High-solid low-viscosity large-particle-size polyvinyl acetate emulsion and preparation method thereof

A technology of polyvinyl acetate and vinyl acetate, applied in the direction of non-polymer adhesive additives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problem of particle size and compressive shear strength changes Small size, poor freeze-thaw stability, small particle size, etc., to achieve the effect of improved freeze-thaw stability, narrow particle size distribution, and large average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

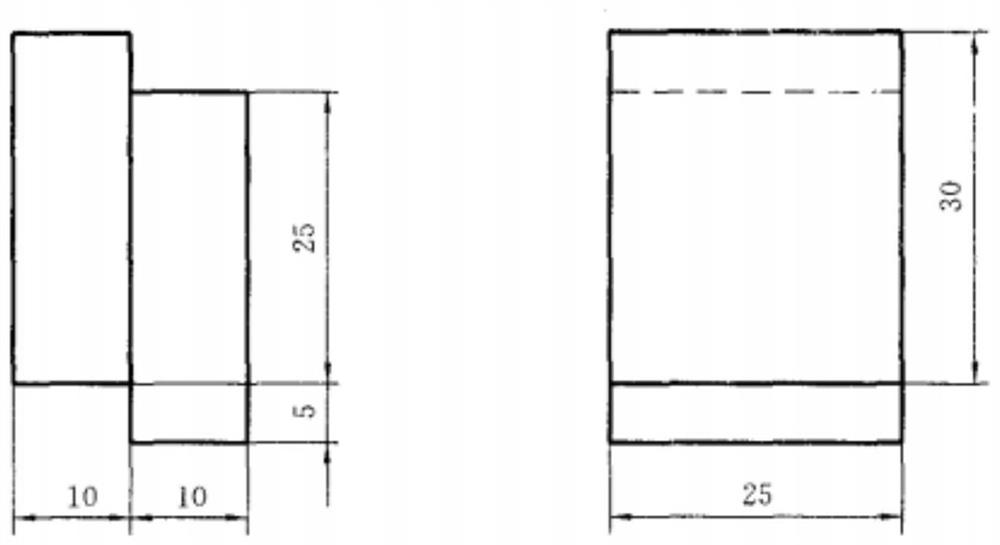

Image

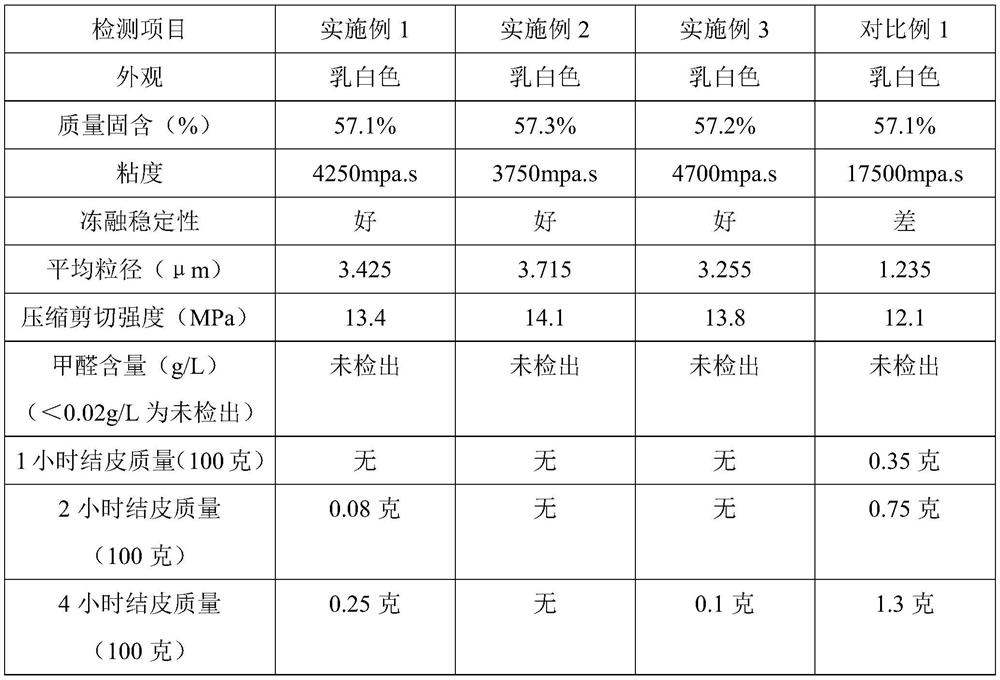

Examples

Embodiment 1

[0029] (1) Dissolve 1 kg of ammonium sulfate in 50 kg of water to obtain a solution of ammonium sulfuricate A solution of 51 kg polymerization; 0.25 kg of FF6M is dissolved in 20 kg of water, resulting in 20.25 kg polymerization of ammonium sulfuricate B dissolution of the polymerization reaction of the FF6M initiator B solution;

[0030] (2) 330 kg of vinyl acetate, 30 kg tertiar carbonate (Vv10), 5 kg methacrylic acid mix mix and mix, 365 kg mixed monomer A; another 3 kg cross-linked monomer methacrylate hydroxyethylene The ester HEMA is dissolved in 20 kg of water to form a crosslinking monomer solution, and it is made of 23 kg monomer solution B;

[0031] (3) Add 360 kg of water, 1 kg defoamer, 1.2 kg buffer acetate, 2 kg emulsifier GENAPOL X 1005, disperse stirred under 50RAD / min, 35 kg of polyvinyl alcohol 1788, 10 kg of polyvinyl alcohol 2488, stirring dispersed for 10 minutes, warmed to 95 ° C, holding up for 60 minutes, then cooling to 55 ° C, adding 110 kg of vinyl ace...

Embodiment 2

[0035] (1) Dissolve 1.5 kg of ammonium sulfate in 50 kg of water, resulting in a solution of ammonium sulfuricate A solution of 51.5 kg polymerization; 0.4 kg of FF6M is dissolved in 20 kg of water, resulting in a 20.4 kg polymerization of ammonium sulfuricate B dissolution of the polymerization reaction of the FF6M initiator B solution;

