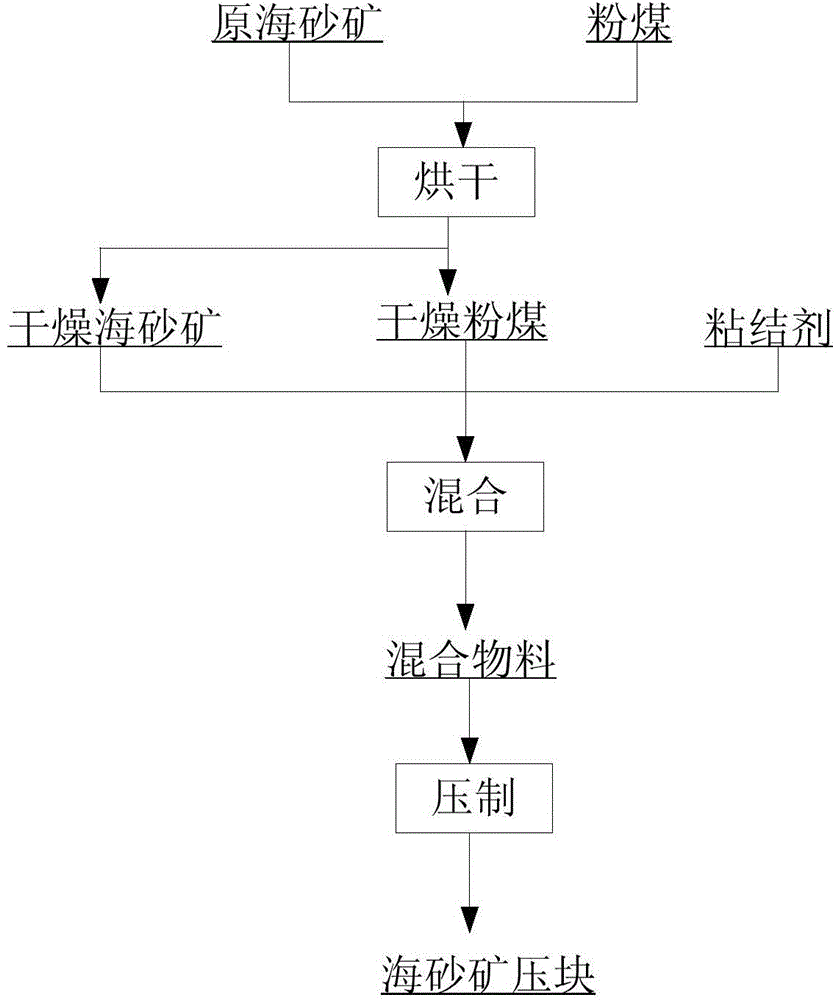

Preparation method for pelletizing and producing yellow phosphorus by phosphorus ore concentrate

The invention provides a preparation method for pelletizing and producing yellow phosphorus by a phosphorus ore concentrate which comprises the following components in terms of producing 1000 Kg of yellow phosphorus: 7100-8500 Kg of phosphorus ore concentrate powder, 1800-2000 Kg of coke dust, 1800-3300 Kg of silica powder, 130 Kg of humic acid and 65 Kg of sodium hydroxide. The preparation method is as follows: grinding formula components by a ball mill; adding a binder composed of the humic acid and the sodium hydroxide, and evenly stirring; processing into a compound pellet by a ball pressing and forming machine; dying by a chain plate dryer; and sending into a yellow phosphorus electric furnace to prepare into a yellow phosphorus finished product. The invention fully utilizes powder phosphate ores and low-grade phosphate ores; the phosphorus ore concentrate powder obtained by mineral separation is produced into a pellet by the binder, and then the pellet is prepared into yellow phosphorus by the electric furnace. Compared with the existing phosphorus preparation by a phosphorus ore concentrate, the invention lowers cost by one time, reduces CO emission by about 35%, reduces electricity consumption by about 40%, improves capacity by 2 times and reduces materials by about 40%. Thus, the invention is an excellent method for solving the problems of high energy consumption, high emission and high pollution for yellow phosphorus production in China.

Owner:瓮安烨烨磷化工实业有限公司

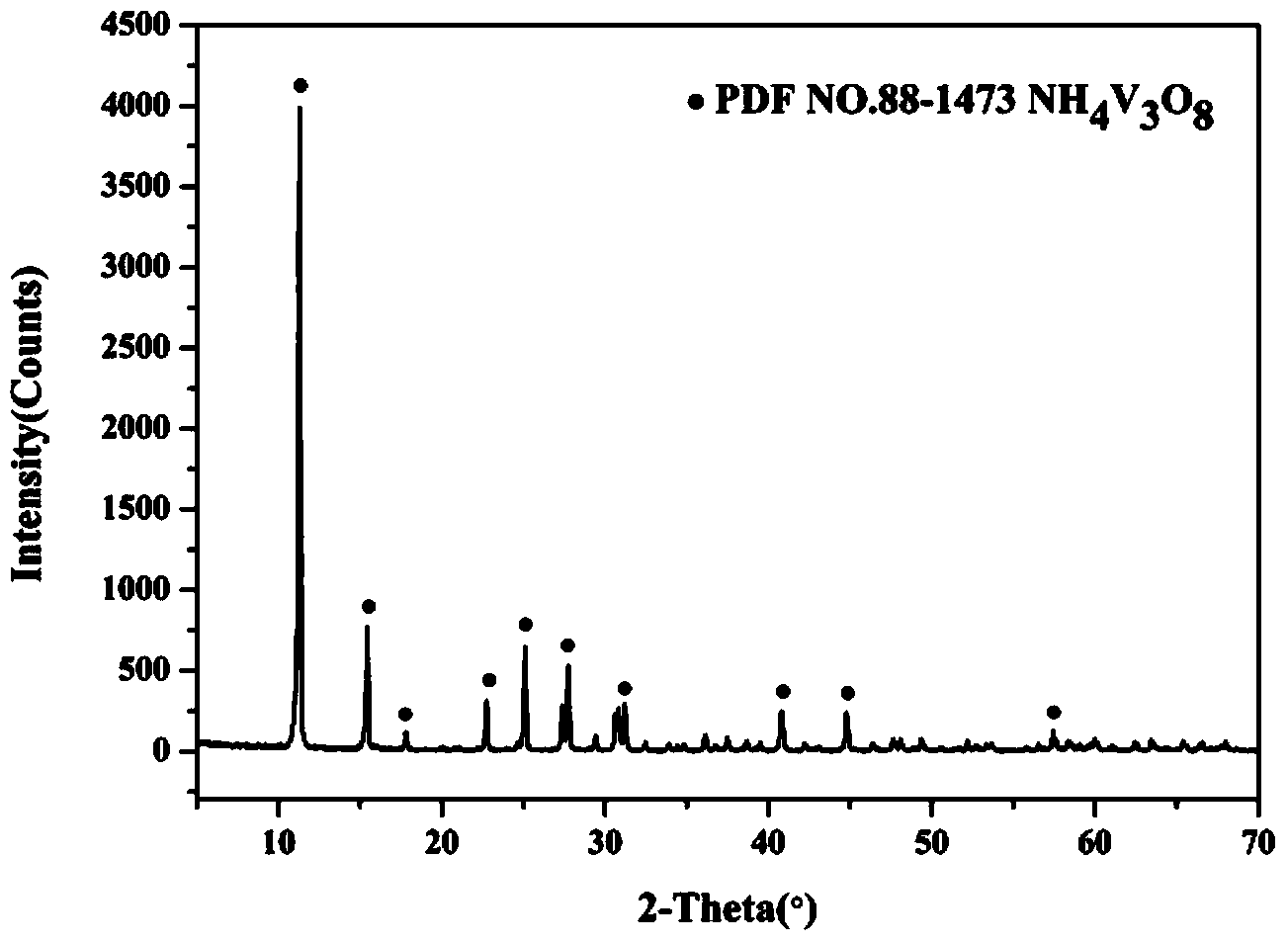

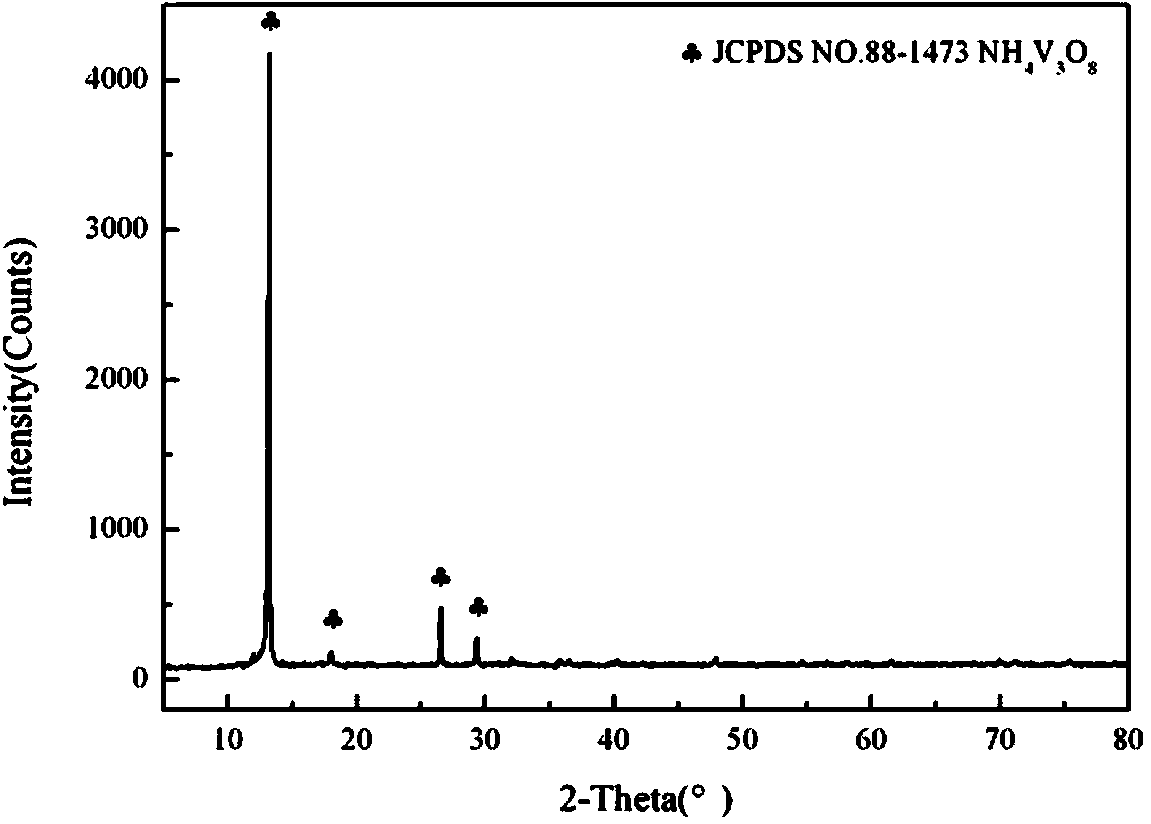

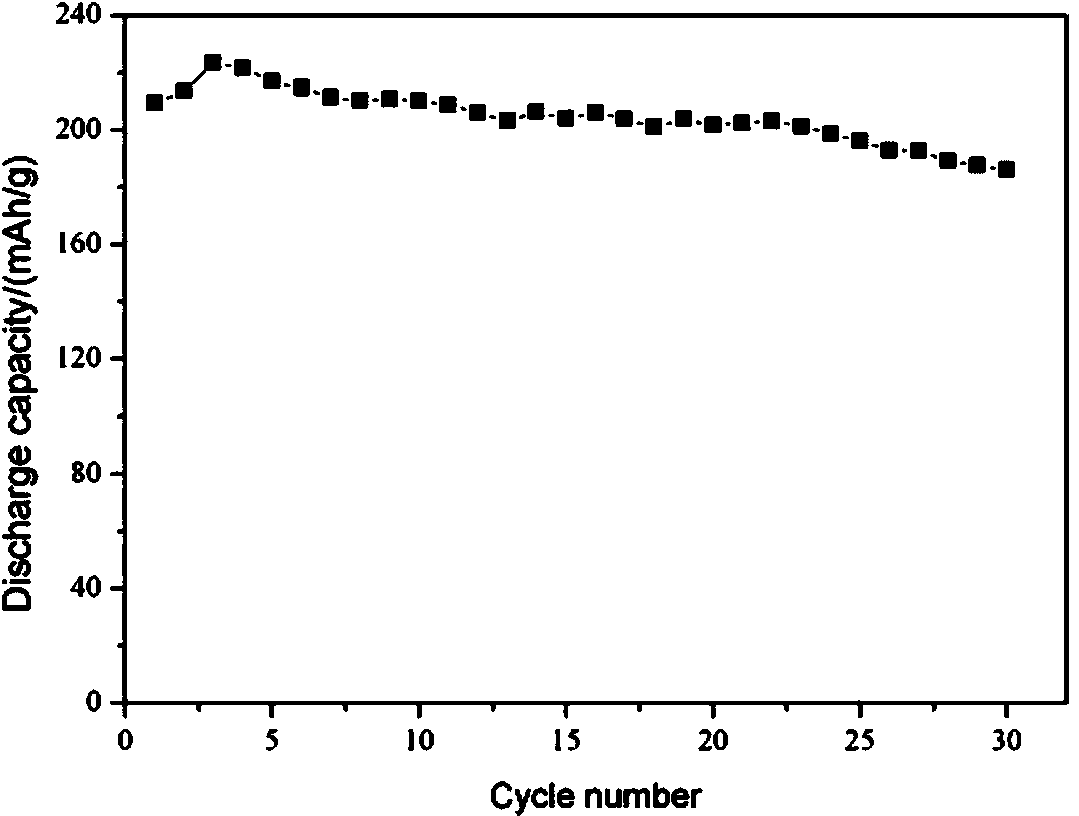

Preparation method of porous structure ammonium vanadate material

ActiveCN103715407AHeating evenlyImprove efficiencyCell electrodesSecondary cellsChemical reactionReaction temperature

