Patents

Literature

42results about How to "Not easy to crust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

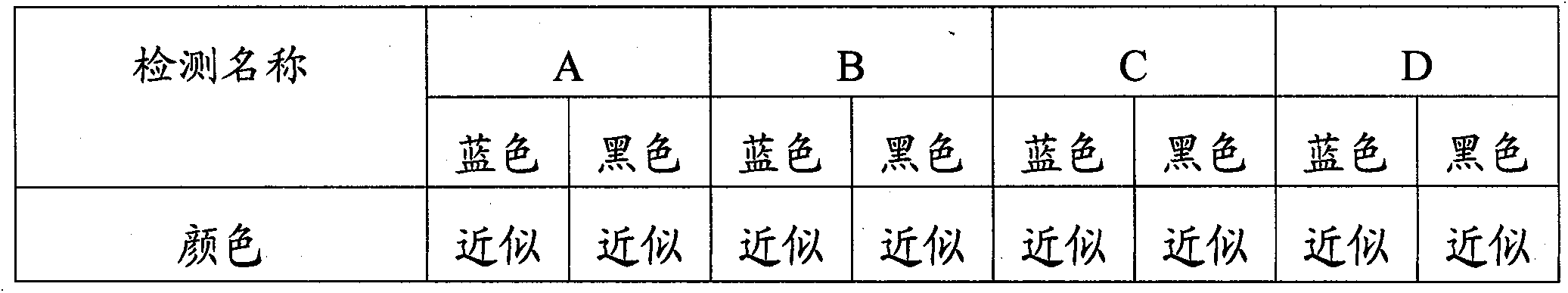

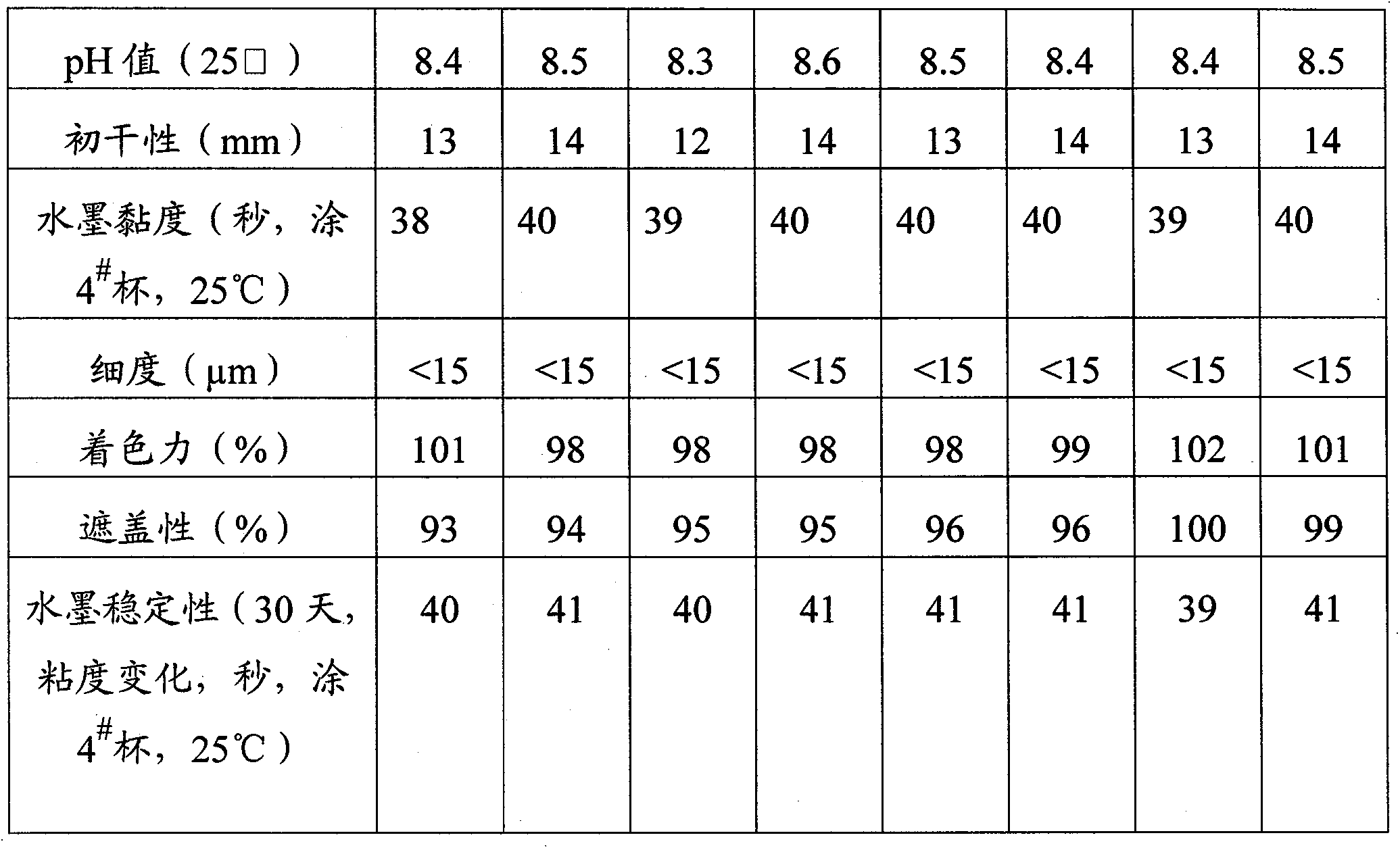

High-covering-power styrene-acrylate emulsion, synthesis method thereof and use thereof in aqueous printing ink

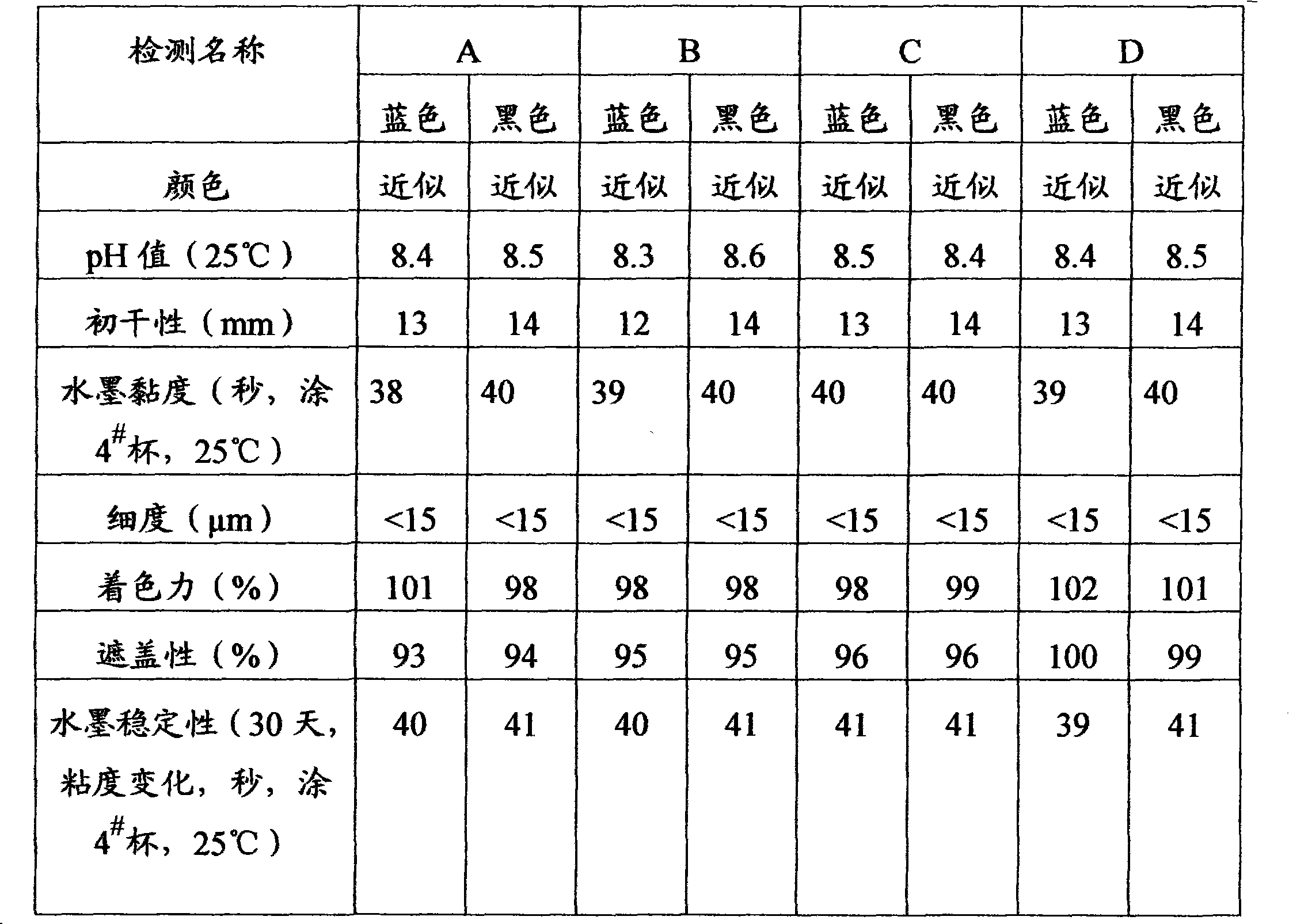

The invention relates to the field of printing ink and discloses high-covering-power styrene-acrylate emulsion, a synthesis method thereof and use thereof in aqueous printing ink. The preparation method comprises: mixing deionized water, an initiator, a lacquer and a composite emulsifier to obtain solution A; regulating the pH value; introducing nitrogen to remove oxygen; mixing a monomer with a molecular weight regulator to obtain solution B; dripping solution B into solution A to perform a chemical reaction; regulating the pH value of shell emulsion and heating to prepare shell emulsion; adding a composite emulsifier and an initiator into the synthesized shell emulsion; dripping a vinyl monomer to synthesize core-shell emulsion; and cooling, regulating the pH value and filtering to obtain the styrene-acrylate emulsion. The invention also provides aqueous printing ink using the high-covering-power styrene-acrylate emulsion. The preparation process is very simple, the reaction processis simple and easy to control, the operability is high, and the method is suitable for large-scale production. The aqueous printing ink disclosed by the invention is high in resolubility, is insusceptible to crusting and blocking printing plate and has high printing adaptability.

Owner:广东天龙油墨有限公司

Preparation method for pelletizing and producing yellow phosphorus by phosphorus ore concentrate

The invention provides a preparation method for pelletizing and producing yellow phosphorus by a phosphorus ore concentrate which comprises the following components in terms of producing 1000 Kg of yellow phosphorus: 7100-8500 Kg of phosphorus ore concentrate powder, 1800-2000 Kg of coke dust, 1800-3300 Kg of silica powder, 130 Kg of humic acid and 65 Kg of sodium hydroxide. The preparation method is as follows: grinding formula components by a ball mill; adding a binder composed of the humic acid and the sodium hydroxide, and evenly stirring; processing into a compound pellet by a ball pressing and forming machine; dying by a chain plate dryer; and sending into a yellow phosphorus electric furnace to prepare into a yellow phosphorus finished product. The invention fully utilizes powder phosphate ores and low-grade phosphate ores; the phosphorus ore concentrate powder obtained by mineral separation is produced into a pellet by the binder, and then the pellet is prepared into yellow phosphorus by the electric furnace. Compared with the existing phosphorus preparation by a phosphorus ore concentrate, the invention lowers cost by one time, reduces CO emission by about 35%, reduces electricity consumption by about 40%, improves capacity by 2 times and reduces materials by about 40%. Thus, the invention is an excellent method for solving the problems of high energy consumption, high emission and high pollution for yellow phosphorus production in China.

Owner:瓮安烨烨磷化工实业有限公司

Method for treatment of urban garbage

A method for treating city garbage includes such steps as classifying the garbage into the garbage A able to be biologically decomposed and the combustible garbage B, loading the garbage A in marsh gas pool to generate marsh gas, using the marsh gas to burn the garbage B in incinerator and installing the duster in the chimney of incinerator to remove the dust from fume.

Owner:张四灿

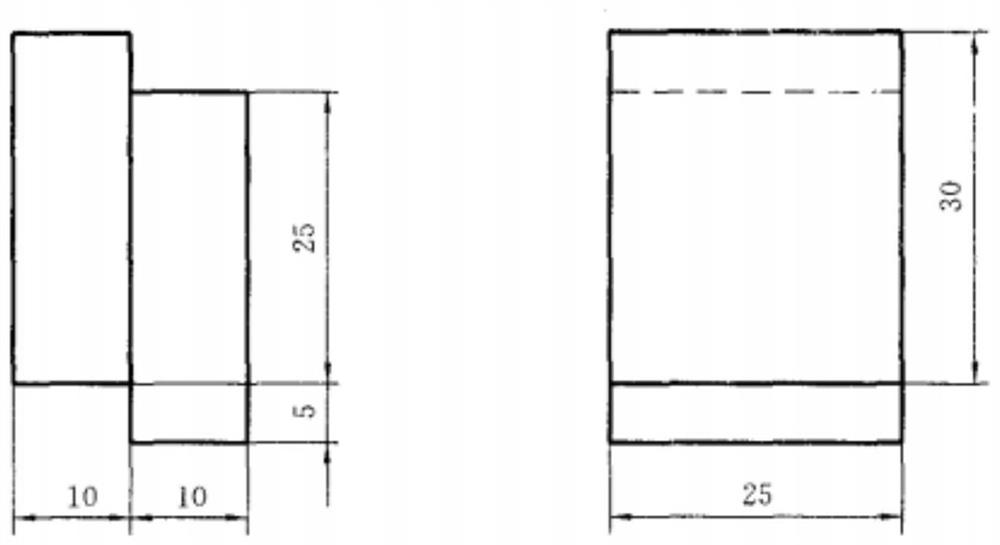

Binder for installation of thermal insulation decorative plate

The invention provides a binder for installation of a thermal insulation decorative plate. The binder comprises, by weight, 25 to 40% of cement, 25 to 45% of silica sand of 20 to 40 meshes, 8 to 15% of silica sand of 40 to 70 meshes, 3 to 8% of silica sand of 70 to 140 meshes, 0 to 5% of talcum powder, 0 to 5% of ground calcium carbonate powder, 2 to 8% of dispersible latex powder, 0 to 1% of cellulose ether, 0 to 0.6% of plant fibers and 0 to 0.5% of a thixotropic agent. The binder for installation of the thermal insulation decorative plate has the characteristics of high adhesion, strong anti-sliding capability, strong initial adhesion, long construction operation time and difficult skinning, effectively solves the problems produced in thermal insulation decorative plate pasting installation, guarantees enough adhesion between a thermal insulation decorative plate and a wall surface, and improves safety of the thermal insulation decorative plate in engineering application.

