High-covering-power styrene-acrylate emulsion, synthesis method thereof and use thereof in aqueous printing ink

A technology of styrene-acrylic emulsion and water-based ink, which is applied in the field of ink, can solve the problems of poor water resistance and weather resistance, easy clogging of printing plates, unstable operation, etc., and achieve stable operability, not easy to skin, and printing adaptability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

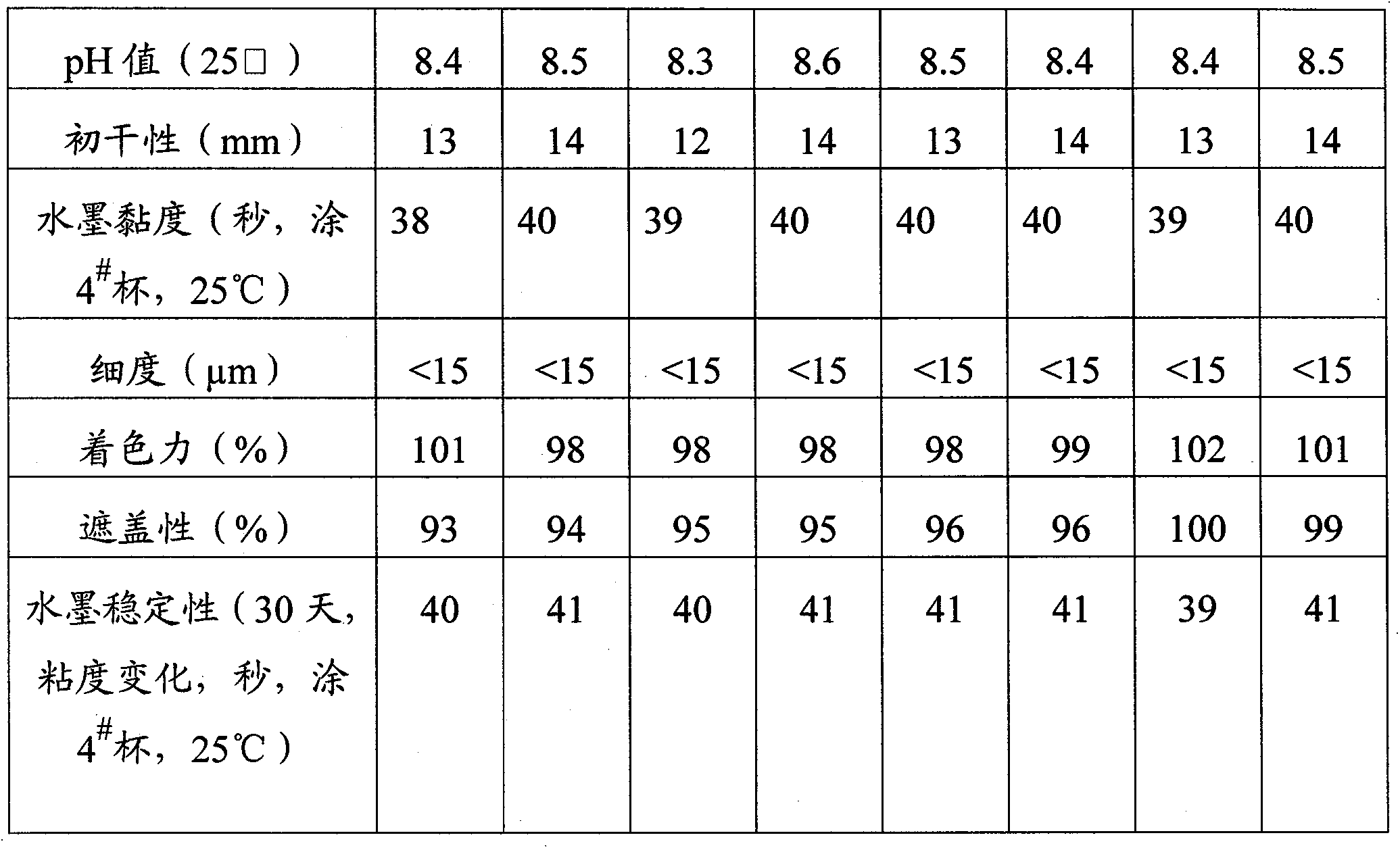

Embodiment 1

[0043] Add 417.32 grams of deionized water, 6.5 grams of composite emulsifier (nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate), 2.5 grams of ammonium persulfate initiator, and 3 grams of protective glue with stirring and dropping In the four-necked flask of the device, reflux condenser, and thermometer, the temperature was raised to 84° C., and 0.3 g of monoethanolamine was added to adjust the pH value at 7.5 to 8.8. Add 71.2 grams of methyl acrylate, 28.8 grams of acrylic acid, and 6.5 grams of tertiary dodecyl mercaptan into the head tank and mix well. Add the mixed monomers dropwise into the flask by "starvation method" within the temperature range of 84°C±2, and the dropwise addition time is 30 minutes. After the dropwise addition, keep warm for 30 minutes and add 16.38 g of monoethanolamine to adjust the pH value of the emulsion in the range of 7.1 to 8.0 to obtain a shell emulsion.

[0044] Add 3.5 grams of composite emulsifier (no...

Embodiment 2

[0046] In a four-neck flask with stirring, dropping device, reflux condenser, and thermometer, add 413.7 grams of deionized water, 0.4 grams of triethanolamine, a composite emulsifier (nonylphenol polyoxyethylene ether, nonylphenol polyoxyethylene (10) 6.6 grams of ether-2-sulfosuccinic acid monoester disodium salt), 3.1 grams of ammonium persulfate initiator, 7 grams of protective glue, and the temperature was raised to 84°C. Add 73.5 grams of butyl acrylate, 29.5 grams of acrylic acid, and 5.5 grams of β-phenyl β-n-dodecylthioethyl phenyl ketone into the high-level tank and mix evenly. "Method" drop the mixed monomers into the flask, and the dropping time is 30 minutes. After the dropwise addition, keep warm for 30 minutes and add 16.7 g of triethanolamine to adjust the pH value of the emulsion in the range of 7.1 to 8.0 to obtain a shell emulsion.

[0047] Dissolve 3.6 grams of composite emulsifier (nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sod...

Embodiment 3

[0049] In a four-neck flask equipped with stirring, dropping device, reflux condenser and thermometer, add 418.87 grams of deionized water, 0.3 grams of ammonia water, composite emulsifier (nonylphenol polyoxyethylene ether, 1-propylene oxide-2 hydroxyl Sodium propanesulfonate) 6 grams, ammonium persulfate initiator 2.35 grams, protective glue 6.5 grams, be warming up to 84 ℃. Add 69.5 grams of ethyl acrylate, 30.5 grams of acrylic acid, and 5.6 grams of tri-mercaptopropanol into the high-level tank and mix evenly. Add the mixed monomers dropwise into the flask by the "starvation method" within the temperature range of 84 ° C ± 2, drop Add time is 30 minutes. After the dropwise addition, keep warm for 30 minutes and add 16.38 g of ammonia water to adjust the pH value of the emulsion in the range of 7.1 to 8.0 to obtain a shell emulsion.

[0050] Dissolve 3.2 grams of composite emulsifier (nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com