The invention provides a preparation method of a porous structure ammonium vanadate material. The preparation method comprises the following steps: dissolving ammonium metavanadate in deionized water so as to obtain a NH4VO3 solution A; adjusting the pH value of the solution A to 1.5-3.0, and then carrying out phonochemistry reaction so as to obtain a solution B; pouring the solution B into a reactor, enabling microwaves and an ultraviolet lamp to simultaneously act on the solution B, heating to 60-90 DEG C, preserving heat, and then naturally cooling to a room temperature; and carrying out centrifugal separation on suspension liquid in the reactor so as to obtain a powder product, washing and drying, thus obtaining the porous structure ammonium vanadate material. The NH4V3O8 microcrystal prepared by the method is uniform in chemical composition and relatively high in purity, is a special porous structure and has good electrochemistry performance when serving as an anode material for a lithium ion battery; the specific area of the material can be effectively enlarged. The preparation method is simple, low in reaction temperature, short in reaction time, environmentally-friendly and suitable for large-scale production; the follow-up treatment is not needed.

Owner:盐城大数据资产经营管理有限公司

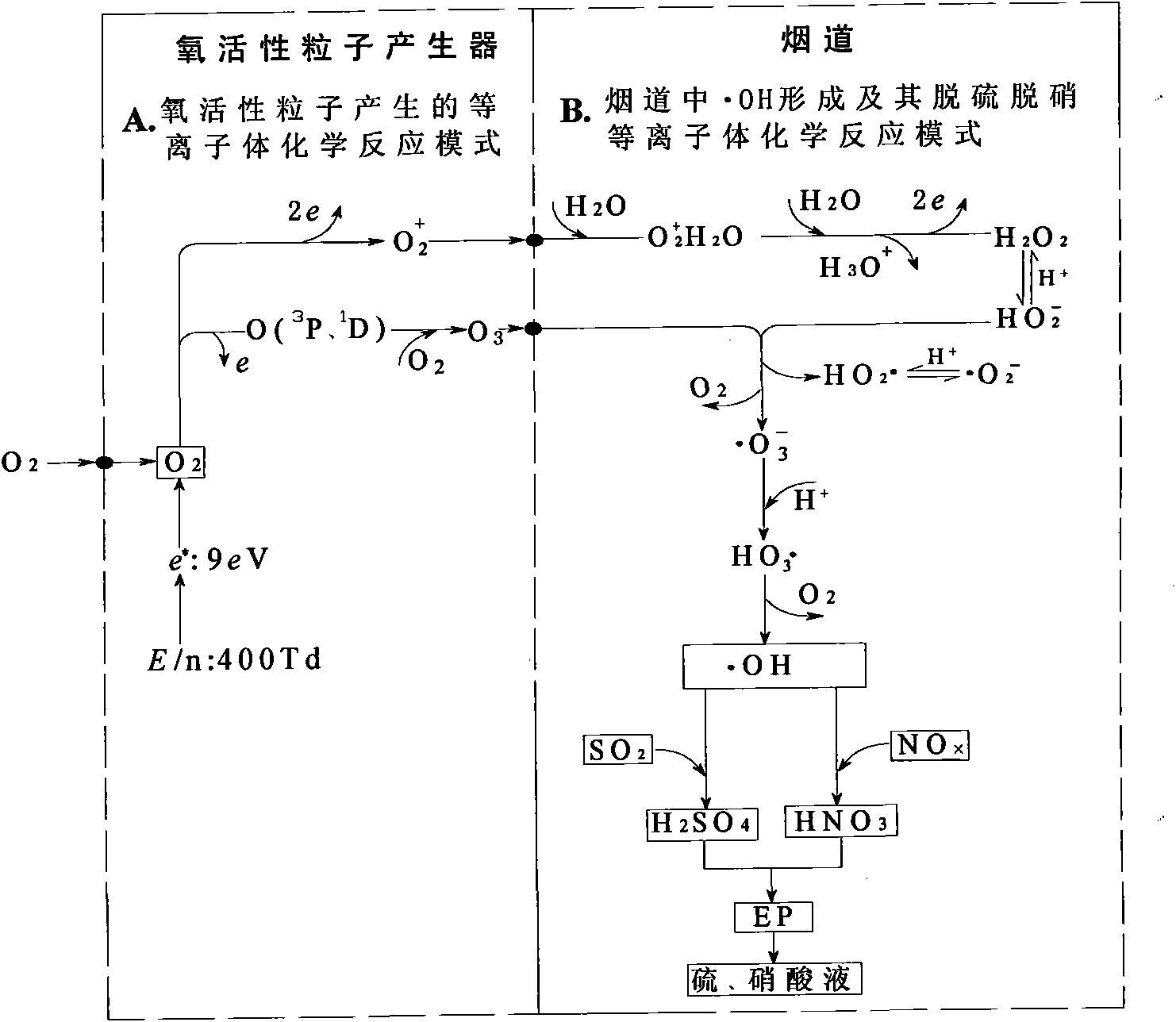

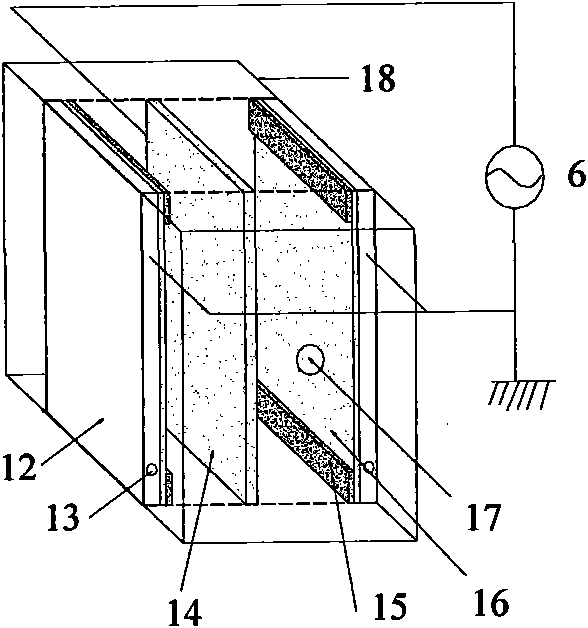

Oxidation sweetening and denitration method for hydroxyl radical of oxygen active particles injected in flue duct

InactiveCN101961596AFast chemical reactionShort processGas treatmentDispersed particle separationOxygenActive particles

The invention discloses an oxidation sweetening and denitration method for hydroxyl radical of oxygen active particles injected in a flue duct, belonging to the technical field of gas ionization discharging, plasma chemistry and environmental engineering application. The invention is characterized in that the oxygen active particles (O<2+>, O3, O(<1>D), O(<3>P)) with the concentration of 80 to 400 mg / L are injected the flue, wherein the O<2+> reacts with the H2O in the flue gas to form the HO2<->initiator, and the oxygen active particles and the HO2<->initiator are subjected to the plasma reaction to form the.OH within the reaction time of 1 mu s to 1 ms. The.OH oxidizes and removes the SO2 and the NOx in the flue gas to generate the submicron acid mist with the reaction time of 1 to 1 s, then the charge coagulation is performed to collect the mixing acid liquid, and finally the sulfuric acid and the nitric acid are separated and purified by chemical methods, wherein the acid resource recovery rate is 50 to 98%. The invention has the effects and the advantages of solving the problems of the existing desulphurization and denitration method of the flue gas, realizing the novel recycling and dry desulphurization and denitration method without using catalysts, absorbent and reducing agents, and generating any re-contaminative by-product and any negative effect to the environment.

Owner:DALIAN MARITIME UNIVERSITY

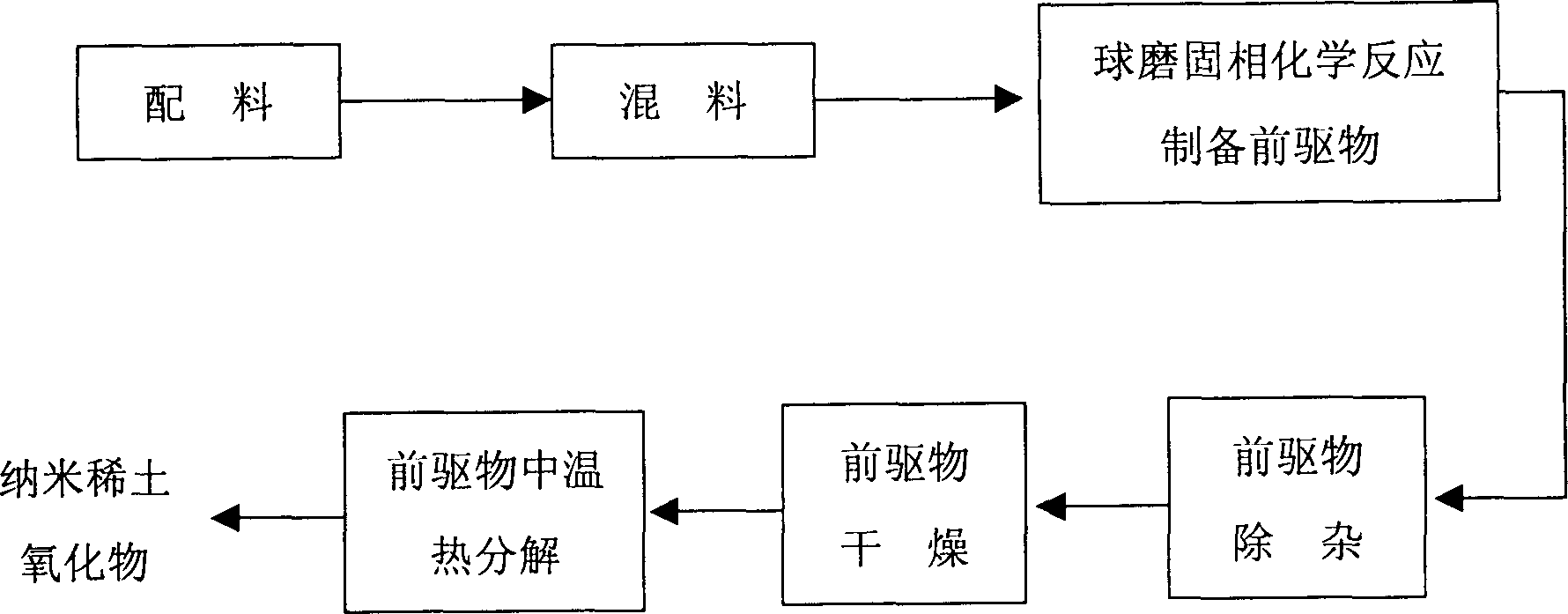

Process for preparing rare-earth nano oxide by ball grinding and solid-phase chemical reaction

InactiveCN1386706AQuick smashIncrease surface areaRare earth metal compoundsSodium acetrizoateRare-earth element

A nano rare-earth oxide is prepared from the inorganic salt of rare-earth element (Ce, La, Pr, Nd, or Tb) and ligand (oxalic acid, sodium oxalate, dicarbonate, 8-hydroxyquinoline, complexon, etc) through proportioning, mixing, and ball grinding while solid-phase chemical reaction to obtain precursor, removing impurities, drying, and medium-temp thermal decomposition. Its advantages are simple process, low cost, saving energy, high purity (more than 99%) and narrow size distribution (10-30 nm).

Owner:SICHUAN UNIV

Method for producing phosphoric acid through ground phosphate rock in fast hot-melting mode

The invention relates to a technique method for producing phosphoric acid in fast hot-melting mode with low-quality and medium-quality ground phosphate rock and silica powder as the raw materials and pulverized coal as the heating energy. The method is characterized in that the ground phosphate rock and the silica powder finish the chemical reaction of calcium phosphate and silica in a rotary-flow melting calcining kiln at the temperature of 1450-1800 DEG C within 2 minutes, calcium metasilicate melted slag and phosphorus pentoxide furnace gas can be produced, phosphoric acid is obtained through heat exchanging, dedusting and hydration absorption of the furnace gas, and cement clinker can be obtained by adding proper amount of additives such as calcium carbonate or calcium oxide powder in the calcium metasilicate melted slag at the temperature of 1400 DEG C. By means of the method, phosphorus pentoxide is prepared from phosphate ore in one step directly, the existing processes of phosphate ore reduction and phosphorus oxidization are omitted, carbon for reducing is saved, and the technological process is simplified. The puzzle that in the existing rotary kiln process, tunnel kiln process and blast furnace process, materials become rings, the kiln temperature is difficult to control, reaction rate is low, the device cannot operate continuously, and industrial application is difficult is solved.