Owner:ASIA CUANON TECH SHANGHAI

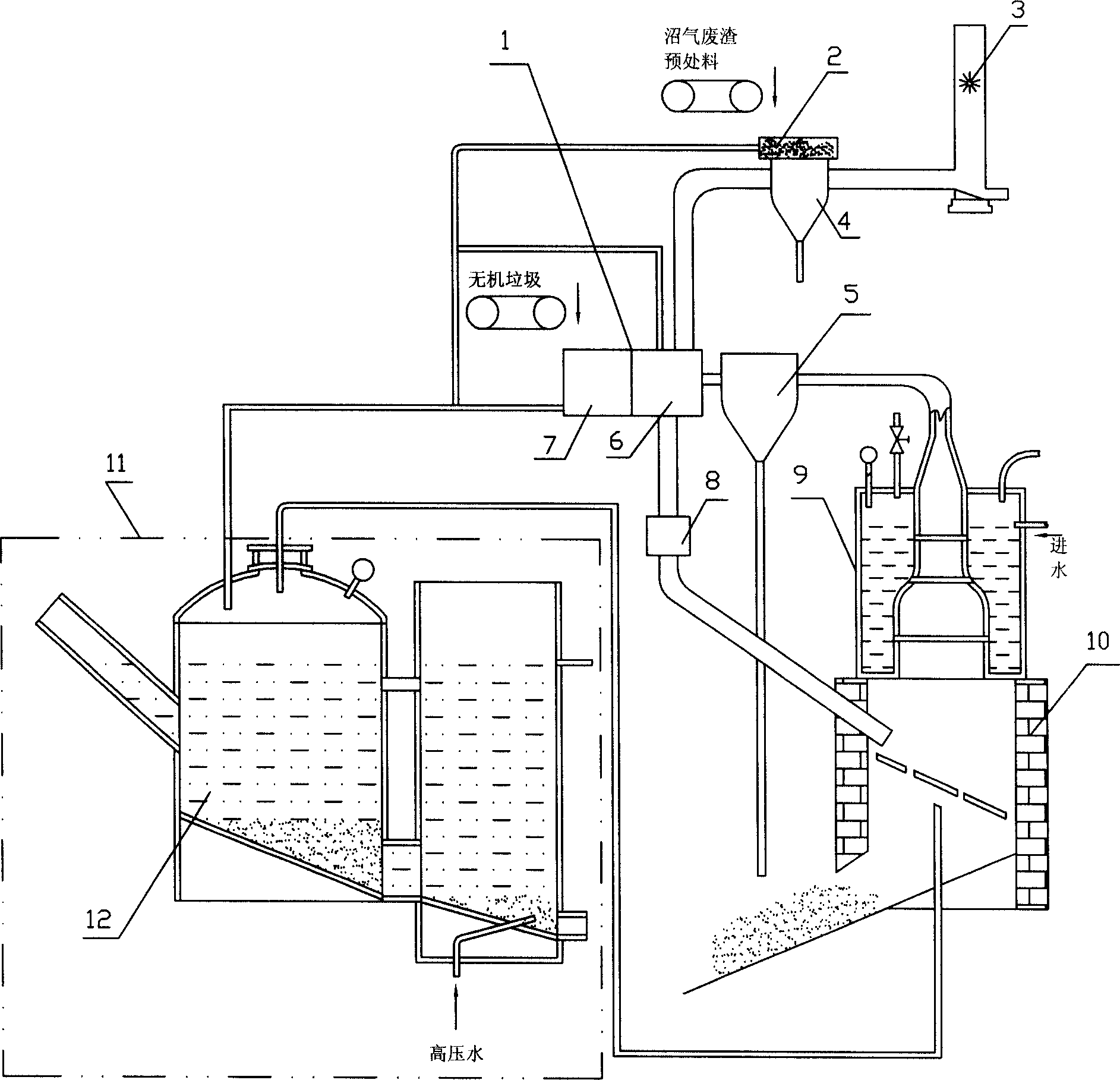

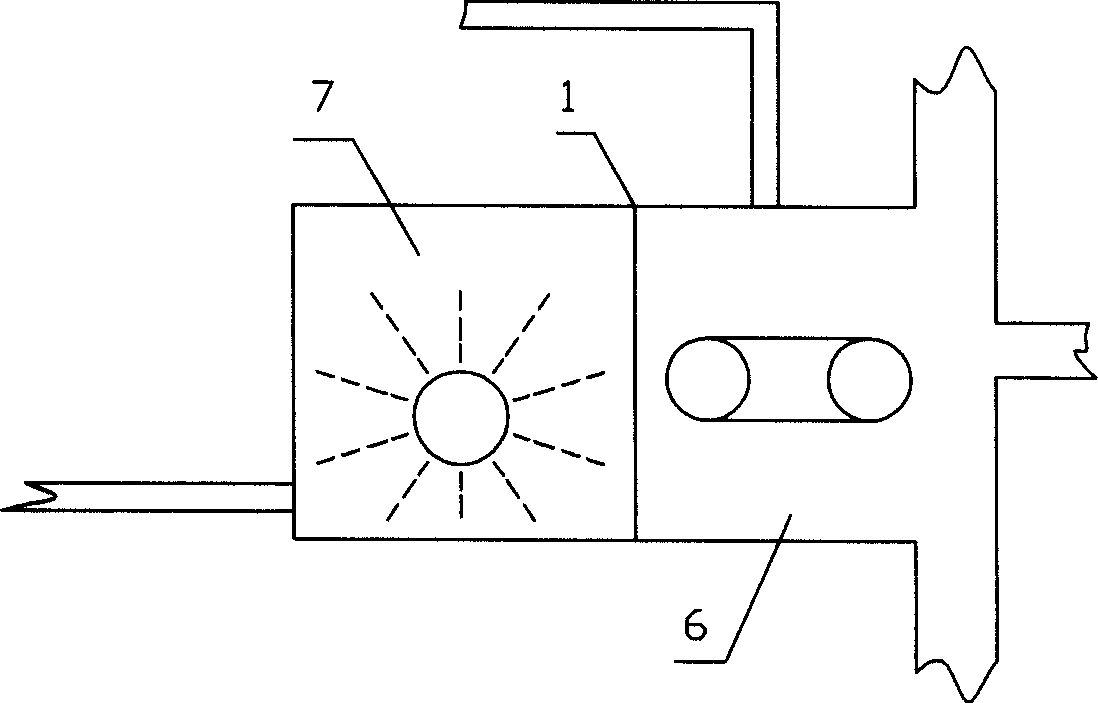

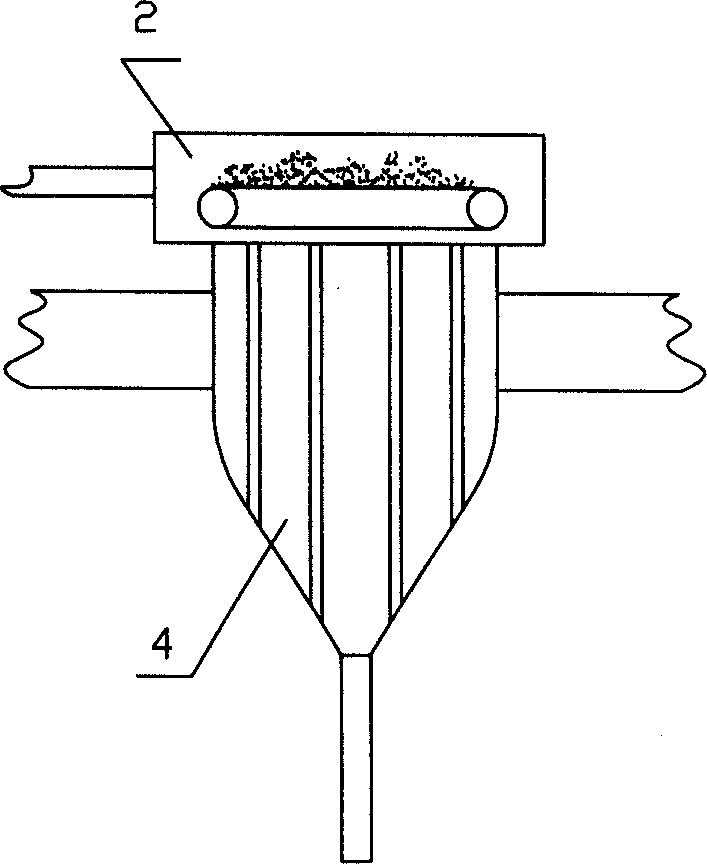

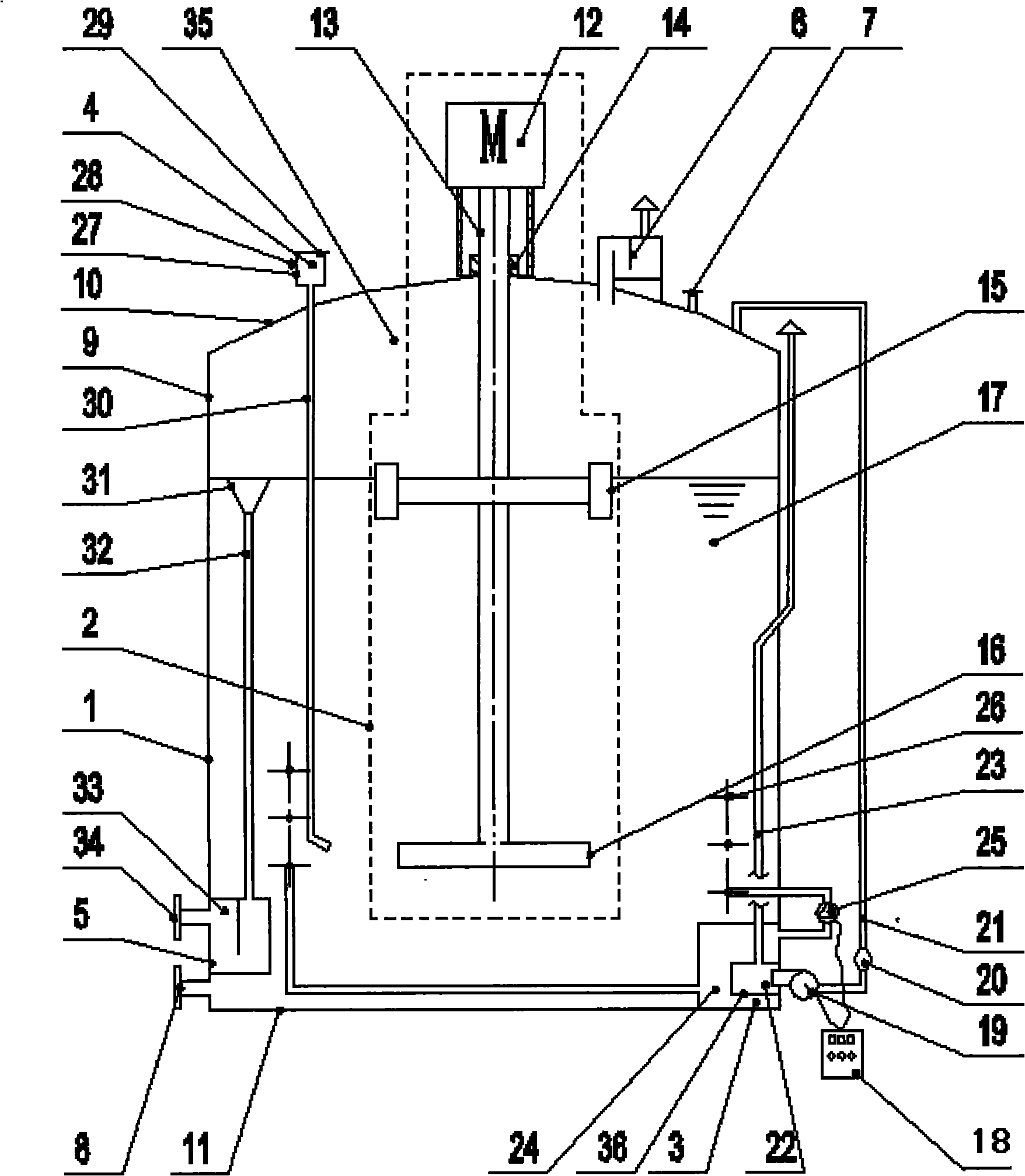

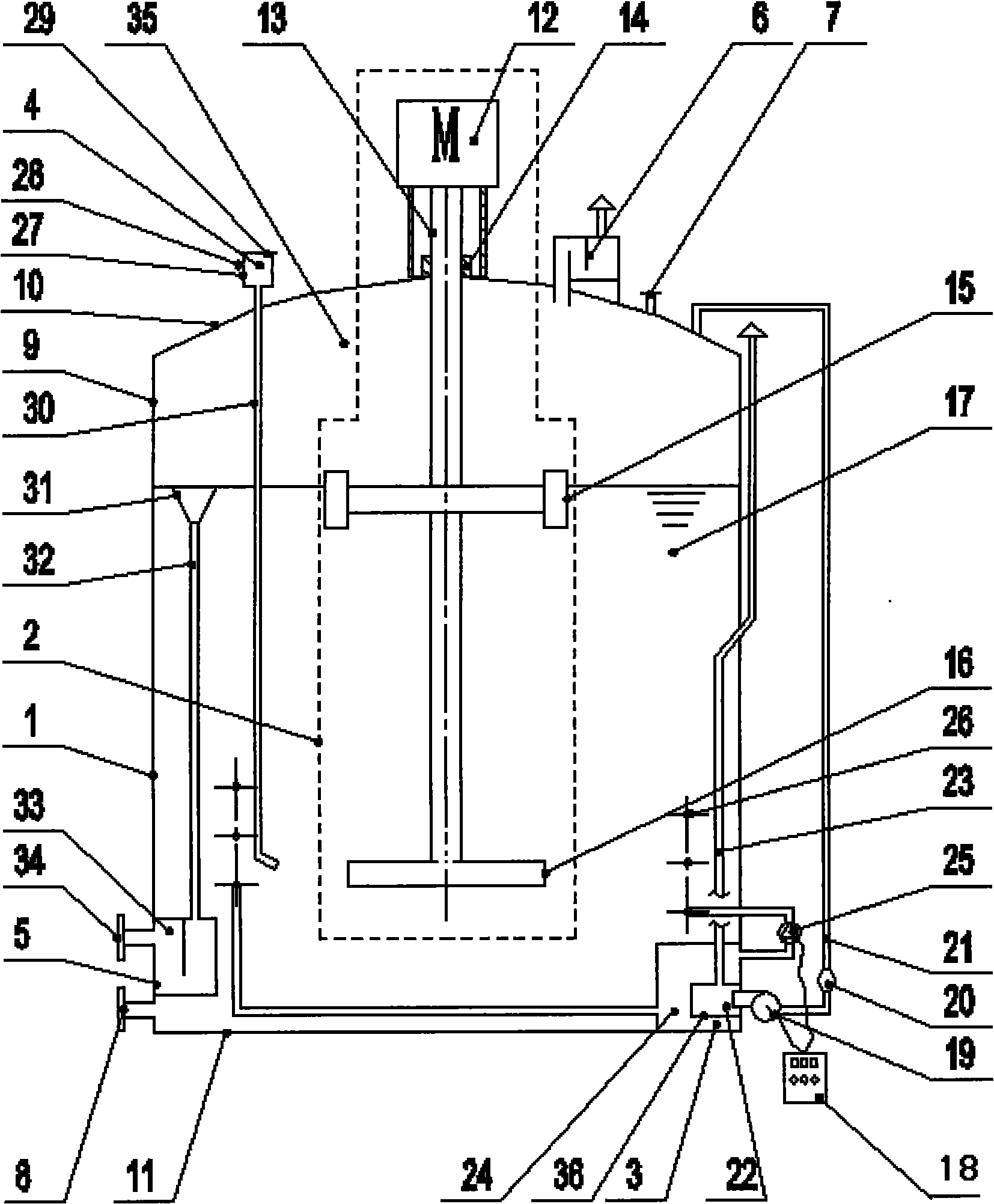

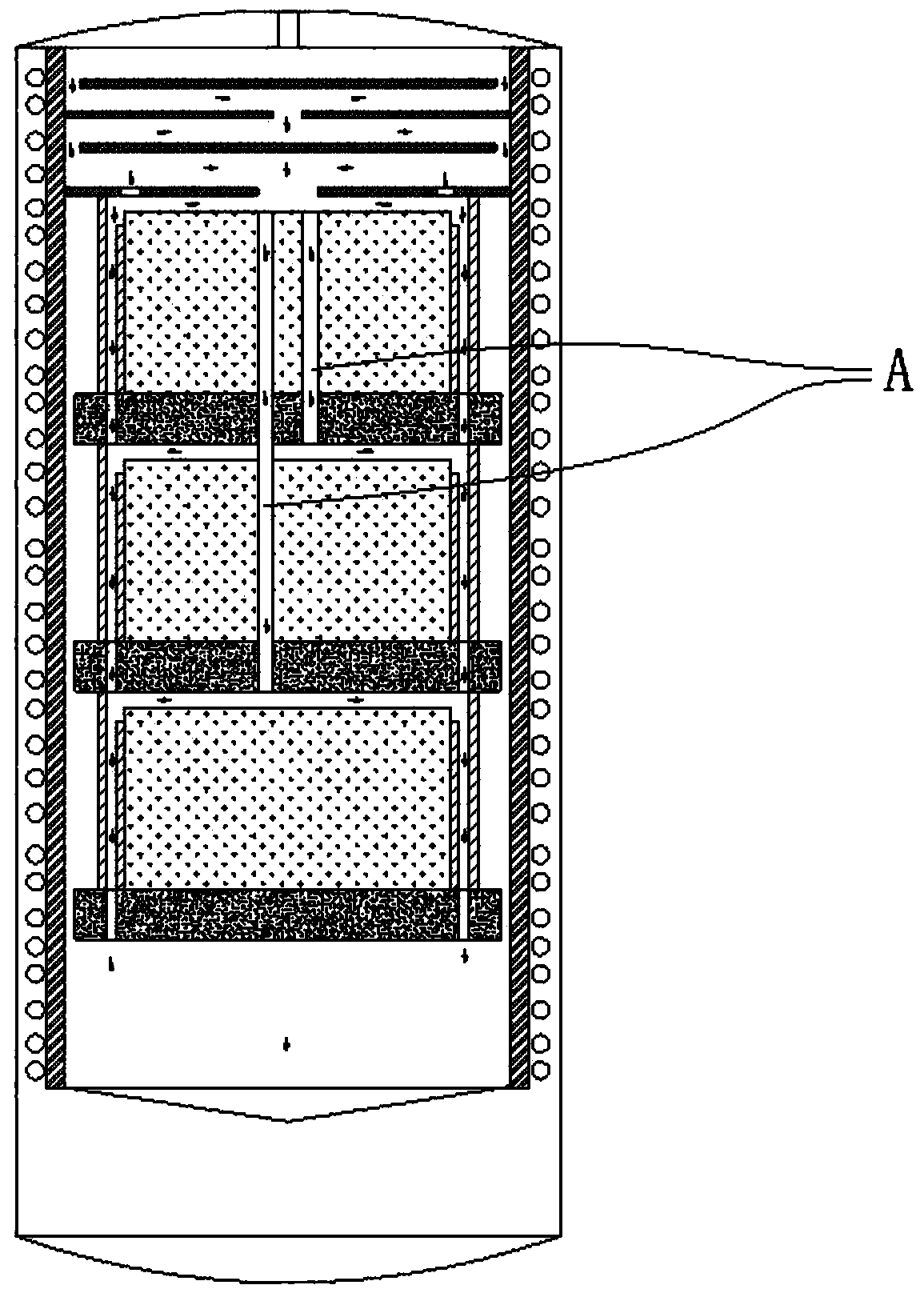

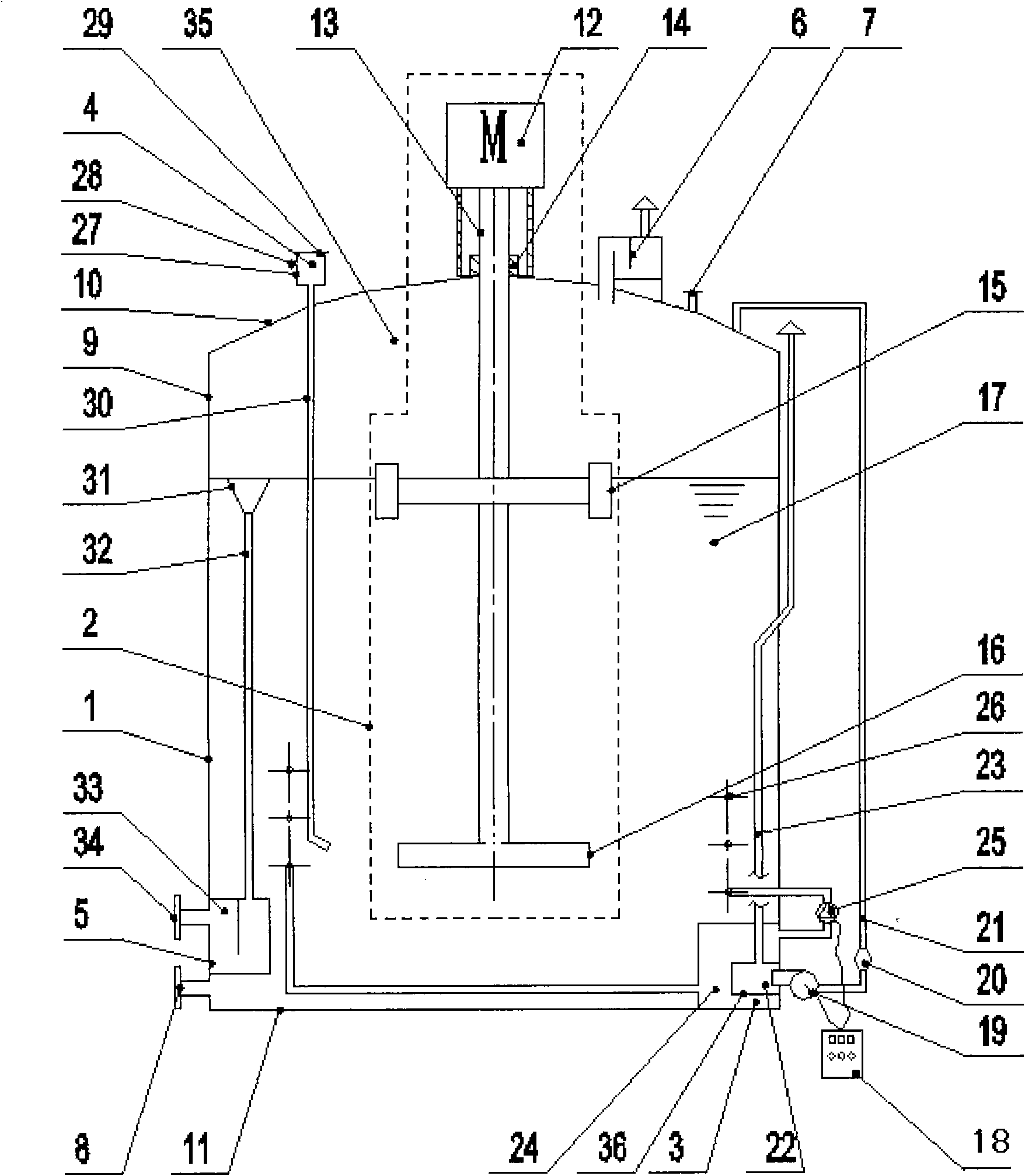

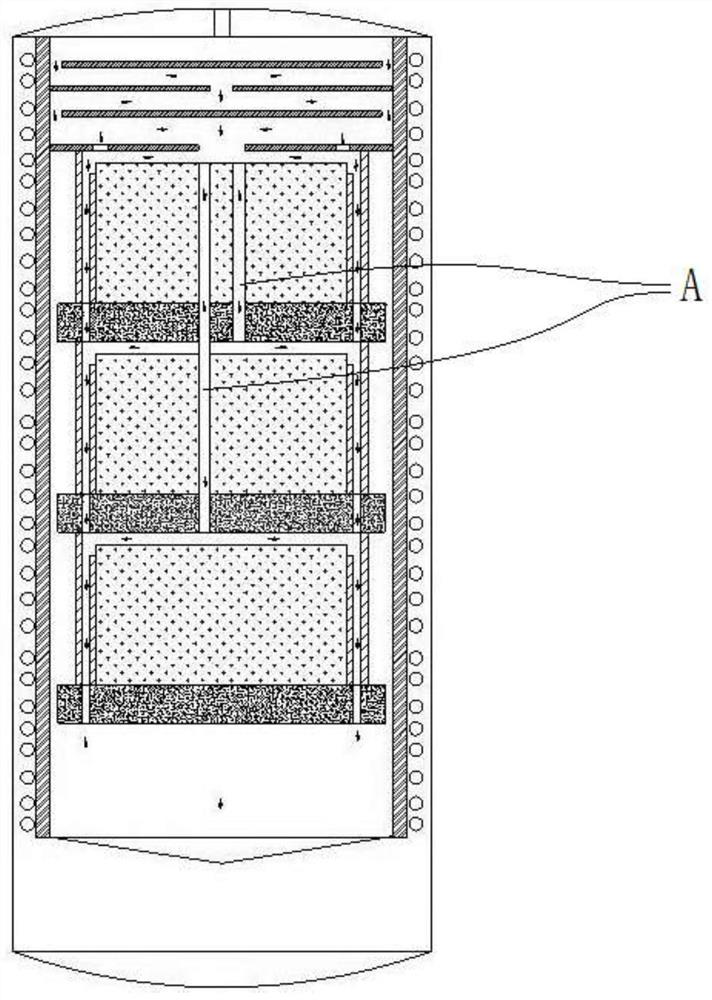

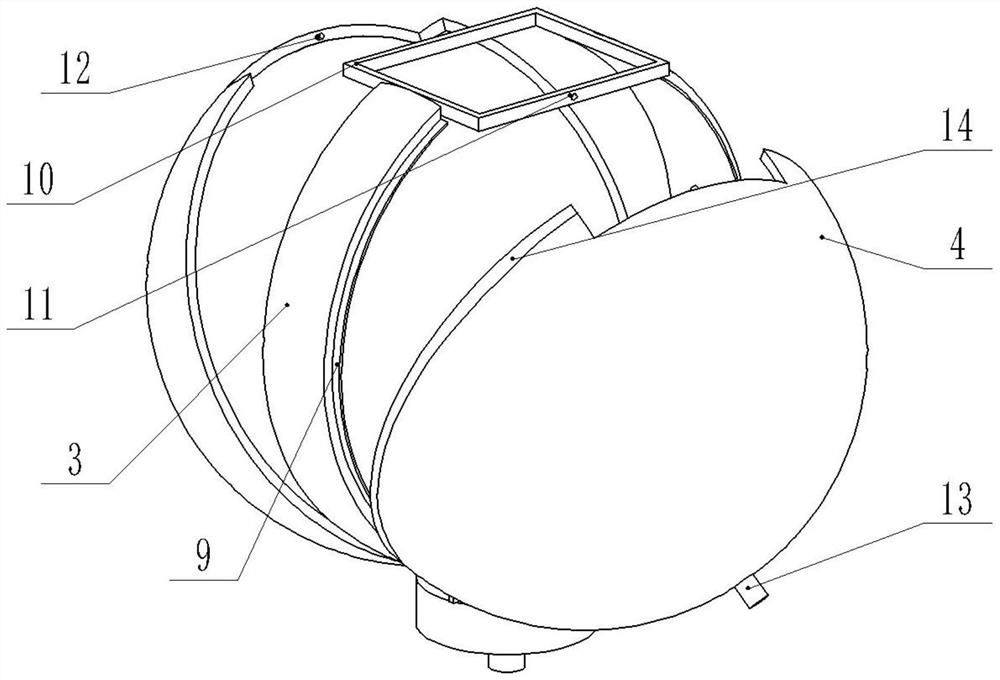

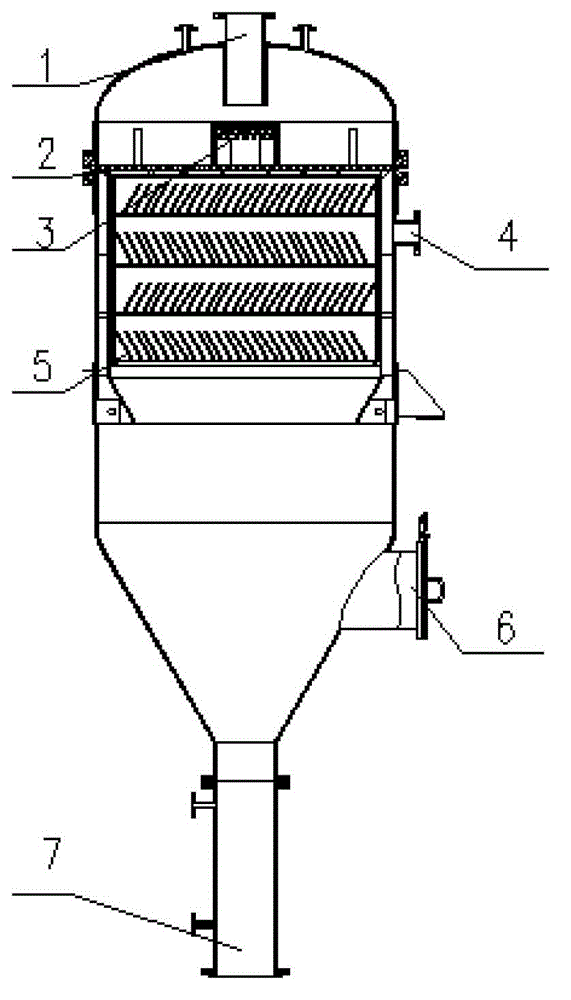

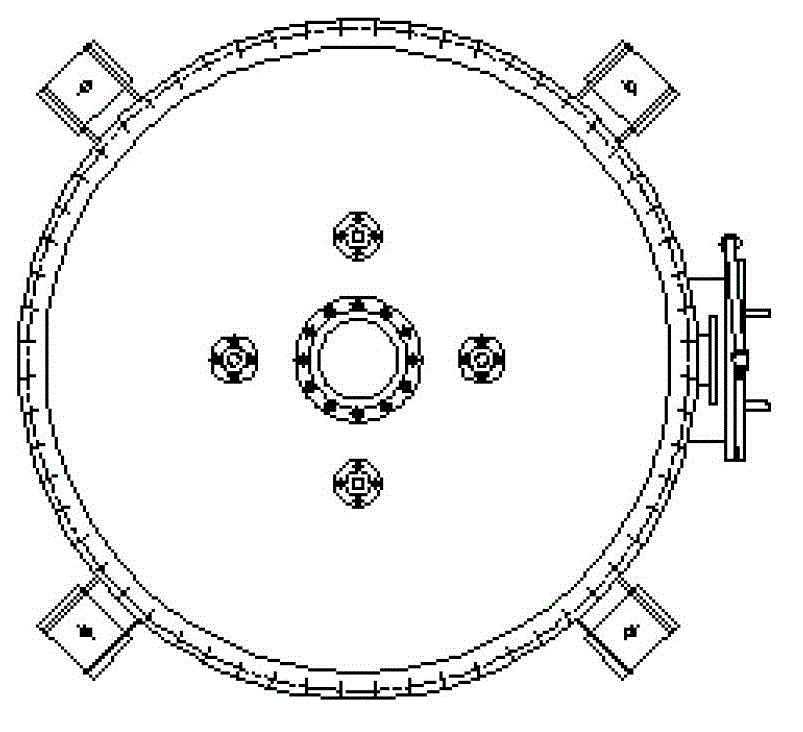

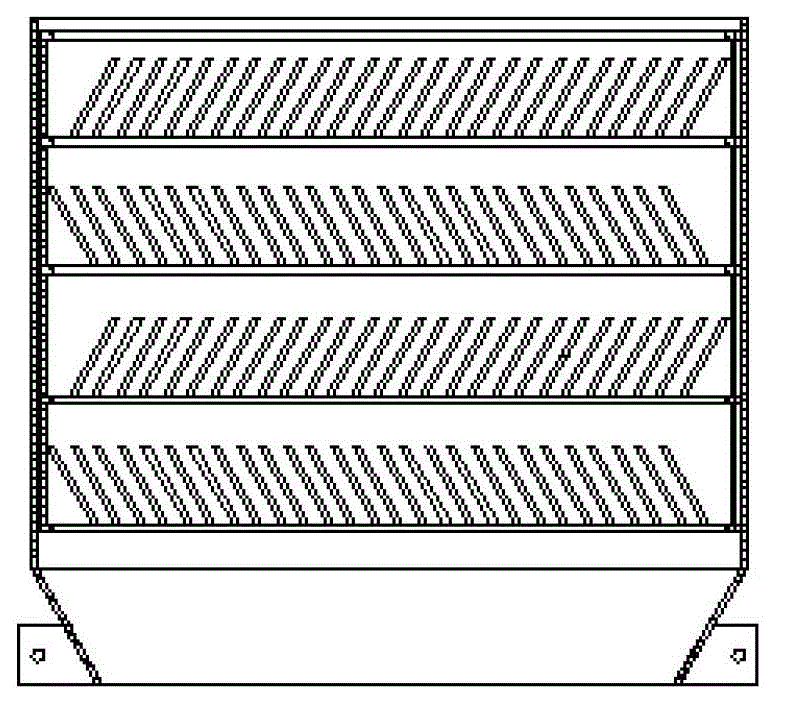

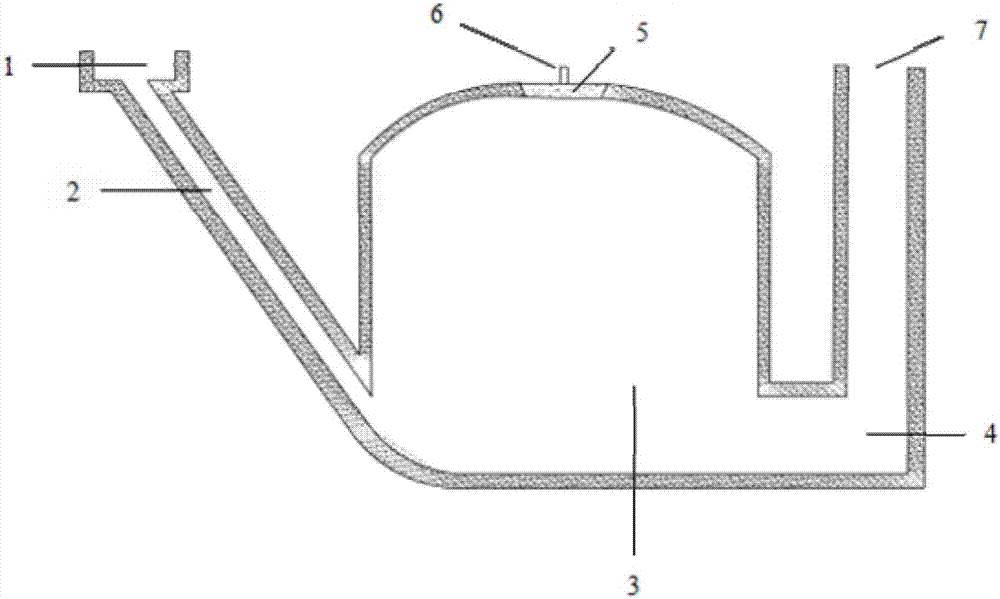

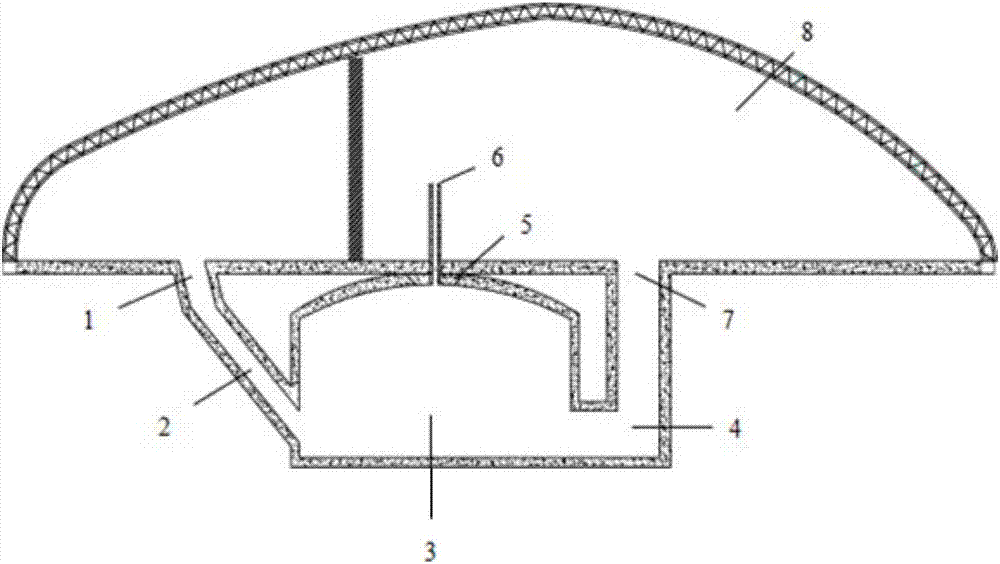

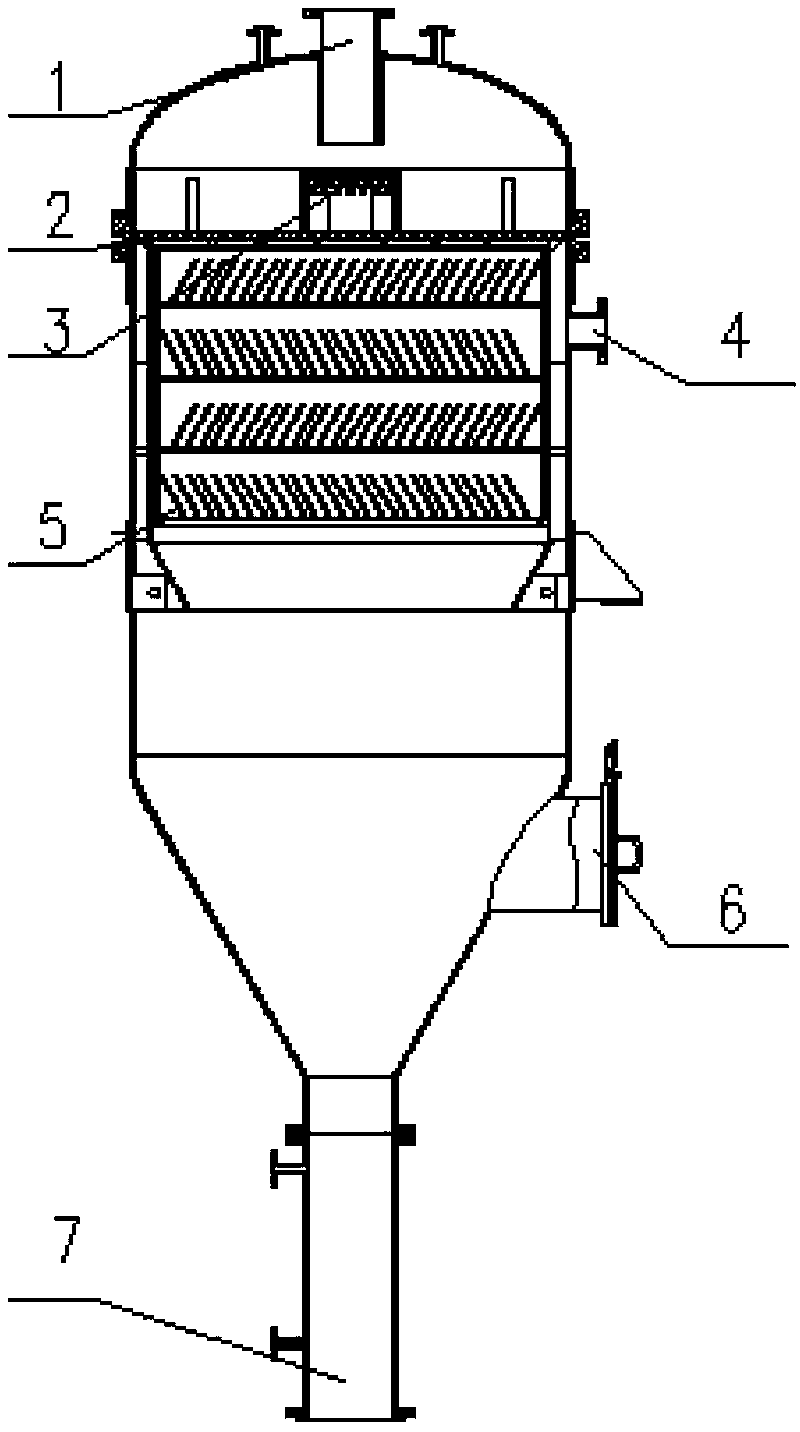

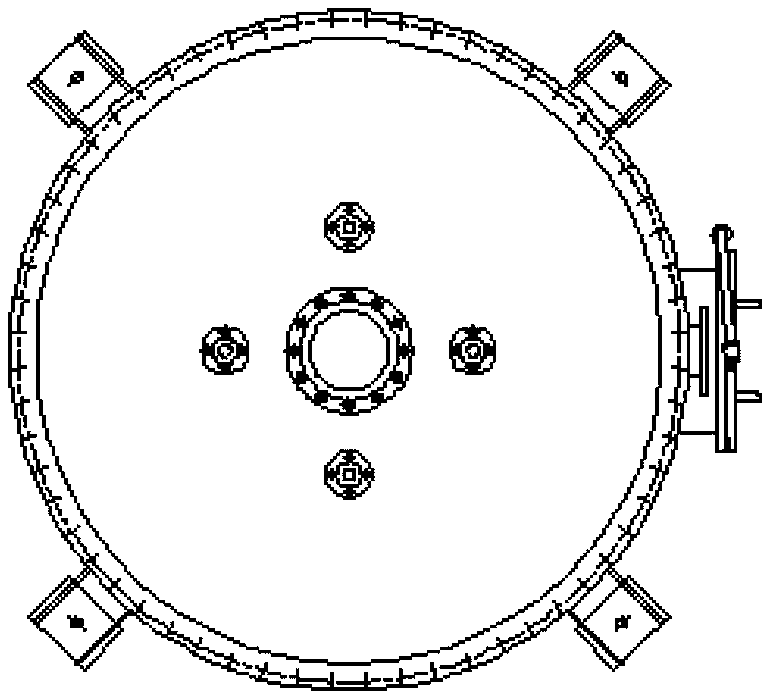

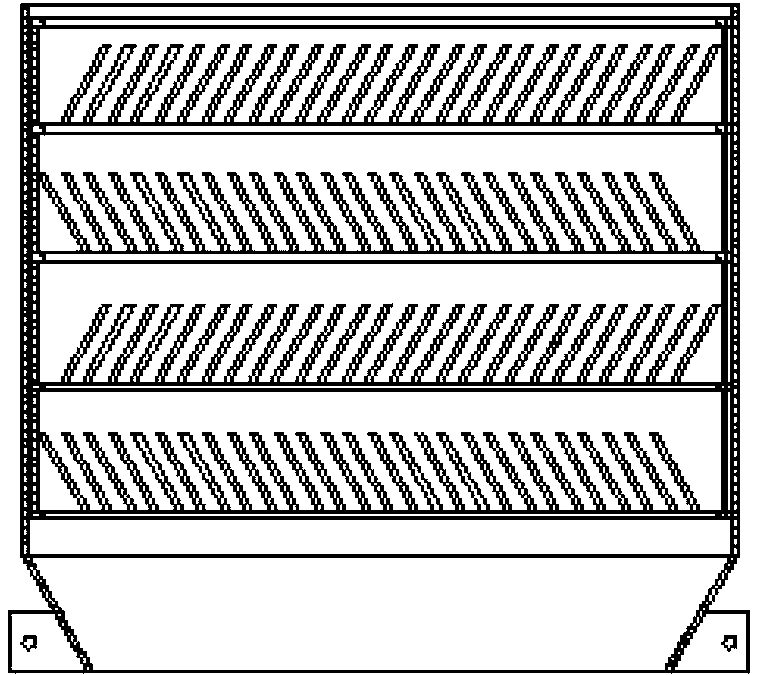

Novel upflow anaerobic reactor

ActiveCN102399683AEasy to operateNot easy to crustBioreactor/fermenter combinationsBiological substance pretreatmentsThermal energySlag

The invention discloses a upflow anaerobic reactor. The novel upflow anaerobic reactor comprises a tank, a stirring cracking assembly, a built-in heat energy conversion unit, a feeding device, a discharge device, a pressure protector, a gas outlet pipe and a slag discharge pipe. The stirring cracking assembly having functions of stirring mixing, cracking and slag removal, the built-in heat energy conversion unit, the discharge device which is sealed by water and can discharge dross, and the feeding device provided with a stored material automatic discharge device are ranged in the tank. The novel upflow anaerobic reactor is easy for operation, does not produce crusting in treatment on a fermentation mixture