[0036](2) 280 kg of vinyl acetate, 40 kg tertiary carbonate (VV10), 10 kg methacrylic acid mixed mix, 330 kg mixed monomer A; another 4 kg crosslinked monomer methacrylate hydroxyethylene The ester HEMA is dissolved in 20 kg of water to form a crosslinking monomer solution, and a 24 kg monomer solution B is made.

[0037] (3) Add 360 kg of water, 1 kg defoamer, 1 kg buffer acetate, and 3 kg of emulsifier GENAPOL X 1005, and stirred under 50RAD / min, 30 kg of polyvinyl alcohol 1788. 15 kg of polyvinyl alcohol 2488, stirred by stirring for 10 minutes, warmed to 95 ° C, heat insulation for 60 minutes, then cooled to 55 ° C, add 150 kg of vinyl ace...

Embodiment 3

[0041] (1) 0.9 kg of ammonium sulfate is dissolved in 50 kg of water, resulting in a solution of ammonium sulfuricate A solution of 50.9 kg of polymerization; dissolving 0.3 kg FF6M in 20 kg of water, resulting in a 20.3 kg polymerization reaction B dissolution of the polymerization reaction of the FF6M initiator B solution;

[0042] (2) 280 kg of vinyl acetate, 35 kg tertiary carbonate (Vv10), 5 kg methacrylic acid mix mix, 320 kg of mixed monomer A; another 6 kg cross-linked monomer methacrylate hydroxyethylene The ester HEMA is dissolved in 20 kg of water to form a crosslinking monomer solution, which is made of 26 kg monomer solution B;

[0043] (3) Add 360 kg of water, 1.5 kg defoamer, 1 kg buffer acetate, 4 kg emulsifier GENAPOL X 1005, dispersed under 50RAD / min, 45 kg of polyvinyl alcohol 1788, After stirring dispersion for 10 minutes, he was warmed to 95 ° C, holding up for 60 minutes, then cooled to 55 ° C, add 150 kg of vinyl acetate generic monomer for monomer emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com