Owner:黄靖元

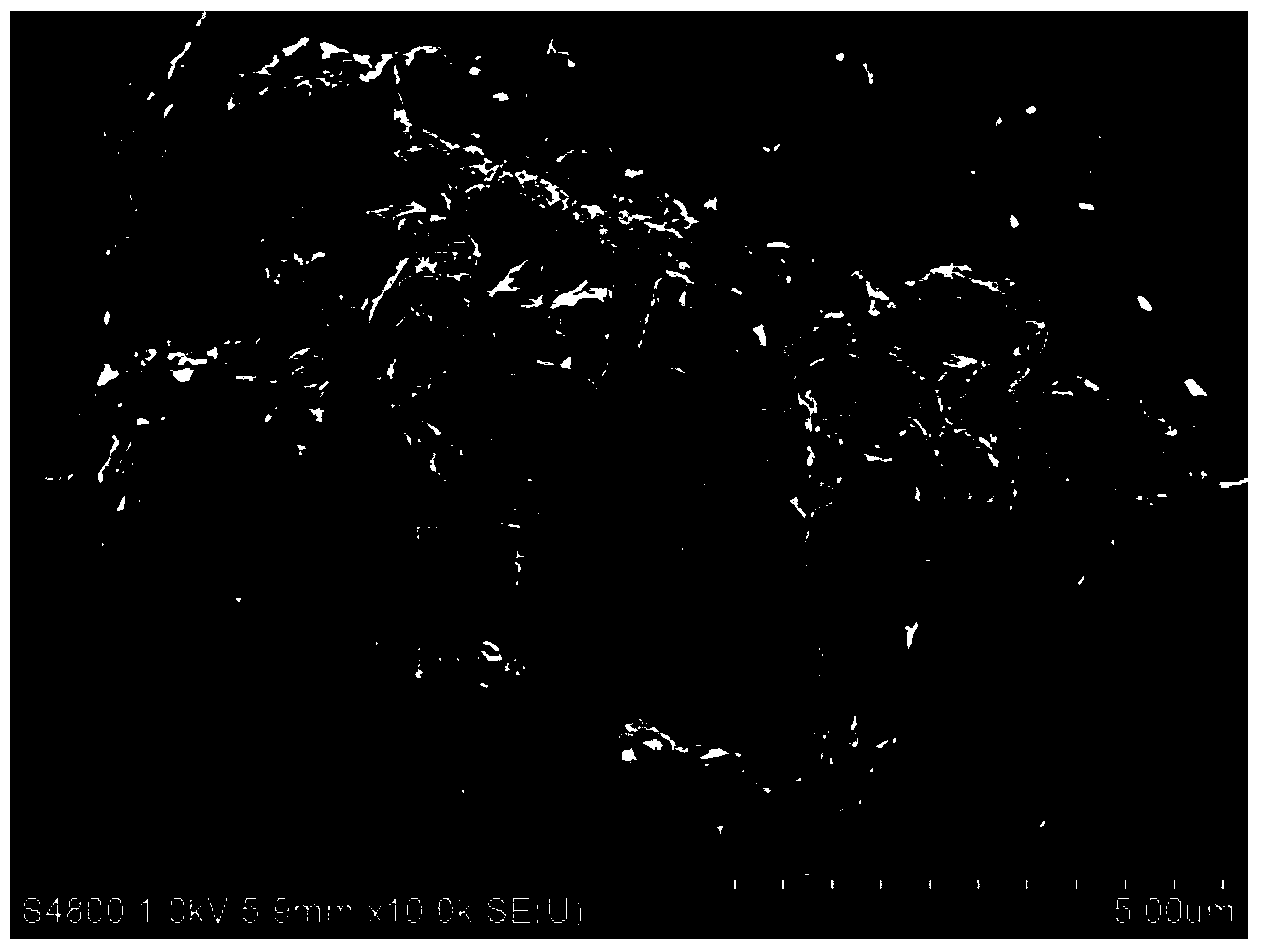

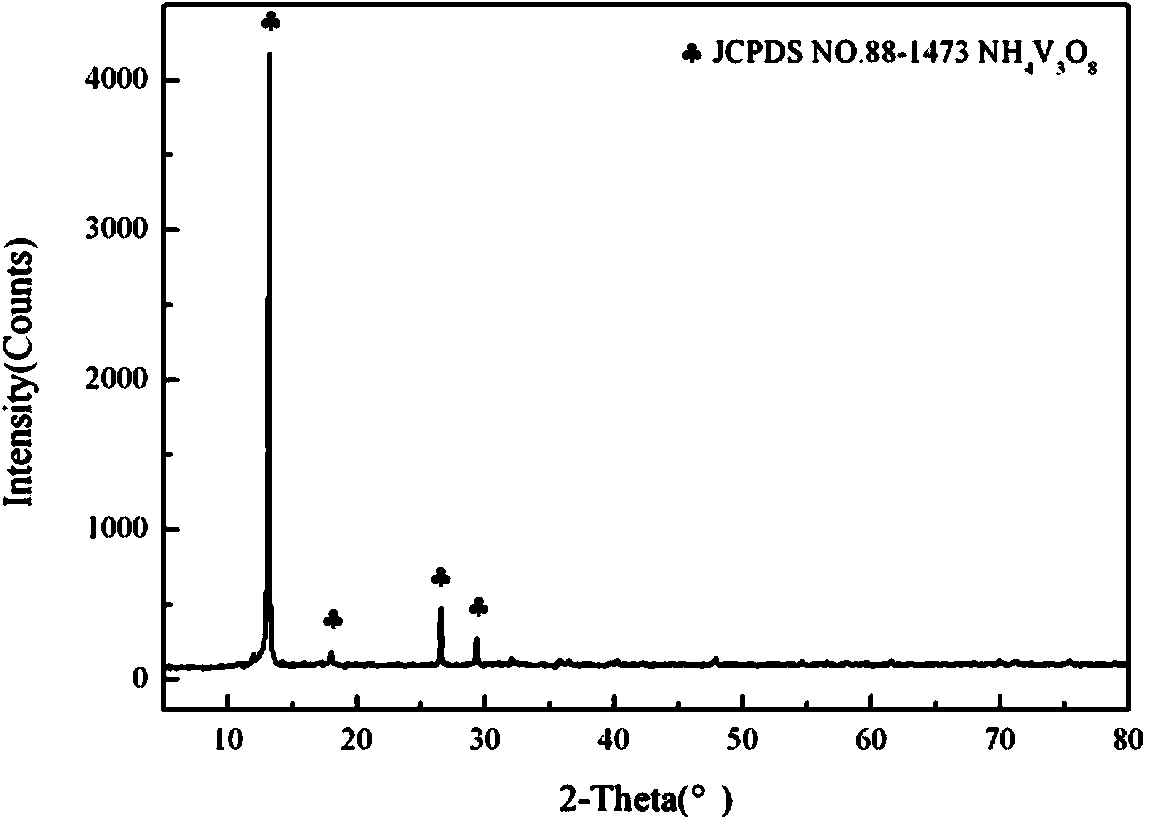

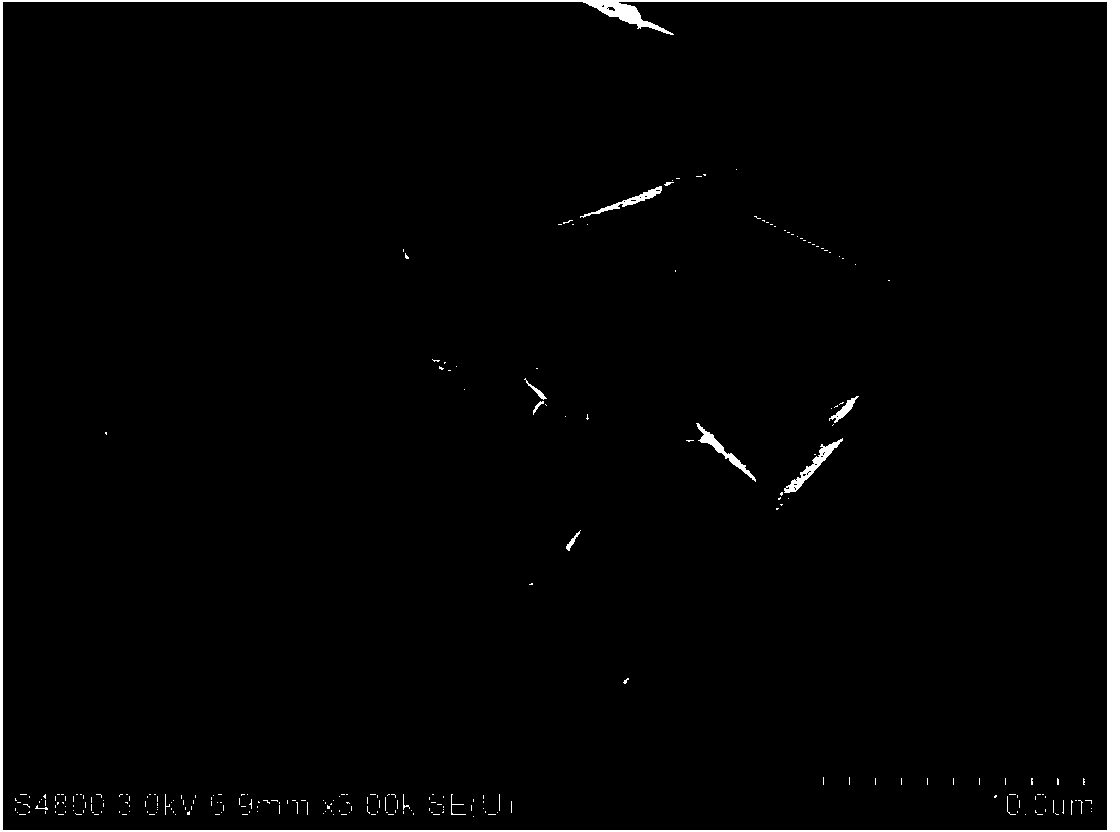

Preparation method for card-shaped NH4V308 micro crystal

ActiveCN103490065AUniform chemical reactionImprove efficiencyCell electrodesNanotechnologyMicrowaveChemical composition

Disclosed is a preparation method for a card-shaped NH4V308 micro crystal. Ammonium metavanadate is dissolved in deionized water to prepare an NH4VO3 solution with the concentration of NH4+ being 0.03-0.15mol / L, and then the pH of the solution is regulated to be 3.5-4.5 to obtain a solution B; microwaves and an ultraviolet lamp simultaneously act on the solution B in a microwave and ultraviolet combined mode, the temperature rises to be at 50-90 DEG C and then is kept, and suspension liquid is obtained; centrifugal separation is carried out on the suspension liquid to obtain powdery products, and then the products are dried. The NH4V308 micro crystal prepared in the method is uniform in chemical composition, is high in purity and is shaped like a card, the thickness of the NH4V308 micro crystal is about 200-500nm, and the NH4V308 micro crystal has good electric chemical performance when serving as anode materials for a lithium ion battery. The preparation method for the card-shaped NH4V308 micro crystal is simple, low in reaction temperature, short in reaction period, without subsequent processing, friendly to the environment, and suitable for large-scale production.