of livestock and poultry night soil, rural domestic organic garbage and straws, allows an uniform and constant reaction temperature, can operate stably and reliably, has low investment and operation costs, a high-load treatment capacity, large TS concentration and short hydraulic retention time. Through the novel upflow anaerobic reactor, a solid content of a fermentation solution is in a range of 8 to 15%; COD clearance is in a range of 60 to 80%; and a biogas yield is in a range of 1.5 to 3m<3> / m<3>*d.

Owner:LIAONING BEIFANG ENVIRONMENTAL PROTECTION

Preparation method of oil-soluble polyurethane grouting liquid

The invention relates to a polyurethane grouting liquid and specifically relates to a preparation method of an oil-soluble polyurethane grouting liquid. The preparation method of the oil-soluble polyurethane grouting liquid comprises the following steps of: firstly preparing a prepolymer with the -NCO content of 9.5-17.5%, further performing heat preservation, then cooling, and adding a toluene type solvent and a catalyst so as to prepare the oil-soluble polyurethane grouting liquid. The oil-soluble polyurethane grouting liquid prepared by the method disclosed by the invention has the advantages of stability, small shrinkage rate in forming, difficulty in crust formation and easiness in storage. The method has the advantages of simplicity, convenience, quickness and effectiveness, anti-seepage and leakage stoppage effects can be realized, and a certain structure reinforcing effect can be further realized. An oil-soluble polyurethane grouting technology is particularly suitable for waterproof treatment against dynamic seepage of underground works and can be widely applied to the fields of water conservation, hydropower, tunnels, municipal administration, industrial and civil buildings and the like.

Owner:ZIBO DEXIN LIANBANG CHEM IND

Environment-friendly anti-counterfeiting printing ink and method for preparing same

The invention discloses an environment-friendly anti-counterfeiting ink and a preparation method thereof. The ink is composed of pure water, resin, propylene glycol, water-based film-forming plasticizer, pigments and fillers, auxiliary agents, water-based gold powder and other components. The present invention uses water-based polyurethane resin as the binder, which has very good flexibility. The resin has a strong ability to disperse and wrap pigments, is not easy to form skins, and has good resolubility and reduction, thereby solving the problem of easy blockage of screen plates during ink printing. In addition, water-based film-forming plasticizer can be added to change the glass transition temperature and film-forming temperature of the resin, and the weather resistance of the ink can be adjusted according to different climates. The selection of two different thickeners can make the thickened ink in a long-term stable viscosity range, which has a significant effect on storage stability. The anti-counterfeiting ink prepared by the invention has the advantages of environmental protection, safety, low odor, good film-forming covering performance, wear resistance and easy scratching, and will not become difficult to scratch off with prolonged storage time after printing.