Owner:盐城抱璞文化传媒有限公司

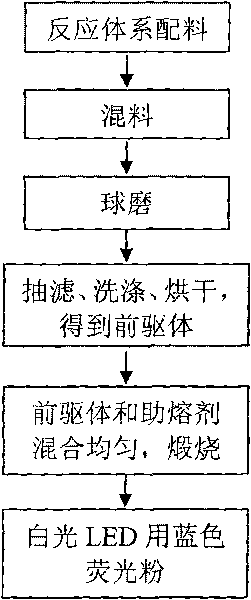

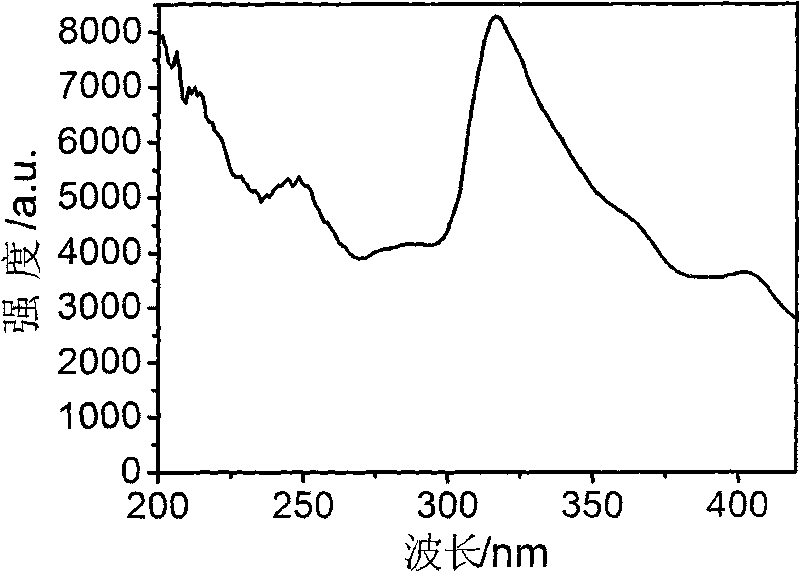

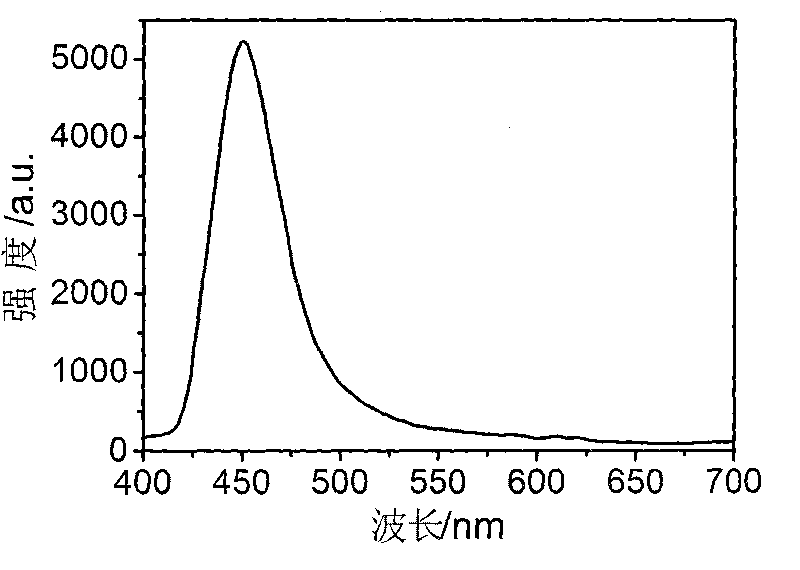

Blue fluorescent powder for white-light LED and preparation method thereof

InactiveCN101735804AHigh luminous intensityGood color renderingGas discharge lamp usageLuminescent compositionsSolid phasesChemistry

The invention relates to blue florescent powder for a white-light LED, belonging to the technical field of rare earth luminescent materials. The blue florescent powder has a chemical formula of: Ca<1-x>SiO3:xEu2+, wherein x is more than 0 and less than 0.2. The preparation method comprises the following steps of: respectively weighing calcium salts, silicic acid, europium nitrate and an appropriate amount of surfactant and fluxing agent according to the stoichiometric ratio in the chemical formula; fully mixing the weighed reactant, the surfactant and an appropriate amount of ligands and then ball-milling, and adding a lubricating agent when in ball-milling; filtering, washing and drying to obtain a precursor; evenly mixing the precursor with the fluxing agent, and then calcining under the reducing atmosphere to obtain the required florescent powder. In the invention, the blue florescent powder for the LED is prepared by adopting a mechanical force solid-phase chemical reaction method, the specific surface area of the reactant is increased by utilizing the shearing force and the impact force generated in the ball-milling process, the contact face and the diffusion speed of the reactant are improved, and the required time in the chemical reaction is shortened. The prepared fluorescent powder has high luminescent strength as well as good color rendering property and stability, and is suitable for LEDs excited by ultraviolet and near ultraviolet.