Owner:张耀忠

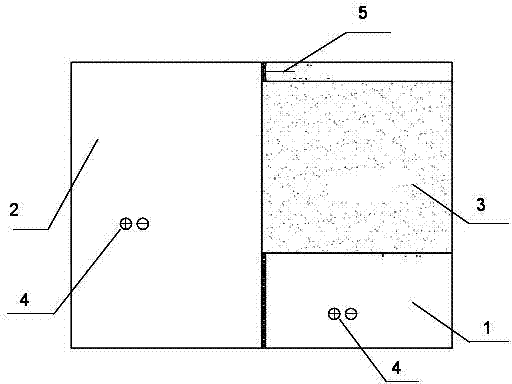

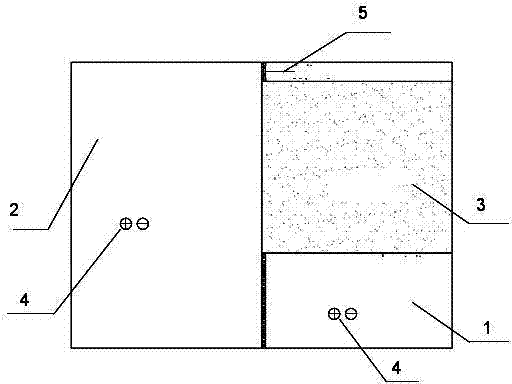

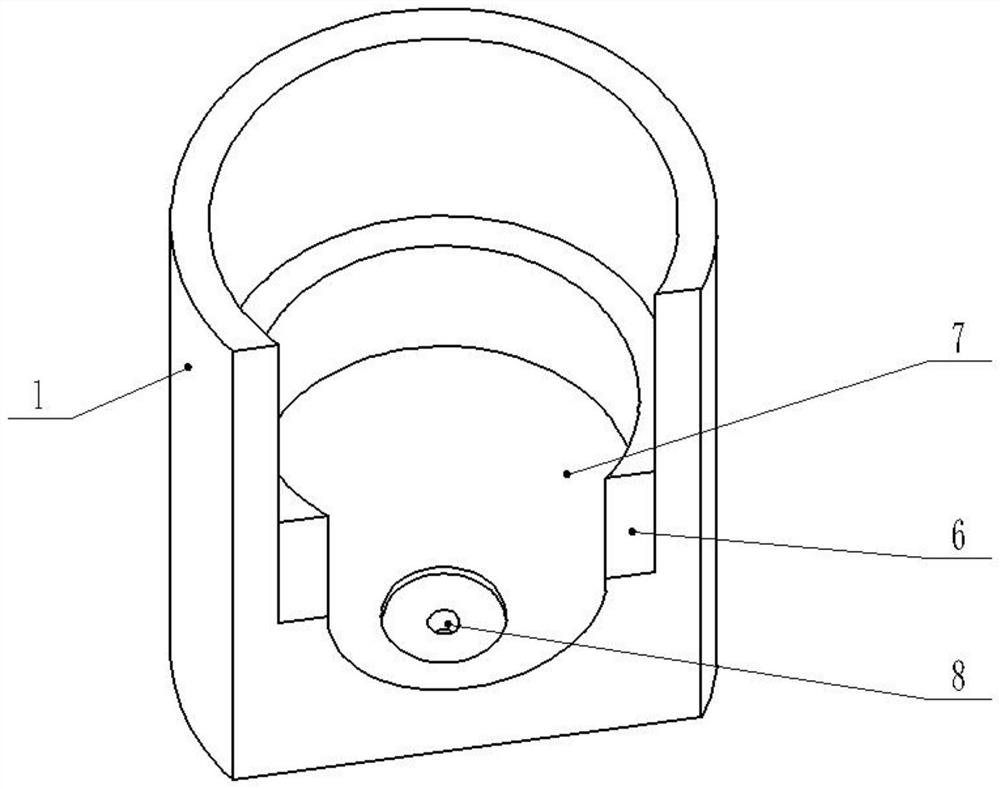

Starting method of magnesium electrolytic cell

InactiveCN102230197AAvoid heat damageNot easy to crustElectrolysis componentsMagnesiumElectrolytic cell

The invention relates to a starting method of a magnesium electrolytic cell. Specifically, the bottom of an electrolysis chamber (1) in a multipolar magnesium electrolytic cell and the central section of a magnesium collection chamber (2) are respectively provided with a set of AC (alternating current) electrodes (4), and the two sets of electrodes are separately controlled. When the electrolytic cell is started, electrolyte prepared in advance is added to submerge the AC electrodes (4) located at the bottom of the electrolysis chamber (1), so that alternating current of the electrodes is to be delivered. The electrolyte is added continuously until reaching a position of 50mm-60mm below a cathode (3) bottom, and is heated to a temperature of 680-700DEG C and maintained at a constant temperature for more than 4 hours. Then, the electrolyte is added to a standard liquid level (5), and when the AC electrodes (4) located at the central section of a magnesium collection chamber (2) are submerged by the electrolyte, alternating current of the electrodes is delivered. After the electrolyte is heated to a temperature of 700DEG C and maintained at a constant temperature for 48 hours, direct current is sent to start the electrolytic cell. For an electrolytic cell started with the method of the invention, the bottom of the electrolytic cell is free of incrustation, and the generated magnesium can gather well. Distribution of cathode current is uniform and distribution of anode current is also measured to be uniform. Thus, the adoption of the method provided in the invention can have a good effect.

Owner:遵宝钛业有限公司

CVI process method for batch quick preparation of carbon/carbon composite crucible enclosure

ActiveCN109354508ANot easy to crustImprove preparation efficiencyPolycrystalline material growthBy pulling from meltDeposition processCarbon composites

The invention discloses a CVI process method for batch quick preparation of a carbon / carbon composite crucible enclosure. By sleeving of crucible enclosure prefabs in different sizes, gas flowing arealimiting is realized; by reasonable setting of a fluid flowing route, the gas flows in a limited narrow area, and detention time of the gas in narrow slits is controlled. Narrow slit flowing has theadvantage that in a pyrolytic carbon deposition process, the prefab surface is less prone to crusting, and accordingly crucible enclosure prefabs can be deposited in high density in one time. When hydrocarbon gas flows through a first crucible enclosure prefab layer from top to bottom, splitting and pyrolytic carbon deposition reaction occurs in a high-temperature environment; when the gas reachesa second crucible enclosure prefab layer, precursors in a gas source are partially consumed, and the consumed precursors are offset by means of gas replenishing. By combination of sleeving and gas replenishing, efficiency in preparation of the carbon / carbon composite crucible enclosure can be greatly improved.

Owner:上海康碳复合材料科技有限公司 +1

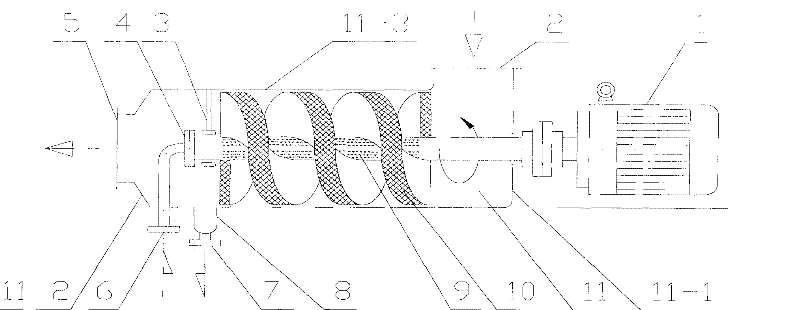

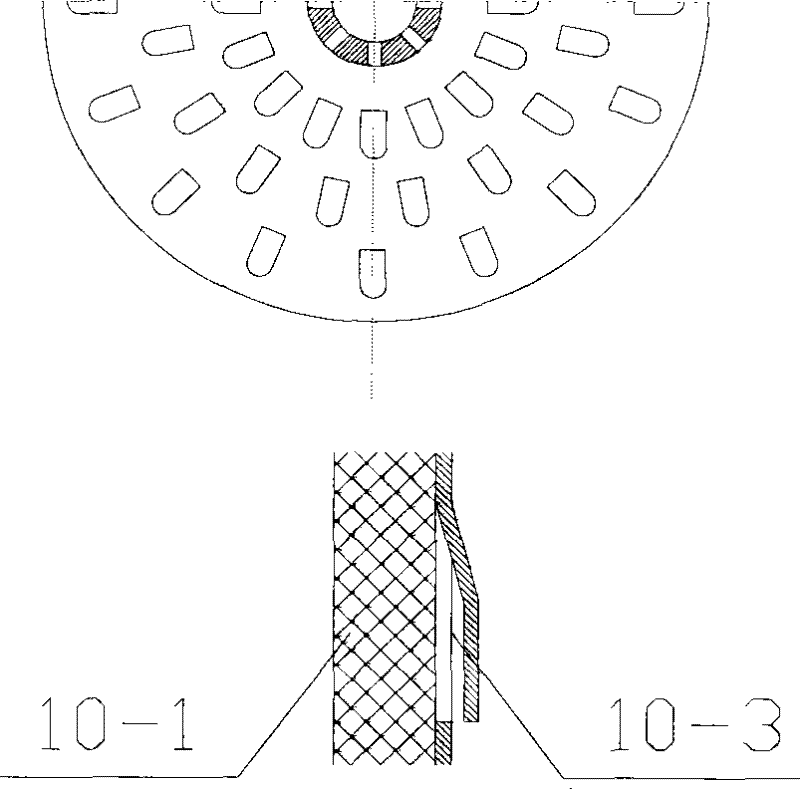

Spiral rotating bed

ActiveCN101721830BSmall footprintSimple structureMixing methodsChemical/physical/physico-chemical stationary reactorsGas phaseEngineering

The invention discloses a spiral rotating bed, comprising a spiral bed layer, a liquid-phase distribution pipe, a shell, a gas-phase inlet, a gas-phase outlet, a liquid-phase inlet, a liquid-phase outlet, and the like, wherein the spiral bed layer is made of porous materials and forms a spiral shape on the axial direction; the liquid-phase distribution pipe is arranged in the axial center of the spiral bed layer and communicated with the liquid-phase inlet; the gas-phase inlet and the gas-phase outlet are arranged at two ends of the shell, and the liquid-phase outlet is arranged at the bottomof the shell. The spiral rotating bed is suitable for gas-liquid mass transfer and reaction, especially the gas-liquid mass transfer and reaction for removing harmful ingredients in gas phase by utilizing liquid phase and with larger gas-liquid. The device has simple structure, small size, high mass transfer efficiency and low pressure drop, can obtain longer gas-liquid two-phase contact paths, realizes forced updating on the surface of droplet surface, and is beneficial to the gas-liquid mass transfer and reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

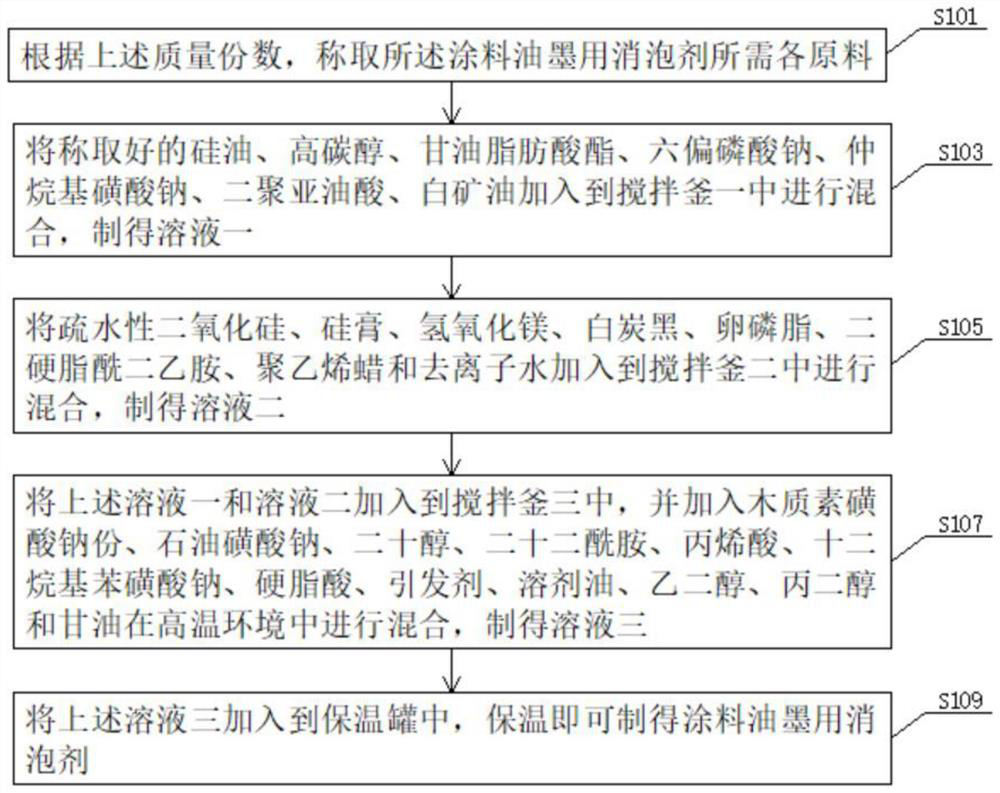

Defoaming agent for paint and ink and preparation method thereof

The invention discloses a defoaming agent for paint and ink and a preparation method of the defoaming agent. The defoaming agent for the paint and the ink is prepared from the following raw materialsin parts by mass: 42-48 parts of silicone oil, 14 -20 parts of hydrophobic silicon dioxide, 14-18 parts of silicon paste, 10-20 parts of higher alcohol, 1-3 parts of glycerin fatty acid ester, 3-5 parts of sodium hexametaphosphate, 1-2 parts of sodium secondary alkyl sulfonate, 4-10 parts of magnesium hydroxide, 5-11 parts of dimer linoleic acid, 5-7 parts of white carbon black, 4-8 parts of whitemineral oil, 8-14 parts of a surfactant, 20-30 parts of polyethylene wax, 10-12 parts of lecithin, 7-18 parts of a thickener, 4-14 parts of a co-emulsifier, 16-20 parts of distearoyl diethylamine and90-110 parts of deionized water. The defoaming agent of the invention has the beneficial effects of good dispersibility, strong affinity, strong foam inhibition capability, fast foam inhibition speed, lasting action time, capacity of realizing difficult generation of fine pinhole foams in the paint, strong high temperature resistance and stability and good compatibility with the paint and enablesthe surface of the paint to not prone to skinning and to have gloss, and a mixed solution of the defoaming agent with the paint has no layering phenomenon .

Owner:安徽銮威化工科技开发有限公司

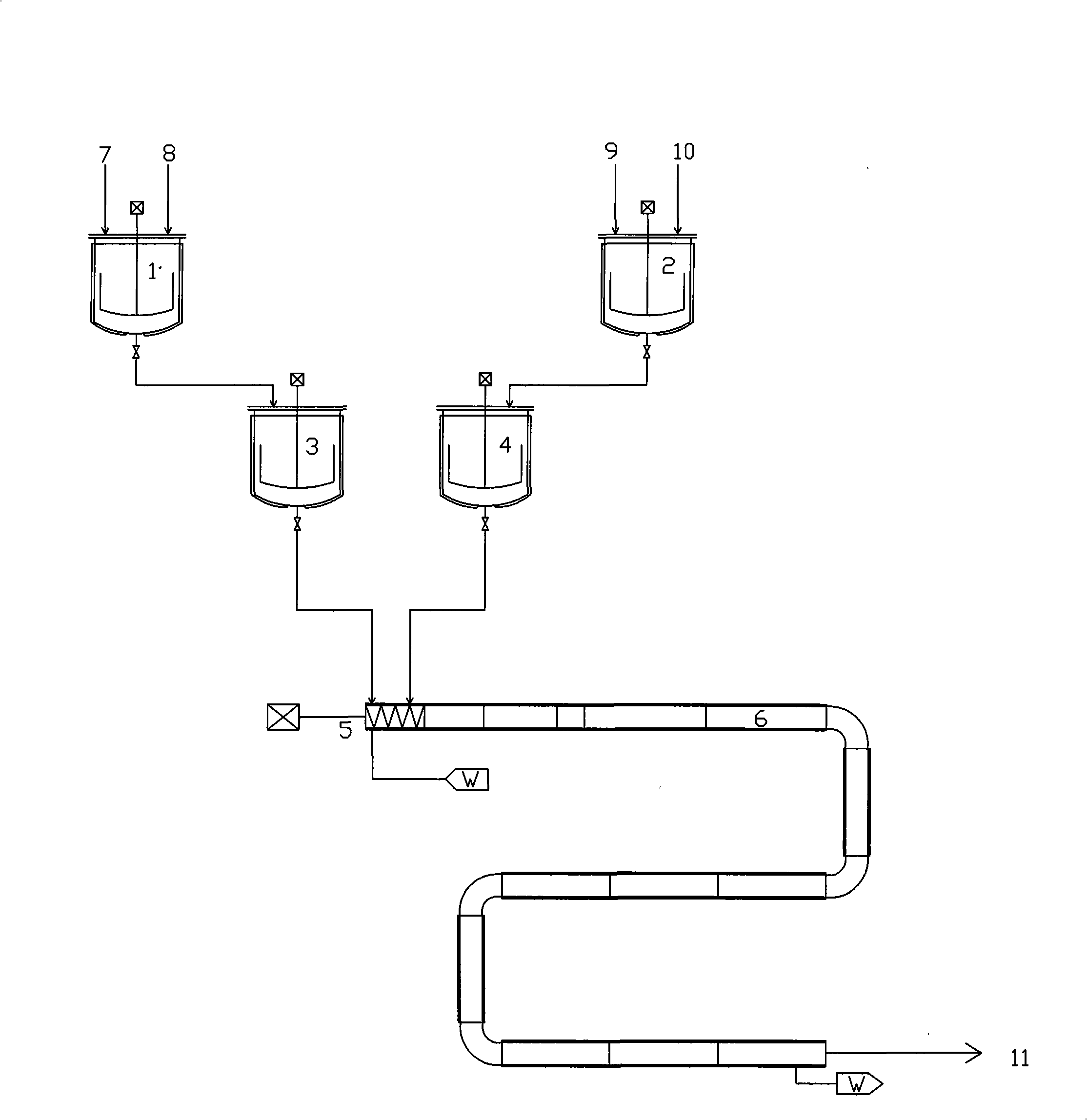

Continuous solution polymerization process for pre-polymerizing spandex

InactiveCN101333279AModerate viscosityImprove cooling effectMonocomponent polyurethanes artificial filamentDiolStatic mixer

The invention provides a continuous solution polymerization method for pre-polymerizing polyurethane, which is mainly characterized in that diisocyanate and polyether diol are respectively dissolved through polar solvents to prepare solutions at certain concentrations; then the two solutions are mixed evenly in a mixer according to specific proportion; the mixed solutions pass through a static mixer pipe with specific length and react thoroughly under specific temperature, producing prepolymer solution with isocyanate groups at both ends. The prepolymer solution can be directly used for chain extension reaction and the macromolecule polyurethane solution produced can be used in filature for producing polyurethane fibre. The invention provides a method to prepare polyurethane prepolymer through continuous solution polymerization; the continuous process of the pre-polymerization of polyurethane can eliminate the differences between different batches in batch polymerization and the prepolymer is of moderate viscosity and is convenient to cool and transfer, and the wall of the reaction pipe is not easy to crust.

Owner:杭州青云新材料股份有限公司

Water-based ink used for plastic package bag printing and a preparing method thereof

Water-based ink used for plastic package bag printing is disclosed. The ink is prepared from, by weight, 30-40 parts of styrene-acrylate copolymer, 4-6 parts of D-806 type water-based wear-resistant wax liquid, 3-5 parts of pigment, 3-5 parts of nanometer alumina, 2-3 parts of a Glide482 type leveling agent, 1-2 parts of castor oil, 1-2 parts of benzyldimethyldodecylammonium chloride, 0.5-1 part of nanometer MoB4 clusters and 60-70 parts of deionized water. A preparing method of the ink is also disclosed. The method includes stirring and mixing the raw materials, uniformly dispersing the mixture and grinding the mixture with a ball mill to obtain the ink. The styrene-acrylate copolymer is adopted as a connecting agent of the ink, the deionized water is adopted as a solvent, and other auxiliary agents in a scientific ratio are also added, and therefore the ink has excellent wear resistance, corrosion resistance and mildew resistance, and is not liable to crust. When the ink is printed on surfaces of plastic package bags, the ink is high in drying speed, not liable to fade and high in gloss, and can play good marking and advertisement roles.

Owner:安徽省临泉县万隆塑料包装有限公司

High-covering-power styrene-acrylate emulsion, synthesis method thereof and use thereof in aqueous printing ink

The invention relates to the field of printing ink and discloses high-covering-power styrene-acrylate emulsion, a synthesis method thereof and use thereof in aqueous printing ink. The preparation method comprises: mixing deionized water, an initiator, a lacquer and a composite emulsifier to obtain solution A; regulating the pH value; introducing nitrogen to remove oxygen; mixing a monomer with a molecular weight regulator to obtain solution B; dripping solution B into solution A to perform a chemical reaction; regulating the pH value of shell emulsion and heating to prepare shell emulsion; adding a composite emulsifier and an initiator into the synthesized shell emulsion; dripping a vinyl monomer to synthesize core-shell emulsion; and cooling, regulating the pH value and filtering to obtain the styrene-acrylate emulsion. The invention also provides aqueous printing ink using the high-covering-power styrene-acrylate emulsion. The preparation process is very simple, the reaction processis simple and easy to control, the operability is high, and the method is suitable for large-scale production. The aqueous printing ink disclosed by the invention is high in resolubility, is insusceptible to crusting and blocking printing plate and has high printing adaptability.

Owner:广东天龙油墨有限公司

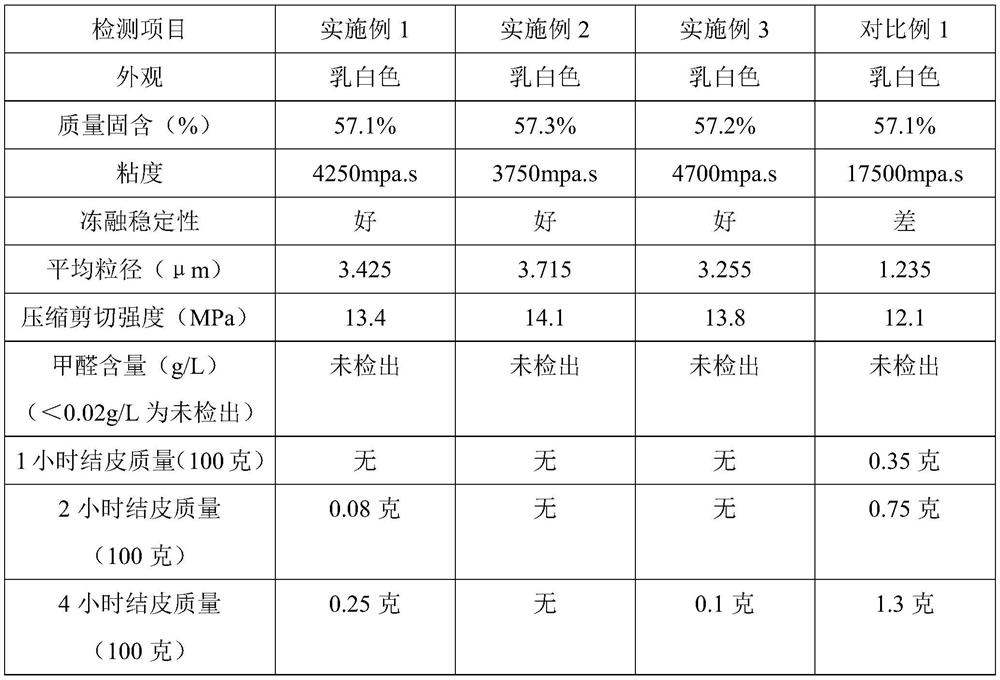

High-solid low-viscosity large-particle-size polyvinyl acetate emulsion and preparation method thereof

PendingCN114031709ALarge particle sizeImprove freeze-thaw stabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCarvacryl acetateReducing agent

The invention discloses a high-solid low-viscosity large-particle-size polyvinyl acetate emulsion and a preparation method thereof, and the emulsion is applied to the technical field of adhesive compounding. The emulsion comprises, in parts by weight, vinyl acetate, vinyl versatate, methacrylic acid, a crosslinking monomer hydroxyethyl methylacrylate (HEMA), deionized water, an emulsifier, polyvinyl alcohol, ammonium persulfate as an initiator, a reducing agent as an initiator, a plasticizer, urea, a defoaming agent and a preservative. According to the invention, a core-shell copolymerization process is adopted, and polymerization is carried out in a manner of early-stage high-bottoming monomers and staged gradual acceleration of rotation speed, so that the emulsion is narrower in particle size distribution, larger in average particle size and lower in viscosity in a later stage; and the defects of small particle size, high viscosity, low compression shear strength, poor freeze-thaw stability, easy surface skinning, aldehyde existence and the like of a traditional high-solid-content polyvinyl acetate emulsion are overcome, and the polyvinyl acetate emulsion has good glue performance and storage stability.

Owner:顶立新材料科技股份有限公司 +1

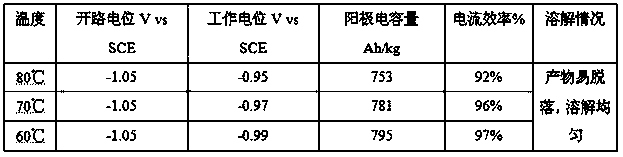

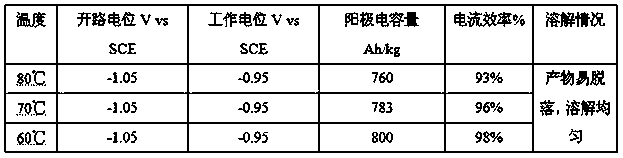

High-efficiency zinc alloy sacrificial anode for high-temperature crude oil deposition water environment

InactiveCN110106509AIncrease working potentialLower grain boundary potentialSeawaterWater environment

The invention provides a high-efficiency zinc alloy sacrificial anode suitable for a high-temperature crude oil deposition water environment. The high-efficiency zinc alloy sacrificial anode is prepared from the compositions in percentage by weight: 0.10-0.25% of Al, 0.05-0.15% of Mg, 0.005-0.009% of Sn, the impurity content including less than or equal to 0.006% of Pb, less than or equal to 0.001% of Cd, less than or equal to 0.001% of Cu, less than or equal to 0.002% of Fe, and the balance of Zn. The high-efficiency zinc alloy sacrificial anode is processed and manufactured through conventional fusion casting, zinc ingots are held through a dedicated graphite crucible, and melted in a heating furnace, Al and an Al-Mg alloy are added into a molten zinc solution in proportion, the productis stirred through a graphite rod, slag is removed, and the product is casted after being removed from the furnace; and the heating furnace selects a coke-fired furnace, an electric furnace, an oil furnace, a gas furnace and the like. According to the high-efficiency zinc alloy sacrificial anode for the high-temperature crude oil deposition water environment, compared with the prior art, the preparation technology and method are mature, operation is easy and convenient, the proportion is reasonable, the service life is long, the protective effect is good, and the high-efficiency zinc alloy sacrificial anode can be widely applied to cathode protection under the high temperature conditions in the fields of seawater and offshore oil.

Owner:SUNRUI MARINE ENVIRONMENT ENG

Novel upflow anaerobic reactor

ActiveCN102399683BEasy to operateNot easy to crustBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringAnaerobic reactor

The invention discloses a upflow anaerobic reactor. The novel upflow anaerobic reactor comprises a tank, a stirring cracking assembly, a built-in heat energy conversion unit, a feeding device, a discharge device, a pressure protector, a gas outlet pipe and a slag discharge pipe. The stirring cracking assembly having functions of stirring mixing, cracking and slag removal, the built-in heat energy conversion unit, the discharge device which is sealed by water and can discharge dross, and the feeding device provided with a stored material automatic discharge device are ranged in the tank. The novel upflow anaerobic reactor is easy for operation, does not produce crusting in treatment on a fermentation mixture of livestock and poultry night soil, rural domestic organic garbage and straws, allows an uniform and constant reaction temperature, can operate stably and reliably, has low investment and operation costs, a high-load treatment capacity, large TS concentration and short hydraulic retention time. Through the novel upflow anaerobic reactor, a solid content of a fermentation solution is in a range of 8 to 15%; COD clearance is in a range of 60 to 80%; and a biogas yield is in a range of 1.5 to 3m<3> / m<3>*d.

Owner:LIAONING BEIFANG ENVIRONMENTAL PROTECTION

Method for preparing metal beryllium by electrolyzing beryllium oxide through fluoride molten salt

ActiveCN114182301AImprove direct yieldShort processCellsProcess efficiency improvementMolten stateAlkaline earth metal

The invention discloses a method for preparing metal beryllium by electrolyzing beryllium oxide through fluoride molten salt, which comprises the following steps: (1) constructing a BeF2-MFn molten salt system, where MFn is one or more of alkali metal fluoride or alkaline earth metal fluoride except beryllium fluoride; (2) adding beryllium oxide into a BeF2-MFn molten salt system in a molten state; and (3) electrolysis is conducted, and solid-state metal beryllium is separated out on the cathode. According to the method, beryllium smelting intermediate product beryllium oxide is adopted as a raw material and dissolved in fused salt, beryllium ions and oxygen ions are dissociated, due to positive and negative phase attraction, the oxygen ions with negative electricity move to an anode and lose electrons, oxygen or carbon-containing gas is obtained, the beryllium ions with positive electricity move to a cathode, and the electrons are reduced into beryllium atoms to be deposited on the surface of the cathode; according to the method, the technological process is greatly shortened, and the direct recovery rate of beryllium is increased; and beryllium oxide is used as a raw material, carbon dioxide and oxygen are generated on the anode, and the method is more environment-friendly.