Owner:SICHUAN UNIV

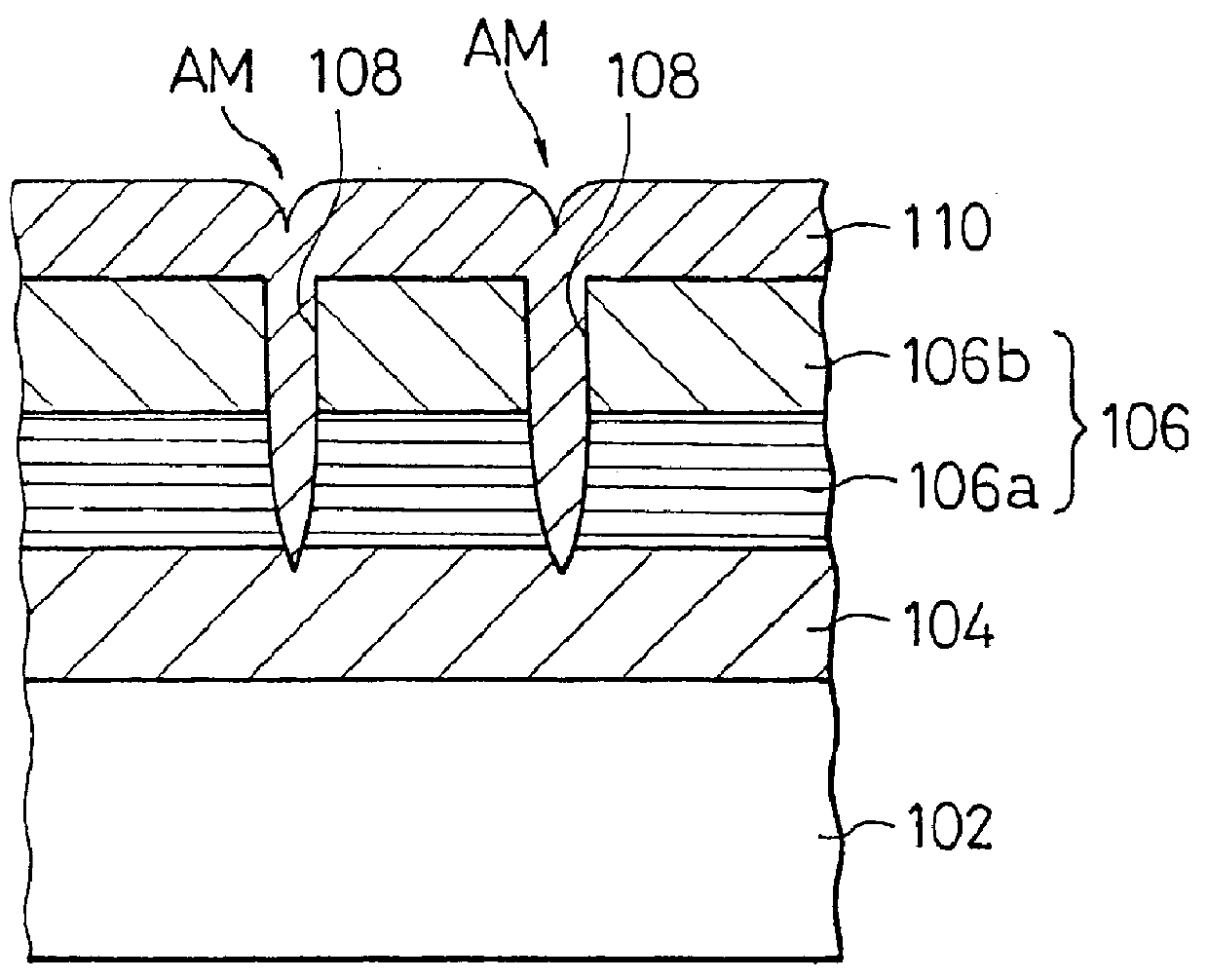

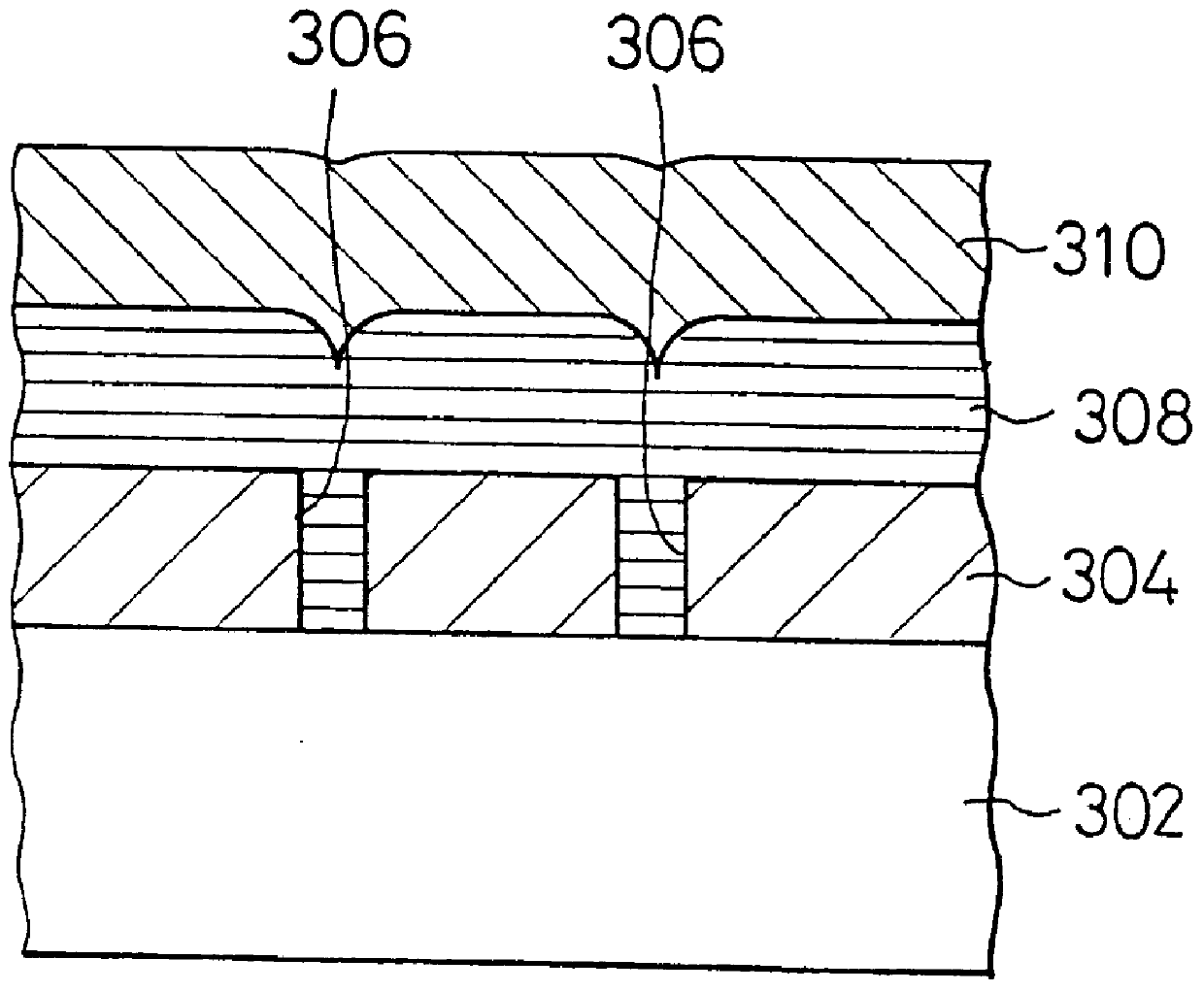

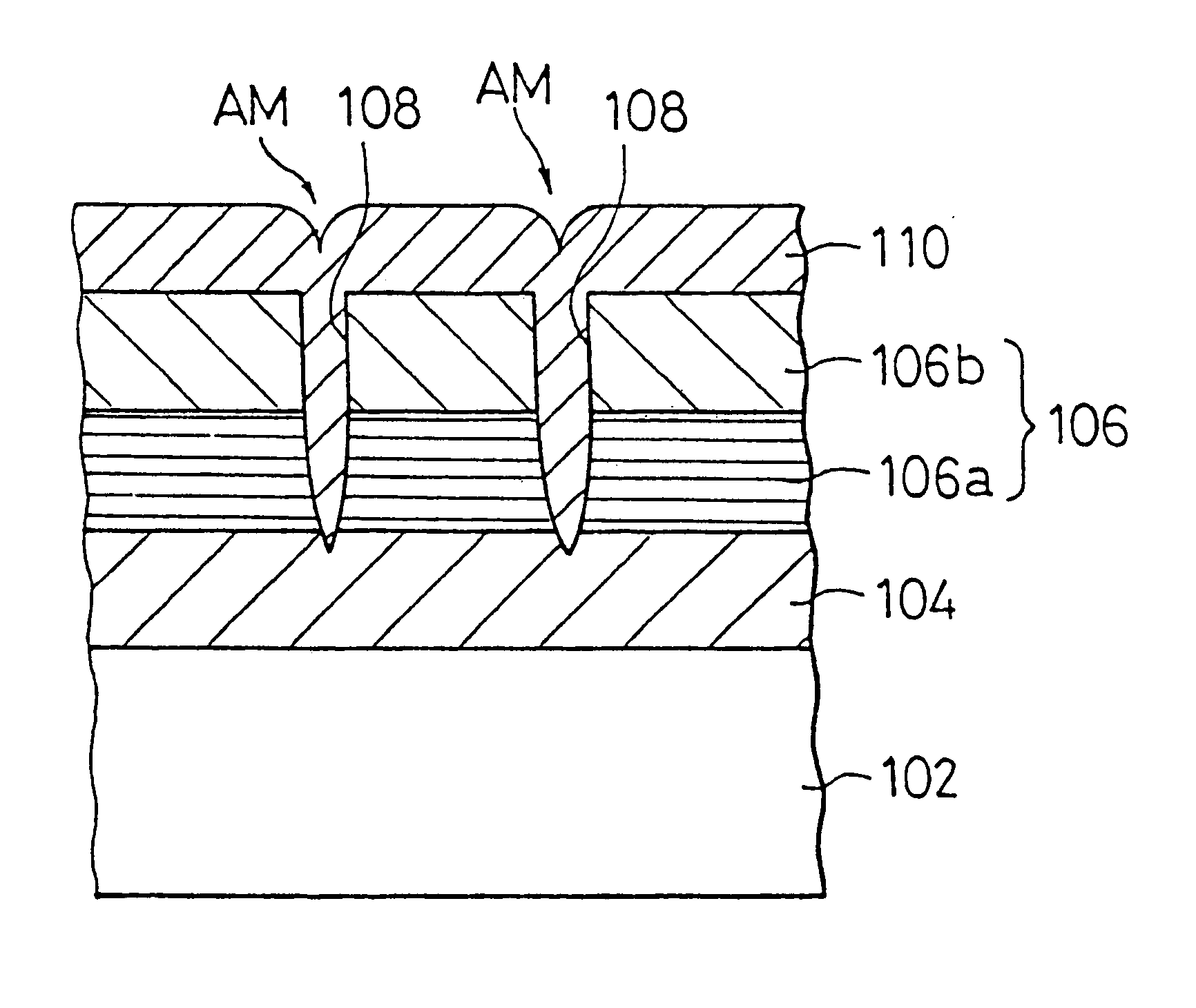

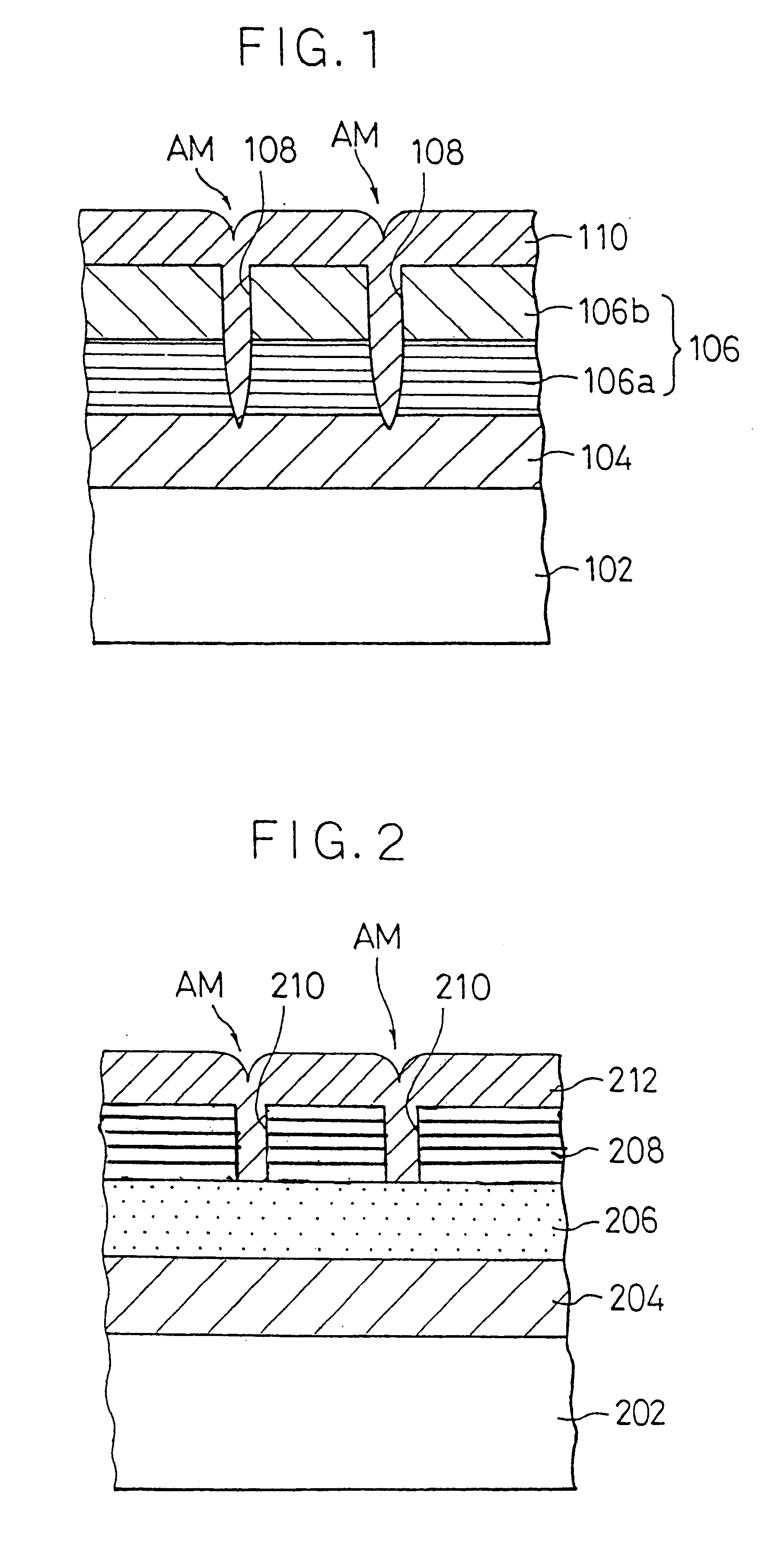

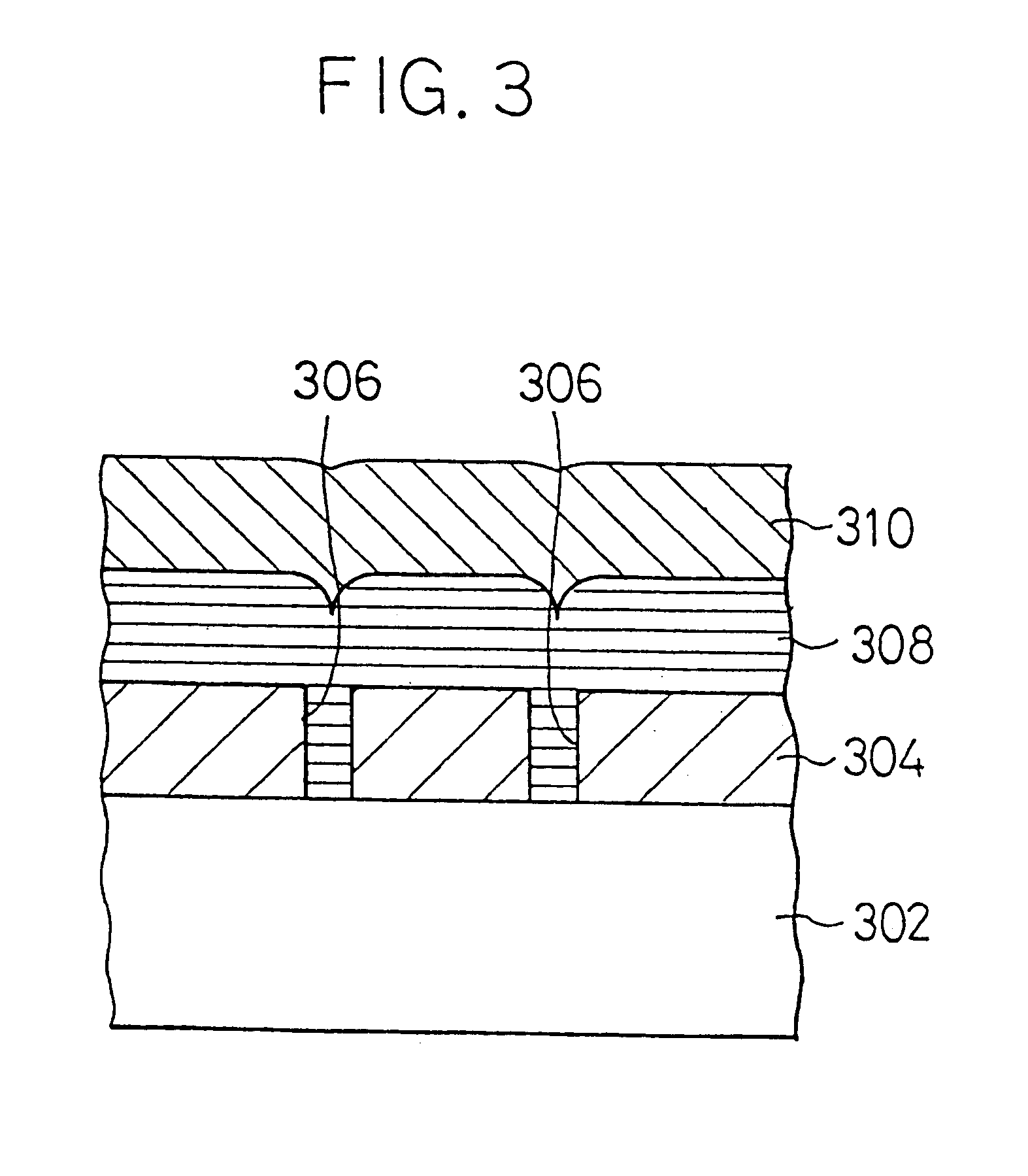

Formation of alignment mark and structure covering the same

InactiveUS6100157AStable maintenanceFast chemical reactionSemiconductor/solid-state device detailsSolid-state devicesSiliconMaterials science

An alignment mark AM appears on the surface of an aluminum (Al) wiring layer 110 when the Al wiring layer is formed to fill up a recess 108 therewith, the recess 108 being formed in oxide layers 104 and 106 formed over the surface of a silicon substrate 102 by etching these layers in part. The depth of the recess 108 is controlled such that there is formed no direct contact between the Al wiring layer 110 and the metallic silicon of the silicon substrate 102. Consequently, in the process of forming the alignment mark, the Al wiring layer 110 is prevented from chemically reacting with the metallic silicon. Thus, there is caused neither deterioration in the quality of oxide films 104 and 106, nor destruction of the alignment mark AM appearing on the surface of the Al wiring layer 110, even if the Al wiring layer 110 is formed by sputtering aluminum on oxide layers and the recess as well at a high temperature.

Owner:LAPIS SEMICON CO LTD

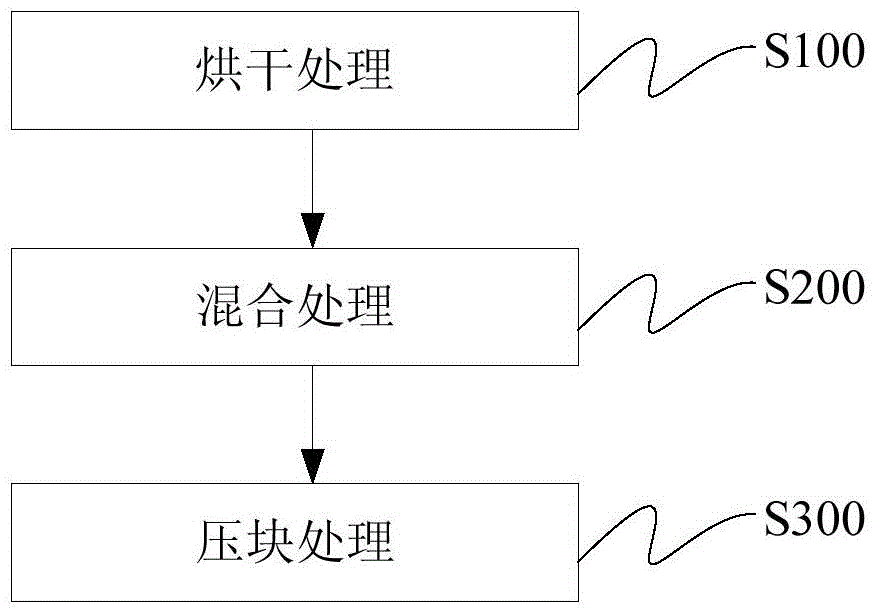

Pretreatment method of marine placer

InactiveCN104593590AImprove smelting efficiencyReduce smelting energy consumptionFluidised-bed furnacesPretreatment methodEngineering

The invention provides a pretreatment method of marine placer. The pretreatment method comprises the steps of performing drying treatment on the raw marine placer and pulverized coal to obtain dry marine placer and dry pulverized coal, mixing the dry marine placer, the dry pulverized coal and a binder to obtain a mixture, and pressing the mixture to obtain a marine placer briquette. The pretreatment method is capable of effectively preparing the marine placer into the marine placer briquette, and then the efficiency and the yield of preparing direct reduction iron from the marine placer can be improved remarkably.

Owner:张诚 +1

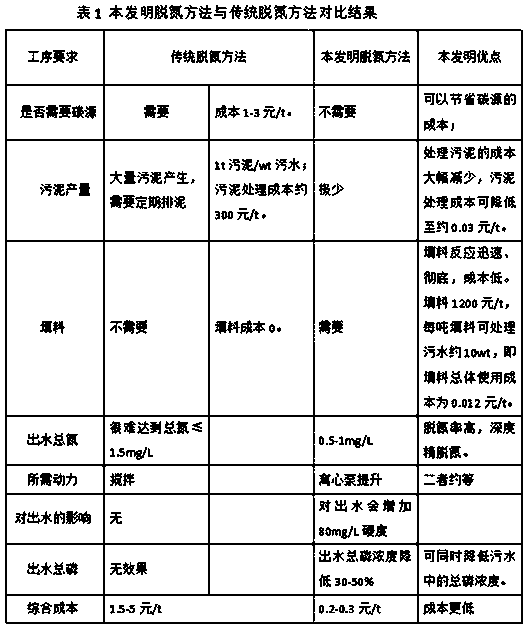

Denitrification filler and method for deep denitrification of municipal sewage

ActiveCN108033557ALow costAbundant sources of raw materialsSpecific water treatment objectivesWater contaminantsSodium silicateMunicipal sewage

The invention discloses denitrification filler and a method for deep denitrification of municipal sewage. The denitrification filler is prepared from the following raw materials by weight percent: 0.5-1.5% of aluminum powder, 8-12% of aluminum hydroxide, 3-8% of sulfur powder, 15-25% of sodium thiosulfate, 1.5-3% of sodium silicate, 40-55% of calcium hydroxide, 1.5-3% of fine sawdust and the balance of water. The denitrification filler is insoluble in the water, can react for a long time, is not powdered or argillation, and is low in cost, rich in source of raw materials and simple in preparation method; the method for the deep denitrification of the municipal sewage combines a chemical method and a biological method, thus having the advantages of being rapid and thorough of the chemical reaction as well as the advantages of being low in cost and having environmental adaptability of the biological method; therefore, the method provided by the invention is an efficient deep denitrification method.

Owner:中原环保股份有限公司

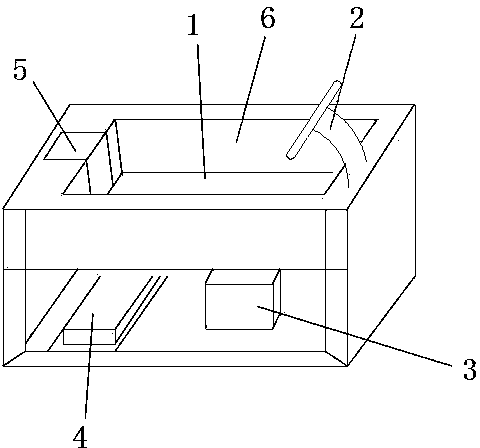

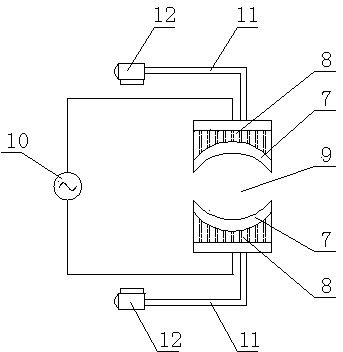

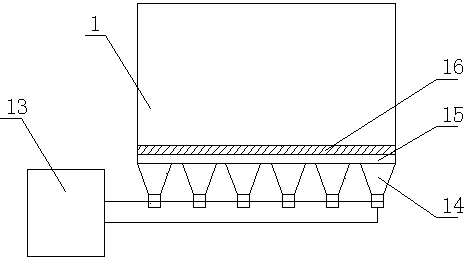

Device and method for degrading pesticide residues in traditional Chinese medicinal materials

InactiveCN103656957AImprove the effect of removing pesticide residues in Chinese herbal medicinesAggressiveChemical protectionPesticide residueHydroxyl radical

The invention discloses a device for degrading pesticide residues in traditional Chinese medicinal materials. The device comprises a cleaning water tank, a hydroxyl radical generator, an ultrasonic system and a photocatalyst. Meanwhile, the invention provides a method for degrading pesticide residues in traditional Chinese medicinal materials. The method comprises the steps of soaking; hydroxyl radical oxidation; ultrasonic cleaning and the like. The device can be used for safely and efficiently cleaning the traditional Chinese medicinal materials and has a favorable pesticide residue removal effect.

Owner:长沙安迪生物科技有限公司

Modified process for synthesis or perovskite ceramics

InactiveUS20070056840A1Improve microstructureEasy to controlOxygen/ozone/oxide/hydroxideIron compoundsCeramicPhotochemistry

The present invention relates to a process for the synthesis of perovskite ceramics and more particularly relates to the preparation of perovskites with general formula LnMO3, where Ln represents lanthanide element and M a transition metal.