Owner:ZHENGZHOU UNIV

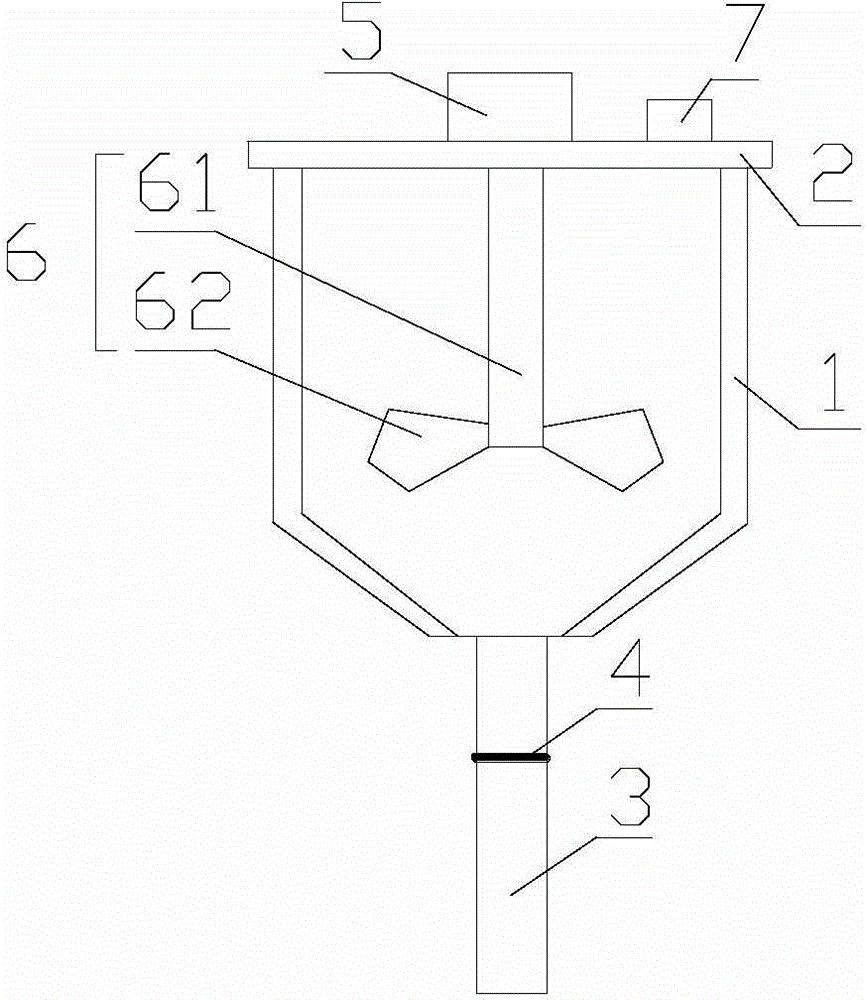

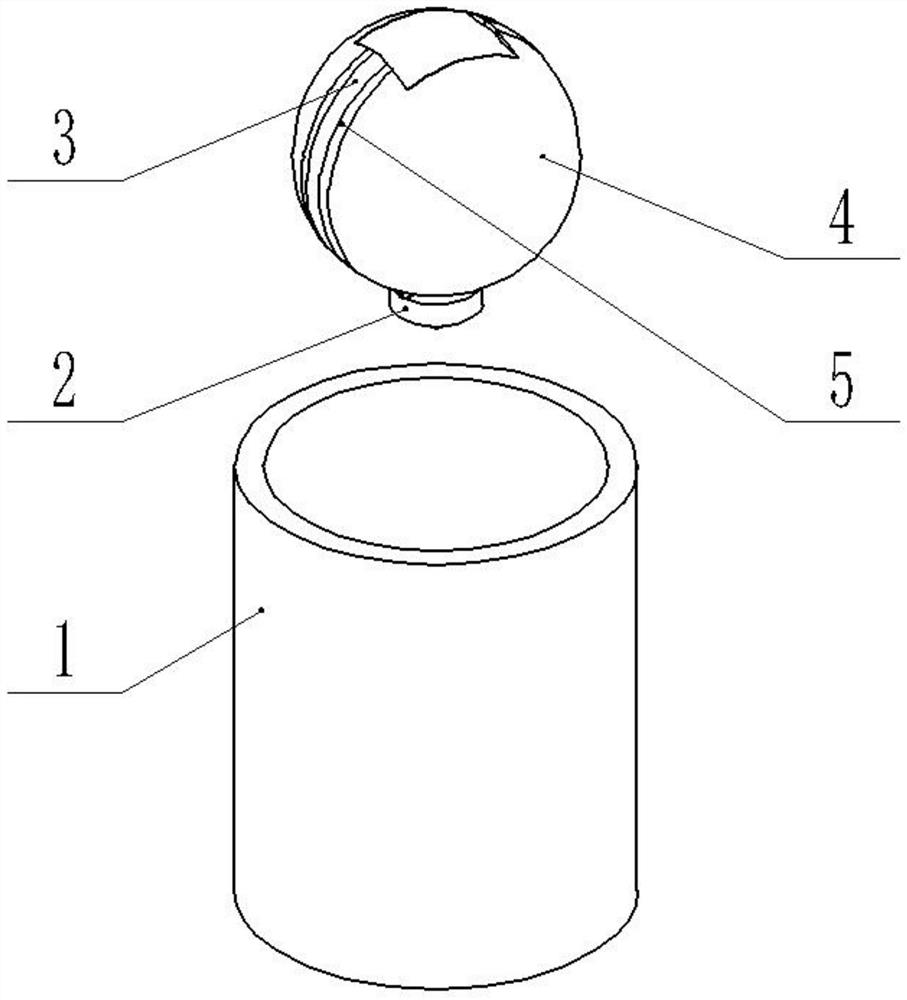

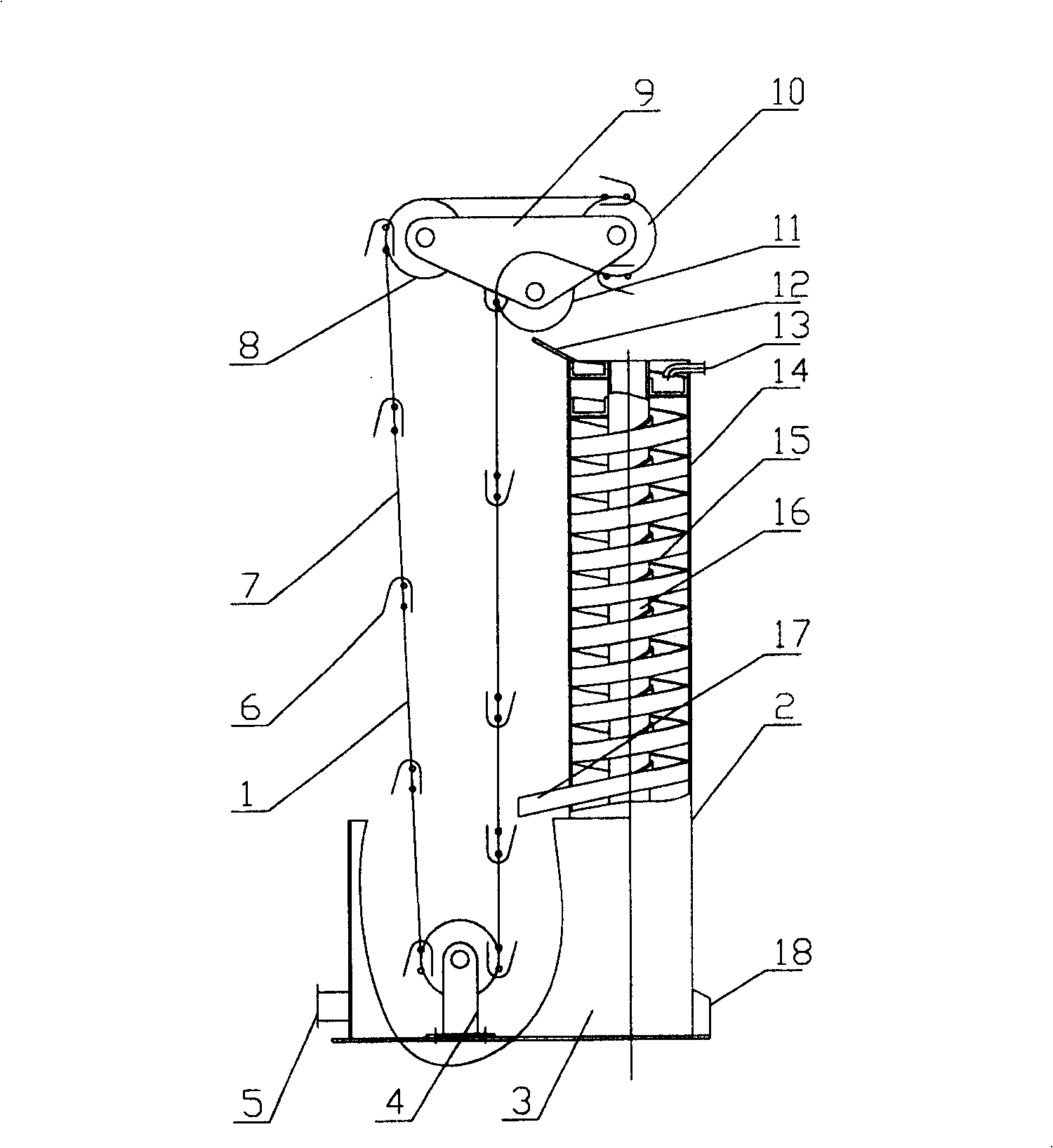

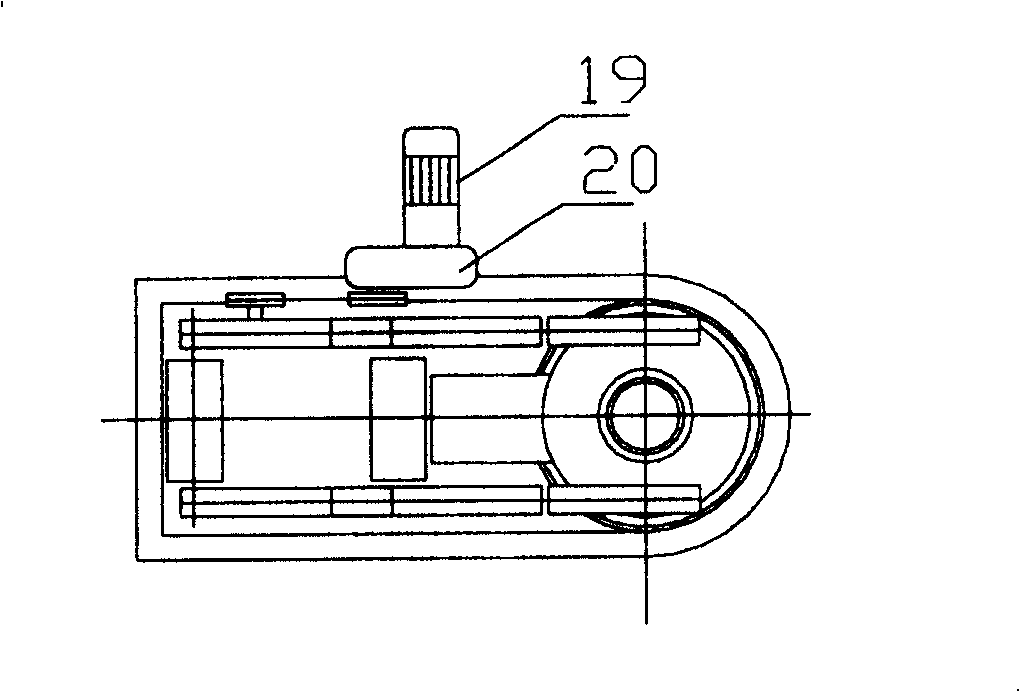

Feeding device of biogas pool

InactiveCN104928170ANot easy to crustNot prone to crustingBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringVALVE PORT

The invention relates to a feeding device of a biogas pool. The feeding device comprises a feeding box, a discharge valve, a driving unit, a stirring mechanism, a pressure sensor and a controller. A top cover is arranged at the top of the feeding box, a discharging hole is arranged in the bottom of the feeding box and is communicated with a discharging pipe, and a discharging pipe is arranged in the discharge pipe; the driving unit is mounted on the top cover, the stirring mechanism is located in the feeding box and comprises a stirring shaft and two stirring pieces, the stirring shaft is connected with the outlet shaft of the driving unit, the stirring pieces are respectively arranged on two sides of the stirring shaft, and a plurality of stabs used for crushing are arranged on outer walls of the stirring pieces; the pressure sensor is arranged in the biogas pool and is connected with the input end of the controller, the controller is mounted on the top cover with the output end being in communication connected with the discharging valve and capable of controlling opening of the discharging valve. By the arrangement, materials in the biogas pool are less prone to crusting, the materials can be automatically fed into the biogas pool according to biogas yield in the biogas pool, and the materials are favorably sufficiently utilized.

Owner:NANAN CITY GREEN BIOGAS TECH DEV & RES INST

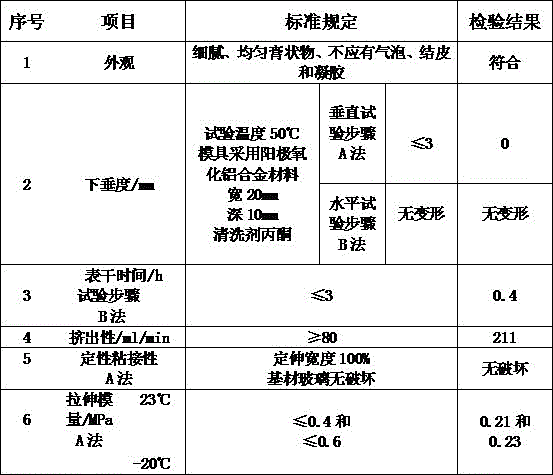

A kind of acid silicone sealant and preparation method thereof

ActiveCN104059596BAvoid the disadvantages of being easy to crystallize and not easy to useChange the cross-linked structureNon-macromolecular adhesive additivesMacromolecular adhesive additivesVacuum pumpingCross-link

The invention discloses an acidic silicone sealant and a preparation method, the preparation method comprises the following steps: 1)preparing the raw materials; 2)adding 200-220 parts of glue 107, 2-6 parts of thixotropic agent in a glue cylinder, vacuum-pumping and stirring for 3-5 minutes; 3)sucking 10-20 parts of cross-linking agent in the glue cylinder after opening a material pumping valve, then closing the material pumping valve; stirring; 4)sucking partial gas phase white carbon black in the glue cylinder by using a membrane pump, stirring; 5)repeatedly operating for 1-4 times on the residual gas phase white carbon black according to step 4); 6)fully mixing 120-130 parts of 330 silicone oil and 0.09-0.15 parts of tin acetate to obtain a mixture; 7)sucking the mixture in the step 2) in the glue cylinder after stirring, then stirring again; keeping degree of vacuum as -0.09--0.1MPa during the stirring process; and 8)filling nitrogen and emptying after stirring in the step 7) to obtain the acidic silicone sealant. The acidic silicone sealant has the advantages of good cementability, strong sealing, difficult skinning and no sagging.

Owner:扬州晨化新材料股份有限公司

A CVI process method for rapidly preparing carbon/carbon composite crucibles in batches

ActiveCN109354508BNot easy to crustImprove production efficiencyPolycrystalline material growthBy pulling from meltCarbon compositesCrucible

The invention discloses a CVI process method for quickly preparing a carbon / carbon composite material crucible side in batches, which restricts the gas flow area through the suit of crucible side prefabricated bodies of different sizes, and reasonably sets the fluid flow route so that the gas is limited in a narrow space. Flow in the area while controlling its residence time in the narrow gap. The advantage of narrow slit flow is that during the pyrolytic carbon deposition process, the surface of the preform is not easy to crust, so that the preform of the crucible side can be deposited to a relatively high density at one time. When the hydrocarbon gas flows through the first layer of crucible from top to bottom When helping the prefabricated body, cracking and pyrolytic carbon deposition reactions occurred in a high-temperature environment. When the gas reached the second layer of the crucible preformed body, part of the precursor in the gas source had been consumed. The combination of consumed precursors, set-up and supplementary gas can greatly improve the efficiency of carbon / carbon composite crucible side preparation.

Owner:上海康碳复合材料科技有限公司 +1

Ultra-thin evenly mixed straw biogas material distribution mode

InactiveCN103667353APromote fermentationGood dispersionWaste based fuelFermentationBiogasEngineering

The invention relates to an ultra-thin evenly mixed straw biogas material distribution mode. By adopting the mode, an anaerobe is promoted to be dispersed in all fermentation liquor, biogas fermentation is facilitated, and the gas efficiency is greatly improved in comparison with the traditional mixing mode. The upper layer of the fermentation liquor is not easily crusted, and is easy to vent, and meanwhile, the ultra-thin evenly mixed straw biogas material distribution mode is simple, convenient and fast to discharge. The ultra-thin evenly mixed straw biogas material distribution mode has the characteristics that the cost is saved, and an energy source is saved.