Owner:COUNCIL OF SCI & IND RES

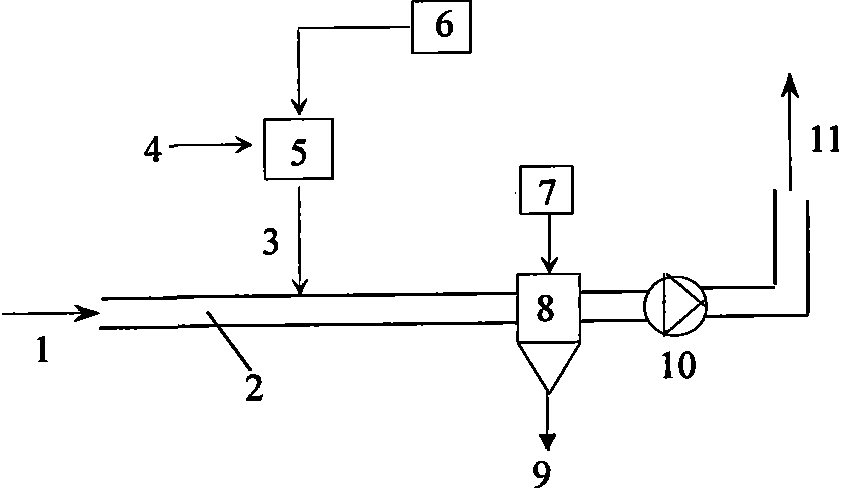

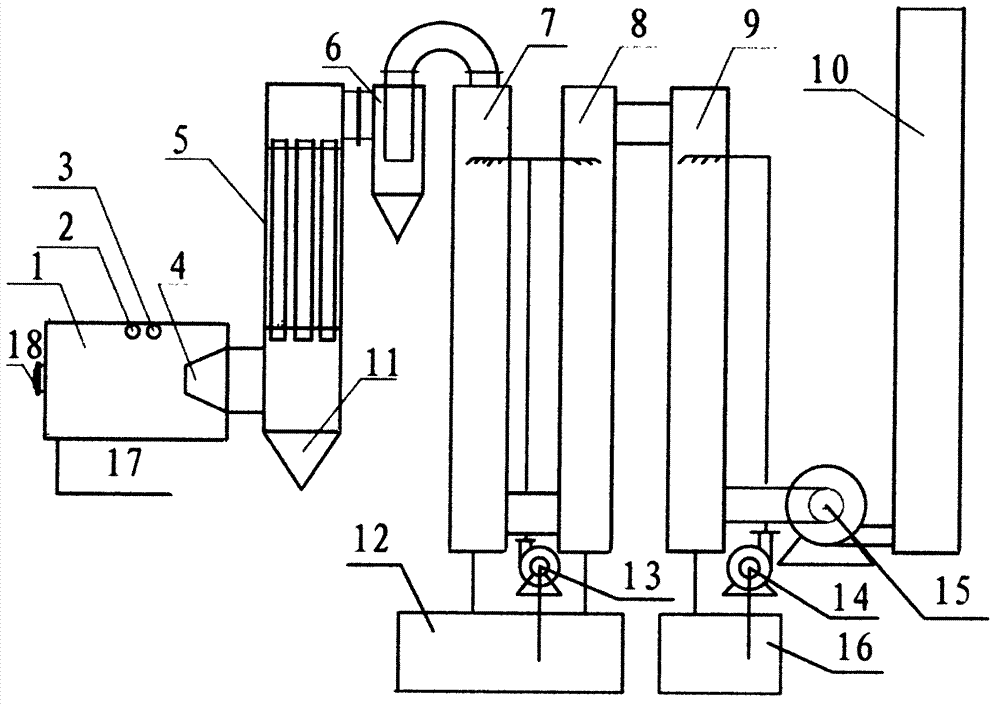

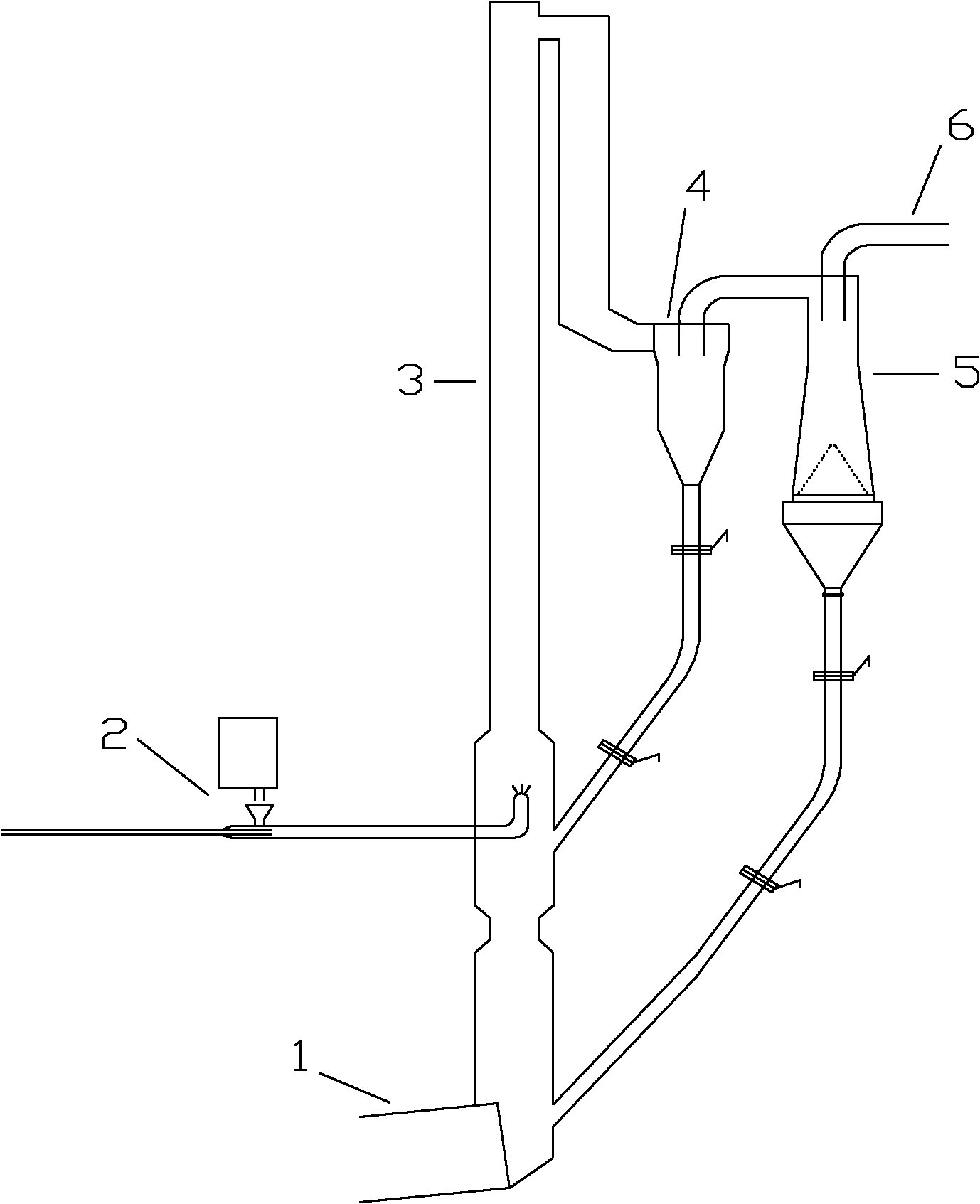

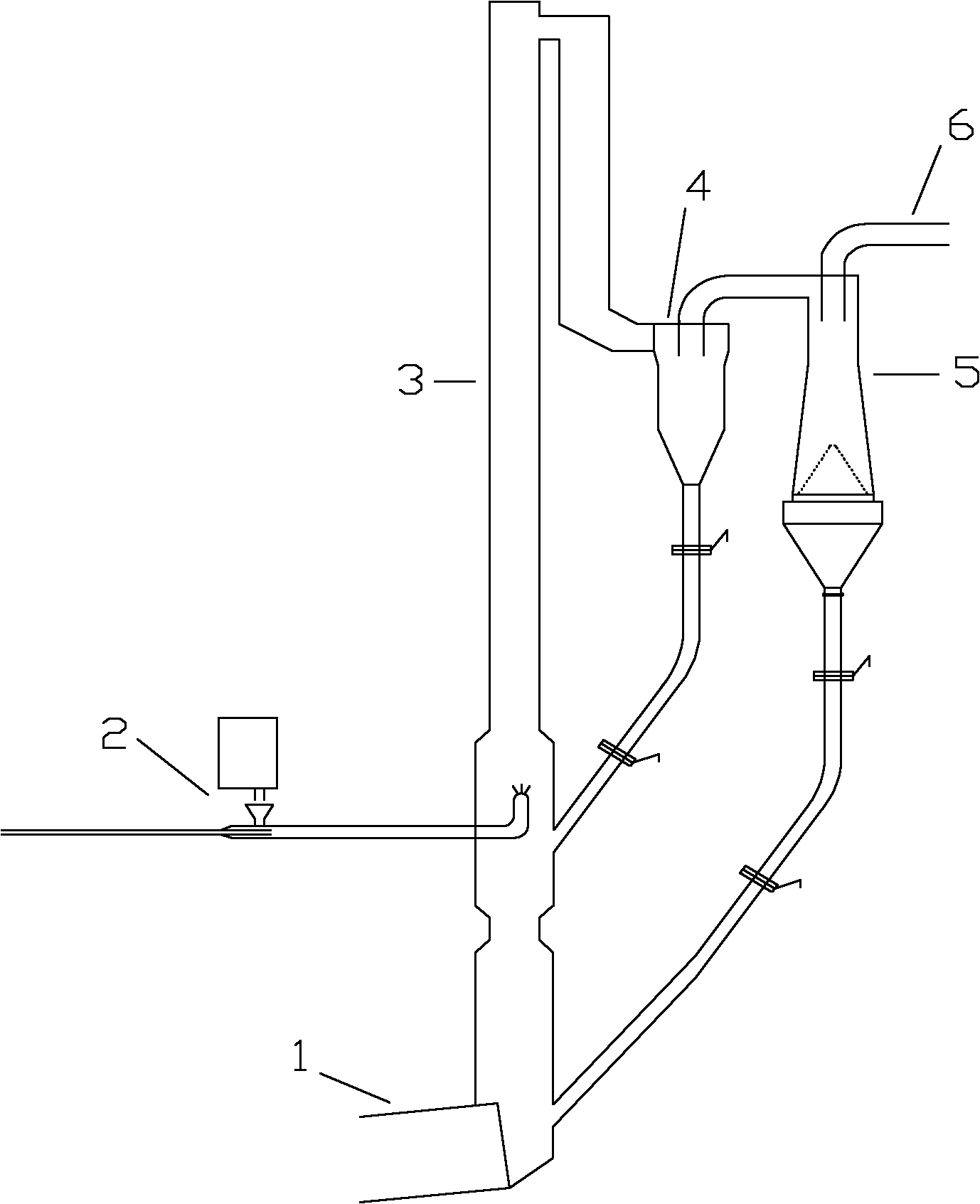

Molybdenite concentrate suspended-state roasting process and equipment

ActiveCN102127634ASave flash dryingPrevent sinteringProcess efficiency improvementHigh concentrationSulfur

The invention discloses a molybdenite concentrate suspended-state roasting process, which comprises the following steps of: firstly, conveying molybdenum concentrate to a suspension roaster by using a gas-moving material spraying device through compressed air, and completing heat exchange in a heat exchange area, wherein the temperature of the heat exchange area is 500 to 750DEG C and the retention period is 2 to 15 seconds; secondly, performing oxidation desulfurization reaction in a reaction area of the suspension roaster to obtain roasted high-sulfur sand, wherein the temperature of the reaction area is 550 to 780DEG C, the air speed is 4 to 25m / s, and the retention period is 2 to 15 seconds; and finally, removing residual sulfur from the roasted high-sulfur sand in a rotary kiln at the temperature of between 550 and 780DEG C for 5 to 60 minutes to obtain roasted high-dissolubility molybdenum sand. The invention also provides molybdenite concentrate suspended-state roasting equipment, which overcomes various defects of stacked state roasting and fluidized roasting, has high thermal efficiency and good product quality, greatly shortens roasting time, can obtain the high-dissolubility low-sulfur molybdenum oxide, and ensures that SO2 in flue gas has high concentration and is convenient to recycle for making acid.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

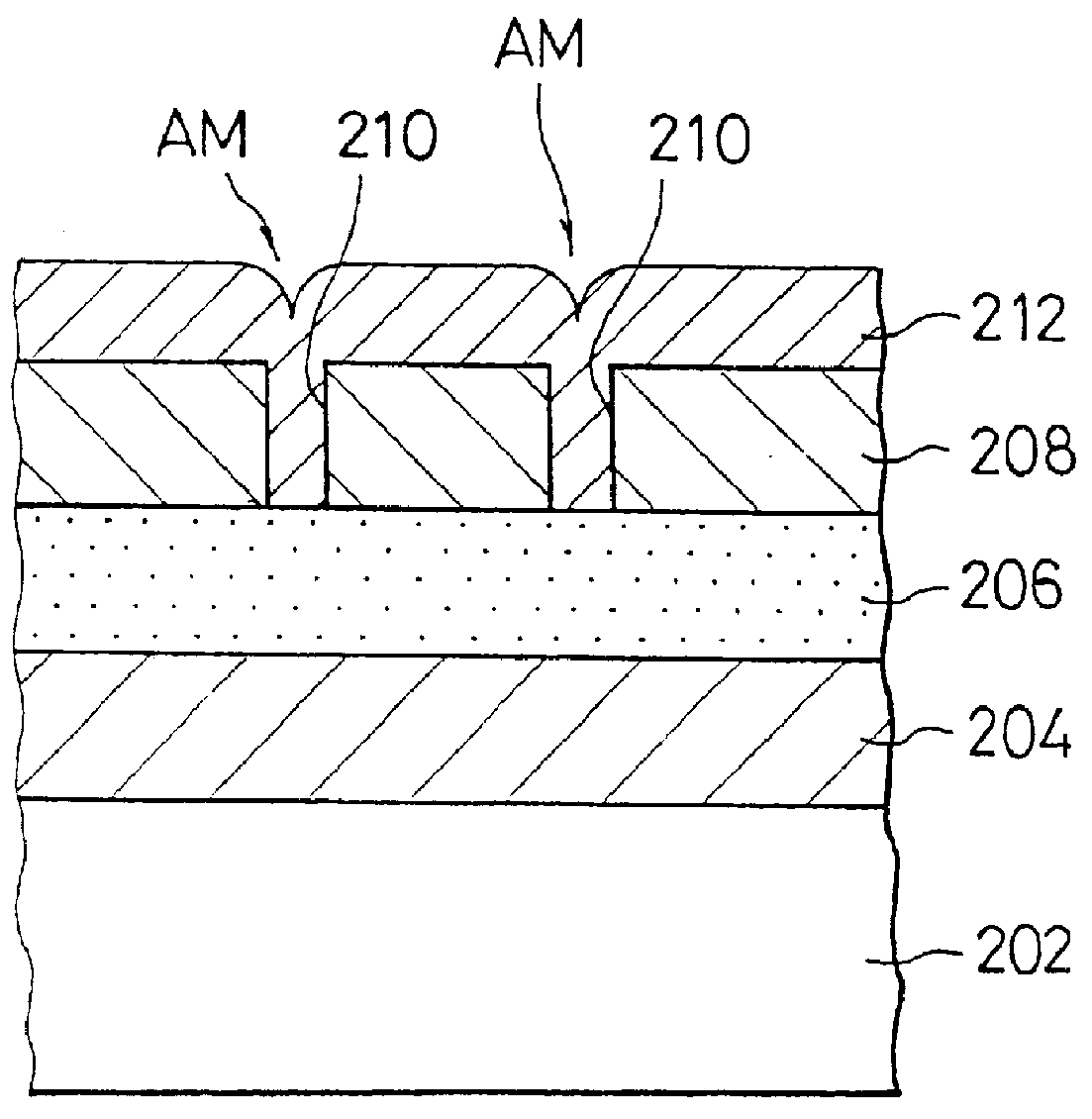

Formation of an alignment mark in the surface of an aluminum layer

InactiveUS6410401B1Stable maintenanceFast chemical reactionSemiconductor/solid-state device detailsSolid-state devicesSiliconMaterials science

An alignment mark appears on the surface of an aluminum wiring layer, when the wiring layer is formed to fill a recess. The recess is formed in oxide layers formed over the surface of a silicon substrate by etching. The depth of the recess is controlled to prevent direct contact between the wiring layer and metallic silicon of the silicon substrate. The wiring layer is thus prevented from chemically reacting with the metallic silicon so that deterioration of the oxide films and destruction of the alignment mark appearing on the surface of the wiring layer are prevented, even if the wiring layer is formed by sputtering aluminum on oxide layers and the recess at a high temperature.

Owner:LAPIS SEMICON CO LTD

Method for preparing flake-shaped NH4V3O8 microcrystalline with microwave-ultrasonic method

The invention discloses a method for preparing flake-shaped NH4V3O8 microcrystalline with a microwave-ultrasonic method. The method includes the steps that ammonium metavanadate is dissolved in deionized water to prepare an NH4VO3 solution with the NH4+ concentration being 0.05-0.20mol / L, and then the PH value of the solution is adjusted to be 4.0-5.5 to obtain a solution B; by adopting a microwave-ultrasonic synthesis mode, microwaves and ultrasonic waves are made to have effects on the solution B, and the temperature is raised to be 40-80 DEG C to obtain suspension liquid; the suspension liquid is separated in a centrifugal mode to obtain powder products, and then drying and grinding are performed. The NH4V3O8 microcrystalline prepared with the method is uniform in chemical composition, high in purity and uniform in morphology, the thickness of the obtained flake-shaped NH4V3O8 microcrystalline is about 100-200nm, and the electrochemical properties of the material is effectively improved. The preparation method is simple, low in reaction temperature, short in reaction period, high in yield, environmentally friendly and suitable for large-scale production, and no subsequent processing is needed.

Owner:盐城抱璞文化传媒有限公司

High-fuel-efficiency biomass fuel

The invention relates to a high-fuel efficiency biomass fuel, and belongs to the field of fuels. According to the invention, octenyl succinic acid modified starch and bacterial cellulose are taken aswall materials, the surface of the wall materials is densified, so that the loss of effective ingredients in the processes of preparation and storage is effectively avoided, the effects of promoting combustion and improving fuel efficiency are achieved, the heat conductivity of the structure of the wall materials is improved; heat can be rapidly led into the inner part in the use process, and micro-explosion occurs to a micro-capsule structure; the occurrence of the micro-explosion, on one side, causes thermoresonance and produces secondary energy, so that the fuel can be completely burned rapidly at high temperature, and the fuel efficiency is further improved; the volume of magnesium oxide expands and shrinks in the use process, so that inner pores and melt materials in a system are redistributed, the excessive expansion of the volume of the fuel is avoided in the combustion process, and the product porosity is also effectively maintained. The invention solves the problems of low combustion efficiency and low use ratio of the current commonly-used biomass fuel.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

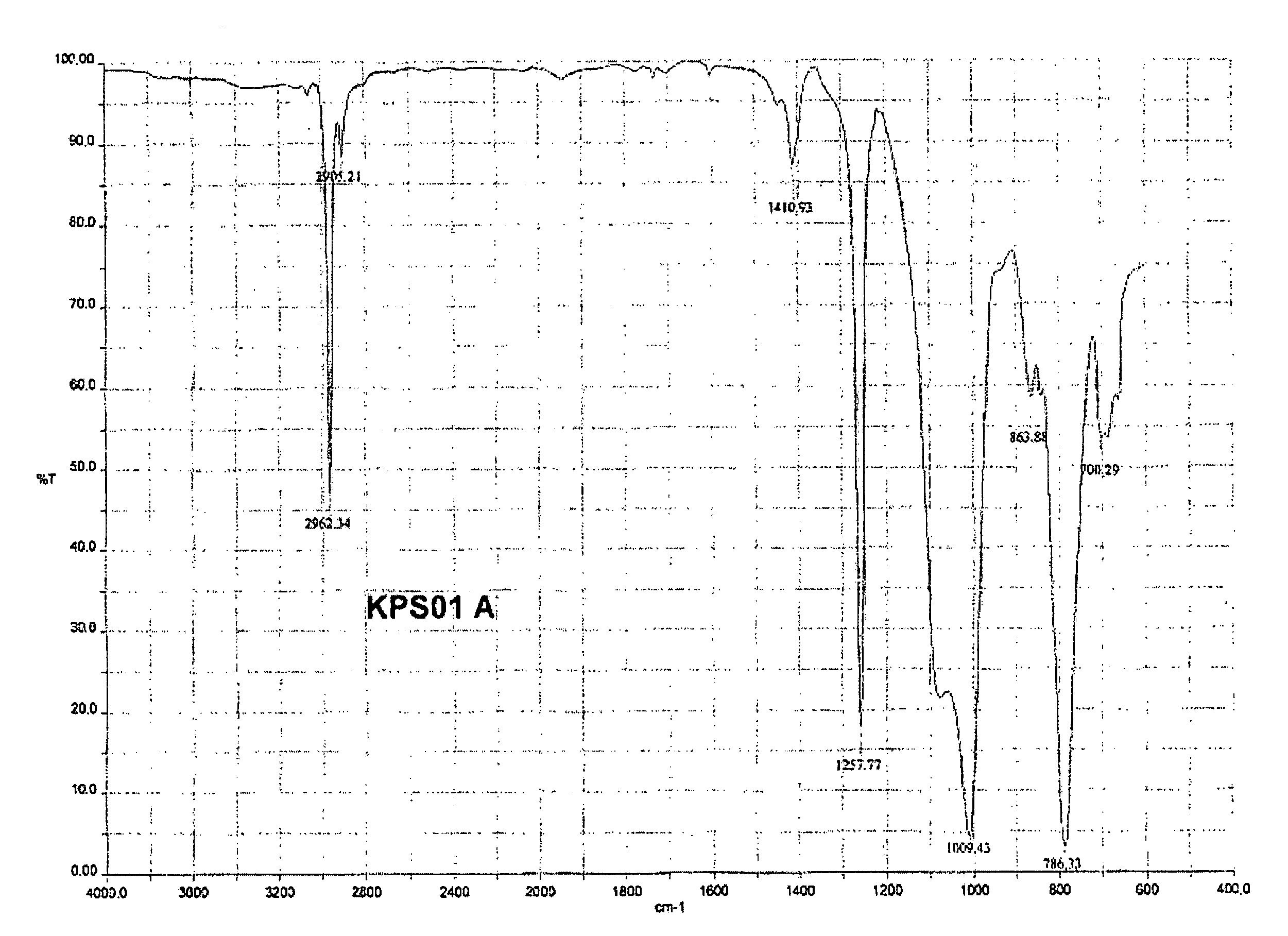

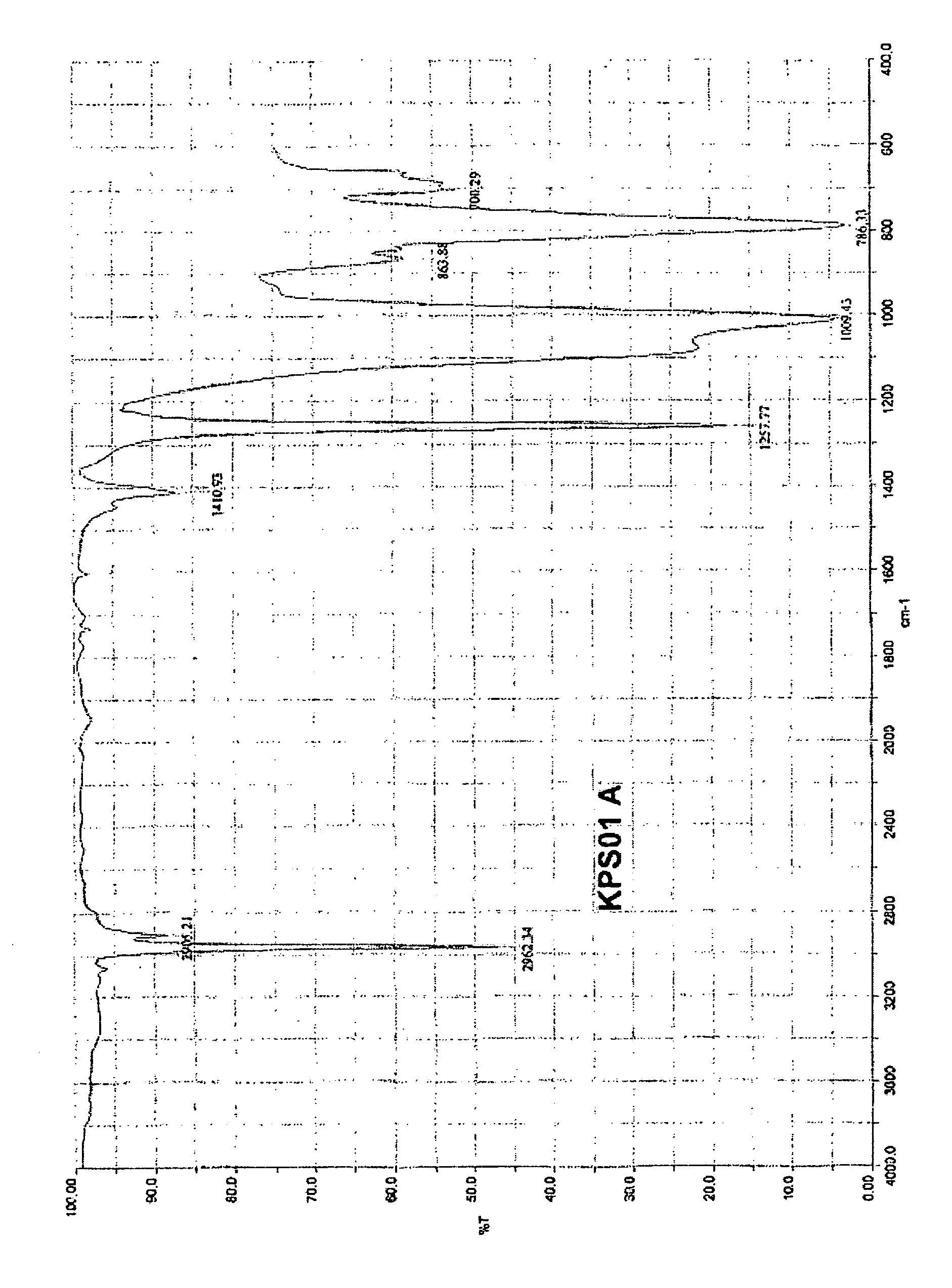

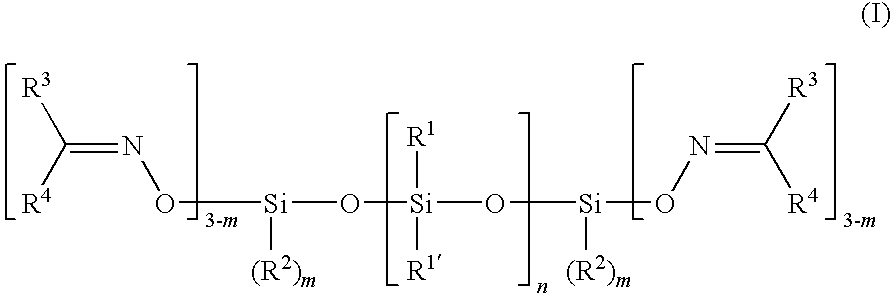

Silicone composition

ActiveUS8618235B2Reduce the smellEffective adhesionPretreated surfacesSpecial tyresPolymer chemistryHigh adhesion

The present invention relates to silicone compositions which comprise at least one ketoximosilane-terminated polydiorganosiloxane and also at least one alkoxysilane. These compositions are neutrally crosslinking and combine a low odor with high adhesion and good storage stability.

Owner:SIKA TECH AG

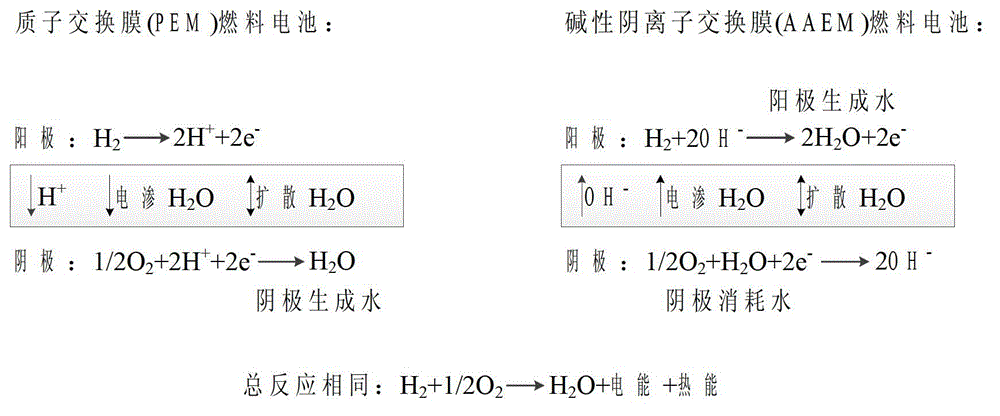

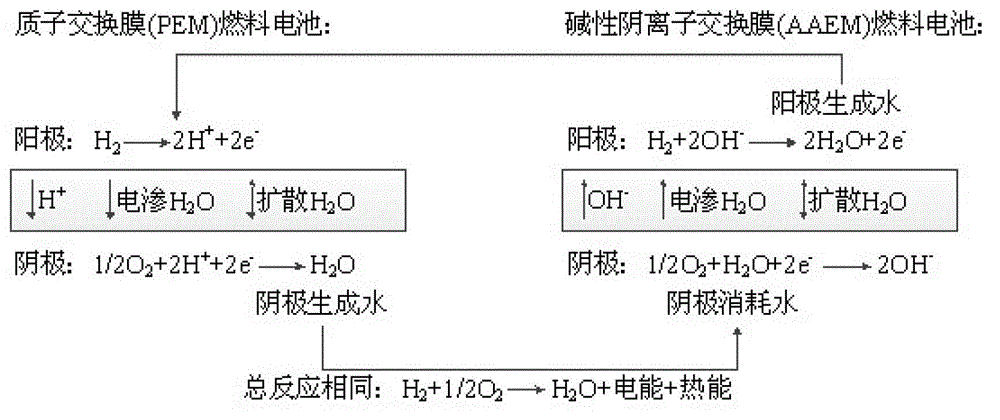

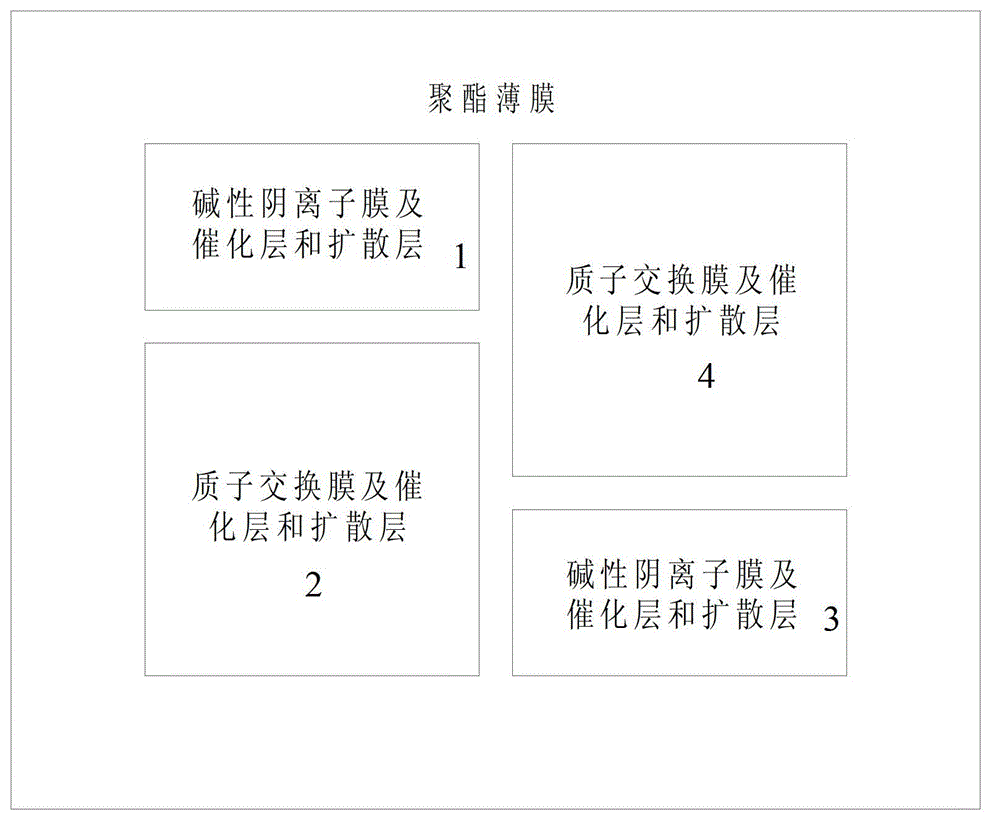

Composite fuel cell

InactiveCN103151547AEasy to useReduce usageWater management in fuel cellsSolid electrolyte fuel cellsFuel cellsEnvironmental engineering

The invention discloses a composite fuel cell. A circulation is formed by a PEM membrane fuel cell and an AAEM membrane fuel cell which are adjacent to each other by utilizing different water generation volumes at the cathodes and the anodes of the PEM membrane fuel cell and the AAEM membrane fuel cell, and a coiled pipeline is arranged on a carbon plate to enable fluid to drive water to flow between two exchange membranes so as to supplement the water consumed at the AAEM cathode by utilizing water generated at the PEM membrane cathode, and also supplement water required for humidifying the PEM membrane anode by utilizing water generated at the AAEM membrane anode.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com