Owner:TIANJIN BEIFANG LANDSCAPE ECOLOGY INST OF SCI & TECH

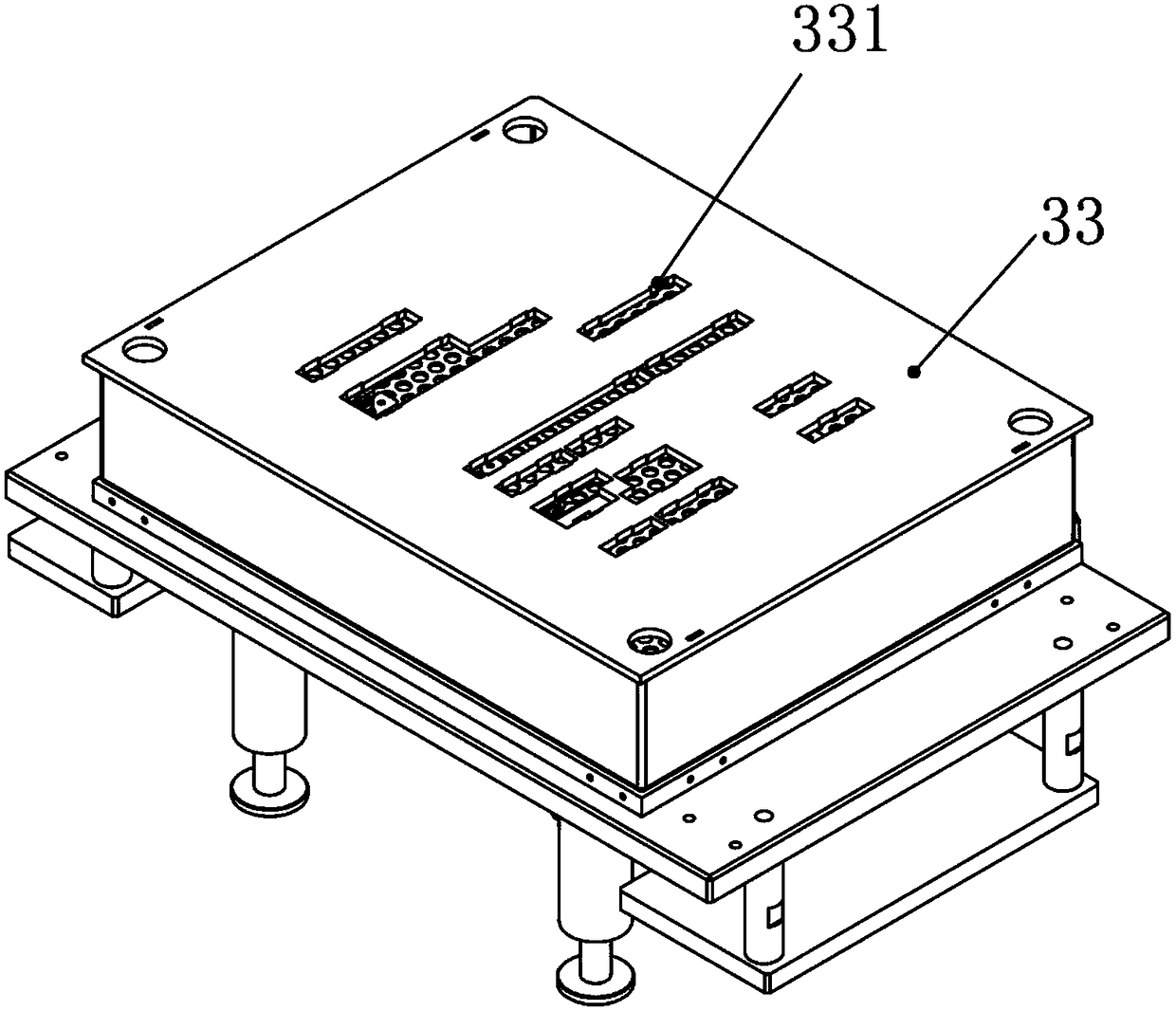

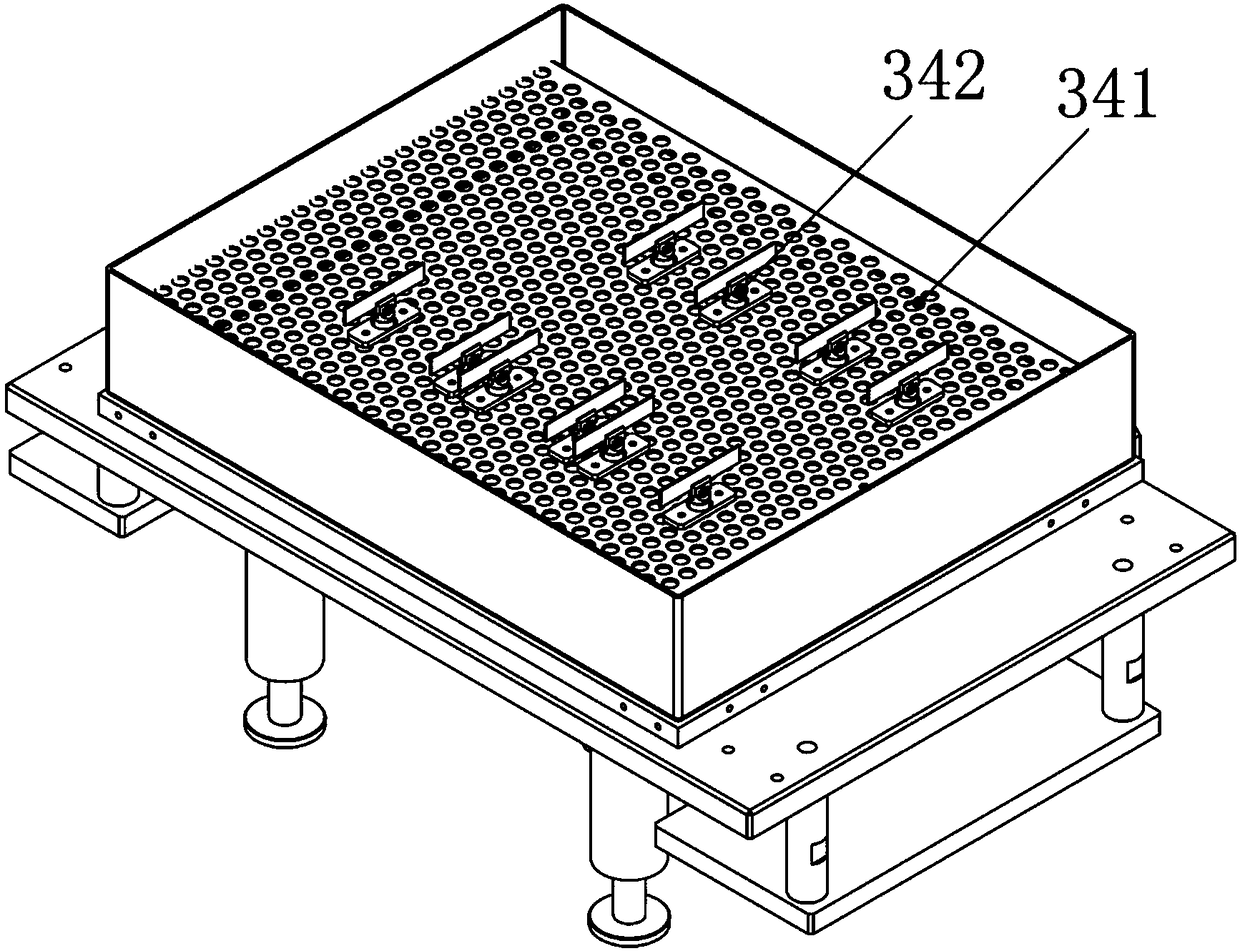

ink fountain

ActiveCN112644162BNot easy to crustEasy to cleanPrinting press partsEngineeringMechanical engineering

Owner:CHONGQING HONGSHENG PRINTING

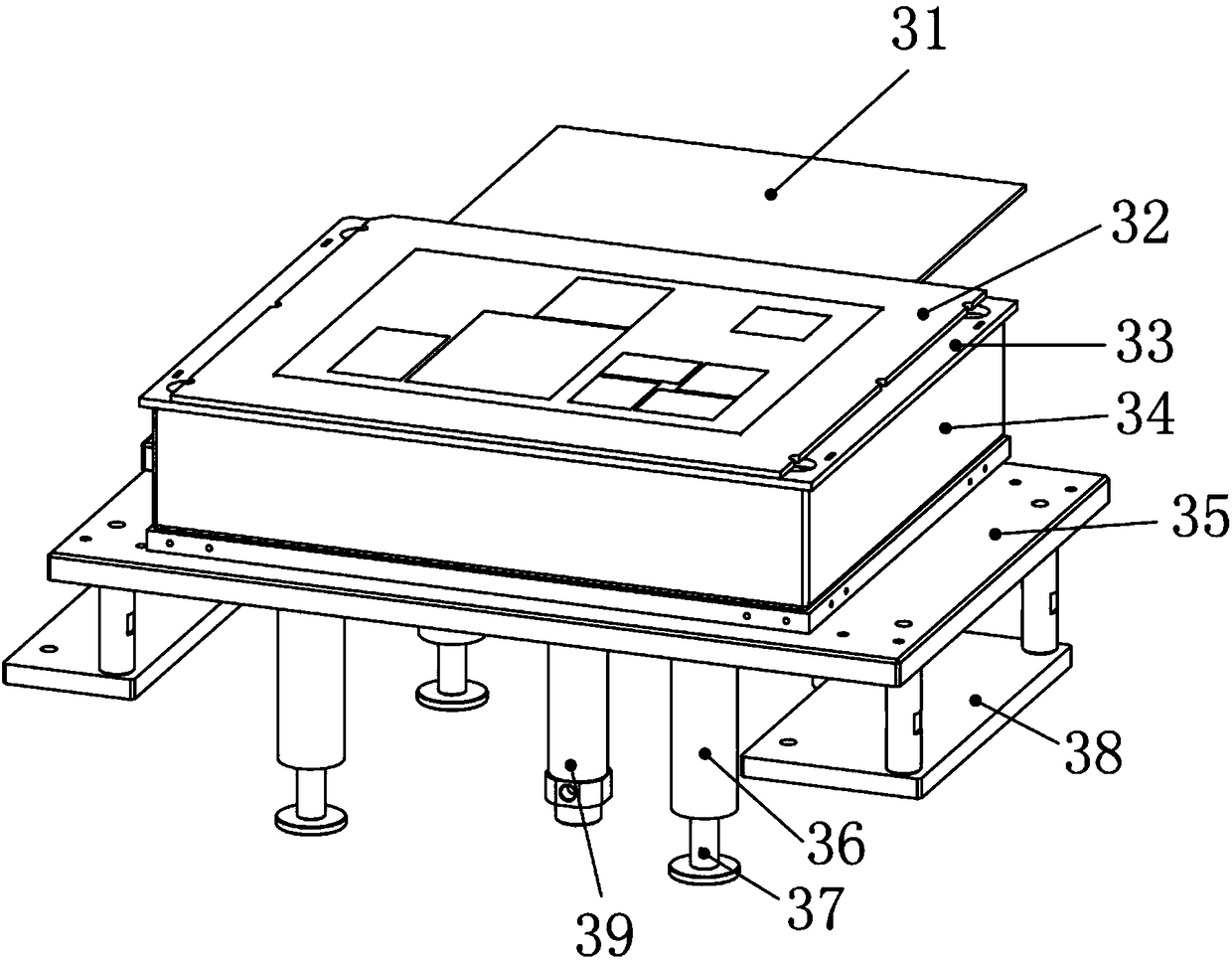

Dispersion liquid film type absorption tower used for organochlorosilane concentrated acid hydrolysis

ActiveCN103183826BMitigate liquid splashImprove distributionSilicon organic compoundsEmulsionAcid catalysis

The invention relates to a dispersion liquid film type absorption tower used for organochlorosilane concentrated acid hydrolysis. The absorption tower comprises a casing, wherein a liquid distribution plate is fixedly mounted between an upper seal head and an outer barrel body of the absorption tower; a splash-proof screen mesh is arranged on the liquid distribution plate; 3-10 layers of neatly arrayed film forming plates are arranged below the liquid distribution plate and are supported horizontally; an included angle between every film forming plate and the water level ranges from 15 degrees to 75 degrees; and film forming plates are arrayed in a staggered manner between adjacent layers. According to the absorption tower, appropriate reacting pressure (0.1 MPa to 0.5 MPa of gauge pressure) enables HCl gas generated by hydrolysis to have sufficient pressure; the dispersion liquid film type absorption tower enables an organic phase and an aqueous phase to be contacted in a film manner, so that the hydrolysis reaction is sufficient without emulsion; and a phase separator is used to separate hydrolysates and concentrated hydrochloric acid rapidly, the hydrolysates are prevented from polymerizing under the acid catalysis, and the qualities of the hydrolysates are improved.

Owner:QINGDAO UNIV OF SCI & TECH

Movable-cover-free cyclic feeding and discharging type methane-generating pit

InactiveCN107022472ADoes not affect outputEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsGreenhouseEngineering

The invention discloses a movable-cover-free cyclic feeding and discharging type methane-generating pit. The methane-generating pit is composed of a feeding hole, a feeding pipe, a pit body of the methane-generating pit, a prefabricated top sealing cover, a gas guide pipe, a water pressure chamber and a discharging hole, wherein the feeding pipe is mounted above the bottom of the pit body of the methane-generating pit and the other end of the feeding pipe is upward introduced out to be communicated with the feeding hole; a channel is arranged at the bottom of the pit body of the methane-generating pit and is communicated with the bottom of the water pressure chamber; the discharging hole is formed in the upper end of the water pressure chamber; the prefabricated top sealing cover is mounted at the upper part of the pit body of the methane-generating pit and is in sealed connection with the pit body of the methane-generating pit; the gas guide pipe is mounted on the prefabricated top sealing cover. The methane-generating pit disclosed by the invention is simple in construction, convenient to use, good in sealing performance and long in service life; material liquid is not easily crusted. By combining a sunlight greenhouse, the problem that gas is not generated in winter is solved; the movable-cover-free cyclic feeding and discharging type methane-generating pit has the characteristic that the gas is normally generated in a whole year.

Owner:CHINA AGRI UNIV

A moving-bed reactor

ActiveCN100438966CReduce energy consumptionSimple structureChemical/physical processesDrive wheelReducer

The invention relates to a move bed reactor, formed by screw reaction bed and lifter. Wherein, the screw reaction bed is formed by outer cylinder, inner cylinder, liquid inlet, material outlet, divert plate, screw reaction bed, and base; the lifter is formed by water tank, driven wheel water outlet, lifting hopper, chain, driving wheel, motor, speed reducer, and frame; the lifter and screw reaction bed share one chassis. The invention is used in solid-liquid neutralization; especially the solid is block material. The invention has simple structure without block.

Owner:CHINA PETROLEUM & CHEM CORP +1

Varnish for water-borne anti-counterfeiting ink and water-borne anti-counterfeiting ink prepared by varnish

Owner:中山市中益油墨涂料有限公司

Concentrated acid hydrolysis system used for organochlorosilane concentrated acid hydrolysis

ActiveCN103183829BQuality improvementAvoid easy cloggingSilicon organic compoundsEmulsionHydrolysate

The invention relates to a concentrated acid hydrolysis system for concentrated acid hydrolysis of organochlorosilane, which takes a dispersed liquid membrane analysis tower as the core and also includes accessory equipment: a static mixer, an oil-water phase separator, and a falling film evaporator. The analysis tower includes a shell. A liquid distribution plate is fixedly installed between the upper head and the outer cylinder of the analysis tower. The upper part of the liquid distribution plate is a splash-proof wire mesh, and the lower part of the liquid distribution plate is a neatly arranged film-forming plate. The film-forming plates are horizontally supported, with a total of 3 to 10 layers. The angle between the forming template and the horizontal plane is 15 to 75 degrees. Between the layers, the film-forming plates are arranged in staggered directions. In the present invention, the HCl gas produced by hydrolysis has sufficient pressure through appropriate reaction pressure (0.1-0.5MPa gauge pressure). The dispersion liquid membrane desorption tower is used to contact the organic phase and the water phase in a film-like manner, so that the hydrolysis reaction is complete and there is no emulsification phenomenon. Use a phase separator to quickly separate the hydrolyzate from concentrated hydrochloric acid to avoid polymerization of the hydrolyzate under acid catalysis and improve the quality of the hydrolyzate.

Owner:QINGDAO UNIV OF SCI & TECH

Film gluing mechanism with page capable of being quickly replaced

ActiveCN108722770AQuick changeEasy to adjustLiquid surface applicatorsFinal product manufactureEngineeringMagnet

Owner:DONGGUAN MARCO AUTOMATION MACHINERY

Antiskid pavement coating

InactiveCN107162471AHigh bonding strengthImprove skid resistanceRoad surfaceUltimate tensile strength

The invention discloses an antiskid pavement coating which comprises, by weight, 80-120 parts of SBS modified asphalt, 15-35 parts of xylene, 4-10 parts of styrenated phenol, 10-24 parts of curing agents, 10-20 parts of dioctyl phthalate and 150-220 parts of aggregates. The antiskid pavement coating is high in bonding strength, good in skid resistance and abrasion resistance, rapid to dry and long in preservation time and not easily caked and crusted in the use process.

Owner:惠州兴鑫涂料化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com